Building Information Modelling, Integrated Project Delivery, and Lean Construction Maturity Attributes: A Delphi Study

Abstract

:1. Research Background and Motivation

- What critical attributes must be assessed in evaluating BIL maturity?

- What is the perceived importance of those attributes by knowledge-related experts?

2. Research Methodology

- The second phase involved compiling a list of sub-attributes to link BIM and IPD to LC principles and establishing the second level of the BIL framework based on the literature. Some attributes were also identified by reviewing the existing BIM assessment tools;

- Two rounds of the Delphi method were used to validate the attributes through an agreement among the selected participants. The Delphi method is used when there is no explicit agreement or actual resources on a specific phenomenon, such as BIL attributes [18]. There are various techniques to initiate the Delphi survey’s development phase. Some studies begin with open-ended questions designed to collect expert suggestions [19]. However, most studies begin with a literature review to establish an initial list of attributes that can be revised and evaluated by the Delphi panel [20]. Hence, using a structured questionnaire and open-ended questions in the Delphi rounds is common. This technique was applied to evaluate the significance of proposed attributes and retrieve other attributes that had been overlooked in the literature review round [21] (Figure 1).

2.1. BIL MM Attributes Identification

- “Reduce the share of non-value-adding activities, cycle time, and variability;

- Simplify by minimizing the number of steps, parts, and linkages;

- Increase output flexibility and process transparency;

- Increase output value through systematic consideration of customer requirements;

- Focus control on the complete process;

- Build continuous improvement into the process;

- Balance flow improvement with conversion improvement and benchmark”.

