Post-High-Temperature Exposure Repeated Impact Response of Steel-Fiber-Reinforced Concrete

Abstract

:1. Introduction

2. Research Significance

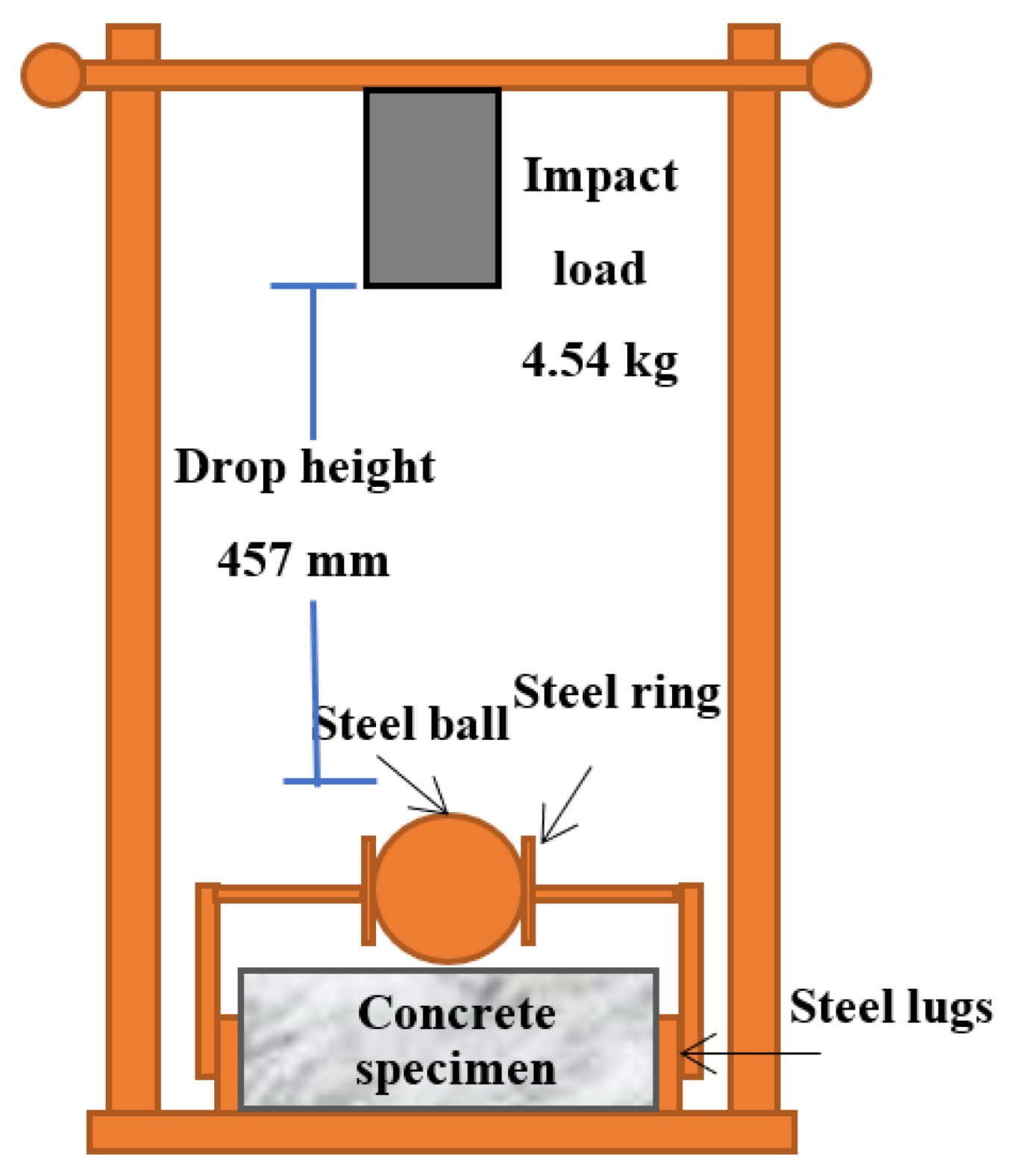

3. ACI 544-2R Repeated-Impact Test

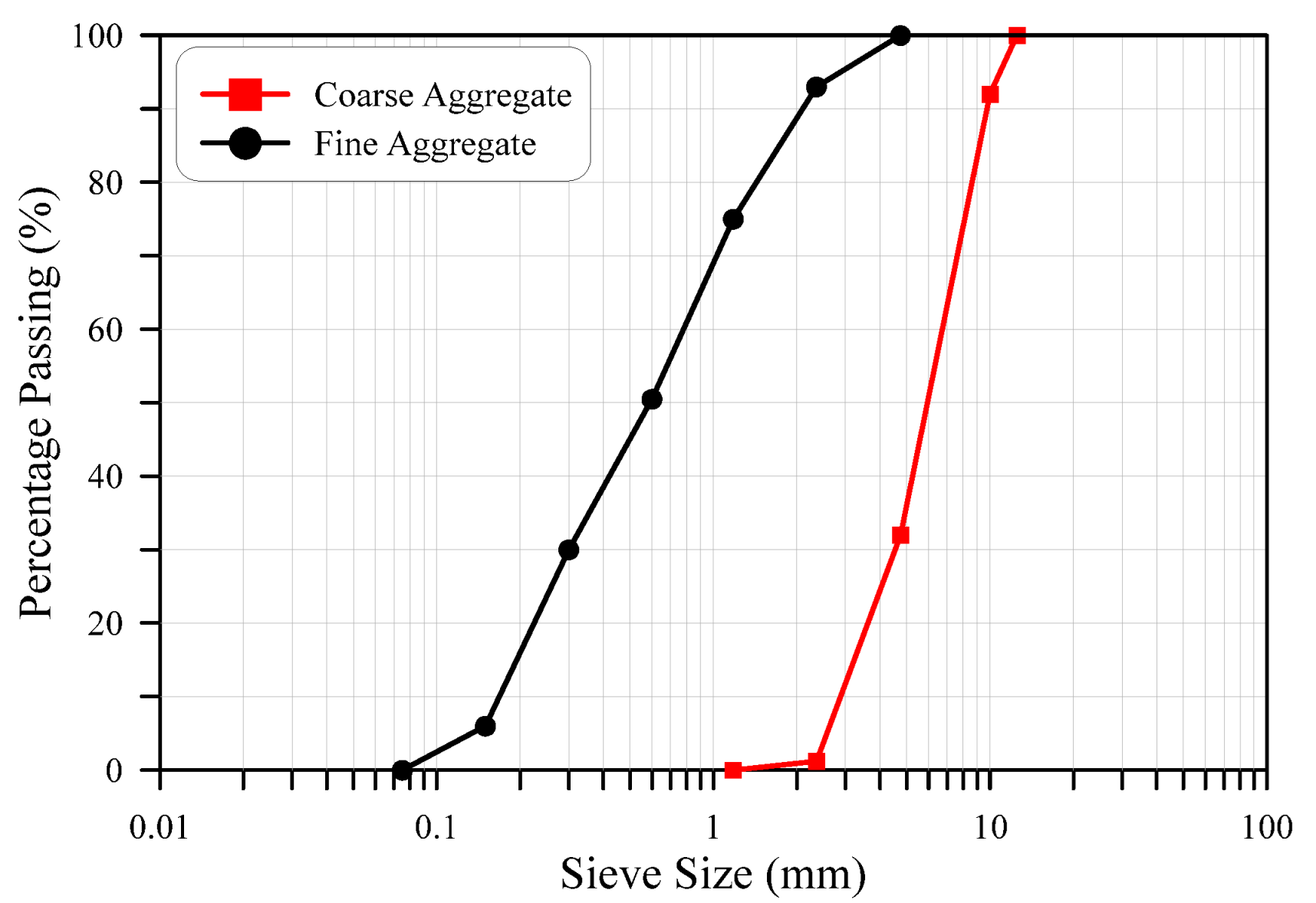

4. Experimental Program

5. Results and Discussion of Control Tests

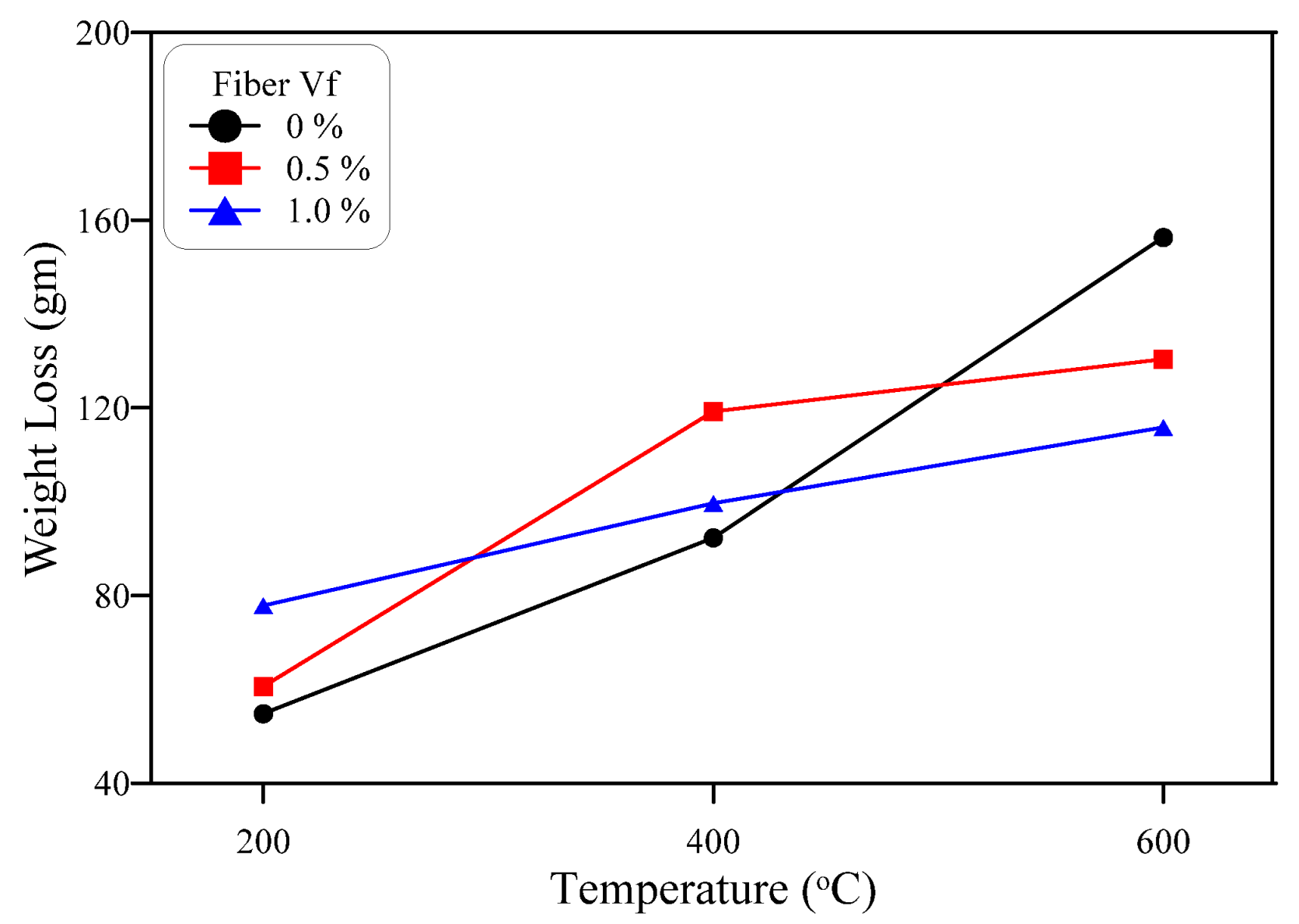

5.1. Weight Loss

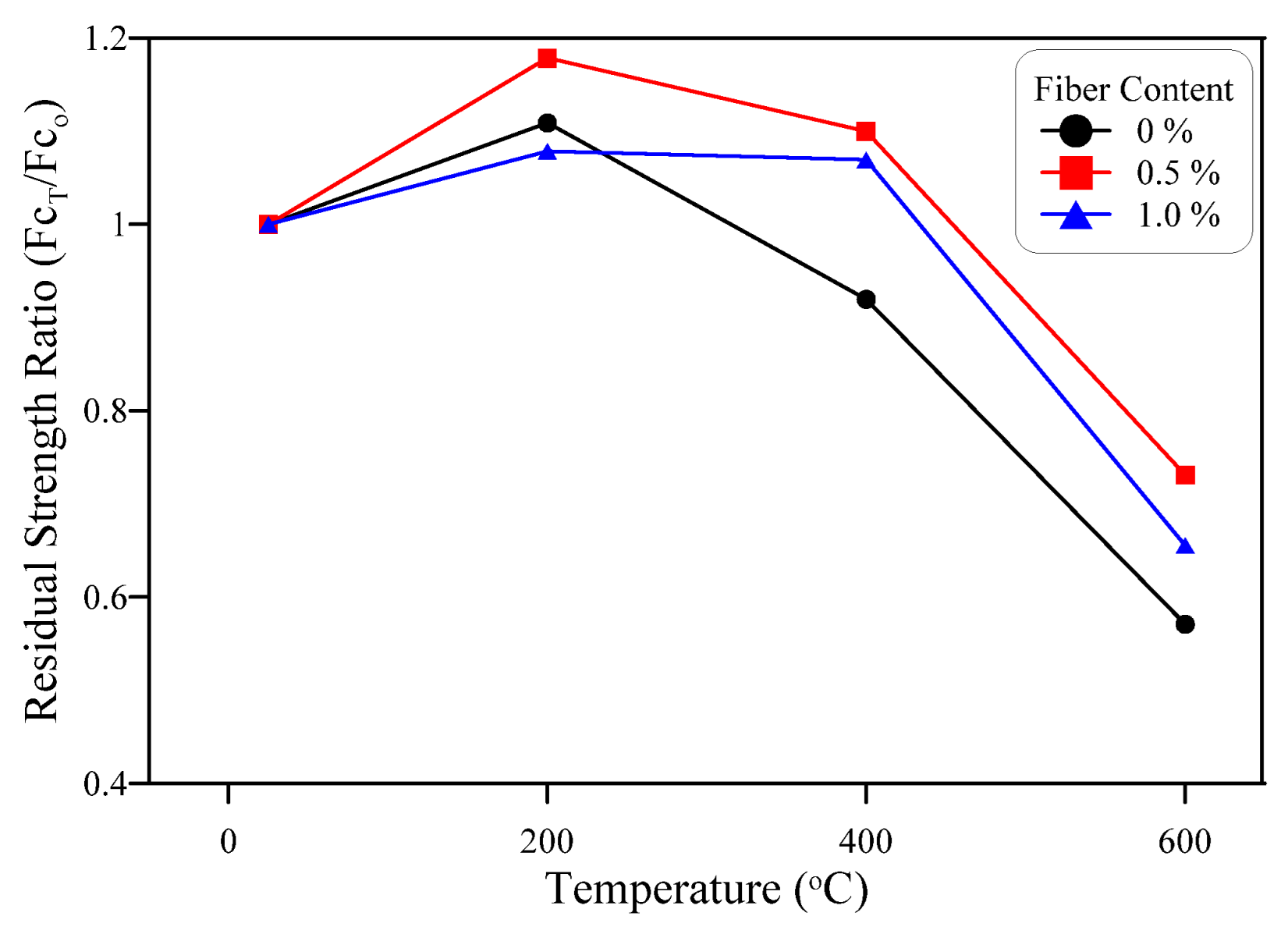

5.2. Compressive Strength

6. Results and Discussion of Impact Numbers

6.1. Influence of Fiber Content

6.2. Residual Impact Numbers of Heated Specimens

7. Cracking and Fracturing of Impact Specimens

7.1. Influence of Fiber Content

7.2. Influence of High-Temperature Exposure

8. Conclusions

- The effect of steel-fiber (SF) inclusion was positive on compressive strength before and after exposure to high temperatures. The inclusion of 0.5% and 1.0% of