Timber Buildings Deconstruction as a Design Solution toward Near Zero CO2e Emissions

Abstract

:1. Introduction

2. State-of-the-Art

- The circular C2C (form cradle to cradle) approach has only been partially investigated;

- Among the case studies analyzed, very few refer to timber construction systems;

- No study has evaluated, within the C2C approach, the potential of wood systems for carbon storage.

- Frame structure;

- XLAM panel structure.

3. Tools and Methods

- –

- To estimate the CO2e,1 component, the emissions from the machinery and equipment required for selective deconstruction operations were considered;

- –

- To estimate the CO2e,2 component, the integration of virgin raw material of the amount of scrap as loss of damaged material, as a result of deconstruction operations, was considered. Emissions result from the production of the amount of material to be integrated and the EC factor from an open-access database, Inventory Carbon and Energy (ICE) [12], corresponding to the A1–A3 phases (cradle to gate);

- –

- To estimate the CO2e,3 component, the emissions derived from transporting the deconstructed materials from the demolition site to the processing/storage company were calculated;

- –

- To estimate the CO2e,4 component, the emissions of the machinery and equipment required for restoring the wooden components, in order to put them back into the market, were calculated;

- –

- To estimate the CO2e,5 component, the negative factor indicated by ICE [12] for the cradle-to-gate phase was considered, multiplied by the amount of material recovered by selective deconstruction (therefore net of the amount of XLAM of scrap). Therefore, this value expresses the potential of the circular approach of the methodology: it corresponds to the gain, in terms of emissions, connected to the reuse of the components in the next life cycle, thus avoiding (for this quantity) the impact related to the extraction of virgin raw material and its transformation (corresponding to the A1–A3 phases).

- Phase I: Definition of the scope of investigation;

- Phase II: Technological characterization of the building;

- Phase III: Estimation of CO2e emissions;

- Phase IV: Assessment of the level of disassembly;

- Phase V: Estimation of waste streams and quantities and the verification of the Italian CAM parameters [13].

3.1. Phase I: Definition of the Scope of Investigation

3.2. Phase II: Technological Characterization of the Building

3.3. Phase III: Estimation of CO2e Emissions

- Positive rate of CO2e,1 from the demolition activities;

- Positive rate of CO2e,2 from scrap resulting from demolition activities;

- Positive rate of CO2e,3 from off-site transport;

- Positive rate of CO2e,4 from transformation/treatment activity for further reuse;

- Negative rate of CO2e,5 as emissions credit for storage in the material.

3.3.1. Positive Rate of CO2e,1 from Demolition Activity

- T0 = time needed to reach the n-th floor (ascent);

- T0′ = time needed to reach the ground floor (descent);

- T1 = time needed to connect the element to the crane hook in the case of XLAM panels and framed panels, seconds needed to load the lift basket in the case of groups of items with L < 3.20 m and P < 2000 kg;

- T2 = time needed to reach the storage site within the construction site (50 m);

- T3 = time needed to load the elements onto a truck and/or articulated truck.

- -

- The one generated by using tools for the connections removal, obtained as the product of the operating time (in seconds) of the tools or the maximum chipping capacity, the number of connections to be removed or the volume to be chipped, and the consumption of the tools by the emission factor (Table 6);

- -

- The one generated by using machinery for the transport to the ground and the loading on a truck and/or articulated truck of an item or groups of items, obtained as the product of the seconds of the operation of the machinery, the number of trips, the consumption of the machinery, and the emission factor (Table 7).

