Properties of Bacterial Copper Slag Concrete

Abstract

:1. Introduction

1.1. Bacillus Subtilis

1.2. Microbiologically Induced Calcium Carbonate Precipitation

2. Experimental Program

2.1. Materials

2.2. Mix Design

2.3. Compressive Strength Test

2.4. Flexural Strength Test

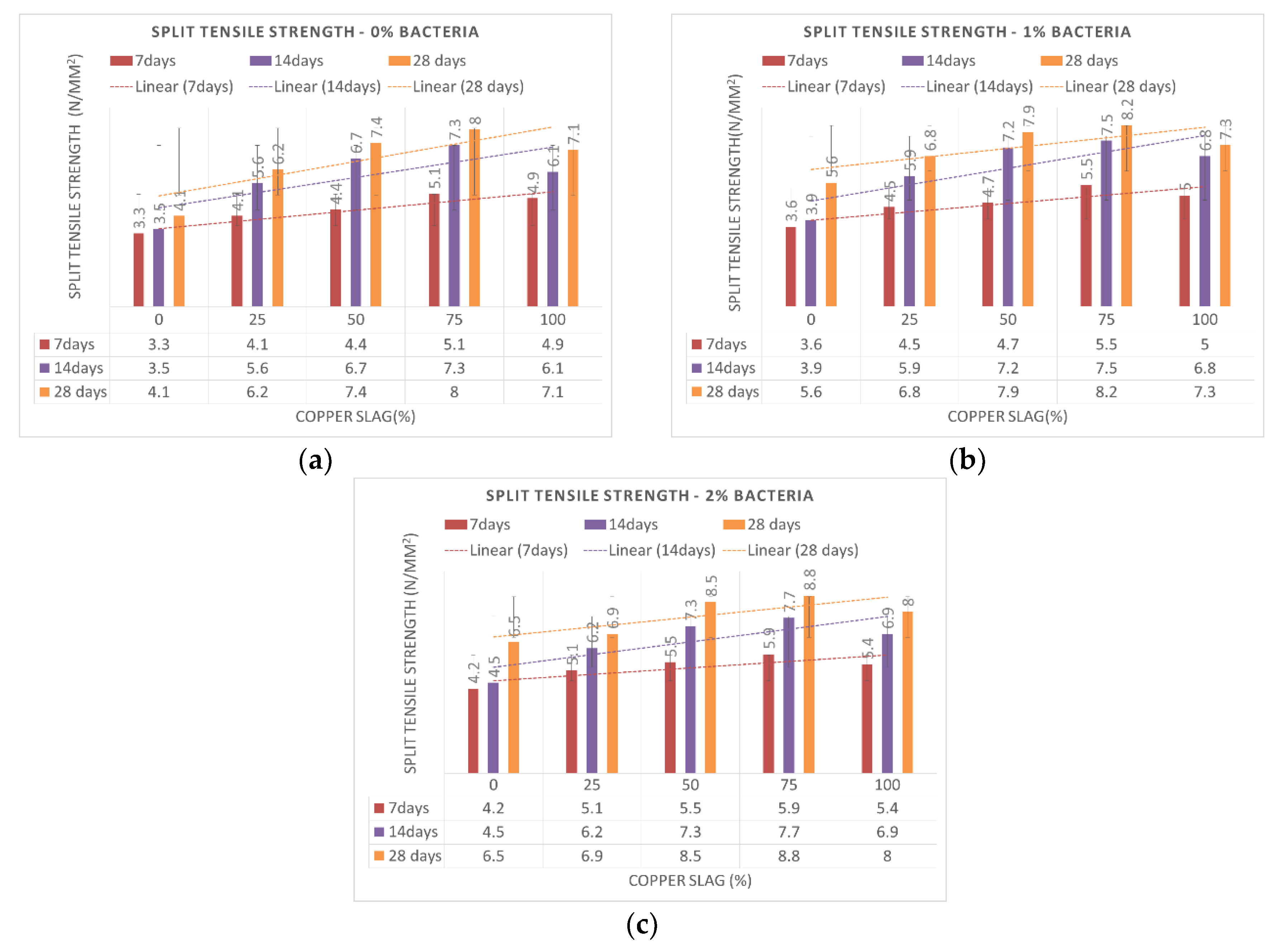

2.5. Split Tensile Strength

