Pavement Condition Index Model for Mechanistic–Empirical Design of Airport Concrete Pavements Considering Environmental Effects

Abstract

:1. Introduction

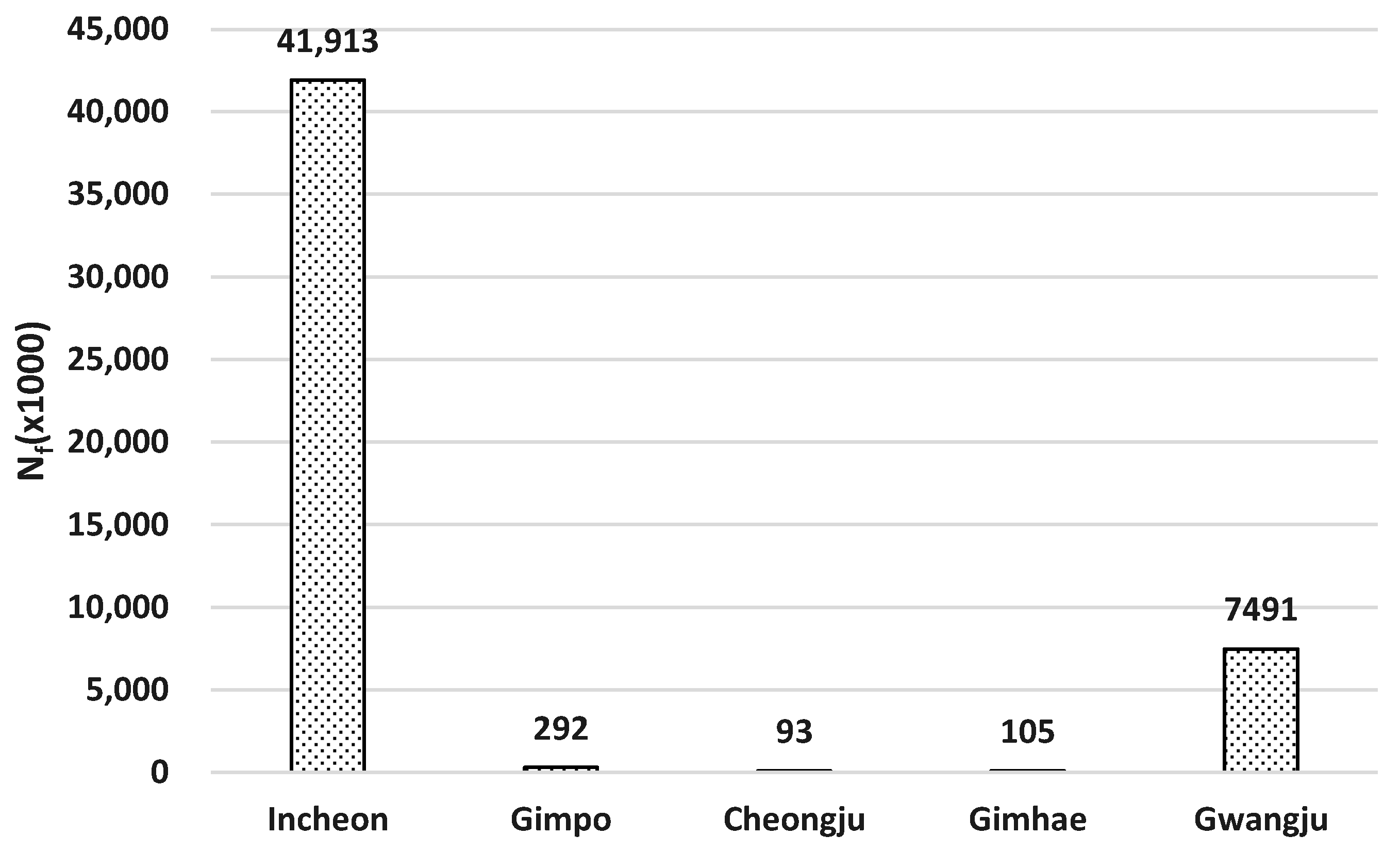

2. Data Collection

2.1. Determination of Target Airports

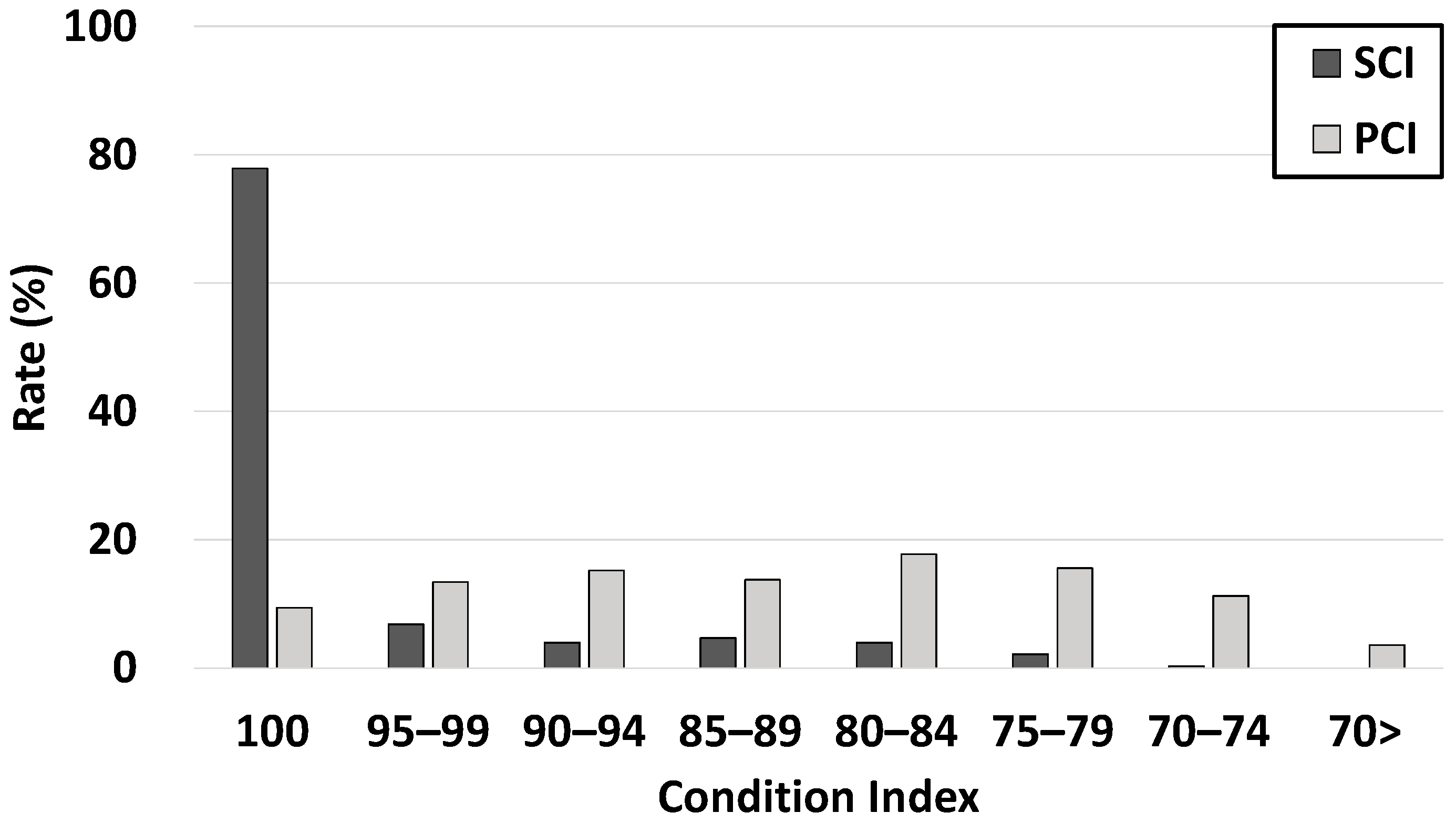

2.2. Investigation of Pavement Conditions

3. Development of PCI Model

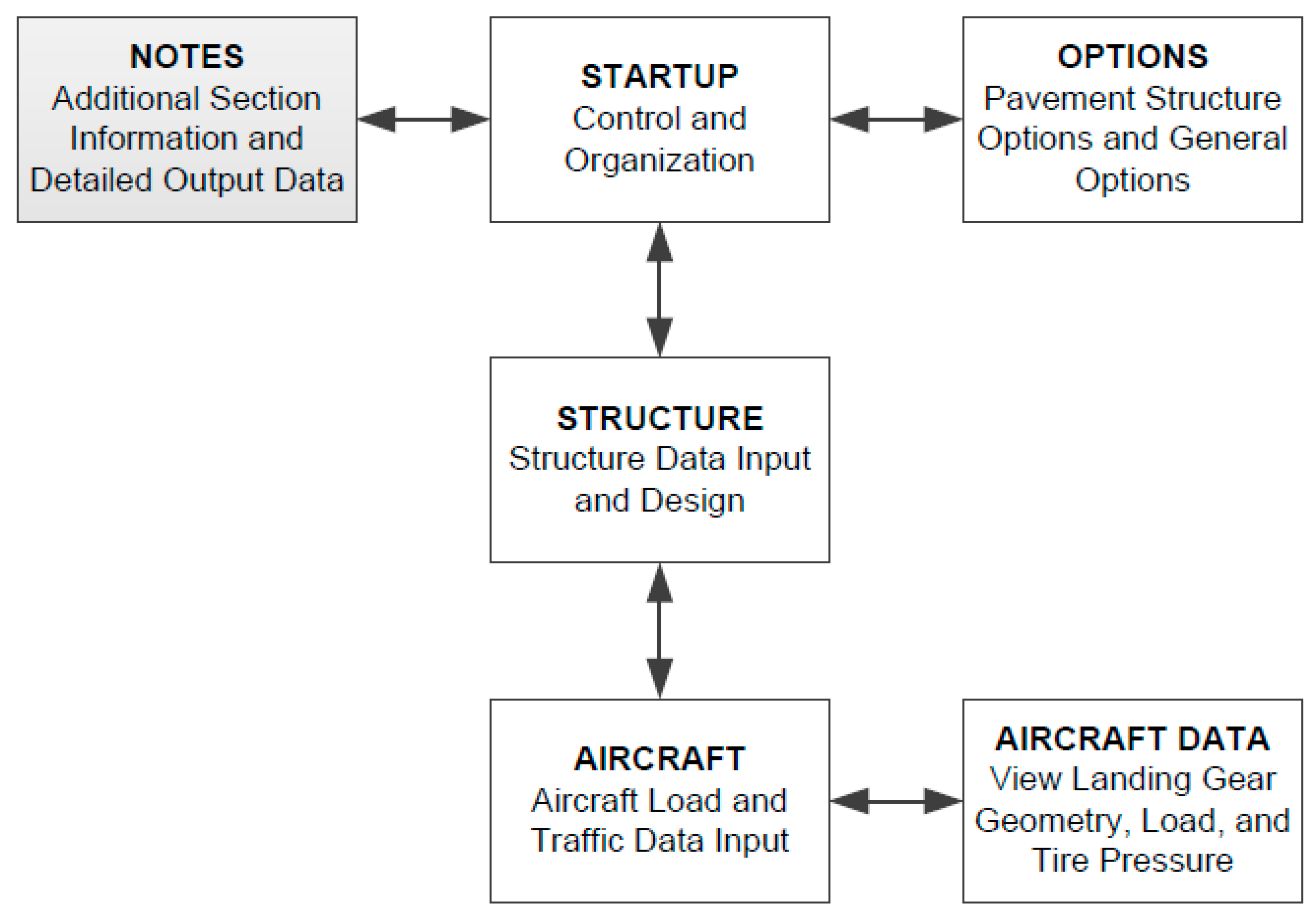