hooked-end SF increased the strength (compared to plain cubes) of unheated specimens by approximately 3% and 17%, respectively, which was attributed to the stiffness enhancement gained by SF. However, this enhancement was more pronounced after exposure to high temperatures where the percentage increase was more than 30% at 600 °C for both SF contents. The additional strength percentage improvement could be attributed to the action of SF as a bridging element that connected the deteriorated microstructure of the heated specimens by crossing the thermal cracks.

- Exposure to 200 °C increased the compressive strength of plain and fibrous specimens by more than 10%, which could be attributed to the increase in surface physical forces due to moisture loss. On the other hand, the decomposition of calcium hydroxide, and the deterioration of the bond between aggregate and cement paste led to a strength loss of approximately 27% to 43% after exposure to 600 °C.

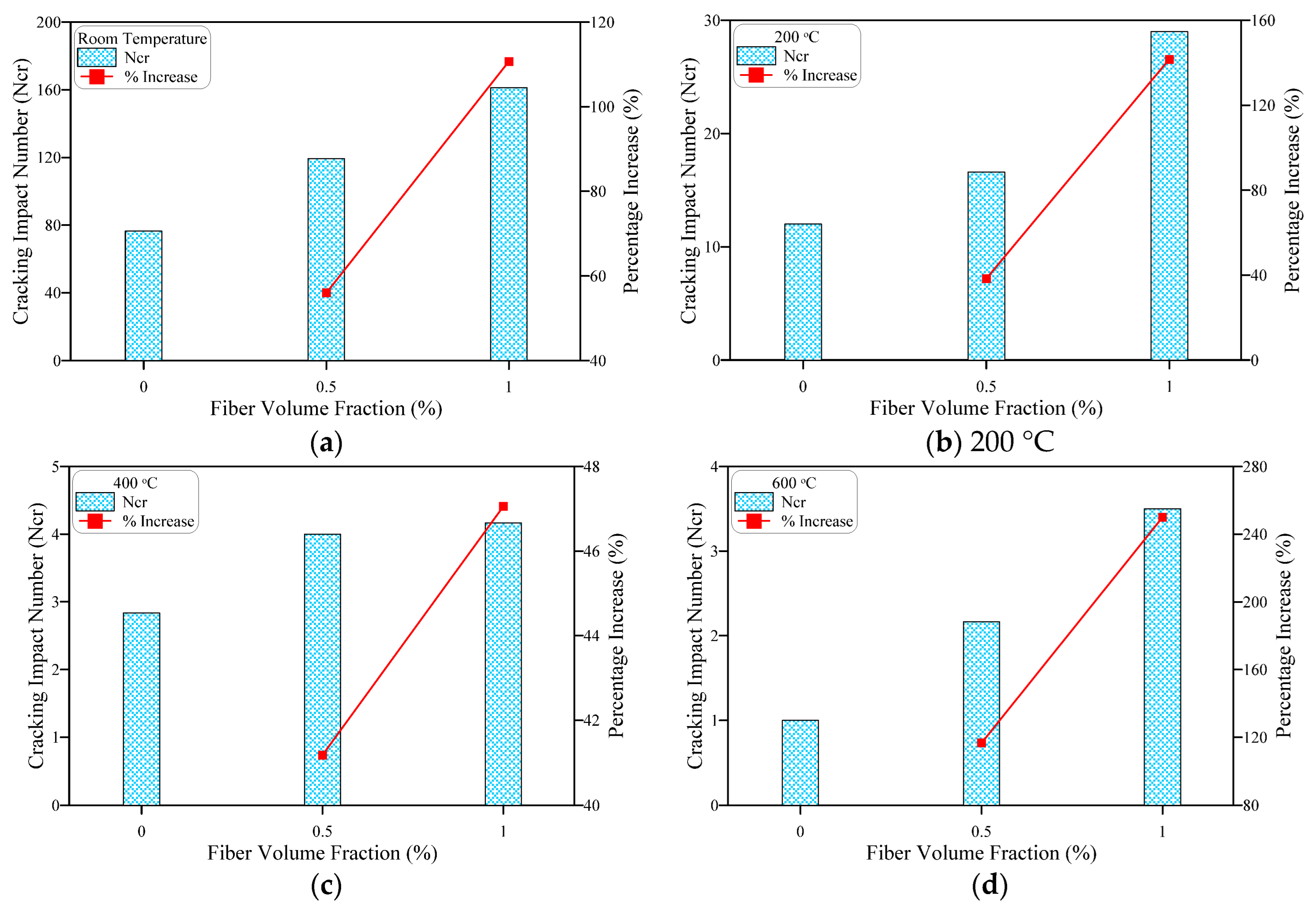

- SF played a major role in boosting the energy absorption capacity and resistance to repeated impacts of the concrete. A percentage development of approximately 40% to 140% of impact resistance at cracking (Ncr) was recorded for unheated specimens and those subjected to 200 °C when 0.5% and 1.0% SF were used. The effect of SF on Ncr was higher at 600 °C than that at a lower temperature, where the percentage developments were 117% and 250% due to using 0.5% and 1.0% SF, respectively, compared to plain specimens exposed to the same temperature. The better action of SF at 600 °C could be attributed to the degree of deterioration in the microstructure reached due to high thermal stresses, which enabled SF to be fully functional in bridging cracks and fragmented elements.

