Comparing the Standards of Life Cycle Carbon Assessment of Buildings: An Analysis of the Pros and Cons

Abstract

:1. Introduction

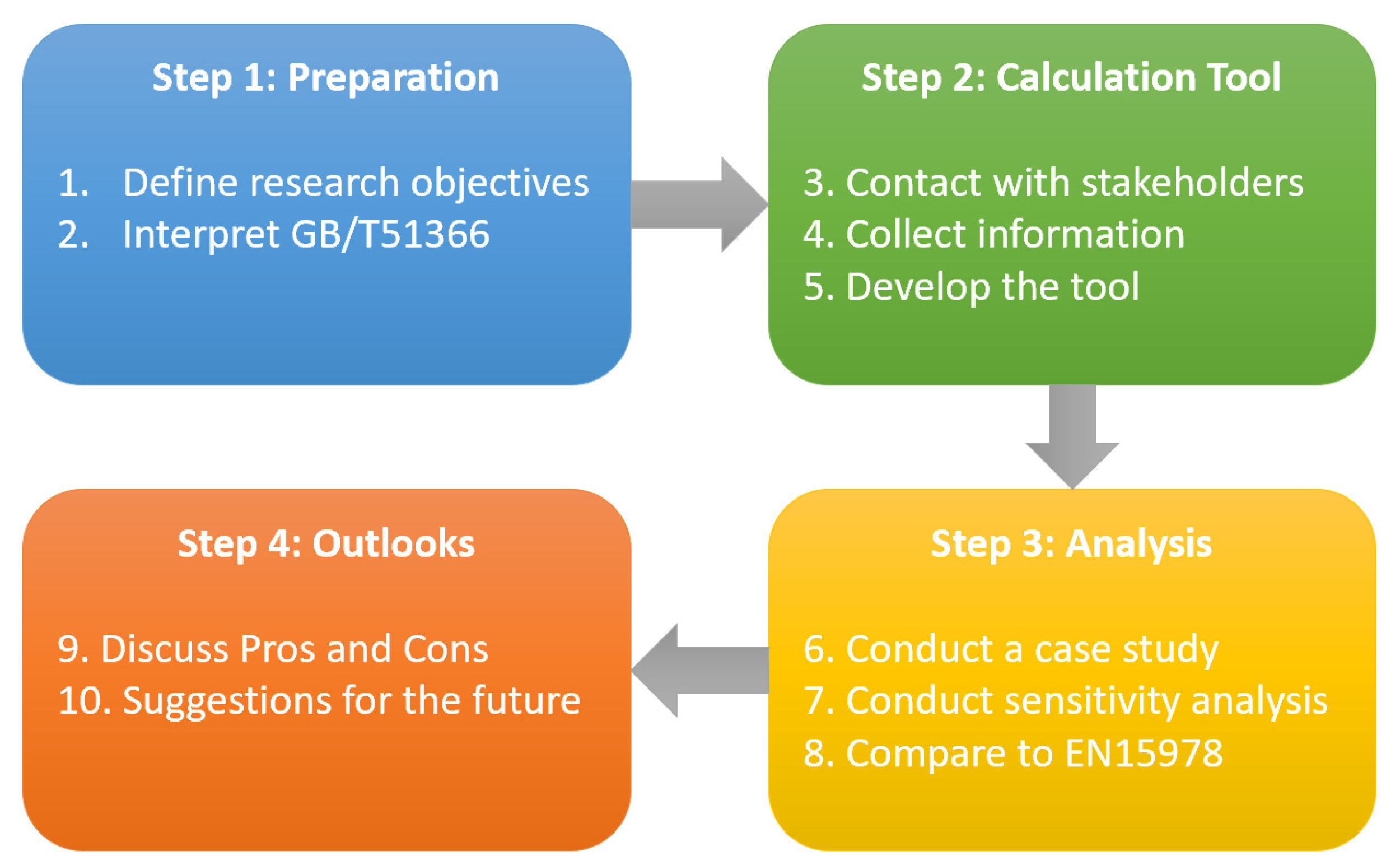

2. Material and Methods

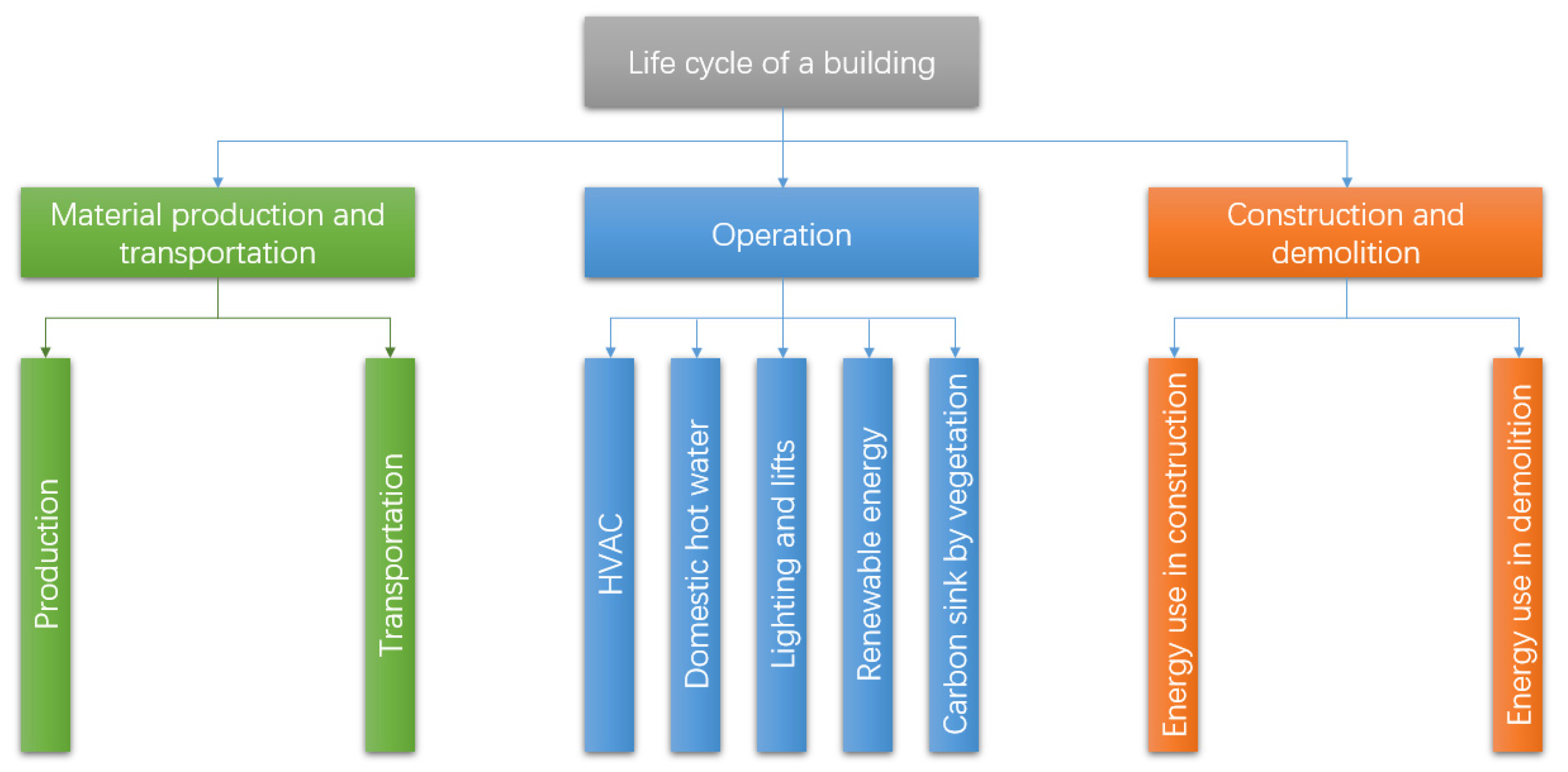

2.1. Scope and Methods of GB/T51366

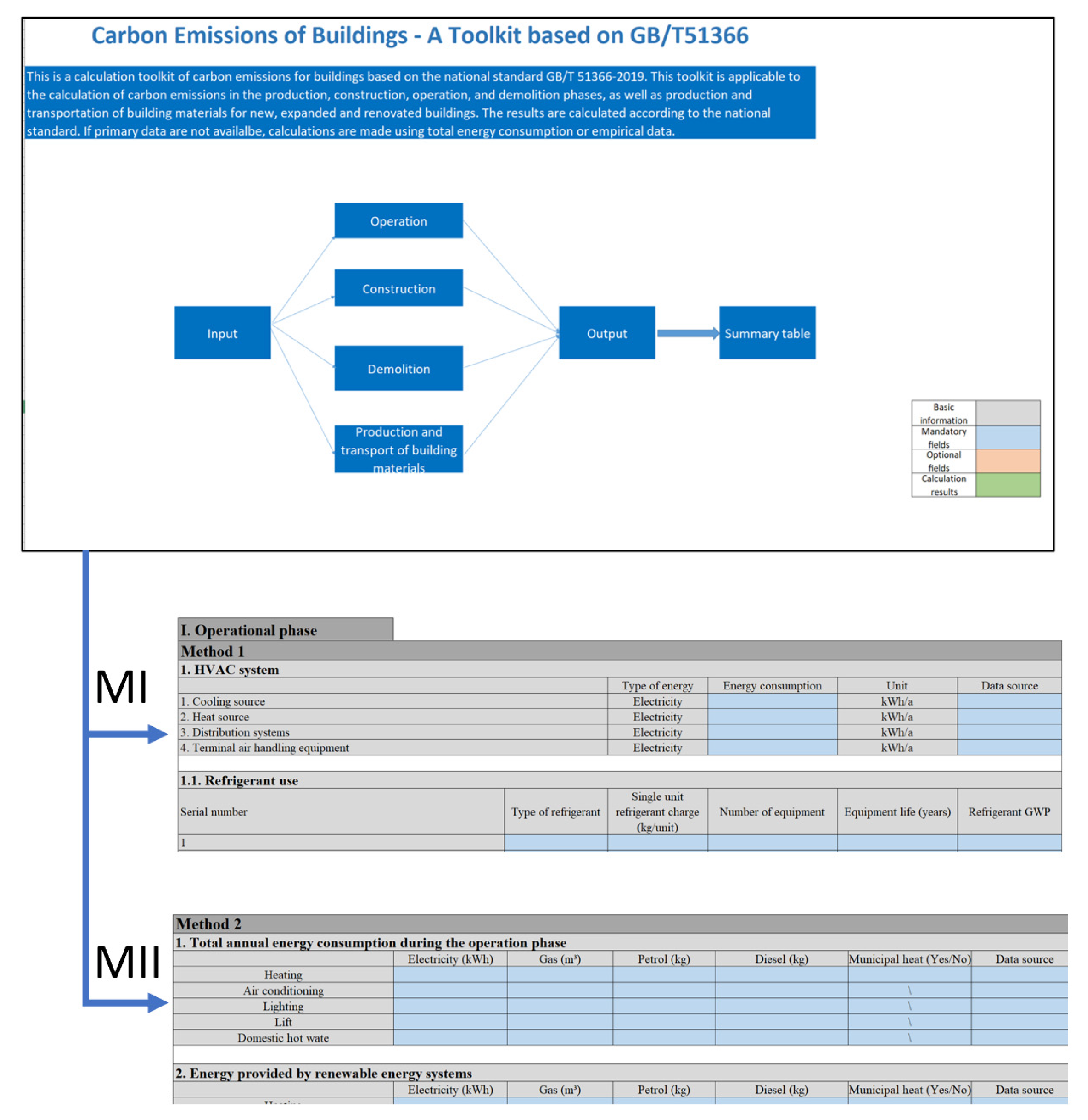

2.2. Development of a Calculation Toolkit Based on GB/T51366

2.2.1. Model Structure

2.2.2. Two Methods of Calculation Based on GB/T51366

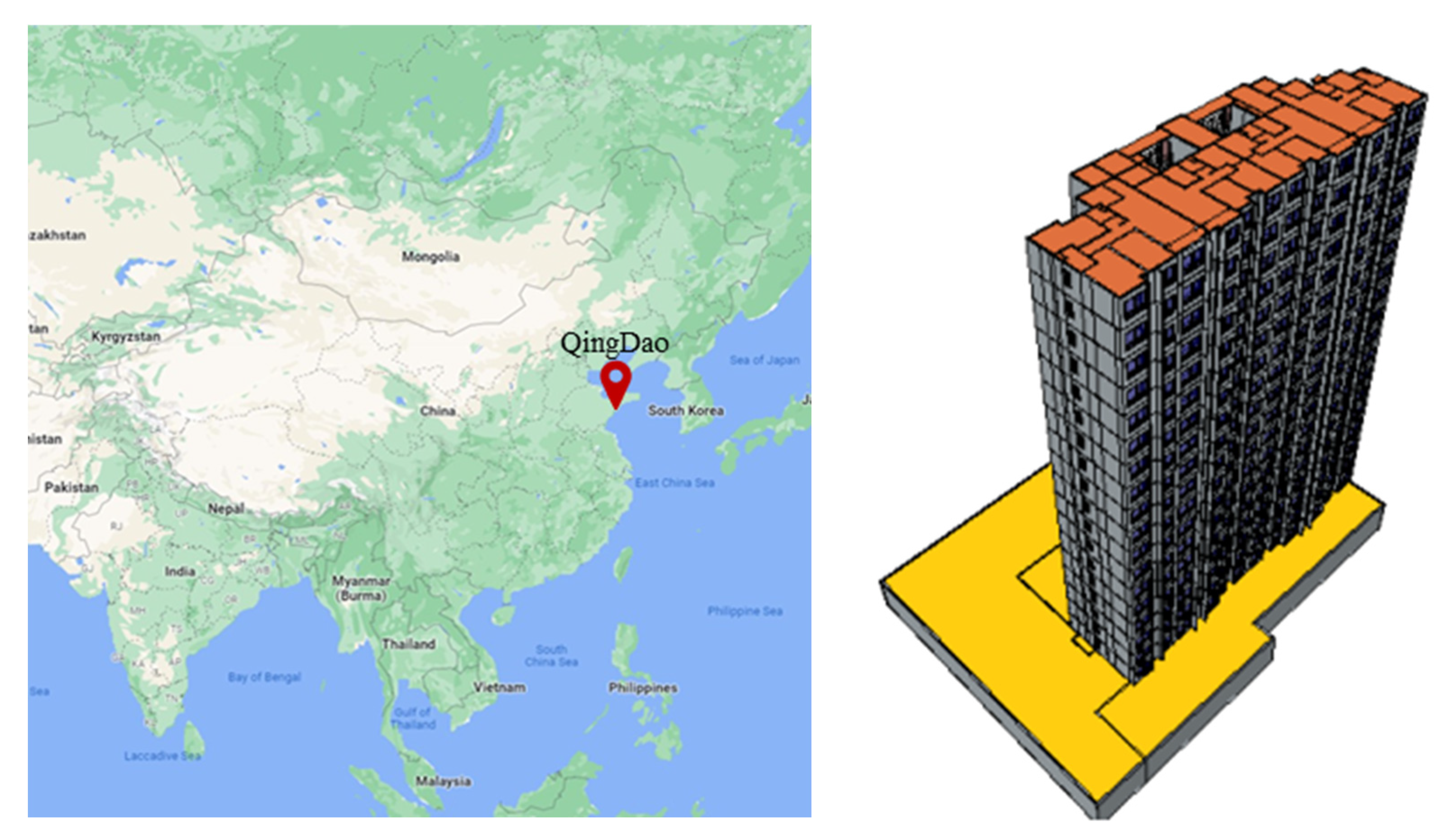

3. Case Study

3.1. Description of the Study Case

3.2. Data Collection

3.3. Results of the Case Study

4. Comparing GB/T51366 and EN15978

4.1. Descriptive Comparison

4.2. Quantitative Comparison

4.2.1. Difference in Scopes

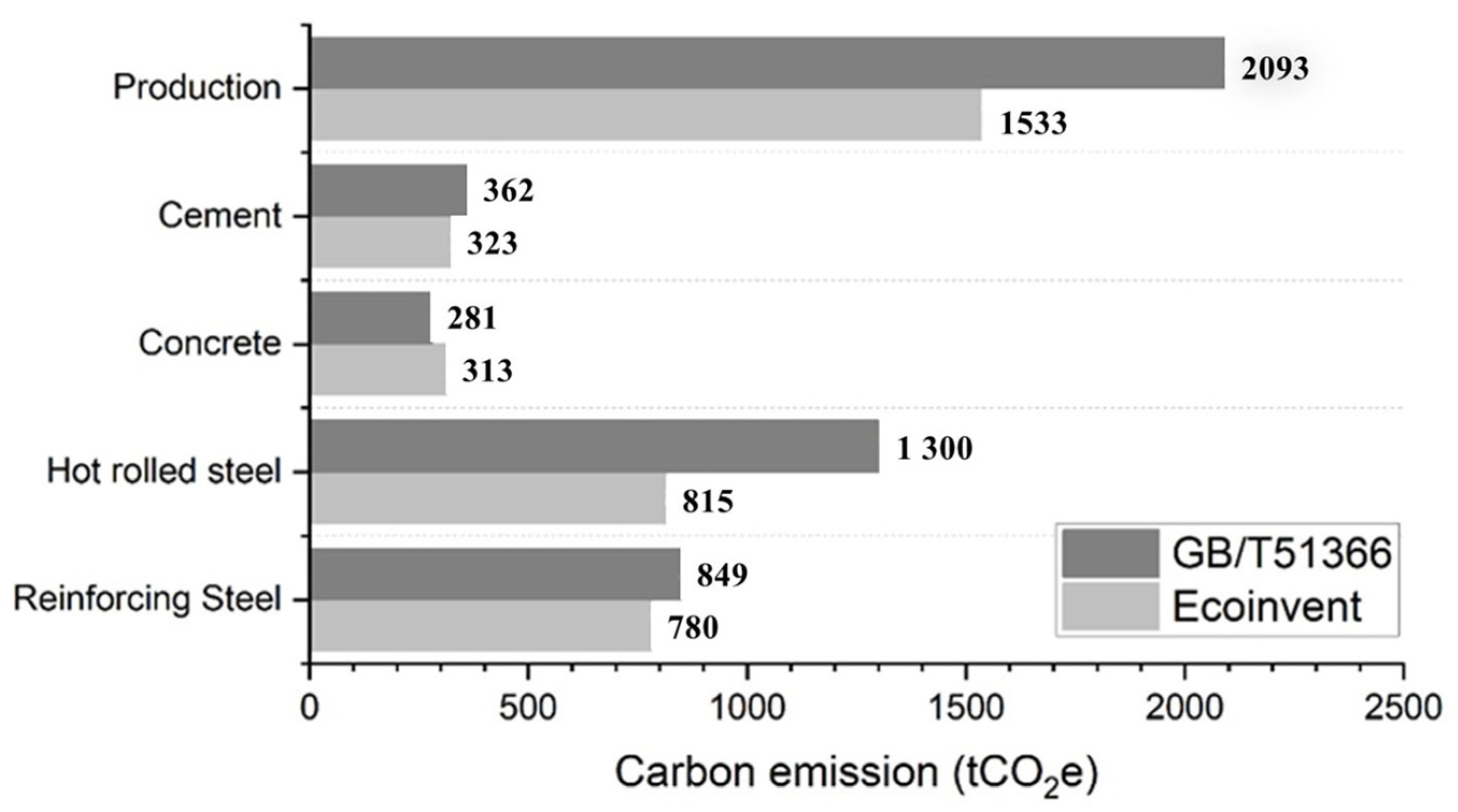

4.2.2. Sensitivity to Emission Factors

5. Discussion

5.1. Summary of the Pros and Cons of GB/T51366

5.2. Challenges in Data Collection

