Barriers and Enablers to the Adoption of Circular Economy Concept in the Building Sector: A Systematic Literature Review

Abstract

:1. Introduction

- What are the key barriers that hinder the progress of transitioning towards a CE within the building sector?

- What strategies can be employed to overcome such barriers and enhance the transition to a CE?

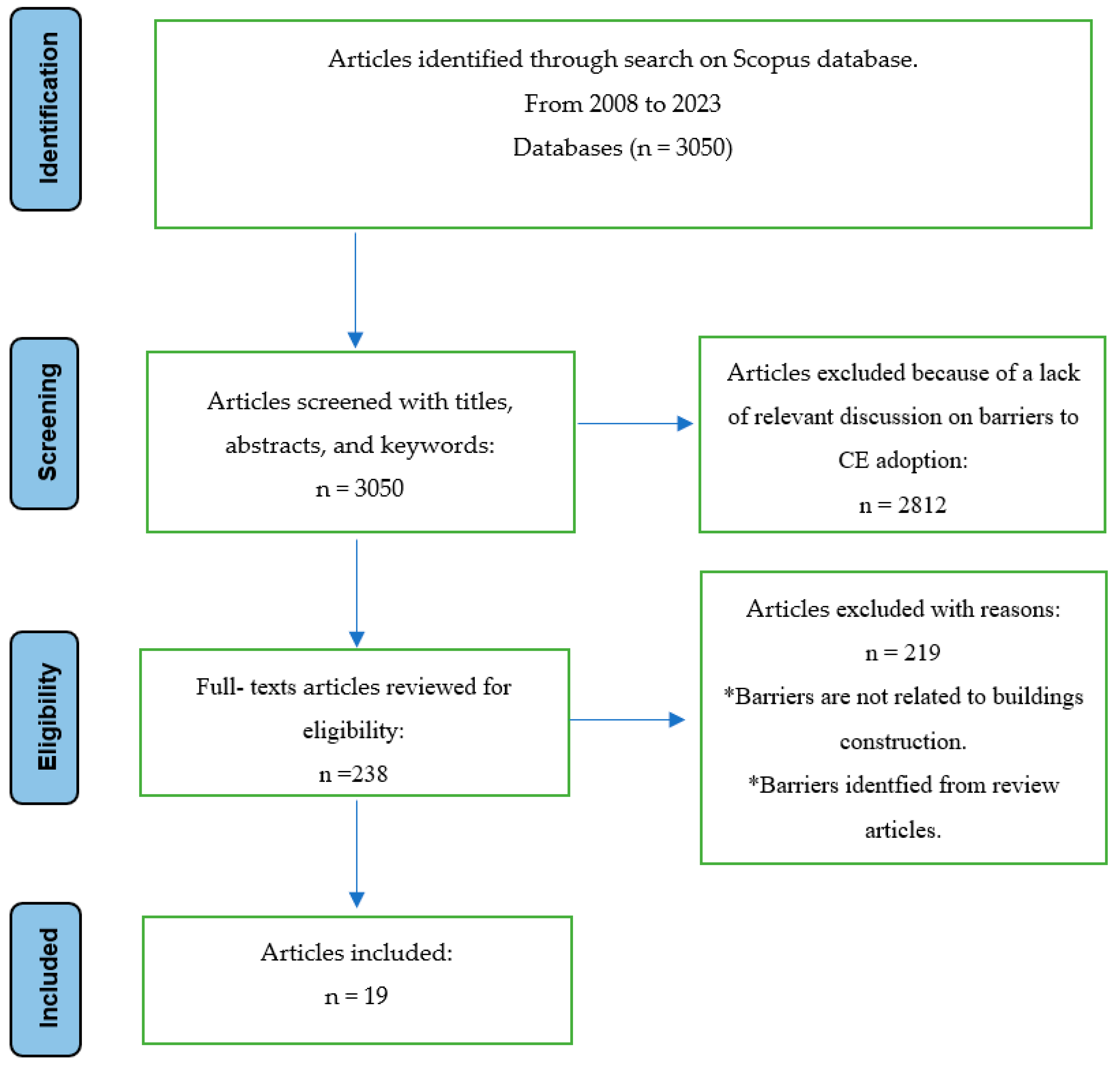

2. Methods

2.1. Research Strategy

2.2. Data Collection

2.3. Data Analysis

3. Results and Discussions

3.1. Data Analysis

Yearly Distribution of the Studies

3.2. Barrier’s Analysis

3.3. Barrier’s Explanation

3.3.1. Awareness Barriers

- Limited knowledge of CE: The lack of knowledge in CE concepts, principles, and potential benefits among stakeholders and policymakers is the second most cited barrier in the awareness category. Adams et al.’s [14] survey findings showed that the level of knowledge in CE is low among clients, designers, and subcontractors. Shooshtarian et al. [18] added that the level of awareness among stakeholders significantly influences various aspects, such as willingness to adopt CE, consensus on viewing CE as part of business ethics, and acknowledgement of CE benefits. Awareness in CE is essential to show its economic and environmental benefits to motivate stakeholders to adopt CE practices. Without this knowledge, stakeholders may overlook the potential economic and environmental gains, missing the opportunity to create more circular and profitable outcomes.

- Lack of CE vision: A CE vision serves as a guiding framework, offering a clear strategic direction with specific objectives and measurable targets. The transition to a CE requires a strategic framework that outlines specific objectives and measurable targets to guide actions and monitor progress [35]. Mahpour et al. [15] studied the CE barriers in construction and demolition waste management. They stated that a lack of a well-defined vision to move towards CE in C&D waste management leads to uncertainty and demotivation for stakeholders to participate in CE practices. Hart et al. [16] highlighted the CE challenges in the built environment and claimed that there is an absence of a coherent vision for CE in the industry that influences decision making towards CE. Unclear CE goals and strategies can discourage stakeholders, who may question the feasibility and practicality of CE practices. Without a coherent vision, decision makers may lack a common understanding of CE’s values and principles.

- Fragment supply chain: Clear communication and coordination towards a common goal between all parts of the supply chain is critical for a CE to work efficiently [36]. The absence of communication and a comprehensive approach within the supply chain has been significant [14,21]. According to Dunant et al. [25], the refusal of a single participant in the supply chain to embrace the reuse of steel can prevent the entire project from progressing. This issue leads to missed opportunities for reuse, recycling, and material recovery. If the supply chain fails to establish effective communication, the successful implementation of a CE within the project’s lifecycle may be compromised.

- Lack of case studies: Case studies are critical as they provide real-world examples of successful implementation that encourage stakeholders to adopt new practices. The absence of evidence showing the economic benefits of design for deconstruction hinders its implementation [23]. Rios et al. [13] emphasised the need to develop more life cycle cost case studies. Without solid case studies, stakeholders would have limited evidence to demonstrate the feasibility and benefits of adopting CE principles in building projects. This lack of evidence can make decision makers hesitant to invest in or implement these practices.