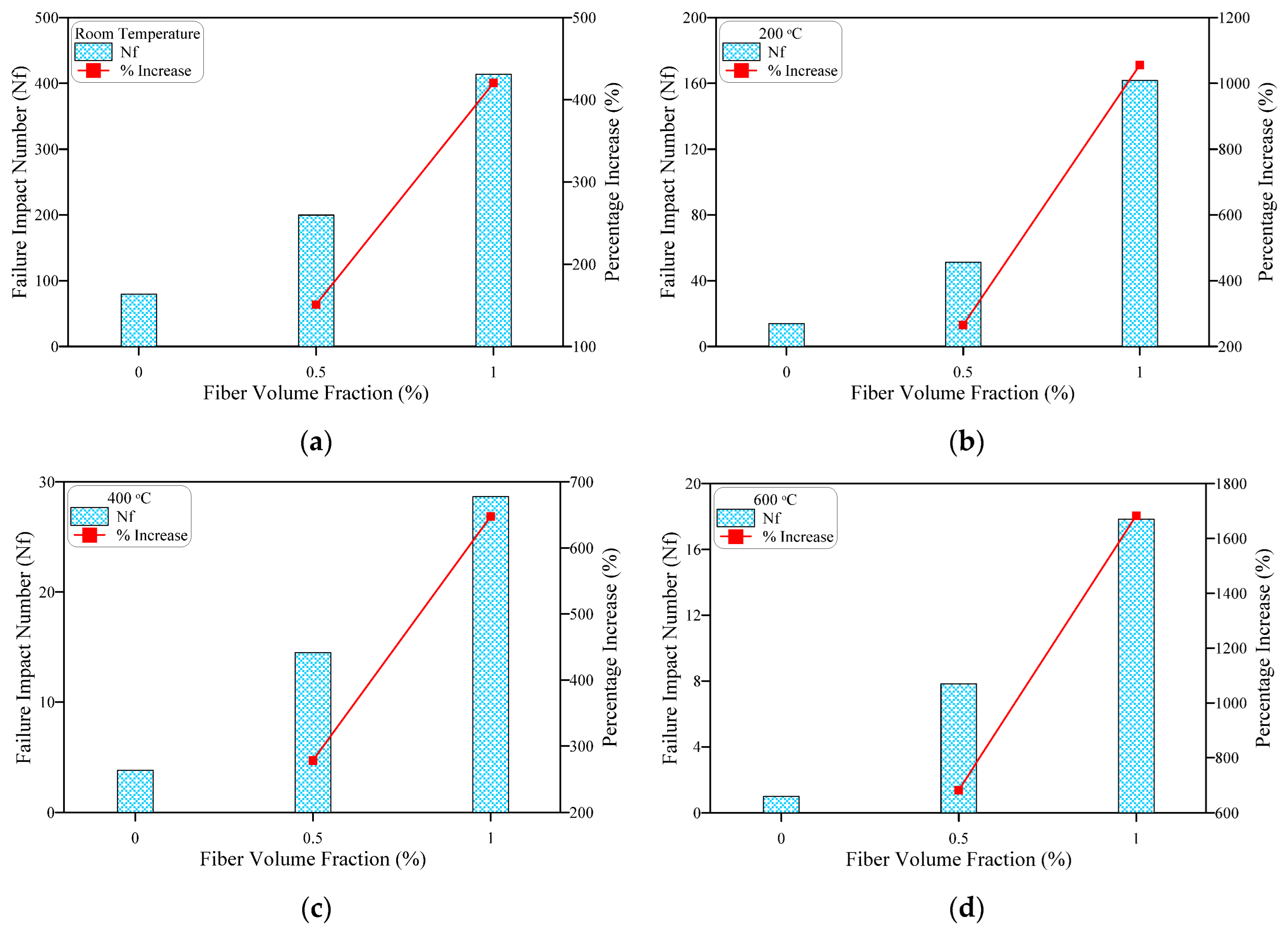

- Steel fibers could provide a much higher enhancement in impact resistance at the failure stage than that at the cracking stage, which was attributed to their main function as tiny crack bridging and reinforcement elements, where their ability to help in sustaining higher tensile stresses is activated after cracking. Compared to plain specimens subjected to the same temperatures, fibrous specimens with 1.0% SF could retain higher Nf by approximately 420% for the unheated specimens, and approximately 650% to 1680% for specimens heated to the adopted high temperatures. The highest percentage development in Nf was also recorded at 600 °C.

- The specimens heated to high temperatures were dramatically deteriorated when subjected to repeated impact loads regardless of the adopted fiber content, where even after exposure to the sub high temperature of 200 °C, the specimens lost more than 80% of their cracking impact resistance and more than 60% of their failure impact resistance, while the impact resistance was almost lost after exposure to 400 and 600 °C. The maximal residual Ncr and Nf percentages were 4% and 7% at 400 °C, and 2.2% and 4% at 600 °C.

