Stabilization of Fluidic Silty Sands with Cement and Steel Slag

Abstract

:1. Introduction

2. Materials

2.1. Fluidic Soil

2.2. Cement

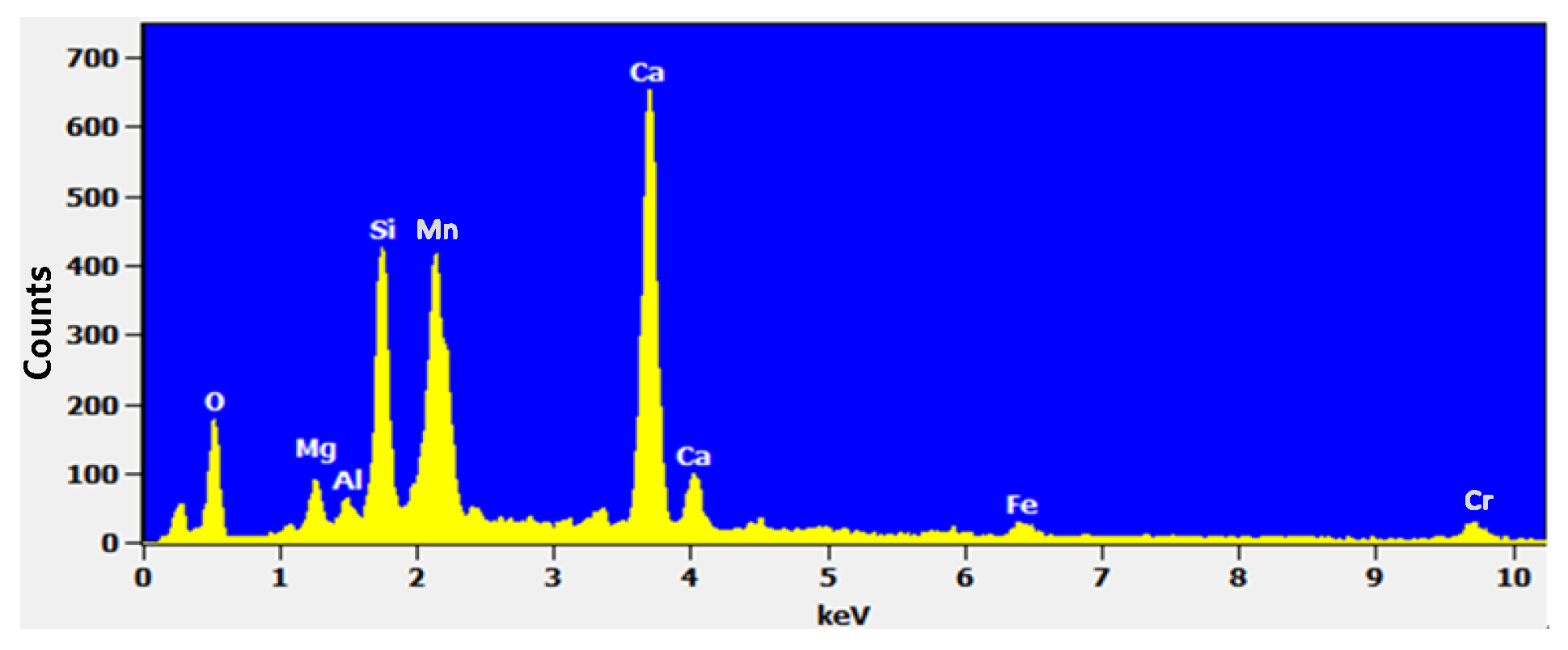

2.3. Steel Slag

3. Test Design

3.1. Test Scheme

3.1.1. Mechanical Strength Tests

3.1.2. Microscopic Tests

3.2. Specimen Preparation

4. Results and Analysis

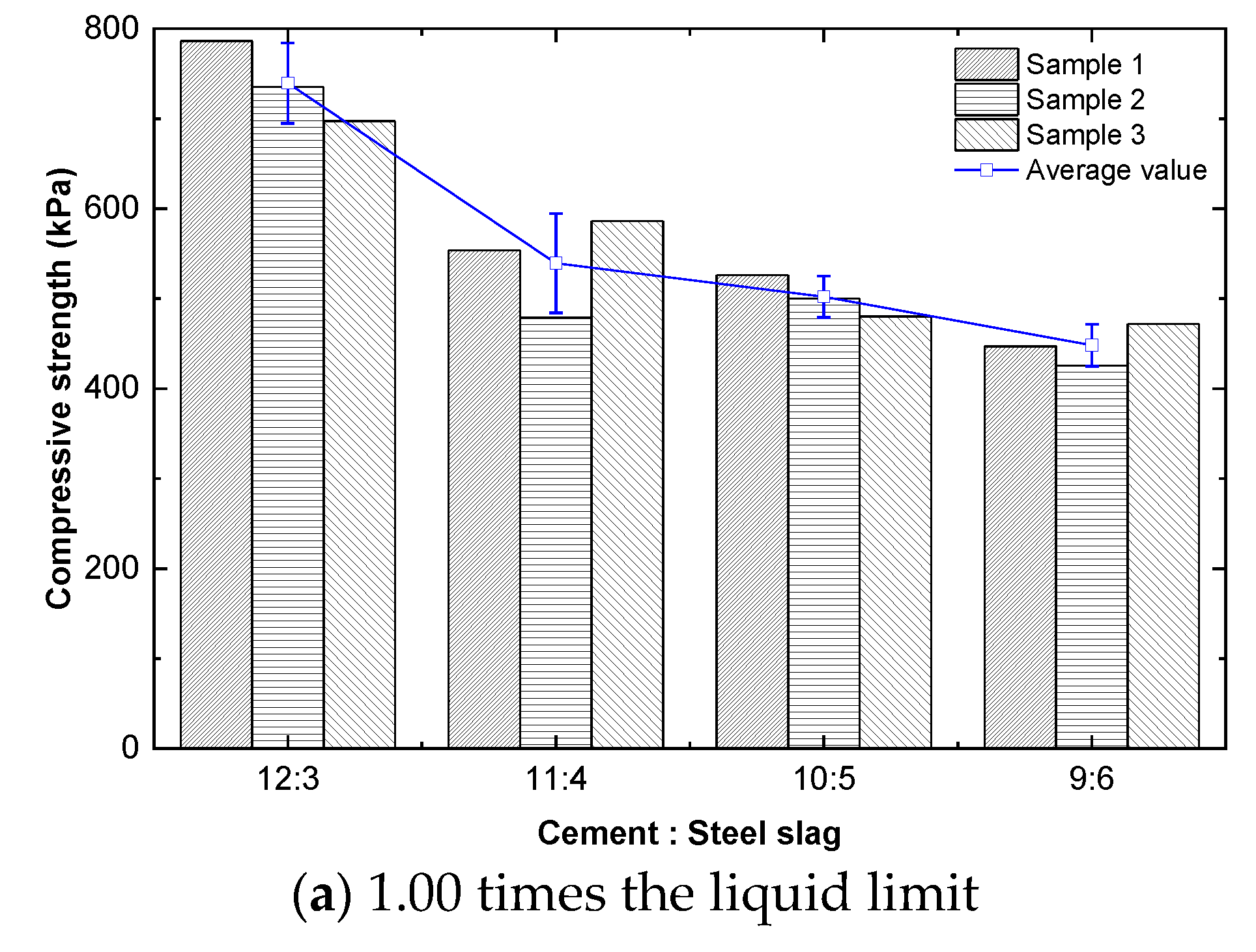