3.3.2. Positive Rate of CO2e,2 from Scrap Resulting from Demolition Operations

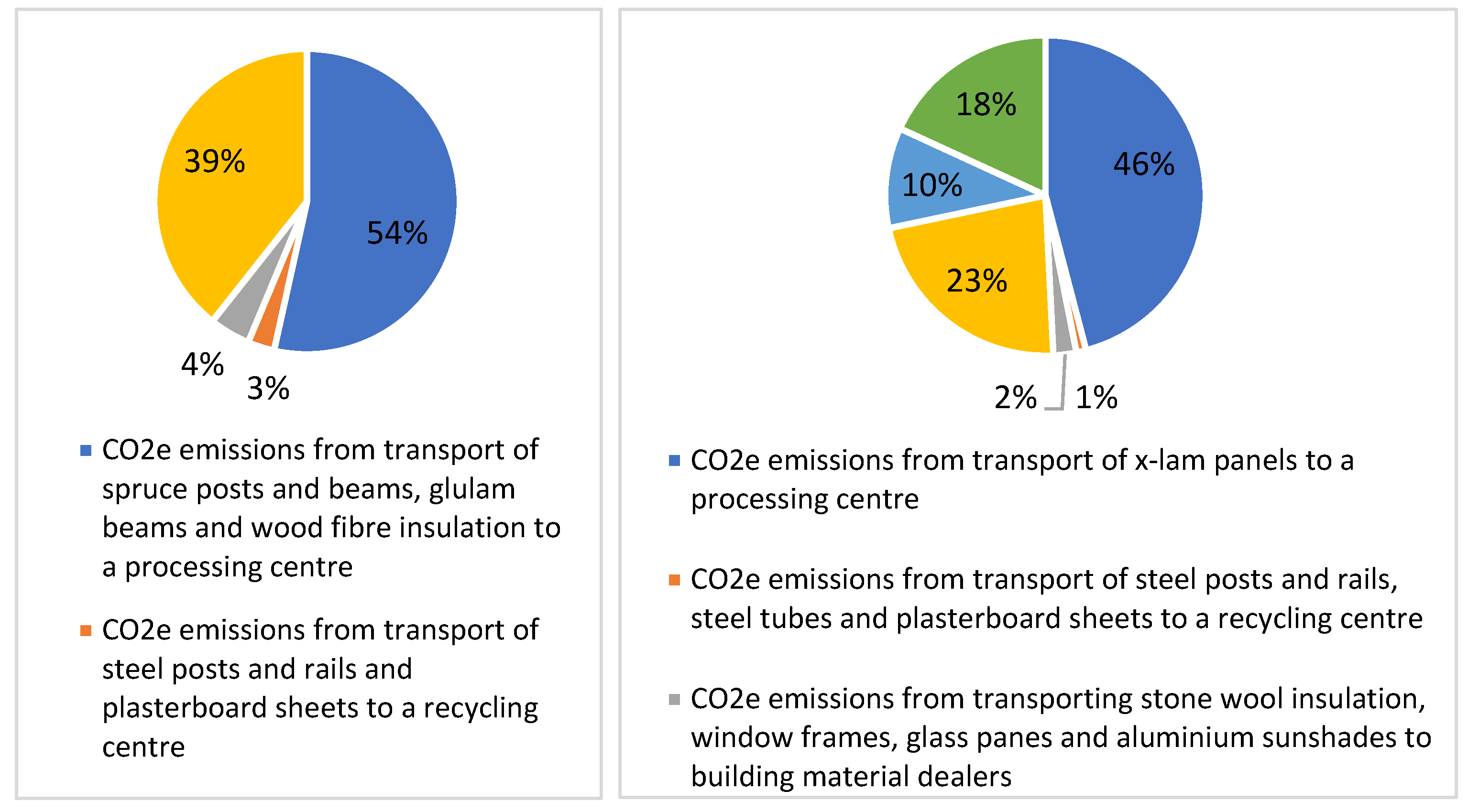

3.3.3. Positive Rate of CO2e,3 from Off-Site Transport

- In the case of future reuse activities, wooden components need to be reconditioned in a processing center before being reintroduced into the production cycle. Therefore, after leaving the construction site, a means of transport drives them to the processing center and then the new construction site.

- In the case of future recycling activities, wooden components are directly transported from the demolition site to a recycling center.

- Components made of other materials are transported to building material dealers in the case of re-use; to recycling centers if they are recyclable; and to disposal centers if a second life is not possible.

- For the disposal of hazardous waste, the only destination of the transport vehicle is the disposal center.