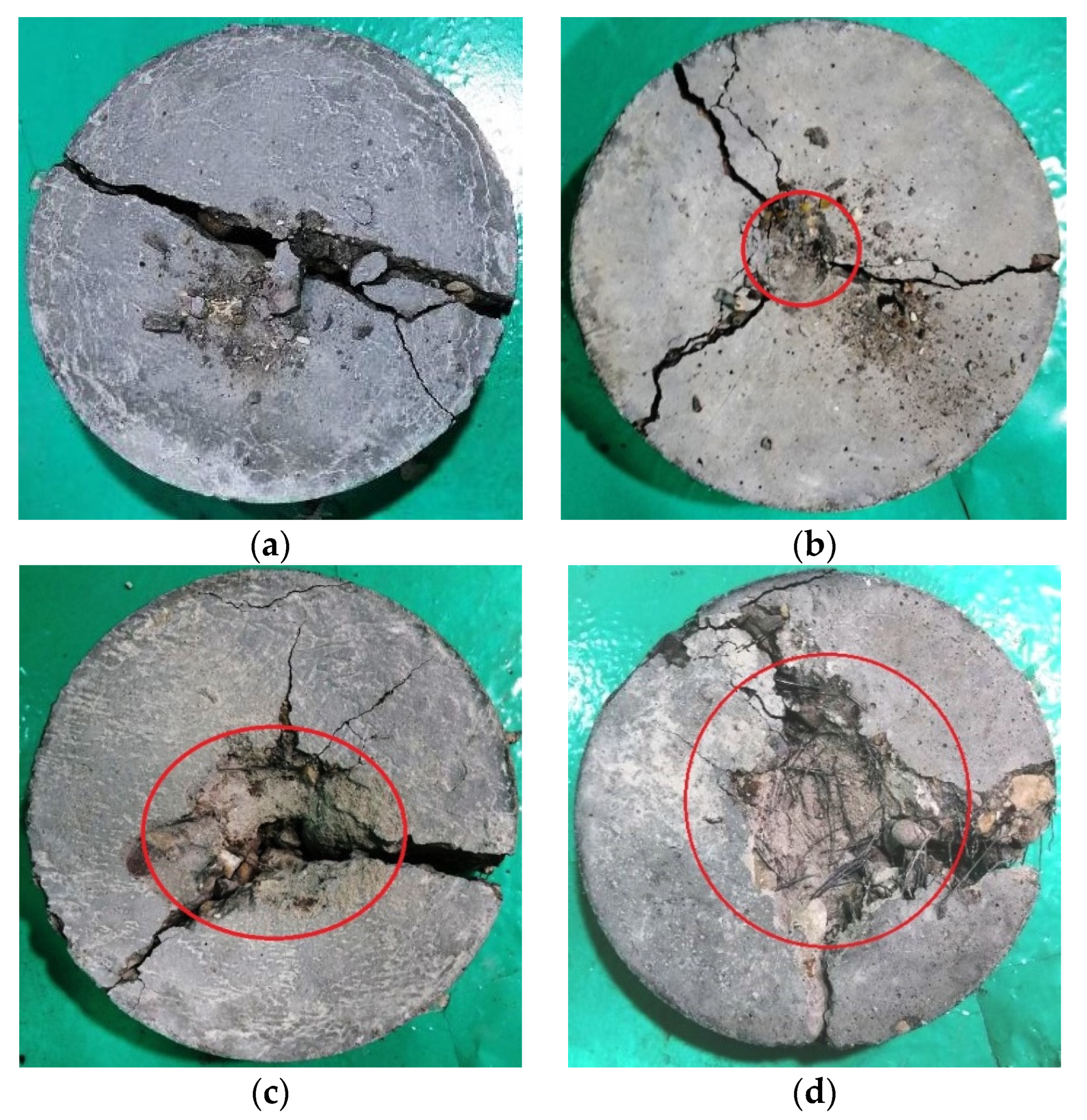

- The specimens heated to 200 °C exhibited a similar fracturing behavior to that of the unheated ones, where minimal central fracturing with line or diagonal cracks was the cause of the brittle failure of the plain specimens, while the SFs composed a central shielding zone that noticeably widened the central fracturing zone of the fibrous specimens, exhibiting more ductile behavior with SF bridged cracks. On the other hand, exposure to 600 °C altered the failure patterns that were more affected by the thermal cracking due to high-temperature exposure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brushlinsky, N.N.; Ahrens, M.; Sokolov, S.V.; Wagner, P. World Fire Statistics, Center of Fire Statistics of CTIF; International Association of Fire and Rescue Services: Ljubljana, Slovenia, 2018. [Google Scholar]

- Arna’ot, F.H.; Abid, S.R.; Özakça, M.; Tayşi, N. Review of concrete flat plate-column assemblies under fire conditions. Fire Saf. J. 2017, 93, 39–52. [Google Scholar] [CrossRef]

- Schneider, U. Properties of Materials at High Temperatures—Concrete; RILEM-Committee 44-PHT, Department of Civil Engineering, University of Kassel: Kassel, Germany, 1985. [Google Scholar]

- Phan, L.T.; Carino, N.J. Effects of test conditions and mixture proportions on behavior of high strength concrete exposed to high temperatures. ACI Mater. J. 2002, 99, 54–66. [Google Scholar]

- Netinger, I.; Kesegic, I.; Guljas, I. The effect of high temperatures on the mechanical properties of concrete made with different types of aggregates. Fire Saf. J. 2011, 46, 425–430. [Google Scholar] [CrossRef]

- Albrektsson, J.; Flansbjer, M.; Lindqvist, J.E.; Jansson, R. Assessment of Concrete Structures after Fire; SP Report 19; SP Technical Research Institute of Sweden: Borås, Sweden, 2011. [Google Scholar]

- Guo, Y.; Zhang, J.; Chen, G.; Xie, Z. Compressive behaviour of concrete structures incorporating recycled concrete aggregates, rubber crumb and reinforced with steel fibre, subjected to elevated temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- Tufail, M.; Shahzada, K.; Gencturk, B.; Wei, J. Effect of elevated temperature on mechanical properties of limestone, quartzite and granite concrete. Int. J. Concr. Struct. Mater. 2017, 11, 17–28. [Google Scholar] [CrossRef]

- Roufael, G.; Beaucour, A.-L.; Eslami, J.; Hoxha, D.; Noumowe, A. Influence of lightweight aggregates on the physical and mechanical residual properties of concrete subjected to high temperatures. Constr. Build. Mater. 2021, 268, 121221. [Google Scholar] [CrossRef]

- Drzymala, T.; Jackiewicz-Rek, W.; Tomaszewski, M.; Kus, A.; Galaj, J.; Sukys, R. Effects of high temperatures on the properties of high performance concrete (HPC). Procedia Eng. 2017, 172, 256–263. [Google Scholar] [CrossRef]

- Phan, L.T.; Carino, N.J. Review of mechanical properties of HSC at elevated temperatures. J. Mater. Civ. Eng. 1998, 10, 58–64. [Google Scholar] [CrossRef]

- Phan, L.T.; Carino, N.J. Code provisions for high strength concrete strength-temperature relationship at elevated temperatures. Mater. Struct. 2003, 36, 91–98. [Google Scholar] [CrossRef]

- Abrams, M.S. Compressive Strength of Concrete at Temperatures to 1600 °F; American Concrete Institute (ACI) SP 25; Temperature and Concrete: Detroit, MI, USA, 1971. [Google Scholar]

- Al-Owaisy, S.R. Post heat exposure properties of steel fiber reinforced concrete. J. Eng. Sustain. Dev. 2006, 10, 194–207. [Google Scholar]

- Dügenci, O.; Haktanir, T. Experimental research for the effect of high temperature on the mechanical properties of steel fiber-reinforced concrete. Constr. Build Mater. 2015, 75, 82–88. [Google Scholar] [CrossRef]

- Chu, H.-Y.; Jiang, J.-Y.; Sun, W.; Zhang, M. Mechanical and physicochemical properties of ferro-siliceous concrete subjected to elevated temperatures. Constr. Build. Mater. 2016, 122, 743–752. [Google Scholar] [CrossRef] [Green Version]

- Deng, Z.H.; Huang, H.Q.; Ye, B.; Wang, H.; Xiang, P. Investigation on recycled aggregate concretes exposed to high temperature by biaxial compressive tests. Constr. Build. Mater. 2020, 244, 118048. [Google Scholar] [CrossRef]

- Cheng, F.P.; Kodur, V.K.R.; Wang, T.C. Stress-strain curves for high strength concrete at elevated temperatures. J. Mater. Civ. Eng. 2004, 16, 84–94. [Google Scholar] [CrossRef]

- Husem, M. The effects of high temperature on compressive and flexural strengths of ordinary and high-performance concrete. Fire Saf. J. 2006, 41, 155–163. [Google Scholar] [CrossRef]

- Al-Owaisy, S.R. Strength and elasticity of steel fiber reinforced concrete at high temperatures. J. Eng. Sustain. Dev. 2007, 11, 125–133. [Google Scholar]

- Toric, N.; Boko, I.; Peroš, B. Reduction of postfire properties of high-strength concrete. Adv. Civ. Eng. 2013, 2013, 712953. [Google Scholar]