5.3. Carbon Sink

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ali, K.A.; Ahmad, M.I.; Yusup, Y. Issues, Impacts, and Mitigations of Carbon Dioxide Emissions in the Building Sector. Sustainability 2020, 12, 7427. [Google Scholar]

- United Nations. 27th United Nations Climate Change Conference. 2022. Available online: https://news.un.org/zh/story/2022/11/1112252 (accessed on 10 December 2022).

- National Bureau of Statistics of the People’s Republic of China. China Statistical Yearbook 2021. 2021. Available online: http://www.stats.gov.cn/tjsj/ndsj/2021/indexch.html (accessed on 6 January 2023). (In Chinese)

- China Association of Building Energy Efficiency. 2022 Series of Research Reports on Carbon Emissions in China’s Urban and Rural Construction Sector. 2023. Available online: https://www.cabee.org/site/content/24420.html (accessed on 4 January 2023). (In Chinese).

- Wu, Y.; Zhang, S.; Jiang, L. Discussion on the current situation of carbon emission and carbon neutral path of China’s buildings. Chongqing Archit. 2021, 20, 66–68. [Google Scholar]

- Xu, T.T.; Kang, C.Y.; Zhang, H. China’s efforts towards carbon neutrality: Does energy-saving and emission-reduction policy mitigate carbon emissions? J. Environ. Manag. 2022, 361, 115286. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Green Building Creation Action Plan. 2020. Available online: http://www.gov.cn/zhengce/zhengceku/2020-07/24/content_5529745.htm (accessed on 6 January 2023). (In Chinese)

- General Office of the State Council of the People’s Republic of China, 2021. Available online: http://www.gov.cn/zhengce/content/2021-10/26/content_5644984.html (accessed on 5 December 2022). (In Chinese)

- General Office of the State Council of the People’s Republic of China. National Standardisation Development Framework. 2021. Available online: http://www.gov.cn/zhengce/2021-10/10/content_5641727.html (accessed on 5 December 2022). (In Chinese)

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. GB/T 55015-2021 General Specification for Energy Efficiency and Renewable Energy Use in Buildings. 2021. Available online: https://www.mohurd.gov.cn/gongkai/fdzdgknr/zfhcxjsbwj/202110/20211013_762460.html (accessed on 6 January 2023). (In Chinese)

- Dong, Y.; Liu, J.; Dong, H.; Luo, G.; Sun, H. Analysis of carbon emission of buildings and research on carbon reduction path. Chongqing Archit. 2023, 22, 5–8. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. GB/T 51366-2019 Standard for Calculating Carbon Emissions from Buildings. 2019. Available online: https://www.mohurd.gov.cn/gongkai/fdzdgknr/tzgg/201905/20190530_240723.html (accessed on 20 November 2022).

- Kloepffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89–94. [Google Scholar] [CrossRef]

- Peng, C. Calculation of a building’s life cycle carbon emissions based on Ecotect and building information modeling. J. Clean. Prod. 2016, 112, 453–465. [Google Scholar] [CrossRef]

- Kumanayake, R.; Luo, H. A tool for assessing life cycle carbon emissions of buildings in Sri Lanka. Build. Environ. 2018, 128, 272–286. [Google Scholar] [CrossRef]

- Oh, B.K.; Glisic, B.; Lee, S.H.; Cho, T.; Park, H.S. Comprehensive investigation of embodied carbon emissions, costs, design parameters, and serviceability in optimum green construction of two-way slabs in buildings. J. Clean. Prod. 2019, 222, 111–128. [Google Scholar] [CrossRef]

- Wu, X.; Peng, B.; Lin, B. A dynamic life cycle carbon emission assessment on green and non-green buildings in China. Energy Build. 2017, 149, 272–281. [Google Scholar] [CrossRef]

- Luo, Z.; Cang, Y.; Zhang, N.; Yang, L.; Liu, J.P. A Quantitative Process-Based Inventory Study on Material Embodied Carbon Emissions of Residential, Office, and Commercial Buildings in China. J. Therm. Sci. 2019, 28, 1236–1251. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.P.; Shen, L.Y.; Tang, L.Y.N. Comparative study of greenhouse gas emissions between off-site prefabrication and conventional construction methods: Two case studies of residential projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Life-cycle assessment and control measures for carbon emissions of typical buildings in China. Build. Environ. 2015, 86, 89–97. [Google Scholar] [CrossRef]

- Teng, Y.; Li, K.; Pan, W.; Ng, T. Reducing building life cycle carbon emissions through prefabrication: Evidence from and gaps in empirical studies. Build. Environ. 2018, 132, 125–136. [Google Scholar] [CrossRef]

- Ding, Z.K.; Liu, S.; Luo, L.W.; Liao, L.H. A building information modeling-based carbon emission measurement system for prefabricated residential buildings during the materialization phase. J. Clean. Prod. 2020, 264, 121728. [Google Scholar] [CrossRef]

- Fenner, A.E.; Kibert, C.J.; Woo, J.; Morque, S.; Razkenari, M.; Hakim, H.; Lu, X.S. The carbon footprint of buildings: A review of methodologies and applications. Renew. Sustain. Energy Rev. 2018, 94, 1142–1152. [Google Scholar] [CrossRef]

- Chastas, P.; Theodosiou, T.; Kontoleon, J.; Bikas, D. Normalising and assessing carbon emissions in the building sector: A review on the embodied CO2 emissions of residential buildings. Build. Environ. 2018, 130, 212–226. [Google Scholar] [CrossRef]

- Pan, W.; Li, K.; Teng, Y. Rethinking system boundaries of the life cycle carbon emissions of buildings. Renew. Sustain. Energy Rev. 2018, 90, 379–390. [Google Scholar] [CrossRef]

- Erdogan, S. Dynamic nexus between technological innovation and buildings Sector’s carbon emission in BRICS countries. J. Environ. Manag. 2021, 293, 112780. [Google Scholar] [CrossRef]

- Jayawardana, J.; Sandanayake, M.; Jayasinghe, J.A.S.C.; Kulatunga, A.K. A comparative life cycle assessment of prefabricated and traditional construction—A case of a developing country. J. Build. Eng. 2023, 72, 106550. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, L.; Yu, M. Comparison and analysis of carbon emissions of traditional, prefabricated, and green material buildings in materialization stage. J. Clean. Prod. 2023, 406, 137152. [Google Scholar] [CrossRef]

- Llorach-Massana, P.; Cirrincione, L.; Sierra-Perez, J.; Scaccianoce, G. Environmental assessment of a new building envelope material derived from urban agriculture wastes: The case of the tomato plants stems. Int. J. Life Cycle Assess. 2023, 28, 813–827. [Google Scholar] [CrossRef]

- Sheep, L.; Allacker, K.; Rock, M. Bio-based building material solutions for environmental benefits over conventional construction products-Life cycle assessment of regenerative design strategies (1/2). Energy Build. 2023, 280, 112767. [Google Scholar]

- Teng, Y.; Li, C.Z.; Shen, G.Q.P.; Yang, Q.W. The impact of life cycle assessment database selection on embodied carbon estimation of buildings. Build. Environ. 2023, 243, 110648. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, S.; Wang, K. Quantitative study of life cycle carbon emissions from 7 timber buildings in China. Int. J. Life Cycle Assess. 2021, 26, 1721–1734. [Google Scholar] [CrossRef]

- Dong, J. Quantitative Study on the Life-Cycle Carbon Emissions of a Nearly Zero Energy Building in the Severe Cold Zones of China. Sustainability 2022, 14, 1148. [Google Scholar]