2.6. Optimum Percentage of Copper Slag and Micro-Organisms

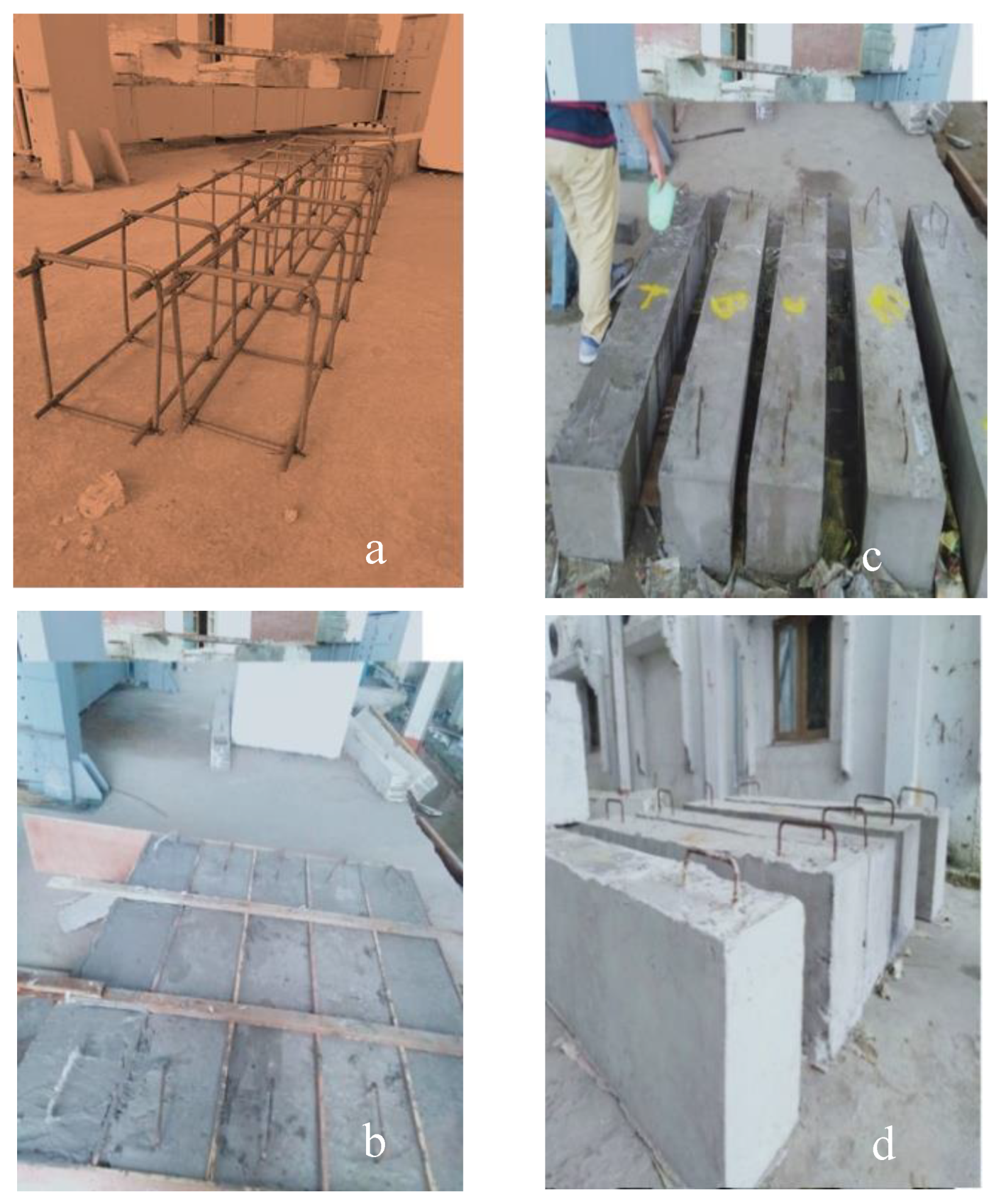

2.7. Beam Casting

2.8. Experimental Setup

2.9. Strain Measurement Using Strain Gauges

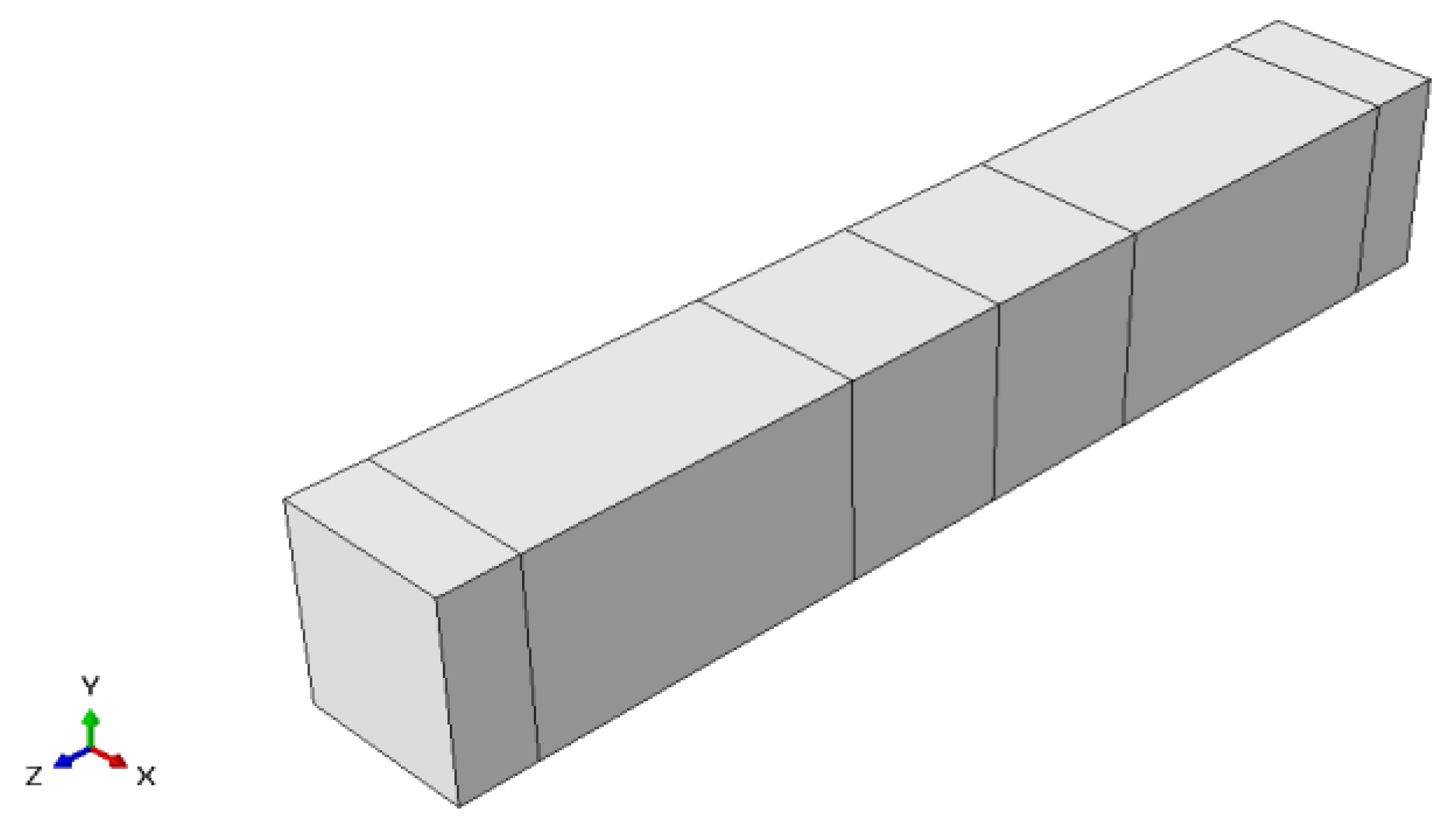

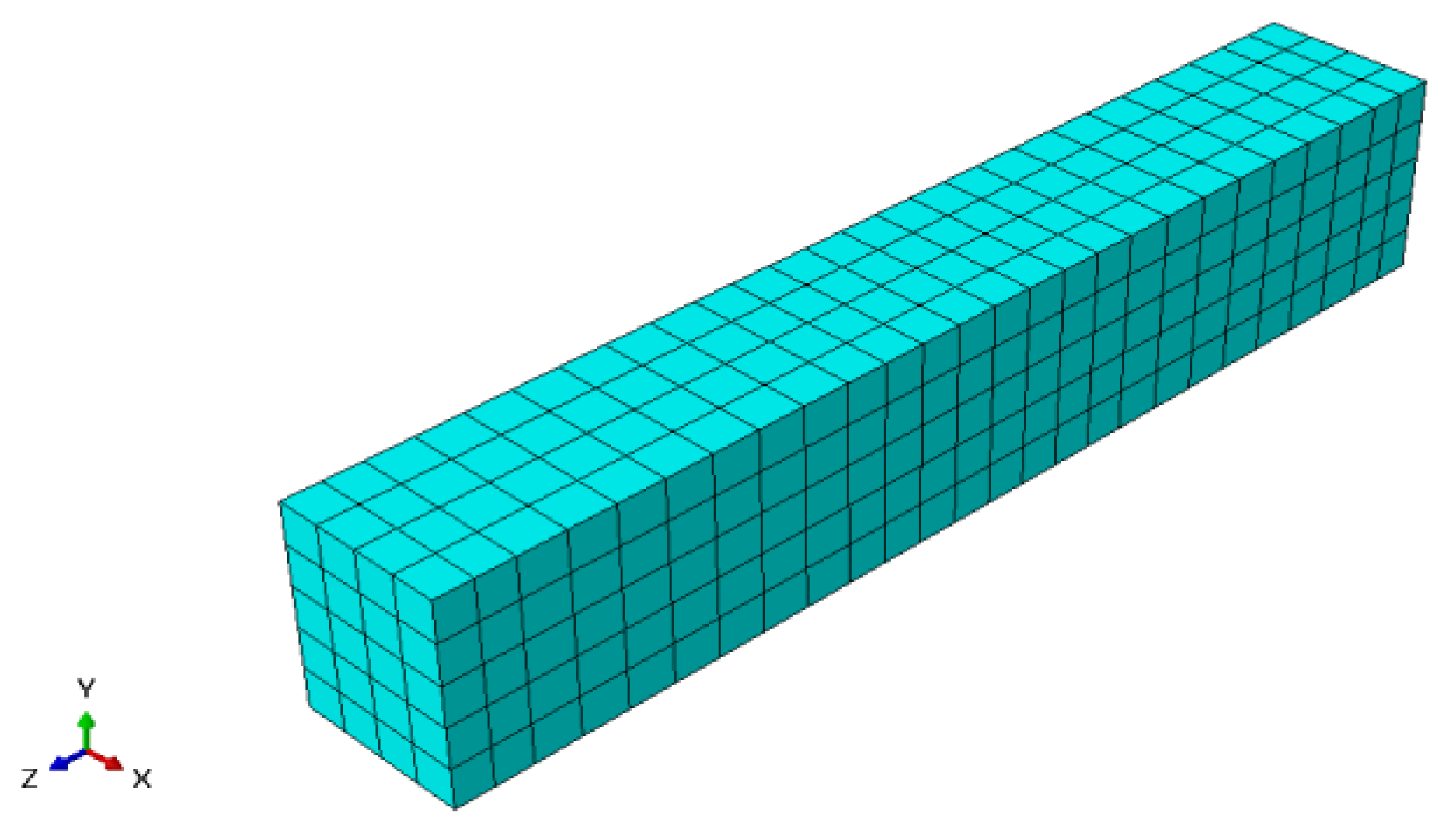

2.10. Analysis of Beam Modelling Using ABAQUS

3. Results and Discussion

3.1. Effect of Copper Slag and Micro-Organisms on the Compressive Strength of Concrete

3.2. Effect of Copper Slag and Micro-Organisms on the Flexural Strength of Concrete

3.3. Effect of Copper Slag and Micro-Organisms on the Split Tensile Strength of Concrete

3.4. Effects of Copper Slag and Bacteria on Flexural Behaviour of RCC Beams

- Beam failure patterns;

- Load–deflection characteristics of RCC beams.

