Potential Benefits of Thermal Insulation in Public Buildings: Case of a University Building

Abstract

:1. Introduction

1.1. Role of Energy Efficiency in the National Strategies

1.2. Previous Studies on Energy Efficiency in Buildings

2. Research Methodology

2.1. The Building Profile

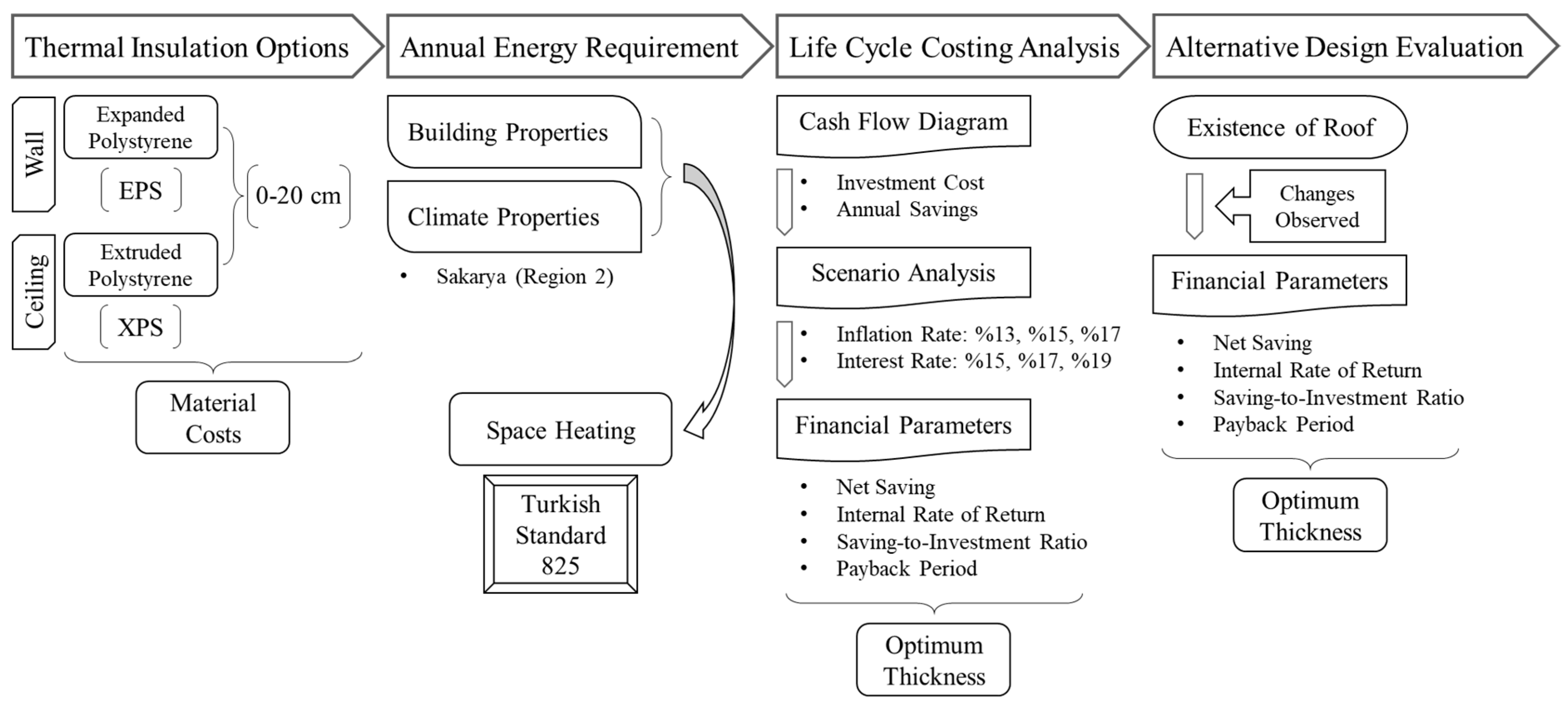

2.2. The Flowchart of Research Methodology

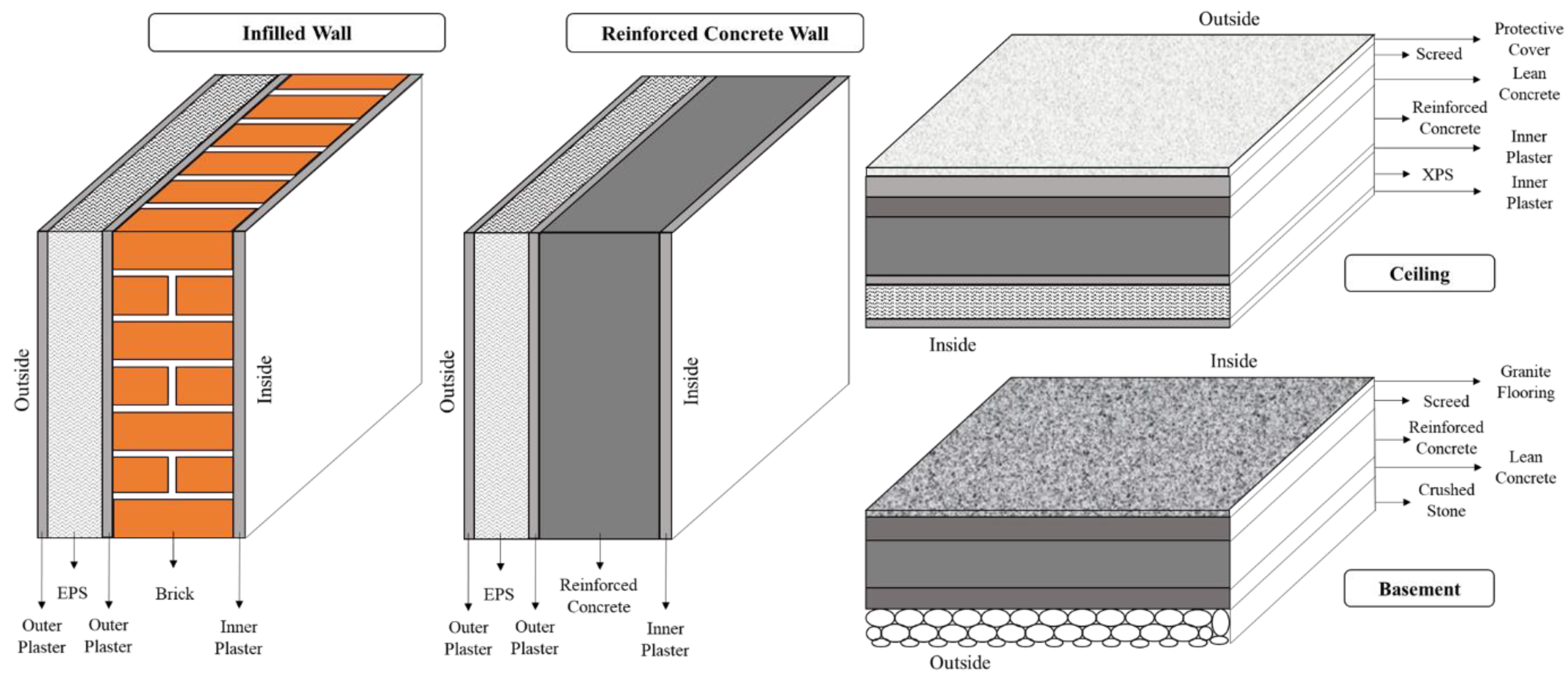

2.3. Determination of Thermal Insulation Options

2.4. Calculation of Annual Energy Requirement

2.5. Limitations of the National Standard

2.6. Life Cycle Costing Analysis

2.7. Evaluation of Alternative Design

3. Research Results and Discussion

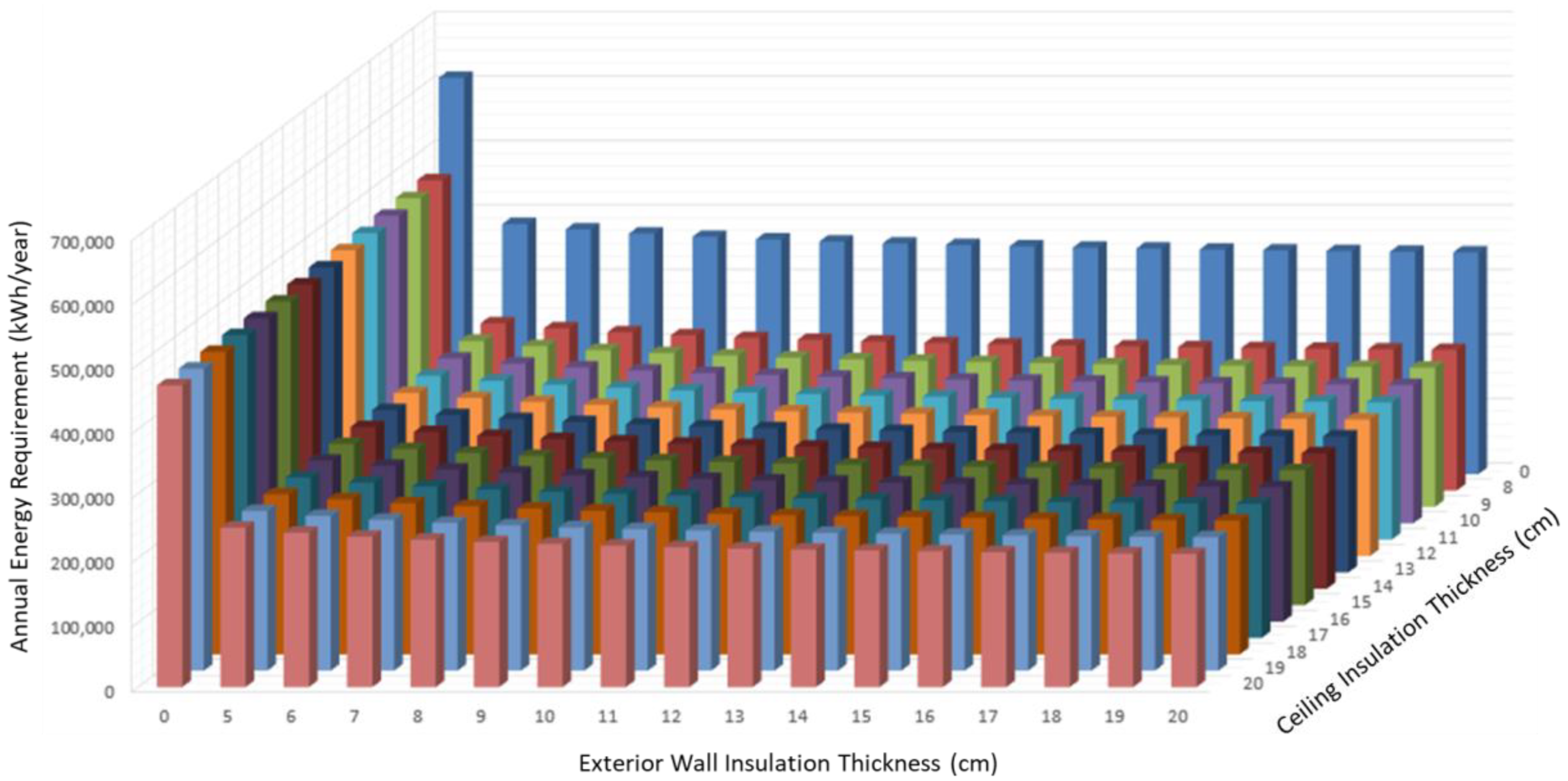

3.1. Annual Energy Requirement and Saving

3.2. Cost of Insulation

3.3. Cash Flow Diagrams

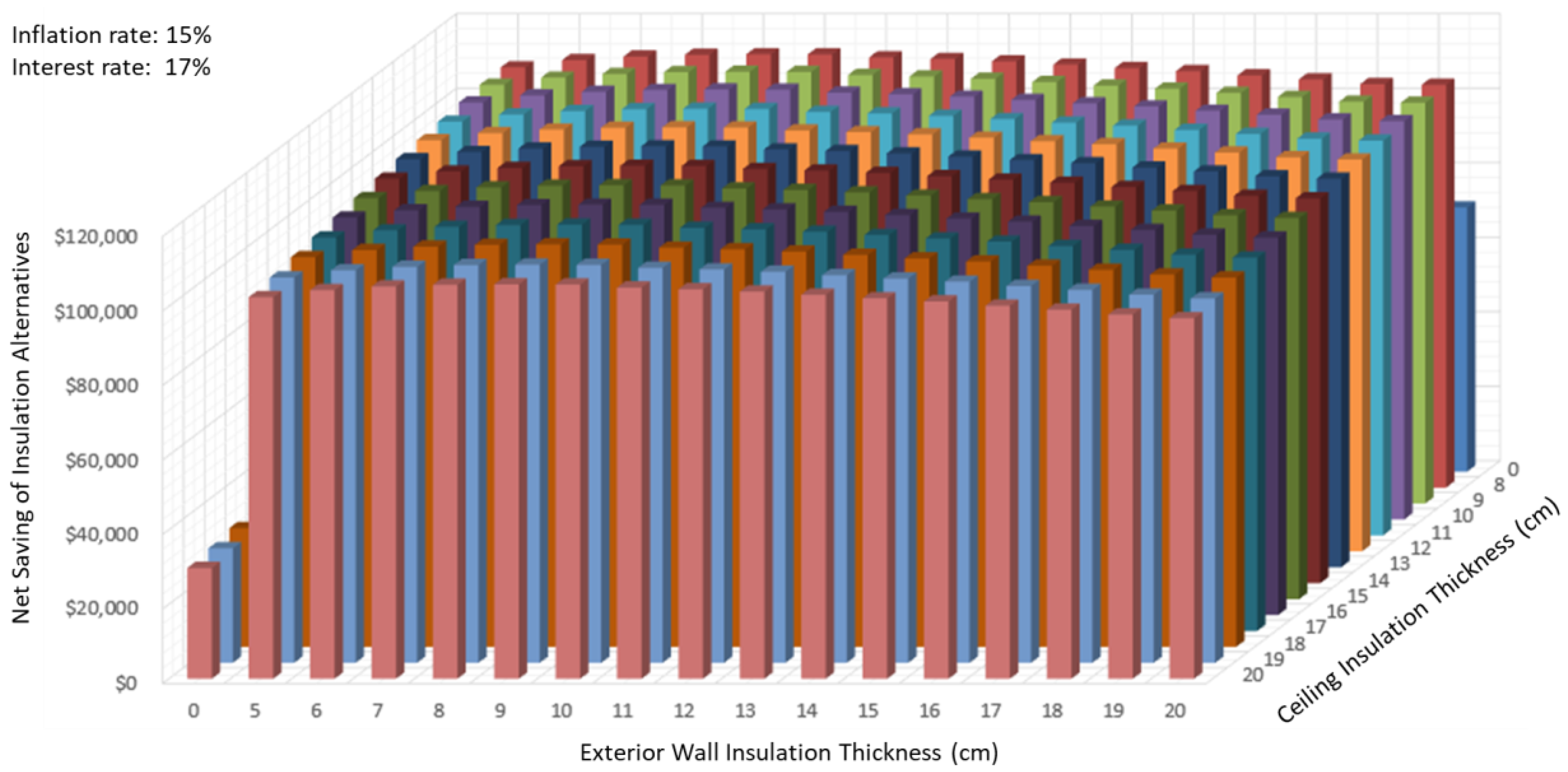

3.4. Scenario Analysis and Optimum Insulation Thickness

3.5. Case of the Inclined Roof

4. Conclusions

- The optimum insulation application depends considerably on the scenario of the inflation and interest rates;

- Benefits of the insulation application are greatly influenced by the building geometry, more specifically, the presence of the inclined roof.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | area (m2) |

| An | building usage area (m2) |