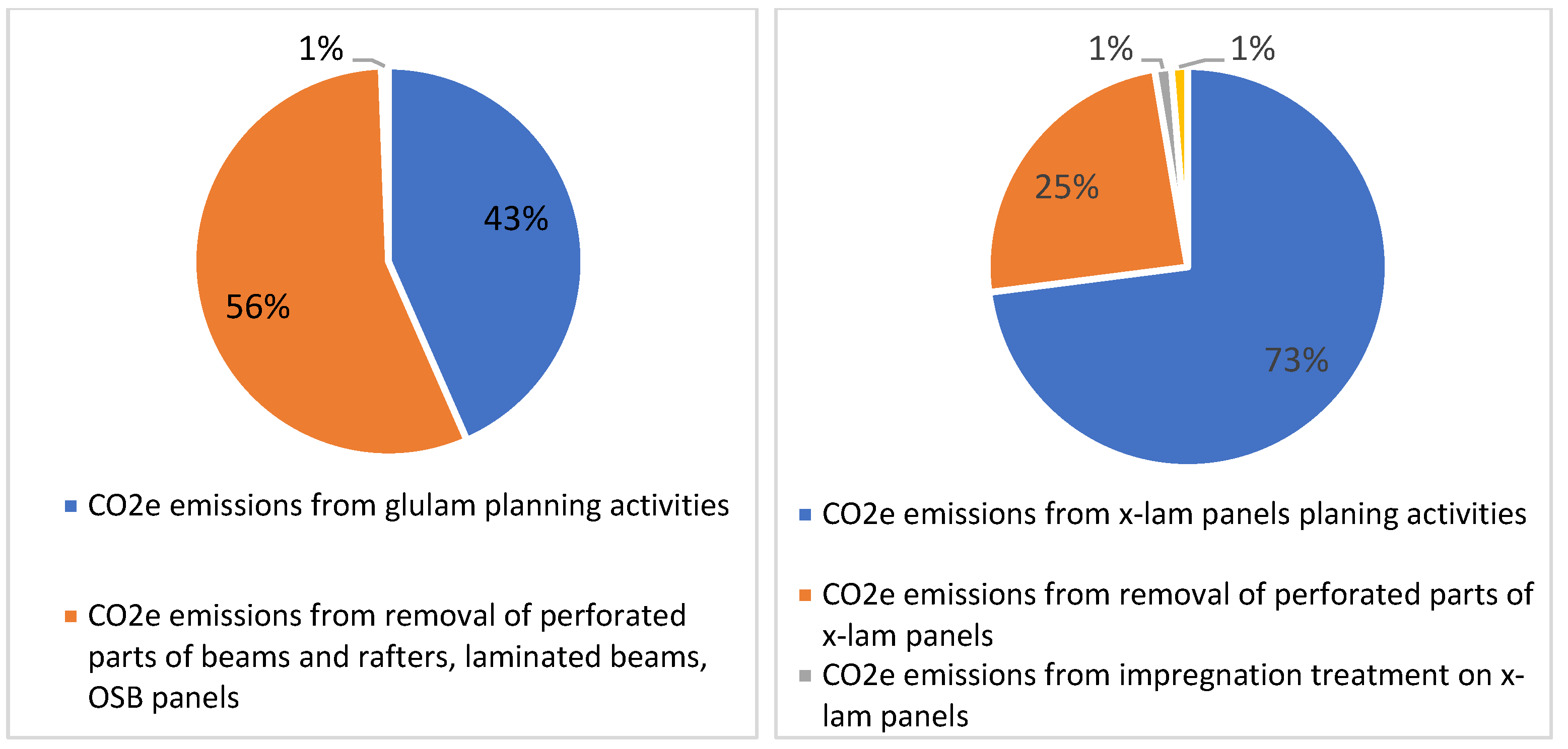

3.3.4. Positive Rate of CO2e,4 from Transformation/Treatment Activity for Further Reuse

3.3.5. Negative Rate of CO2e,5 as Emissions Credit for Storage in Material

3.4. Phase IV: Assessment of the Level of Disassembly

3.4.1. UNI Method

3.4.2. Integrated Experimental Method

3.5. Phase V: Estimation of Waste Streams and Quantities and Verification of CAM Parameters

- Processing centers: By-products with a future destination in processing centers are intended for re-use;

- Recycling centers: By-products with a future destination in recycling centers are intended for recycling activities. This quantity also includes the percentage of scrap;

- Recycling centers: Dangerous and non-dangerous waste with a future destination in disposal centers are intended for disposal activities.

4. Application to the Case Studies

- –

- Buildings made with predominantly dry technology system;

- –

- No.1 building made with a wood framed construction system;

- –

- No.1 building made with a XLAM panel construction system;

- –

- The selected buildings must present the characteristics of contemporary architectural works, in terms of the quantity of publications, citations, and web presence.

4.1. Pre-Demolition Verification

4.2. Estimation of CO2e Emissions

5. Results

5.1. Results Obtained from the Estimation CO2e,1 Emissions from Demolition Activity

5.2. Results Obtained from the Estimation of the CO2e,2 Emissions from Scrap Resulting from Demolition Activities

5.3. Results Obtained from the Estimation of CO2e,3 Emissions from Off-Site Transport

5.4. Results Obtained from the Estimation of the CO2e,4 Emissions from Transformation/Treatment for Further Reuse

5.5. Results Obtained from the Estimation of the CO2e,5 Emissions Credit for Storage in the Material

5.6. Assessment of the Level of Disassembly

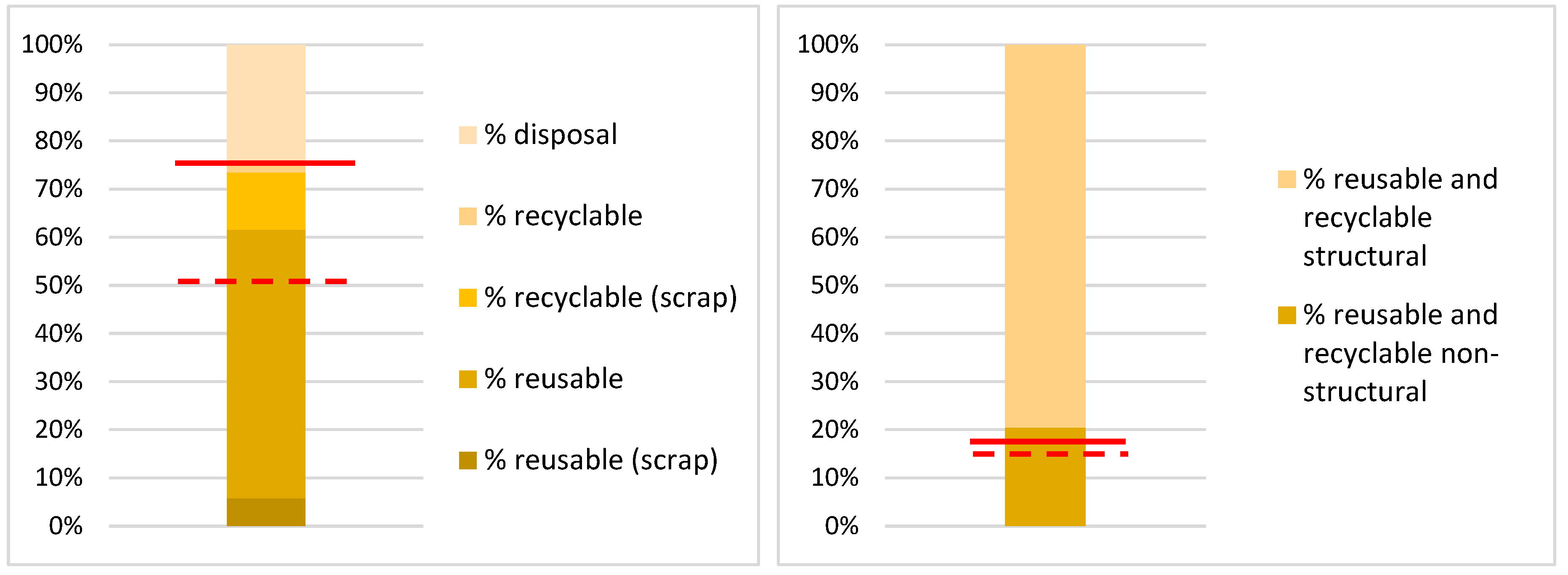

5.7. Estimation of Waste Streams and Quantities and Verification of CAM Parameters

- –

- At least 50 percent weight/weight of the building components and prefabricated elements excluding systems must be subject to selective demolition at end-of-life and be recyclable or reusable;

- –

- At least 15 percent of the above percentage must be non-structural materials.

