Critical Challenges and Potential for Widespread Adoption of Mass Timber Construction in Australia—An Analysis of Industry Perceptions

Abstract

:1. Introduction

- i.

- explore key characteristics of MTCPs and project scopes based on a brief review of global MTC projects;

- ii.

- identify barriers and opportunities in the widespread application of MTC in Australia through a perception analysis of the industry experts;

- iii.

- propose recommendations for overcoming the barriers to adopting MTC in Australia.

2. Materials and Methods

2.1. Literature Review

2.1.1. The Development of MTC Technology

2.1.2. Mass Timber Products and Building Systems

2.1.3. The Key Characteristics of Mass Timber Products (MTPs)

2.1.4. The Key Characteristics of the Global MTC Projects

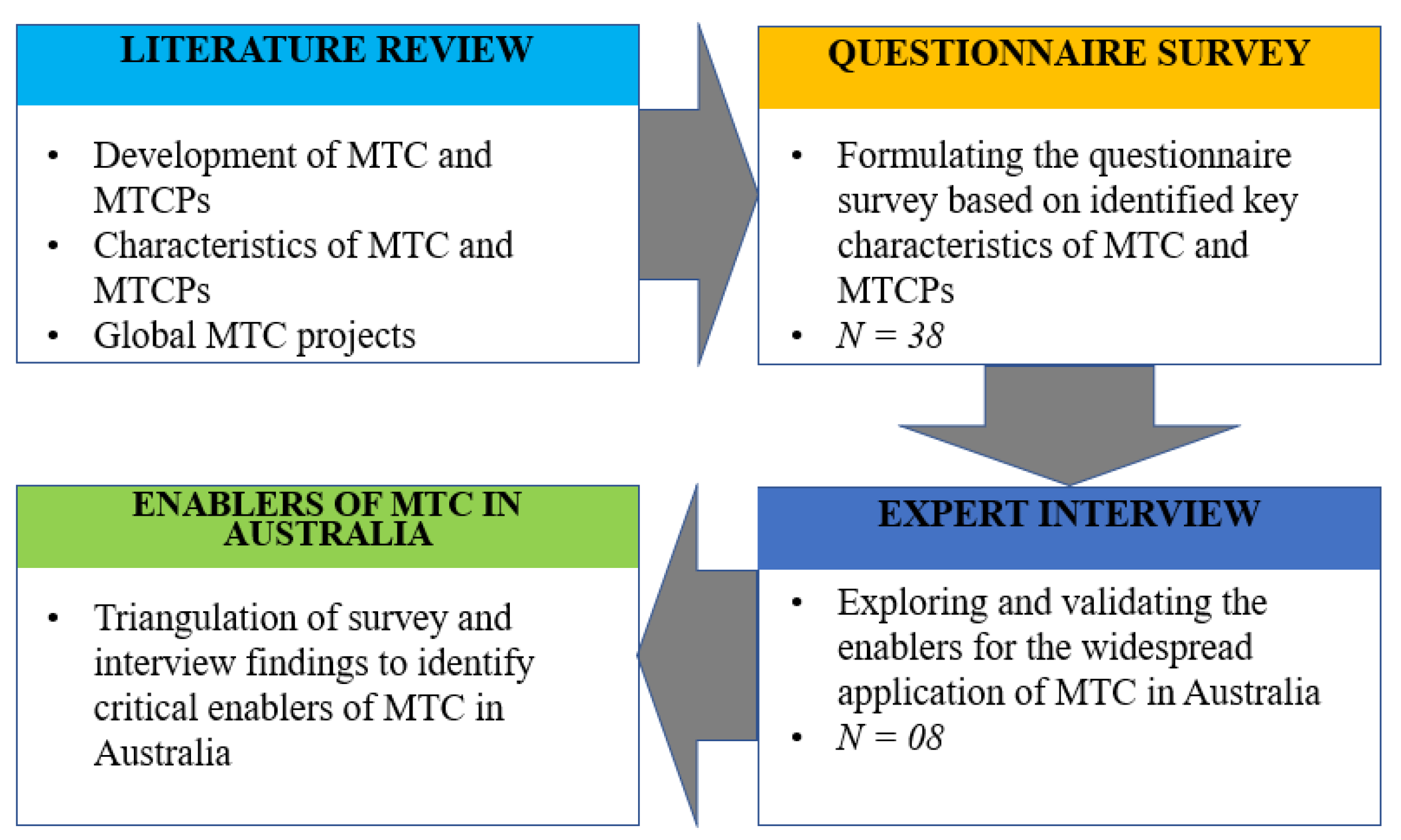

2.2. Data Collection Tools

- a brief review of global MTC projects to analyse the key characteristics of MTC products and projects and their applicability in the Australian context;

- a perception survey to identify project typology, barriers, and opportunities in the widespread application of MTC in Australia;

- expert interviews to validate survey findings and frame the recommendation to overcome identified barriers in Australia.