4.1. Optimum Mixing Ratio Analysis

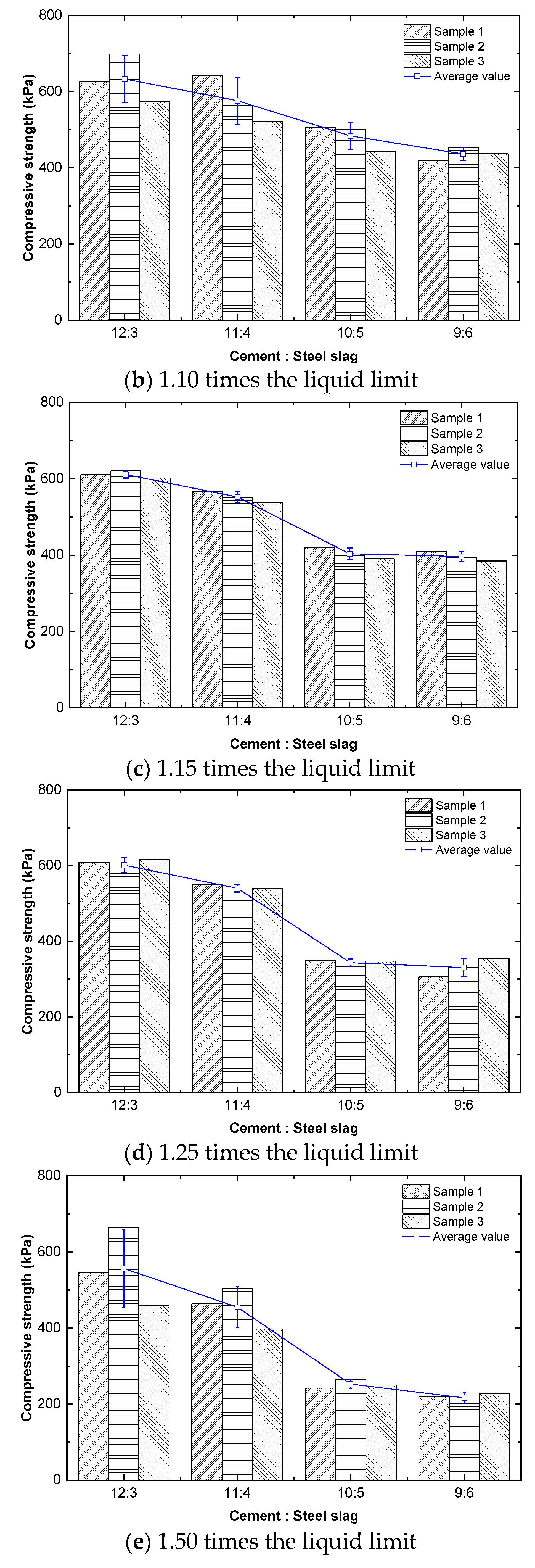

4.2. Influence of Initial Water Content on the Mechanical Performance of CSFSS

4.3. Influence of Curing Age on the Mechanical Performance of CSFSS

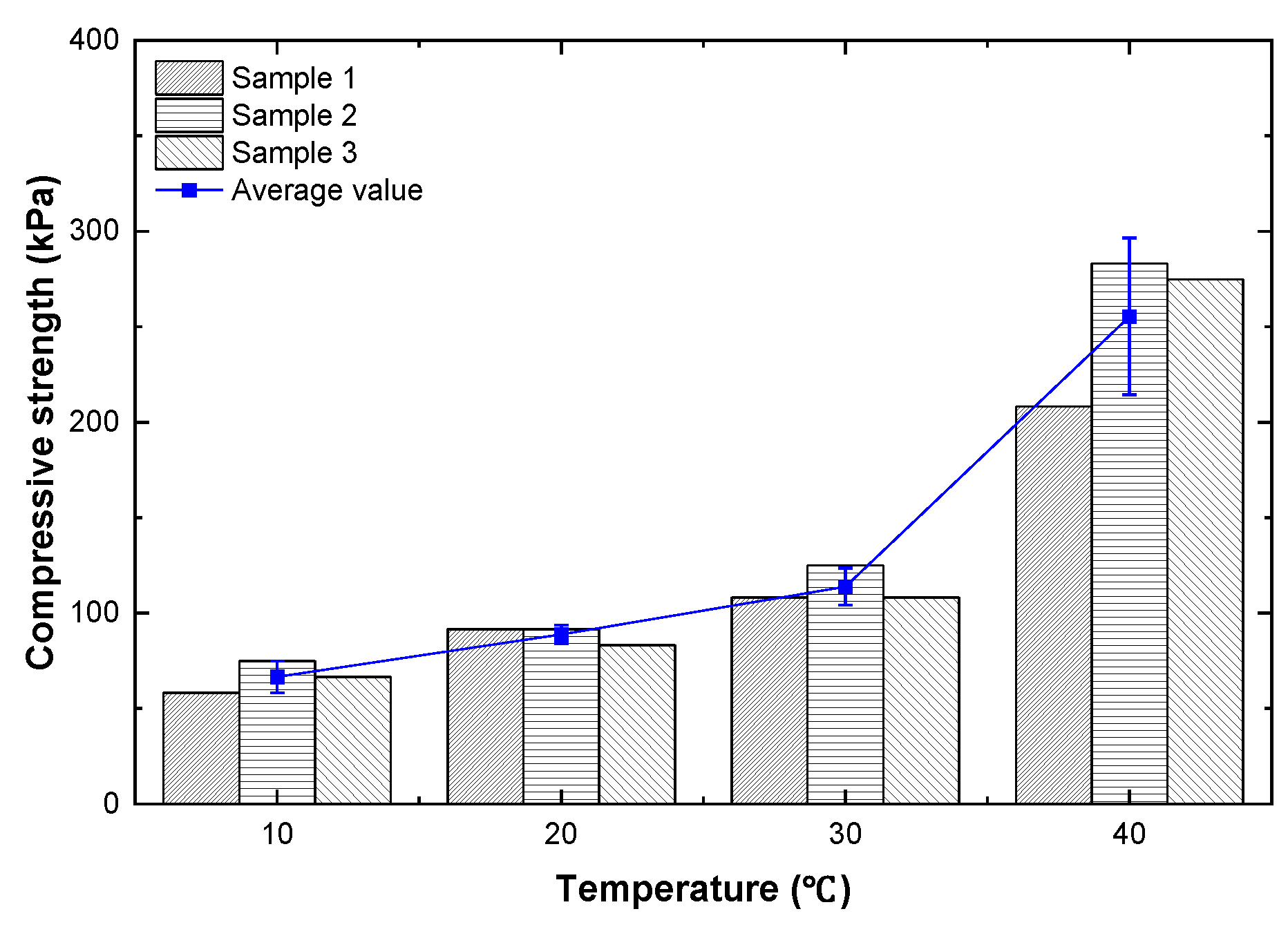

4.4. Influence of Curing Temperature on the Mechanical Performance of CSFSS

5. Discussion

5.1. Stabilization Mechanism