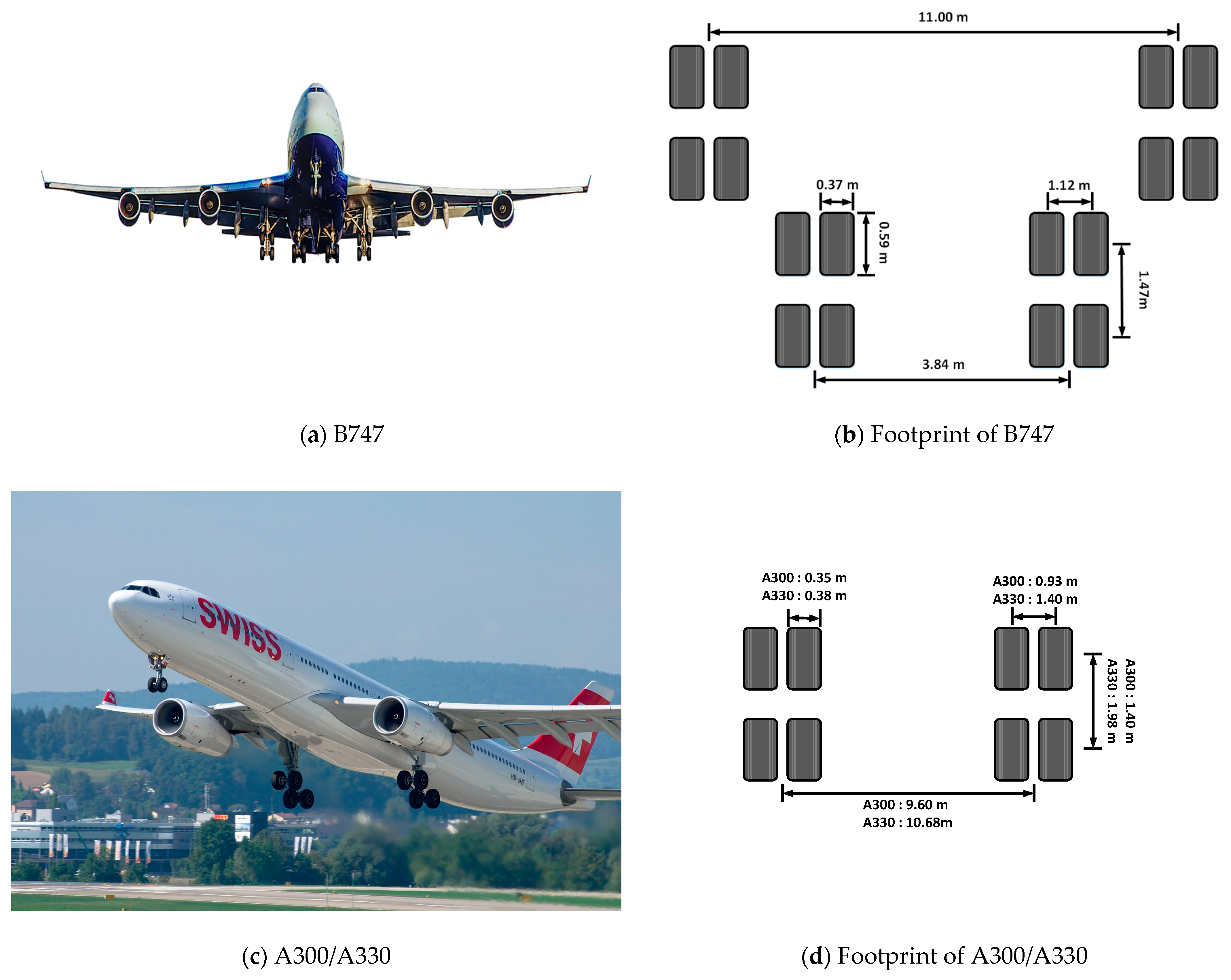

3.1. Finite Element Model for Predicting Minimum and Maximum Tensile Stress

3.2. Fatigue Model

3.3. PCI Model

4. Conclusions

- (1)

- Survey results for the pavement conditions of seven target runways were collected from five target airports, for which information regarding pavement design was accessible. Most sample sections yielded an SCI of 100 regardless of the pavement age. Therefore, the