3. Results and Discussion

3.1. Demographic Data of the Survey Respondents

3.2. Demographic of the Expert Interviews

3.3. Survey Respondents’ Prior Experience with MTC Projects

3.4. Knowledge of MTPs

3.5. Benefits of MTC Projects over Traditional Construction Projects

3.6. Key Characteristics of Suitable MTC Products and Projects in Australia

3.7. Suitable Heights for MTC

3.8. MTC Project Scale

3.9. Critical Technical/Material Limitations of MTC

3.10. The Main Barriers to Widespread Acceptance of MTC

3.11. Project-Level Challenges

3.12. Pathways to the Widespread Adoption of MTC in Australia

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Project Name and Location | Completion Year | Project Type and Space Use | Project Cost | Project Duration | Project Size (m² or ft²) | Reported Benefits and Motivation | Number of Storey/Heights | Timber Features/Construction |

|---|---|---|---|---|---|---|---|---|

| Forte, Melbourne, Australia | 2013 | Residential building with multifunctional ground floor | AUD 11 Million | 10 months | - | 5-star energy rating, 1451 tonnes of carbon saving 7.7 ML of water $300 per year on energy and water bills | 10 storeys (32 m) | 759 CLT panels (485 tonnes of timber), honeycomb construction on top of a concrete frame with a rain screen façade system |

| Library at the Dock, Melbourne, Australia | 2014 | Public building-library with exhibition and café | AUD 26 Million (AUD 8666/m2) | 60 days (timber frame) | 3000 m² | 6-star Green Star Rating | 3 storeys (10 m) | Glulam beam and columns with CLT floor panels and recycled hardwood |

| Aveo Bella Vista, Sydney, Australia | 2017 | Mixed-use building with a waterfront bistro, wellness centre and aged care residence | AUD 75 Million (AUD 12,500/m2) | 160 days timber works | 60,000 m² | Only 160 days for timber works (timber tower construction work, 86 days, and timber installation work, 74 days) | 10 storeys (36 m) | 4156 CLT panels (3000 m3) used in shear walls, Glulam beams and structural steel column |

| The Incubator at Macquarie University, NSW, Australia | 2018 | Academic building | AUD 8 Million (AUD 8394/m2) | 12 months (erected in 37 days) | 953 m² | 60% less energy and heating requirements | single storey (3.5 m) | CLT, Glulam, Victoria Iron Ash, Australian hardwood and pine LVL |

| La Trobe University Student Accommodation, Melbourne, Australia | 2020 | Student accommodation | AUD 100 Million (AUD 160k/bed) | 18 months | 624 beds | 5-star Green Star Rating, 2 6-storey arch-shaped buildings | 6 storeys (20 m) | 4500 m3 CLT panels and GLT columns |

| Daramu House, Sydney, Australia | 2019 | Mixed-use building with commercial space (10,000 m2) and retail space (680 m2) | - | 10,680 m2 | 6-star Green Star Design and As-Built Green Star Rating, 97% of all construction materials are used from recycled sources | 7 storeys (30 m) | 2290 m³ glued laminated timber | |

| 25 King Street, Brisbane, Australia | 2018 | Office building | - | 8 days of timber works and 15 months | 14,921 m2 | 6-star Design and As-Built Green Star rating, Carbon Neutrality by Climate Active, 6-star NABERS Energy Rating, 4.5-star NABERS Water, 3.0-star NABERS Waste | 10 storeys (52 m) | 6 m × 8 m timber grid, CLT walls, roof, and floor plates in European spruce, supported by glulam columns and beams in European spruce, with the addition of supplementary glulam beams reinforced with European hardwood LVL. Construction duration was only 20% compared to steel and concrete buildings |

