Use of Industrial Silica Sand as a Fine Aggregate in Concrete—An Explorative Study

Abstract

:1. Introduction

2. Materials and Methods

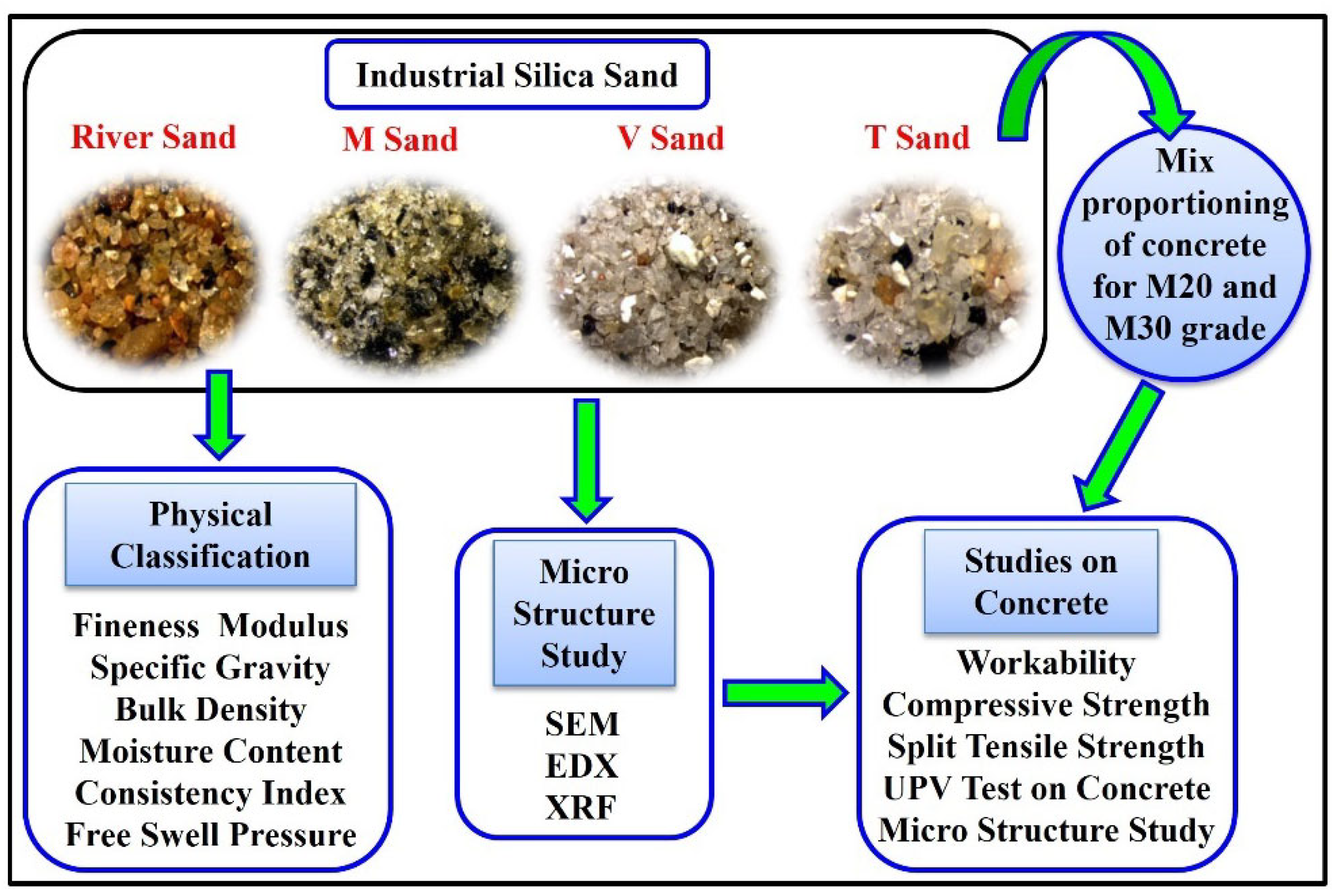

2.1. Methodology

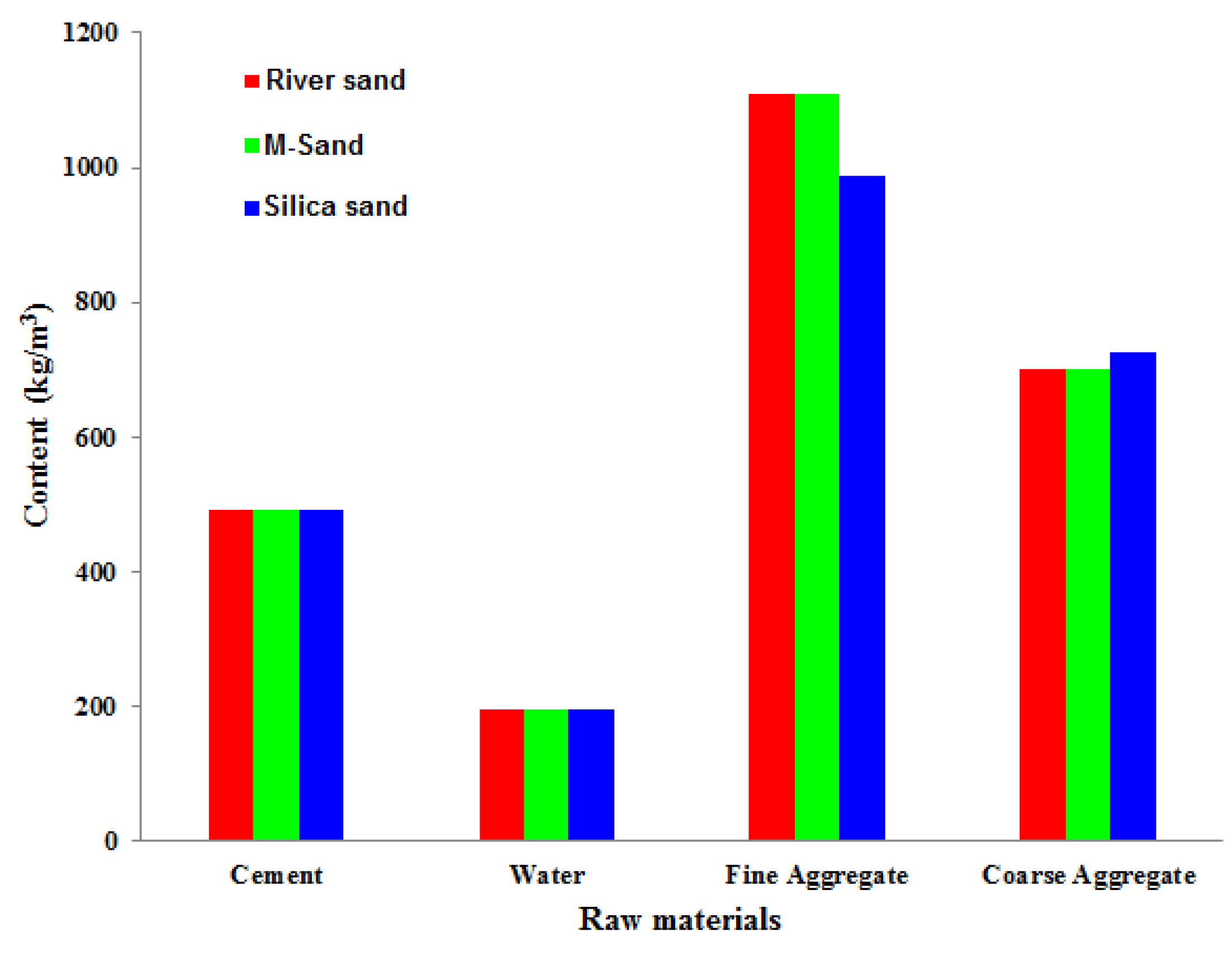

2.2. Materials and Mix Proportions

2.3. Studies on Silica Sand

2.3.1. Physical Properties of Silica Sand

2.3.2. Micro Studies on Silica Sand

2.4. Tests on Concrete

2.4.1. Workability

2.4.2. Compressive Strength and Split Tensile Strength

2.4.3. UPV Test

2.4.4. Microstructure Studies on Concrete

3. Results and Discussion

3.1. Physical Classifications

3.1.1. Fineness Modulus