PCI, which exhibited uniformly varying distributions according to the pavement age, was used as an indicator of the pavement conditions to establish the PCI model.

- (2)

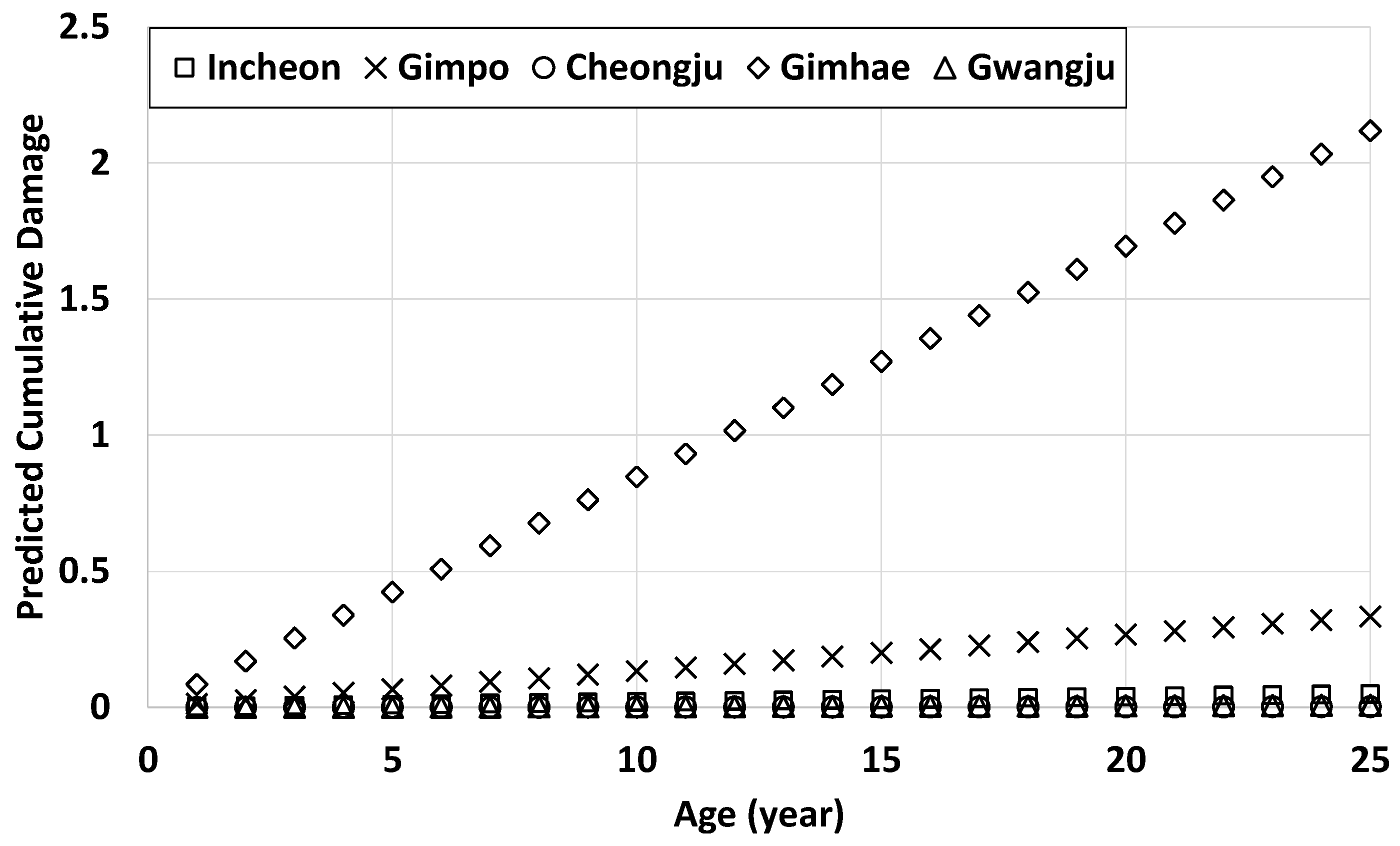

- A fatigue model reflecting the minimum tensile stress generated by only the environmental loads and the maximum tensile stress from combined environmental and traffic loads was used to predict the fatigue damage.