3.4.1. Failure Patterns of Beams

3.4.2. Load–Deflection Behaviour of the Beam

3.4.3. Load–Deflection Pattern from ABAQUS

3.4.4. Comparison of Experimental and Numerical Deflection Parameters

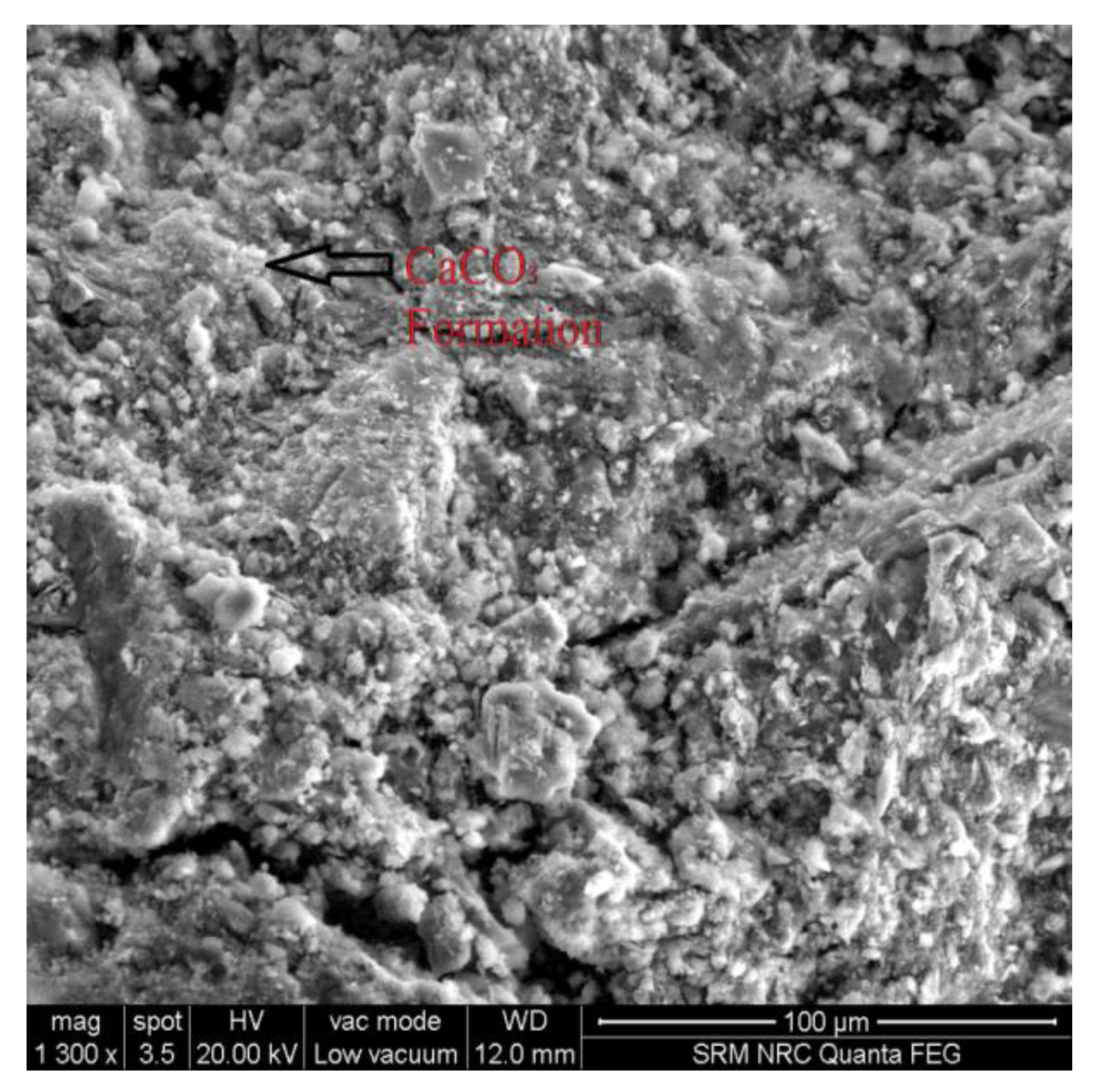

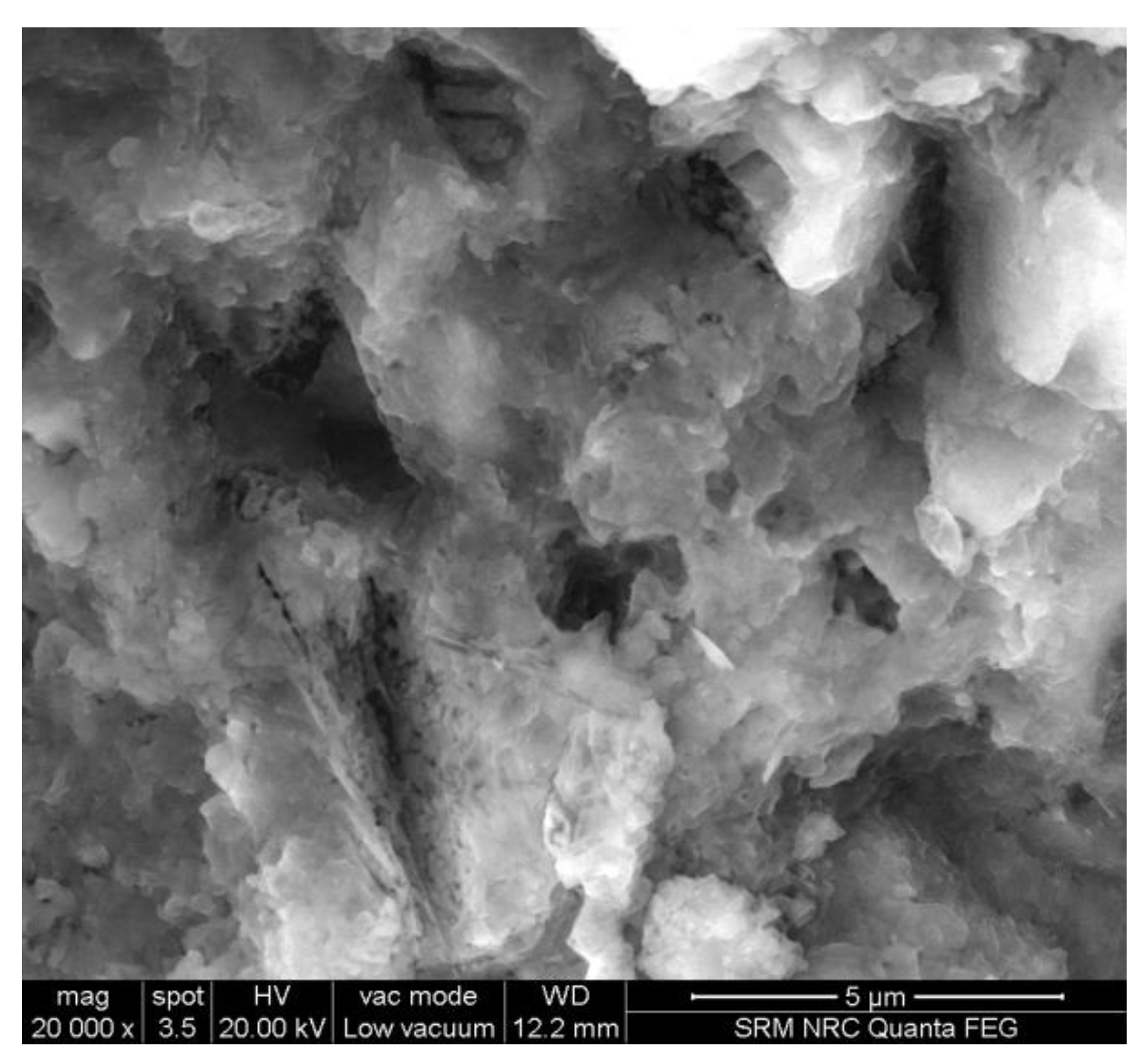

3.5. SEM Images

4. Conclusions

- By substituting copper slag for fine aggregate in concrete, waste disposal can be made more efficient and material costs may be reduced.

- MICP is a new, innovative phenomenon that has the potential to enhance the quality of copper slag concrete.

- The addition of micro-organisms to copper slag concrete enhances its mechanical properties and permits material savings.

- A 75% replacement of copper slag with fine aggregate treated with 1% bacteria by weight of cement produced concrete with better strength as compared to the control mix and regular copper slag concrete.

- A 75% replacement of copper slag with fine aggregate treated with 2% bacteria by weight of cement produced concrete with better strength as compared the control mix.

- In comparison to the strength of the control mix, the strength of the mix containing the 100% copper slag replacement and 2% bacteria was lower.

- The optimum percentage of the combination of waste materials was found to be a 75% replacement of copper slag treated with 2% bacteria.

- According to the load–deflection curves, the initial cracking load and ultimate load of the bacterial copper slag specimens improved by 40% to 45% when compared to the control concrete specimen.