- Li, J. Energy performance heterogeneity in China’s buildings sector: A data-driven investigation. Renew. Sustain. Energy Rev. 2016, 58, 1587–1600. [Google Scholar] [CrossRef]

- Huang, L.Z.; Krigsvoll, G.; Johansen, F.; Liu, Y.P.; Zhang, X.L. Carbon emission of global construction sector. Renew. Sustain. Energy Rev. 2018, 81, 1906–1916. [Google Scholar] [CrossRef]

- Abeydeera, L.H.U.W.; Mesthrige, J.W.; Samarasinghalage, T.I. Global Research on Carbon Emissions: A Scientometric Review. Sustainability 2019, 11, 3972. [Google Scholar] [CrossRef]

- Li, C.Z.; Lai, X.L.; Xiao, B.; Tam, V.W.Y. A holistic review on life cycle energy of buildings: An analysis from 2009 to 2019. Renew. Sustain. Energy Rev. 2020, 134, 110372. [Google Scholar] [CrossRef]

- Yan, J.Y.; Lu, Q.C.; Tang, J.Q.; Chen, L.; Hong, J.K.; Broyd, T. Digital Tools for Revealing and Reducing Carbon Footprint in Infrastructure, Building, and City Scopes. Builds 2022, 12, 1097. [Google Scholar] [CrossRef]

- Williams, J.; Mitchell, R.; Raicic, V.; Vellei, M. Less is more: A review of low energy standards and the urgent need for an international universal zero energy standard. J. Build. Eng. 2016, 6, 65–74. [Google Scholar] [CrossRef]

- De Wolf, C.; Pomponi, F.; Moncaster, A. Measuring embodied carbon dioxide equivalent of buildings: A review and critique of current industry practice. Energy Build. 2017, 140, 68–80. [Google Scholar] [CrossRef]

- Rasmussen, F.N.; Malmqvist, T.; Moncaster, A.; Wiberg, A.H. Analysing methodological choices in calculations of embodied energy and GHG emissions from buildings. Energy Build. 2018, 158, 1487–1498. [Google Scholar] [CrossRef]

- Piccardo, C.; Gustavsson, L. Implications of different modelling choices in primary energy and carbon emission analysis of buildings. Energy Build. 2021, 247, 111145. [Google Scholar] [CrossRef]

- BSI. EN-15978 (2011) Sustainability of Construction Works. Assessment of Environmental Performance of Buildings. Calculation Method. 2011. Available online: https://standards.iteh.ai/catalog/standards/cen/62c22cef-5666-4719-91f9-c21cb6aa0ab3/en-15978-2011 (accessed on 10 September 2023).

- USGBC. LEED v4.1 Building Design and Construction. In Getting Started Guide for Beta Participants. 2019. Available online: http://refhub.elsevier.com/S2352-710200036-X/sref42 (accessed on 10 September 2023).

- BRE. 2016 BREEAM International New Construction. In Technical Manual SD233 2.0. Building Research Establishment Group. Available online: http://refhub.elsevier.com/S2352-710200036-X/sref44 (accessed on 10 September 2023).

- Pushkar, S. Life-Cycle Assessment of LEED-CI v4 Projects in Shanghai, China: A Case Study. Sustainability 2023, 15, 5722. [Google Scholar] [CrossRef]

- Lessard, Y.; Anand, C.; Blanchet, P. LEED v4: Where Are We Now? Critical Assessment through the LCA of an Office Building Using a Low Impact Energy Consumption Mix. J. Ind. Ecol. 2018, 22, 1105–1116. [Google Scholar] [CrossRef]

- Sartori, T.; Drogemuller, R.; Omrani, S.; Lamari, F. A schematic framework for Life Cycle Assessment (LCA) and Green Building Rating System (GBRS). J. Build. Eng. 2021, 38, 10. [Google Scholar] [CrossRef]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An Internet of Things-enabled BIM platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- China Academy of Building Research. 1988. Available online: https://www.pkpm.cn/ (accessed on 20 December 2022). (In Chinese).

- Yang, X.N.; Hu, M.M.; Wu, J.B.; Zhao, B. Building-information-modeling enabled life cycle assessment, a case study on carbon footprint accounting for a residential building in China. J. Clean. Prod. 2018, 183, 729–743. [Google Scholar] [CrossRef]

- Dong, Y.; Ng, S.T.; Liu, P. A comprehensive analysis towards benchmarking of life cycle assessment of buildings based on systematic review. Build. Environ. 2021, 204, 108162. [Google Scholar] [CrossRef]

- Lou, Y.Y.; Ye, Y.Y.; Yang, Y.Z.; Zuo, W.D. Long-term carbon emission reduction potential of building retrofits with dynamically changing electricity emission factors. Build. Environ. 2022, 210, 108683. [Google Scholar] [CrossRef]

- Du, Q.; Shao, L.; Zhou, J.; Huang, N.; Bao, T.N.; Hao, C.C. Dynamics and scenarios of carbon emissions in China’s construction industry. Sustain. Cities Soc. 2019, 48, 101556. [Google Scholar] [CrossRef]

- Yang, H.H.; Li, X.; Ma, L.W.; Li, Z. Using system dynamics to analyse key factors influencing China’s energy-related CO2 emissions and emission reduction scenarios. J. Clean. Prod. 2021, 320, 128811. [Google Scholar] [CrossRef]

- Huo, T.F.; Ma, Y.L.; Xu, L.B.; Feng, W.; Cai, W.G. Carbon emissions in China’s urban residential building sector through 2060: A dynamic scenario simulation. Energy 2022, 254, 124395. [Google Scholar] [CrossRef]