3.1.2. Specific Gravity and Bulk Density

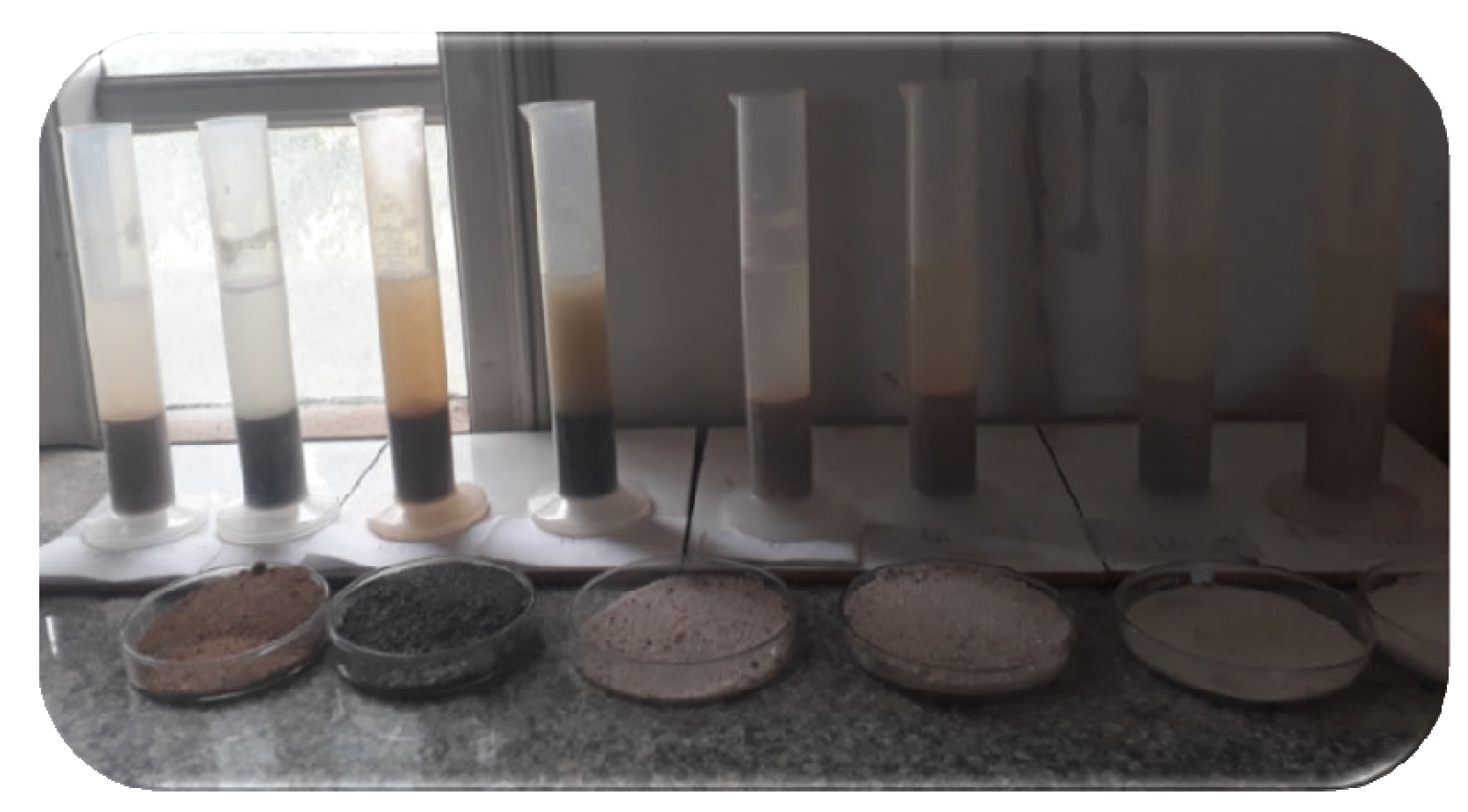

3.1.3. Moisture Content, Consistency Index and Free Swell Pressure

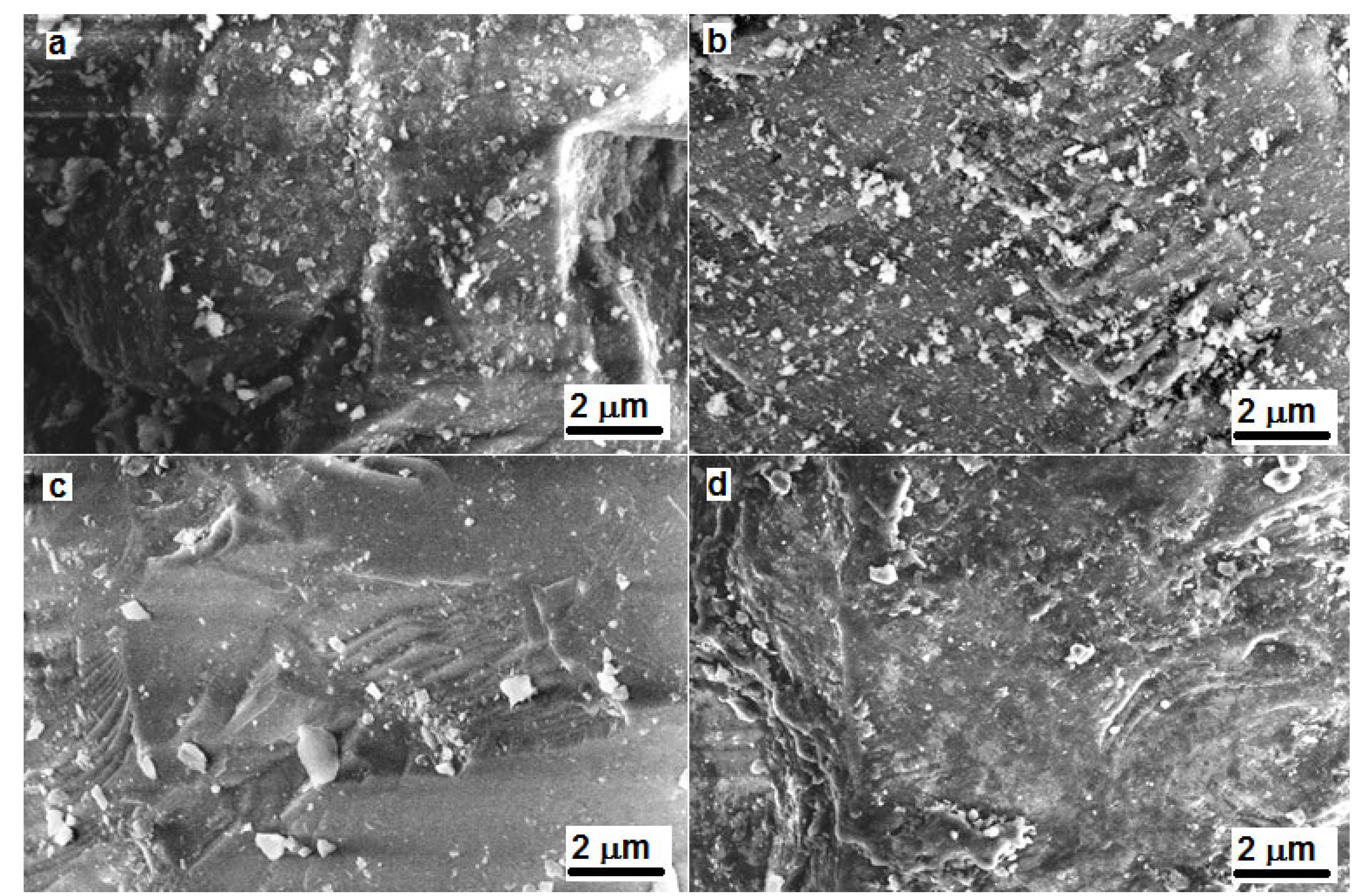

3.2. Microstructure of Sand Samples

3.3. Experiments on Concrete

3.3.1. Mix Proportioning

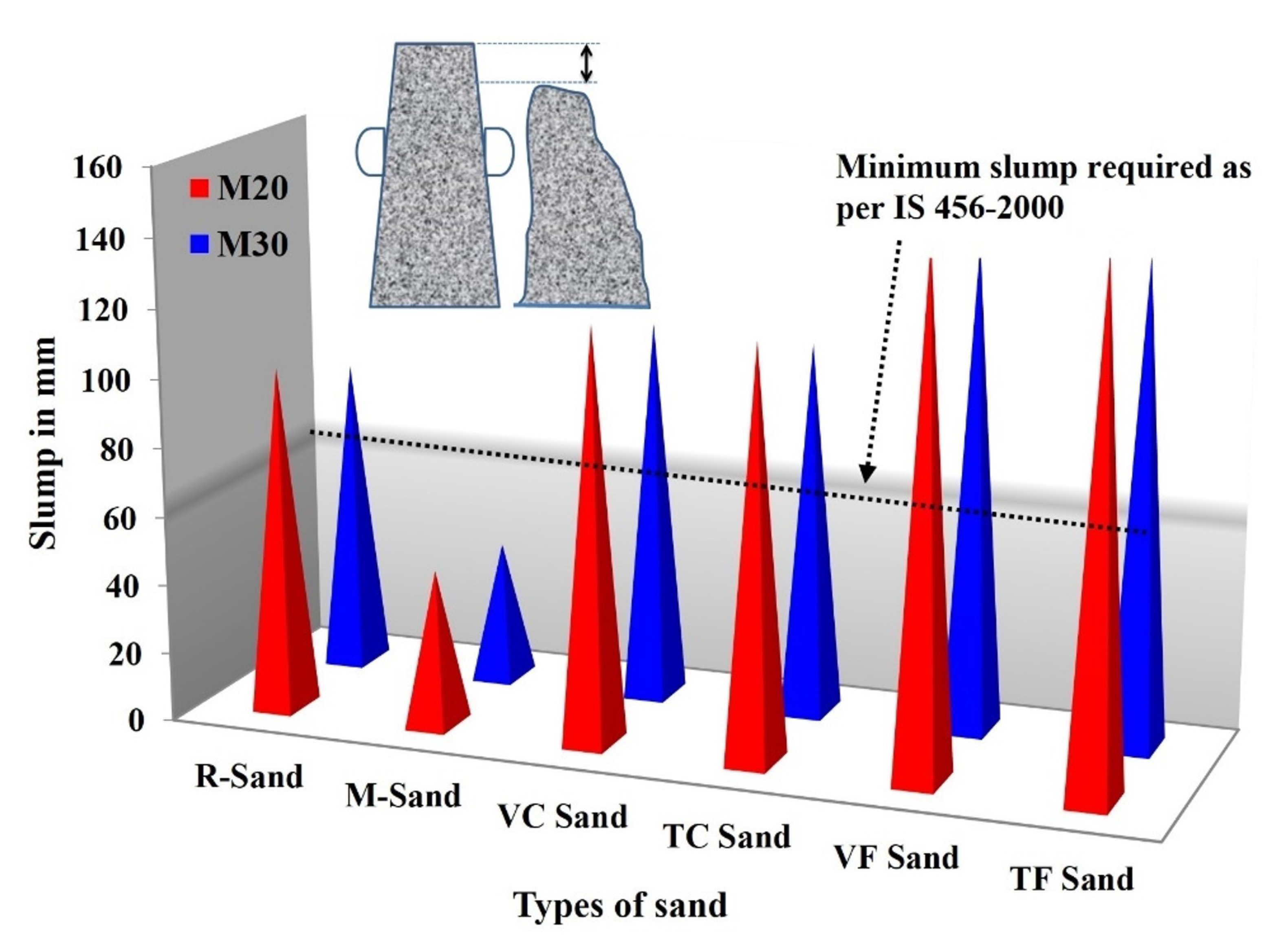

3.3.2. Workability of Concrete

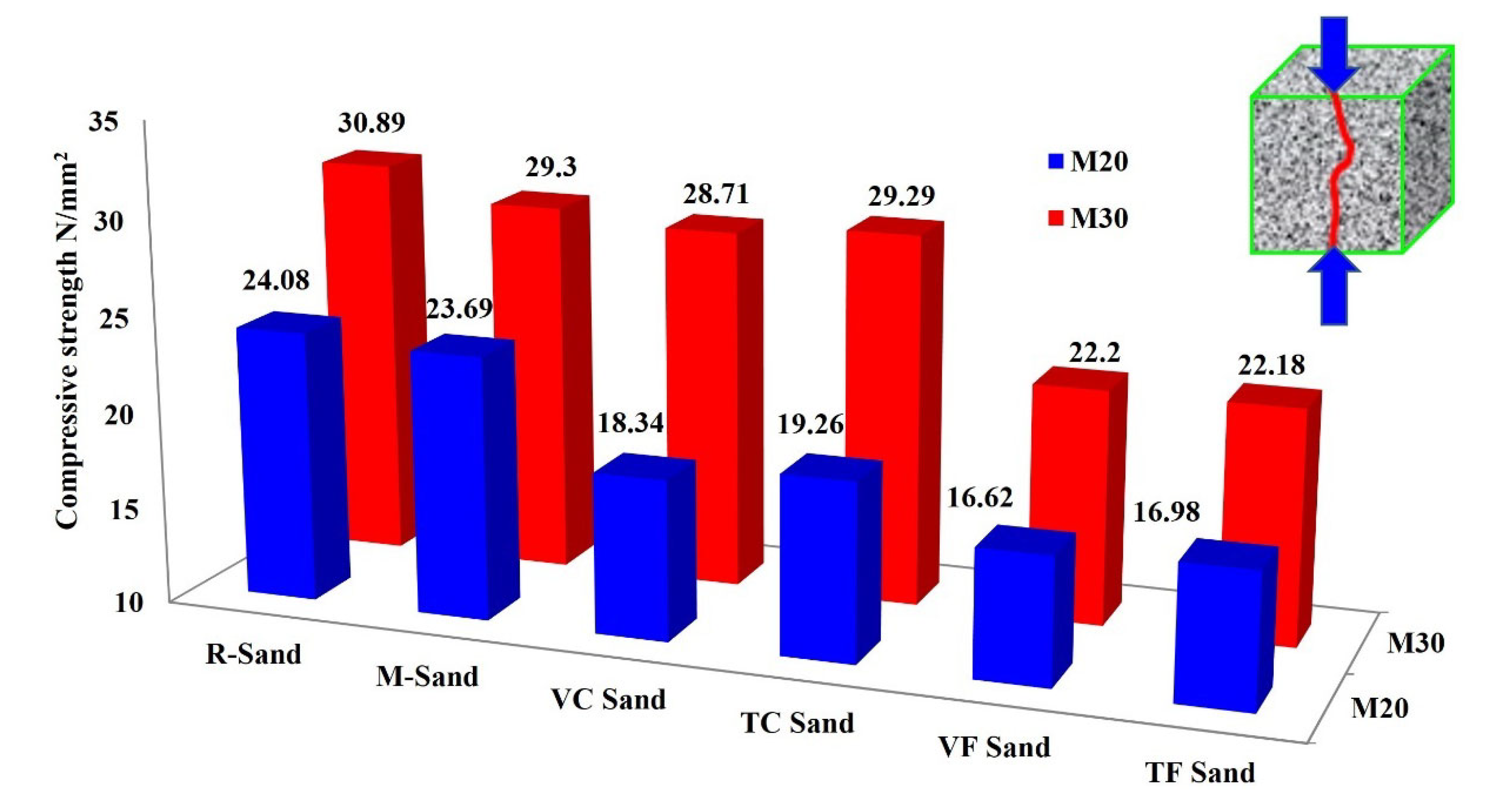

3.3.3. Compressive strength of Concrete

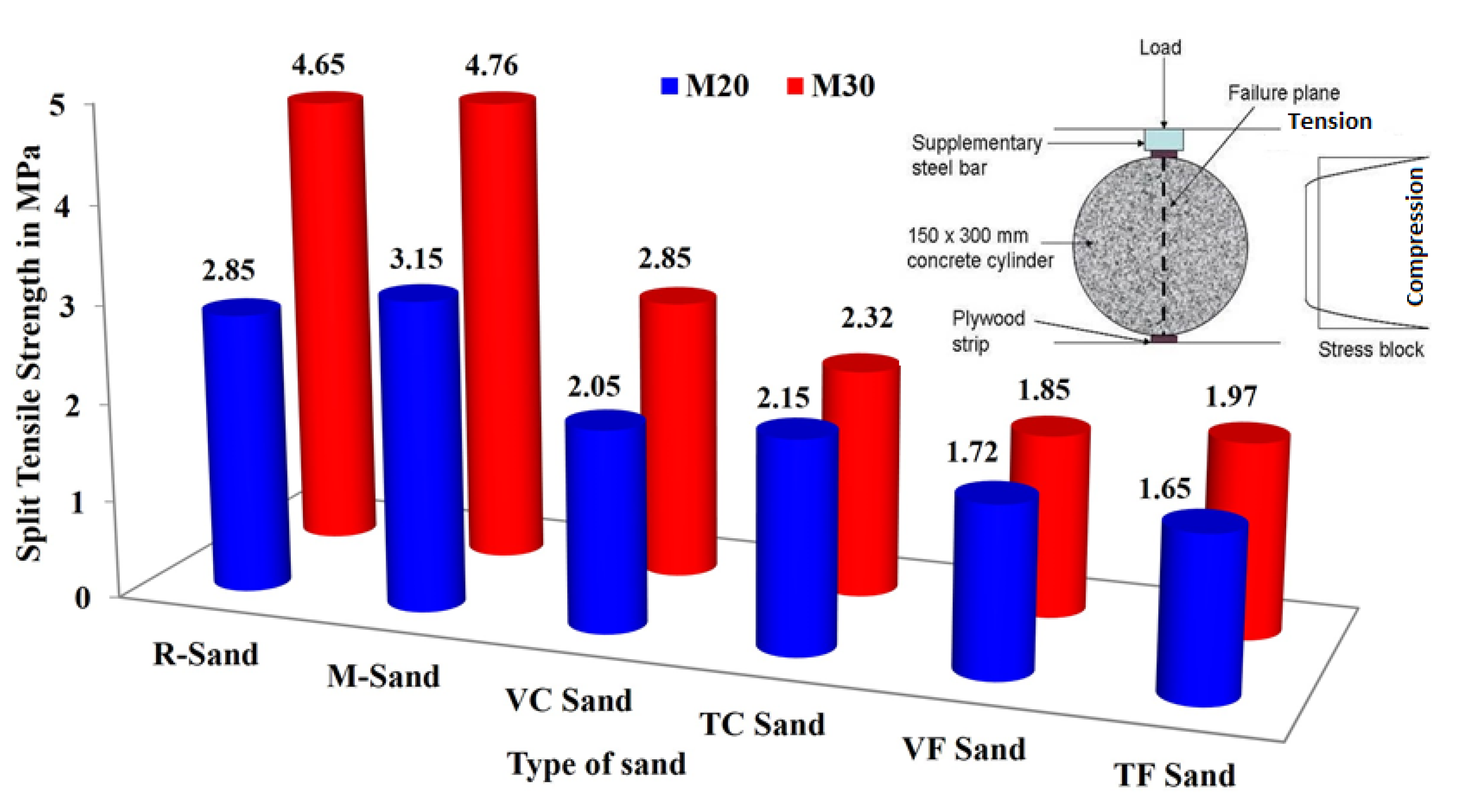

3.3.4. Split Tensile Strength of Concrete

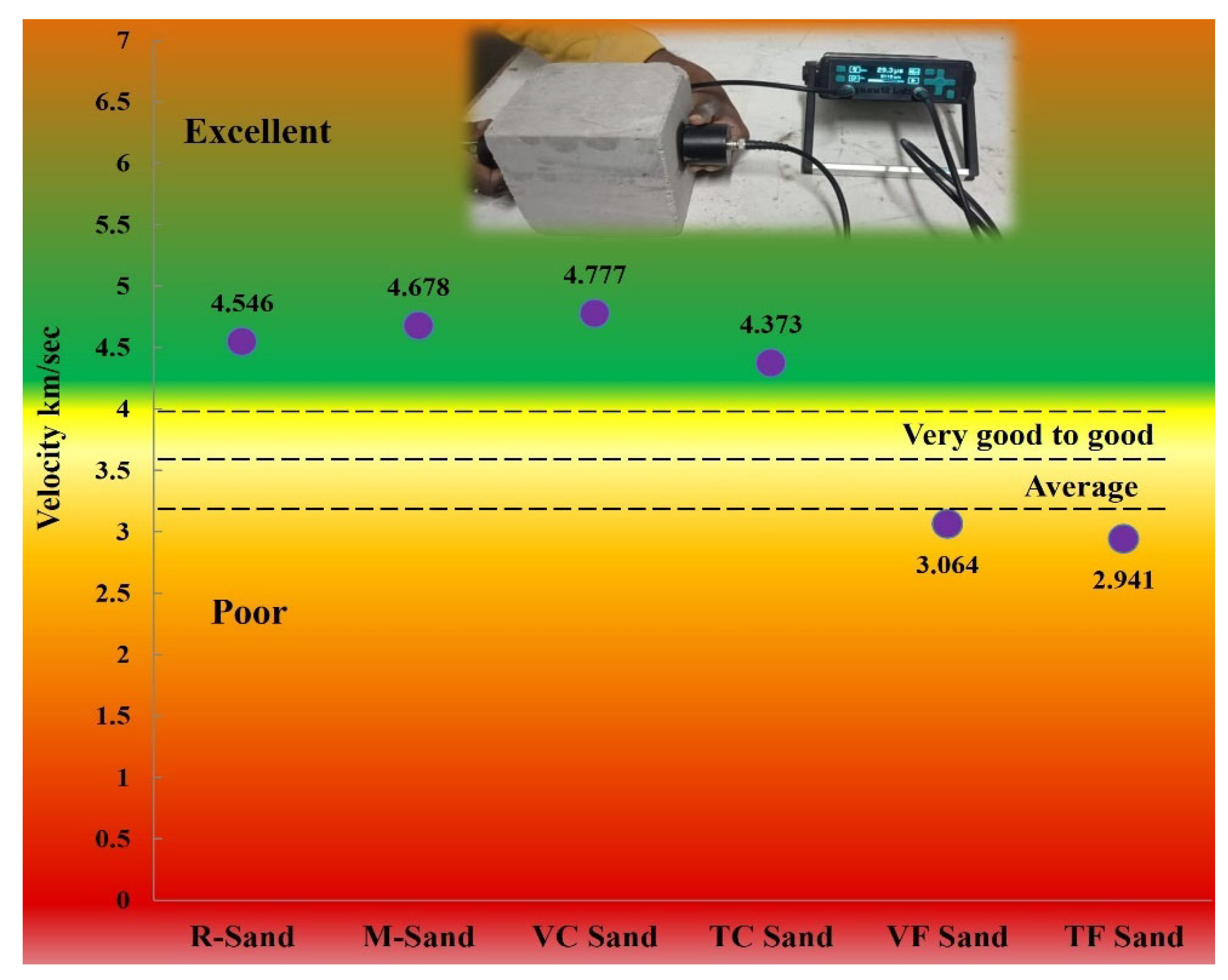

3.3.5. UPV Test on Concrete

3.4. Microstructure Studies on Concrete Powder