- A comparison between the load–deflection curves generated by the ABAQUS finite element software and those obtained from the experimental data revealed a slight divergence, which may be attributable to shoddy workmanship and improper specimen handling. However, the error percentages between the numerical and experimental results were as small as possible.

- Ultimately, it can be stated that a 75% copper slag replacement treated with 2% bacteria could be a viable alternative to regular conventional concrete, as it results in enhanced concrete performance.

- Based on the scanning electron microscope analysis, it can be concluded that the improvement in the overall performance of copper slag concrete was due to the action of bacteria and the formation of calcite, which was identified by the polygonal crystals.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brindha, D.; Nagan, S. Utilization of Copper Slag as a Partial Replacement of FineAggregate in Concrete. Int. J. Earth Sci. Eng. 2010, 3, 579–585. [Google Scholar]

- Brindha, D.; Baskaran, T.; Nagan, S. Assessment of Corrosion and Durability Characteristics of Copper Slag Admixed Concrete. Int. J. Civ. Struct. Eng. 2010, 1, 483–488. [Google Scholar]

- Khalifa, S.; Abdullah Al-Saidy, A.-J.H.; Ramzi, T. Effect of copper slag as a fine aggregate on the properties of cement mortars and concrete. Constr. Build. Mater. 2011, 25, 933–938. [Google Scholar] [CrossRef]