| Macquarie University Clinical Education Building, Sydney, Australia | 2020 | Academic building | - | 7 months | 3325 m2 | Approximately 700 tonnes of timber structure will save the carbon emission equivalent of 5 to 6 years of energy consumption during operation 28 kW array offsets approximately 10–20% of annual energy use | 4 storeys | Cross-laminated timber (CLT) walls, and CLT floors supported by a 2.4 m by 15 m grid of glued laminated timber (glulam) columns and beams |

| Dalston Works, London, UK | 2017 | Residential building-affordable home | - | 130 weeks | 155,000 ft² (14,420 m2) | 80% less onsite construction duration Sequestered carbon of 2866 tons in its CLT Lightweight (1/5th) compared to steel and concrete structures. | 10 storeys (33.8 m) | CLT panels (136,000 cubic feet), 121-unit development is made entirely of CLT, from the external, party, and core walls, through to the floors and stairs |

| Stadthaus, London, UK | 2009 | Residential building-affordable home | GBP 1420/ft2 | 9 weeks for timber structure (by 4 carpenters) | 2890 m² | 310 tonnes of carbon saving, 15% cost saving (£1750/ft2) compared to a concrete building Project duration reduced from 72 to 49 weeks | 9 storeys (30 m) | CLT panels, honeycomb and centralised wooden elevator and stair cores |

| West Buckland School, Barnstaple, Devon | 2010 | Academic building | GBP 4.8 Million (GBP 3428/m2) | 12 months (erected in 37 days) | 1400 m² | CO2 emissions: 8 kg/m2/yr | 2 storeys (6.4 m) | Glulam beams and CLT panels |

| Tamedia, Zurich, Switzerland | 2013 | Commercial office building-headquarters and radio studios for the Swiss media company Tamedia | EUR 40 Million | 4 months for a wooden structure | 8900 m² | The cost was around 20% higher than the traditional concrete construction | 7 storeys (20 m) | Glulam beams and columns with CLT floor plates (2000 m3 of spruce wood) |

| Stadtwerke Lubeck HQ, Lubeck, Germany | 2014 | Commercial office building | EUR 17.5 Million | - | 13,856 m² | A total of 2438 m³ of timber was used in the construction from PEFC-certified suppliers | 4 storeys (12 m) | Glulam beams and columns with CLT floors and walls |

| Mjøstårnet, Brumunddal, Norway | 2019 | Mixed-use building | - | - | 11,000 m² | 4 storeys at a time in 5 construction stages | 18 storeys (85.4 m) | CLT elevator shaft, Glulam columns and beams |

| Treet, Bergen, Norway | 2019 | Multi-storey residential | - | - | 3780 m² | Built as a passive house and with universal design | 14 storeys (48 m) | Glulam trusses and prefabricated building modules, laminated timber framework. The stacking of modules is divided in phases: 4 + powerfloor (platform) + 4 + powerfloor (platform) + 4 |

| Museum of Fine Arts Houston, Houston, TX, USA | 2018 | Public building | - | - | 39,000 ft² | High-quality daylight | 3 storeys (12 m) | DLT roof panels supported with Glulam post, CNC, beam substructure, and steel connections |

| Carbon 12, Portland, OR, USA | 2018 | Residential | - | - | 3902 m² | Equipped to handle an earthquake or other natural disaster A solar-ready roof | 8 storeys (26 m) | Glulam post and beams and CLT floors and roof with a still core |

| The Soto, San Antnio, TX, USA | 2019 | Commercial | - | - | 120,000 ft² | Reduced cost LEED certification | 6 storeys (45 m) | DLT panels for floors and roof decks, supported by Glulam beam and column (20’ × 30’ grid), 1 storey of concrete with full-depth brick façade |

| T3 Atlanta, Atlanta, GA, USA | 2019 | Industrial warehouse | - | - | 205,000 ft² | LEED® certification | 7 storeys (45 m) | DLT floor and roof panels over Glulam post and beam substructure with a steel brace frame lateral system |

| 111 East Grand Office, Des Moines, IA, USA | 2019 | Commercial | - | - | 76,000 ft² | 1180 m3 of timber Equivalent to 284 tons of sequestered carbon and 1042 tons of sequestered CO2 | 4 storeys (45 m) | Spruce glulam beams and columns frame the 40′–0″ × 6′–8″ DLT panels with pre-cast concrete walls and a core lateral system. The project applied integrated project delivery (IPD) approach with virtual design and construction (VDC) |