| Fw | correction factor for windows |

| G | solar energy permeation factor of the transparent elements |

| g┴ | solar energy permeation factor measured under laboratory conditions |

| H | specific heat loss of the building (W/K) |

| I | monthly average solar radiation intensity (W/m2) |

| i | interest rate (%) |

| Inv | investment (USD) |

| IRR | internal rate of return (%) |

| na | air changing ratio |

| N | period of the study (year) |

| NS | net savings (USD) |

| PBP | payback period (year) |

| Qm | monthly heating energy consumption (kWh/month) |

| Qyear | annual heating energy consumption (kWh/year) |

| r | monthly average shading factor of the transparent surfaces |

| S | saving |

| SIR | savings-to-investment ratio |

| t | time |

| U | heat transfer coefficient ((W/m2)/K) |

| V | volume (m3) |

| η | average usage factor of heat gain |

| θ | temperature (°C) |

| φ | average heat gain (W) |

| Subscripts | |

| ce | ceiling |

| ed | exterior door |

| ew | exterior wall |

| fl | floor |

| gl | glazing |

| in | inside |

| j | month |

| k | direction |

| out | outside |

| s | solar |

| tr | transfer |

| ven | ventilation |

References

- Zune, M.; Pantua, C.A.J.; Rodrigues, L.; Gillott, M. A review of traditional multistage roofs design and performance in vernacular buildings in Myanmar. Sustain. Cities Soc. 2020, 60, 102240. [Google Scholar] [CrossRef]

- Bertoldi, P. Policies for energy conservation and sufficiency: Review of existing policies and recommendations for new and effective policies in OECD countries. Energy Build. 2022, 264, 112075. [Google Scholar] [CrossRef]

- Buonomano, A.; Barone, G.; Forzano, C. Advanced energy technologies, methods, and policies to support the sustainable development of energy, water and environment systems. Energy Rep. 2022, 8, 4844–4853. [Google Scholar] [CrossRef]

- International Energy Agency. Tracking Buildings 2020; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Mariano-Hernández, D.; Hernández-Callejo, L.; Zorita-Lamadrid, A.; Duque-Pérez, O.; García, F.S. A review of strategies for building energy management system: Model predictive control, demand side management, optimization, and fault detect & diagnosis. J. Build. Eng. 2021, 33, 101692. [Google Scholar]

- Lu, C.; Li, S.; Lu, Z. Building energy prediction using artificial neural networks: A literature survey. Energy Build. 2022, 262, 111718. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Ahmad, L.; Milani, M.; Montorsi, L.; Venturelli, M. Energy efficiency in industry: EU and national policies in Italy and the UK. Energy 2019, 172, 255–269. [Google Scholar] [CrossRef]