- Khalifa-Al-Jabria, S.; Makoto Hisada, B.; Salem Al-Oraimi, H.; Al-Saidy, A. Copper slag as sand replacement for high-performance concret. Cem. Concr. Compos. 2009, 31, 483–488. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, W.; Ma, G. The optimum content of copper slag as a fine aggregate in high strength concrete. Mater. Des. 2010, 31, 2878–2883. [Google Scholar] [CrossRef]

- Khalifa Al-Jabri, S.; Abdullah Al-Saidy, M.H.H.; Al-Oraimi, S.K. Performance of high strength concrete made with copper slag as a fine aggregate. Constr. Build. Mater. 2009, 23, 2132–2140. [Google Scholar] [CrossRef]

- Shaikh, N.A.; Tapkire, P.P. A Partial Replacement of Fine Aggregate by Copper Slag in Concrete. Int. J. Eng. Comput. Sci. 2016, 5, 19809–19812. [Google Scholar]

- Wu, W.; Zhang, W.; Ma, G. Mechanical properties of copper slag reinforced concrete under dynamic compression. Constr. Build. Mater. 2010, 24, 910–917. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Taha, R.A.; Al-Hashmi, A.; Al-Harthy, A.S. Effect of copper slag and cement by-pass dust addition on mechanical properties of concrete. Constr. Build. Mater. 2006, 20, 322–331. [Google Scholar] [CrossRef]

- Meenakshi, S.S.; Ilangovan, R. Performance of Copper slag and ferrous slag as partial replacement of Sand in Concrete. Int. J. Civ. Struct. Eng. 2011, 1, 918–927. [Google Scholar]