| Kajstaden Tall Timber Building, Västerås, Sweden | 2019 | Residential | - | - | 2400 m² | Total carbon dioxide saving is estimated to be 550 tonnes of CO2 Energy-efficient house Short, safe, and quieter project delivery | 9 storeys (30 m) | CLT panels, flooring, and walls |

| Sara Cultural Centre (Sara Kulturhus), Skellefteå, Sweden | 2021 | Mixed-use building | - | - | 30,000 m² | 431,000-cubic-feet of wood store about 6000 tons of carbon dioxideCarbon-negative design | 20 storeys (75 m) | CLT panels with glulam columns and beams, steel structure. The 20-storey tower is made up of prefabricated timber modules with a core of cross-laminated timber |

| NMIT Arts and Media Building, Nelson, New Zealand | 2010 | Public building | NZD 5.3 m (NZD 2676/m2) | - | 1980 m2 | 4% higher than a concrete structure Shorter delivery (22%) compared to the concrete structure Save around 15% of total annual energy consumption | 3 storeys (10 m) | Innovative timber technology and seismic design. Post-tensioned LVL shear walls, LVL gravity frames, and timber floors. LVL-coupled shear walls for seismic layer bracing |

| Wynn Williams House, Christchurch, New Zealand | 2015 | Commercial building for office space (cost of $15 m) | NZD 15 m (NZD 2500/m2) | - | 6000 m² | Reduced cost of $2500 per m2, significantly less than published rates of $2700–$3000 per m2 for the Christchurch office building | 6 storeys (20 m) | Posttensioned LVL beams connected with posttensioned concrete columns |

| Miyamura Veterinary Clinic, Tokyo, Japan | 2015 | Hospital building- animal hospital with hospitalisation facilities | 8 months | 250 m² | 100% wood structure with high fire resistance up to 1hr (Tokyo’s required regulation is 45 min) Optimal thermal and acoustic performance | 3 storeys (10 m?) | Traditional post-and-beam wooden structure and LVL | |

| Wohnhochhaus (WoHo), Berlin, Germany | Proposed- 2024 | Residential building | 18,000 m² | Carbon neutral Mixed-used building | 29 storeys (98 m) | CLT floor, glulam column with a reinforced concrete core | ||

| W350, Tokyo, Japan | Proposed-2041 | Mixed-use building with a hotel, residential units, and commercial spaces | GBP 4.2 b | 455,000 m² | 185,000 m3 of timber Approximately 120,250 tonnes of carbon saving | 70 storeys (350 m) | 90% of the hybrid braced tube structure using LVL beams, columns, and diagonal steel braces |

References

- Campbell, A. Mass Timber in the Circular Economy: Paradigm in Practice? In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Thomas Telford Ltd.: London, UK, 2018. [Google Scholar]

- Kremer, P.; Symmons, M. Overcoming Psychological Barriers to Widespread Acceptance of Mass Timber Construction in Australia; Report no. PNA309-1213; Forest & Wood Products Australia Limited: Melbourne, Australia, 2016. [Google Scholar]

- Crawford, R.H.; Cadorel, X. A framework for assessing the environmental benefits of mass timber construction. Procedia Eng. 2017, 196, 838–846. [Google Scholar] [CrossRef]

- Smith, R.E.; Griffin, G.; Rice, T.; Hagehofer-Daniell, B. Mass timber: Evaluating construction performance. Arch. Eng. Des. Manag. 2018, 14, 127–138. [Google Scholar] [CrossRef]

- GlobalABC. Global Status Report for Buildings and Construction: Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector. 2019. Available online: https://www.worldgbc.org/news-media/2019-global-status-report-buildings-and-construction (accessed on 15 May 2022).