5.2. Reaction Mechanisms

5.2.1. XRD Pattern

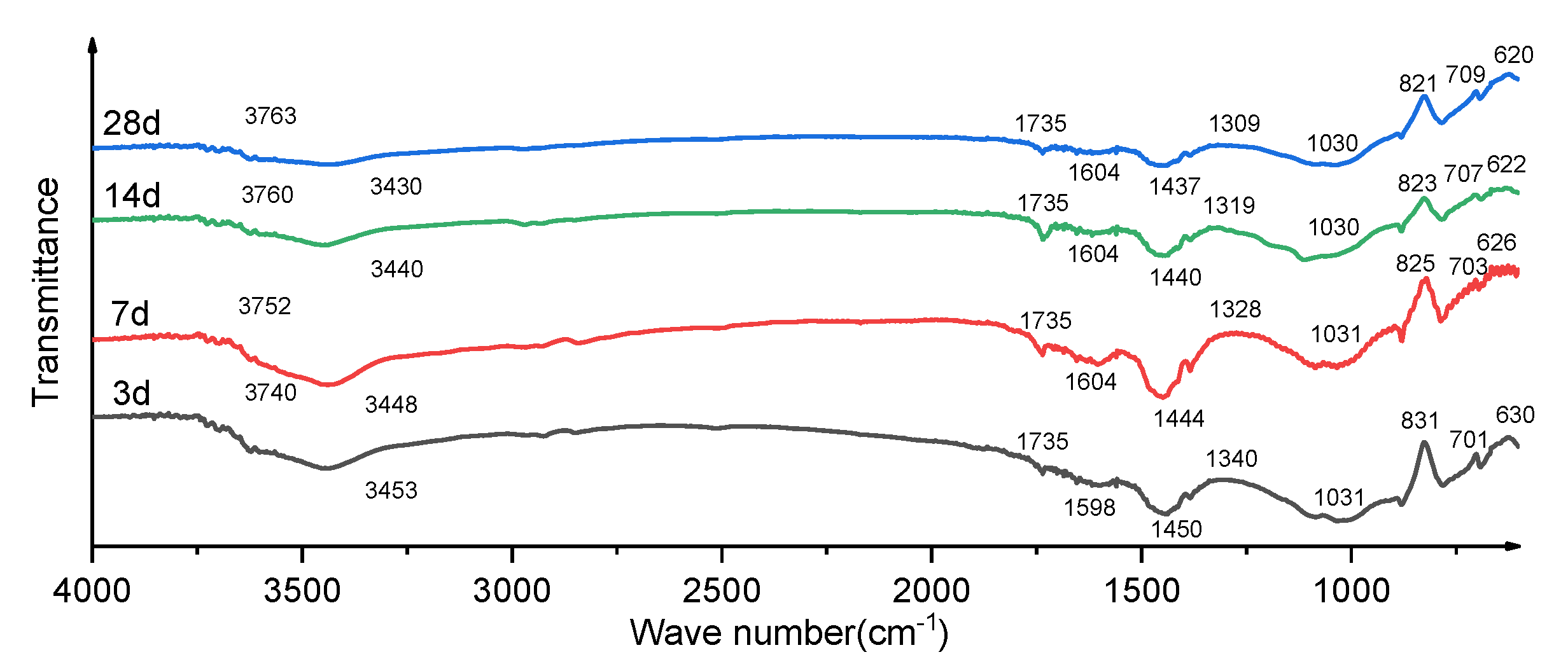

5.2.2. FTIR Spectra

6. Conclusions

- (1)

- Considering the minimum engineering requirement of greater than 100 kPa and the economic and environmental benefits, the optimum cement/steel slag ratio could be 9:6, regardless of the initial water content. Meanwhile, controlling the initial water content of fluidic silty sands before they are stabilized is significant for engineering practices.

- (2)

- Adding steel slag was more conducive to fluidic silty sands’ early strength improvement. A high temperature accelerated the production of more CSH/CAH gels. Therefore, appropriate curing conditions would favor the mechanical performance development of CSFSS.

- (3)