- Aslani, A.; Bakhtiar, A.; Akbarzadeh, M.H. Energy-efficiency technologies in the building envelope: Life cycle and adaptation assessment. J. Build. Eng. 2019, 21, 55–63. [Google Scholar] [CrossRef]

- Najjar, M.; Figueiredo, K.; Hammad, A.W.; Haddad, A. Integrated optimization with building information modeling and life cycle assessment for generating energy efficient buildings. Appl. Energy 2019, 250, 1366–1382. [Google Scholar] [CrossRef]

- Kalmár, F. Summer operative temperatures in free running existing buildings with high glazed ratio of the facades. J. Build. Eng. 2016, 6, 236–242. [Google Scholar] [CrossRef]

- Sharma, S.K.; Mohapatra, S.; Sharma, R.C.; Alturjman, S.; Altrjman, C.; Mostarda, L.; Stephan, T. Retrofitting existing buildings to improve energy performance. Sustainability 2022, 14, 666. [Google Scholar] [CrossRef]

- Pohoryles, D.; Bournas, D.; Da Porto, F.; Caprino, A.; Santarsiero, G.; Triantafillou, T. Integrated seismic and energy retrofitting of existing buildings: A state-of-the-art review. J. Build. Eng. 2022, 61, 105274. [Google Scholar] [CrossRef]

- Grossman, P.Z. Energy shocks, crises and the policy process: A review of theory and application. Energy Policy 2015, 77, 56–69. [Google Scholar] [CrossRef]

- Caglayan, S.; Ozorhon, B.; Kurnaz, L. Nationwide mapping of optimum wall insulation thicknesses: A stochastic approach. J. Therm. Sci. Technol. 2022, 42, 169–202. [Google Scholar] [CrossRef]

- Economidou, M.; Todeschi, V.; Bertoldi, P.; D’Agostino, D.; Zangheri, P.; Castellazzi, L. Review of 50 years of EU energy efficiency policies for buildings. Energy Build. 2020, 225, 110322. [Google Scholar] [CrossRef]

- Kinley, R. Climate change after Paris: From turning point to transformation. Clim. Policy 2017, 17, 9–15. [Google Scholar] [CrossRef]

- European Parliament and Council. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on energy efficiency, amending Directives 2009/125/EC and 2010/30/EU and repealing Directives 2004/8/EC and 2006/32/EC. Off. J. Eur. Union 2012, 14112012, 1–56. [Google Scholar]

- Presidente Della Repubblica Italiana. ‘Decree 34/2020. Misure Urgenti in Materia di Salute, Sostegno al Lavoro e All’economia, Nonché di Politiche Sociali Connesse All’emergenza Epidemiologica da COVID-19 Gazzetta Ufficiale Della Repubblica Italiana n. 21 del 19.05.2020′; Gazzetta Ufficiale Della Repubblica Italiana: Rome, Italy, 2020. [Google Scholar]

- MENR. The National Energy Efficiency Action Plan; Republic of Türkiye Ministry of Energy and Natural Resources: Ankara, Turkey, 2018. [Google Scholar]

- MENR. Türkiye National Energy Plan; Republic of Türkiye Ministry of Energy and Natural Resources: Ankara, Turkey, 2022. [Google Scholar]

- Caglayan, S.; Ozorhon, B.; Ozcan, G.; Yigit, S. A life cycle costing approach to determine the optimum insulation thickness of existing buildings. J. Therm. Sci. Technol. 2020, 40, 1–14. [Google Scholar]

- Hussein, M.H.; Monna, S.; Abdallah, R.; Juaidi, A.; Albatayneh, A. Improving the thermal performance of building envelopes: An approach to enhancing the building energy efficiency code. Sustainability 2022, 14, 16264. [Google Scholar] [CrossRef]

- He, Y.; Chen, Y.; Chen, Z.; Deng, Z.; Yuan, Y. Impacts of occupant behavior on building energy consumption and energy savings analysis of upgrading ASHRAE 90.1 energy efficiency standards. Buildings 2022, 12, 1108. [Google Scholar] [CrossRef]

- Wang, X.; Yuan, J.; You, K.; Ma, X.; Li, Z. Using real building energy use data to explain the energy performance gap of energy-efficient residential buildings: A case study from the hot summer and cold winter zone in China. Sustainability 2023, 15, 1575. [Google Scholar] [CrossRef]

- Runge, J.; Zmeureanu, R. Forecasting energy use in buildings using artificial neural networks: A review. Energies 2019, 12, 3254. [Google Scholar] [CrossRef]

- Le, L.T.; Nguyen, H.; Dou, J.; Zhou, J. A comparative study of PSO-ANN, GA-ANN, ICA-ANN, and ABC-ANN in estimating the heating load of buildings’ energy efficiency for smart city planning. Appl. Sci. 2019, 9, 2630. [Google Scholar] [CrossRef]

- Pham, A.-D.; Ngo, N.-T.; Truong, T.T.H.; Huynh, N.-T.; Truong, N.-S. Predicting energy consumption in multiple buildings using machine learning for improving energy efficiency and sustainability. J. Clean. Prod. 2020, 260, 121082. [Google Scholar] [CrossRef]

- Belussi, L.; Barozzi, B.; Bellazzi, A.; Danza, L.; Devitofrancesco, A.; Fanciulli, C.; Ghellere, M.; Guazzi, G.; Meroni, I.; Salamone, F.; et al. A review of performance of zero energy buildings and energy efficiency solutions. J. Build. Eng. 2019, 25, 100772. [Google Scholar] [CrossRef]

- Lidelöw, S.; Örn, T.; Luciani, A.; Rizzo, A. Energy-efficiency measures for heritage buildings: A literature review. Sustain. Cities Soc. 2019, 45, 231–242. [Google Scholar] [CrossRef]

- Farzaneh, H.; Malehmirchegini, L.; Bejan, A.; Afolabi, T.; Mulumba, A.; Daka, P.P. Artificial intelligence evolution in smart buildings for energy efficiency. Appl. Sci. 2021, 11, 763. [Google Scholar] [CrossRef]

- Nair, G.; Verde, L.; Olofsson, T. A review on technical challenges and possibilities on energy efficient retrofit measures in heritage buildings. Energies 2022, 15, 7472. [Google Scholar] [CrossRef]