6. Discussions

6.1. CO2e Emissions of Module C and Consequent Benefits in Module D (UNI 15978)

6.1.1. Villa GP: Discussion of Results, with Reference to the Application of Modules C and D

6.1.2. Via Cenni Complex: Discussion of Results, with Reference to the Application of Modules C and D

6.2. Compliance with the Disassembly Threshold (Italian CAM)

6.2.1. Villa GP: Discussion of Results, with Reference to Italian CAM Compliance

6.2.2. Via Cenni Complex: Discussion of Results, with Reference to Italian CAM Compliance

6.3. Overall Considerations

- –

- In terms of CO2e emissions, in the end-of-life phase, the Via Cenni complex presents a more virtuous construction system compared to Villa GP;

- –

- In terms of the disassembly potentiality, the Via Cenni complex, while exceeding both thresholds imposed by the Italian CAM, presented lower values compared to Villa GP as well as a residual amount of materials to be taken for disposal.

- –

- With regard to the level of CO2e emissions at the end-of-life, the case study of greater volume (Via Cenni complex) allowed us to optimize the use of machinery in the deconstruction and transport phases;

- –

- Regarding the level of disassembly potentiality, the XLAM construction system has more complex connections, and is therefore more difficult to be disassembled than a ‘frame’ construction system.

7. Conclusions

- –

- Easy selective demolition process, resulting in waste reduction and a high reuse rate of components at the end-of-life;

- –

- Consequent reduction in virgin raw material as a result of the system’s potential use at the end-of-life;

- –

- Possibility of reducing the overall emissions of the wooden building ( near zero) due to the carbon storage properties of the wooden components.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions ‘Fit for 55’: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality COM(2021) 550 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52021DC0550&from=EN (accessed on 10 April 2022).

- Giordano, R.; Serra, V.; Tortalla, E.; Aghemo, C. Embodied Energy and Operational Energy Assessment in the Framework of Nearly Zero Energy Building and Building Energy Rating. Energy Procedia 2015, 78, 3204–3209. [Google Scholar] [CrossRef] [Green Version]

- United Nations Environment Programme. 2022 Global Status Report for Buildings and Construction. Available online: https://globalabc.org/sites/default/files/2022-11/FULL%20REPORT_2022%20Buildings-GSR_1.pdf (accessed on 20 November 2022).

- Thormark, C. A low energy building in a life cycle—Its embodied energy, energy need for operation and recycling potential. Build. Environ. 2002, 37, 429–435. [Google Scholar] [CrossRef]

- BS EN 15978:2011; Sustainability of Construction Work—Sassessment of Environmental Performance of Buildings—Calculation Method (Incorporating Corrigendum November 2011). British Standards Institution: London, UK, 2011. Available online: https://www.greenbooklive.com/filelibrary/EN_15804/PN326-BRE-EN-15978-Methodology.pdf (accessed on 20 January 2020).

- Wu, H.J.; Yuan, Z.W.; Zhang, L.; Bi, J. Life cycle energy consumption and CO2 emission of an office building in China. Int. J. Life Cycle Assess 2012, 17, 105–118. [Google Scholar] [CrossRef]

- Bontempi, E. How to perform a material recovery sustainability evaluation preliminary to LCA? Resour. Environ. Sustain. 2022, 9, 100074. [Google Scholar] [CrossRef]

- Rabani, M.; Madessa, B.H.; Ljungström, M.; Aamodt, L.; Løvvold, S.; Nord, N. Life cycle analysis of GHG emissions from the building retrofitting: The case of a Norwegian office building. Build. Environ. 2021, 204, 108159. [Google Scholar] [CrossRef]

- Di Ruocco, G.; Melella, R.; Marino, V. An integrated assessment method for the sustainability of the opaque building envelope in residential buildings with Italian GBC-HOME certification. Archit. Eng. Des. Manag. 2021, 18, 545–570. [Google Scholar] [CrossRef]

- Di Ruocco, G.; Melella, R.; Cucco, P.; Capuano, C. Sustainable strategies for the recovery and conservation of historical buildings. LCA approach for CO2e reduction. Sustain. Mediterr. Constr. 2021, 127–132. Available online: http://www.sustainablemediterraneanconstruction.eu/SMC/The%20Magazine%20n.14_files/1416.pdf (accessed on 10 January 2022).

- Gomes, R.; Dinis Silvestre, J.; de Brito, J. Environmental, economic and energy life cycle assessment “from cradle to cradle” (3E-C2C) of flat roofs. J. Build. Eng. 2020, 32, 101436. [Google Scholar] [CrossRef]

- Jones, C.I.; Hammond, G. Embodied energy and carbon in construction materials. Proc. ICE Energy 2008, 161, 87–98. [Google Scholar] [CrossRef] [Green Version]

- Italian Ministerial Decree 11/10/2017—Criteri Ambientali Minimi (Minimum Environmental Criteria) for the Contracting of Design and Works Services for New Construction, Renovation and Maintenance of Public Buildings, Ministry of Environment and Land and Sea Protection. Available online: https://www.gazzettaufficiale.it/eli/gu/2017/11/06/259/sg/pdf (accessed on 2 January 2020).