- Brindha, D.; Nagan, S. Durability Studies on Copper Slag Admixed Concrete. Asian J. Civ. Eng.-Build. Hous. 2011, 12, 563–578. [Google Scholar]

- Binaya, P.A.; Seshadri, S.T.A.; Srinivasa, R.B. An Experimental Investigation on Optimum Usage of Copper Slag as Fine Aggregate in Copper Slag Admixed Concrete. Int. J. Curr. Eng. Technol. 2014, 4, 3646–3648. [Google Scholar]

- Najimi, M.; Sobhani, J.; Pourkhorshidi, A.R. Durability of copper slag contained concrete exposed to sulfate attack. Constr. Build. Mater. 2011, 25, 1895–1905. [Google Scholar] [CrossRef]

- Tamil, S.P.; Lakshmi, N.P.; Ramya, G. Experimental Study on Concrete Using Copper Slag as Replacement Material of Fine Aggregate. Civ. Environ. Eng. 2014, 4, 5. [Google Scholar] [CrossRef]

- Pradeep, K.A.; Akila, D. An Experimental Work on Concrete by Adding Bacillus Subtilis. Int. J. Emerg. Technol. Eng. 2015, 2, 69–73. [Google Scholar]

- Khan, F.; Kachchhap, A.; Kumar, P.; Soan, K. Self Healing Concrete or Bio-Concrete to Repair Cracks. Adv. Appl. Math. Sci. 2022, 21, 5397–5403. [Google Scholar]

- Shobana, K.; Thenmozhi, R. Experimental investigation of self-repairing bio concrete in self compacting concrete. Mater. Express 2022, 12, 705–712. [Google Scholar] [CrossRef]

- Chetty, K.; Garbe, U.; Wang, Z.; Zhang, S.; McCarthy, T.; Hai, F. Bioconcrete based on sulfate-reducing bacteria granules: Cultivation, mechanical properties, and self-healing performance. J. Sustain. Cem. Based Mater. 2022, 11, 1–12. [Google Scholar] [CrossRef]

- Jin, C.; Yu, R.; Shui, Z. Fungi—A neglected candidate for the application of self healing Concrete. Front. Built Environ. 2018, 4, 64. [Google Scholar] [CrossRef] [Green Version]

- Stanaszek-Tomal, E. Bacterial Concrete as a Sustainable Building Material? Sustainablity 2020, 12, 696. [Google Scholar] [CrossRef] [Green Version]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U. Past and present techniques of self-healing in cementitious materials. A critical review on efficiency of implemented treatments. J. Mater. Res. Technol. 2020, 9, 6883–6899. [Google Scholar] [CrossRef]

- Pappupreethi, K.; Velluva, R.A.; Magudeaswaran, P. Bacterial Concrete: A Review. Int. J. Civ. Eng. Technol. 2017, 8, 588–594. [Google Scholar]

- Sunil, P.R.; Seshagiri, R.M.V.; Aparnac, P.; Sasikalac, C. Performance Of Standard Grade Bacterial (Bacillus Subtilis) Concrete. Asian J. Civ. Eng. -Build. Hous. 2010, 11, 43–55. [Google Scholar]

- Griño, A.A., Jr.; Ma, K.M.D.; Ongpeng, J.M.C. Bio-Influenced Self-Healing Mechanism in Concrete and Its Testing: A Review. Appl. Sci. 2020, 10, 5161. [Google Scholar] [CrossRef]

- Schwantes-Cezario, N.; Peres, M.V.N.N.; Fruet, T.K.; Nogueira, G.S.F.; Toralles, B.M.; De Souza Cezario, D. Crack filling in concrete by addition of Bacillus subtilis spores—Preliminary study. DYNA 2018, 85, 132–139. [Google Scholar] [CrossRef]

- Khaliq, W.; Ehsan, B.M. Crack healing in concrete using various bio influenced self-healing techniques. Constr. Build. Mater. 2016, 102, 349–357. [Google Scholar] [CrossRef]

- Deby, L.; Kaviyarasi, P.; Anbalagan, M. Experimental Investigation on Concrete using Copper Slag as Fine Aggregate with Bacterial Admixture. Int. J. Emerg. Technol. Eng. Res. 2017, 5, 11–15. [Google Scholar]

- Manas, S.; Adak, D.; Tamang, A.; Chattopadhyay, B.; Mandalb, S. Genetically-enriched microbe-facilitated self-healing concrete—A sustainable material for a new generation of construction technology. RSC Adv. 2015, 5, 105363–105371. [Google Scholar] [CrossRef]

- Shukla, A.; Gupta, N.; Singh, K.R.; Bajaj, P.K.V.; Ayalew, F. Performance Evaluation of Bio Concrete by Cluster and Regression Analysis for Environment Protection. Hindawi Comput. Intell. Neurosci. 2022, 2022, 4411876. [Google Scholar] [CrossRef]

- Seshagiri, R.M.V.; Srinivasa, R.V.; Hafsa, M.; Veena, P.; Anusha, P. Review Paper Bioengineered Concrete—A Sustainable Self-Healing Construction Material. Res. J. Eng. Sci. 2013, 2, 45–51. [Google Scholar]

- IS:12269; Indian Standard Ordinary Portland Cement, 53 Grade-Specification. Bureau of Indian Standards: New Delhi, India, 1987.

