Experimental Investigation on the Axial Compressive Behaviour of Cold-Formed Steel-Concrete Composite Columns Infilled with Various Types of Fibre-Reinforced Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Description

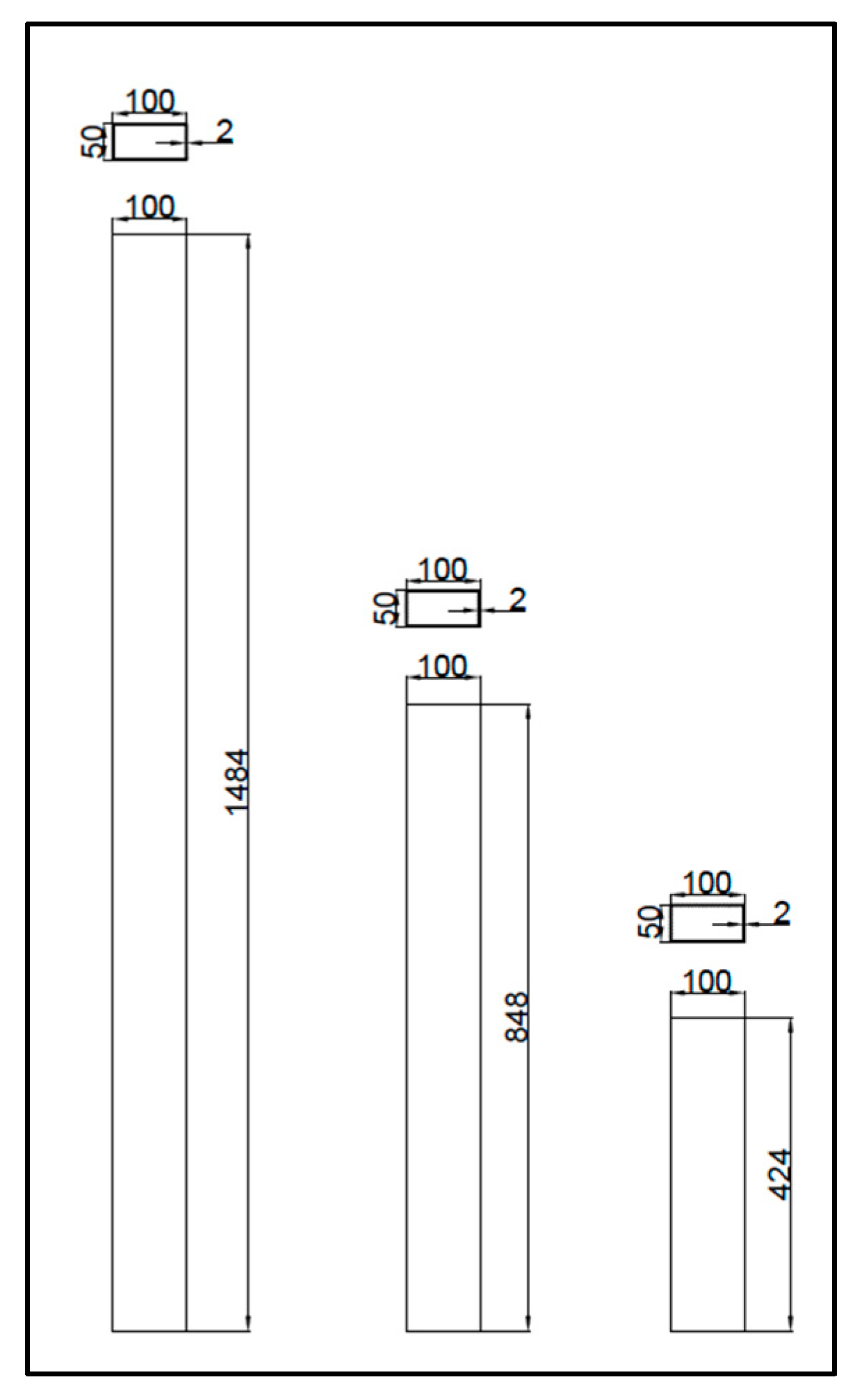

2.2. Test Specimen

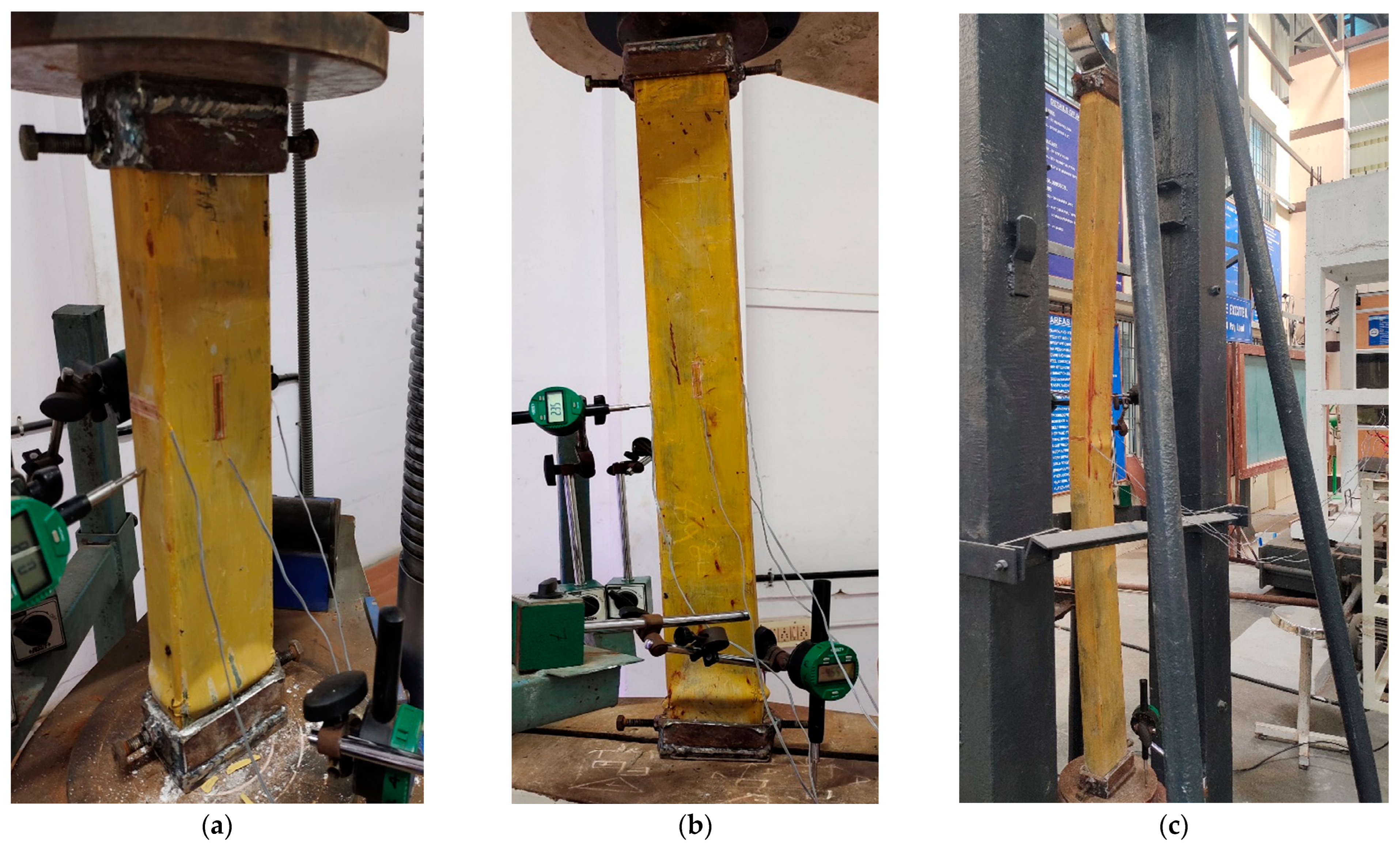

2.3. Specimen Preparation and Experimental Procedure

3. Results

3.1. Failure Modes