- Lack of adequate information in building design: A significant barrier related to the reuse of building materials and components is the absence of data about their quantity, condition, and availability [37]. Tingley et al. [24] claimed that there is insufficient data regarding the existing structure and the materials. The absence of data regarding the safe and effective reuse of materials hinders stakeholder in making informed decisions, leading to a disincentive to adopt circular economy practices. Furthermore, the lack of data on the availability and sources of reclaimed materials can lead to a poor and inefficient supply chain.

3.3.2. Technical Barriers

- Building complexity: Buildings are complicated due to their multi-layered composite structure such as steel-reinforced concrete components and inaccessible joints, and they undergo modifications over time, making it difficult to comprehend from a CE standpoint how to recover the steel or other reusable elements. According to Couto and Couto [38], it can be technically difficult to manage the dismantling, sorting, and recycling of these different materials. Furthermore, the size of construction materials, jointing techniques that do not ease disassembly, and the complexity of material composition are frequent design issues [39]. The difficulties involved with detaching bricks, particularly when combined with Ordinary Portland Cement, and the reuse of reinforced concrete parts are more common [16]. Building data management is challenging due to its complexity [29,40]. Missing or inaccurate building data during the design phase inhibits efficient life cycle assessment (LCA) for the end-of-life phase [41].

- Quality of materials at EOL: The poor quality of building materials as they approach the end of their useful life might be an obstacle to the implementation of CE in the building sector. When construction materials reach the end of their useful life, their quality, condition, and readiness for reuse or recycling can have a substantial influence on their circularity potential [16]. Reusing materials frequently necessitates that they be in good condition and suitable for the intended purpose. Poor-quality materials may not match these standards, limiting their recyclability. Another difficulty is that material deterioration on-site during disassembly might render certain components useless. It is caused by incorrect deconstruction procedures due to a lack of adequate training and/or buildings created without taking the deconstruction process into account [42].

- Policy and regulatory: Inadequate regulations and management policies impede the achievement of a zero-waste society and exacerbate the development gap in the CE [15]. The construction industry is governed by a plethora of regulations, standards, and norms that vary by location and authority. These regulations’ inconsistencies and contradictions might cause confusion and impede the adoption of circular practices. The lack of CE-specific regulation was regarded as a significant constraint [22]. Luciano et al. [30] added that the ambiguous end-of-waste rules, as well as a lack of CE-specific legislation, pose significant challenges to CE implementation. Unclear policies create uncertainty and ambiguity regarding CE regulations regarding the rules and regulations governing CE practices. This uncertainty can deter businesses and investors from committing to CE initiatives, as they may be unsure about compliance requirements and the legal framework for operating in a circular manner.

- Lacking standardisation/classification/certification/traceability/quality assurance: Material standardisation, classification, and certification play a crucial role in establishing consistent frameworks and guidelines for circular practices. The absence of standardised methodologies and criteria make the assessment of circularity performance for different buildings or construction projects challenging. The absence of recognised certification schemes for circular products can hinder trust in the market. The quality and performance of materials and products through their lifecycles is essential. If there is a lack of quality assurance processes, there may be concerns about the durability, safety, and reliability of reused or recycled materials. This can deter stakeholders from adopting circular practices due to uncertainty about the long-term performance of circular building components. Moreover, traceability is crucial to understand the origin, composition, and lifecycle of materials and products. It ensures that materials can be properly tracked, assessed for their circularity, and safely reused or recycled. Without robust traceability systems, it becomes challenging to validate claims about the circularity of materials and to ensure they meet the required standards [30].

- Lack of flexibility: Building codes are rigid and prescriptive, often favouring traditional linear construction practices rather than adopting circular principles. The inflexibility of building codes can limit innovation and hinder the adoption of circular strategies such as adaptive reuse, deconstruction, and material recovery. According to Kanters [21], there is a lack of flexibility in building codes and regulations as design codes generally favour specifying new materials.

- Lack of CE metrics/tools/design: The absence of adequate measures and tools analysing the circularity of buildings becomes a challenging task. The absence of standardised indicators and performance measures for circularity makes it difficult to assess the environmental, social, and economic impacts of construction projects. To promote the widespread adoption of deconstruction, it is crucial to develop suitable tools and techniques for the safe and cost-effective removal of structural components. These tools serve as a necessary prerequisite for facilitating the dismantling process while ensuring safety and economic viability [38]. Benites et al. [33] asserted that current tools (LEED, Green Star, BREEAM) are inadequate in promoting and accelerating circular and regenerative practices in the built environment.

3.3.3. Economic and Market Barriers

- Lack of market mechanisms for recovery: This refers to the absence of efficient and effective mechanisms that enable the recovery and reuse of materials and products in the market. Currently, the availability of markets for reclaimed materials is limited [43], which results in unpredictable fluctuations in the unit cost of reclaimed components [44]. Dunant et al. [25] asserted that there is an absence of a substantial market to sell reused steel, as it is primarily limited to being sold as scrap. The success of building deconstruction and the reuse of components is linked to the availability of distribution points for material sale [23]. The absence of an efficient reused materials market can drive increased demand for resource extraction and the production of new materials to meet market needs, consequently depleting valuable resources and resulting in inefficient resource management.

- Cost of virgin materials: The selection of materials is influenced by cost rather than environmental benefits [27]. According to Essoussi and Linton [45], recycling is more expensive than using virgin materials, while Watson [46] believes recycled materials are cheaper. Nevertheless, Addis [47] stated that the price of recycled products cannot be predicted compared to their virgin counterparts, emphasising that the cost of recycled material depends on its nature. Other authors believe the low prices of virgin materials make it desirable for businesses to use them over reused or recycled materials [16,17,20,27,43]. The perception that virgin materials are cheaper in the short term can influence material selection decisions. The impact here is significant, as it can lead to the continued depletion of natural resources and inhibit the growth of circular practices.

- Supply and demand: Lack of consumer awareness about CE principles affects the demand for purchasing sustainable materials. In some markets, consumer awareness and demand for these products may still be relatively low. Tingley et al. [24] stated that the emergence of steel stockists is improbable unless there is a demand for reused steel and business advantage. As a result, there is a mismatch between the supply and demand of reused, recycled, and dismountable products [20,21,22,30,31,43]. The mismatch between supply and demand in reused/recycled materials can lead to inefficiencies and financial burdens. Excess supply can result in storage costs as materials need to be stored, managed, and maintained, incurring expenses related to warehousing and logistics. Conversely, insufficient supply can lead to an increased reliance on virgin materials, which results in environmental impacts.

- Unclear financial case: An unclear financial case refers to a situation in which the economic benefits of a particular investment are uncertain or difficult to quantify. Investors may therefore be hesitant to participate in circular construction projects until they perceive a clear economic return. According to Akinade et al. [23], developing a business case for design for deconstruction could be challenging. Benites et al. [33] claimed investments in CE practices are subject to long-term unpredictability as a result of fluctuating or ambiguous regulations. Innovations in circular construction methods and technologies may be slower to develop when there’s a lack of investment and incentives due to financial uncertainty.