- (3)

- Moreover, a 3D FEA was conducted to calculate the minimum and maximum tensile stresses induced by the environmental and traffic loads. Additionally, a multilinear regression model based on the FEA results was developed to determine the minimum and maximum tensile stresses to be used as input variables for the fatigue model.

- (4)

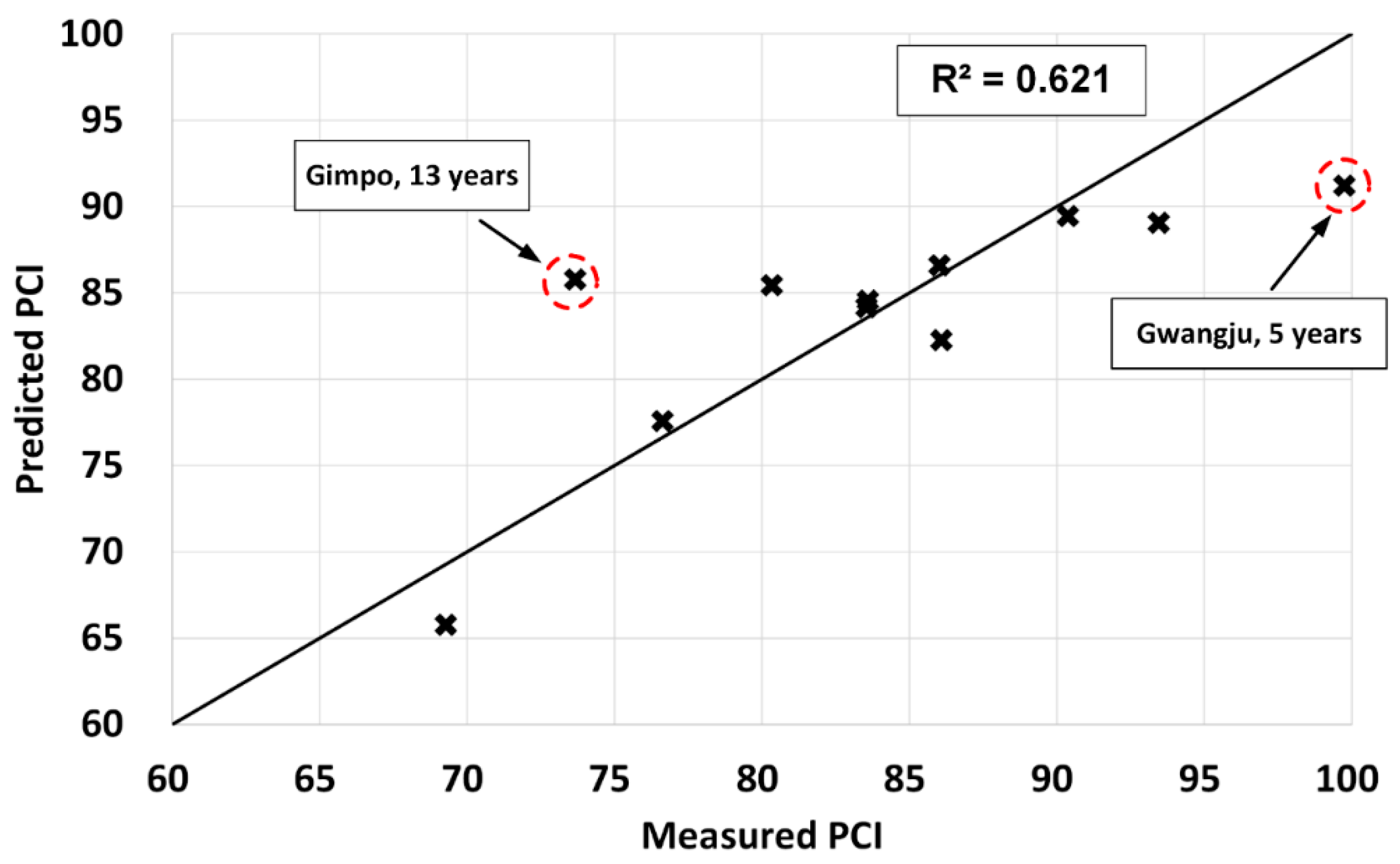

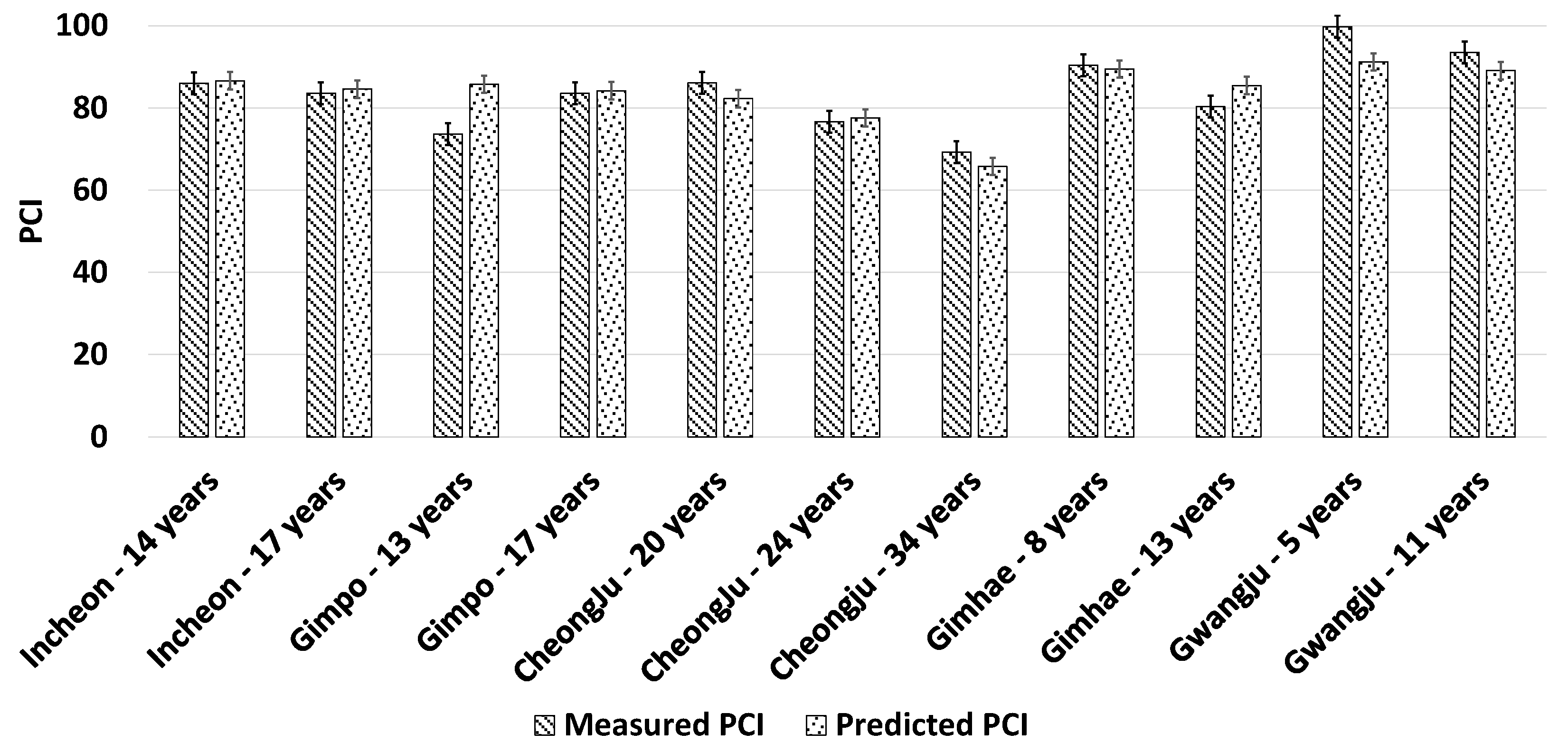

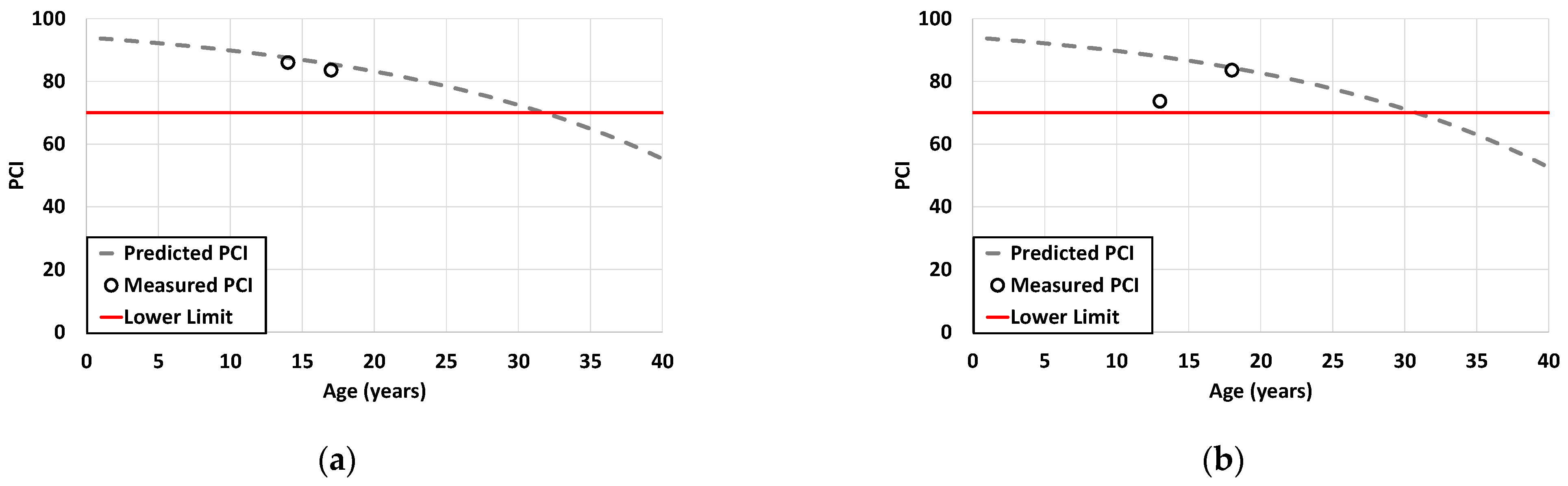

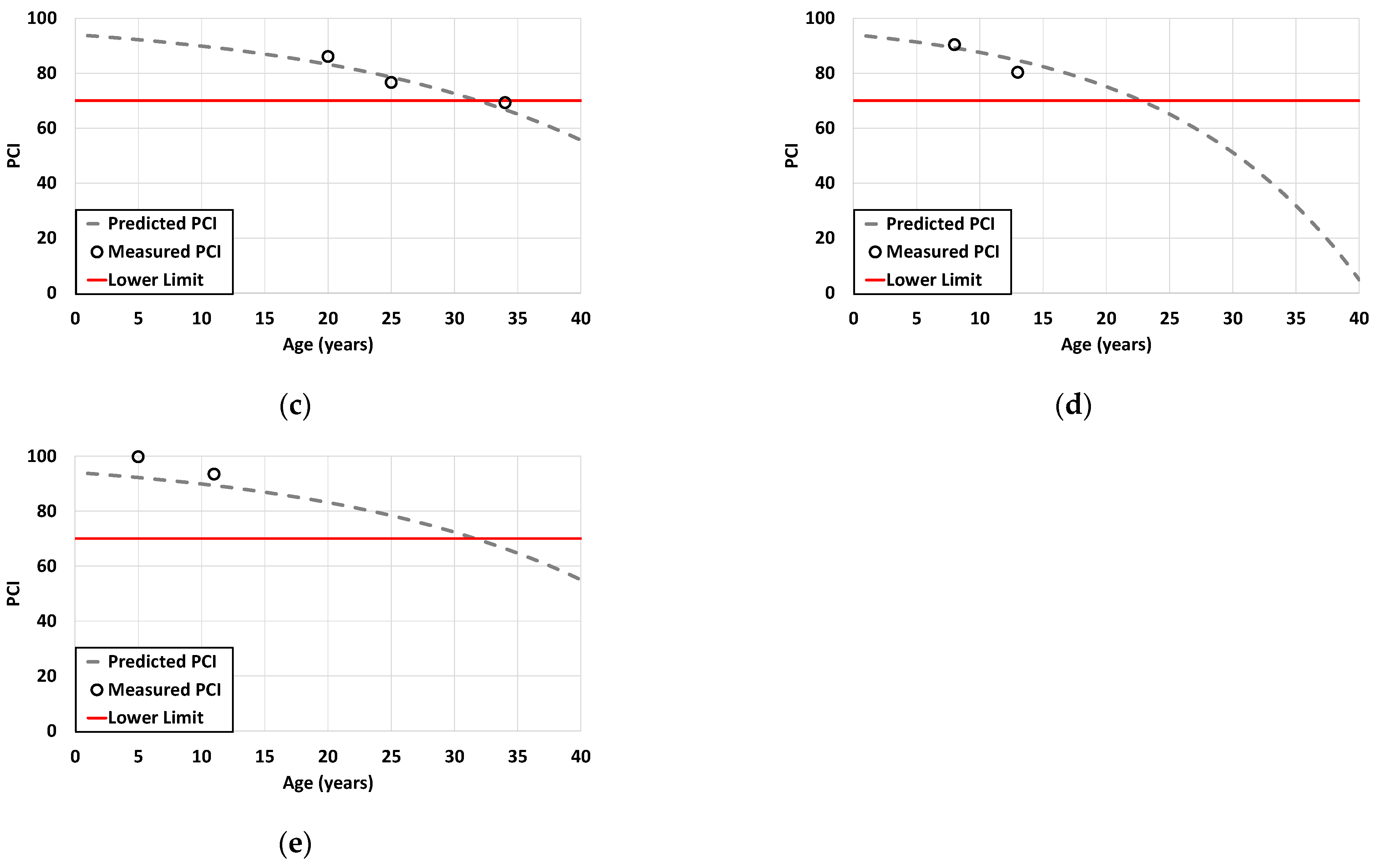

- Consequently, the proposed PCI model was developed using an exponential function to predict the decrease in PCI with respect to cumulative fatigue damage and pavement age. The actual PCIs of the target runways were compared with the predicted PCIs to verify the validity of the proposed PCI model. The proposed model successfully predicted the actual PCI with a relatively high coefficient of determination (0.621) between the actual and predicted PCIs.

- (5)

- The PCIs obtained in this study can be used to design airport programs. In future research, by collecting data from more airports and employing various prediction methods to develop and compare PCI models, we anticipate that the robustness of the PCI will be enhanced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MOLTMA. Road Pavement Structure Design Guidelines; Ministry of Land, Transport and Maritime Affairs: Sejong, Republic of Korea, 2011. [Google Scholar]

- ARA Inc. Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures; NCHRP 1-37A; National Coop-erative Highway Research Program: Washington, DC, USA, 2004. [Google Scholar]