- Serale, G.; Fiorentini, M.; Capozzoli, A.; Bernardini, D.; Bemporad, A. Model predictive control (MPC) for enhancing building and HVAC system energy efficiency: Problem formulation, applications and opportunities. Energies 2018, 11, 631. [Google Scholar] [CrossRef]

- Bughio, M.; Khan, M.S.; Mahar, W.A.; Schuetze, T. Impact of passive energy efficiency measures on cooling energy demand in an architectural campus building in Karachi, Pakistan. Sustainability 2021, 13, 7251. [Google Scholar] [CrossRef]

- Chippagiri, R.; Gavali, H.R.; Ralegaonkar, R.V.; Riley, M.; Shaw, A.; Bras, A. Application of sustainable prefabricated wall technology for energy efficient social housing. Sustainability 2021, 13, 1195. [Google Scholar] [CrossRef]

- Meena, C.S.; Prajapati, A.N.; Kumar, A.; Kumar, M. Utilization of solar energy for water heating application to improve building energy efficiency: An experimental study. Buildings 2022, 12, 2166. [Google Scholar] [CrossRef]

- Albatayneh, A.; Albadaineh, R.; Juaidi, A.; Abdallah, R.; Zabalo, A.; Manzano-Agugliaro, F. Enhancing the energy efficiency of buildings by shading with PV panels in semi-arid climate zone. Sustainability 2022, 14, 17040. [Google Scholar] [CrossRef]

- TEC. Turkish Earthquake Code: Regulations on Structures Constructed in Disaster Regions; Ministry of Public Works and Settlement: Ankara, Turkiye, 2007. [Google Scholar]

- Arslan, M.H. An evaluation of effective design parameters on earthquake performance of RC buildings using neural networks. Eng. Struct. 2010, 32, 1888–1898. [Google Scholar] [CrossRef]

- TS 825; Thermal İnsulation Requirements for Buildings. Turkish Standard Institution: Ankara, Turkiye, 2008.

- Dombaycı, A. Degree-days maps of Turkey for various base temperatures. Energy 2009, 34, 1807–1812. [Google Scholar] [CrossRef]

| Solar Radiation | Months | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| January | February | March | April | May | June | July | August | September | October | November | December | |

| Isouth | 72 | 84 | 87 | 90 | 92 | 95 | 93 | 93 | 89 | 82 | 67 | 64 |

| Inorth | 26 | 37 | 52 | 66 | 79 | 83 | 81 | 73 | 57 | 40 | 27 | 22 |

| Ieast/west | 43 | 57 | 77 | 90 | 114 | 122 | 118 | 106 | 81 | 59 | 41 | 37 |

| Month | Region 1 | Region 2 | Region 3 | Region 4 |

|---|---|---|---|---|

| January | 8.4 | 2.9 | −0.3 | −5.4 |

| February | 9.0 | 4.4 | 0.1 | −4.7 |

| March | 11.6 | 7.3 | 4.1 | 0.3 |

| April | 15.8 | 12.8 | 10.1 | 7.9 |

| May | 21.2 | 18.0 | 14.4 | 12.8 |

| June | 26.3 | 22.5 | 18.5 | 17.3 |

| July | 28.7 | 24.9 | 21.7 | 21.4 |

| August | 27.6 | 24.3 | 21.2 | 21.1 |

| September | 23.5 | 19.9 | 17.2 | 16.5 |

| October | 18.5 | 14.1 | 11.6 | 10.3 |

| November | 13.0 | 8.5 | 5.6 | 3.1 |

| December | 9.3 | 3.8 | 1.3 | −2.8 |

| Region | Uew | Uce | Ubs | Ugl |

|---|---|---|---|---|

| Region 1 | 0.70 | 0.45 | 0.70 | 2.40 |

| Region 2 | 0.60 | 0.40 | 0.60 | 2.40 |

| Region 3 | 0.50 | 0.30 | 0.45 | 2.40 |

| Region 4 | 0.40 | 0.25 | 0.40 | 2.40 |

| Uew Coefficient (W/m2K) | Uce Coefficient (W/m2K) | |||||

|---|---|---|---|---|---|---|

| Thickness | Infilled Wall | RC Wall | Thickness | Ceiling | ||

| Thickness of EPS insulation on the exterior wall (cm) | 0 | 1.670 | 3.239 | Thickness of XPS insulation on the ceiling (cm) | 0 | 2.479 |

| 1 | 1.102 | 1.620 | 1 | 1.451 | ||

| 2 | 0.838 | 1.107 | 2 | 1.026 | ||

| 3 | 0.676 | 0.841 | 3 | 0.793 | ||

| 4 | 0.576 | 0.678 | 4 | 0.647 | ||

| 5 | 0.488 | 0.568 | 5 | 0.546 | ||

| 6 | 0.428 | 0.489 | 6 | 0.472 | ||

| 7 | 0.381 | 0.429 | 7 | 0.416 | ||

| 8 | 0.344 | 0.382 | 8 | 0.372 | ||

| 9 | 0.313 | 0.344 | 9 | 0.336 | ||

| 10 | 0.287 | 0.314 | 10 | 0.307 | ||

| 11 | 0.266 | 0.288 | 11 | 0.282 | ||

| 12 | 0.247 | 0.266 | 12 | 0.261 | ||

| 13 | 0.231 | 0.247 | 13 | 0.243 | ||

| 14 | 0.216 | 0.231 | 14 | 0.227 | ||

| 15 | 0.204 | 0.217 | 15 | 0.213 | ||

| 16 | 0.193 | 0.204 | 16 | 0.201 | ||

| 17 | 0.183 | 0.193 | 17 | 0.190 | ||

| 18 | 0.173 | 0.183 | 18 | 0.180 | ||

| 19 | 0.165 | 0.174 | 19 | 0.171 | ||

| 20 | 0.158 | 0.165 | 20 | 0.163 | ||

| Exterior Wall Insulation Thickness (cm) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | ||

| Ceiling Insulation Thickness (cm) | 0 | 615,056 0 | 387,987 227,069 | 379,657 235,399 | 373,268 241,788 | 368,210 246,846 | 364,107 250,950 | 360,710 254,346 | 357,852 257,205 | 355,413 259,643 | 353,308 261,748 | 351,473 263,583 | 349,858 265,198 | 348,427 266,630 | 347,149 267,907 | 346,001 269,055 | 344,965 270,092 | 344,024 271,032 |