- Arna’ot, F.H.; Abbass, A.A.; Abualtemen, A.A.; Abid, S.R.; Özakça, M. Residual strength of high strength concentric column-SFRC flat plate exposed to high temperatures. Constr. Build. Mater. 2017, 154, 204–218. [Google Scholar] [CrossRef]

- Sultan, H.K.; Alyaseri, I. Effects of elevated temperatures on mechanical properties of reactive powder concrete elements. Constr. Build. Mater. 2020, 261, 120555. [Google Scholar] [CrossRef]

- Alimrani, N.; Balazs, G.L. Investigations of direct shear of one-year old SFRC after exposed to elevated temperatures. Constr. Build. Mater. 2020, 254, 119308. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, S.; Zhang, N.; Zhou, Y. Low-velocity flexural impact response of steel fiber reinforced concrete subjected to freeze-thaw cycles in NaCl solution. Constr. Build. Mater. 2015, 101, 522–526. [Google Scholar] [CrossRef]

- Salaimanimagudam, M.P.; Suribabu, C.R.; Murali, G.; Abid, S.R. Impact response of hammerhead pier fibrous concrete beams designed with topology optimization. Period. Polytech. Civ. Eng. 2020, 64, 1244–1258. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, S.; Liu, Y. Effect of weight and drop height of hammer on the flexural impact performance of fiber-reinforced concrete. Constr. Build. Mater. 2017, 140, 31–35. [Google Scholar] [CrossRef]

- Pan, Y.; Wu, C.; Cheng, X.; Li, V.C.; He, L. Impact fatigue behaviour of GFRP mesh reinforced engineered cementitious composites for runway pavement. Constr. Build. Mater. 2020, 230, 116898. [Google Scholar] [CrossRef]

- Wang, W.; Chouw, N. The behaviour of coconut fibre reinforced concrete (CFRC) under impact loading. Constr. Build. Mater. 2017, 134, 452–461. [Google Scholar] [CrossRef]

- Abid, S.R.; Gunasekaran, M.; Ali, S.H.; Kadhum, A.L.; Al-Gasham, T.S.; Fediuk, R.; Vatin, N.; Karelina, M. Impact performance of steel fiber-reinforced self-compacting concrete against repeated drop weight impact. Crystals 2021, 11, 91. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Vatin, N.I. Experimental and Analytical Modeling of Flexural Impact Strength of Preplaced Aggregate Fibrous Concrete Beams. Materials 2022, 15, 3857. [Google Scholar] [CrossRef]

- Hrynyk, T.D.; Vecchio, F.J. Beahvior of steel fiber-reinforced concrete slabs under impact loads. ACI Struct. J. 2014, 111, 1213–1224. [Google Scholar] [CrossRef]

- Koutas, L.N.; Bournas, D.A. Flexural strengthening of two-way RC slabs with textile-reinforced mortar: Experimental investigation and design equations. J. Compos. Constr. 2017, 21, 04016065. [Google Scholar] [CrossRef]

- Batran, T.Z.; Ismail, M.K.; Hassan, A.A.A. Behavior of novel hybrid lightweight concrete composites under drop-weight impact loading. Structures 2021, 34, 2789–2800. [Google Scholar] [CrossRef]

- Batarlar, B.; Hering, M.; Bracklow, F.; Kühn, T.; Beckmann, B.; Curbach, M. Experimental investigation on reinforced concrete slabs strengthened with carbon textiles under repeated impact loads. Structural Concrete. 2021, 22, 120–131. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, W.; Tran, T.T.; Pham, T.M.; Hao, H.; Chen, Z.; Elchalakani, M. Experimental and numerical study on concrete beams reinforced with Basalt FRP bars under static and impact loads. Compos. Struct. 2021, 263, 113648. [Google Scholar] [CrossRef]

- Said, A.M.I.; Mabrook Mouwainea, E. Experimental investigation on reinforced concrete slabs under high-mass low velocity repeated impact loads. Structures 2022, 35, 314–324. [Google Scholar] [CrossRef]

- Gopalaratnam, V.S.; Shah, S.P.; John, R. A modified instrumented charpy test for cement-based composites. Exp. Mech. 1984, 24, 102–111. [Google Scholar] [CrossRef]

- Yu, R.; Van Beers, L.; Spiesz, P.; Brouwers, H.J.H. Impact resistance of a sustainable Ultra-High Performance Fibre Reinforced Concrete (UHPFRC) under pendulum impact loadings. Constr. Build. Mater. 2016, 107, 203–215. [Google Scholar] [CrossRef]

- Ziada, M.; Erdem, S.; Tammam, Y.; Kara, S.; Lezcano, R.A.G. The effect of basalt fiber on mechanical, microstructural, and high-temperature properties of fly ash-based and basalt powder waste-filled sustainable geopolymer mortar. Sustainability 2021, 13, 12610. [Google Scholar] [CrossRef]

- ACI 544.2R-89; Measurement of Properties of Fiber Reinforced Concrete. American Concrete Institute: Farmington Hills, MI, USA, 1999; Volume 89, pp. 1–12.

- Soroushian, P.; Nagi, M.; Alhozaimy, A. Statistical variations in the mechanical properties of carbon fiber reinforced cement composites. ACI Mater. J. 1992, 89, 131–138. [Google Scholar] [CrossRef]

- Badr, A.; Ashour, A.F. Modified ACI drop-weight impact test for concrete. ACI Mater. J. 2005, 102, 249–255. [Google Scholar] [CrossRef]

- Myers, J.J.; Tinsley, M. Impact resistance of blast mitigation material using modified aci drop-weight impact test. ACI Mater. J. 2013, 110, 339–348. [Google Scholar] [CrossRef]

- Fakharifar, M.; Dalvand, A.; Arezoumandi, M.; Sharbatdar, M.K.; Chen, G.; Kheyroddin, A. Mechanical properties of high performance fiber reinforced cementitious composites. Comput. Chem. Eng. 2014, 71, 510–520. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R. The impact resistance and mechanical properties of reinforced self-compacting concrete with recycled glass fibre reinforced polymers. J. Clean. Prod. 2016, 124, 312–324. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. The impact resistance and mechanical properties of self-compacting concrete reinforced with recycled CFRP pieces. Compos. Part B Eng. 2016, 92, 360–376. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A. The impact resistance and mechanical properties of the reinforced self-compacting concrete incorporating recycled CFRP fiber with different lengths and dosages. Compos. Part B Eng. 2017, 112, 74–92. [Google Scholar] [CrossRef]

- Badr, A.; Ashour, A.F.; Platten, A.K. Statistical variations in impact resistance of polypropylene fibre-reinforced concrete. Int. J. Impact Eng. 2006, 32, 1907–1920. [Google Scholar] [CrossRef] [Green Version]

- Alavi Nia, A.; Hedayatian, M.; Nili, M.; Sabet, V.A. An experimental and numerical study on how steel and polypropylene fibers affect the impact resistance in fiber-reinforced concrete. Int. J. Impact Eng. 2012, 46, 62–73. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alrshoudi, F.; Tahir, M.M.; Alyousef, R.; Alghamdi, H.; Alharbi, Y.R.; Alsaif, A. Performance evaluation of novel prepacked aggregate concrete reinforced with waste polypropylene fibers at elevated temperatures. Constr. Build. Mater. 2020, 259, 120418. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. The effects of silica fume and polypropylene fibers on the impact resistance and mechanical properties of concrete. Constr. Build. Mater. 2010, 24, 927–933. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A.A.; Lachemi, M. Performance of Self-Consolidating Engineered Cementitious Composite under Drop-Weight Impact Loading. J. Mater. Civ. Eng. 2019, 31, 04018400. [Google Scholar] [CrossRef]

