Workability, Mechanical Properties, and Microstructure Analysis of Bottom Ash Mortar Reinforced with Recycled Tire Steel Fiber

Abstract

:1. Introduction

2. Materials and Methods

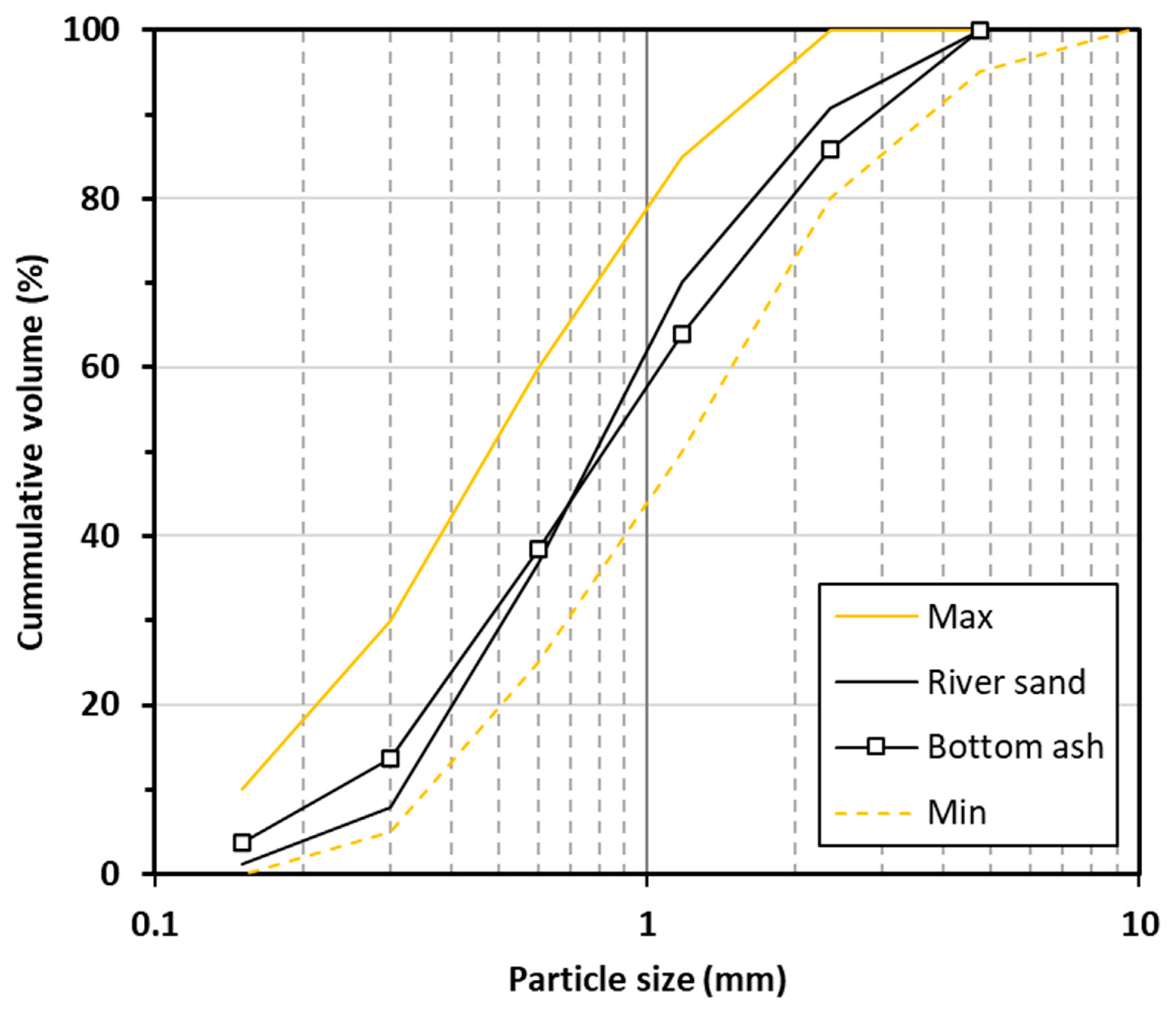

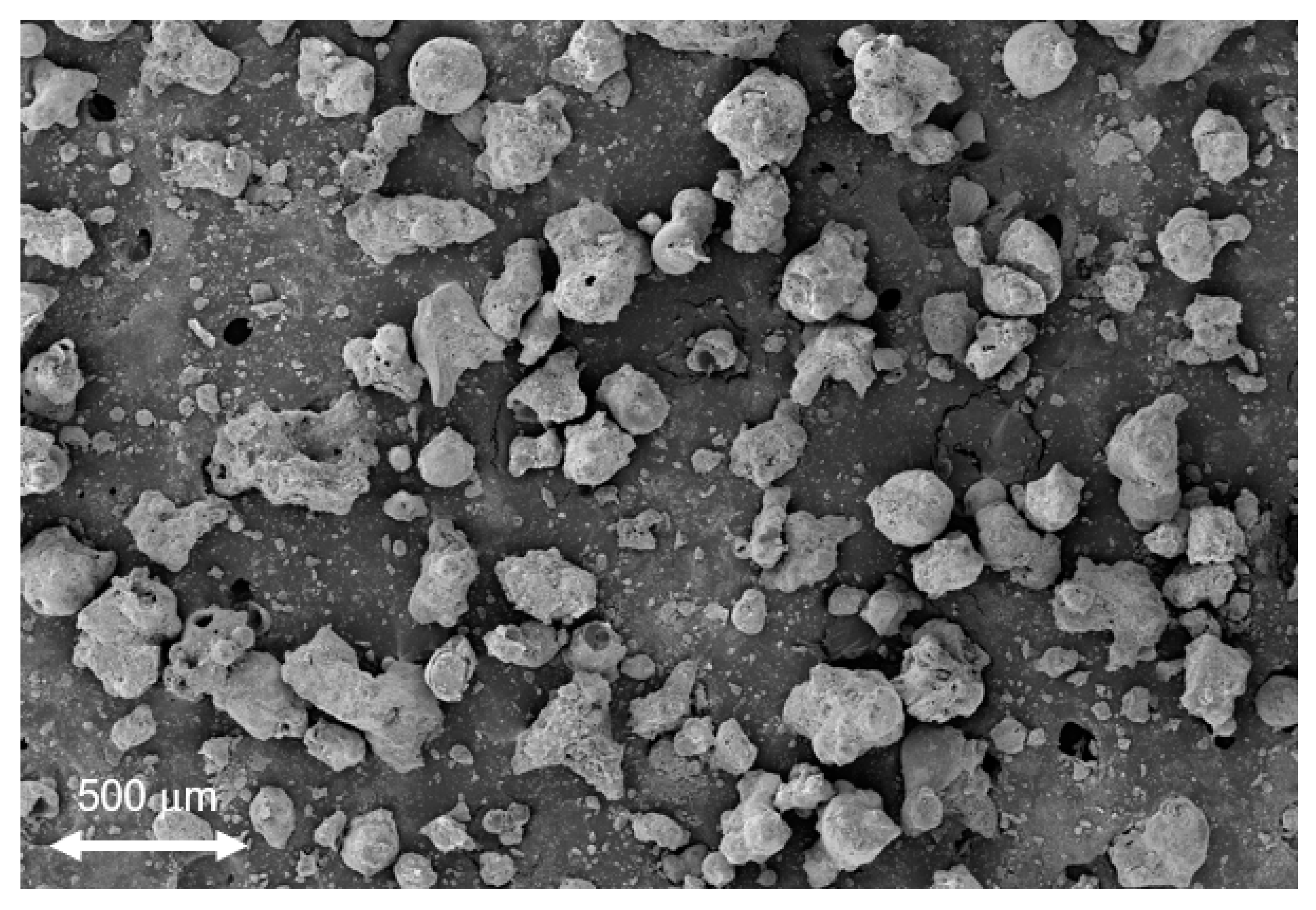

2.1. Materials

2.2. Methods

2.2.1. Flow Table Test

2.2.2. Setting Time Test

2.2.3. Length Change Test

2.2.4. Compressive Strength Test

2.2.5. Splitting Test

2.2.6. Flexural Test

2.2.7. Microstructural Analysis

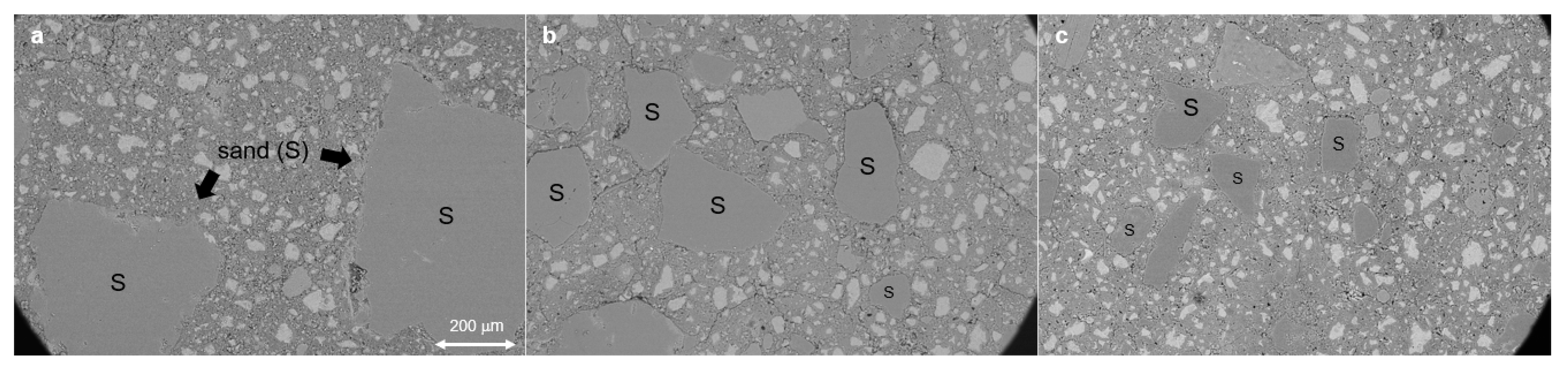

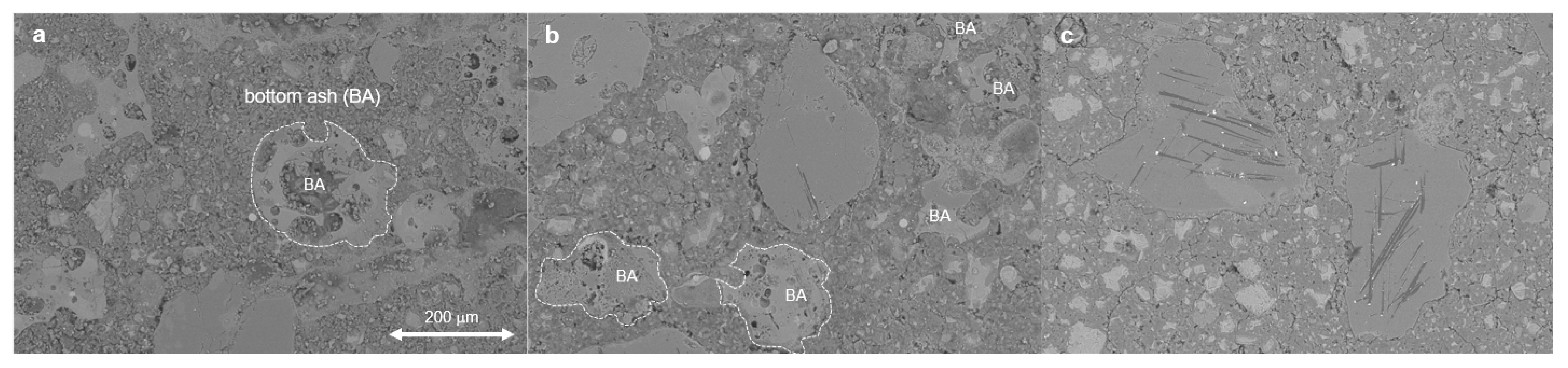

- SEM equipped with EDX.The mortar specimens were prepared with a diameter of 25 mm and a height of 10 mm at 1, 7, and 28 d to observe their microstructures at different curing ages and compare their microstructure evolution. Based on a previous study [42], the prepared specimens were soaked in an acetone solution for 2 d and then placed in a vacuum dryer for 3 d to stop hydration and avoid carbonation. The surface of the samples was polished with silicon carbide no. 400, no. 800, and no. 1200, followed by a diamond powder with sizes of no. 9, no. 3, and, finally, no. 1, respectively. Before capturing the samples’ microstructures, a gold coating was applied to the surface of the samples to attract electrons and increase the samples’ conductivity. To examine the physical appearance, back-scattered electron (BSE) images were obtained at 20 kV and a magnification of 100×. The EDX was used to examine the chemical appearance to identify the key elements of hydration products, such as Ca, Si, Na, and Fe, under “spot scanning mode” and “map scanning mode”, presenting the atomic percentage and weight percentage, respectively.