| 8 | 481,319 133,737 | 259,360 355,696 | 251,509 363,547 | 245,501 369,555 | 240,754 374,303 | 236,908 378,149 | 233,728 381,328 | 231,056 384,000 | 228,778 386,278 | 226,814 388,243 | 225,102 389,954 | 223,597 391,459 | 222,264 392,793 | 221,074 393,982 | 220,006 395,050 | 219,042 396,014 | 218,168 398,909 | |

| 9 | 479,072 135,984 | 257,282 357,775 | 249,441 365,615 | 243,440 371,616 | 238,700 376,357 | 234,859 380,197 | 231,684 383,372 | 229,016 386,041 | 226,742 388,315 | 224,780 390,276 | 223,071 391,985 | 221,568 393,488 | 220,237 394,819 | 219,049 396,007 | 217,983 397,073 | 217,021 398,036 | 216,148 400,572 | |

| 10 | 477,220 137,836 | 255,569 359,487 | 247,737 367,319 | 241,743 373,313 | 237,008 378,049 | 233,172 381,885 | 230,001 385,056 | 227,335 387,721 | 225,064 389,992 | 223,105 391,951 | 221,398 393,658 | 219,898 395,159 | 218,568 396,488 | 217,382 397,674 | 216,317 398,739 | 215,356 399,700 | 214,484 401,966 | |

| 11 | 475,667 139,389 | 254,135 360,922 | 246,309 368,747 | 240,321 374,736 | 235,590 379,466 | 231,758 383,299 | 228,590 386,466 | 225,928 389,129 | 223,659 391,398 | 221,702 393,355 | 219,997 395,060 | 218,498 396,559 | 217,170 397,887 | 215,985 399,071 | 214,921 400,135 | 213,961 401,095 | 213,090 403,151 | |

| 12 | 474,346 140,710 | 252,915 362,142 | 245,095 369,961 | 239,112 375,945 | 234,385 380,672 | 230,556 384,501 | 227,391 387,666 | 224,731 390,326 | 222,464 392,593 | 220,509 394,548 | 218,805 396,251 | 217,308 397,749 | 215,981 399,075 | 214,797 400,259 | 213,735 401,321 | 212,776 402,281 | 211,906 404,170 | |

| 13 | 473,208 141,848 | 251,865 363,192 | 244,050 371,006 | 238,071 376,985 | 233,347 381,709 | 229,521 385,535 | 226,359 388,698 | 223,701 391,355 | 221,436 393,621 | 219,482 395,574 | 217,780 397,276 | 216,284 398,772 | 214,958 400,098 | 213,776 401,281 | 212,714 402,342 | 211,756 403,301 | 210,886 405,056 | |

| 14 | 472,218 142,838 | 250,952 364,105 | 243,142 371,915 | 237,166 377,890 | 232,445 382,611 | 228,622 386,435 | 225,461 389,595 | 222,805 392,251 | 220,542 394,515 | 218,590 396,467 | 216,889 398,167 | 215,394 399,663 | 214,069 400,987 | 212,887 402,169 | 211,826 403,230 | 210,869 404,187 | 210,000 405,834 | |

| 15 | 471,349 143,707 | 250,150 364,906 | 242,344 372,712 | 236,372 378,684 | 231,654 383,402 | 227,832 387,224 | 224,674 390,382 | 222,019 393,037 | 219,757 395,299 | 217,806 397,250 | 216,107 398,950 | 214,612 400,444 | 213,289 401,768 | 212,108 402,949 | 211,048 404,009 | 210,091 404,966 | 209,223 406,522 | |

| 16 | 470,580 144,476 | 249,441 365,615 | 241,639 373,417 | 235,669 379,387 | 230,954 384,103 | 227,134 387,922 | 223,977 391,079 | 221,324 393,732 | 219,063 395,993 | 217,114 397,943 | 215,415 399,642 | 213,921 401,135 | 212,598 402,458 | 211,418 403,638 | 210,358 404,698 | 209,402 405,654 | 208,535 407,135 | |

| 17 | 469,895 145,162 | 248,809 366,247 | 241,010 374,046 | 235,043 380,013 | 230,330 384,727 | 226,512 388,544 | 223,357 391,700 | 220,705 394,351 | 218,445 396,611 | 216,496 398,560 | 214,798 400,258 | 213,306 401,751 | 211,983 403,073 | 210,804 404,253 | 209,745 405,312 | 208,789 406,268 | 207,922 407,684 | |

| 18 | 469,280 145,777 | 248,243 366,813 | 240,447 374,610 | 234,482 380,574 | 229,770 385,286 | 225,954 389,102 | 222,800 392,256 | 220,150 394,907 | 217,891 397,166 | 215,943 399,114 | 214,246 400,811 | 212,754 402,303 | 211,432 403,624 | 210,253 404,804 | 209,194 405,862 | 208,239 406,817 | 207,372 408,179 | |

| 19 | 468,725 146,331 | 247,732 367,324 | 239,939 375,118 | 233,976 381,080 | 229,266 385,790 | 225,451 389,605 | 222,298 392,758 | 219,649 395,407 | 217,391 397,665 | 215,444 399,613 | 213,747 401,309 | 212,256 402,800 | 210,935 404,122 | 209,756 405,300 | 208,698 406,358 | 207,743 407,313 | 206,877 408,179 | |

| 20 | 468,222 146,834 | 247,269 367,787 | 239,478 375,578 | 233,517 381,539 | 228,809 386,247 | 224,995 390,061 | 221,844 393,213 | 219,195 395,861 | 216,938 398,118 | 214,992 400,065 | 213,296 401,761 | 211,805 403,251 | 210,484 404,572 | 209,306 405,750 | 208,249 406,808 | 207,294 407,762 | 206,428 408,628 | |

| Thickness (cm) | Expanded Polystyrene (EPS) | Extruded Polystyrene (XPS) | Stone Wool | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Mat. | Aux. | App. | Total | Mat. | Aux. | App. | Total | ||