- Ali, M.A.E.M.; Soliman, A.M.; Nehdi, M.L. Hybrid-fiber reinforced engineered cementitious composite under tensile and impact loading. Mater. Des. 2017, 117, 139–149. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Dhang, N.; Gupta, A.P. Statistical variations in impact resistance of steel fiber-reinforced concrete subjected to drop weight test. Cem. Concr. Res. 1999, 29, 989–995. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Mugahed Amran, Y.H.; Abdelgader, H.S.; Fediuk, R.; Susrutha, A.; Poonguzhali, K. Impact performance of novel multi-layered prepacked aggregate fibrous composites under compression and bending. Structures 2020, 28, 1502–1515. [Google Scholar] [CrossRef]

- Mahakavi, P.; Chithra, R. Impact resistance, microstructures and digital image processing on self-compacting concrete with hooked end and crimped steel fiber. Constr. Build. Mater. 2019, 220, 651–666. [Google Scholar] [CrossRef]

- Murali, G.; Prasad, N.; Klyuev, S.; Fediuk, R.; Abid, S.R.; Amran, M.; Vatin, N. Impact resistance of functionally layered two-stage fibrous concrete. Fibers 2021, 9, 88. [Google Scholar] [CrossRef]

- Song, P.S.; Wu, J.C.; Hwang, S.; Sheu, B.C. Statistical analysis of impact strength and strength reliability of steel-polypropylene hybrid fiber-reinforced concrete. Constr. Build. Mater. 2005, 19, 1–9. [Google Scholar] [CrossRef]

- Song, P.S.; Wu, J.C.; Hwang, S.; Sheu, B.C. Assessment of statistical variations in impact resistance of high-strength concrete and high-strength steel fiber-reinforced concrete. Cem. Concr. Res. 2005, 35, 393–399. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. Combined effect of silica fume and steel fibers on the impact resistance and mechanical properties of concrete. Int. J. Impact Eng. 2010, 37, 879–886. [Google Scholar] [CrossRef]

- Rahmani, T.; Kiani, B.; Shekarchi, M.; Safari, A. Statistical and experimental analysis on the behavior of fiber reinforced concretes subjected to drop weight test. Constr. Build. Mater. 2012, 37, 360–369. [Google Scholar] [CrossRef]

- Yildirim, S.T.; Ekinci, C.E.; Findik, F. Properties of hybrid fiber reinforced concrete under repeated impact loads 1. Russ. J. Nondestruct. Test. 2010, 46, 538–546. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A.A. Impact resistance and mechanical properties of self-consolidating rubberized concrete reinforced with steel fibers. J. Mater. Civ. Eng. 2017, 29, 04016193. [Google Scholar] [CrossRef]

- AbdelAleem, B.H.; Ismail, M.K.; Hassan, A.A.A. The combined effect of crumb rubber and synthetic fibers on impact resistance of self-consolidating concrete. Constr. Build. Mater. 2018, 162, 816–829. [Google Scholar] [CrossRef]

- Ding, Y.; Li, D.; Zhang, Y.; Azevedo, C. Experimental investigation on the composite effect of steel rebars and macro fibers on the impact behavior of high performance self-compacting concrete. Constr. Build. Mater. 2017, 136, 495–505. [Google Scholar] [CrossRef]

- Chen, X.Y.; Ding, Y.N.; Azevedo, C. Combined effect of steel fibres and steel rebars on impact resistance of high performance concrete. J. Cent. South Univ. Technol. 2011, 18, 1677–1684. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Abdelgader, H.S.; Amran, Y.H.M.; Shekarchi, M.; Wilde, K. Repeated Projectile Impact Tests on Multi-Layered Fibrous Cementitious Composites. Int. J. Civ. Eng. 2021, 19, 635–651. [Google Scholar] [CrossRef]

- Haridharan, M.K.; Matheswaran, S.; Murali, G.; Abid, S.R.; Fediuk, R.; Mugahed Amran, Y.H.; Abdelgader, H.S. Impact response of two-layered grouted aggregate fibrous concrete composite under falling mass impact. Constr. Build. Mater. 2020, 263, 120628. [Google Scholar] [CrossRef]

- Kathirvel, P.; Murali, G.; Vatin, N.I.; Abid, S.R. Experimental Study on Self Compacting Fibrous Concrete Comprising Magnesium Sulphate Solution Treated Recycled Aggregates. Materials 2022, 15, 340. [Google Scholar] [CrossRef]

- Murali, G.; Prasad, N.; Abid, S.R.; Vatin, N.I. Response of Functionally Graded Preplaced Aggregate Fibrous Concrete with Superior Impact Strength. Buildings 2022, 12, 563. [Google Scholar] [CrossRef]

- Vatin, N.I.; Murali, G.; Abid, S.R.; de Azevedo, A.R.G.; Tayeh, B.; Dixit, S. Enhancing the Impact Strength of Prepacked Aggregate Fibrous Concrete Using Asphalt-Coated Aggregates. Materials 2022, 15, 2598. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, M.; Vatin, N.I.; Fediuk, R. DropWeight Impact Test on Prepacked Aggregate Fibrous Concrete—An Experimental Study. Materials 2022, 15, 3096. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M. Combined effect of multi-walled carbon nanotubes, steel fibre and glass fibre mesh on novel two-stage expanded clay aggregate concrete against impact loading. Crystals 2021, 11, 720. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Karthikeyan, K.; Haridharan, M.K.; Amran, M.; Siva, A. Low-velocity impact response of novel prepacked expanded clay aggregate fibrous concrete produced with carbon nano tube, glass fiber mesh and steel fiber. Constr. Build. Mater. 2021, 284, 122749. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Depak, S.R.; Hariharan, K.R.; Abid, S.R.; Murali, G.; Cecchin, D.; Fediuk, R.; Mugahed Amran, Y.H.; Abdelgader, H.S.; Khatib, J.M. Standard and modified falling mass impact tests on preplaced aggregate fibrous concrete and slurry infiltrated fibrous concrete. Constr. Build. Mater. 2021, 298, 123857. [Google Scholar] [CrossRef]

- Abid, S.R.; Abdul-Hussein, M.L.; Ayoob, N.S.; Ali, S.H.; Kadhum, A.L. Repeated drop-weight impact tests on self-compacting concrete reinforced with micro-steel fiber. Heliyon 2020, 6, e03198. [Google Scholar] [CrossRef] [PubMed]

- Abid, S.R.; Ali, S.H.; Goaiz, H.A.; Al-Gasham, T.S.; Kadhim, A.L. Impact resistance of steel fiber-reinforced self-compacting concrete. Mag. Civ. Eng. 2021, 105, 2712–8172. [Google Scholar] [CrossRef]