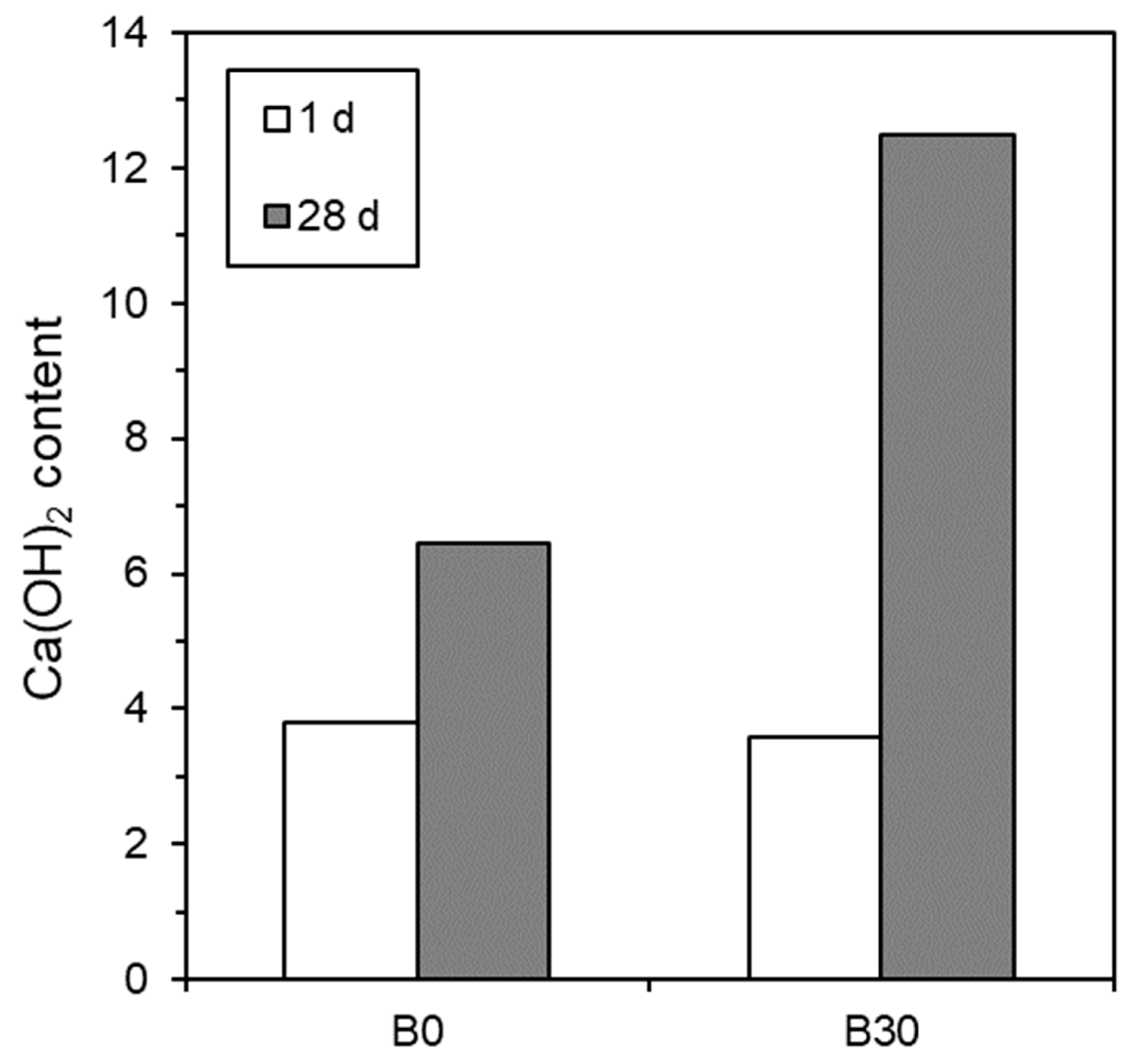

- TGATGA was carried out to examine the decomposition of the plain mortar and mortar containing 30% BA at different curing ages of 1 and 28 d. The mortar specimens were prepared with a size of 5 × 5 mm2, placed in an acetone solution for 2 d, stored in a vacuum dryer for 3 d to stop hydration, and then ground until they became a powder with a weight not more than 100 mg. The TGA test was started at room temperature under a fixed heating rate of 10 C/min until the final temperature reached 1000 °C. The percent mass loss at different testing temperatures, known as the TG curve, can be used to identify the decomposition of a hydration product. The decomposition temperature ranges of hydration products were summarized in a previous study [43]. For example, CSH is associated with a range of 150–400 °C, and Ca(OH)2 is associated with a range of 400–550 °C. Moreover, the mass loss content of the hydration products of interest like Ca(OH)2 can be calculated from the TG curve using a previous study’s equation [10].