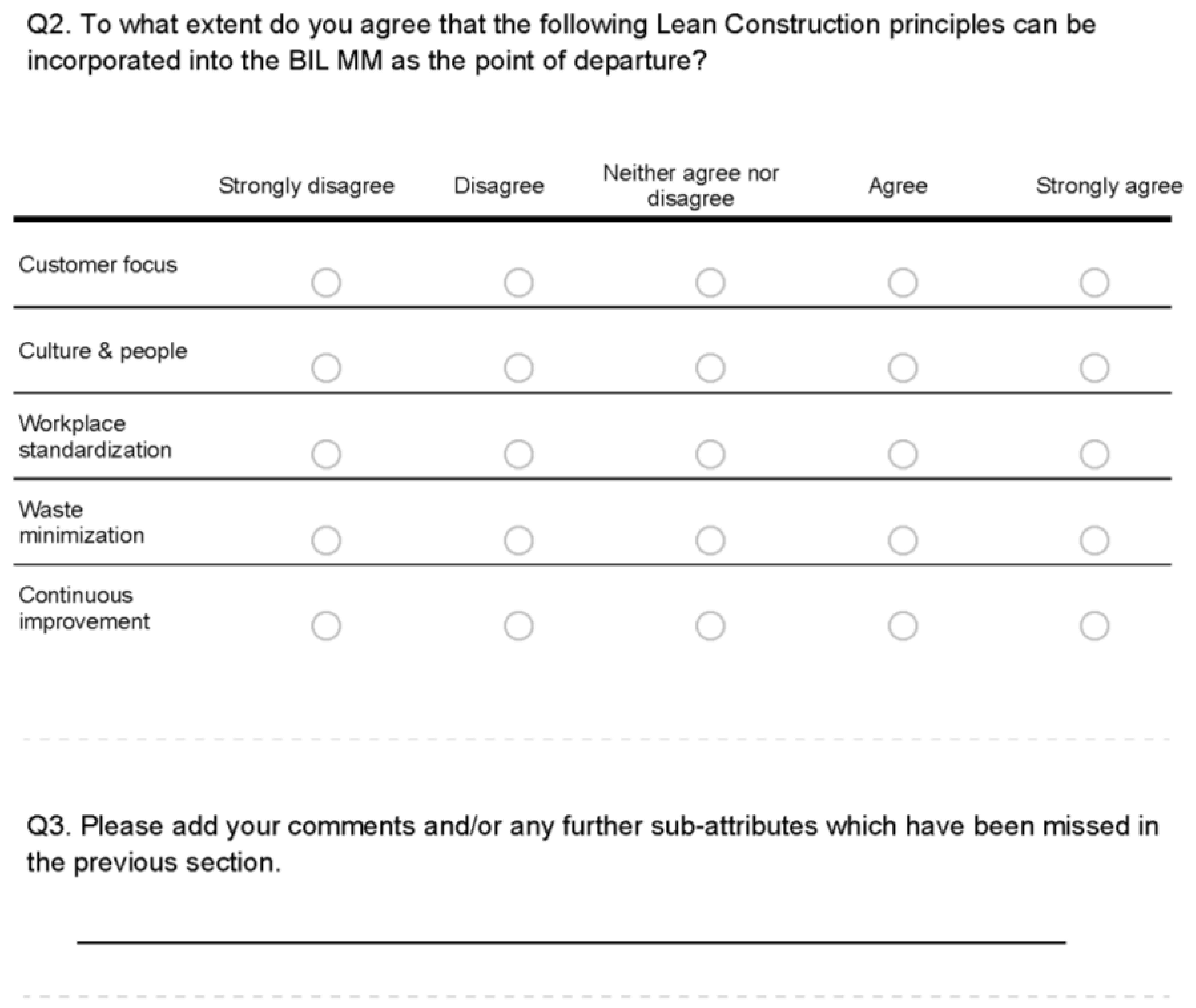

- “Customer focus;

- Culture/people;

- Workplace standardization;

- Waste minimization;

- Continuous improvement”.

2.1.1. Customer Focus

2.1.2. Culture/People

2.1.3. Workplace Standardization

2.1.4. Waste Minimization

2.1.5. Continuous Improvement (CI)

2.2. Delphi Method

- There were less than 15% changes in the levels of consensus, which was a sign of ending the Delphi rounds [85];

- Most of the BIL maturity sub-attributes reached a specific agreement on their level of importance [71];

- The high stability of Kendall’s W between rounds indicated that repeating Delphi rounds would not contribute further to this study.

| Attribute | M | SD | OA | A | SA | Sub-Attribute | M | SD | OA | A | SA |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Customer focus | 4.38 | 0.74 | 84.62 | 30.77% | 53.85% |

| 4.23 | 0.58 | 92.31% | 61.54% | 30.77% |

| 4.77 | 0.42 | 100% | 23.08% | 76.92% | ||||||

| 4.54 | 0.63 | 92.31% | 30.77% | 61.54% | ||||||

| Culture and people | 4.31 | 0.72 | 84.61 | 38.46% | 46.15% |

| 4.08 | 0.62 | 84.62% | 61.54% | 23.08 |

| 4.38 | 0.62 | 92.3% | 46.15% | 46.15% | ||||||

| 4.69 | 0.61 | 92.3% | 15.38% | 76.92% | ||||||

| 4.31 | 0.72 | 84.61% | 38.46% | 46.15% | ||||||

| 3.46 | 0.63 | 38.46% | 30.77% | 7.69% | ||||||

| 4.62 | 0.49 | 100% | 38.46% | 61.54% | ||||||

| 4.77 | 0.58 | 84.62% | 7.69% | 84.62% | ||||||

| Workplace standardization | 4.38 | 0.62 | 92.31 | 46.15% | 46.15% |

| 4.46 | 0.63 | 92.31% | 38.46% | 53.85% |

| 4.00 | 0.78 | 69.23% | 38.46% | 30.77% | ||||||

| 3.92 | 0.73 | 69.23% | 46.15% | 23.08% | ||||||

| 4.00 | 0.96 | 69.23% | 30.77% | 38.46% | ||||||

| 3.85 | 0.53 | 76.92% | 69.23% | 7.69% | ||||||

| Waste minimization | 4.54 | 0.63 | 92.31 | 30.77% | 61.54% |

| 4.15 | 0.77 | 76.92% | 38.46% | 38.46% |

| 4.62 | 0.49 | 100% | 38.46% | 61.54% | ||||||

| 4.00 | 0.78 | 69.23% | 38.46% | 30.77% | ||||||

| 3.62 | 0.74 | 46.15% | 30.77% | 15.38% | ||||||

| 4.23 | 0.70 | 84.61% | 46.15% | 38.46% | ||||||

| 4.23 | 0.89 | 69.23% | 15.38% | 53.85% | ||||||

| 4.69 | 0.46 | 100% | 30.77% | 69.23% | ||||||

| Continuous improvement | 4.54 | 0.63 | 92.31 | 30.77% | 61.54% |

| 4.31 | 0.61 | 92.31% | 53.85% | 38.46% |

| 4.38 | 0.62 | 92.31% | 46.15% | 46.15% | ||||||

| 4.23 | 0.58 | 92.31% | 61.54% | 30.77% | ||||||

| 4.54 | 0.75 | 84.61% | 15.38% | 69.23% |

3. Discussion

4. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A. The Delphi Survey Questionnaire Example