- Abid, S.R.; Abdul Hussein, M.L.; Ali, S.H.; Kazem, A.F. Suggested modified testing techniques to the ACI 544-R repeated drop-weight impact test. Constr. Build. Mater. 2020, 244, 118321. [Google Scholar] [CrossRef]

- Jabir, H.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Klyuev, S.; Fediuk, R.; Vatin, N.; Promakhov, V.; Vasilev, Y. Experimental tests and reliability analysis of the cracking impact resistance of uhpfrc. Fibers 2020, 8, 74. [Google Scholar] [CrossRef]

- Schrader, E.K. Impact Resistance and Test Procedure for Concrete. J. Am. Concr. Inst. 1981, 78, 141–146. [Google Scholar] [CrossRef]

- Mehdipour, S.; Nikbin, I.M.; Dezhampanah, S.; Mohebbi, R.; Moghadam, H.; Charkhtab, S.; Moradi, A. Mechanical properties, durability and environmental evaluation of rubberized concrete incorporating steel fiber and metakaolin at elevated temperatures. J. Clean Prod. 2020, 254, 120126. [Google Scholar] [CrossRef]

- Al-ameri, R.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Özakça, M. Residual repeated impact strength of concrete exposed to elevated temperatures. Crystals 2021, 11, 941. [Google Scholar] [CrossRef]

- Al-Ameri, R.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Özakça, M.; Vatin, N.I. Residual Impact Performance of ECC Subjected to Sub-High Temperatures. Materials 2022, 15, 454. [Google Scholar] [CrossRef]

- Al-Ameri, R.A.; Abid, S.R.; Özakça, M. Mechanical and Impact Properties of Engineered Cementitious Composites Reinforced with PP Fibers at Elevated Temperatures. Fire 2022, 5, 3. [Google Scholar] [CrossRef]

- Foglar, M.; Hajek, R.; Fladr, J.; Pachman, J.; Stoller, J. Full-scale experimental testing of the blast resistance of HPFRC and UHPFRC bridge decks. Constr. Build. Mater. 2017, 145, 588–601. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Mechanical and structural behaviors of ultra-high-performance fiber-reinforced concrete subjected to impact and blast. Constr. Build. Mater. 2017, 149, 416–431. [Google Scholar] [CrossRef]

- Sun, D.; Xu, Y.; Wang, P.; Zhou, J.; Jin, F.; Li, H.; Fan, H. Blast responses of carbon-fiber reinforced polymer tubular columns filled with seawater sea-sand concrete. Compos. Struct. 2021, 278, 114692. [Google Scholar] [CrossRef]

- Abada, M.; Ibrahim, A.; Jung, S.J. Improving Blast Performance of Reinforced Concrete Panels Using Sacrificial Cladding with Hybrid-Multi Cell Tubes. Modelling 2021, 2, 149–165. [Google Scholar] [CrossRef]

- Prasad, N.; Murali, G.; Abid, S.R.; Vatin, N.; Fediuk, R.; Amran, M. Effect of Needle Type, Number of Layers on FPAFC Composite against Low-Velocity Projectile Impact. Buildings 2021, 11, 668. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Fang, J.; Su, Y.; Wu, C. Ultra-high performance concrete targets against high velocity projectile impact—A-state-of-the-art review. Int. J. Impact Eng. 2022, 160, 104080. [Google Scholar] [CrossRef]

- Lee, M.; Park, G.K.; Kim, S.W.; Kwak, H.G. Damage characteristics of high performance fiber-reinforced cement composites panels subjected to projectile impact. Int. J. Mech. Sci. 2022, 214, 106919. [Google Scholar] [CrossRef]

- Feng, J.; Gao, X.; Li, J.; Dong, H.; He, Q.; Liang, J.; Sun, W. Penetration resistance of hybrid-fiber-reinforced high-strength concrete under projectile multi-impact. Constr. Build. Mater. 2019, 202, 341–352. [Google Scholar] [CrossRef]

- Mina, A.L.; Petrou, M.F.; Trezos, K.G. Resistance of an optimized ultra-high performance fiber reinforced concrete to projectile impact. Buildings 2021, 11, 63. [Google Scholar] [CrossRef]

- Lankard, D.R.; Birkimer, D.L.; Fondriest, F.F.; Snyder, M.J. Effect of Moisture Content on the Structural Properties of Portland Cement Concrete Exposed to Temperatures Up to 500F; ACI Special Publication SP-25; Temperature and Concrete: Detroit, MI, USA, 1971; pp. 59–102. [Google Scholar]

- Abid, S.R.; Abbass, A.A.; Murali, G.; Al-Sarray, M.L.J.; Nader, I.A.; Ali, S.H. Repeated Impact Response of Normal- and High-Strength Concrete Subjected to Temperatures up to 600 °C. Materials 2022, 15, 5283. [Google Scholar] [CrossRef]

- Zoldners, N.G. Thermal Properties of Concrete under Sustained Elevated Temperatures; ACI Special Publication SP-25; Temperature and Concrete: Detroit, MI, USA, 1971; pp. 1–31. [Google Scholar]

| Chemical Composition (%) | |||||

| SiO2 | Fe2O3 | Al2O3 | CaO | MgO | SO3 |

| 20.1 | 3.6 | 4.58 | 61.4 | 2.12 | 2.65 |

| Physical Properties | |||||

| Loss on Ignition (%) | Specific Surface | Specific Gravity | |||

| 1.37 | 368 | 3.15 | |||

| Material | M0 | M0.5 | M1.0 |

|---|---|---|---|

| Cement | 450 | 450 | 450 |

| Sand | 675 | 670 | 665 |

| Gravel | 990 | 982 | 974 |

| Water | 207 | 207 | 207 |

| Steel fiber | 0 | 39.25 | 78.5 |

| Superplasticizer | 0.74 | 1.3 | 1.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abid, S.R.; Abbass, A.A.; Murali, G.; Al-Sarray, M.L.J.; Nader, I.A.; Ali, S.H. Post-High-Temperature Exposure Repeated Impact Response of Steel-Fiber-Reinforced Concrete. Buildings 2022, 12, 1364. https://doi.org/10.3390/buildings12091364

Abid SR, Abbass AA, Murali G, Al-Sarray MLJ, Nader IA, Ali SH. Post-High-Temperature Exposure Repeated Impact Response of Steel-Fiber-Reinforced Concrete. Buildings. 2022; 12(9):1364. https://doi.org/10.3390/buildings12091364

Chicago/Turabian StyleAbid, Sallal R., Ahmmad A. Abbass, Gunasekaran Murali, Mohammed L. J. Al-Sarray, Islam A. Nader, and Sajjad H. Ali. 2022. "Post-High-Temperature Exposure Repeated Impact Response of Steel-Fiber-Reinforced Concrete" Buildings 12, no. 9: 1364. https://doi.org/10.3390/buildings12091364

APA StyleAbid, S. R., Abbass, A. A., Murali, G., Al-Sarray, M. L. J., Nader, I. A., & Ali, S. H. (2022). Post-High-Temperature Exposure Repeated Impact Response of Steel-Fiber-Reinforced Concrete. Buildings, 12(9), 1364. https://doi.org/10.3390/buildings12091364