- High upfront cost: Shifting to a CE model requires investment in new strategies, technologies, and infrastructure. Such investments require high upfront costs [16,17,18,22,39], which makes it difficult for some businesses to shift to more circular practices. Guerra and Leite [22] added that large companies are susceptible to invest in circular strategies, while businesses with limited budgets may face challenges with adopting circular strategies. Higher costs and time are employed when implementing CE practices [13,23,39]. Benites et al. [33] claimed that additional cost is associated with implementing circular practices. The lack of standardisation of reused materials results in a higher construction cost as reused materials often require additional tests and consultations to acquire the required certificates and permissions [37]. Tingley et al. [24] asserted that the deconstruction process requires extra time, more labourers, and the cost of product re-certification.

- Cost of removing contaminated materials: Removing contaminated and hazardous materials such as asbestos in existing buildings is costly [48]. Asbestos is a naturally occurring mineral that was widely used in building construction materials due to its strength and durability [49]. Asbestos removal refers to the process of safely removing asbestos from contaminated materials in a building. Couto and Couto [38] claimed that safe and effective asbestos removal in older buildings that are being considered for deconstruction necessitates special training, handling protocols, and specialised equipment. The existence of asbestos in old buildings requires additional costs due to the management of hazardous materials. As a result, the deconstruction process can be both expensive and time-consuming due to the high price of separating recyclable materials from contaminated ones [41].

3.3.4. Implementation Barriers

- Lack of storage facilities: Deconstruction projects often involve dismantling building components over time. Building deconstruction is not usually considered due to material storage and transportation necessity. Storage and transportation charges will eventually raise the entire project expenditure [23]. Materials salvaged from deconstruction require careful handling and storage to preserve their quality and condition. Tingley et al. [24] argue that steel stockists are unlikely to adopt reused steel until there is a significant business advantage in doing so. This suggests that businesses need strong financial incentives to invest in storage facilities for reused materials. Therefore, the absence of storage facilities can be a factor against implementing the principles of CE.

- Site constraints: Off-site sorting and direct landfilling could contribute to major environmental consequences, whereas on-site sorting results in net environmental advantages [15]. It is thought that the construction industry is hesitant to undertake on-site sorting in comparison to the existing dominating cradle-to-grave technique due to space and financial constraints, tight timetables, and more labour and administrative efforts [50]. This short-term cost-saving approach associated with off-site sorting may make it a more attractive option from a budget perspective, which can create resistance to adopting more circular construction practices.

- Inadequate CE infrastructure to support CE management: A key obstacle is the existing stock of buildings and infrastructure that do not adhere to circularity principles [14]. However, the challenges to applying CE to conventional structures are mostly connected to their monolithic form, architectural elements that result in a lack of standards, and an inadequate closed-loop supply chain [51]. The existing of non-circular infrastructure may not be economically viable to retrofit for circularity. The high cost and complexity of adapting conventional structures to circular principles can deter investment in CE initiatives. Moreover, monolithic structures in conventional buildings can make disassembly and material recovery challenging, resulting in a significant loss of resources during deconstruction.

- Conservative and non-collaborative industry operating within a linear economy: The construction sector is considered conservative, with limited flexibility to adopt new practices due to perceived financial risks. The construction sector’s close relationship with other sectors, particularly the financial sector, makes the transition to a CE more challenging because other industries would have to undergo the same change at the same time [21]. The industry’s risk aversion leads to a reluctance to embrace and invest in new circular methods and technologies. This results in resistance to any changes that might disrupt established norms.

3.3.5. Support/Promotion Barriers

- Lack of incentives: It refers to the absence or insufficiency of motivating factors that encourage individuals, businesses, or other stakeholders to adopt or engage in CE practices. There is a lack of well-structured and targeted financial incentives for CE practices [33]. These incentives can offset the initial costs associated with transitioning to more circular processes, making these practices more financially attractive. The absence of these incentives could lead businesses to perceive CE practices as a financial burden, which could potentially reduce their motivation to implement them. The absence of incentives not only affects businesses but also hinders individuals and consumers from participating in the CE. Without clear benefits or rewards for recycling, reusing, or making circular choices, individuals may lack the motivation to change their behaviours.

- Lack of government support: Government support, in the form of tax incentives, regulatory frameworks, and policy initiatives plays a vital role in promoting and accelerating the transition to a CE. The lack of tax incentives or government support is a major hindrance to the transition to CE [17,27,30]. The role of governments is important as it encourages businesses to adopt circular practices by reducing the financial burden and offsetting the costs associated with transitioning to circular models. The lack of government support can create uncertainty and reluctance among businesses and investors. Government involvement is important as it provides a clear roadmap and legal framework within which businesses can operate, making it easier for them to align their strategies with CE principles.

3.3.6. Social Barriers

- Unrealistic hypothesis/Social flexibility: There is a prevalent negative viewpoint towards reclaimed materials, with a preference for buildings constructed using new materials rather than those utilising recovered materials [25]. Additionally, the value embedded within construction and demolition waste is often overlooked, with many industry professionals failing to recognise it as a valuable resource [50]. This limited perspective hampers the realisation of the full potential of reclaimed materials and impedes their widespread adoption in construction practices. Negative perceptions of reclaimed materials can lead to reduced market demand for these materials in construction projects. This limits the economic viability of reusing and recycling materials, which affects the circular economy’s progress.

- Lack of interest in CE: Stakeholders within the supply chain, including suppliers and distributors, may be hesitant to change established processes or invest in new technologies required for circularity [14]. The limited interest in the CE is often due to a lack of awareness of its advantages or a misconception that it is incompatible with conventional profit-driven approaches Without compelling incentives for businesses and individuals to engage in the CE, there may be little motivation to change established practices. This lack of interest discourages innovation and investment in the CE. For example, businesses may be less likely to invest in research and development of new circular technologies and business models if they do not believe that there will be a return on their investment.