References

- Ling, F.Y.Y.; Teo, P.X.; Li, S.; Zhang, Z.; Ma, Q. Adoption of Integrated Project Delivery practices for superior project performance. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2020, 12, 05020014. [Google Scholar] [CrossRef]

- Ozorhon, B.; Karahan, U. Critical success factors of building information modeling implementation. J. Manag. Eng. 2017, 33, 04016054. [Google Scholar] [CrossRef]

- Sacks, R.; Koskela, L.; Dave, B.A.; Owen, R. Interaction of lean and building information modeling in construction. J. Constr. Eng. Manag. 2010, 136, 968–980. [Google Scholar] [CrossRef] [Green Version]

- Azhar, S.; Nadeem, A.; Mok, J.Y.; Leung, B.H. Building Information Modeling (BIM): A new paradigm for visual interactive modeling and simulation for construction projects. In Proceedings of the First International Conference on Construction in Developing Countries, Loughborough, UK, 14–16 May 2008; pp. 435–446. [Google Scholar]

- Jones, B. Integrated Project Delivery (IPD) for Maximizing Design and Construction Considerations Regarding Sustainability. Procedia Eng. 2014, 95, 528–538. [Google Scholar] [CrossRef] [Green Version]

- Albalkhy, W.; Sweis, R. Barriers to adopting lean construction in the construction industry: A literature review. Int. J. Lean Six Sigma 2020, 12, 210–236. [Google Scholar] [CrossRef]

- Machado, C.S.; Brahmi, B.F.; Kamari, A. Understanding the Benefits of BIM/Lean/IPD framework when carried-out simultaneously. In Proceedings of the International Conference of Architectural Science Association, Auckland, New Zealand, 26–27 November 2020; pp. 1273–1282. [Google Scholar]

- Andersen, E.S.; Jessen, S.A. Project maturity in organizations. Int. J. Proj. Manag. 2003, 21, 457–461. [Google Scholar] [CrossRef]

- Paulk, M.C. The Capability Maturity Model: Guidelines for Improving the Software Process; Addison-Wesley Professional: Boston, MA, USA, 1995; Available online: https://resources.sei.cmu.edu/asset_files/technicalreport/1993_005_001_16211.pdf (accessed on 15 November 2022).

- Rashidian, S.; Drogemuller, R.; Omrani, S. The compatibility of existing BIM maturity models with lean construction and integrated project delivery. J. Inf. Technol. Constr. (ITcon) 2022, 27, 496–511. [Google Scholar] [CrossRef]

- Rodegheri, P.M.; Serra, S.M.B. Maturity models to evaluate lean construction in Brazilian projects. Braz. J. Oper. Prod. Manag. 2020, 17, 1–21. [Google Scholar] [CrossRef]

- Siebelink, S.; Voordijk, J.T.; Adriaanse, A. Developing and testing a tool to evaluate BIM maturity: Sectoral analysis in the Dutch construction industry. J. Constr. Eng. Manag. 2018, 144, 05018007. [Google Scholar]

- Wu, C.; Xu, B.; Mao, C.; Li, X. Overview of BIM maturity measurement tools. J. Inf. Technol. Constr. 2017, 22, 34–62. [Google Scholar]

- Evans, M.; Farrell, P.; Elbeltagi, E.; Dion, H. Barriers to integrating lean construction and integrated project delivery (IPD) on construction megaprojects towards the global integrated delivery (GID) in multinational organizations: Lean IPD&GID transformative initiatives. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- Viana, M.L.; Hadikusumo, B.H.W.; Mohammad, M.Z.; Kahvandi, Z. Integrated Project Delivery (IPD): An updated review and analysis case study. J. Eng. Proj. Prod. Manag. 2020, 10, 147–161. [Google Scholar]

- Koskela, L.; Howell, G.; Ballard, G.; Tommelein, I. The foundations of lean construction. Des. Constr. Build. Value 2002, 291, 211–226. [Google Scholar]