- Westergaard, H.H. New Formulas for Stresses in Concrete Pavements of Airfields. Trans. Am. Soc. Civ. Eng. 1948, 113, 425–444. [Google Scholar] [CrossRef]

- FAA AC 150/5320-6E; Standard for Airport Pavement Design and Evaluation. Office of Airport Safety and Standards, Federal Aviation Administration: Washington, DC, USA, 2009.

- FAA AC 150/5320-6F; Standard for Airport Pavement Design and Evaluation. Office of Airport Safety and Standards, Federal Aviation Administration: Washington, DC, USA, 2016.

- Park, H.W.; Kim, D.H.; Shim, C.S.; Jeong, J.H. Behavior of Airport Concrete Pavement Slabs Exposed to Environmental Loadings. Appl. Sci. 2020, 10, 2618. [Google Scholar] [CrossRef]

- Wang, Q.A.; Dai, Y.; Ma, Z.G.; Lin, J.F.; Ni, Y.Q.; Ren, W.X.; Jiang, J.; Yang, X.; Yan, J.R. Towards high-precision data modeling of SHM measurements using an improved sparse Bayesian learning scheme with strong generalization ability. Struct. Health Monit. 2023, 14759217231170316. [Google Scholar] [CrossRef]

- Wang, Q.-A.; Zhang, C.; Ma, Z.-G.; Ni, Y.-Q. Modelling and forecasting of SHM strain measurement for a large-scale sus-pension bridge during typhoon events using variational heteroscedastic Gaussian process. Eng. Struct. 2022, 251, 113554. [Google Scholar] [CrossRef]

- Rollings, R.S. Design of Overlays for Rigid Airport Pavements; Report No.: DOT/FAA/PM-87/19, AD-A194 331, Federal Aviation Administration: Washington, DC, USA, 1988. [Google Scholar]