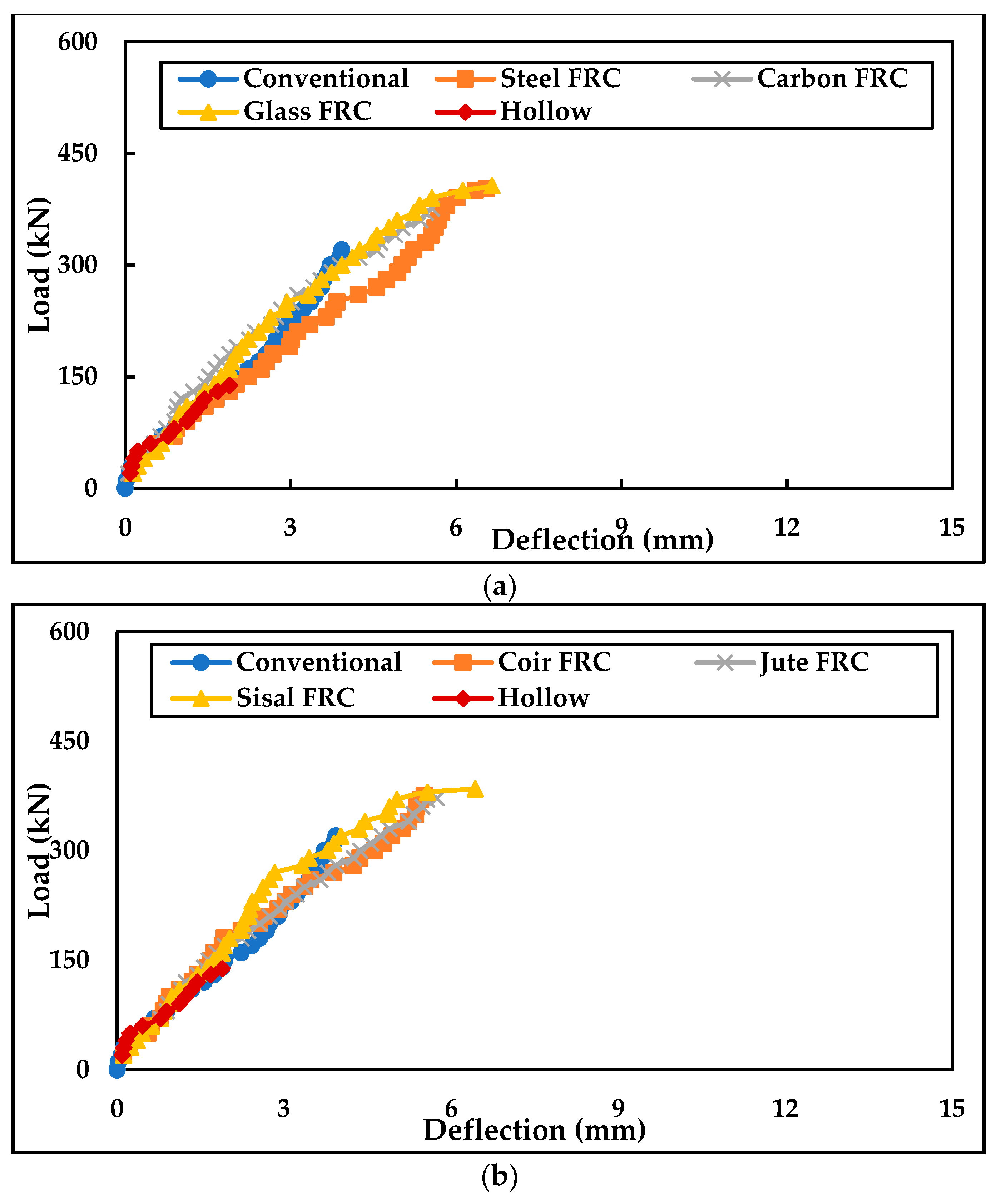

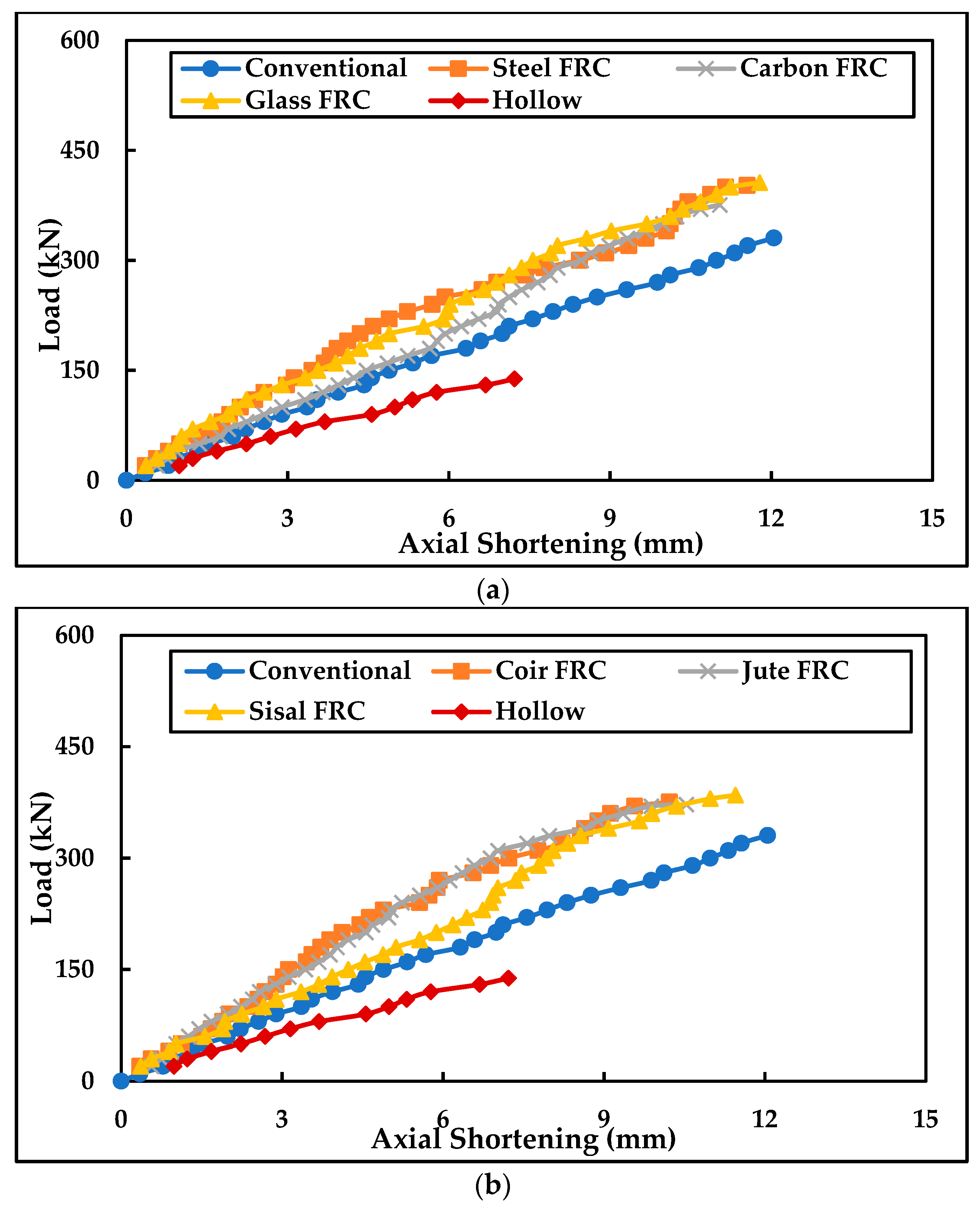

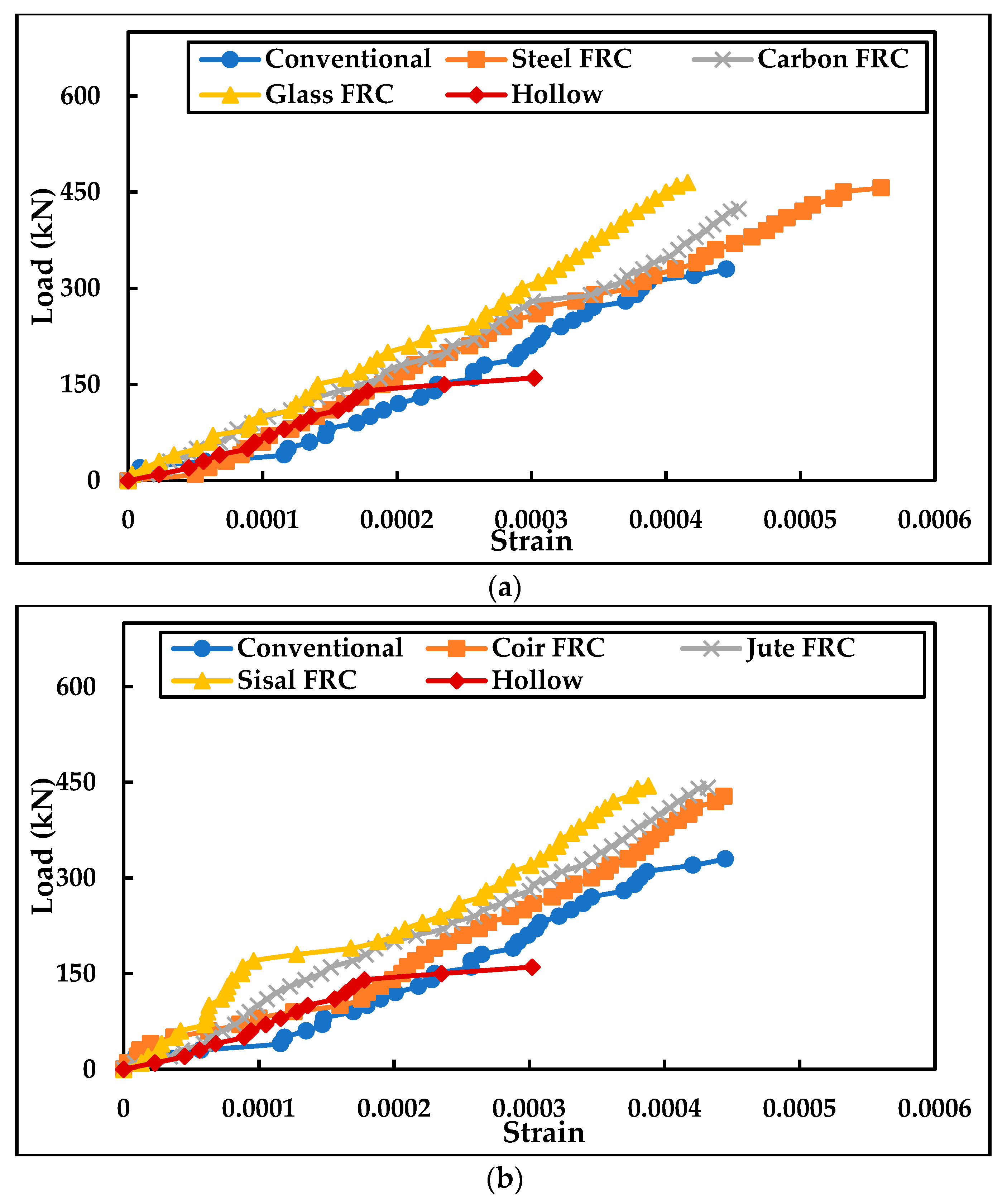

3.1.1. Medium Column

3.1.2. Short Column

3.1.3. Stub Column

3.1.4. Theoretical Investigation

4. Conclusions

- With the use of glass, steel, and sisal fibre-reinforced concrete infill, the maximum ultimate load of a steel tubular column filled with FRC was observed;