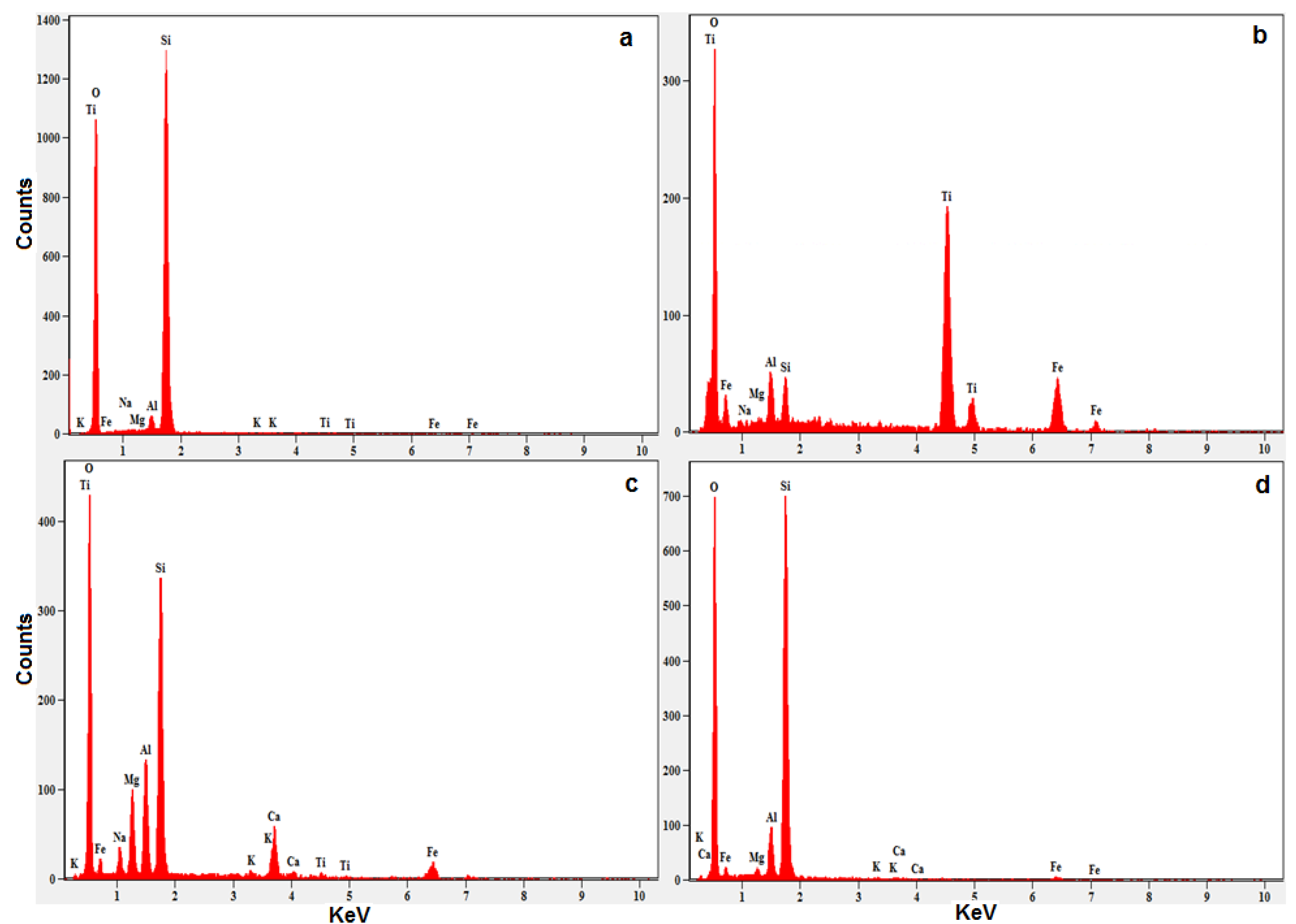

3.4.1. SEM/EDX

3.4.2. XRD

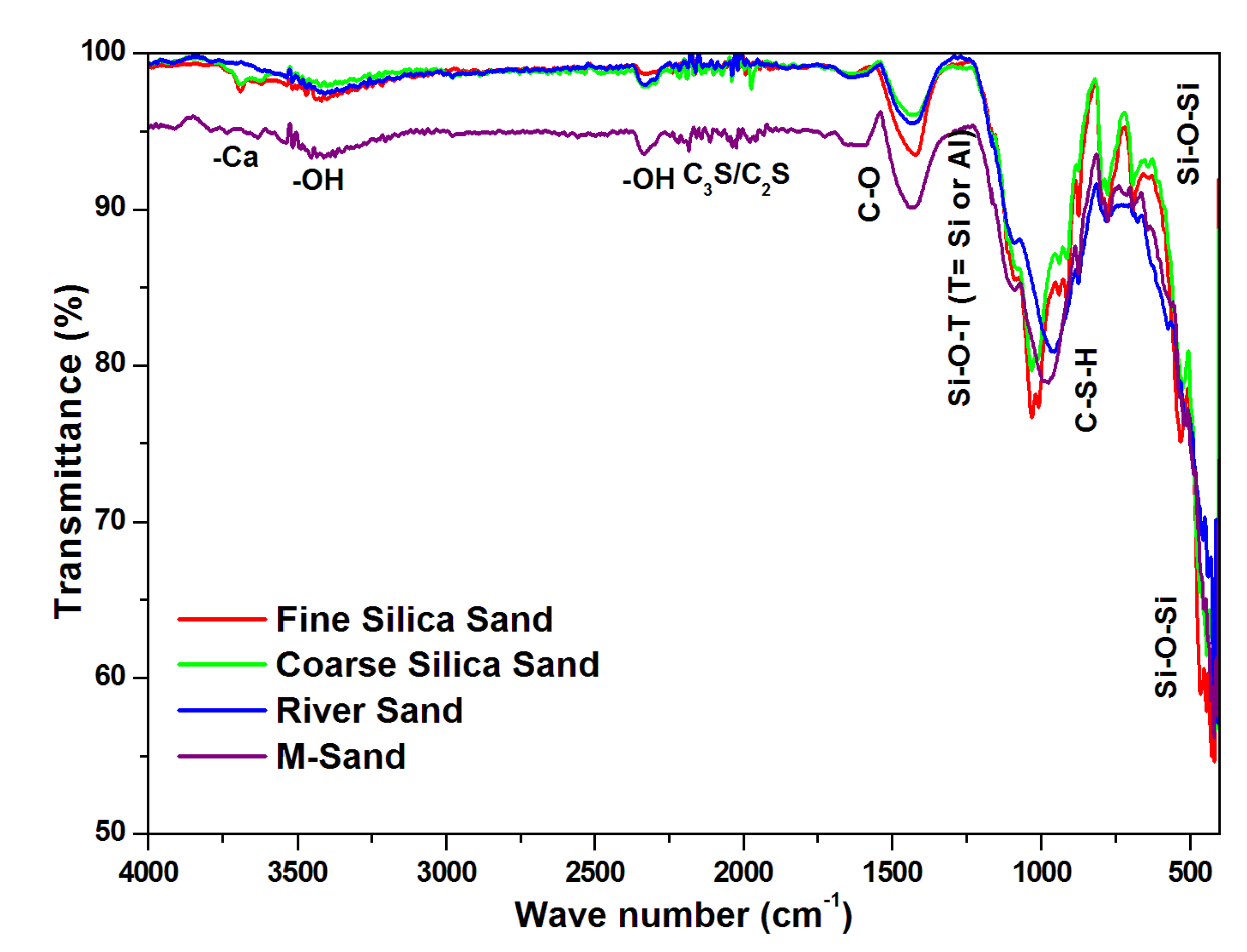

3.4.3. FTIR

4. Conclusions

- ➢

- Based on the physical classifications, the investigated silica sand samples were falls under Zone IV, the presence of fine sand is more than the allowable limit. As per codal recommendation, the sand samples of Zone IV are not recommended for concrete construction.

- ➢

- Even the coarser sand samples (VC and TC) were also finer than river sand and M sand as viewed under the SEM. This fineness in silica sand samples is due to presence of the small fragments of iron-titanium and quartz grains.

- ➢

- As per XRF elemental composition, silica sand samples have higher silica phase than the iron and titanium phase. However, in R sand and M sand iron phase is predominant than silica.

- ➢

- Silica sand does not have any amorphous mineral phase and all minerals are in inert state as observed in XRD. Hence, it acts only as a filler in the concrete.

- ➢

- Due to the roughness of the sand particles’ surfaces, silica sand concrete is more workable than river sand and M sand concrete (by about 40%).

- ➢

- The 28 day’s compressive strength of concrete for M20 and M30 grades were observed. In that, all investigated samples were failed to achieve the nominal strength. Finer sand samples exhibit lesser strength of all mixes. Same trend was observed in split tensile strength.

- ➢

- At 28 days, the M20 grade concrete displays 24 MPa and 23.7 MPa depending on the nominal mix of river sand and M sand. While finer sand concrete (VF and TF) displays 16.6 MPa, coarser sand concrete (VC and TC) displays 18.4 MPa and 19.3 MPa.

- ➢

- At 28 days, M30 grade concrete with a nominal mix of river sand and M sand displays 30 MPa and 29.3 MPa. The compressive strengths of coarser sand concrete (VC and TC) and finer sand concrete (VF and TF) are 28.7 MPa and 29.3 MPa, respectively.