- ASTM D6433-07; Standard Practice for Roads and Parking Lots Pavement Condition Index Survey. American Society for Testing and Materials: West Conshohocken, PA, USA, 2007.

- Jeong, J.H.; Zollinger, D.G. Early-Age Curling and Warping Behavior: Insights from a Fully Instrumented Test-Slab System. Transp. Res. Rec. 2004, 1896, 66–74. [Google Scholar] [CrossRef]

- Jeong, J.H.; Zollinger, D.G. Environmental Effects on the Behavior of Jointed Plain Concrete Pavements. J. Traffic Eng. 2005, 131, 140–148. [Google Scholar] [CrossRef]

- Kim, D.H.; Ma, K.H.; Park, H.W.; Jeong, J.H. Development of Maximum Tensile Stress Prediction Model for Airport Concrete Pavements Using Environmental and B777 Aircraft Gear Loadings. Int. J. Highw. Eng. 2018, 20, 93–102. [Google Scholar] [CrossRef]

- Ma, K.H.; Park, H.W.; Seo, J.S.; Mo, S.H.; Jeong, J.H. Analysis of Maximum Tensile stress on the airport concrete pavement by Aircraft types. In Proceedings of the Spring Korean Society of Road Engineers, Seoul, Republic of Korea, 3 August 2019. [Google Scholar]

- Park, H.W.; Shim, C.S.; Lim, J.S.; Joe, N.H.; Jeong, J.H. Development of Three-Dimensional Finite Element Model for Structure Analysis of Airport Concrete Pavements. Int. J. Highw. Eng. 2017, 19, 67–74. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, M.; Xiao, R.; Polaczyk, P.; Bai, Y.; Huang, B. An investigation of structural responses of inverted pavements by numerical approaches considering nonlinear stress-dependent properties of unbound aggregate layer. Constr. Build. Mater. 2021, 303, 124505. [Google Scholar] [CrossRef]