- Diekmann, J.E.; Balonick, J.; Krewedl, M.; Troendle, L. Measuring lean conformance. In Proceedings of the 11th Annual Conference of the International Group for Lean Construction, Blacksburg, VA, USA, 22–24 July 2003. [Google Scholar]

- Ruppert, J.; Duncan, R.G. Defining and characterizing ecosystem services for education: A Delphi study. J. Res. Sci. Teachnol. 2017, 54, 737–763. [Google Scholar] [CrossRef]

- Esmaeilpoorarabi, N.; Yigitcanlar, T.; Guaralda, M.; Kamruzzaman, M. Evaluating place quality in innovation districts: A Delphic hierarchy process approach. Land Use Policy 2018, 76, 471–486. [Google Scholar] [CrossRef]

- Habibi, A.; Sarafrazi, A.; Izadyar, S. Delphi technique theoretical framework in qualitative research. Int. J. Eng. Sci. 2014, 3, 8–13. [Google Scholar]

- Malakouti, M.; Faizi, M.; Hosseini, S.-B.; Norouzian-Maleki, S. Evaluation of flexibility components for improving housing quality using fuzzy TOPSIS method. J. Build. Eng. 2019, 22, 154–160. [Google Scholar] [CrossRef]

- Wendler, R. The maturity of maturity model research: A systematic mapping study. Inf. Softw. Technol. 2012, 54, 1317–1339. [Google Scholar] [CrossRef]

- Benachio, G.L.F.; Freitas, M.d.C.D.; Tavares, S.F. Interactions between lean construction principles and circular economy practices for the construction industry. J. Constr. Eng. Manag. 2021, 147, 04021068. [Google Scholar] [CrossRef]

- Sweis, G.J.; Hiyassat, M.; Al-Hroub, F.F. Assessing lean conformance by first-grade contractors in the Jordanian construction industry. Constr. Innov. 2016, 16, 446–459. [Google Scholar] [CrossRef]

- Emmitt, S.; Sander, D.; Christoffersen, A.K. The value universe: Defining a value based approach to lean construction. In Proceedings of the IGLC, Sydney, Australia, 19–21 July 2005; pp. 57–64. [Google Scholar]

- Bayhan, H.G.; Demirkesen, S.; Zhang, C.; Tezel, A. A lean construction and BIM interaction model for the construction industry. Prod. Plan. Control 2021, 1–28. [Google Scholar] [CrossRef]

- Khanzode, A.; Fischer, M.; Reed, D. Case study of the implementation of the lean project delivery system (LPDS) using virtual building technologies on a large healthcare project. In Proceedings of the 13th International Group for Lean Construction Conference: Proceedings, Sydney, Australia, 19–21 July 2005; pp. 153–160. [Google Scholar]

- AIA. Integrated Project Delivery: A Guide; AIA: Washington, DC, USA, 2007. [Google Scholar]

- Nesensohn, C.; Bryde, D.; Ochieng, E.; Fearon, D.; Hackett, V. Assessing lean construction maturity. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction: Understanding and Improving Project Based Production, IGLC 2014, Oslo, Norway, 25–27 June 2014; pp. 1157–1168. [Google Scholar]

- O’Loingsigh, M.; Hore, A.; McAuley, B.; Deeney, J. Aligning BIM and lean methodologies within the capital works management framework in Ireland. In Proceedings of the Computing in Civil and Building Engineering (2014), Orlando, FL, USA, 23–25 June 2014; pp. 1522–1529. [Google Scholar]

- Green, S.D.; May, S.C. Lean construction: Arenas of enactment, models of diffusion and the meaning of ‘leanness’. Build. Res. Inf. 2005, 33, 498–511. [Google Scholar] [CrossRef]

- Ahmed, S.; Hossain, M.M.; Haq, I. Implementation of lean construction in the construction industry in Bangladesh: Awareness, benefits and challenges. Int. J. Build. Pathol. Adapt. 2020, 39, 368–406. [Google Scholar] [CrossRef]

- Tezel, A.; Nielsen, Y. Lean Construction Conformance among Construction Contractors in Turkey. J. Manag. Eng. 2013, 29, 236–250. [Google Scholar] [CrossRef]

- Schimanski, M.; Monizza, M. The Last Planner® System and Building Information Modeling in Construction Execution: From an Integrative Review to a Conceptual Model for Integration. Appl. Sci. 2020, 10, 821. [Google Scholar] [CrossRef]