- UNFCCC. Paris Agreement; United Nations Framework Convention on Climate Change: Paris, France, 2015. [Google Scholar]

- Karlsson, I.; Rootzén, J.; Johnsson, F.; Erlandsson, M. Achieving net-zero carbon emissions in construction supply chains–A multidimensional analysis of residential building systems. Dev. Built Environ. 2021, 8, 100059. [Google Scholar] [CrossRef]

- Fei, W.; Opoku, A.; Agyekum, K.; Oppon, J.A.; Ahmed, V.; Chen, C.; Lok, K.L. The critical role of the construction industry in achieving the sustainable development goals (SDGs): Delivering projects for the common good. Sustainability 2021, 13, 9112. [Google Scholar] [CrossRef]

- Yu, M.; Wiedmann, T.; Crawford, R.; Tait, C. The carbon footprint of Australia’s construction sector. Proc. Eng. 2017, 180, 211–220. [Google Scholar] [CrossRef]

- Li, J.; Rismanchi, B.; Ngo, T. Feasibility study to estimate the environmental benefits of utilising timber to construct high-rise buildings in Australia. Build. Environ. 2019, 147, 108–120. [Google Scholar] [CrossRef]

- CTB&UH. WoHo, Berlin. 2021. Available online: https://www.skyscrapercenter.com/building/woho/40366 (accessed on 12 June 2022).

- Dezeen. World’s Tallest Timber Tower Proposed for Tokyo. 2018. Available online: https://www.dezeen.com/2018/02/19/sumitomo-forestry-w350-worlds-tallest-wooden-skyscraper-conceptual-architecture-tokyo-japan/ (accessed on 12 December 2021).

- Moelven. Mjøstårnet. 2022. Available online: https://www.moelven.com/mjostarnet/ (accessed on 2 February 2022).

- Architecture. World’s Tallest Hybrid Timber Tower to House Atlassian HQ in Sydney. 2020. Available online: https://architectureau.com/articles/worlds-tallest-hybrid-timber-tower-to-be-built-in-sydney/ (accessed on 2 June 2022).

- Evison, D.C.; Kremer, P.D.; Guiver, J. Mass timber construction in Australia and New Zealand—Status, and economic and environmental influences on adoption. Wood Fiber Sci. 2018, 50, 128–138. [Google Scholar] [CrossRef]

- AISC. Industries: Construction. 2022. Available online: https://nationalindustryinsights.aisc.net.au/industries/construction (accessed on 5 November 2021).

- Kremer, P.D.; Fahy, P.; Zaman, A. Understanding the risk and reward in the adoption of Mass Timber Construction in Australia. Mass Timber Constr. J. 2019, 2, 15–20. [Google Scholar] [CrossRef]

- Industry Edge. Australia’s Growing CLT Market. 2020. Available online: https://industryedge.com.au/new-cross-laminated-timber-facility-in-australia/ (accessed on 9 October 2021).

- Kasbar, M. Investigating the Performance of the Construction Process of an 18-Storey Mass Timber Hybrid Building; University of British Columbia: Vancouver, BC, Canada, 2017. [Google Scholar]

- Harte, A.M. Mass timber–The emergence of a modern construction material. J. Struct. Integr. Maint. 2017, 2, 121–132. [Google Scholar] [CrossRef]

- Lehmann, S. Developing a prefabricated low-carbon construction system using cross-laminated timber (CLT) panels for multistorey inner-city infill housing in Australia. J. Green Build. 2012, 7, 131–150. [Google Scholar] [CrossRef]

- Schickhofer, G. Starrer und Nachgiebiger Verbund bei Geschichteten, Flächenhaften Holzstrukturen; Verlag der Technischen Universität Graz: Graz, Germany, 1994. [Google Scholar]

- Greenspec. Crosslam Timber/CLT—A Brief History. 2022. Available online: https://www.greenspec.co.uk/building-design/crosslam-timber-history-and-production/ (accessed on 3 June 2022).

- Espinoza, O.; Rodríguez-Trujillo, V.; Laguarda-Mallo, M.; Buehlmann, U. Cross-laminated timber: Status and research needs in Europe. BioResources 2016, 11, 281–295. [Google Scholar] [CrossRef]

- Grasser, K.K. Development of Cross Laminated Timber in the United States of America; University of Tennessee: Knoxville, TN, USA, 2015. [Google Scholar]

- Eurostat. Wood Products—Production and Trade. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Wood_products_-_production_and_trade#Primary_wood_products (accessed on 5 June 2022).

- ABARES. Australian Forest and Wood Product Statistics: September and December Quarters 2018; Australian Government, Department of Agriculture, Fisheries and Forestry: Canberra, Australia, 2018. [Google Scholar]

- Pei, S.; Rammer, D.; Popovski, M.; Williamson, T.; Line, P.; van de Lindt, P.L. An overview of CLT Research and Implementation in North America. In Proceedings of the WCTE 2016, Vienna, Austria, 22–25 August 2016. [Google Scholar]

- XLam. Manufacture and Supply of CLT & GLT. 2022. Available online: http://www.xlam.co.nz (accessed on 18 April 2022).