- ➢

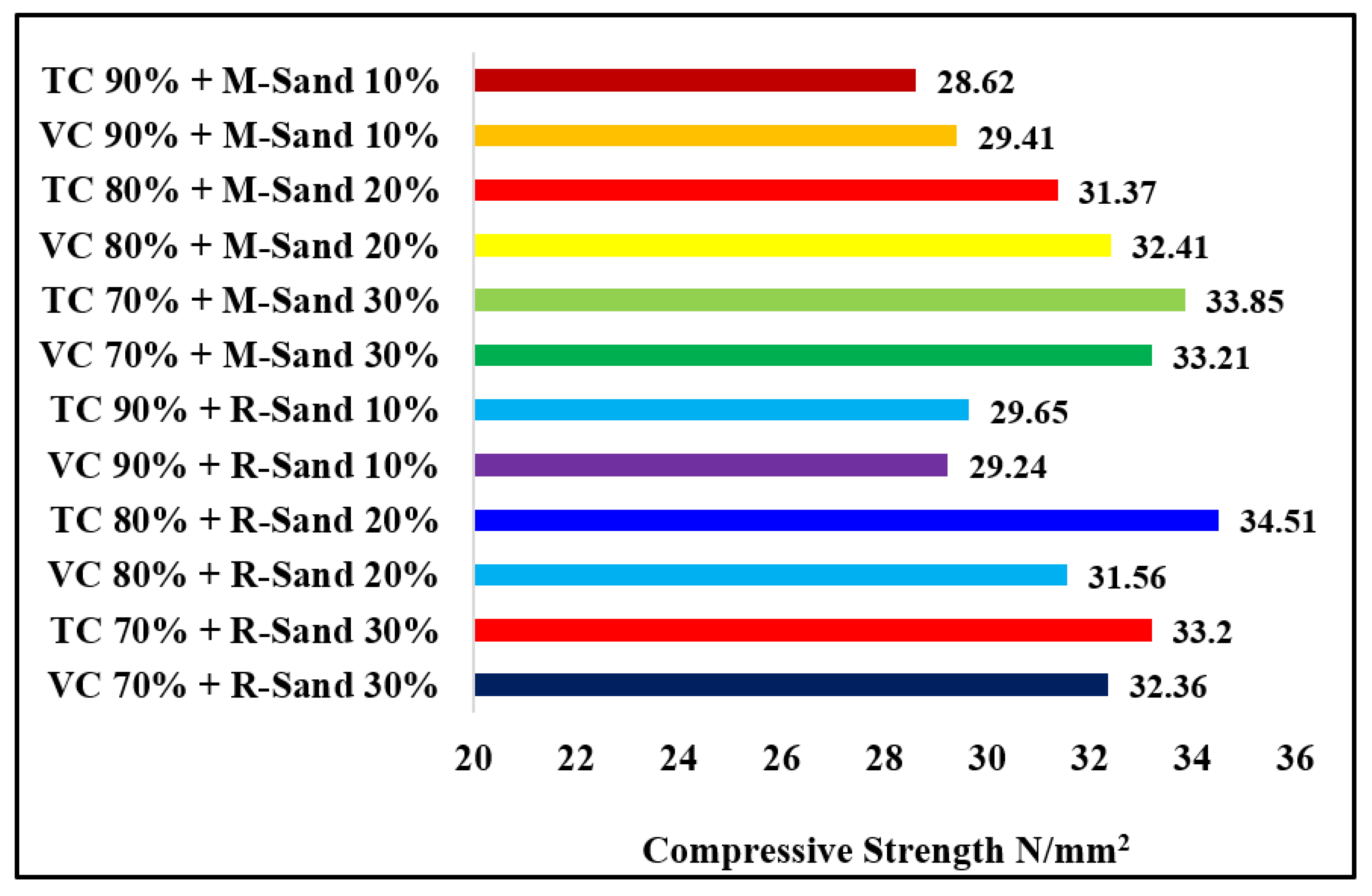

- To improve their strength performance and coarseness, coarser sand samples (VC and TC) were added with minor percentages of R sand and M sand (10%, 20% and 30%).

- ➢

- The compressive and split tensile strength of the modified mixes perform better than the nominal silica sand mixes.

- ➢

- The mix which contains 80% coarser silica sand (TC) with 20% river sand attained the maximum bending to compression is 34.5 MPa and tensile strength of 3.5 MPa at 28 days which was greatest of all mixes.

- ➢

- The microstructure as studied by SEM, EDX, XRD and FTIR for all sand samples concrete confirms the formation of hydration products and silica sand could compete well with the nominal sands.

- ➢

- Well-developed and distributed microstructure were observed in all sand concretes. Minor phase of calcium hydroxide in all mixes indicates that it was utilized maximum in the cement hydration.

- ➢

- Microstructure images shows well developed CSH crystal and dense images were observed with silica sand mix.

- ➢

- In all the mixes, quartz (SiO2) and CSH were the major peak found. Minor peaks of C2S and C3S were found in the mixes indicating that they are almost consumed in the cement hydration.

- ➢

- In FTIR, similar bending and stretching of spectrum were observed in all concrete. Fine silica sand, coarse silica sand and river sand concrete exhibits almost same spectrum than M sand concrete. This may be due to the similar elemental composition of silica sand and river sand.

- ➢

- Results of the microstructural investigation suggest that silica sand can be conveniently used as a fine aggregate in making good quality concrete and construction materials.

- ➢

- The utilization of silica sand instead of river sand up to 30% replacement will reduces cost up to 7.5% for one cubic meter of concreting.

- ➢

- Based on the study, it is recommended to use silica sand partially in concrete as replacement for fine aggregate up to some extent for sustainable and eco- friendly construction.

- ➢

- Further study on precast Ferro cement panels and ready mix plant with silica sand will explore on effective utilization of silica sand in thin elements and for strengthening purpose.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ren, Q.; Tao, Y.; Jiao, D.; De Schutter, G.; Jiang, Z. Rheological properties of concrete with manufactured sand: A multi-level prediction. Cem. Concr. Compos. 2022, 133, 104647. [Google Scholar] [CrossRef]

- Beddaa, H.; Ben Fraj, A.; Lavergne, F.; Torrenti, J.-M. Reuse of Untreated Fine Sediments as Filler: Is It More Beneficial than Incorporating Them as Sand? Buildings 2022, 12, 211. [Google Scholar] [CrossRef]

- Mao, W.; Cao, C.; Li, X.; Qian, J.; Dang, Y. An Experimental Investigation on the Effects of Limestone Fines in Manufactured Sands on the Performance of Magnesia Ammonium Phosphate Mortar. Buildings 2022, 12, 249. [Google Scholar] [CrossRef]

- Jignesh, K.; Vaniya, S.R. Effect of use of silica sand as fine material in concrete. Int. J. Innov. Res. Sci. Technol. 2015, 2, 266–271. [Google Scholar]

- Kazim, T.; Nehdi, M.L. Flexural toughness of sustainable ECC with high-volume substitution of cement and silica sand. Constr. Build. Mater. 2021, 270, 121438. [Google Scholar]

- Pachipala, S. A Study on Mechanical Properties of Concrete using Silica Sand as Partial Replacement of Cement. Int. J. Civ. Eng. 2017, 4, 34–39. [Google Scholar] [CrossRef]

- Chaudhary, J.L.; Harison, A.; Srivastava, V. Sand as cement replacement in PPC concrete. Int. J. Res. Eng. Technol. 2015, 4, 55–58. [Google Scholar]

- Siddique, R.; de Schutter, G.; Noumowe, A. Effect of used-foundry sand on the mechanical properties of concrete. Constr. Build. Mater. 2009, 23, 976–980. [Google Scholar] [CrossRef]

- Siddique, R.; Aggarwal, Y.; Aggarwal, P.; Kadri, E.-H.; Bennacer, R. Strength, durability, and micro-structural properties of concrete made with used-foundry sand (UFS). Constr. Build. Mater. 2011, 25, 1916–1925. [Google Scholar] [CrossRef]

- Prabhu, G.G.; Hyun, J.H.; Kim, Y.Y. Effects of foundry sand as a fine aggregate in concrete production. Constr. Build. Mater. 2014, 70, 514–521. [Google Scholar] [CrossRef]

- Bhandari, P.; Tajne, K.M. Use of foundry sand in conventional concrete. Int. J. Latest Trend. Eng. Technol. 2016, 6, 249–254. [Google Scholar]

- Md, S.; Wahab, A.; Md, A.K. A study on the mechanical properties of concrete by replacing sand with waste foundry sand. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 83–88. [Google Scholar]

- Aggarwal, Y.; Siddique, R. Microstructure and properties of concrete using bottom ash and waste foundry sand as partial replacement of fine aggregates. Constr. Build. Mater. 2014, 54, 210–223. [Google Scholar] [CrossRef]

- Daniel-Mkpume, C.C.; Okonkwo, E.G.; Aigbodion, V.S.; Offor, P.O.; Nnakwo, K.C. Silica sand modified aluminium composite an empirical study of the physical, mechanical and morphological properties. Mater. Res. Express. 2019, 6, 076539. [Google Scholar] [CrossRef]

- Shetty, K.K.; Nayak, G.; Shetty, K.R. Self-compacting concrete using red mud and used foundry sand. Int. J. Res. Eng. Technol. 2014, 3, 708–711. [Google Scholar]

- Lam, L.H.; Lam, D.D.; Duy, H.P. The effect of Vietnam’s nano-silica on mechanical properties of high-performance concrete. Transp. Comm. Sci. J. 2021, 72, 76–83. [Google Scholar]