- When compared to hollow steel tubular columns, the ultimate load of FRC-infilled rectangular steel columns was enhanced up to three times. Hence, fibre-reinforced concrete-infilled steel tubular columns can be effectively used in structures with high loads;

- In the stub, short, and medium columns, the load-carrying capacity of the glass fibre-reinforced concrete-infilled steel tubular column was observed to be higher than the other types of fibre-reinforced concrete-infilled steel tubular columns. The percentage increase was observed as 203.88%, 193.48%, and 190.03% when compared to hollow cold-formed steel tubular columns in medium, short, and stub columns, respectively;

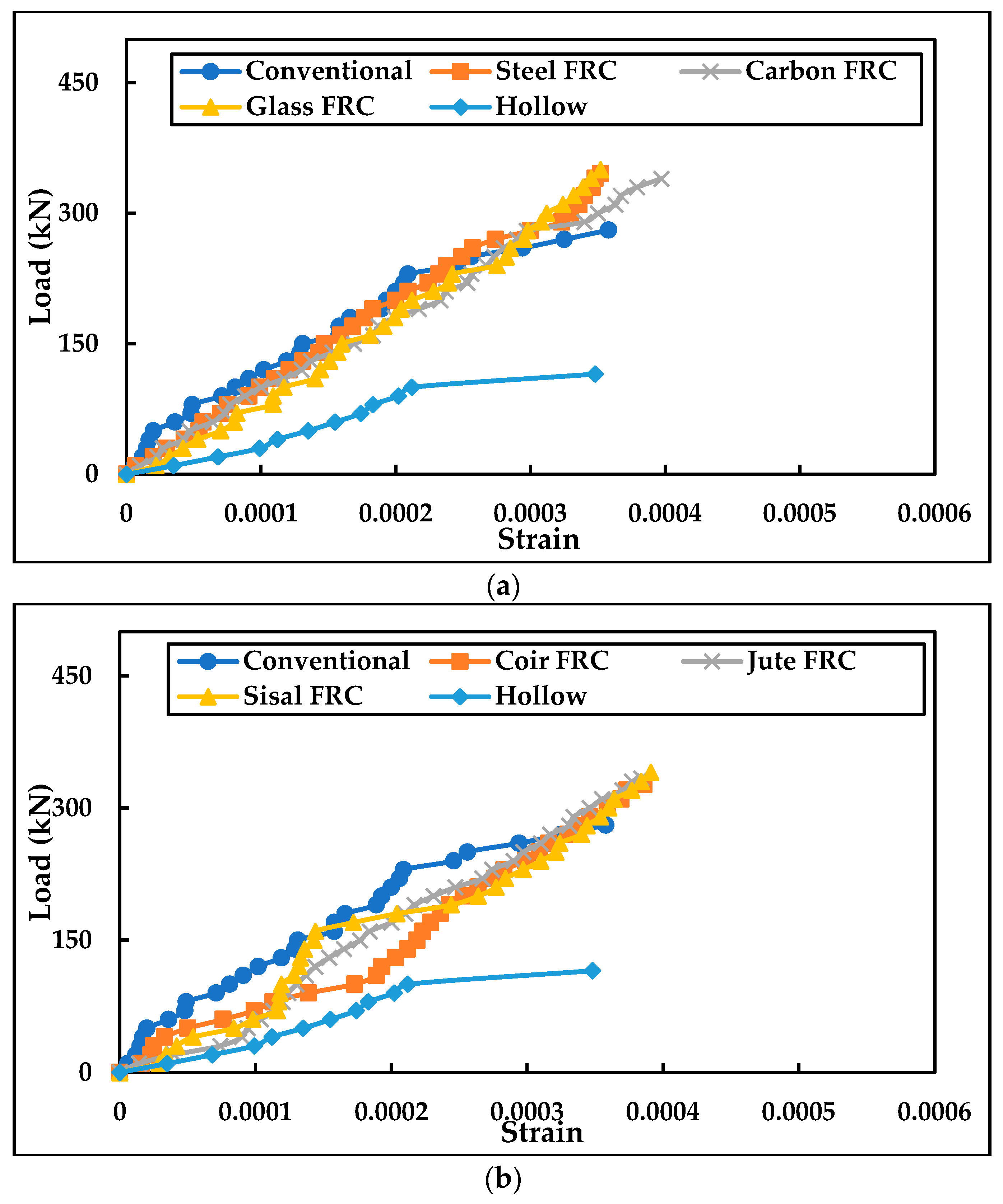

- The load-strain plots showed that the steel fibre-reinforced concrete-infilled columns performed well in terms of ductility during the testing of the stub, short, and medium columns;