- Killian, J.; Abdallah, M.; Clevenger, C. Industry Feedback on Implementing Pull Planning in the Construction Industry. In Proceedings of the Construction Research Congress 2020: Project Management and Controls, Materials, and Contracts—Selected Papers from the Construction Research Congress 2020, Tempe, AZ, USA, 8–10 March 2020; pp. 515–524. [Google Scholar]

- Sbiti, M.; Beddiar, K.; Beladjine, D.; Perrault, R.; Mazari, B. Toward BIM and LPS Data Integration for Lean Site Project Management: A State-of-the-Art Review and Recommendations. Buildings 2021, 11, 196. [Google Scholar] [CrossRef]

- Toledo, M.; Olivares, K.; González, V. Exploration of a lean-BIM planning framework: A last planner system and BIM-based case study. In Proceedings of the IGLC 2016—24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016; pp. 3–12. [Google Scholar]

- Locatelli, G.; Mancini, M.; Gastaldo, G.; Mazza, F. Improving projects performance with lean construction: State of the art, applicability and impacts. Organ. Technol. Manag. Constr. Int. J. 2013, 5, 775–783. [Google Scholar] [CrossRef]

- Ahmed, M.; Wong, L. The barriers of the implementation of lean construction in Klang Valley, Malaysia. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Ulaanbaatar, Mongolia, 10–13 September 2020; IOP Publishing: Bristol, UK, 2020; p. 012043. [Google Scholar]

- Liao, L.; Teo, E.A.L. Managing critical drivers for building information modelling implementation in the Singapore construction industry: An organizational change perspective. Int. J. Constr. Manag. 2018, 19, 240–256. [Google Scholar] [CrossRef]

- Durdyev, S.; Hosseini, M.R.; Martek, I.; Ismail, S.; Arashpour, M. Barriers to the use of integrated project delivery (IPD): A quantified model for Malaysia. Eng. Constr. Archit. Manag. 2019, 27, 186–204. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of Building Information Modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef] [Green Version]

- Orr, C. Lean leadership in construction. In Proceedings of the 13th Annual Conference of the International Group for Lean Construction (IGLC-13), Sydney, Australia, 19–21 July 2005; pp. 345–351. [Google Scholar]

- Ashcraft, H. Transforming project delivery: Integrated project delivery. Oxf. Rev. Econ. Policy 2022, 38, 369–384. [Google Scholar] [CrossRef]

- Liu, Y.; Van Nederveen, S.; Hertogh, M. Understanding effects of BIM on collaborative design and construction: An empirical study in China. Int. J. Proj. Manag. 2017, 35, 686–698. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, K. A study of lean construction and visual management tools through cluster analysis. Ain Shams Eng. J. 2021, 12, 1153–1162. [Google Scholar] [CrossRef]

- Rogers, J.; Chong, H.-Y.; Preece, C. Adoption of Building Information Modelling technology (BIM): Perspectives from Malaysian engineering consulting services firms. Eng. Constr. Archit. Manag. 2015, 22, 424–445. [Google Scholar] [CrossRef]

- Dalui, P.; Elghaish, F.; Brooks, T.; McIlwaine, S. Integrated Project Delivery with BIM: A Methodical Approach within the UK Consulting Sector. J. Inf. Technol. Constr. 2021, 26, 922–935. [Google Scholar] [CrossRef]

- Bascoul, A.M.; Tommelein, I.D.; Douthett, D. Visual Management of Daily Construction Site Space Use. Front. Built Environ. 2020, 6, 139. [Google Scholar] [CrossRef]

- Eastman, C.M.; Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Gurevich, U.; Sacks, R. Examination of the effects of a KanBIM production control system on subcontractors’ task selections in interior works. Autom. Constr. 2014, 37, 81–87. [Google Scholar] [CrossRef]

- Oral, E.L.; Mıstıkoglu, G.; Erdis, E. JIT in developing countries—A case study of the Turkish prefabrication sector. Build. Environ. 2003, 38, 853–860. [Google Scholar] [CrossRef]

- Lu, Q.; Won, J.; Cheng, J.C. A financial decision making framework for construction projects based on 5D Building Information Modeling (BIM). Int. J. Proj. Manag. 2016, 34, 3–21. [Google Scholar] [CrossRef]