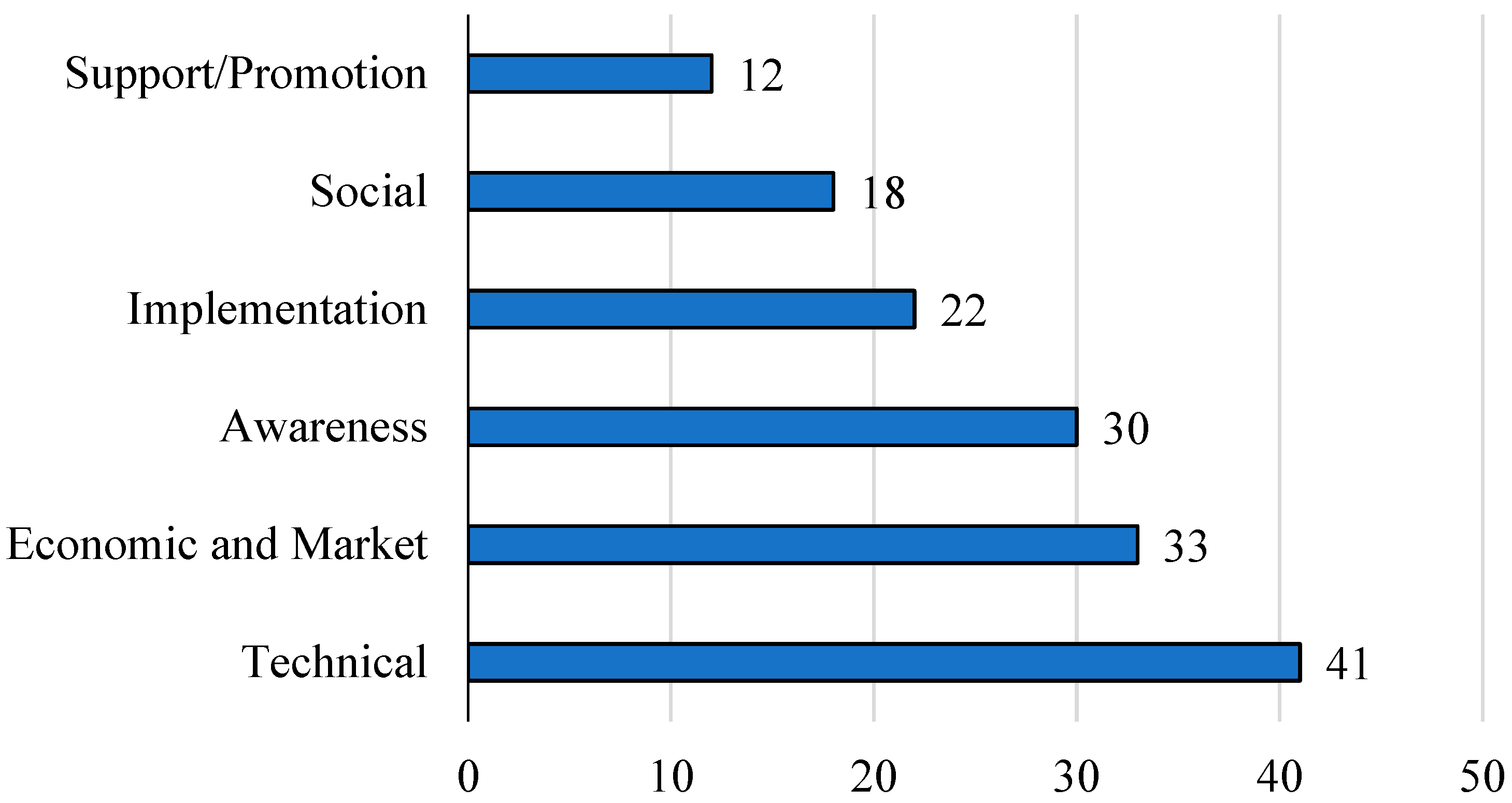

3.4. Frequency Analysis

3.5. Barrier Category Frequency

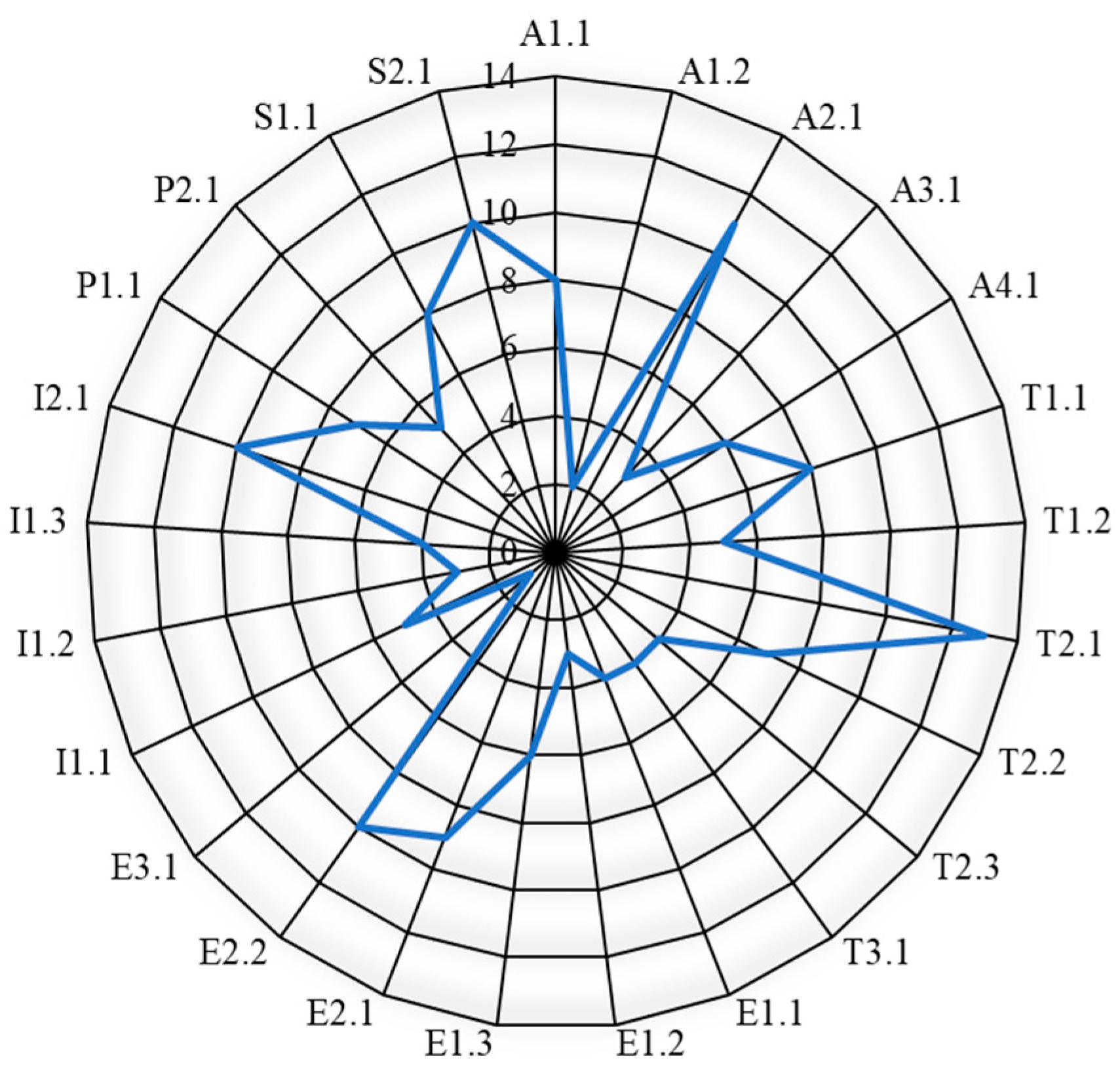

3.6. Barrier and Enabler Frequency per Article

3.7. Co-Occurrence Analysis

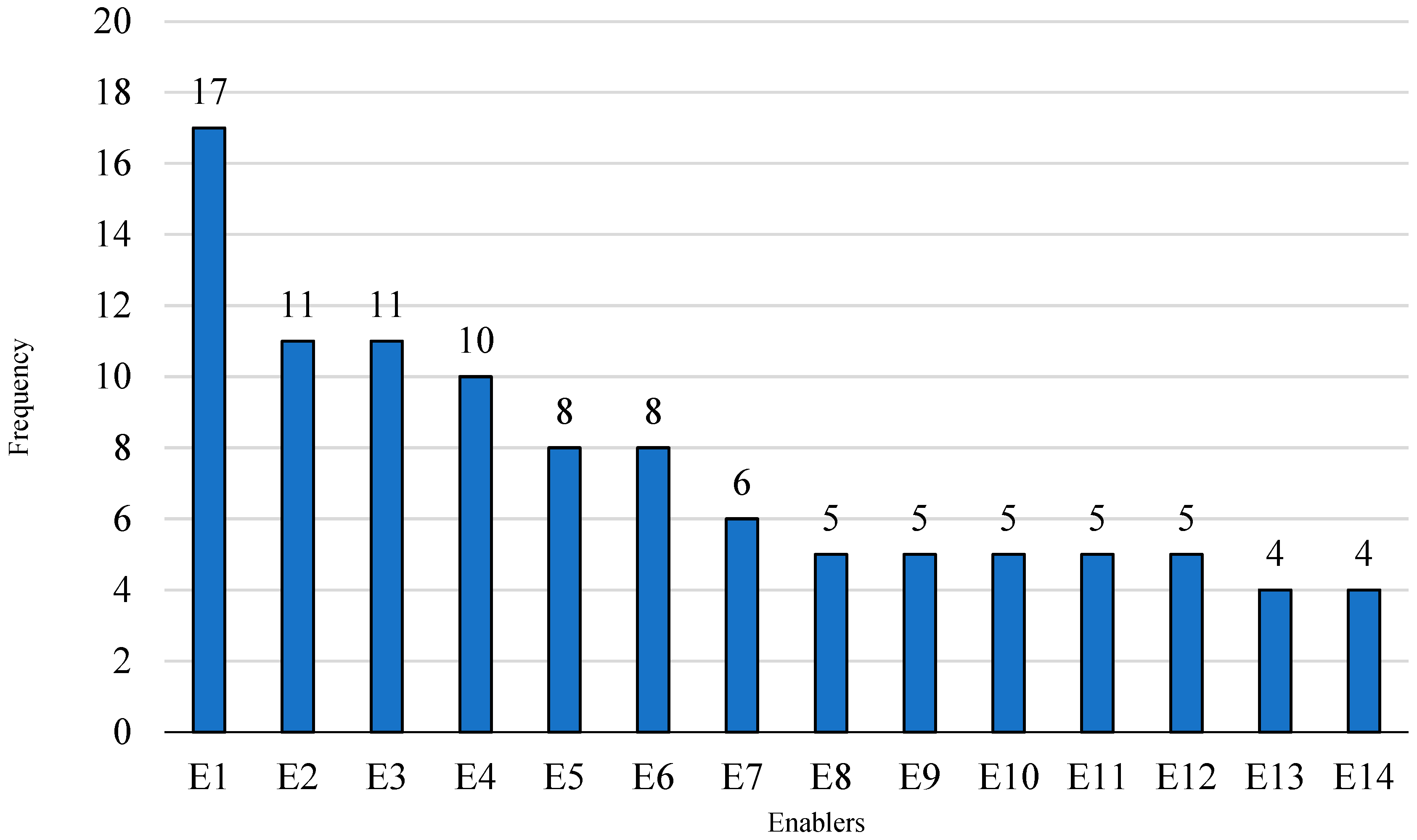

3.8. Enablers for Enforcing CE

Enabler’s Explanation

3.9. Mapping Enablers to CE Barriers

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Global Alliance for Buildings and Construction (GlobalABC). 2018 Global Status Report: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; International Energy Agency: Vienna, Austria; United Nations Environment Programme: Nairobi, Kenya, 2018. [Google Scholar]

- Ness, D.A.; Xing, K. Toward a Resource-Efficient Built Environment: A Literature Review and Conceptual Model. J. Ind. Ecol. 2017, 21, 572–592. [Google Scholar] [CrossRef]

- Jørgensen, S.; Pedersen, L.J.T. The Circular Rather than the Linear Economy. In RESTART Sustainable Business Model Innovation; Palgrave Studies in Sustainable Business In Association with Future Earth; Palgrave Macmillan: Cham, Switzerland, 2018; pp. 103–120. [Google Scholar]

- Ellen MacArthur Foundation. Towards the Circular Economy: Opportunities for the Consumer Goods Sector. Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-2-opportunities-for-the-consumer-goods (accessed on 7 December 2022).

- Neves, S.A.; Marques, A.C. Drivers and Barriers in the Transition from a Linear Economy to a Circular Economy. J. Clean. Prod. 2022, 341, 130865. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy: Economic and Business Rationale for an Accelerated Transition. Available online: https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an (accessed on 1 March 2023).

- Sariatli, F. Linear Economy Versus Circular Economy: A Comparative and Analyzer Study for Optimization of Economy for Sustainability. Visegr. J. Bioecon. Sustain. Dev. 2017, 6, 31–34. [Google Scholar] [CrossRef]