- Data Sheet for Impact Wrench HILTI SIW 22T-A 1/2″. Available online: https://www.hilti.it/c/CLS_POWER_TOOLS_7124/CLS_IMPACT_DRIVERS_WRENCHES_7124/CLS_CORDLESS_IMPACT_WRENCHES_7124/r4265 (accessed on 8 April 2021).

- Data Sheet for Impact Wrench HILTI SID 8-A22. Available online: https://www.hilti.it/c/CLS_POWER_TOOLS_7124/CLS_IMPACT_DRIVERS_WRENCHES_7124/CLS_CORDLESS_IMPACT_DRIVERS_7124/r4659308 (accessed on 8 April 2021).

- Data Sheet for Demolition Hammer HILTI 3000-AVR. Available online: https://www.hilti.it/c/CLS_POWER_TOOLS_7124/CLS_DEMOLITION_HAMMER_BREAKER_SUB_7124/CLS_DEMOLITION_HAMMER_BREAKER_7124/r9671577 (accessed on 8 April 2021).

- Data Sheet for Demolition Hammer HILTI TE 700-AVR SDS MAX. Available online: https://www.hilti.it/c/CLS_POWER_TOOLS_7124/CLS_DEMOLITION_HAMMER_BREAKER_SUB_7124/CLS_DEMOLITION_HAMMER_BREAKER_7124/r5005 (accessed on 8 April 2021).

- Italian Standard UNI 8290/1-1981; Residential Building—Technological System—Classification and Terminology. Available online: https://store.uni.com/uni-8290-1-1981-a122-1983 (accessed on 17 December 2020).

- Construction. Needs of the End-User. Classification, Italian Standard UNI 8289-1981. Sustainability in Construction-Needs and Requirements of Environmental Compatibility of Residential Projects and Similar, Offices and Similar, of New Construction and Renovation, Italian Standard UNI 11277-2008. Available online: http://store.uni.com/catalogo/uni-11277-2008 (accessed on 17 December 2020).

- Norma UNI 11228-1:2009; Ergonomia-Movimentazione Manuale—Parte 1: Sollevamento e Trasporto. Available online: http://store.uni.com/catalogo/uni-iso-11228-1-2009 (accessed on 17 December 2020).

- Data Sheet for Vertical Lift—ALIMAK HEK TPL 2000. Available online: https://www.archiproducts.com/it/prodotti/alimak/elevatore-da-cantiere-hek-tpl-2000-2000-d-1800_80122 (accessed on 12 April 2021).

- Data Sheet for Telescopic Handler—JCB 525-60E. Available online: https://www.jcb.com/it-it/products/movimentatori-telescopici/525-60e-hi-viz (accessed on 12 April 2021).

- Data Sheet for Telescopic Handler—JCB 541-70. Available online: https://www.jcb.com/it-it/products/movimentatori-telescopici/541-70 (accessed on 12 April 2021).

- Data Sheet for Telescopic crane—LIEBHER LTM 1040-2.1. Available online: https://www.lectura-specs.it/it/modello/gru/gru-fuoristrada-971405-liebherr/ltm-1040-2-1-1148034 (accessed on 12 April 2021).

- Data Sheet for Self-Moving Vertical Platform—GENIE GS-4655. Available online: https://www.genielift.com/it/aerial-lift-products/Slab-scissor-lifts/gs-4655 (accessed on 14 April 2021).

- Data Sheet for Self-Moving Vertical Platform with Telescopic Arm—GENIE SX-105 XC. Available online: https://www.genielift.com/it/aerial-lift-products/telescopic-boom-lifts/sx-105-xc (accessed on 14 April 2021).

- Film Corresponding to a Real Case. Connection of the Element to the Crane Hook: XLAM Wooden House Construction in 12 Days. Available online: https://www.youtube.com/watch?v=gh4-V2tIq84&t=418s (accessed on 14 April 2021).

- Mayer, M.; Bechthold, M. Development of policy metrics for circularity assessment in building assemblies. Econ. Policy Energy Environ. 2018, 1, 57–84. [Google Scholar] [CrossRef]

- Film Corresponding to a Real Case. Loading the Elevator Basket. Available online: https://www.youtube.com/watch?v=6WZscEY4OCk&t=2s&ab_channel=AlimakHek (accessed on 18 April 2021).

- Film Corresponding to a Real Case. Loading a Truck with a Telescopic Crane. Available online: https://www.youtube.com/watch?v=YDp6NROFVsc&t=409s&ab_channel=ISOLPANCOSTRUZIONIINLEGNO (accessed on 18 April 2021).

- Film Corresponding to a Real Case. Loading a Lorry with a Mover. Available online: https://www.youtube.com/watch?v=LWbV3u7VLRQ&t=73s&ab_channel=LaorencHoxha (accessed on 18 April 2021).

- The Environmental Performance in Construction (EPiC), University of Melbourne. Available online: https://msd.unimelb.edu.au/research/projects/current/environmental-performance-in-construction/about (accessed on 17 December 2020).