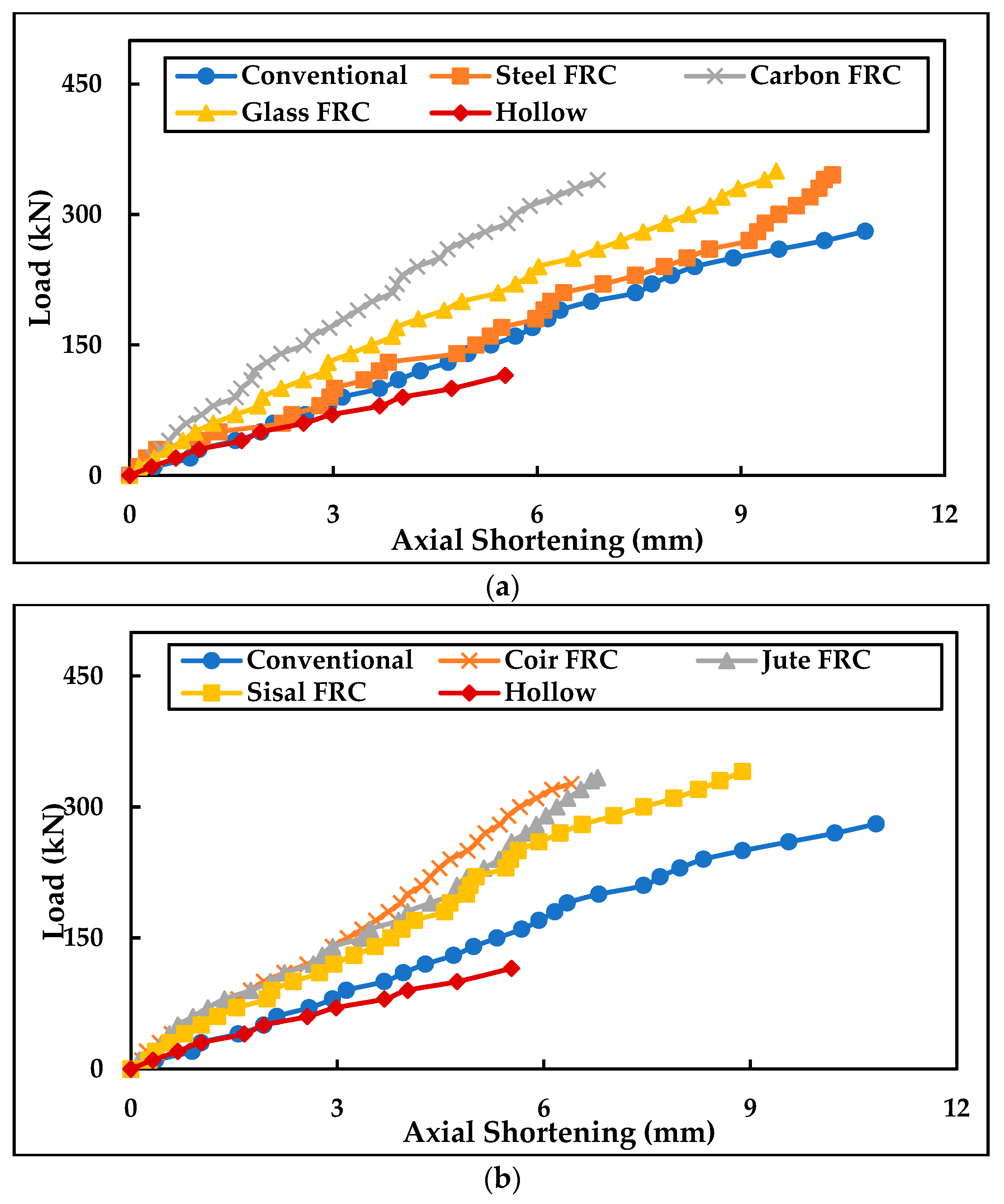

- It was discovered that the in-filled medium columns made of glass fibre-reinforced concrete experienced 12.10% less axial shortening than the other in-filled medium columns. When compared to other in-filled short columns, steel fibre-reinforced concrete’s axial shortening was determined to be 11.50% less. It was discovered that the axial shortening of the steel fibre-reinforced concrete in-filled stub columns was 11.50% less than that of the other in-filled stub columns;

- CFST columns with a low slenderness ratio (λ = 20 and 40) failed due to local buckling and crushing of the concrete infill. Contrarily, concrete-filled steel tubular columns with greater slenderness ratios (λ = 70) demonstrated column failure through overall buckling of the composite column;

- Due to the crushing of in-fills on the approach of failure, the bottom of each column that was in-filled with concrete buckled externally;

- The single curvature buckling failure pattern was the one that was seen in the axially loaded medium column;

- Fibre-reinforced concrete-infilled steel tubular columns had the ability to take more deformations and strain before failure than conventional concrete-filled steel tubular columns and hollow tubular columns, which shows improved ductile behaviour;

- Glass, steel, and sisal fibre-reinforced concrete improved the overall behaviour of the column and hence can be effectively used in cold-formed steel tubular columns as infill in structural applications;

- The performance of natural fibres infilled concrete was low due to the non-uniform dispersion of fibres within the column due to its fibre characteristics;

- Due to its poor ductile behaviour, the axial shortening of the column was noted to be at its lowest with the use of carbon, coir, jute, and sisal fibre-reinforced concrete infill;