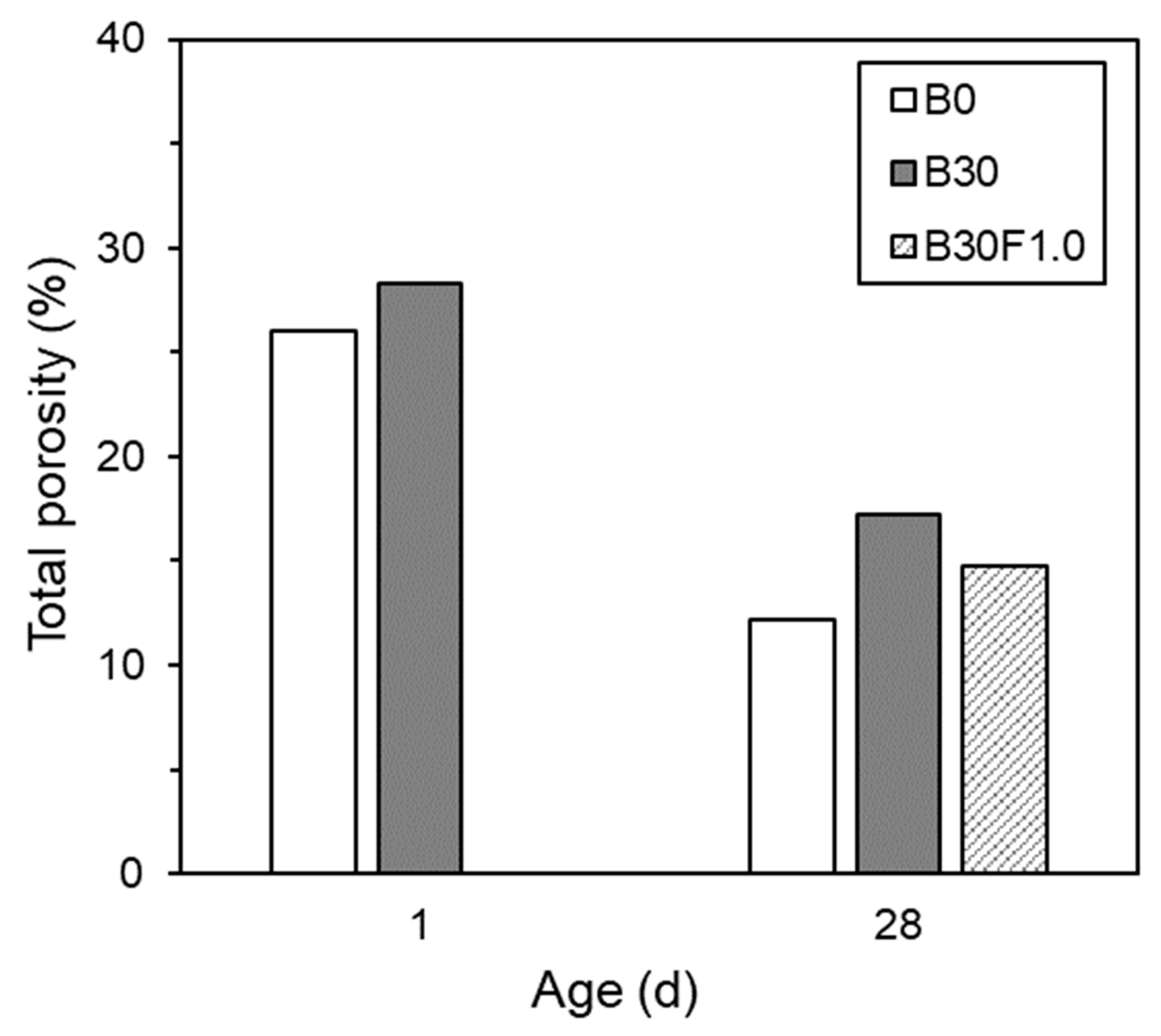

- MIPAs mentioned in Section 2.1 Materials, pore structures were examined using the MIP technique. The plain mortar and mortar containing 30% BA were prepared with a size of 15 × 15 × 15 mm3 at different curing ages of 1 and 28 d to observe the pore evolution, such as the total porosity and pore size distribution. The prepared specimens were soaked in an acetone solution for 2 d and then stored in a vacuum dryer for 3 d to stop hydration. For the MIP procedure, mercury under high pressure was penetrated into the sample to fill the space between each pore; the volume of used mercury is known as “intrusion”. Then, the mercury was taken from the filled pores, known as “extrusion”. At this stage, some of the mercury remained in the pores, resulting in a difference between the intrusion volume and the extrusion volume, which is caused by ink-bottle pores, as explained in a previous study [44].