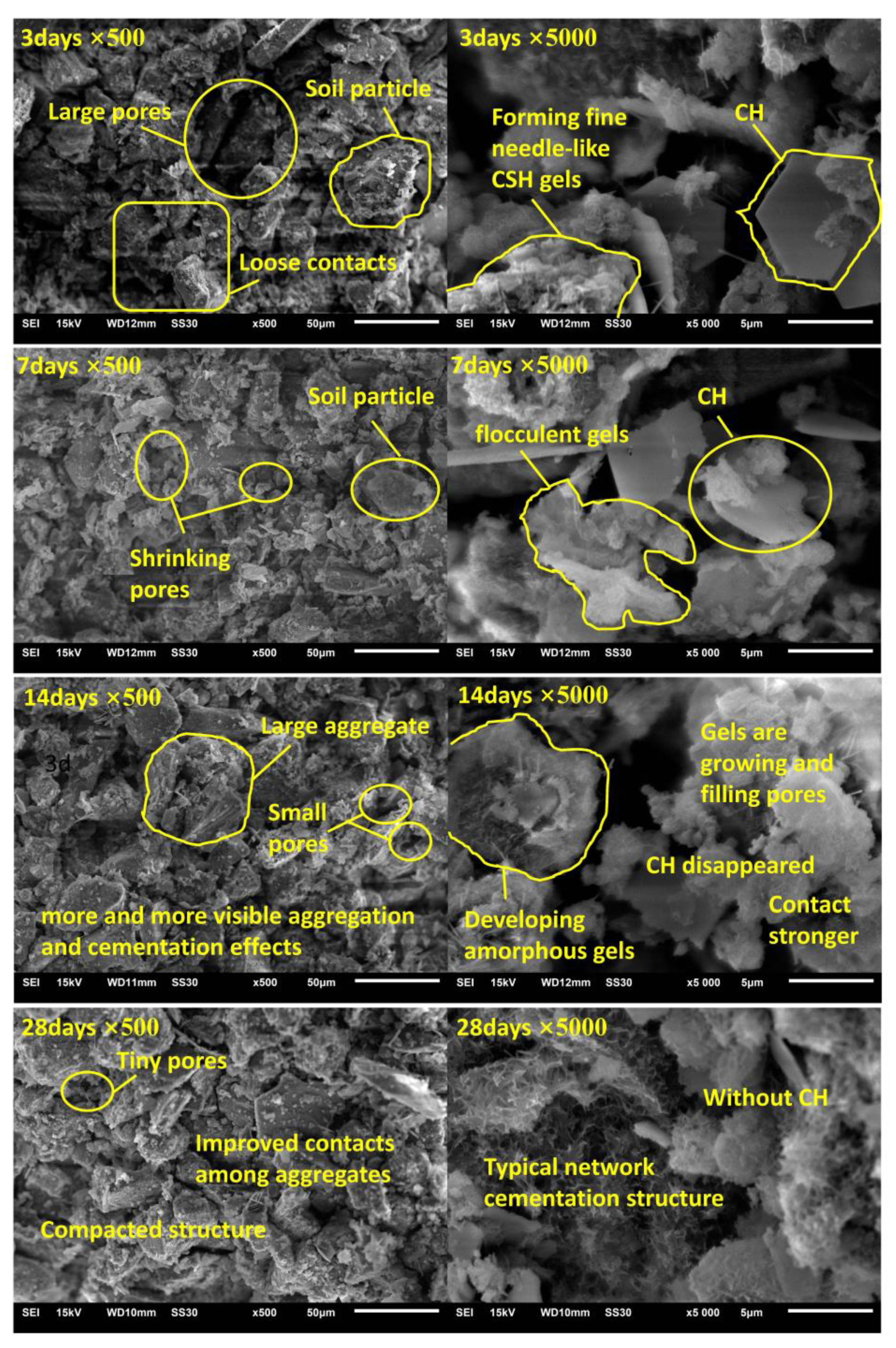

- With the development of the curing age, the large pores in the fluidic silty sands shrunk into tiny pores, and their previous loose structures were significantly integrated and compacted. That proved the contributions of cement and steel slag to the mechanical performance improvement of fluidic silty sands. The CH appeared first and then disappeared, indicating that the steel slag should have a pozzolanic reaction with the by-products of cement hydration.

- (4)

- The addition of steel slag could positively affect the formation of gel materials in cement-stabilized fluidic silty sands. The detected OH and CH vibration peaks indicated that cement hydration and pozzolanic reactions occurred during the soil stabilization. The outcomes of this study could provide a reference for the engineering application of CSFSS.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, T. Mechanism and application of impact compaction in foundation stabilization of hydraulic reclaimed silty fine sand ground. J. Univ. Sci. Technol. Beijing 2010, 32, 536–542. [Google Scholar]

- Kim, Y.T.; Ahn, J.; Han, W.J.; Gabr, M.A. Experimental Evaluation of Strength Characteristics of Stabilized Dredged Soil. J. Mater. Civ. Eng. 2010, 22, 539–544. [Google Scholar] [CrossRef]

- Toda, K.; Sato, H.; Weerakoon, N.; Otake, T.; Nishimura, S.; Sato, T. Key Factors Affecting Strength Development of Steel Slag-Dredged Soil Mixtures. Minerals 2018, 8, 174. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.; Shi, C.; Pan, S. Characteristics of steel slags and their use in cement and concrete—A review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Zeng, L.; Bian, X.; Zhao, L.; Wang, Y.; Hong, Z. Effect of phosphogypsum on physiochemical and mechanical behaviour of cement stabilized dredged soil from Fuzhou, China. Geomech. Energy Environ. 2021, 25, 100195. [Google Scholar] [CrossRef]

- Liu, M.; Dong, Y.; Zang, M.; Cai, G.; Lu, H. Experimental Study on Solidified Lake Sediment Based on Industrial Solid Waste and Construction Waste: Stabilization and Mechanism. Buildings 2023, 13, 2053. [Google Scholar] [CrossRef]

- Lang, L.; Song, C.; Xue, L.; Chen, B. Effectiveness of waste steel slag powder on the strength development and associated micro-mechanisms of cement-stabilized dredged sludge. Constr. Build. Mater. 2020, 240, 117975. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Raksachon, Y. Role of Fly Ash on Strength and Microstructure Development in Blended Cement Stabilized Silty Clay. Soils Found. 2009, 49, 85–98. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Chen, B. Strength evolutions of varying water content-dredged sludge stabilized with alkali-activated ground granulated blast-furnace slag. Constr. Build. Mater. 2021, 275, 122111. [Google Scholar] [CrossRef]

- Ma, C.; Chen, L.; Chen, B. Experimental Study of Effect of Fly Ash on Self-Compacting Rammed Earth Construction Stabilized with Cement-Based Composites. J. Mater. Civ. Eng. 2016, 28, 04016022. [Google Scholar] [CrossRef]

- Xie, G.; Tao, C.; Shen, X. Influence of silica fume on early strength of middle and low-dosage of cement soil. Concrete 2012, 88–90. [Google Scholar] [CrossRef]