- Further studies can be conducted by providing additional dispersion agents for the fibre-reinforced concrete infill, and different types of fibres can be incorporated into the infill. Similar studies can be carried out, varying the loading conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shanmugam, N.; Lakshmi, B. State of the art report on steel–Concrete composite columns. J. Constr. Steel Res. 2001, 57, 1041–1080. [Google Scholar] [CrossRef]

- Han, L.-H.; Li, W.; Bjorhovde, R. Developments and advanced applications of concrete-filled steel tubular (CFST) structures: Members. J. Constr. Steel Res. 2014, 100, 211–228. [Google Scholar] [CrossRef]

- Zhao, X.-L.; Han, L.-H.; Lu, H. Concrete-Filled Tubular Member, 1st ed.; Spon Press: Oxford, UK, 2010. [Google Scholar]

- Rahnavard, R.; Craveiro, H.D.; Lopes, M.; Simões, R.A.; Laím, L.; Rebelo, C. Concrete-filled cold-formed steel (CF-CFS) built-up columns under compression: Test and design. Thin-Walled Struct. 2022, 179, 109603. [Google Scholar] [CrossRef]

- Evirgen, B.; Tuncan, A.; Taskin, K. Structural behavior of concrete filled steel tubular sections (CFT/CFSt) under axial compression. Thin-Walled Struct. 2014, 80, 46–56. [Google Scholar] [CrossRef]

- Uy, B. Strength of concrete filled steel box columns incorporating local buckling. J. Struct. Eng. 2000, 126, 341–352. [Google Scholar] [CrossRef]

- Ren, Q.X.; Han, L.H.; Lam, D.; Hou, C. Experiments on special-shaped CFST stub columns under axial compression. J. Constr. Steel Res. 2014, 98, 123–133. [Google Scholar] [CrossRef]

- He, Z.; Zhou, X. Strength design curves and an effective width formula for coldformed steel columns with distortional buckling. Thin-Walled Struct. 2014, 79, 62–70. [Google Scholar] [CrossRef]

- Ge, H.B.; Usami, T. Strength analysis of concrete-filled thin-walled steel box columns. J. Constr. Steel Res. 1994, 30, 259–281. [Google Scholar] [CrossRef]

- Huang, C.S.; Yeh, Y.K.; Liu, G.Y.; Hu, H.T.; Tsai, K.C.; Weng, Y.T.; Wang, S.H.; Wu, M.H. Axial load behaviour of stiffened concrete filled steel columns. J. Struct. Eng. 2002, 28, 593–598. [Google Scholar] [CrossRef] [Green Version]

- Tao, Z.; Han, L.-H.; Wang, Z.-B. Experimental behaviour of stiffened concrete-filled thin-walled hollow steel structural (HSS) stub columns. J. Constr. Steel Res. 2005, 61, 962–983. [Google Scholar] [CrossRef]

- Nassirnia, M.; Heidarpour, A.; Zhao, X.L.; Minkkinen, J. Innovative hollow corrugated columns: A fundamental study. Eng. Struct. 2015, 94, 43–53. [Google Scholar] [CrossRef]

- Tao, Z.; Han, L.H.; Wang, D.Y. Strength and ductility of stiffened thin-walled hollow steel structural stub columns filled with concrete. Thin-Walled Struct. 2008, 46, 1113–1128. [Google Scholar] [CrossRef]

- Shen, J.; Wadee, M.A. Length effects on interactive buckling in thin-walled rectangular hollow section struts. Thin-Walled Struct. 2018, 128, 152–170. [Google Scholar] [CrossRef]

- Thai, H.-T.; Uy, B.; Khan, M.; Tao, Z.; Mashiri, F. Numerical modelling of concrete-filled steel box columns incorporating high strength materials. J. Constr. Steel Res. 2014, 102, 256–265. [Google Scholar] [CrossRef]

- Ellobody, E.; Young, B. Structural performance of cold-formed high strength stainless steel columns. J. Constr. Steel Res. 2005, 61, 1631–1649. [Google Scholar] [CrossRef]

- Senthilkumar, R.; Divya, M.; Roy, S.D. Behaviour of cold-formed steel-concrete composite columns under axial compression: Experimental and numerical study. Structures 2022, 44, 487–502. [Google Scholar]

- Zhang, S.; Li, X.; Li, J.; Lu, W.; Chen, J. Behavior comparison of seven-types of steel–Concrete composite stub columns under axial compression. Eng. Struct. 2022, 252, 113637. [Google Scholar] [CrossRef]

- Fam, A.; Qie, F.S.; Rizkalla, S. Concrete-filled steel tubes subjected to axial compression and lateral cyclic loads. Eng. Struct. 2004, 130, 631–640. [Google Scholar] [CrossRef] [Green Version]

- Giakoumelis, G.; Lam, D. Axial capacity of circular concrete-filled tube columns. J. Constr. Steel Res. 2004, 60, 1049–1068. [Google Scholar] [CrossRef]

- Yu, Z.-W.; Ding, F.-X.; Cai, C. Experimental behavior of circular concrete-filled steel tube stub columns. J. Constr. Steel Res. 2007, 63, 165–174. [Google Scholar] [CrossRef]

- Ricles, J.M.; Paboojian, S.D. Seismic performance of steel-encased composite columns. J. Struct. Eng. 1994, 120, 2474–2494. [Google Scholar] [CrossRef]

- Mirza, S.A.; Hyttinen, V.; Hyttinen, E. Physical tests and analyses of composite steel-concrete beam-columns. J. Struct. Eng. 1996, 122, 1317–1326. [Google Scholar] [CrossRef]

- Lai, B.; Liew, J.R.; Wang, T. Buckling behaviour of high strength concrete encased steel composite columns. J. Constr. Steel Res. 2019, 154, 27–42. [Google Scholar] [CrossRef]