| 1 | 0.68 | 2.57 | 3.90 | 7.15 | 1.17 | 2.57 | 3.90 | 7.64 | 0.43 |

| 2 | 1.35 | 2.57 | 3.90 | 7.82 | 2.34 | 2.57 | 3.90 | 8.81 | 0.86 |

| 3 | 2.02 | 2.57 | 3.90 | 8.49 | 3.51 | 2.57 | 3.90 | 9.98 | 1.29 |

| 4 | 2.70 | 2.57 | 3.90 | 9.17 | 4.69 | 2.57 | 3.90 | 11.16 | 1.72 |

| 5 | 3.38 | 2.63 | 3.90 | 9.91 | 5.85 | 2.63 | 3.90 | 12.38 | 2.15 |

| 6 | 4.05 | 2.63 | 3.90 | 10.58 | 7.02 | 2.63 | 3.90 | 13.55 | 2.58 |

| 7 | 4.72 | 2.67 | 3.95 | 11.34 | 8.20 | 2.67 | 3.95 | 14.82 | 3.01 |

| 8 | 5.40 | 2.67 | 4.00 | 12.07 | 9.36 | 2.67 | 4.00 | 16.03 | 3.44 |

| 9 | 6.07 | 2.72 | 4.00 | 12.79 | 10.54 | 2.72 | 4.00 | 17.26 | 3.87 |

| 10 | 6.74 | 2.72 | 4.00 | 13.46 | 11.70 | 2.72 | 4.00 | 18.42 | 4.30 |

| 11 | 7.43 | 2.92 | 4.05 | 14.40 | 12.87 | 2.92 | 4.05 | 19.84 | 4.73 |

| 12 | 8.10 | 2.92 | 4.05 | 15.07 | 14.05 | 2.92 | 4.05 | 21.02 | 5.16 |

| 13 | 8.77 | 2.95 | 4.05 | 15.77 | 15.21 | 2.95 | 4.05 | 22.21 | 5.59 |

| 14 | 9.44 | 2.95 | 4.15 | 16.54 | 16.39 | 2.95 | 4.15 | 23.49 | 6.02 |

| 15 | 10.12 | 3.03 | 4.15 | 17.30 | 17.56 | 3.03 | 4.15 | 24.74 | 6.45 |

| 16 | 10.79 | 3.03 | 4.15 | 17.97 | 18.73 | 3.03 | 4.15 | 25.91 | 6.88 |

| 17 | 11.46 | 3.06 | 4.25 | 18.77 | 19.90 | 3.06 | 4.25 | 27.21 | 7.31 |

| 18 | 12.13 | 3.12 | 4.25 | 19.50 | 21.07 | 3.12 | 4.25 | 28.44 | 7.74 |

| 19 | 12.82 | 3.15 | 4.35 | 20.32 | 22.24 | 3.15 | 4.35 | 29.74 | 8.17 |

| 20 | 13.49 | 3.15 | 4.35 | 20.99 | 23.41 | 3.15 | 4.35 | 30.91 | 8.60 |

| Insulation | Year | NS (USD) | IRR (%) | SIR (-) | PBP (Years) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 5 | 13 | 17 | 20 | |||||

| Wall: none Ceiling: 8 cm | −16,672 | 3867 | 4447 | 6763 | 20,688 | 36,184 | 55,031 | 39,718 | 37.55 | 3.38 | 5–6 |

| Wall: 5 cm Ceiling: 8 cm | −37,140 | 10,284 | 11,827 | 17,987 | 55,024 | 96,237 | 146,364 | 112,838 | 42.30 | 4.04 | 4–5 |

| Wall: 5 cm Ceiling: 20 cm | −52,612 | 10,634 | 12,229 | 18,599 | 56,894 | 99,508 | 151,339 | 102,464 | 34.30 | 2.95 | 6–7 |

| Wall: 6 cm Ceiling: none | −21,854 | 6806 | 7827 | 11,904 | 36,414 | 63,689 | 96,863 | 77,401 | 45.88 | 4.54 | 3–4 |

| Wall: 8 cm Ceiling: 15 cm | −50,664 | 11,085 | 12,748 | 19,388 | 59,310 | 103,733 | 157,764 | 110,996 | 36.13 | 3.19 | 5–6 |

| Wall: 9 cm Ceiling: 8 cm | −43,101 | 10,933 | 12,573 | 19,123 | 58,497 | 102,311 | 155,603 | 116,344 | 39.86 | 3.70 | 4–5 |

| Wall: 9 cm Ceiling: 20 cm | −58,573 | 11,278 | 12,970 | 19,725 | 60,340 | 105,534 | 160,504 | 105,895 | 33.24 | 2.81 | 6–7 |

| Wall: 12 cm Ceiling: 15 cm | −56,852 | 11,429 | 13,144 | 19,990 | 61,150 | 106,951 | 162,660 | 109,824 | 34.19 | 2.93 | 6–7 |

| Wall: 18 cm Ceiling: 20 cm | −72,438 | 11,762 | 13,526 | 20,572 | 62,930 | 110,065 | 167,395 | 99,091 | 29.79 | 2.37 | 7–8 |

| Wall: 19 cm Ceiling: 14 cm | −66,400 | 11,686 | 13,439 | 20,439 | 62,525 | 109,356 | 166,317 | 104,023 | 31.37 | 2.57 | 6–7 |

| Exterior Wall Insulation Thickness (cm) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | ||

| Ceiling Insulation Thickness (cm) | 0 | 75,275 | 77,401 | 78,523 | 79,143 | 79,384 | 79,429 | 78,709 | 78,351 | 77,790 | 76,971 | 76,078 | 75,295 | 74,179 | 73,153 | 71,912 | 70,922 | |

| 8 | 39,718 | 112,838 | 114,762 | 115,723 | 116,212 | 116,344 | 116,299 | 115,500 | 115,074 | 114,454 | 113,583 | 112,643 | 111,819 | 110,666 | 109,606 | 108,335 | 108,169 | |

| 9 | 39,389 | 112,438 | 114,358 | 115,316 | 115,802 | 115,932 | 115,884 | 115,084 | 114,657 | 114,035 | 113,163 | 112,222 | 111,397 | 110,243 | 109,183 | 107,911 | 107,594 | |

| 10 | 38,957 | 111,947 | 113,863 | 114,819 | 115,303 | 115,431 | 115,382 | 114,580 | 114,151 | 113,529 | 112,656 | 111,714 | 110,889 | 109,734 | 108,672 | 107,400 | 106,969 | |