- COMMISSION DECISION of 18 December 2014 Amending Decision 2000/532/EC on the List of Waste Pursuant to Directive 2008/98/EC of the European Parliament and of the Council (Text with EEA Relevance) (2014/955/EU). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32014D0955&from=EN (accessed on 17 December 2020).

- Data Sheet for Circular Table Saw—Bosch GTS 10 XC PROFESSIONAL. Available online: https://www.bosch-professional.com/it/it/products/gts-10-xc-0601B30400 (accessed on 22 April 2021).

- Data Sheet for CNC Machining Centre—BIESSE Uniteam UT. Available online: https://www.biesse.com/it/legno/centri-di-lavoro/uniteam-ut (accessed on 22 April 2021).

- Data Sheet for Electric Planer—FELDER GROUP FORMAT 4 Plan 51 L. Available online: https://www.felder-group.com/it-it/prodotti/pialle-a-filo-e-spessore-c1948/pialla-a-filo-plan-51l-p3272 (accessed on 22 April 2021).

- Data Sheet for Spray Gun—WAGNER Airless Sprayer Control Pro 350 M. Available online: https://www.wagner-group.com/it/fai-da-te/prodotti-accessori/prodotto/airless-sprayer-control-pro-350-m/ (accessed on 22 April 2021).

- Longo, D. Decostruzione e Riuso: Procedure e Tecniche di Valorizzazione dei Residui Edilizi in Italia; Alinea Editrice s.r.l.: Firenze, Italy, 2007; ISBN 8860551226. [Google Scholar]

- European Commission: EU Construction and Demolition Waste Management Protocol—29/09/2016. Available online: https://ec.europa.eu/docsroom/documents/20509/ (accessed on 18 July 2021).

- European Commission: Guidelines for the Waste Audits before Demolition and Renovation Works of Buildings. EU Construction and Demolition Waste Management. 2018. Available online: https://ec.europa.eu/docsroom/documents/31521 (accessed on 20 October 2022).

- United Nations General Assembly—Transforming Our World: The 2030 Agenda for Sustainable Development. Available online: https://www.un.org/en/development/desa/population/migration/generalassembly/docs/globalcompact/A_RES_70_1_E.pdf (accessed on 20 October 2022).

- GlobalABC, 2019 Global Status Report for Buildings and Construction—Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector. 1 January 2020. Available online: https://globalabc.org/resources/publications/2019-global-status-report-buildings-and-construction (accessed on 5 March 2021).

- Direttiva 2008/98/CE del Parlamento Europeo e del Consiglio del 19 Novembre 2018 Relativa ai Rifiuti e che Abroga Alcune Direttive. Available online: https://eur-lex.europa.eu/legal-content/IT/TXT/?uri=celex:32008L0098 (accessed on 5 March 2021).

- Annuario dei Dati Ambientali—Rifiuti, ISPRA. 2019. Available online: https://www.isprambiente.gov.it/files2020/pubblicazioni/stato-ambiente/annuario-2020/11Rifiuti2019.pdf (accessed on 10 January 2021).

- Van Der Lugt, P. Carbon Storage Utilising Timber Products. Enviromental Ind. Mag. 2012, 76–80. Available online: https://research.tudelft.nl/en/publications/carbon-storage-utilising-timber-products (accessed on 18 July 2021).

| Connection Type | Tools | Model |

|---|---|---|

| Nailing | Nail extractor | INNOVA |

| Bolts | Impact wrench | HILTI-SIW 22T-A 1/2″ [14] |

| Screwing | Impact wrench | HILTI-SID 8-A 22 [15] |

| Snap-in joints and/or snap-in joints | Manual disassembly | / |

| Simple overlapping | Manual disassembly | / |

Hydraulic and air binders | Demolition hammer | HILTI 3000-AVR for concrete slabs [16] HILTI—TE 700 SDS MAX for plaster and tiles [17] |

| Ground Floor | |||

|---|---|---|---|

| Weight (P) and Size (L) of Elements | Ground Transport Modes | Machines | Model |

| P < 25 kg L < 3.2 m | Manual ground transport | / | / |

| P < 25 kg L > 3.2 m | Manual ground transport | / | / |

| P > 25 kg L < 3.2 m | Ground transport in group of elements (P < 2000 kg) inside the elevator basket | Elevator | ALIMAK HEK—TPL 2000 |

| P > 25 kg L > 3.2 m | Ground transport of the single element by telescopic crane | Telescopic crane | LIEBHER—LTM 100-2.1 |

| XLAM panel and framed panel | Ground transport of the single element by telescopic crane | Telescopic crane | LIEBHER—LTM 100-2.1 |

| Next Floor | |||

| P < 25 kg L < 3.2 m | Ground transport in group of elements (P < 2000 kg) inside the elevator basket | Elevator | ALIMAK HEK—TPL 2000 |

| P < 25 kg L > 3.2 m | Ground transport of the single element by telescopic crane | Telescopic crane | LIEBHER—LTM 100-2.1 |

| P > 25 kg L < 3.2 m | Ground transport in group of elements (P < 2000 kg) inside the elevator basket | Elevator | ALIMAK HEK—TPL 2000 |

| P > 25 kg L > 3.2 m | Ground transport of the single element by telescopic crane | Telescopic crane | LIEBHER—LTM 100-2.1 |

| XLAM panel and framed panel | Ground transport of the single element by telescopic crane | Telescopic crane | LIEBHER—LTM 100-2.1 |

| Weight (P) and Size (L) of Elements | Ground Transport Modes | Machines | Model |