3. Results

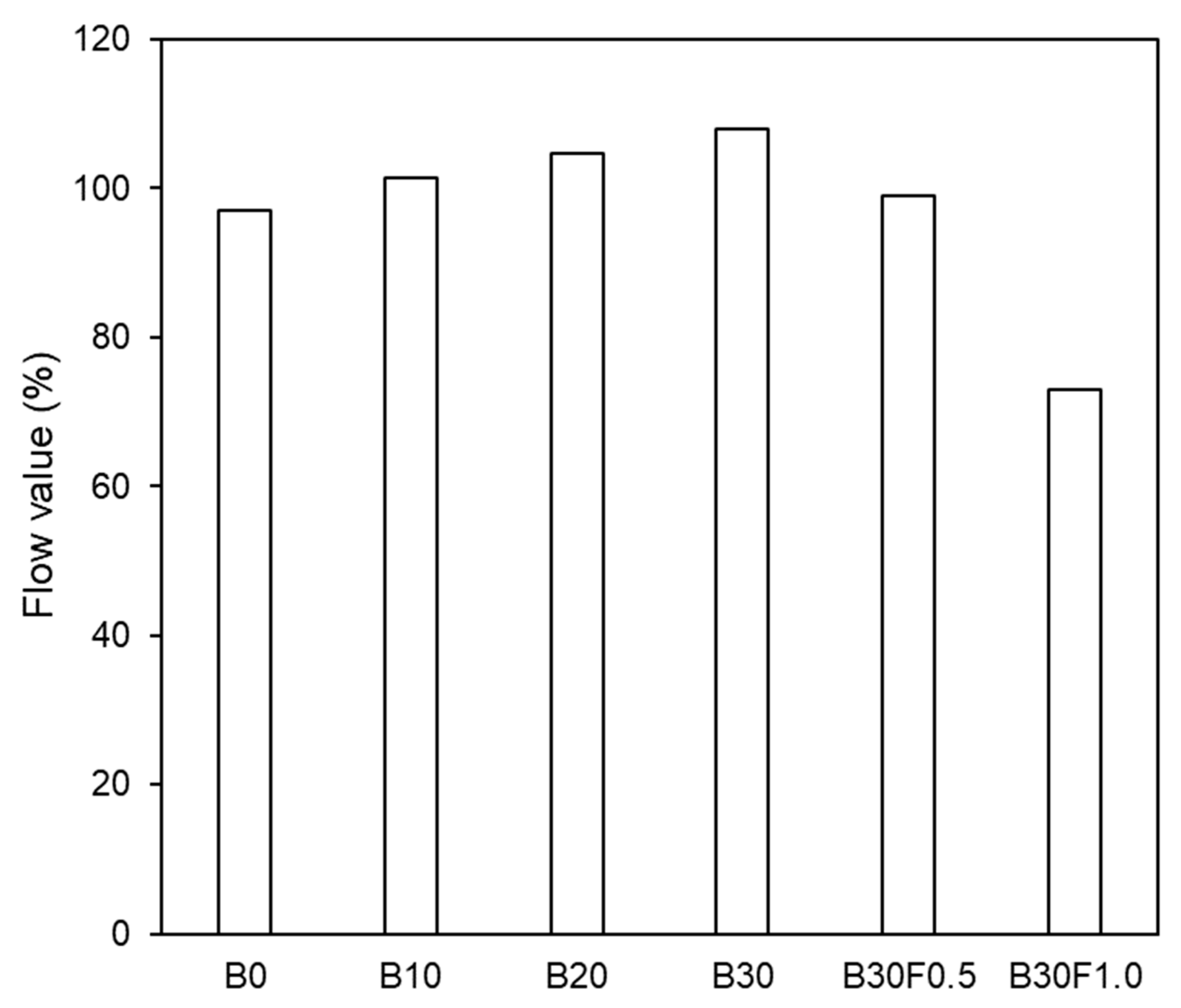

3.1. Flow Value

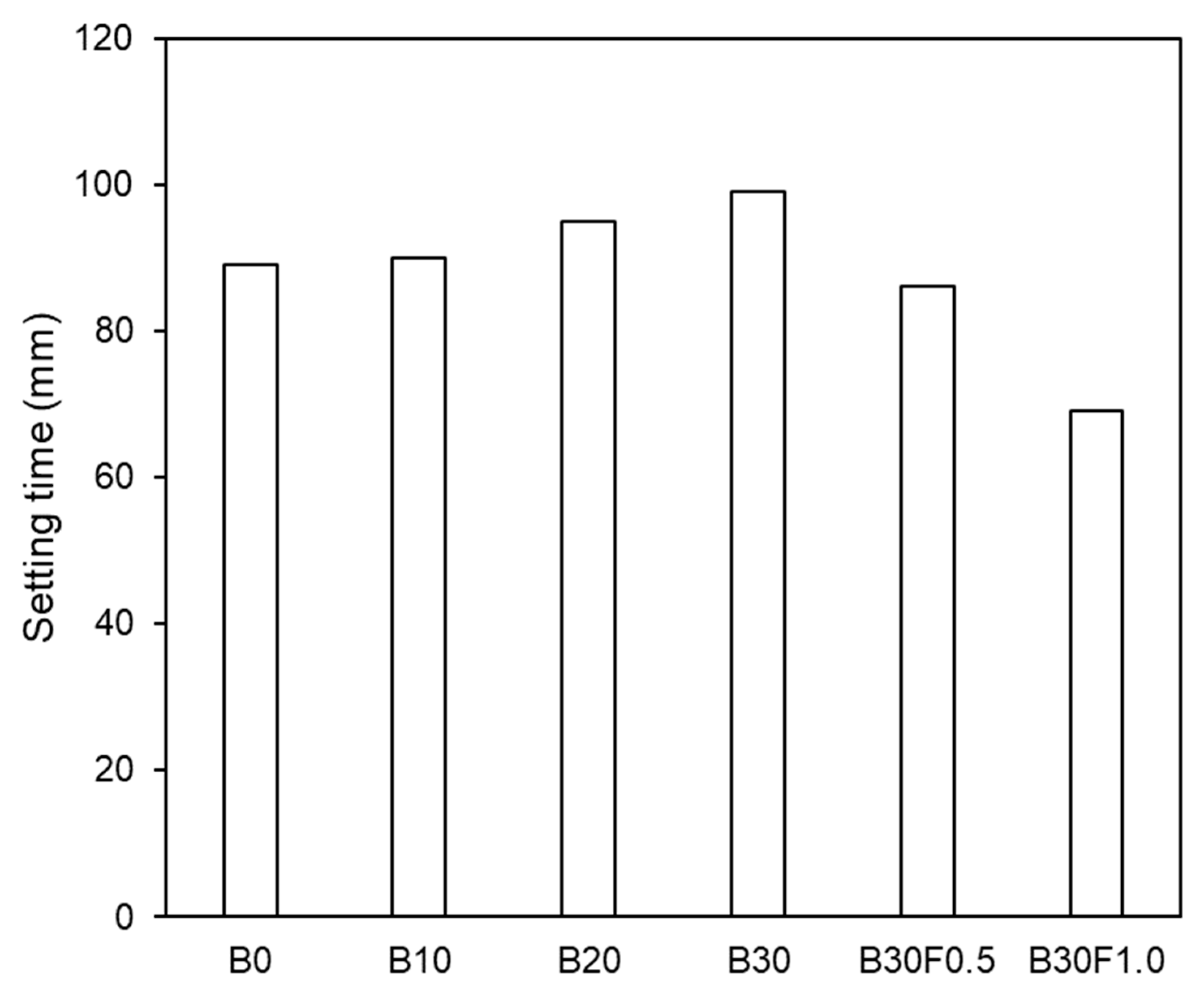

3.2. Setting Time

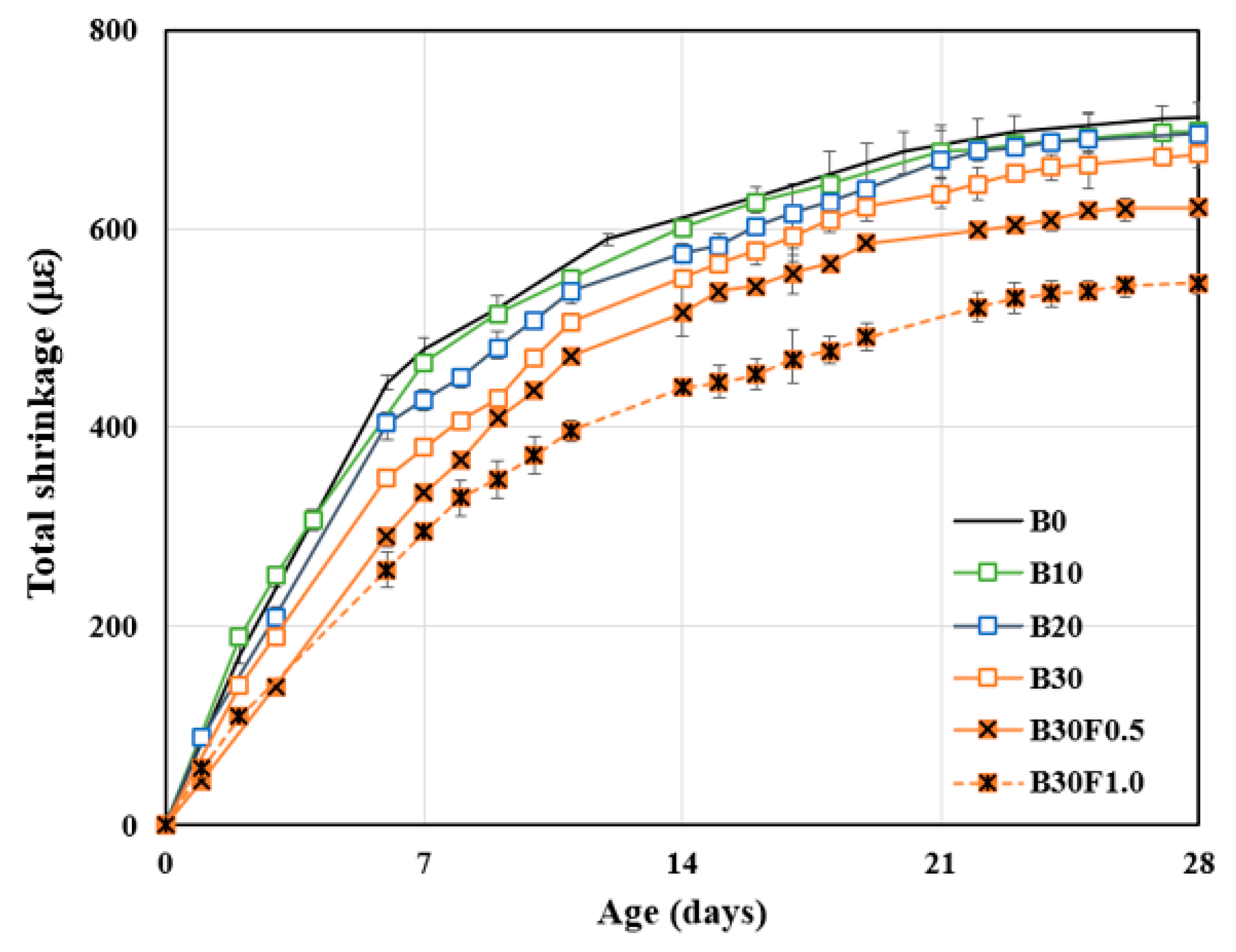

3.3. Total Shrinkage

3.4. Compressive Strength

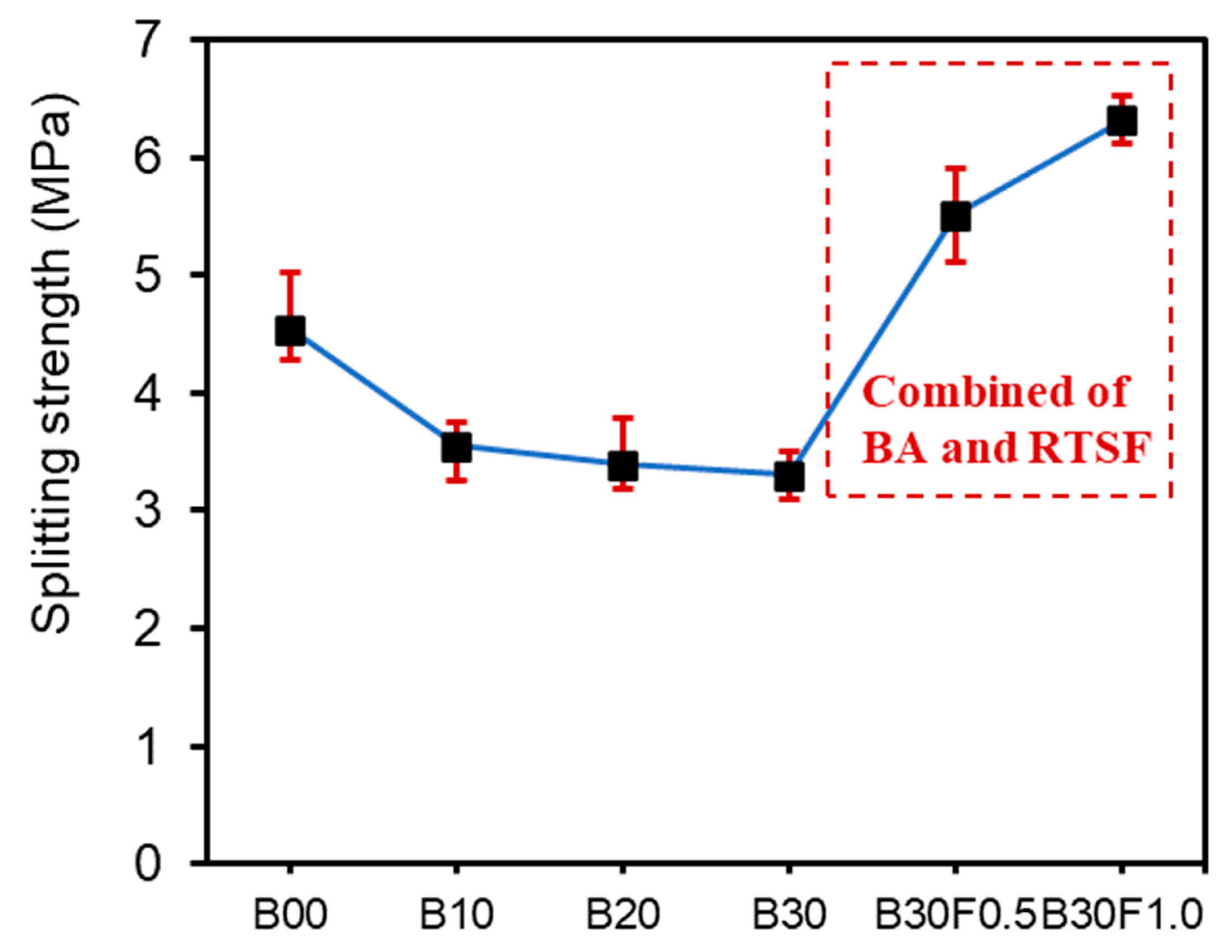

3.5. Splitting Strength

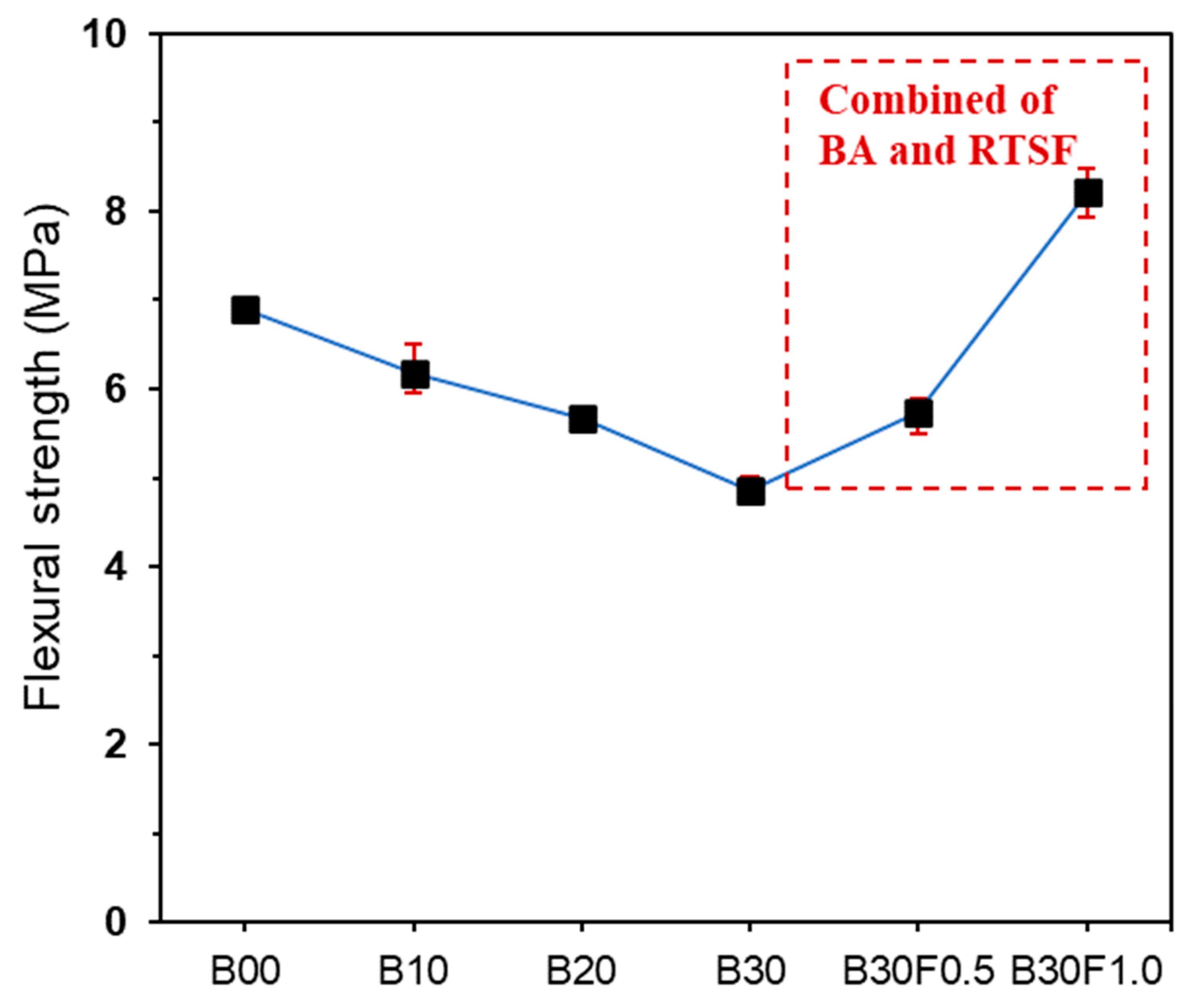

3.6. Flexural Strength

3.7. Microstructure Characteristics

3.7.1. Microstructure Using SEM Equipped with EDX

3.7.2. TG Curve and Ca(OH)2 Content Using TGA

3.7.3. Pore Structure Using MIP

4. Discussion

5. Conclusions

- The addition of BA improved the workability of fresh mortar.

- As the percentage of BA in the mixture increased, the setting time also increased, primarily due to BA’s desorption properties.

- Mortar containing 30% BA exhibited a significant increase in compressive strength, particularly after 28 days of curing. This enhancement amounted to a 56.3% increase in strength compared to that of plain mortar.

- A microstructural analysis revealed that the mortar with BA exhibited a denser microstructure, which contributed to the development of higher strength. The increased hydration and refinement of pores from 1 day to 28 days supported this observation.