- Jiang, X.; Gabrielson, J.; Huang, B.; Bai, Y.; Polaczyk, P.; Zhang, M.; Hu, W.; Xiao, R. Evaluation of inverted pavement by structural condition indicators from falling weight deflectometer. Constr. Build. Mater. 2022, 319, 125991. [Google Scholar] [CrossRef]

- Park, H.W.; Kim, D.H.; Lim, J.S.; Shim, C.S.; Jeong, J.H. Prediction of differential drying shrinkage of airport concrete pavement slabs. Int. J. Pavement Eng. 2021, 22, 752–762. [Google Scholar] [CrossRef]

- IIAC. Pavement Evaluation Report of Incheon International Airport; Incheon International Airport Corporation: Incheon, Republic of Korea, 2015. [Google Scholar]

- Park, J.Y.; Lim, J.S.; Kim, S.H.; Jeong, J.H. Improvement of Fatigue Model of Concrete Pavement Slabs Using Environmental Loading. Int. J. Highw. Eng. 2011, 13, 103–115. [Google Scholar] [CrossRef]

- Park, J.Y.; Yeom, W.S.; Kim, S.H.; Jeong, J.H. Environmental load for design of airport concrete pavements. Proc. Inst. Civ. Eng. Transp. 2015, 168, 139–149. [Google Scholar] [CrossRef]

- Mohamed, A.R.; Hansen, W. Effect of nonlinear temperature gradient on curling stress in concrete pavements. Trans-Portation Res. Rec. 1997, 1568, 65–71. [Google Scholar] [CrossRef]

- Airbus, S.A.S. AC A300—Airplane Characteristics for Airport Planning; Airbus S.A.S.: Leiden, The Netherlands, 2009. [Google Scholar]

- Airbus, S.A.S. AC A310—Airplane Characteristics for Airport Planning; Airbus S.A.S.: Leiden, The Netherlands, 2009. [Google Scholar]

- Airbus, S.A.S. AC A318—Airplane Characteristics Airport and Maintenance Planning; Airbus S.A.S.: Leiden, The Netherlands, 2019. [Google Scholar]

- Airbus, S.A.S. AC A319/A319neo—Airplane Characteristics Airport and Maintenance Planning; Airbus S.A.S.: Leiden, The Netherlands, 2019. [Google Scholar]

- Airbus, S.A.S. AC A320/A320neo—Airplane Characteristics Airport and Maintenance Planning; Airbus S.A.S.: Leiden, The Netherlands, 2019. [Google Scholar]

- Airbus, S.A.S. AC A321/A321neo—Airplane Characteristics Airport and Maintenance Planning; Airbus S.A.S.: Leiden, The Netherlands, 2019. [Google Scholar]

- Airbus, S.A.S. AC A330—Airplane Characteristics Airport and Maintenance Planning; Airbus S.A.S.: Leiden, The Netherlands, 2019. [Google Scholar]

- Airbus, S.A.S. AC A340-200/-300—Airplane Characteristics Airport and Maintenance Planning; Airbus S.A.S.: Leiden, The Netherlands, 2019. [Google Scholar]

- Airbus, S.A.S. AC A350-900/-1000—Airplane Characteristics Airport and Maintenance Planning; Airbus S.A.S.: Leiden, The Netherlands, 2019. [Google Scholar]

- Airbus, S.A.S. AC A380—Airplane Characteristics Airport and Maintenance Planning; Airbus S.A.S.: Leiden, The Netherlands, 2019. [Google Scholar]

- Boeing Commercial Airplanes. 707—Airplane Characteristics Airport Planning; D6-58332; Boeing Commercial Airplanes: Seal Beach, CA, USA, 2011. [Google Scholar]

- Boeing Commercial Airplanes. 720—Airplane Characteristics Airport Planning; D6-58323; Boeing Commercial Airplanes: Seal Beach, CA, USA, 2011. [Google Scholar]

- Boeing Commercial Airplanes. 727—Airplane Characteristics Airport Planning; D6-58324; Boeing Commercial Airplanes: Seal Beach, CA, USA, 2011. [Google Scholar]

- Boeing Commercial Airplanes. 747-400—Airplane Characteristics for Airport Planning; D6-58326-1; Boeing Commercial Airplanes: Seal Beach, CA, USA, 2011. [Google Scholar]

- Boeing Commercial Airplanes. 757-200/300—Airplane Characteristics for Airport Planning; D6-58327; Boeing Commercial Airplanes: Seal Beach, CA, USA, 2011. [Google Scholar]

- Boeing Commercial Airplanes. 767—Airplane Characteristics for Airport Planning; D6-58328; Boeing Commercial Airplanes: Seal Beach, CA, USA, 2011. [Google Scholar]

- Boeing Commercial Airplanes. 777-200/300—Airplane Characteristics for Airport Planning; D6-58329; Boeing Commercial Airplanes: Seal Beach, CA, USA, 2011. [Google Scholar]

- Boeing Commercial Airplanes. 737—Airplane Characteristics for Airport Planning; D6-58325-6; Boeing Commercial Airplanes: Seal Beach, CA, USA, 2013. [Google Scholar]

- Boeing Commercial Airplanes. 717-200—Airplane Characteristics Airport Planning; D6-58330; Boeing Commercial Airplanes: Seal Beach, CA, USA, 2014. [Google Scholar]

- Boeing Commercial Airplanes. 777-200LR/-300ER/-Freighter—Airplane Characteristics for Airport Planning; D6-58329-2; Boeing Commercial Air-planes: Seal Beach, CA, USA, 2015. [Google Scholar]

- Boeing Commercial Airplanes. 787—Airplane Characteristics for Airport Planning; D6-58333; Boeing Commercial Airplanes: Seal Beach, CA, USA, 2018. [Google Scholar]

- Lee, J.H.; Kim, Y.T.; Tonn, S.; Cho, N.H.; Jeong, J.H. Airport Concrete Pavement Design by Environmental and Double Dual Tandem Gear Loadings. Proc. Inst. Civ. Eng. 2019, 172, 210–220. [Google Scholar] [CrossRef]

- Darter, M.I. Design of Zero-Maintenance Plain Jointed Concrete Pavement, Volume 1: Development of Design Procedures; Report No.: FHWA-RD-77-III, Federal Highway Administration: Washington, DC, USA, 1977. [Google Scholar]

- Roesler, J.R. Fatigue of Concrete Beams and Slabs. Ph.D. Thesis, University of Illinois, Urbana, IL, USA, 1998. [Google Scholar]