- European Commission. Questions and Answers on the Commission Communication “Towards a Circular Economy ” and the Waste Targets Review. Available online: https://ec.europa.eu/commission/presscorner/detail/en/MEMO_14_450 (accessed on 1 March 2023).

- Stahel, W.R. The Circular Economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Kubbinga, B.; Bamberger, M.; van Noort, E.; van den Reek, D.; Blok, M.; Roemers, G.; Hoek; Faes, J. (Eds.) A Framework for Circular Buildings; Circle Economy, DGBC, Metabolic and SGS: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. The Ecodesign Methodologies to Achieve Buildings’ Deconstruction: A Review and Framework. Sustain. Prod. Consum. 2022, 30, 566–583. [Google Scholar] [CrossRef]

- Rios, F.C.; Grau, D.; Bilec, M. Barriers and Enablers to Circular Building Design in the US: An Empirical Study. J. Constr. Eng. Manag. 2021, 147, 04021117. [Google Scholar] [CrossRef]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular Economy in Construction: Current Awareness, Challenges and Enablers. Proc. Inst. Civ. Eng.-Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- Mahpour, A. Prioritizing Barriers to Adopt Circular Economy in Construction and Demolition Waste Management. Resour. Conserv. Recycl. 2018, 134, 216–227. [Google Scholar] [CrossRef]

- Hart, J.; Adams, K.; Giesekam, J.; Tingley, D.; Pomponi, F. Barriers and Drivers in a Circular Economy: The Case of the Built Environment. Procedia Cirp 2019, 80, 619–624. [Google Scholar] [CrossRef]

- Bilal, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R. Current State and Barriers to the Circular Economy in the Building Sector: Towards a Mitigation Framework. J. Clean. Prod. 2020, 276, 123250. [Google Scholar] [CrossRef]