- Rashid, R.S.M.; Salem, S.M.; Azreen, N.M.; Voo, Y.L.; Haniza, M.; Shukri, A.A.; Yahya, M.-S. Effect of elevated temperature to radiation shielding of ultra-high performance concrete with silica sand or magnetite. Constr. Build. Mater. 2020, 262, 120567. [Google Scholar] [CrossRef]

- Mahalakshmi, S.H.V.; Veerendrakumar, C.K. Experimental study on M-sand in self-compacting concrete with and without silica fume. Mater. Today Proc. 2020, 27, 1061–1065. [Google Scholar] [CrossRef]

- Arjun, N.; Vennila, A.; Sreevidya, V. Experimental study on self-compacting concrete with foundry sand and glass powder. Int. J. Chem. Technol. Res. 2017, 10, 390–395. [Google Scholar]

- Basar, H.M.; Aksoy, N.D. The effect of waste foundry sand (WFS) as partial replacement of sand on the mechanical, leaching and micro-structural characteristics of ready-mixed concrete. Constr. Build. Mater. 2012, 35, 508–515. [Google Scholar] [CrossRef]

- Gopinath, E. Experimental study on silica sand using bottom ash on metal casting. Mater. Today Proc. 2021, 46, 4884–4891. [Google Scholar] [CrossRef]

- Sadarang, J.; Nayak, R.K. Utilization of fly ash as an alternative to silica sand for green sand mould casting process. J. Manuf. Process. 2021, 68, 1553–1561. [Google Scholar] [CrossRef]

- Belmahi, S.; Mohamed, Z.; Abdelkader, H. Valuation of foundry sand in the construction sector. Leban. Sci. J. 2021, 22, 112–126. [Google Scholar] [CrossRef]

- Pilegis, M.; Gardner, D.; Lark, R. An Investigation into the Use of Manufactured Sand as a 100% Replacement for Fine Aggregate in Concrete. Materials 2016, 9, 440. [Google Scholar] [CrossRef]

- Rathore, A.; Kushwaha, P.K.; Gangwar, M. A review on use of manufactured sand in concrete production. Int. J. Adv. Res. Dev. 2018, 3, 97–100. [Google Scholar]

- Shanmugavadivu, P.M.; Malathy, R.; Sindhu, M.; Eskezia, H.; Gerba, A.F.; Gudeta, Y. The effect of manufactured sand in concrete. Int. J. Adv. Sci. Technol. 2020, 29, 4809–4820. [Google Scholar]

- Shanmugavadivu, P.M.; Malathy, R.; Sindu, M.; Eskezia, H.; Gudeta, Y. Structural properties of concrete with the replacement of natural sand by manufactured sand. J. Xidian Univ. 2020, 14, 1707–1712. [Google Scholar]

- Kothai, L.; Malathy, R. Strength studies on self-compacting concrete with manufactured sand as partial replacement of natural sand. Eur. J. Sci. Res. 2012, 89, 490–496. [Google Scholar]

- Setiati, N.R. The Potential Use of Silica Sand as Nanomaterials for mortar. In Proceedings of the 3rd International Conference on Construction and Building Engineering (ICONBUILD), Palembang, Indonesia, 14–17 August 2017; AIP Conference Proceedings, no. 1903. pp. 050010-1–050010-7. [Google Scholar] [CrossRef]

- Nathan, L.S. Study on structural behaviour of silica sand in concrete. J. Eng. Applied Sci. 2018, 13, 10837–10838. [Google Scholar]

- Poornima, V.; Ananthkumar, M.; Kumar, S.B.; Ahamed, K.I. Suitability of dolomite silica-sand in partial replacement with m- sand for cement mortar. IOP Conf. Series: Mater. Sci. Eng. 2019, 577, 012135. [Google Scholar] [CrossRef]

- IS 1489-1991; Portland-Pozzolana Cement Specification. Bureau of Indian Standards: New Delhi, India, 1991.

- IS 10262: 2019; Concrete Mix Proportioning—Guidelines. Bureau of Indian Standards: New Delhi, India, 2019.

- IS 2386-1 (1963); Methods of Test for Aggregates for Concrete, Part I: Particle Size and Shape. Bureau of Indian Standards: New Delhi, India, 1963.

- IS 383: 1970; Specification for Coarse and Fine Aggregates from Natural Sources for Concrete [CED 2: Cement and Concrete]. Bureau of Indian Standards: New Delhi, India, 1970.

- IS 2720-3-2 (1980); Methods of Test for Soils, Part 3: Determination of Specific Gravity, Section 2: Fine, Medium and Coarse-Grained Soils. Bureau of Indian Standards: New Delhi, India, 1980.

- Guedes, M.; Evangelista, L.; Brito, J.; Ferro, A.C. Microstructural characterization of concrete prepared with recycled ag-gregates. Microsc. Microanal. 2013, 19, 1222–1230. [Google Scholar] [CrossRef] [PubMed]

- Siddique, R. Effect of fine aggregate replacement with Class F fly ash on the mechanical properties of concrete. Cem. Concr. Res. 2003, 33, 539–547. [Google Scholar] [CrossRef]

- IS 1199-1959; Methods of Sampling and Analysis of Concrete. Bureau of Indian Standards: New Delhi, India, 1959.

- IS 516-2004; Method of Test for Strength of Concrete. Bureau of Indian Standards: New Delhi, India, 2004.

- IS 13311-1 (1992); Method of Non-Destructive Testing of Concrete, Part 1: Ultrasonic Pulse Velocity. Bureau of Indian Standards: New Delhi, India, 1992.

- Reddy, P.N.; Naqash, J.A. Experimental study on TGA, XRD and SEM Analysis of Concrete with Ultrafine Slag. Int. J. Eng. 2019, 32, 679–684. [Google Scholar]

- Kumar, S.V.; Rajkumar, R.; Umamaheswari, N. Study on Mechanical and Microstructure Properties of Concrete Prepared Using Metakaolin, Silica Fume and Manufactured Sand. Rasayan J. Chem. 2019, 12, 1383–1389. [Google Scholar] [CrossRef]

- El-Hassan, H.; Elkholy, S. Performance Evaluation and Microstructure Characterization of Steel Fiber–Reinforced Alkali-Activated Slag Concrete Incorporating Fly Ash. J. Mater. Civ. Eng. 2019, 31, 04019223. [Google Scholar] [CrossRef]

- Malathy, R.; Prabakaran, M.; Kalaiselvi, K.; Chung, I.M.; Kim, S.H. Comparative polyphenol composition, antioxidant and anticorrosion properties in various parts of Panax ginseng extracted in different solvents. Appl. Sci. 2021, 11, 93. [Google Scholar] [CrossRef]

- Hemapriya, V.; Prabakaran, M.; Chitra, S.; Swathika, M.; Kim, S.H.; Chung, I.M. Utilization of biowaste as an eco-friendly bi-odegradable corrosion inhibitor for mild steel in 1 mol/L HCl solution. Arab. J. Chem. 2020, 13, 8684–8696. [Google Scholar] [CrossRef]

- Malathy, R.; Arivoli, M.; Chung, I.-M.; Prabakaran, M. Effect of surface-treated energy optimized furnace steel slag as coarse aggregate in the performance of concrete under corrosive environment. Constr. Build. Mater. 2021, 284, 122840. [Google Scholar] [CrossRef]

- Yuan, G.; Prabakaran, M.; Qilong, S.; Lee, J.S.; Chung, I.-M.; Gopiraman, M.; Song, K.-H.; Kim, I.S. Cyclodextrin functionalized cellulose nanofiber composites for the faster adsorption of toluene from aqueous solution. J. Taiwan Inst. Chem. Eng. 2017, 70, 352–358. [Google Scholar] [CrossRef]

- Chung, I.-M.; Kim, S.-H.; Prabakaran, M. Evaluation of Phytochemical, Polyphenol Composition and Anti-corrosion Capacity of Cucumis anguria L. Leaf Extract on Metal Surface in Sulfuric Acid Medium. Prot. Met. Phys. Chem. Surf. 2020, 56, 214–224. [Google Scholar] [CrossRef]

- Chung, I.-M.; Malathy, R.; Priyadharshini, R.; Hemapriya, V.; Kim, S.-H.; Prabakaran, M. Inhibition of mild steel corrosion using Magnolia kobus extract in sulphuric acid medium. Mater. Today Commun. 2020, 25, 101687. [Google Scholar] [CrossRef]

- IS: 2720 (Part 5), 1985; Code of Determination of Liquid Limit. Bureau of Indian Standards: New Delhi, India, 1985.