- Asgari, A. Evaluation of Concrete Pavement Service Life Using Three-dimensional Nonlinear Finite Element Analysis and Nonlinear Fatigue Damage Model. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2004. [Google Scholar]

- Murdock, J.W.; Kesler, C.E. Effect of Range of Stress on Fatigue Strength of Plain Concrete Beam. J. Am. Concr. Inst. 1958, 30, 221–231. [Google Scholar]

- Aas-Jakobsen, L. Fatigue of Concrete Beams and Columns. In Division of Concrete Structures; Bulletin No.70-1; NTH: Trondheim, Norway, 1970. [Google Scholar]

- Tepfers, R.; Kutti, T. Fatigue Strength of Plain, Ordinary, and Lightweight Concrete. J. Am. Concr. Inst. 1979, 76, 635–652. [Google Scholar]

- Shi, X.P.; Fwa, T.F.; Tan, S.A. Flexural fatigue strength of plain concrete. Mater. J. 1993, 90, 435–440. [Google Scholar]

- MOLTMA. Road Pavement Structure Design Handbook; Ministry of Land, Transport and Maritime Affairs: Sejong, Republic of Korea, 2011. [Google Scholar]

- KAC. Cheongju Airport Pavement Condition Evaluation Report; Korea Airport Corporation: Seoul, Republic of Korea, 2017. [Google Scholar]

| Target Airport | Target Runway | Survey Area (m2) | Year of Survey | Pavement Age at Survey |

|---|---|---|---|---|

| Incheon | 1st and 2nd runways | 450,000 | 2013/2017 | 13/17 |

| Gimpo | New runway | 192,000 | 2009/2014 | 12/17 |

| Cheongju | Old and new runways | 288,015 | 2012 (NR and OR) /2017 (NR) | 20/25 /34 (2012) |

| Gimhae | New runway | 192,000 | 2008/2013 | 8/13 |

| Gwangju | East-side runway | 127,575 | 2007/2013 | 5/11 |

| Distress Type | PCI | SCI | |

|---|---|---|---|

| 1. | Blow-up | √ | |

| 2. | Corner break | √ | √ |

| 3. | Cracks: longitudinal, transverse, and diagonal | √ | √ |

| 4. | Durability (“D”) cracking | √ | |

| 5. | Joint seal damage | √ | |

| 6. | Patching, small | √ | |

| 7. | Patching, large and utility cuts | √ | |

| 8. | Pop-outs | √ | |

| 9. | Pumping | √ | |

| 10. | Scaling | √ | |

| 11. | Settlement or faulting | √ | |

| 12. | Shattered slab/intersecting cracks | √ | √ |

| 13. | Shrinkage cracking | √ | √ |

| 14. | Spalling (longitudinal and transverse joint) | √ | √ |

| 15. | Spalling (corner) | √ | √ |

| 16. | Alkali–silica reaction (ASR) | √ | |

| Airport | Slab Thickness (mm) | AC (mm) | CTB (mm) | Subbase (mm) | Joint Spacing (m) | Design Aircraft | Converted Average Annual Departure |

|---|---|---|---|---|---|---|---|

| Incheon | 500 | 50 | 150 | 150 | 6.00 | B747 | 82,000 |

| Gimpo | 400 | 200 | - | 300 | 7.50 | B747 | 3900 |

| Cheongju | 400 | - | - | 350 | 7.62 | B747 | 10 |

| Gimhae | 350 | - | 150 | 200 | 7.50 | A330 | 8900 |

| Gwangju | 400 | - | 150 | 300 | 7.62 | A300 | 2400 |

| Category | Concrete Slab | Lean Concrete Subbase | Subbase | Subgrade | |

|---|---|---|---|---|---|

| Elastic modulus | (psi) | 4,000,000 | 500,000 | 75,000 | 15,000 |

| (MPa) | 28,000 | 3447 | 517 | 103 | |

| Poisson’s ratio | 0.18 | 0.2 | 0.35 | 0.4 | |

| Unit weight (kN/m3) | 23.0 | 22.0 | 21.0 | 19.0 | |

| Coefficient of thermal expansion (/°C) | 9.927 × 10−6 | - | - | - | |

| Coefficient of friction | 4.8 | - | |||

| Gear Type | a | b | c | d | e | f |

|---|---|---|---|---|---|---|

| Environmental Load only | −0.154 | 0.409 | −0.005 | 0.044 | 0 | 0.000232 |

| Environmental Load + Dual Gear | 2.426 | 0.151 | −0.00944 | 0.091 | 1.285 | −0.0000818 |

| Environmental Load + Dual-Tandem Gear | 0.335 | 0.473 | −0.000873 | 0.094 | 1.082 | −0.0000524 |

| Environmental Load + Double Dual-Tandem Gear (B747) | 3.404 | 0.164 | −0.00119 | 0.094 | 1.841 | −0.0000472 |

| Environmental Load + Triple Dual-Tandem Gear (B777) | 1.170 | 0.408 | −0.00870 | 0.039 | 1.372 | −0.000746 |

| Environmental Load + Triple Dual-Tandem Gear (A380) | 2.403 | 0.146 | −0.00893 | 0.105 | 2.061 | −0.00042 |

| Target Airport | Maximum Tensile Stress (MPa) | Minimum Tensile Stress (MPa) | Stress Ratio |

|---|---|---|---|

| Incheon | 0.66 | 2.56 | 0.26 |

| Gimpo | 1.50 | 3.60 | 0.42 |

| Cheongju | 1.64 | 3.81 | 0.43 |

| Gimhae | 1.67 | 3.80 | 0.44 |

| Gwangju | 1.16 | 2.99 | 0.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H.-W.; Kim, J.M.; Lee, J.H.; Lee, D.S.; Jeong, J.-H. Pavement Condition Index Model for Mechanistic–Empirical Design of Airport Concrete Pavements Considering Environmental Effects. Buildings 2023, 13, 2512. https://doi.org/10.3390/buildings13102512

Park H-W, Kim JM, Lee JH, Lee DS, Jeong J-H. Pavement Condition Index Model for Mechanistic–Empirical Design of Airport Concrete Pavements Considering Environmental Effects. Buildings. 2023; 13(10):2512. https://doi.org/10.3390/buildings13102512

Chicago/Turabian StylePark, Hae-Won, Jong Myung Kim, Jae Hoon Lee, Dae Sik Lee, and Jin-Hoon Jeong. 2023. "Pavement Condition Index Model for Mechanistic–Empirical Design of Airport Concrete Pavements Considering Environmental Effects" Buildings 13, no. 10: 2512. https://doi.org/10.3390/buildings13102512