- Shooshtarian, S.; Hosseini, M.R.; Kocaturk, T.; Arnel, T.; Garofano, N.T. Circular Economy in the Australian AEC Industry: Investigation of Barriers and Enablers. Build. Res. Inf. 2023, 51, 56–68. [Google Scholar] [CrossRef]

- Ababio, B.K.; Lu, W. Barriers and Enablers of Circular Economy in Construction: A Multi-System Perspective towards the Development of a Practical Framework. Constr. Manag. Econ. 2023, 41, 3–21. [Google Scholar] [CrossRef]

- Hartwell, R.; Macmillan, S.; Overend, M. Circular Economy of Façades: Real-World Challenges and Opportunities. Resour. Conserv. Recycl. 2021, 175, 105827. [Google Scholar] [CrossRef]

- Kanters, J. Circular Building Design: An Analysis of Barriers and Drivers for a Circular Building Sector. Buildings 2020, 10, 77. [Google Scholar] [CrossRef]

- Guerra, B.C.; Leite, F. Circular Economy in the Construction Industry: An Overview of United States Stakeholders’ Awareness, Major Challenges, and Enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Akinade, O.; Oyedele, L.; Oyedele, A.; Delgado, J.M.D.; Bilal, M.; Akanbi, L.; Ajayi, A.; Owolabi, H. Design for Deconstruction Using a Circular Economy Approach: Barriers and Strategies for Improvement. Prod. Plan. Control 2020, 31, 829–840. [Google Scholar] [CrossRef]

- Tingley, D.D.; Cooper, S.; Cullen, J. Understanding and Overcoming the Barriers to Structural Steel Reuse, a UK Perspective. J. Clean. Prod. 2017, 148, 642–652. [Google Scholar] [CrossRef]

- Dunant, C.F.; Drewniok, M.P.; Sansom, M.; Corbey, S.; Allwood, J.M.; Cullen, J.M. Real and Perceived Barriers to Steel Reuse across the UK Construction Value Chain. Resour. Conserv. Recycl. 2017, 126, 118–131. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In The Sage Handbook of Organizational Research Methods; Sage Publications Ltd.: New York, NY, USA, 2009; pp. 671–689. [Google Scholar]

- Oyedele, L.O.; Ajayi, S.O.; Kadiri, K.O. Use of Recycled Products in UK Construction Industry: An Empirical Investigation into Critical Impediments and Strategies for Improvement. Resour. Conserv. Recycl. 2014, 93, 23–31. [Google Scholar] [CrossRef]

- Charef, R.; Emmitt, S. Uses of Building Information Modelling for Overcoming Barriers to a Circular Economy. J. Clean. Prod. 2021, 285, 124854. [Google Scholar] [CrossRef]

- Torgautov, B.; Zhanabayev, A.; Tleuken, A.; Turkyilmaz, A.; Mustafa, M.; Karaca, F. Circular Economy: Challenges and Opportunities in the Construction Sector of Kazakhstan. Buildings 2021, 11, 501. [Google Scholar] [CrossRef]

- Luciano, A.; Cutaia, L.; Altamura, P.; Penalvo, E. Critical Issues Hindering a Widespread Construction and Demolition Waste (CDW) Recycling Practice in EU Countries and Actions to Undertake: The Stakeholder’s Perspective. Sustain. Chem. Pharm. 2022, 29, 100745. [Google Scholar] [CrossRef]

- Giorgi, S.; Lavagna, M.; Wang, K.; Osmani, M.; Liu, G.; Campioli, A. Drivers and Barriers towards Circular Economy in the Building Sector: Stakeholder Interviews and Analysis of Five European Countries Policies and Practices. J. Clean. Prod. 2022, 336, 130395. [Google Scholar] [CrossRef]

- Tirado, R.; Aublet, A.; Laurenceau, S.; Habert, G. Challenges and Opportunities for Circular Economy Promotion in the Building Sector. Sustainability 2022, 14, 1569. [Google Scholar] [CrossRef]

- Benites, H.S.; Osmond, P.; Prasad, D. Inquiry on Perceptions and Practices of Built Environment Professionals Regarding Regenerative and Circular Approaches. Buildings 2023, 13, 63. [Google Scholar] [CrossRef]

- Mackenbach, S.; Zeller, J.C.; Osebold, R. A Roadmap towards Circularity—Modular Construction as a Tool for Circular Economy in the Built Environment. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 052027. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a Circular Economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Kazancoglu, I.; Sagnak, M.; Mangla, S.K.; Kazancoglu, Y. Circular Economy and the Policy: A Framework for Improving the Corporate Environmental Management in Supply Chains. Bus. Strategy Environ. 2021, 30, 590–608. [Google Scholar] [CrossRef]

- Kozminska, U. Circular Design: Reused Materials and the Future Reuse of Building Elements in Architecture. Process, Challenges and Case Studies. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012033. [Google Scholar] [CrossRef]

- Couto, J.; Couto, A. Analysis of Barriers and the Potential for Exploration of Deconstruction Techniques in Portuguese Construction Sites. Sustainability 2010, 2, 428–442. [Google Scholar] [CrossRef]

- Rios, F.C.; Chong, W.K.; Grau, D. Design for Disassembly and Deconstruction—Challenges and Opportunities. Procedia Eng. 2015, 118, 1296–1304. [Google Scholar] [CrossRef]

- Göswein, V.; Carvalho, S.; Cerqueira, C.; Lorena, A. Circular Material Passports for Buildings—Providing a Robust Methodology for Promoting Circular Buildings. IOP Conf. Ser. Earth Environ. Sci. 2022, 1122, 012049. [Google Scholar] [CrossRef]

- Charef, R.; Morel, J.-C.; Rakhshan, K. Barriers to Implementing the Circular Economy in the Construction Industry: A Critical Review. Sustainability 2021, 13, 12989. [Google Scholar] [CrossRef]

- Rahla, K.M.; Bragança, L.; Mateus, R. Obstacles and Barriers for Measuring Building’s Circularity. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012058. [Google Scholar] [CrossRef]

- Iacovidou, E.; Purnell, P. Mining the Physical Infrastructure: Opportunities, Barriers and Interventions in Promoting Structural Components Reuse. Sci. Total Environ. 2016, 557, 791–807. [Google Scholar] [CrossRef]

- Geyer, R.; Jackson, T. Supply Loops and Their Constraints: The Industrial Ecology of Recycling and Reuse. Calif. Manag. Rev. 2004, 46, 55–73. [Google Scholar] [CrossRef]

- Essoussi, L.H.; Linton, J.D. New or Recycled Products: How Much Are Consumers Willing to Pay? J. Consum. Mark. 2010, 27, 458–468. [Google Scholar] [CrossRef]

- Watson, M. A Review of Literature and Research on Public Attitudes, Perceptions and Behaviour Relating to Remanufactured, Repaired and Reused Products. In Report for the Centre for Remanufacturing and Reuse; The University of Sheffield: Sheffield, UK, 2008; pp. 1–26. [Google Scholar]