- Aziz, M.; Hamza, M.; Rasool, A.M.; Ali, U.; Ahmed, T.; Kharal, Z.N.; Khan, A.H.; Rehman, Z.U. Use of Graphene Oxide Nanomaterial to Improve Mechanical Properties of Cement-Treated Silty Soil. Arab. J. Sci. Eng. 2023, 48, 5603–5618. [Google Scholar] [CrossRef]

- Gupta, A.; Arora, V.K.; Biswas, S. Contaminated dredged soil stabilization using cement and bottom ash for use as highway subgrade fill. Int. J. Geo-Eng. 2017, 8, 1–13. [Google Scholar] [CrossRef]

- Dungca, J.R.; Lao, W.D.T.; Lim, M.; Lu, W.D.; Redelicia, J.C.P. Vertical permeability of dredged soil stabilized with fly-ash based geopolymer for road embankment. Int. J. Geomate 2019, 16, 8–14. [Google Scholar] [CrossRef]

- Ingunza, M.P.D.; de Araújo Pereira, K.L.; Junior, O.F.D.S. Use of sludge ash as a stabilizing additive in soil-cement mixtures for use in road pavements. J. Mater. Civ. Eng. 2015, 27, 6014027. [Google Scholar] [CrossRef]

- Yun, J.; Song, Y.; Lee, J.; Kim, T. Strength characteristics of the cement-stabilized surface layer in dredged and reclaimed marine clay, Korea. Mar. Georesources Geotechnol. 2006, 24, 29–45. [Google Scholar] [CrossRef]

- Marzano, I.P.; Al-Tabbaa, A.; Grisolia, M. Influence of Curing Temperature on the Strength of Cement-Stabilisedartificial Clays. In Proceedings of the 2nd International Workshop on Geotechnics of Soft Soils, Glasgow, Germany, 3–5 September 2008; pp. 257–262. [Google Scholar]

- Zhang, R.J.; Lu, Y.T.; Tan, T.S.; Phoon, K.K.; Santoso, A.M. Long-term effect of curing temperature on the strength behavior of cement-stabilized clay. J. Geotech. Geoenviron. 2014, 140, 4014045. [Google Scholar] [CrossRef]

- Lu, L.; Ma, Q.; Hu, J.; Li, Q. Mechanical Properties, Curing Mechanism, and Microscopic Experimental Study of Polypropylene Fiber Coordinated Fly Ash Modified Cement–Silty Soil. Materials 2021, 14, 5441. [Google Scholar] [CrossRef]

- Bahmani, S.H.; Huat, B.B.K.; Asadi, A.; Farzadnia, N. Stabilization of residual soil using SiO2 nanoparticles and cement. Constr. Build. Mater. 2014, 64, 350–359. [Google Scholar] [CrossRef]

- Chae, S.R.; Moon, J.; Yoon, S.; Farzadnia, N. Advanced Nanoscale Characterization of Cement Based Materials Using X-Ray Synchrotron Radiation: A Review. Int. J. Concr. Struct. Mater. 2013, 7, 95–110. [Google Scholar] [CrossRef]

- Zhang, T.-S.; Liu, F.-T.; Liu, S.-Q.; Zhou, Z.-H.; Cheng, X.; Odler, I.; Hinrichs, W.; Bland, C.H.; Sharp, J.H.; Barker, A.P.; et al. Factors influencing the properties of a steel slag composite cement. Adv. Cem. Res. 2008, 20, 145–150. [Google Scholar] [CrossRef]

- Dong, Q.; Wang, G.; Chen, X.; Tan, J.; Gu, X. Recycling of steel slag aggregate in portland cement concrete: An overview. J. Clean. Prod. 2020, 282, 124447. [Google Scholar] [CrossRef]

- Mozejko, C.A.; Francisca, F.M. Enhanced mechanical behavior of compacted clayey silts stabilized by reusing steel slag. Constr. Build. Mater. 2020, 239, 117901. [Google Scholar] [CrossRef]

- Yong-Feng, D.; Tong-Wei, Z.; Yu, Z.; Qian-Wen, L.; Qiong, W. Mechanical behaviour and microstructure of steel slag-based composite and its application for soft clay stabilisation. Eur. J. Environ. Civ. Eng. 2017, 1–16. [Google Scholar] [CrossRef]