- The addition of recycled tire steel fiber (RTSF) further improved the mechanical properties of the mortar. The RTSF acted as a reinforcement, increasing the compressive, splitting tensile, and flexural strengths by 25%, 46%, and 40%, respectively, when added at 1%.

- The combination of BA and RTSF effectively reduced the total shrinkage by nearly 30%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Solid Waste Management. Available online: https://www.worldbank.org/en/topic/urbandevelopment/brief/solid-waste-management (accessed on 14 August 2023).

- News Release Coal Ash Production and Use 2021. Available online: https://acaa-usa.org/wp-content/uploads/2022/12/2021-Production-and-Use-Survey-Results-FINAL.pdf (accessed on 14 August 2023).

- Rodríguez-Álvaro, R.; Seara-Paz, S.; González-Fonteboa, B.; Ferrándiz-Mas, V.; Paine, K. Waste-Based porous materials as water reservoirs for the internal curing of Concrete: A review. Constr. Build. Mater. 2021, 299, 124244. [Google Scholar] [CrossRef]

- Rodríguez-Álvaro, R.; Seara-Paz, S.; González-Fonteboa, B.; Etxeberria, M. Study of different granular by-products as internal curing water reservoirs in concrete. J. Build. Eng. 2022, 45, 103623. [Google Scholar] [CrossRef]

- Kim, H.K.; Lee, H.K. Hydration kinetics of high-strength concrete with untreated coal bottom ash for internal curing. Cem. Concr. Compos. 2018, 91, 67–75. [Google Scholar] [CrossRef]

- Maldonado-Alameda, A.; Giro-Paloma, J.; Svobodova-Sedlackova, A.; Formosa, J.; Chimenos, J.M. Municipal solid waste incineration bottom ash as alkali-activated cement precursor depending on particle size. J. Clean. Prod. 2020, 242, 118443. [Google Scholar] [CrossRef]

- Hamada, H.; Alattar, A.; Tayeh, B.; Yahaya, F.; Adesina, A. Sustainable application of coal bottom ash as fine aggregates in concrete: A comprehensive review. Case Stud. Constr. Mater. 2022, 16, e01109. [Google Scholar] [CrossRef]

- Gao, X.; Yuan, B.; Yu, Q.L.; Brouwers, H.J.H. Characterization and application of municipal solid waste incineration (MSWI) bottom ash and waste granite powder in alkali activated slag. J. Clean. Prod. 2017, 164, 410–419. [Google Scholar] [CrossRef]

- Nakararoj, N.; Nhat Ho Tran, T.; Sukontasukkul, P.; Attachaiyawuth, A.; Tangchirapat, W.; Chee Ban, C.; Rattanachu, P.; Jaturapitakkul, C. Effects of High-Volume bottom ash on Strength, Shrinkage, and creep of High-Strength recycled concrete aggregate. Constr. Build. Mater. 2022, 356, 129233. [Google Scholar] [CrossRef]

- Chindasiriphan, P.; Meenyut, B.; Orasutthikul, S.; Jongvivatsakul, P.; Tangchirapat, W. Influences of high-volume coal bottom ash as cement and fine aggregate replacements on strength and heat evolution of eco-friendly high-strength concrete. J. Build. Eng. 2023, 65, 105791. [Google Scholar] [CrossRef]

- Balapour, M.; Zhao, W.; Garboczi, E.J.; Oo, N.Y.; Spatari, S.; Hsuan, Y.G.; Billen, P.; Farnam, Y. Potential use of lightweight aggregate (LWA) produced from bottom coal ash for internal curing of concrete systems. Cem. Concr. Compos. 2020, 105, 103428. [Google Scholar] [CrossRef]

- Promsaeng, A.; Krammart, P.; Sancharoen, P.; Tangtermsirikul, S. Effect of Using Bottom Ash as Internal Curing Material on Compressive Strength of Concrete. In Proceedings of the 10th Annual Concrete Conference, Dusit Island, Chiang Rai, Thailand, 20–22 October 2014. [Google Scholar]

- Bai, Y.; Darcy, F.; Basheer, P.A.M. Strength and drying shrinkage properties of concrete containing furnace bottom ash as fine aggregate. Constr. Build. Mater. 2005, 19, 691–697. [Google Scholar] [CrossRef]

- Kim, H.K.; Jang, J.G.; Choi, Y.C.; Lee, H.K. Improved chloride resistance of high-strength concrete amended with coal bottom ash for internal curing. Comput. Chem. Eng. 2014, 71, 334–343. [Google Scholar] [CrossRef]

- Lee, H.K.; Kim, H.K.; Hwang, E.A. Utilization of power plant bottom ash as aggregates in fiber-reinforced cellular concrete. Waste Manag. 2010, 30, 274–284. [Google Scholar] [CrossRef] [PubMed]

- Wyrzykowski, M.; Ghourchian, S.; Sinthupinyo, S.; Chitvoranund, N.; Chintana, T.; Lura, P. Internal curing of high performance mortars with bottom ash. Cem. Concr. Compos. 2016, 71, 1–9. [Google Scholar] [CrossRef]

- Mousa, A. Utilization of coal bottom ash from thermal power plants as a cement replacement for building: A promising sustainable practice. J. Build. Eng. 2023, 74, 106885. [Google Scholar] [CrossRef]

- Bheel, N.; Khoso, S.; Baloch, M.H.; Benjeddou, O.; Alwetaishi, M. Use of waste recycling coal bottom ash and sugarcane bagasse ash as cement and sand replacement material to produce sustainable concrete. Environ. Sci. Pollut. Res. 2022, 29, 52399–52411. [Google Scholar] [CrossRef]

- Aghaee, K.; Khayat, K.H. Effect of internal curing and shrinkage-mitigating materials on microstructural characteristics of fiber-reinforced mortar. Constr. Build. Mater. 2023, 386, 131527. [Google Scholar] [CrossRef]

- Chimeremeze, P.; Adegoke, A.; Abu, I.; Mohamed, M.; Abd, A.A.; Mayowa, E.; Milad, A. Case Studies in Construction Materials Mechanical characteristics of hardened basalt fiber expanded clay concrete cylinders. Case Stud. Constr. Mater. 2022, 17, e01368. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Dai, C. Development of banana fibers and wood bottom ash modified cement mortars. Constr. Build. Mater. 2020, 241, 118041. [Google Scholar] [CrossRef]

- Michalik, A.; Chyliński, F.; Piekarczuk, A.; Pichór, W. Evaluation of recycled tyre steel fibres adhesion to cement matrix. J. Build. Eng. 2023, 68, 106146. [Google Scholar] [CrossRef]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of Hybrid Fiber Reinforced Concrete with Recycled and Industrial Steel Fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Mechanical properties of SFRC using blended manufactured and recycled tyre steel fibres. Constr. Build. Mater. 2018, 163, 376–389. [Google Scholar] [CrossRef]

- Al-Kamyani, Z.; Figueiredo, F.P.; Hu, H.; Guadagnini, M.; Pilakoutas, K. Shrinkage and flexural behaviour of free and restrained hybrid steel fibre reinforced concrete. Constr. Build. Mater. 2018, 189, 1007–1018. [Google Scholar] [CrossRef]

- Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Mechanical properties of SFRC using blended Recycled Tyre Steel Cords (RTSC) and Recycled Tyre Steel Fibres (RTSF). Constr. Build. Mater. 2018, 187, 553–564. [Google Scholar] [CrossRef]

- Alsaif, A.; Bernal, S.A.; Guadagnini, M.; Pilakoutas, K. Freeze-thaw resistance of steel fibre reinforced rubberised concrete. Constr. Build. Mater. 2019, 195, 450–458. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.R.; Abdollahnejad, Z.; Nematollahi, B.; Sanjayan, J.G.; Illikainen, M. A comparison of the effects of pozzolanic binders on the hardened-state properties of high-strength cementitious composites reinforced with waste tire fibers. Compos. Part B Eng. 2019, 162, 134–153. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. Fresh and hardened properties of self-compacting concrete reinforced with hybrid recycled steel-polypropylene fiber. J. Mater. Civ. Eng. 2017, 29, 1–15. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. Experimental study on engineering properties of concrete reinforced with hybrid recycled tyre steel and polypropylene fibres. J. Clean. Prod. 2020, 259, 120914. [Google Scholar] [CrossRef]

- ASTM C150/C150M-20; Standard Specification for Portland Cement. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2020; pp. 1–9. [CrossRef]

- ASTM C128-15; Standard Test Method for Rlative Density (Specific Gravity) and Absorption of Fine Aggregate. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2015; pp. 1–6.

- ASTM C33-03; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2003.

- ASTM C1761/C1761M-15: ASTM C1761-15; Standard Specification for Lightweight Aggregate for Internal Curing of Concrete. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2015; pp. 1–8.

- Zhong, H.; Poon, E.W.; Chen, K.; Zhang, M. Engineering properties of crumb rubber alkali-activated mortar reinforced with recycled steel fibres. J. Clean. Prod. 2019, 238, 117950. [Google Scholar] [CrossRef]

- ASTM C1437-15; Standard Test Method for Flow of Hydraulic Cement MOrtar. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2015; pp. 1–2.

- ASTM C807-13; Standard Test Method for Time of Setting of Hydraulic Cement Mortar by Modified Vicat Needle. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2013; pp. 1–3.

- ASTM C157/C157M-14; Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and concrete. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2014; Volume 08, pp. 1–7.

- ASTM C109/C109M-16; Standard Test Method for Compressive Strength of Hydraulic Cement. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2016; pp. 1–10.

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2017; p. 5.

- ASTM C1609-19: C 1609/C 1609M-05; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading) 1. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2019; pp. 1–9. [CrossRef]

- Tu, W.; Zhu, Y.; Fang, G.; Wang, X.; Zhang, M. Internal curing of alkali-activated fly ash-slag pastes using superabsorbent polymer. Cem. Concr. Res. 2019, 116, 179–190. [Google Scholar] [CrossRef]

- Chindasiriphan, P.; Yokota, H.; Kawabata, Y.; Pimpakan, P. Combined effect of rice husk ash and superabsorbent polymer on self-healing capability of mortar. Constr. Build. Mater. 2022, 338, 127588. [Google Scholar] [CrossRef]

- Ghourchian, S.; Wyrzykowski, M.; Lura, P.; Shekarchi, M.; Ahmadi, B. An investigation on the use of zeolite aggregates for internal curing of concrete. Constr. Build. Mater. 2013, 40, 135–144. [Google Scholar] [CrossRef]

- Kim, H.K.; Ha, K.A.; Lee, H.K. Internal-curing efficiency of cold-bonded coal bottom ash aggregate for high-strength mortar. Constr. Build. Mater. 2016, 126, 1–8. [Google Scholar] [CrossRef]

- Wang, Y.; Chan, C.L.; Leong, S.H.; Zhang, M. Engineering properties of strain hardening geopolymer composites with hybrid polyvinyl alcohol and recycled steel fibres. Constr. Build. Mater. 2020, 261, 120585. [Google Scholar] [CrossRef]

- Atiş, C.D.; Karahan, O. Properties of steel fiber reinforced fly ash concrete. Constr. Build. Mater. 2009, 23, 392–399. [Google Scholar] [CrossRef]

- Lasseuguette, E.; Burns, S.; Simmons, D.; Francis, E.; Chai, H.K.; Koutsos, V.; Huang, Y. Chemical, microstructural and mechanical properties of ceramic waste blended cementitious systems. J. Clean. Prod. 2019, 211, 1228–1238. [Google Scholar] [CrossRef]

- Flores-Alés, V.; Martín-del-Río, J.J.; Alducin-Ochoa, J.M.; Torres-González, M. Rehydration on high temperature-mortars based on recycled glass as aggregate. J. Clean. Prod. 2020, 275, 124139. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | CaO | K2O | TiO2 | Na2O | SO3 | Others |

|---|---|---|---|---|---|---|---|---|

| 27.00 | 14.00 | 23.20 | 25.80 | 2.97 | 0.66 | 0.69 | 3.03 | 1.51 |

| Length, L (mm) | Nominal Diameter, D (μm) | Aspect Ratio (L/D) | Density (g/m3) | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|

| 20 | 150 | 7.8 | 2850 | 0.69 | 200 |

| Mix | OPC (kg/m3) | w/c Ratio | Sand (kg/m3) | BA (kg/m3) | RTSF (kg/m3) |

|---|---|---|---|---|---|

| B0 | 898.9 | 0.35 | 1038.0 | - | - |

| B10 | 898.9 | 0.35 | 934.2 | 70.4 | - |

| B20 | 898.9 | 0.35 | 830.4 | 140.8 | - |

| B30 | 898.9 | 0.35 | 726.6 | 211.2 | - |

| B30F0.5 | 898.9 | 0.35 | 726.6 | 211.2 | 39.0 |

| B30F1.0 | 898.9 | 0.35 | 726.6 | 211.2 | 78.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markpiban, P.; Sahamitmongkol, R. Workability, Mechanical Properties, and Microstructure Analysis of Bottom Ash Mortar Reinforced with Recycled Tire Steel Fiber. Buildings 2023, 13, 2514. https://doi.org/10.3390/buildings13102514

Markpiban P, Sahamitmongkol R. Workability, Mechanical Properties, and Microstructure Analysis of Bottom Ash Mortar Reinforced with Recycled Tire Steel Fiber. Buildings. 2023; 13(10):2514. https://doi.org/10.3390/buildings13102514

Chicago/Turabian StyleMarkpiban, Pochpagee, and Raktipong Sahamitmongkol. 2023. "Workability, Mechanical Properties, and Microstructure Analysis of Bottom Ash Mortar Reinforced with Recycled Tire Steel Fiber" Buildings 13, no. 10: 2514. https://doi.org/10.3390/buildings13102514

APA StyleMarkpiban, P., & Sahamitmongkol, R. (2023). Workability, Mechanical Properties, and Microstructure Analysis of Bottom Ash Mortar Reinforced with Recycled Tire Steel Fiber. Buildings, 13(10), 2514. https://doi.org/10.3390/buildings13102514