- IS:383; Coarse and Fine Aggregate for Concrete- Specification. Bureau of Indian Standards: New Delhi, India, 2016.

- IS:10262; Recommended Guidelines for Concrete Mix Design. Bureau of Indian Standards: New Delhi, India, 2009.

- IS:516; Method of Tests for the Strength of the Concrete. Bureau of Indian Standards: New Delhi, India, 1959.

- IS:456; Plain And Reinforced Concrete -Code Of Practice. Bureau of Indian Standards: New Delhi, India, 2000.

- IS:5816; Splitting Tensile Strength of Concrete: Bureau of Indian Standard. Bureau of Indian Standards: New Delhi, India, 1999.

| Properties | Value |

|---|---|

| Specific gravity | 3.15 |

| Fineness modulus (%) | 1.5 |

| Standard consistency (%) | 31.6 |

| Initial setting time (minutes) | 100 |

| Final setting time (minutes) | 210 |

| Properties | Value |

|---|---|

| Specific gravity | 2.7 |

| Water absorption (%) | 0.91 |

| Impact value (%) | 10.2 |

| Crushing Value (%) | 12.8 |

| Properties | Value |

|---|---|

| Specific gravity | 2.65 |

| Zone | II |

| Fineness modulus | 2.82 |

| Water absorption (%) | 1.85 |

| Properties | Value |

|---|---|

| Particle size (mm) | 0.3 to 4.0 |

| Particle shape | Irregular |

| Appearance | Black and Glassy |

| Specific gravity | 3.86 |

| Unit weight (Kg/m3) | 3600 |

| Fineness modulus | 4.437 |

| Hardness | 6–7 |

| Water absorption (%) | 0.13 |

| Moisture content (%) | 0.1% |

| Chemical Component | Percentage |

|---|---|

| Fe | 4.087 |

| Fe2O3 | 52 |

| Fe3O4 | 8 |

| SiO2 | 27.85 |

| CaO | 3.78 |

| S | 0.9 |

| Cu | 0.65 |

| Compressive Strength (Cube Samples) | 0% Copper Slag | 25% Copper Slag | 50% Copper Slag | 75% Copper Slag | 100% Copper Slag |

|---|---|---|---|---|---|

| 0% bacteria | 3 | 3 | 3 | 3 | 3 |

| 1% bacteria | 3 | 3 | 3 | 3 | 3 |

| 2% bacteria | 3 | 3 | 3 | 3 | 3 |

| Flexural Strength (Prism Samples) | 0% Copper Slag | 25% Copper Slag | 50% Copper Slag | 75% Copper Slag | 100% Copper Slag |

|---|---|---|---|---|---|

| 0% bacteria | 3 | 3 | 3 | 3 | 3 |

| 1% bacteria | 3 | 3 | 3 | 3 | 3 |

| 2% bacteria | 3 | 3 | 3 | 3 | 3 |

| Split Tensile Strength (Cylinder Samples) | 0% Copper Slag | 25% Copper Slag | 50% Copper Slag | 75% Copper Slag | 100% Copper Slag |

|---|---|---|---|---|---|

| 0% bacteria | 3 | 3 | 3 | 3 | 3 |

| 1% bacteria | 3 | 3 | 3 | 3 | 3 |

| 2% bacteria | 3 | 3 | 3 | 3 | 3 |

| Sl. No. | Percentage of Bacteria (%) | Optimum Percentage of Copper Slag | Compressive Strength at Optimum Percentage of Copper Slag (N/mm2) |

|---|---|---|---|

| 1 | 0 | 75 | 26.8 |

| 2 | 1 | 75 | 40.8 |

| 3 | 2 | 75 | 45.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rohini, I.; Padmapriya, R. Properties of Bacterial Copper Slag Concrete. Buildings 2023, 13, 290. https://doi.org/10.3390/buildings13020290

Rohini I, Padmapriya R. Properties of Bacterial Copper Slag Concrete. Buildings. 2023; 13(2):290. https://doi.org/10.3390/buildings13020290

Chicago/Turabian StyleRohini, I., and R. Padmapriya. 2023. "Properties of Bacterial Copper Slag Concrete" Buildings 13, no. 2: 290. https://doi.org/10.3390/buildings13020290

APA StyleRohini, I., & Padmapriya, R. (2023). Properties of Bacterial Copper Slag Concrete. Buildings, 13(2), 290. https://doi.org/10.3390/buildings13020290