- Joblot, L.; Paviot, T.; Deneux, D.; Lamouri, S. Building Information Maturity Model specific to the renovation sector. Autom. Constr. 2019, 101, 140–159. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, D.; Li, J. A dedicated collaboration platform for integrated project delivery. Autom. Constr. 2018, 86, 199–209. [Google Scholar] [CrossRef]

- Temel, B.A.; Başağa, H.B.; Temel, M.U.; Yılmaz, G.K.; Nasery, M.M. Big Room concept in project management and control. J. Constr. Eng. Manag. Innov. 2019, 2, 204–214. [Google Scholar] [CrossRef]

- Du, J.; Zou, Z.; Shi, Y.; Zhao, D. Zero latency: Real-time synchronization of BIM data in virtual reality for collaborative decision-making. Autom. Constr. 2018, 85, 51–64. [Google Scholar] [CrossRef]

- Bajjou, M.; Chafi, A. The potential effectiveness of lean construction principles in reducing construction process waste: An input-output model. J. Mech. Eng. Sci. 2018, 12, 4141–4160. [Google Scholar] [CrossRef]

- Klein, L.L.; Tonetto, M.S.; Avila, L.V.; Moreira, R. Management of lean waste in a public higher education institution. J. Clean. Prod. 2021, 286, 125386. [Google Scholar] [CrossRef]

- Won, J.; Cheng, J.C.; Lee, G. Quantification of construction waste prevented by BIM-based design validation: Case studies in South Korea. Waste Manag. 2016, 49, 170–180. [Google Scholar] [CrossRef]

- Al Hattab, M.; Hamzeh, F. Simulating the dynamics of social agents and information flows in BIM-based design. Autom. Constr. 2018, 92, 1–22. [Google Scholar] [CrossRef]

- Igwe, C.; Nasiri, F.; Hammad, A. An empirical study on non-physical waste factors in the construction industry. Eng. Constr. Archit. Manag. 2021, 29, 4088–4106. [Google Scholar] [CrossRef]

- Park, C.-S.; Lee, D.-Y.; Kwon, O.-S.; Wang, X. A framework for proactive construction defect management using BIM, augmented reality and ontology-based data collection template. Autom. Constr. 2013, 33, 61–71. [Google Scholar] [CrossRef]

- Bajjou, M.S.; Chafi, A.; Ennadi, A. Development of a Conceptual Framework of Lean Construction Principles: An Input–Output Model. J. Adv. Manuf. Syst. 2019, 18, 1–34. [Google Scholar] [CrossRef]

- Igwe, C.; Hammad, A.; Nasiri, F. Influence of lean construction wastes on the transformation-flow-value process of construction. Int. J. Constr. Manag. 2020, 22, 2598–2604. [Google Scholar] [CrossRef]

- Demirkesen, S.; Sadikoglu, E.; Jayamanne, E. Investigating effectiveness of time studies in lean construction projects: Case of Transbay Block 8. Prod. Plan. Control 2022, 33, 1283–1303. [Google Scholar] [CrossRef]

- Douglas, J.; Jiju Antony, P.; Antony, J.; Douglas, A. Waste identification and elimination in HEIs: The role of Lean thinking. Int. J. Qual. Reliab. Manag. 2015, 32, 970–981. [Google Scholar] [CrossRef]

- Dave, B.; Koskela, L.; Kiviniemi, A.; Tzortzopoulos, P.; Owen, R. Implementing Lean in Construction: Lean Construction and BIM; CIRIA: London, 2013. [Google Scholar]

- Love, P.E.; Lopez, R.; Kim, J.T. Design error management: Interaction of people, organization and the project environment in construction. Struct. Infrastruct. Eng. 2014, 10, 811–820. [Google Scholar] [CrossRef]

- Koseoglu, O.; Sakin, M.; Arayici, Y. Exploring the BIM and lean synergies in the Istanbul Grand Airport construction project. Eng. Constr. Archit. Manag. 2018, 25, 1339–1354. [Google Scholar] [CrossRef]

- Omotayo, T.S.; Boateng, P.; Osobajo, O.; Oke, A.; Obi, L.I. Systems thinking and CMM for continuous improvement in the construction industry. Int. J. Product. Perform. Manag. 2019, 69, 271–296. [Google Scholar] [CrossRef]

- Pekuri, A.; Herrala, M.; Aapaoja, A.; Haapasalo, H. Applying Lean in construction–cornerstones for implementation. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012; pp. 18–20. [Google Scholar]