- Braulio-Gonzalo, M.; Jorge-Ortiz, A.; Bovea, M.D. How are indicators in Green Building Rating Systems addressing sustainability dimensions and life cycle frameworks in residential buildings? Environ. Impact Assess. Rev. 2022, 95, 106793. [Google Scholar] [CrossRef]

- Vandervaeren, C.; Galle, W.; Stephan, A.; De Temmerman, N. More than the sum of its parts: Considering interdependencies in the life cycle material flow and environmental assessment of demountable buildings. Resour. Conserv. Recycl. 2022, 177, 106001. [Google Scholar] [CrossRef]

- China Architecture and Building Press. Building Construction Handbook, 5th ed.; China Architecture and Building Press: Beijing, China, 2012. (In Chinese) [Google Scholar]

- Zhang, X.; Wang, F. Analysis of embodied carbon in the building life cycle considering the temporal perspectives of emissions: A case study in China. Energy Build. 2017, 155, 404–413. [Google Scholar] [CrossRef]

- Pan, X.F.; Uddin, M.K.; Ai, B.W.; Pan, X.Y.; Saima, U. Influential factors of carbon emissions intensity in OECD countries: Evidence from symbolic regression. J. Clean. Prod. 2019, 220, 1194–1201. [Google Scholar] [CrossRef]

- Geng, Y.B.; Wang, Z.T.; Shen, L.; Zhao, J.N. Calculating of CO2 emission factors for Chinese cement production based on inorganic carbon and organic carbon. J. Clean. Prod. 2019, 217, 503–509. [Google Scholar] [CrossRef]

- Wen, L.; Bai, L.; Zhang, E. System dynamic modeling and scenario simulation on Beijing industrial carbon emissions. Environ. Eng. Res. 2016, 21, 355–364. [Google Scholar] [CrossRef]

- Xu, P.Y.; Zhu, J.J.; Li, H.T.; Xiong, Z.H.; Xu, X.X. Coupling analysis between cost and carbon emission of bamboo building materials: A perspective of supply chain. Energy Build. 2023, 280, 112718. [Google Scholar] [CrossRef]

- Ouyang, X.L.; Lin, B.Q. An analysis of the driving forces of energy-related carbon dioxide emissions in China’s industrial sector. Renew. Sustain. Energy Rev. 2015, 45, 838–849. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2006. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/index.html (accessed on 25 November 2022).

- Intergovernmental Panel on Climate Change. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2019. Available online: https://www.ipcc.ch/report/2019-refinement-to-the-2006-ipcc-guidelines-for-national-greenhouse-gas-inventories/ (accessed on 25 November 2022).

- Han, J.; Meng, X.; Zhou, X.; Yi, B.L.; Liu, M.; Xiang, W.N. A long-term analysis of urbanization process, landscape change, and carbon sources and sinks: A case study in China’s Yangtze River Delta region. J. Clean. Prod. 2016, 141, 1040–1050. [Google Scholar] [CrossRef]

| LC Stage | MI | MII |

|---|---|---|

| Production | GB/T51366 | GB/T51366 |

| Transportation | GB/T51366 | GB/T51366 |

| Operation | GB/T51366, IPCC2006, IPCC2019 | Third-party report *, GB/T51366, IPCC2006, IPCC2019 |

| Construction | GB/T51366, GB/T2589 | Third-party report *, empirical data, GB/T51366, GB/T2589 |

| Demolition | GB/T51366, GB/T2589 | Third-party report *, empirical data, GB/T51366, GB/T2589 |

| Construction Material | Amount | Unit | Transport Mode | Transportation Distance (km) |

|---|---|---|---|---|

| Steel | 373.84 | t | Light diesel truck (load 2 t); Medium diesel truck (load 8 t); Heavy diesel wagon transport (46 t load) | 150 |

| Concrete | 951.59 | t | Heavy diesel wagon transport (46 t load) | 150 |

| Portland cement | 491.95 | t | Heavy diesel wagon transport (46 t load) | 150 |

| Lime | 53.69 | t | Heavy diesel wagon transport (46 t load) | 150 |

| Natural sand | 765.64 | t | Heavy diesel wagon transport (46 t load) | 150 |

| Gravel | 544.02 | t | Heavy diesel wagon transport (46 t load) | 150 |

| Northeast pine, imported pine | 0.05 | m3 | Heavy diesel wagon transport (46 t load) | 20 |

| Specification material | 40.27 | m3 | Heavy diesel wagon transport (46 t load) | 20 |

| Clay bricks | 68.39 | m3 | Heavy diesel wagon transport (46 t load) | 20 |

| Mechanized red bricks | 30.34 | m3 | Heavy diesel wagon transport (46 t load) | 20 |

| Floor tile cylinder bricks | 783.05 | m3 | Heavy diesel wagon transport (46 t load) | 20 |

| External brick | 119.77 | m3 | Heavy diesel wagon transport (46 t load) | 20 |

| Doors and windows | 1410.18 | t | Medium diesel trucking (load 8 t), Heavy duty diesel trucking (30 t capacity) | 30 |

| Roofing polystyrene foam board | 66.867 | t | Heavy diesel wagon transport (46 t load) | 30 |

| Extruded plastic insulation board | 1420.45 | t | Heavy diesel wagon transport (46 t load) | 50 |

| Copper pipes | 2.883 | m3 | Light diesel truck (load 2 t) | 40 |

| Cable | 7.11 | m3 | Light diesel truck (load 2 t) | 40 |

| Reddan anti-rust paint | 6.47 | m3 | Light diesel truck (load 2 t) | 35 |

| Plastic drainage pipe | 3.64 | t | Light diesel truck (load 2 t) | 35 |

| Steel-plastic composite pipe | 53.71 | m3 | Light diesel truck (load 2 t) | 30 |