- Addis, B. Building with Reclaimed Components and Materials: A Design Handbook for Reuse and Recycling; Routledge: London, UK, 2006. [Google Scholar]

- Dewees, D.N. Controlling Asbestos in Buildings: An Economic Investigation; Routledge: London, UK, 2016. [Google Scholar]

- Lee, R.J.; Orden, D.R.V.; Corn, M.; Crump, K.S. Exposure to Airborne Asbestos in Buildings. Regul. Toxicol. Pharm. 1992, 16, 93–107. [Google Scholar] [CrossRef]

- Purchase, C.K.; Zulayq, D.M.A.; O’Brien, B.T.; Kowalewski, M.J.; Berenjian, A.; Tarighaleslami, A.H.; Seifan, M. Circular Economy of Construction and Demolition Waste: A Literature Review on Lessons, Challenges, and Benefits. Materials 2022, 15, 76. [Google Scholar] [CrossRef] [PubMed]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. How to Normalize Cooccurrence Data? An Analysis of Some Well-known Similarity Measures. J. Am. Soc. Inf. Sci. 2009, 60, 1635–1651. [Google Scholar] [CrossRef]

- Alasmari, E.; Martinez-Vazquez, P.; Baniotopoulos, C. A Systematic Literature Review of the Adoption of Building Information Modelling (BIM) on Life Cycle Cost (LCC). Buildings 2022, 12, 1829. [Google Scholar] [CrossRef]

- AlJaber, A.; Alasmari, E.; Martinez-Vazquez, P.; Baniotopoulos, C. Life Cycle Cost in Circular Economy of Buildings by Applying Building Information Modeling (BIM): A State of the Art. Buildings 2023, 13, 1858. [Google Scholar] [CrossRef]

- Marzouk, M.; Azab, S.; Metawie, M. BIM-Based Approach for Optimizing Life Cycle Costs of Sustainable Buildings. J. Clean. Prod. 2018, 188, 217–226. [Google Scholar] [CrossRef]

- Alasmari, E.; Martinez-Vazquez, P.; Baniotopoulos, C. An Analysis of the Qualitative Impacts of Building Information Modelling (BIM) on Life Cycle Cost (LCC): A Qualitative Case Study of the KSA. Buildings 2023, 13, 2071. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Aschenbrenner, P.; Ragossnig, A. Material Passports for the End-of-Life Stage of Buildings: Challenges and Potentials. J. Clean. Prod. 2021, 319, 128702. [Google Scholar] [CrossRef]

- Tuvayanond, W.; Prasittisopin, L. Design for Manufacture and Assembly of Digital Fabrication and Additive Manufacturing in Construction: A Review. Buildings 2023, 13, 429. [Google Scholar] [CrossRef]

- Rashid, A.A.; Koç, M. Additive Manufacturing for Sustainability and Circular Economy: Needs, Challenges, and Opportunities for 3D Printing of Recycled Polymeric Waste. Mater. Today Sustain. 2023, 24, 100529. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Ferdous, W.; Kamchoom, V. Microplastics in Construction and Built Environment. Dev. Built Environ. 2023, 15, 100188. [Google Scholar] [CrossRef]

| No | Reference | Year | No | Reference | Year |

|---|---|---|---|---|---|

| 1 | Oyedele et al. [27] | 2014 | 11 | Hartwell et al. [20] | 2021 |

| 2 | Adams et al. [14] | 2017 | 12 | Charef and Emmitt [28] | 2021 |

| 3 | Dunant et al. [25] | 2017 | 13 | Torgautov et al. [29] | 2021 |

| 4 | Tingley et al. [24] | 2017 | 14 | Guerra and Leite [22] | 2021 |

| 5 | Mahpour [15] | 2018 | 15 | Luciano et al. [30] | 2022 |

| 6 | Akinade et al. [23] | 2020 | 16 | Giorgi et al. [31] | 2022 |

| 7 | Kanters [21] | 2020 | 17 | Tirado et al. [32] | 2022 |

| 8 | Bilal et al. [17] | 2020 | 18 | Sala Benites et al. [33] | 2023 |

| 9 | Mackenbach et al. [34] | 2020 | 19 | Shooshtarian et al. [18] | 2023 |

| 10 | Rios et al. [13] | 2021 |

| Category | Sub-Category | Barrier Code | Barrier | Reference |

|---|---|---|---|---|

| Awareness | Knowledge | A1.1 | Limited knowledge of CE | [13,14,15,17,18,24,28,33] |

| A1.2 | Lack of CE vision | [15,33] | ||

| Supply chain | A2.1 | Fragment supply chain | [13,14,15,17,18,20,21,24,25,32,33] | |

| Literature | A3.1 | Lack of case studies | [13,15,23] | |

| Metrics | A4.1 | Lack of adequate information in building design | [15,20,23,24,27,28] | |

| Technical | Technology | T1.1 | Building complexity | [13,14,20,23,24,28,29,32] |

| T1.2 | Quality of materials at EOL | [13,21,23,24,27] | ||

| Regulatory | T2.1 | Policy and legislation | [13,14,15,17,18,22,23,24,25,27,30,31,34] | |

| T2.2 | Lacking standardization/certification/traceability/quality assurance/classification | [13,14,23,25,28,30,31] | ||

| T2.3 | Lack of flexibility in building codes and regulations | [20,21,23,33] | ||

| Tools | T3.1 | Lack of CE metrics/tools/design | [17,21,23,31] | |

| Economic and market | Market | E1.1 | Lack of market mechanisms for recovery | [13,14,23,25] |

| E1.2 | Cost of virgin materials | [17,20,27] | ||

| E1.3 | A mismatch between supply and demand of reused materials | [20,21,23,24,30,31] | ||

| Cost | E2.1 | Unclear financial case | [13,14,22,23,24,25,28,33,34] | |

| E2.2 | High upfront cost | [17,18,22,23,24,25,29,30,31,33] | ||

| Value for money | E3.1 | Cost of removing contaminated materials | [28] | |

| Implementation | Infrastructure | I1.1 | Availability and Storage facilities | [23,24,25,28,32] |

| I1.2 | Site constraints | [15,22,28] | ||

| I1.3 | Inadequate CE infrastructure to support CE management | [14,20,28,33] | ||

| Management | I2.1 | Conservative and non-collaborative industry operating within a linear economy | [13,15,20,21,22,24,25,28,31,32] | |

| Support/promotion | Incentives | P1.1 | Lack of incentives | [13,14,15,17,18,24,33] |

| Government Support | P2.1 | Lack of government support | [17,24,27,30,33] | |

| Social | Perception/Flexibility | S1.1 | Unrealistic hypothesis/Social flexibility | [13,15,20,25,27,28,29,34] |