|---|---|---|---|

| P < 25 kg L < 4.00 kg | Manual loading on truck | / | / |

| P < 25 kg L > 4.00 m | Manual loading on truck | / | / |

| P > 25 kg L < 4.00 m | Loading a group of elements anchored to the fork of a telescopic handler on truck | Telescopic handler | JCB—525-60E (P < 2000 kg) JCB—541-70 (P < 4100 kg) |

| P > 25 kg L > 4.00 m | Loading the single element with a telescopic crane on track | Telescopic crane | LIEBHER—LTM 1040-2.1 |

| XLAM panel and framed panel | Loading the single element with a telescopic crane on track | Telescopic crane | LIEBHER—LTM 1040-2.1 |

| Works at Height | Machines | Model |

|---|---|---|

| Maximum indoor working height 15.95 m Maximum outdoor working height 8.55 m | Self-moving vertical platform | GENIE—GS 4655 |

| Maximum working height 34 m | Self-moving vertical platform with telescopic arm | GENIE—SX-105 XC |

| Tools and Machines | Time Required to Remove a Single Connection | Source |

|---|---|---|

| Nail extractor | 10 < s < 40 | Data collected in literature [28] |

| Impact wrench | s < 10 | Data collected in literature [28] |

| Manual disassembly | s < 10 | Data collected in literature [28] |

| Demolition hammer | 2.4 m3/h | Data sheet [16] |

| Demolition hammer | 0.072 m3/h | Data sheet [17] |

| Tool | Operating Seconds or Maximum Capacity | Removed Connections or Volume | Tool Consumption | Emission Factor | CO2e Emissions |

|---|---|---|---|---|---|

| Nail extractor | S | n | - | 0.01 kg CO2e/h | kg CO2e |

| Impact wrench | S | n | 0.11 kWh | 0.44 kg CO2e/h | kg CO2e |

| Demolition hammer for slab | h/m3 | m3 | 0.97 kWh | 0.44 kg CO2e/h | kg CO2e |

| Machine | Operating Seconds | Number of Trips | Machine Consumption | Emission Factor | CO2e Emissions |

|---|---|---|---|---|---|

| Self-moving vertical platform | s | n | 7.20 kWh | 0.44 kg CO2e/kWh | kg CO2e |

| Self-moving vertical platform with telescopic arm | s | n | 3.94 L/h | 2.64 kg CO2e/L diesel | kg CO2e |

| Elevator | s | n | 12.16 kW | 0.44 kg CO2e/kWh | kg CO2e |

| Telescopic crane | s | n | 15.14 L/h | 2.64 kg CO2e/L diesel | kg CO2e |

| Telescopic handler | s | n | 5.1 L/h | 2.64 kg CO2e/L diesel | kg CO2e |

| Telescopic handler | s | n | 24 kWh | 0.44 kg CO2e/kW | kg CO2e |

| 0% | 80% | 90% | 100% |

|---|---|---|---|

| Wet system | Adhesive system | Dry system with clamping technology | Dry system with interlocking technique |

| Hydraulic and air binders | Fusion adhesives, evaporation adhesives | Nailing, bolting, screwing | Simple overlapping, snap-in |

| Activities | Machines | Model | Speed (m/s) |

|---|---|---|---|

| Removal of perforated parts | Circular table saw | BOSCH—GTS 10 XC PROFESSIONAL | 0.017 |

| Removal of perforated parts | Electric circular saw | BIESSE—UNITEAM UT | 0.14 |

| Removal of surface material | Electric planer | FORMAT 4—plan 51 L | 0.033 |

| Impregnation treatment | Spray gun | WAGNER—Airless Sprayer Control Pro 350 M | 7.5 m2/min |

| Processing Activities | Element Dimensions | Number of Activities | Speed | Power | Emission Factor | CO2e Emissions |

|---|---|---|---|---|---|---|

| Cutting with a circular table saw | m | N | h/m | 2.1 kW | 0.44 kg CO2e/kWh | kg CO2e |

| Cutting with electric circular saw | m | N | h/m | 22 kW | 0.44 kg CO2e/kWh | kg CO2e |

| Planing | m | N | h/m | 5.5 kW | 0.44 kg CO2e/kWh | kg CO2e |

| Impregnation spray treatment | m2 | N | h/m2 | 0.6 kW | 0.44 kg CO2e/kWh | kg CO2e |

| Building System | Laying Technology | LID |

|---|---|---|

| Wet system | Hydraulic and air binders | 0 |

| Adhesive system | Fusion adhesives, evaporation adhesives | 0 |

| Dry system with clamping technique | Nailing, bolting, screwing | 3 |

| Dry system with interlock technique | Snap-in | 3 |

| Dry system with juxtaposition technique | Simple overlapping | 5 |

| Building System and Laying Technology p = 0.60 | Damage Caused by Handling and Transport p = 0.20 | Processing Activities p = 0.20 |

|---|---|---|

| Wet system—hydraulic and air binders|0% | Fragile elements, high probability of damage|20% | Non-reusability|0% |

| Adhesive system—fusion adhesives, evaporation adhesives|25% | Transport to the ground and loading onto a lorry, L > 14 m|40% | Cutting of perforated parts|25% |

| Dry system with clamping technique—nailing|50% | Transport to the ground and loading onto a lorry, L < 14 m|40% | Planing|50% |