| 11 | 38,139 | 111,080 | 112,993 | 113,946 | 114,428 | 114,554 | 114,504 | 113,701 | 113,271 | 112,648 | 111,774 | 110,832 | 110,005 | 108,850 | 107,788 | 106,516 | 105,996 | |

| 12 | 37,472 | 110,370 | 112,281 | 113,231 | 113,712 | 113,837 | 113,785 | 112,981 | 112,551 | 111,927 | 111,052 | 110,109 | 109,283 | 108,127 | 107,065 | 105,791 | 105,202 | |

| 13 | 36,708 | 109,569 | 111,477 | 112,426 | 112,906 | 113,029 | 112,977 | 112,172 | 111,741 | 111,116 | 110,241 | 109,297 | 108,470 | 107,314 | 106,251 | 104,978 | 104,332 | |

| 14 | 35,797 | 108,626 | 110,532 | 111,480 | 111,958 | 112,081 | 112,027 | 111,221 | 110,789 | 110,164 | 109,288 | 108,345 | 107,517 | 106,360 | 105,297 | 104,023 | 103,331 | |

| 15 | 34,868 | 107,668 | 109,573 | 110,519 | 110,996 | 111,118 | 111,063 | 110,257 | 109,824 | 109,199 | 108,322 | 107,378 | 106,550 | 105,393 | 104,330 | 103,056 | 102,326 | |

| 16 | 33,968 | 106,743 | 108,646 | 109,591 | 110,067 | 110,188 | 110,133 | 109,326 | 108,893 | 108,267 | 107,390 | 106,445 | 105,617 | 104,460 | 103,396 | 102,122 | 101,360 | |

| 17 | 32,909 | 105,661 | 107,563 | 108,507 | 108,982 | 109,102 | 109,047 | 108,239 | 107,806 | 107,179 | 106,302 | 105,357 | 104,529 | 103,371 | 102,307 | 101,033 | 100,244 | |

| 18 | 31,894 | 104,625 | 106,526 | 107,469 | 107,943 | 108,063 | 108,006 | 107,198 | 106,764 | 106,137 | 105,260 | 104,315 | 103,486 | 102,328 | 101,264 | 99,990 | 99,178 | |

| 19 | 30,768 | 103,481 | 105,381 | 106,323 | 106,796 | 106,915 | 106,858 | 106,050 | 105,616 | 104,989 | 104,111 | 103,166 | 102,336 | 101,178 | 100,114 | 98,839 | 97,818 | |

| 20 | 29,768 | 102,464 | 104,362 | 105,304 | 105,777 | 105,895 | 105,838 | 105,029 | 104,594 | 103,967 | 103,089 | 102,143 | 101,314 | 100,156 | 99,091 | 97,816 | 96,795 | |

| No | Interest Rate | Inflation Rate | Optimum Thickness | Financial Parameters | ||||

|---|---|---|---|---|---|---|---|---|

| Wall | Ceiling | NS (USD) | IRR | SIR | PBP | |||

| 1 | %15 | %13 | 9 cm | 8 cm | 118,680 | 37.89% | 3.75 | 4–5 years |

| 2 | %15 | %15 | 10 cm | 8 cm | 147,259 | 39.24% | 4.31 | 4–5 years |

| 3 | %15 | %17 | 10 cm | 8 cm | 182,503 | 41.21% | 5.10 | 4–5 years |

| 4 | %17 | %13 | 8 cm | 8 cm | 94,015 | 38.57% | 3.26 | 4–5 years |

| 5 | %17 | %15 | 9 cm | 8 cm | 116,344 | 39.86% | 3.70 | 4–5 years |

| 6 | %17 | %17 | 10 cm | 8 cm | 143,982 | 41.21% | 4.24 | 4–5 years |

| 7 | %19 | %13 | 7 cm | 8 cm | 74,707 | 39.24% | 2.86 | 4–5 years |

| 8 | %19 | %15 | 8 cm | 8 cm | 92,401 | 40.54% | 3.22 | 4–5 years |

| 9 | %19 | %17 | 9 cm | 8 cm | 114,074 | 41.83% | 3.65 | 4–5 years |

| No | Interest Rate | Inflation Rate | Optimum Thickness | Financial Parameters | ||||

|---|---|---|---|---|---|---|---|---|

| Wall | Ceiling | NS (USD) | IRR | SIR | PBP | |||

| 1 | %15 | %13 | 9 cm | 11 cm | 142,007 | 50.25% | 5.53 | 3–4 years |

| 2 | %15 | %15 | 10 cm | 12 cm | 172,673 | 50.51% | 6.20 | 3–4 years |

| 3 | %15 | %17 | 10 cm | 14 cm | 210,586 | 51.68% | 7.18 | 3–4 years |

| 4 | %17 | %13 | 8 cm | 10 cm | 115,587 | 52.24% | 4.93 | 3–4 years |

| 5 | %17 | %15 | 9 cm | 11 cm | 139,504 | 52.24% | 5.45 | 3–4 years |

| 6 | %17 | %17 | 10 cm | 12 cm | 169,154 | 52.49% | 6.10 | 3–4 years |

| 7 | %19 | %13 | 7 cm | 10 cm | 94,948 | 53.90% | 4.40 | 3–4 years |

| 8 | %19 | %15 | 8 cm | 10 cm | 113,861 | 54.23% | 4.87 | 3–4 years |

| 9 | %19 | %17 | 9 cm | 11 cm | 137,072 | 54.22% | 5.37 | 3–4 years |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaya, R.; Caglayan, S. Potential Benefits of Thermal Insulation in Public Buildings: Case of a University Building. Buildings 2023, 13, 2586. https://doi.org/10.3390/buildings13102586

Kaya R, Caglayan S. Potential Benefits of Thermal Insulation in Public Buildings: Case of a University Building. Buildings. 2023; 13(10):2586. https://doi.org/10.3390/buildings13102586

Chicago/Turabian StyleKaya, Reyhan, and Semih Caglayan. 2023. "Potential Benefits of Thermal Insulation in Public Buildings: Case of a University Building" Buildings 13, no. 10: 2586. https://doi.org/10.3390/buildings13102586

APA StyleKaya, R., & Caglayan, S. (2023). Potential Benefits of Thermal Insulation in Public Buildings: Case of a University Building. Buildings, 13(10), 2586. https://doi.org/10.3390/buildings13102586