| Granite strips | 17.44 | m3 | Light diesel truck (load 2 t) | 30 |

| Chlorinated polyethylene coil plane | 117.15 | m3 | Light diesel truck (load 2 t) | 30 |

| Petroleum asphalt (No.30) | 0.891 | m3 | Medium diesel truck (load 8 t) | 30 |

| Polyurethane coated film | 4.855 | m2 | Medium diesel truck (load 8 t) | 2000 |

| Emission Source | Annual Electricity Consumption (kWh/a) | Energy Consumption per Unit Area (kWh/m2/a) | |

|---|---|---|---|

| Heating and air conditioning | Heating | 101,954 | 14.62 |

| Air conditioning | 38,201 | 5.481 | |

| Lighting | 38,803 | 5.567 | |

| Lift and hot water | Elevator | 5010 | 0.719 |

| Domestic hot water | 2059 | 0.295 | |

| Total | 186,027 | 26.69 | |

| Stage | Area | Unit | Energy Consumption of Small Construction Equipment (kWh) | Gasoline Consumption (kg) | Diesel Consumption (kg) | Electricity Consumption (kWh) |

|---|---|---|---|---|---|---|

| Construction | 6969.91 | m2 | 500 | N.A. | 5852 | 16,724 |

| Demolition | 6969.91 | m2 | 500 | N.A. | 5267 | 15,052 |

| Life Cycle Stage | Amount | Unit | Amount | Unit | Contribution |

|---|---|---|---|---|---|

| Material production | 2,093,082 | kgCO2e | 300.3 | kgCO2e/m2 | 20.2% |

| Material transportation | 4129 | kgCO2e | 0.592 | kgCO2e/m2 | 0.04% |

| Operation | 8,217,637 | kgCO2e | 23.6 | kgCO2e/m2/yr | 79.2% |

| Construction | 33,371 | kgCO2e | 4.79 | kgCO2e/m2 | 0.32% |

| Demolition | 30,043 | kgCO2e | 4.47 | kgCO2e/m2 | 0.29% |

| Total | 10,381,153 | kgCO2e | 1489 | kgCO2e/m2 | 100% |

| Standard | GB/T51366 | EN15978 |

|---|---|---|

| Scope of buildings | Civil buildings | All buildings |

| Building types | New, refurbishment, and extension works | New, refurbishment, and extension works |

| Calculation methods | Emission factor method | Emission factor method |

| Impact categories | Single category of climate change | Various impact categories * |

| System boundary | Whole life cycle, some processes are excluded (maintenance, renovation, water) | Whole life cycle |

| Data quality | Strict requirement | Strict requirement |

| Reporting | Not specified | Specified |

| Scenario description | Not detailed | Detailed |

| Accounting for the gross amount | Not specified | Consideration of losses due to multiple factors (transport, processing, design, etc.) |

| Building Materials | Concrete | Brick or Brock | Steel | Wood | Finishing Materials | Other |

|---|---|---|---|---|---|---|

| Wastage rate (%) | 1.5 | 5 | 3 | 5 | 2.5 | 5.5 |

| Building Materials | Service Life | Number of Replacements |

|---|---|---|

| Fire doors | 10 | 4 |

| Aluminum doors and windows | 30 | 1 |

| Plastic doors and windows | 30 | 1 |

| Material | Emission Factor (Ecoinvent) | Unit | Emission Factor (GB/T51366) | Unit |

|---|---|---|---|---|

| Reinforcing Steel | 2150 | kgCO2/t | 2340 | kgCO2/t |

| Hot rolled steel | 1950 | kgCO2/t | 3110 | kgCO2/t |

| Concrete | 329 | kgCO2/m3 | 295 | kgCO2/m3 |

| Cement | 657 | kgCO2/m3 | 735 | kgCO2/m3 |

| Aspects | Pros | Cons |

|---|---|---|

| Scope | The standard covers full life cycle of a building, including material production, transportation, construction, operation, and demolition. | Several processes are not involved: Production: the emissions from manufacturing of building equipment; Construction and demolition: transportation of machinery, transportation of workers, water consumption; Operation: maintenance, refurbishment, replacement, repairing, water supply. |

| Calculation method | Detailed calculation methods for each process are provided. | Calculation method of carbon sink is not provided. |

| Data collection | Default data of emission factors are provided. | Very difficult to collect all the required data by the standard. |

| Application | There are many reports and software based on the standard. | Difficult for the industry to use without adjustments of data and calculation methods. |

| Others | The first life cycle standard for buildings in China. | The accuracy is not comparable to overseas standards. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Yang, T.; Liu, P.; Xu, Z. Comparing the Standards of Life Cycle Carbon Assessment of Buildings: An Analysis of the Pros and Cons. Buildings 2023, 13, 2417. https://doi.org/10.3390/buildings13102417

Dong Y, Yang T, Liu P, Xu Z. Comparing the Standards of Life Cycle Carbon Assessment of Buildings: An Analysis of the Pros and Cons. Buildings. 2023; 13(10):2417. https://doi.org/10.3390/buildings13102417

Chicago/Turabian StyleDong, Yahong, Tingyi Yang, Peng Liu, and Zhenyan Xu. 2023. "Comparing the Standards of Life Cycle Carbon Assessment of Buildings: An Analysis of the Pros and Cons" Buildings 13, no. 10: 2417. https://doi.org/10.3390/buildings13102417