- Ammar, A.; Copping, A.; Shepher, P.; Duncan, A. Using the ARUP BIM maturity measure to demonstrate BIM implementation in practice. In Proceedings of the 32nd Annual ARCOM Conference, Manchester, UK, 5–7 September 2016; pp. 25–34. [Google Scholar]

- Nascimento, D.L.d.M.; Sotelino, E.D.; Lara, T.P.S.; Caiado, R.G.G.; Ivson, P. Constructability in Industrial Plants Construction: A BIM-Lean Approach Using the Digital Obeya Room Framework. J. Civ. Eng. Manag. 2017, 23, 1100–1108. [Google Scholar] [CrossRef] [Green Version]

- Skulmoski, G.J.; Hartman, F.T.; Krahn, J. The Delphi method for graduate research. J. Inf. Technol. Educ. Res. 2007, 6, 1–21. [Google Scholar] [CrossRef]

- Adu-McVie, R.; Yigitcanlar, T.; Erol, I.; Xia, B. Classifying innovation districts: Delphi validation of a multidimensional framework. Land Use Policy 2021, 111, 105779. [Google Scholar] [CrossRef]

- Hallowell, M.R.; Gambatese, J.A. Qualitative research: Application of the Delphi method to CEM research. J. Constr. Eng. Manag. 2010, 136, 99–107. [Google Scholar] [CrossRef]

- Giel, I. Framework for Evaluating the BIM Competencies of Building Owners. Comput. Civ. Build. Eng. 2014, 2014, 552–559. [Google Scholar]

- Weidman, J.E.; Miller, K.R.; Christofferson, J.P.; Newitt, J.S. Best practices for dealing with price volatility in commercial construction. Int. J. Constr. Educ. Res. 2011, 7, 276–293. [Google Scholar] [CrossRef]

- Yeung, J.F.Y.; Chan, A.P.C.; Chan, D.W.M.; Li, L.K. Development of a partnering performance index (PPI) for construction projects in Hong Kong: A Delphi study. Constr. Manag. Econ. 2007, 25, 1219–1237. [Google Scholar] [CrossRef]

- Głuszek, E. Use of the e-Delphi method to validate the corporate reputation management maturity model (CR3M). Sustainability 2021, 13, 12019. [Google Scholar] [CrossRef]

- Barnes, S.J.; Mattsson, J. Understanding current and future issues in collaborative consumption: A four-stage Delphi study. Technol. Forecast. Soc. Chang. 2016, 104, 200–211. [Google Scholar] [CrossRef] [Green Version]

- Julsrud, T.E.; Priya Uteng, T. Technopolis, shared resources or controlled mobility? A net-based Delphi-study to explore visions of future urban daily mobility in Norway. Eur. J. Futur. Res. 2015, 3, 10. [Google Scholar] [CrossRef]

- Perveen, S.; Kamruzzaman, M.; Yigitcanlar, T. Developing policy scenarios for sustainable urban growth management: A Delphi approach. Sustainability 2017, 9, 1787. [Google Scholar] [CrossRef] [Green Version]

- Heiko, A. Consensus measurement in Delphi studies: Review and implications for future quality assurance. Technol. Forecast. Soc. Chang. 2012, 79, 1525–1536. [Google Scholar]

- Azzouz, A. Current Perspectives and Future Directions of BIM Assessment Methods. Ph.D. Thesis, University of Bath, Bath, UK, 2016. [Google Scholar]

- Chen, Y.; Dib, H.; Cox, R.F. A measurement model of building information modelling maturity. Constr. Innov. 2014, 14, 186–209. [Google Scholar] [CrossRef]

| Participants | Profession | Years of Experience | Expertise Area | Type of Organization |

|---|---|---|---|---|

| R1 | Civil Engineer | 10 | BIM, LC | A large business |

| R2 | Continuous improvement lead | 18 | Lean, IPD | A large business |

| R3 | Digital engineering project manager | 9 | BIM, IPD, LC | A large business |

| R4 | BIM and digital engeeing manager/ Academic | 17 | BIM, LC, IPD | A large business |

| R5 | Academic/ Construction and project manager | 20 | BIM, MM | A large business |

| R6 | Quantity surveyor/ Constructors association executive | 30 | LC, IPD | A micro-business |