- Aboutaha, R.S.; Machado, R.I. Seismic resistance of steel-tubed high-strength reinforced-concrete columns. J. Struct. Eng. 1999, 125, 485–494. [Google Scholar] [CrossRef]

- Brown, N.K.; Kowalsky, M.J.; Nau, J.M. Impact of D/t on seismic behavior of reinforced concrete filled steel tubes. J. Constr. Steel Res. 2015, 107, 111–123. [Google Scholar] [CrossRef]

- Xiamuxi, A.; Liu, X.R.; Hasegawa, A. Study of the concrete in reinforced concrete-filled steel tube column under axial loading. J. Constr. Steel Res. 2020, 170, 106111. [Google Scholar] [CrossRef]

- Wang, Q.X.; Zhao, D.Z.; Guan, P. Experimental study on the strength and ductility of steel tubular columns filled with steel-reinforced concrete. Eng. Struct. 2004, 26, 907–915. [Google Scholar] [CrossRef]

- Cai, J.M.; Pan, J.L.; Wu, Y.F. Mechanical behavior of steel-reinforced concrete-filled steel tubular (SRCFST) columns under uniaxial compressive loading. Thin-Wall Struct. 2015, 97, 1–10. [Google Scholar] [CrossRef]

- Farajpourbonab, E.; Kute, S.Y.; Inamdar, V.M. Steel-reinforced concrete-filled steel tubular columns under axial and lateral cyclic loading. Int. J. Adv. Struct. Eng. 2018, 10, 61–72. [Google Scholar] [CrossRef] [Green Version]

- Hassanein, M.; Kharoob, O.; Liang, Q. Circular concrete-filled double skin tubular short columns with external stainless steel tubes under axial compression. Thin-Walled Struct. 2013, 73, 252–263. [Google Scholar] [CrossRef]

- Li, Y.-J.; Han, L.-H.; Xu, W.; Tao, Z. Circular concrete-encased concrete-filled steel tube (CFST) stub columns subjected to axial compression. Mag. Concr. Res. 2016, 68, 995–1010. [Google Scholar] [CrossRef]

- Ayough, P.; Sulong, N.H.R.; Ibrahim, Z. Analysis and review of concrete-filled double skin steel tubes under compression. Thin-Walled Struct. 2020, 148, 106495. [Google Scholar] [CrossRef]

- Xiong, M.X.; Xiong, D.X.; Liew, J.Y.R. Axial performance of short concrete filled steel tubes with high-and ultra-high-strength materials. Eng. Struct. 2017, 136, 494–510. [Google Scholar] [CrossRef]

- Liang, Q.Q.; Fragomeni, S. Nonlinear analysis of circular concrete-filled steel tubular short columns under axial loading. J. Constr. Steel Res. 2009, 65, 2186–2196. [Google Scholar] [CrossRef]

- Li, W.; Chen, B.; Han, L.-H.; Lam, D. Experimental study on the performance of steel-concrete interfaces in circular concrete-filled double skin steel tube. Thin-Walled Struct. 2020, 149, 106660. [Google Scholar] [CrossRef]

- Lahlou, K.; Lachemi, M.; Aïtcin, P.-C. Confined high-strength concrete under dynamic compressive loading. J. Struct. Eng. 1999, 125, 1100–1108. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, S.; Zhang, X.; Guo, L. Behavior and strength of circular tube confined reinforced-concrete (CTRC) columns. J. Constr. Steel Res. 2009, 65, 1447–1458. [Google Scholar] [CrossRef]

- Wang, X.D.; Liu, J.P.; Zhang, S.M. Behavior of short circular tubed-reinforced-concrete columns subjected to eccentric compression. Eng. Struct. 2015, 105, 77–86. [Google Scholar] [CrossRef]

- Cao, X.-Y.; Shen, D.; Feng, D.-C.; Wang, C.-L.; Qu, Z.; Wu, G. Seismic retrofitting of existing frame buildings through externally attached sub-structures: State of the art review and future perspectives. J. Build. Eng. 2022, 57, 104904. [Google Scholar] [CrossRef]

- Sulaiman, A.; Hunaiti, Y.; Abdel-Jaber, M.; Abdel-Jaber, M. Compressive behavior of light–gauge steel tubes filled with concrete containing recycled aggregates. Int. Rev. Appl. Sci. Eng. 2022, 13, 185–196. [Google Scholar] [CrossRef]

- Ibrahim, A.Z.; Hunaiti, Y.; El-Nimri, R. Behavior of light-gauge steel short columns filled with normal and lightweight aggregate concrete under concentric axial loading. J. Appl. Eng. Sci. 2022, 20, 1040–1052. [Google Scholar]

- More, F.M.D.S.; Subramanian, S.S. Impact of fibres on the mechanical and durable behaviour of fibre-reinforced concrete. Buildings 2022, 12, 1436. [Google Scholar] [CrossRef]

| Cross-Sectional Dimensions of the Hollow Column | Thickness of the Steel Tube | Length | Concrete Infill |