- Plackner, H. First Industrial CLT Manufacturer in Japan Starts in April. 2015. Available online: https://www.timber-online.net/sawn_timber/2015/11/first_industrialcltmanufacturerinjapanstartsinapril.html (accessed on 25 May 2022).

- RaM. Cross Laminated Timber (CLT)—Global Market Trajectory & Analytics. 2021. Available online: https://www.researchandmarkets.com/reports/5141054/cross-laminated-timber-clt-global-market (accessed on 6 March 2022).

- Boyle, I. Mass Timber Building Systems: Understanding the Options. 2015. Available online: https://www.woodworks.org/wp-content/uploads/BOYLE-Mass-Timber-Building-Systems-Understanding-the-Options-WSF-151209.pdf (accessed on 13 June 2021).

- Gong, M. Lumber-Based Mass Timber Products in Construction, in Timber Buildings and Sustainability; IntechOpen: London, UK, 2019; p. 85808. [Google Scholar] [CrossRef]

- Naturally:Wood. Brock Commons Tallwood House—Design and Preconstruction Overview. 2021. Available online: https://www.naturallywood.com/wp-content/uploads/2020/08/brock-commons-design-preconstruction-overview_case-study_naturallywood.pdf (accessed on 5 September 2021).

- Tall-wood. A Look into Post-and-Beam and Post-and-Plate Mass Timber Systems. 2021. Available online: https://tall-wood.com/post-and-beam-mass-timber-systems/ (accessed on 12 July 2021).

- MTCC. Understanding the Mass Timber Code Proposals: A Guide for Building Officials. 2018. Available online: https://www.awc.org/pdf/tmt/MTCC-Guide-Print-20180919.pdf (accessed on 12 November 2021).

- Bénichou, N.; Sultan, M.A. Fire resistance performance of lightweight wood-framed assemblies. Fire Technol. 2000, 36, 184–219. [Google Scholar] [CrossRef]

- Craig, S.; Halepaska, A.; Ferguson, K.; Rains, P.; Elbrecht, J.; Freear, A.; Kennedy, D.; Moe, K. The design of mass timber panels as heat-exchangers (dynamic insulation). Front. Built Environ. 2021, 6, 606258. [Google Scholar] [CrossRef]

- Woodsolutions. Laminated Veneer Lumber (LVL). Available online: https://www.woodsolutions.com.au/wood-species/wood-products/laminated-veneer-lumber-lvl (accessed on 22 April 2022).

| Timber Building Systems | Description | Common Timber Products | References |

|---|---|---|---|

| Mass timber floor and wall systems or panel systems | CLT, NLT, GLT, LSL, and LVL panels are commonly used mass timber products as floor, decking, wall, and panel systems. CLT panels have multiple layers of wood glued under pressure, with parallel boards in each layer in a different direction, usually coming in 3,5,7, and 9 layers | Cross-laminated timber (CLT), nail-laminated timber (NLT), glued laminated timber (GLT), laminated strand lumber (LSL) and laminated veneer lumber (LVL), dowel-laminated timber (DLT). | Lehmann [21]; Harte [20]; Boyle [32]; Gong [33] |

| Hybrid mass timber systems | It includes the combination of concrete foundation and various mass timber products as core building elements and metal connectors. | Wood–concrete composite (WCC) | Boyle [32]; Naturally:Wood [34] |

| Post-and-beam systems | It builds without load-bearing walls, and it is a skeleton frame composed of decking, beams, and posts. Glulam (GL), PSL/SCL, and LVL/SCL are commonly used as post and beam systems. | GL, PSL (SCL), LVL (SCL) | Boyle [32]; Gong [33] |

| Post-and-plate systems | Post-and-plate systems refer to the structural system using only columns to support the decking system. | Post-and-plate system or point-supported. | Tall-wood [35] |