- IS 2720-26 (1987); Method of Test for Soils, Part 26: Determination of pH Value. Bureau of Indian Standards: New Delhi, India, 1987.

- IS: 2720 (Part 40) 1977; Code of Free Swell Index of Soils. Bureau of Indian Standards: New Delhi, India, 1977.

- IS 456:2000; Plain and Reinforced Concrete–Code of Practice [CED 2: Cement and Concrete]. Bureau of Indian Standards: New Delhi, India, 2000.

- Manokaran, G.; Prabakaran, M. Evaluation of antioxidant and anticorrosion activities of Ligularia fischeri plant extract. Chem. Sci. Eng. Res. 2019, 1, 16–24. [Google Scholar] [CrossRef]

- Rabadiya, H.M.; Vaniya, S.R.; Parikh, K.B. A study on properties of self-compacting concrete using silica sand as partial re-placement of fine aggregate. Int. J. Emerging Technol. Innov. Res. 2016, 3, 59–69. [Google Scholar]

- Mohammad, T.S.; Mohammed, A.A. Ultrasonic Pulse Velocity and Morphology of High Strength Concrete with PVC Waste Aggregate. Int. J. Recent Technol. Eng. 2020, 8, 3783–3788. [Google Scholar] [CrossRef]

- Seghir, N.T.; Benaimeche, O.; Krzywiński, K.; Sadowski, Ł. Ultrasonic evaluation of cement-based building materials modified using marble powder sourced from industrial wastes. Buildings 2020, 10, 38. [Google Scholar] [CrossRef]

- Malathy, R.; Chung, I.-M.; Prabakaran, M. Characteristics of fly ash based concrete prepared with bio admixtures as internal curing agents. Constr. Build. Mater. 2020, 262, 120596. [Google Scholar] [CrossRef]

- Waghmare, S. Microstructural analysis of M30 grade concrete using scanning electron microscopy (SEM). Int. J. Eng. Res. Appl. 2020, 10, 65–71. [Google Scholar]

- Saran, A.S.A.; Harish, T. Strength, microstructure of sustainable high performance concrete. Int. J. Recent Technol. Eng. 2019, 8, 4694–4700. [Google Scholar] [CrossRef]

- Alehyen, S.; El Achouri, M.; Taibi, M. Characterization, microstructure and properties of fly ash-based geopolymer. JMES 2017, 8, 1783–1796. [Google Scholar]

- Manoharan, T.; Laksmanan, D.; Mylsamy, K.; Sivakumar, P.; Sircar, A. Engineering properties of concrete with partial utilization of used foundry sand. Waste Manag. 2018, 71, 454–460. [Google Scholar] [CrossRef]

- Chopra, D.; Siddique, R.; Kunal. Strength, permeability and microstructure of self-compacting concrete containing rice husk ash. Biosyst. Eng. 2015, 30, 72–80. [Google Scholar] [CrossRef]

- Kavitha, O.; Shanthi, V.; Arulraj, G.P.; Sivakumar, V. Microstructural studies on eco-friendly and durable Self-compacting concrete blended with metakaolin. Appl. Clay Sci. 2016, 124–125, 143–149. [Google Scholar] [CrossRef]

- Medina, C.; del Bosque, I.S.; Frías, M.; de Rojas, M.S. Design and characterisation of ternary cements containing rice husk ash and fly ash. Constr. Build. Mater. 2018, 187, 65–76. [Google Scholar] [CrossRef]

- Horgnies, M.; Chen, J.J.; Bouillon, C. Overview about the use of Fourier Transform Infrared spectroscopy to study cementitious materials. WIT Trans. Eng. Sci. 2013, 77, 251–262. [Google Scholar] [CrossRef]

- Malathy, R.; Shanmugam, R.; Chung, I.-M.; Kim, S.-H.; Prabakaran, M. Mechanical and Microstructural Properties of Composite Mortars with Lime, Silica Fume and Rice Husk Ash. Processes 2022, 10, 1424. [Google Scholar] [CrossRef]

- Stuart, B.H. Infrared Spectroscopy: Fundamentals and Applications; John Wiley and Sons Ltd.: Chichester, UK, 2004. [Google Scholar]

| Type of Sand | Fineness Modulus Value | Classification and Ranges | |

|---|---|---|---|

| R sand | 3.654 | Very Coarse sand | Above 3.2 |

| M sand | 3.624 | Very Coarse sand | Above 3.2 |

| TF Sand | 1.732 | Very fine sand | Below 2.2 |

| VF Sand | 1.760 | Very fine sand | Below 2.2 |

| TC Sand | 2.678 | Medium sand | 2.6 to 2.9 |

| VC Sand | 2.900 | Medium sand | 2.9 to 3.2 |

| Sand Samples | Ca | Fe | Si | Ti | Er |

|---|---|---|---|---|---|

| River sand | 4.00 | 66.76 | 6.00 | 23.24 | - |

| M sand | 21.97 | 65.41 | 10.17 | - | 2.45 |

| Fine silica sand | - | 33.97 | 45.27 | 20.76 | - |

| Coarse silica sand | - | 44.44 | 30.85 | 24.71 | - |

| Element | Weight % | Atomic % | Error % |

|---|---|---|---|

| (a). Fine silica sand concrete | |||

| C | 54.3 | 64.5 | 10.0 |

| O | 34.2 | 30.5 | 11.1 |

| Mg | 0.5 | 0.3 | 16.2 |

| Al | 1.1 | 0.6 | 10.0 |

| Si | 3.9 | 2.0 | 5.9 |

| Ca | 6.0 | 2.1 | 5.3 |

| (b). Coarse silica sand concrete | |||

| C | 50.2 | 61.6 | 10.2 |

| O | 34.6 | 31.9 | 11.3 |

| Al | 1.0 | 0.5 | 11.3 |

| Si | 5.0 | 2.6 | 5.7 |

| Ca | 8.9 | 3.3 | 4.9 |

| Sc | 0.4 | 0.1 | 33.6 |

| (c). Natural river sand concrete | |||

| C | 43.5 | 55.1 | 10.6 |

| O | 38.6 | 36.7 | 11.1 |

| Mg | 0.4 | 0.3 | 21.6 |

| Al | 1.6 | 0.9 | 9.1 |

| Si | 5.7 | 3.1 | 5.5 |

| S | 0.6 | 0.3 | 17.6 |

| Ca | 9.1 | 3.5 | 4.6 |

| Sc | 0.4 | 0.1 | 33.3 |

| (d). M Sand concrete | |||

| C | 52.7 | 63.5 | 10.0 |

| O | 34.5 | 31.2 | 11.2 |

| Al | 1.3 | 0.7 | 9.3 |

| Si | 3.5 | 1.8 | 6.1 |

| S | 0.3 | 0.1 | 32.3 |

| Ca | 6.5 | 2.4 | 5.0 |

| Fe | 1.1 | 0.3 | 21.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malathy, R.; Rajagopal Sentilkumar, S.R.; Prakash, A.R.; Das, B.B.; Chung, I.-M.; Kim, S.-H.; Prabakaran, M. Use of Industrial Silica Sand as a Fine Aggregate in Concrete—An Explorative Study. Buildings 2022, 12, 1273. https://doi.org/10.3390/buildings12081273

Malathy R, Rajagopal Sentilkumar SR, Prakash AR, Das BB, Chung I-M, Kim S-H, Prabakaran M. Use of Industrial Silica Sand as a Fine Aggregate in Concrete—An Explorative Study. Buildings. 2022; 12(8):1273. https://doi.org/10.3390/buildings12081273

Chicago/Turabian StyleMalathy, Ramalingam, Sellamuthu Ramachandran Rajagopal Sentilkumar, Annamalai Rangasamy Prakash, B. B. Das, Ill-Min Chung, Seung-Hyun Kim, and Mayakrishnan Prabakaran. 2022. "Use of Industrial Silica Sand as a Fine Aggregate in Concrete—An Explorative Study" Buildings 12, no. 8: 1273. https://doi.org/10.3390/buildings12081273

APA StyleMalathy, R., Rajagopal Sentilkumar, S. R., Prakash, A. R., Das, B. B., Chung, I.-M., Kim, S.-H., & Prabakaran, M. (2022). Use of Industrial Silica Sand as a Fine Aggregate in Concrete—An Explorative Study. Buildings, 12(8), 1273. https://doi.org/10.3390/buildings12081273