|---|---|---|---|

| 100 mm × 50 mm | 2 mm | 424 mm | No infill-Hollow |

| Conventional concrete | |||

| Steel fibre-reinforced concrete | |||

| Carbon fibre-reinforced concrete | |||

| Glass fibre-reinforced concrete | |||

| Coir fibre-reinforced concrete | |||

| Jute fibre-reinforced concrete | |||

| Sisal fibre-reinforced concrete | |||

| 848 mm | No infill-Hollow | ||

| Conventional concrete | |||

| Steel fibre-reinforced concrete | |||

| Carbon fibre-reinforced concrete | |||

| Glass fibre-reinforced concrete | |||

| Coir fibre-reinforced concrete | |||

| Jute fibre-reinforced concrete | |||

| Sisal fibre-reinforced concrete | |||

| 1484 mm | No infill-Hollow | ||

| Conventional concrete | |||

| Steel fibre-reinforced concrete | |||

| Carbon fibre-reinforced concrete | |||

| Glass fibre-reinforced concrete | |||

| Coir fibre-reinforced concrete | |||

| Jute fibre-reinforced concrete | |||

| Sisal fibre-reinforced concrete |

| Type of Infill | Type of Column | ||

|---|---|---|---|

| Medium Column | Short Column | Stub Column | |

| Hollow | 115.21 kN | 138 kN | 160.22 kN |

| Conventional concrete | 280.6 kN | 330.5 kN | 366.50 kN |

| Steel FRC | 345.44 kN | 402.12 kN | 456.62 kN |

| Carbon FRC | 339.62 kN | 375.65 kN | 424.22 kN |

| Glass FRC | 350.10 kN | 405.92 kN | 464.68 kN |

| Coir FRC | 326.52 kN | 375.45 kN | 428.18 kN |

| Jute FRC | 333.48 kN | 372.15 kN | 442.12 kN |

| Sisal FRC | 340.42 kN | 384.66 kN | 444.40 kN |

| Type of Infill | Stiffness (kN/mm) | ||

|---|---|---|---|

| Medium Column | Short Column | Stub Column | |

| Hollow | 70.25 | 73.21 | 72.83 |

| Conventional concrete | 77.52 | 80.22 | 79.16 |

| Steel FRC | 58.26 | 61.40 | 59.69 |

| Carbon FRC | 57.67 | 67.57 | 64.77 |

| Glass FRC | 61.41 | 61.05 | 62.29 |

| Coir FRC | 59.05 | 68.02 | 64.20 |

| Jute FRC | 61.53 | 64.84 | 66.39 |

| Sisal FRC | 61.90 | 59.83 | 62.42 |

| Type of Infill | Ductility Index | ||

|---|---|---|---|

| Medium Column | Short Column | Stub Column | |

| Hollow | 0.61 | 0.62 | 0.62 |

| Conventional concrete | 0.69 | 0.74 | 0.72 |

| Steel FRC | 0.92 | 0.90 | 0.90 |

| Carbon FRC | 0.86 | 0.88 | 0.87 |

| Glass FRC | 0.89 | 0.90 | 0.88 |

| Coir FRC | 0.88 | 0.85 | 0.84 |

| Jute FRC | 0.87 | 0.84 | 0.83 |

| Sisal FRC | 0.91 | 0.87 | 0.87 |

| Type of Infill | Ultimate Load (kN) | |||

|---|---|---|---|---|

| EC 4 | ACI 318-11 | AISC 360-16 | AS 5100-6 | |

| Hollow | 157.68 | 157.68 | 157.68 | 141.92 |

| Conventional concrete | 335.21 | 308.58 | 308.58 | 248.43 |

| Steel FRC | 359.90 | 329.22 | 329.22 | 263.00 |

| Carbon FRC | 340.95 | 313.46 | 313.46 | 251.88 |

| Glass FRC | 359.50 | 329.22 | 329.22 | 263.00 |

| Coir FRC | 363.47 | 332.6 | 332.6 | 265.39 |

| Jute FRC | 359.50 | 329.22 | 329.22 | 263.00 |

| Sisal FRC | 360.38 | 329.98 | 329.98 | 263.53 |

| Codal Provision | Types of Columns | Experimental Ultimate Load/Theoretical Ultimate Load | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Hollow | Conventional Concrete | Steel FRC | Carbon FRC | Glass FRC | Coir FRC | Jute FRC | Sisal FRC | ||

| EC 4 | Medium column | 0.74 | 0.84 | 0.96 | 1 | 0.98 | 0.9 | 0.93 | 0.95 |

| Short column | 0.88 | 0.99 | 1.12 | 1.11 | 1.13 | 1.04 | 1.04 | 1.07 | |

| Stub column | 1.02 | 1.1 | 1.27 | 1.25 | 1.3 | 1.18 | 1.23 | 1.24 | |

| ACI 318-11 | Medium column | 0.74 | 0.91 | 1.05 | 1.09 | 1.07 | 0.99 | 1.02 | 1.04 |

| Short column | 1.02 | 1.19 | 1.39 | 1.36 | 1.42 | 1.29 | 1.35 | 1.35 | |

| Stub column | 1.02 | 1.19 | 1.39 | 1.36 | 1.42 | 1.29 | 1.35 | 1.35 | |

| AISC 360-16 | Medium column | 0.74 | 0.91 | 1.05 | 1.09 | 1.07 | 0.99 | 1.02 | 1.04 |

| Short column | 0.98 | 1.34 | 1.53 | 1.5 | 1.55 | 1.42 | 1.42 | 1.46 | |

| Stub column | 1.13 | 1.48 | 1.74 | 1.69 | 1.77 | 1.62 | 1.69 | 1.69 | |

| AS 5100-6 | Medium column | 0.82 | 1.13 | 1.32 | 1.35 | 1.34 | 1.24 | 1.27 | 1.3 |

| Short column | 0.98 | 1.34 | 1.53 | 1.5 | 1.55 | 1.42 | 1.42 | 1.46 | |

| Stub column | 1.13 | 1.48 | 1.74 | 1.69 | 1.77 | 1.62 | 1.69 | 1.69 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

More, F.M.D.S.; Subramanian, S.S. Experimental Investigation on the Axial Compressive Behaviour of Cold-Formed Steel-Concrete Composite Columns Infilled with Various Types of Fibre-Reinforced Concrete. Buildings 2023, 13, 151. https://doi.org/10.3390/buildings13010151

More FMDS, Subramanian SS. Experimental Investigation on the Axial Compressive Behaviour of Cold-Formed Steel-Concrete Composite Columns Infilled with Various Types of Fibre-Reinforced Concrete. Buildings. 2023; 13(1):151. https://doi.org/10.3390/buildings13010151

Chicago/Turabian StyleMore, Florence More Dattu Shanker, and Senthil Selvan Subramanian. 2023. "Experimental Investigation on the Axial Compressive Behaviour of Cold-Formed Steel-Concrete Composite Columns Infilled with Various Types of Fibre-Reinforced Concrete" Buildings 13, no. 1: 151. https://doi.org/10.3390/buildings13010151