| Interest | S2.1 | Lack of interest in CE | [13,14,15,20,22,27,28,29,32,34] |

| No | Reference | Barrier | Enabler | No | Reference | Barrier | Enabler |

|---|---|---|---|---|---|---|---|

| 1 | Tingley et al. [24] | 13 | 8 | 11 | Oyedele et al. [27] | 7 | 8 |

| 2 | Akinade et al. [23] | 13 | 6 | 12 | Kanters [21] | 6 | 4 |

| 3 | Rios et al. [13] | 13 | 10 | 13 | Giorgi et al. [31] | 6 | 6 |

| 4 | Charef and Emmitt [28] | 12 | 2 | 14 | Guerra and Leite [22] | 6 | 5 |

| 5 | Mahpour [15] | 11 | 5 | 15 | Luciano et al. [30] | 5 | 3 |

| 6 | Adams et al. [14] | 10 | 10 | 16 | Shooshtarian et al. [18] | 5 | 6 |

| 7 | Hartwell et al. [20] | 10 | 5 | 17 | Tirado et al. [32] | 5 | 4 |

| 8 | Dunant et al. [25] | 9 | 3 | 18 | Torgautov et al. [29] | 4 | 4 |

| 9 | Sala Benites et al. [33] | 9 | 7 | 19 | Mackenbach et al. [34] | 4 | 4 |

| 10 | Bilal et al. [17] | 8 | 5 |

| Awareness | Technical | Economic Mad Market | Implementation | Support/Promotion | Social | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | A2 | A3 | A4 | T1 | T2 | T3 | E1 | E2 | E3 | I1 | I2 | P1 | P2 | S1 | S2 | |

| A1 | 0 | 7 | 2 | 3 | 4 | 7 | 1 | 4 | 8 | 1 | 5 | 3 | 5 | 2 | 3 | 4 |

| A2 | 0 | 0 | 2 | 3 | 7 | 10 | 2 | 7 | 7 | 0 | 6 | 5 | 5 | 4 | 4 | 4 |

| A3 | 0 | 0 | 0 | 2 | 2 | 3 | 0 | 2 | 2 | 0 | 2 | 2 | 2 | 0 | 2 | 2 |

| A4 | 0 | 0 | 0 | 0 | 5 | 6 | 1 | 5 | 4 | 1 | 6 | 3 | 2 | 2 | 4 | 4 |

| T1 | 0 | 0 | 0 | 0 | 0 | 12 | 2 | 9 | 10 | 1 | 8 | 5 | 3 | 3 | 5 | 7 |

| T2 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 12 | 14 | 0 | 10 | 8 | 7 | 5 | 7 | 7 |

| T3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 3 | 0 | 1 | 1 | 1 | 1 | 0 | 0 |

| E1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 9 | 0 | 5 | 6 | 4 | 4 | 4 | 4 |

| E2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 7 | 4 | 6 | 4 | 5 | 7 |

| E3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 |

| I1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 6 | 4 | 2 | 4 | 5 |

| I2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 1 | 4 | 3 |

| P1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 2 | 3 |

| P2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| S1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 7 |

| S2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| No | Enabler Code | Enabler | Reference |

|---|---|---|---|

| 1 | E1 | Circular economy-supportive policy | [13,14,15,17,18,20,21,22,23,24,27,29,30,32,33,34] |

| 2 | E2 | Financial incentives | [13,14,15,17,18,20,22,24,27,30,33] |

| 3 | E3 | Technology and innovation for circular building tools | [13,14,15,17,18,24,29,31,32,33,34] |

| 4 | E4 | Stakeholders’ collaboration and engagement | [15,18,22,23,25,27,31,32,33,34] |

| 5 | E5 | Use of building information modelling (BIM) | [13,14,18,23,27,28,29,31,33] |

| 6 | E6 | Circular business models | [13,14,18,20,21,24,30,31] |

| 7 | E7 | Awareness campaigns | [13,14,17,22,27,32] |

| 8 | E8 | Standardization and certification of reclaimed materials | [14,20,22,27,34] |

| 9 | E9 | Design guidelines for circular buildings | [13,14,18,23,24] |

| 10 | E10 | Development of reused materials market mechanisms | [14,21,23,25,33] |

| 11 | E11 | Education and research | [13,15,17,24,27] |

| 12 | E12 | More materials storage and recycling facilities | [13,20,21,24,25] |

| 13 | E13 | Circular building case studies | [13,14,23,24] |

| 14 | E14 | Materials passports | [27,28,29,31,33] |

| Barrier Code | Enablers to CE Barriers | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BIM | Awareness Campaigns | CE-Supportive Policy | Education and Research | Financial Incentives | Stakeholder Collaboration and Engagement | Material Passports | Design Guidelines for Circular Buildings | Circular Business Models | Technology and Innovation for Circular Building Tools | More Materials Storage and Recycling Facilities | Standardisation and Certification Reclaimed Materials | Circular Building Case Studies | Development of Reused Materials Market Mechanisms | |

| A1.1 | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| A1.2 | ✓ | ✓ | ✓ | |||||||||||

| A2.1 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| A3.1 | ✓ | |||||||||||||

| A4.1 | ✓ | ✓ | ✓ | |||||||||||

| T1.1 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| T1.2 | ✓ | |||||||||||||

| T2.1 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| T2.2 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| T2.3 | ✓ | ✓ | ||||||||||||

| T3.1 | ✓ | ✓ | ✓ | ✓ | ||||||||||

| E1.1 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||

| E1.2 | ✓ | |||||||||||||

| E1.3 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| E2.1 | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| E2.2 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||

| E3.1 | ✓ | ✓ | ✓ | |||||||||||

| I1.1 | ✓ | ✓ | ✓ | |||||||||||

| I1.2 | ✓ | ✓ | ✓ | |||||||||||

| I1.3 | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| I2.1 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||

| P1.1 | ✓ | ✓ | ✓ | |||||||||||

| P2.1 | ✓ | ✓ | ✓ | |||||||||||

| S1.1 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||

| S2.1 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

AlJaber, A.; Martinez-Vazquez, P.; Baniotopoulos, C. Barriers and Enablers to the Adoption of Circular Economy Concept in the Building Sector: A Systematic Literature Review. Buildings 2023, 13, 2778. https://doi.org/10.3390/buildings13112778

AlJaber A, Martinez-Vazquez P, Baniotopoulos C. Barriers and Enablers to the Adoption of Circular Economy Concept in the Building Sector: A Systematic Literature Review. Buildings. 2023; 13(11):2778. https://doi.org/10.3390/buildings13112778

Chicago/Turabian StyleAlJaber, Abdulaziz, Pedro Martinez-Vazquez, and Charalampos Baniotopoulos. 2023. "Barriers and Enablers to the Adoption of Circular Economy Concept in the Building Sector: A Systematic Literature Review" Buildings 13, no. 11: 2778. https://doi.org/10.3390/buildings13112778

APA StyleAlJaber, A., Martinez-Vazquez, P., & Baniotopoulos, C. (2023). Barriers and Enablers to the Adoption of Circular Economy Concept in the Building Sector: A Systematic Literature Review. Buildings, 13(11), 2778. https://doi.org/10.3390/buildings13112778