- Wu, Y.; Shi, K.; Yu, J.; Han, T.; Li, D. Research on Strength Degradation of Soil Solidified by Steel Slag Powder and Cement in Seawater Erosion. J. Mater. Civ. Eng. 2020, 32, 4020181. [Google Scholar] [CrossRef]

- GB/T 50123-201; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019. (In Chinese)

- Hossain, M.B.; Barman, Z.; Dey, M. Properties of locally available river dredged soil stabilized with cement. Progress. Agric. 2021, 32, 71–77. [Google Scholar] [CrossRef]

- Boardman, D.I.; Rogers, C.D.F.; Glendinning, S. Development of stabilisation and solidification in lime-clay mixes. Geotechnique 2001, 51, 533–543. [Google Scholar] [CrossRef]

- Rao, S.M.; Shivananda, P. Role of curing temperature in progress of lime-soil reactions. Geotech. Geol. Eng. 2005, 23, 79–85. [Google Scholar] [CrossRef]

- Wang, S.; Su, J.; Wu, Z.; Ma, W.; Li, Y.; Hui, H. Silty Clay Stabilization Using Metakaolin-Based Geopolymer Binder. Front. Phys-Lausanne 2021, 9, 769786. [Google Scholar] [CrossRef]

- Wang, S.; Xue, Q.; Zhu, Y.; Li, G.; Wu, Z.; Zhao, K. Experimental study on material ratio and strength performance of geopolymer-improved soil. Constr. Build. Mater. 2020, 267, 120469. [Google Scholar] [CrossRef]

- Tanaka, H.; Sakai, Y.; Hino, R. Formation of Na-A and -X zeolites from waste solutions in conversion of coal fly ash to zeolites. Mater. Res. Bull. 2002, 37, 1873–1884. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Z.; Wang, Y.; Feng, J. Preparation and Properties of Alkali Activated Metakaolin-Based Geopolymer. Materials 2016, 9, 767. [Google Scholar] [CrossRef] [PubMed]

- Kamruzzaman, A.H.M.; Chew, S.H.; Lee, F.H. Microstructure of cement-treated Singapore marine clay. Proc. Inst. Civ. Eng.–Ground Improv. 2006, 10, 113–123. [Google Scholar] [CrossRef]

- Santos, V.H.J.M.; Pontin, D.; Ponzi, G.G.D.; Stepanha, A.S.d.G.e.; Martel, R.B.; Schütz, M.K.; Einloft, S.M.O.; Vecchia, F.D. Application of Fourier Transform infrared spectroscopy (FTIR) coupled with multivariate regression for calcium carbonate (CaCO3) quantification in cement. Constr. Build. Mater. 2021, 313, 125413. [Google Scholar] [CrossRef]

| Soil | Natural Water Content (%) | Specific Gravity | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index |

|---|---|---|---|---|---|

| Silty sand | 43.6 | 2.7 | 40.2 | 24.3 | 15.9 |

| Chemical Components | CaO | SiO2 | Al2O3 | Fe2O3 | MgO |

|---|---|---|---|---|---|

| Mass ratio (%) | 57.4 | 21.7 | 7.5 | 2.9 | 1.7 |

| Chemical Components | CaO | SiO2 | MgO | Al2O3 | Fe2O3 |

|---|---|---|---|---|---|

| Mass ratio (%) | 59.2 | 29.1 | 3.9 | 1.4 | 6.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, L.; Deng, X.; Zhang, M.; Wang, S.; Li, B.; Ji, J. Stabilization of Fluidic Silty Sands with Cement and Steel Slag. Buildings 2023, 13, 2705. https://doi.org/10.3390/buildings13112705

Gu L, Deng X, Zhang M, Wang S, Li B, Ji J. Stabilization of Fluidic Silty Sands with Cement and Steel Slag. Buildings. 2023; 13(11):2705. https://doi.org/10.3390/buildings13112705

Chicago/Turabian StyleGu, Leilei, Xianjun Deng, Mei Zhang, Shengnian Wang, Bin Li, and Jiufa Ji. 2023. "Stabilization of Fluidic Silty Sands with Cement and Steel Slag" Buildings 13, no. 11: 2705. https://doi.org/10.3390/buildings13112705

APA StyleGu, L., Deng, X., Zhang, M., Wang, S., Li, B., & Ji, J. (2023). Stabilization of Fluidic Silty Sands with Cement and Steel Slag. Buildings, 13(11), 2705. https://doi.org/10.3390/buildings13112705