| R7 | Building Engineer/ Academic | 8 | BIM, IPD | A large business |

| R8 | Mechanical engineering director | 25 | BIM, IPD | A small business |

| R9 | BIM/computation lead | 10 | BIM, IPD | A large business |

| R10 | Architectural Design manager | 30 | BIM | A large business |

| R11 | Digital technologies manager | 39 | BIM, IPD | A medium business |

| R12 | Architect/Director | 19 | BIM | A large business |

| R13 | Digital engineering director | 11 | BIM, IPD, LC | A large business |

| R14 | BIM Consultant | 10 | BIM, IPD, LC | A large business |

| R15 | Construction manageer | 19 | BIM, LC | A small business |

| Attribute | M | SD | OA | A | SA | Sub-Attribute | M | SD | OA | A | SA |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Customer focus | 4.21 | 0.94 | 64.28% | 7.14% | 57.14% |

| 3.86 | 0.83 | 71.43% | 50.00% | 21.43% |

| 4.79 | 0.41 | 100% | 21.43% | 78.57% | ||||||

| 4.64 | 0.61 | 92.86% | 21.43% | 71.43% | ||||||

| Culture and people | 4.43 | 0.73 | 85.71% | 28.57% | 57.14% |

| 3.86 | 0.99 | 70.88% | 42.86% | 28.57% |

| 4.29 | 0.7 | 85.72% | 42.86% | 42.86% | ||||||

| 4.64 | 0.61 | 92.86% | 21.43% | 71.43% | ||||||

| 4.71 | 0.59 | 92.86% | 14.29% | 78.57% | ||||||

| 3.5 | 0.5 | 50.00% | 50.00% | 0.00% | ||||||

| 4.5 | 0.63 | 92.85% | 35.71% | 57.14% | ||||||

| 4.5 | 0.63 | 92.85% | 35.71% | 57.14% | ||||||

| Workplace standardization | 4.57 | 0.62 | 92.86% | 28.57% | 64.29% |

| 4.29 | 0.8 | 78.57% | 28.57% | 50.00% |

| 3.86 | 0.74 | 64.29% | 42.86% | 21.43% | ||||||

| 4.07 | 0.88 | 64.29% | 21.43% | 42.86% | ||||||

| 3.71 | 1.39 | 71.42% | 35.71% | 35.71% | ||||||

| 3.93 | 0.8 | 64.28% | 35.71% | 28.57% | ||||||

| Waste minimization | 4.43 | 0.73 | 85.71% | 28.57% | 57.14% |

| 4.14 | 1.12 | 78.57% | 28.57% | 50.00% |

| 3.71 | 1.33 | 71.42% | 35.71% | 35.71% | ||||||

| 3.64 | 1.11 | 64.29% | 42.86% | 21.43% | ||||||

| 3.75 | 1.09 | 66.67% | 41.67% | 25.00% | ||||||

| 4.00 | 1.07 | 78.57% | 42.86% | 35.71% | ||||||

| 3.79 | 1.15 | 57.14% | 21.43% | 35.71% | ||||||

| 4.14 | 1.12 | 78.57% | 28.57% | 50.00% | ||||||

| Continuous improvement | 4.36 | 1.11 | 85.72% | 21.43% | 64.29% |

| 4.43 | 0.62 | 92.86% | 42.86% | 50.00% |

| 4.29 | 0.88 | 71.43% | 14.29% | 57.14% | ||||||

| 4.00 | 0.76 | 71.43% | 42.86% | 28.57% | ||||||

| 4.29 | 0.8 | 78.57% | 28.57% | 50.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rashidian, S.; Drogemuller, R.; Omrani, S. Building Information Modelling, Integrated Project Delivery, and Lean Construction Maturity Attributes: A Delphi Study. Buildings 2023, 13, 281. https://doi.org/10.3390/buildings13020281

Rashidian S, Drogemuller R, Omrani S. Building Information Modelling, Integrated Project Delivery, and Lean Construction Maturity Attributes: A Delphi Study. Buildings. 2023; 13(2):281. https://doi.org/10.3390/buildings13020281

Chicago/Turabian StyleRashidian, Sara, Robin Drogemuller, and Sara Omrani. 2023. "Building Information Modelling, Integrated Project Delivery, and Lean Construction Maturity Attributes: A Delphi Study" Buildings 13, no. 2: 281. https://doi.org/10.3390/buildings13020281