| Dry system with clamping technique—bolting, screwing|75% | Ground transportation with lifting devices|60% | Impregnating spray treatment|75% |

| Dry system with interlock and juxtaposition technique—snap and simple interlocking|100% | Manual transport|100% | General cleaning|100% |

| CO2e emissions rate from demolition activity | 64.12 kg CO2e |

| CO2e emissions rate from scrap resulting from demolition activities | 1272.96 kg CO2e |

| CO2e emissions rate from off-site transport | 989.15 kg CO2e |

| CO2e emissions rate from transformation/treatment activity for further re-use | 80.55 kg CO2e |

| Negative CO2e gained from wood storage | −3489.65 kg CO2e |

| ∑CO2e emissions | −1082.87 kg CO2e |

| CO2e emissions rate from demolition activity | 3292.76 kg CO2e |

| CO2e emissions rate from scrap resulting from demolition activities | 3328.82 kg CO2e |

| CO2e emissions rate from off-site transport | 5812.66 kg CO2e |

| CO2e emissions rate produced by processing/treatment activity for further reuse | 663.37 kg CO2e |

| Negative CO2e emissions gained from wood storage | −129,437.17 kg CO2e |

| ∑CO2e emissions | −116,339.56 kg CO2e |

| Villa GP | ||

| Emission positive rate | +2406.78 kg CO2e | +2.916 kg CO2e/m3 |

| Negative rate gained from wood storage | −3689.65 kg CO2e | −4.470 kg CO2e/m3 |

| Via Cenni Complex | ||

| Emission positive rate | +13,097.61 kg CO2e | +1.080 kg CO2e/m3 |

| Negative rate gained from wood storage | −129,437.17 kg CO2e | −10.670 kg CO2e/m3 |

| Technical Element | LID—UNI Method | LID—Experimental Method |

|---|---|---|

| Vertical perimeter walls | 0.70 | 0.70 |

| Vertical exterior windows frames | 0.80 | 0.86 |

| Internal frame walls | 0.70 | 0.70 |

| Internal plasterboard walls | 0.70 | 0.83 |

| Vertical internal windows frames | 0.80 | 0.86 |

| Stairs | 0.40 | 0.75 |

| Balconies | 0.70 | 0.75 |

| Protection elements | 0.60 | 0.54 |

| Floor | 0.70 | 0.71 |

| Roofs | 0.70 | 0.71 |

| Technical Element | LID—UNI Method | LID—Experimental Method |

|---|---|---|

| Vertical elevation structure | 0 | 0.26 |

| Horizontal elevation structure | 0 | 0.26 |

| Perimeter walls | 0.60 | 0.67 |

| External frames | 0.80 | 0.83 |

| XLAM internal walls | 0.60 | 0.67 |

| Internal plasterboard walls | 0.70 | 0.81 |

| Internal frames | 0.80 | 0.86 |

| Stairs | 0.60 | 0.74 |

| Balconies | 0.60 | 0.67 |

| Protection elements | 0.73 | 0.87 |

| XLAM floor | 0.60 | 0.67 |

| Concrete floor | 0 | 0.16 |

| Roofs | 0.60 | 0.67 |

| Total Waste Generated That Can Be Reused and Recycled—Villa GP | Percent | Total | Non Structural |

|---|---|---|---|

| Quantity of reusable material—structural materials | 39.84% | 100% (>50%) | |

| Quantity of reusable material (scrap)—structural materials | 4.43% | ||

| Quantity of reusable material—non-structural materials | 19.98% | 55.73% (>15%) | |

| Quantity of reusable material (scrap)—non-structural materials | 0.08% | ||

| Quantity of recyclable material (scrap)—non-structural materials | 3.57% | ||

| Quantity of recyclable material—non-structural materials | 32.10% |

| Total Waste Generated That Can Be Reused and Recycled—Via Cenni Complex | Percent | Total | Non Structural |

|---|---|---|---|

| Quantity of reusable material—structural materials | 54.12% | 75.25% (>50%) | |

| Quantity of reusable material (scrap)—structural materials | 5.73% | ||

| Quantity of reusable material—non-structural materials | 1.63% | 15.41% (>15%) | |

| Quantity of reusable material (scrap)—non-structural materials | 0.06% | ||

| Quantity of recyclable material (scrap)—non-structural materials | 11.92% | ||

| Quantity of recyclable material—non-structural materials | 1.80% | ||

| Quantity of material to be discarded | 24.75% | 24.75% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Ruocco, G.; Melella, R.; Sabatano, L. Timber Buildings Deconstruction as a Design Solution toward Near Zero CO2e Emissions. Buildings 2023, 13, 157. https://doi.org/10.3390/buildings13010157

Di Ruocco G, Melella R, Sabatano L. Timber Buildings Deconstruction as a Design Solution toward Near Zero CO2e Emissions. Buildings. 2023; 13(1):157. https://doi.org/10.3390/buildings13010157

Chicago/Turabian StyleDi Ruocco, Giacomo, Roberta Melella, and Laura Sabatano. 2023. "Timber Buildings Deconstruction as a Design Solution toward Near Zero CO2e Emissions" Buildings 13, no. 1: 157. https://doi.org/10.3390/buildings13010157

APA StyleDi Ruocco, G., Melella, R., & Sabatano, L. (2023). Timber Buildings Deconstruction as a Design Solution toward Near Zero CO2e Emissions. Buildings, 13(1), 157. https://doi.org/10.3390/buildings13010157