| Indicators | Parameters | In Percent | Count |

|---|---|---|---|

| Affiliation (N = 38) | Builder/developer | 38% | 16 |

| Contractor/subcontractor | 14% | 6 | |

| Consultant | 36% | 15 | |

| Other: | 12% | 5 | |

| Role (N = 38) | Builder | 17% | 7 |

| Architect/designer | 17% | 7 | |

| Engineer | 14% | 6 | |

| Project personnel | 29% | 12 | |

| Other | 24% | 10 | |

| Company size (N = 38) | Small (<5 employees) | 21% | 8 |

| Medium (5–50 employees) | 32% | 12 | |

| Large (>50 employees) | 47% | 18 | |

| Average years of experience project (N = 38) | 1–5 years | 29% | 11 |

| 5–10 years | 16% | 6 | |

| 10–20 years | 21% | 8 | |

| 20 years or above | 34% | 13 |

| Expert/Interviewees | Role/Affiliation | Company Size/No. of Employees | Years of Experience |

|---|---|---|---|

| Interviewee 1 | Managing director, engineering consulting firm | 5–20 | 25 |

| Interviewee 2 | Senior structural engineer, engineering consulting firm | Above 100 | 8 |

| Interviewee 3 | Structural engineer, engineering consulting firm | 100+ | 14 |

| Interviewee 4 | Principal of research and development, architecture and planning | 50–100 | 20 |

| Interviewee 5 | Technical sales and engineer, mtc manufacturer | 50–100 | 7 |

| Interviewee 6 | Design coordinator, builder | 100+ | 2 |

| Interviewee 7 | Director, construction, engineering, quantity surveying, chartered surveying, building surveying, and building services engineers working with MTC | 100+ | 25 |

| Interviewee 8 | CEO, industry-funded association representing all segments of the timber industry, from forestry and manufacturing to supply | 5 | 38 |

| Field | Mean | Std Deviation |

|---|---|---|

| Limited loading capacity | 3.08 | 0.84 |

| Limited size of the panels | 2.84 | 0.90 |

| Challenges of connection/joint | 3.22 | 0.79 |

| Lack of fire resistance | 3.00 | 1.05 |

| Lack of structural integrity | 3.49 | 1.00 |

| Rotting issues | 3.13 | 1.03 |

| Internal vs. external applications; interoperability with other systems | 2.95 | 0.89 |

| Field | Mean | Std Deviation |

| Lack of local manufacturers | 3.03 | 0.74 |

| Lack of local suppliers | 3.03 | 0.78 |

| Lack of financial support | 3.11 | 0.88 |

| Public liability insurance | 3.22 | 1.03 |

| Long lead times | 2.95 | 0.89 |

| Current legislation with strict combustibility requirements | 2.82 | 1.00 |

| Lack of demand/market | 2.61 | 1.04 |

| Unskilled labour | 2.71 | 1.02 |

| Higher project/maintenance cost | 2.74 | 1.12 |

| Insufficient knowledge and technical information on MTC | 2.89 | 0.88 |

| Wrong ideas about the performance of MTC products | 2.79 | 0.95 |

| Durability and quality of materials (fire resistance, noise, moisture, etc.) | 2.37 | 1.04 |

| Level of market share and marketing of more traditional materials than MTC | 2.63 | 0.98 |

| Lack of regulatory requirements, including building codes/standards/specifications | 2.82 | 0.88 |

| Other | 3.33 | 0.47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaman, A.; Chan, Y.-Q.; Jonescu, E.; Stewart, I. Critical Challenges and Potential for Widespread Adoption of Mass Timber Construction in Australia—An Analysis of Industry Perceptions. Buildings 2022, 12, 1405. https://doi.org/10.3390/buildings12091405

Zaman A, Chan Y-Q, Jonescu E, Stewart I. Critical Challenges and Potential for Widespread Adoption of Mass Timber Construction in Australia—An Analysis of Industry Perceptions. Buildings. 2022; 12(9):1405. https://doi.org/10.3390/buildings12091405

Chicago/Turabian StyleZaman, Atiq, Ying-Qi Chan, Emil Jonescu, and Iain Stewart. 2022. "Critical Challenges and Potential for Widespread Adoption of Mass Timber Construction in Australia—An Analysis of Industry Perceptions" Buildings 12, no. 9: 1405. https://doi.org/10.3390/buildings12091405

APA StyleZaman, A., Chan, Y.-Q., Jonescu, E., & Stewart, I. (2022). Critical Challenges and Potential for Widespread Adoption of Mass Timber Construction in Australia—An Analysis of Industry Perceptions. Buildings, 12(9), 1405. https://doi.org/10.3390/buildings12091405