Compressive Test Investigation and Numerical Simulation of Polyvinyl-Alcohol (PVA)-Fiber-Reinforced Rubber Concrete

Abstract

1. Introduction

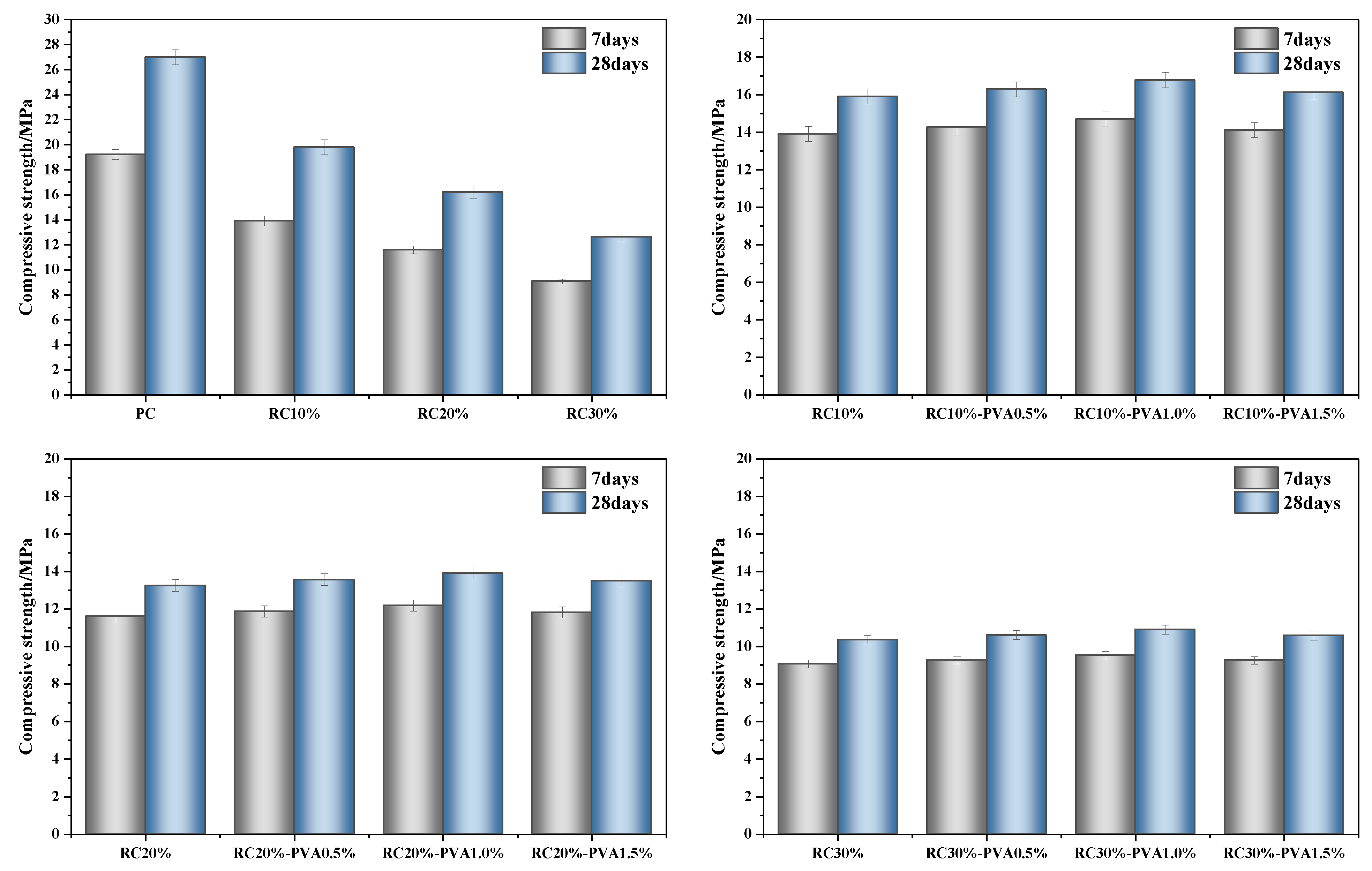

2. Test Overview

2.1. Test Materials

2.2. Test Mix Proportion

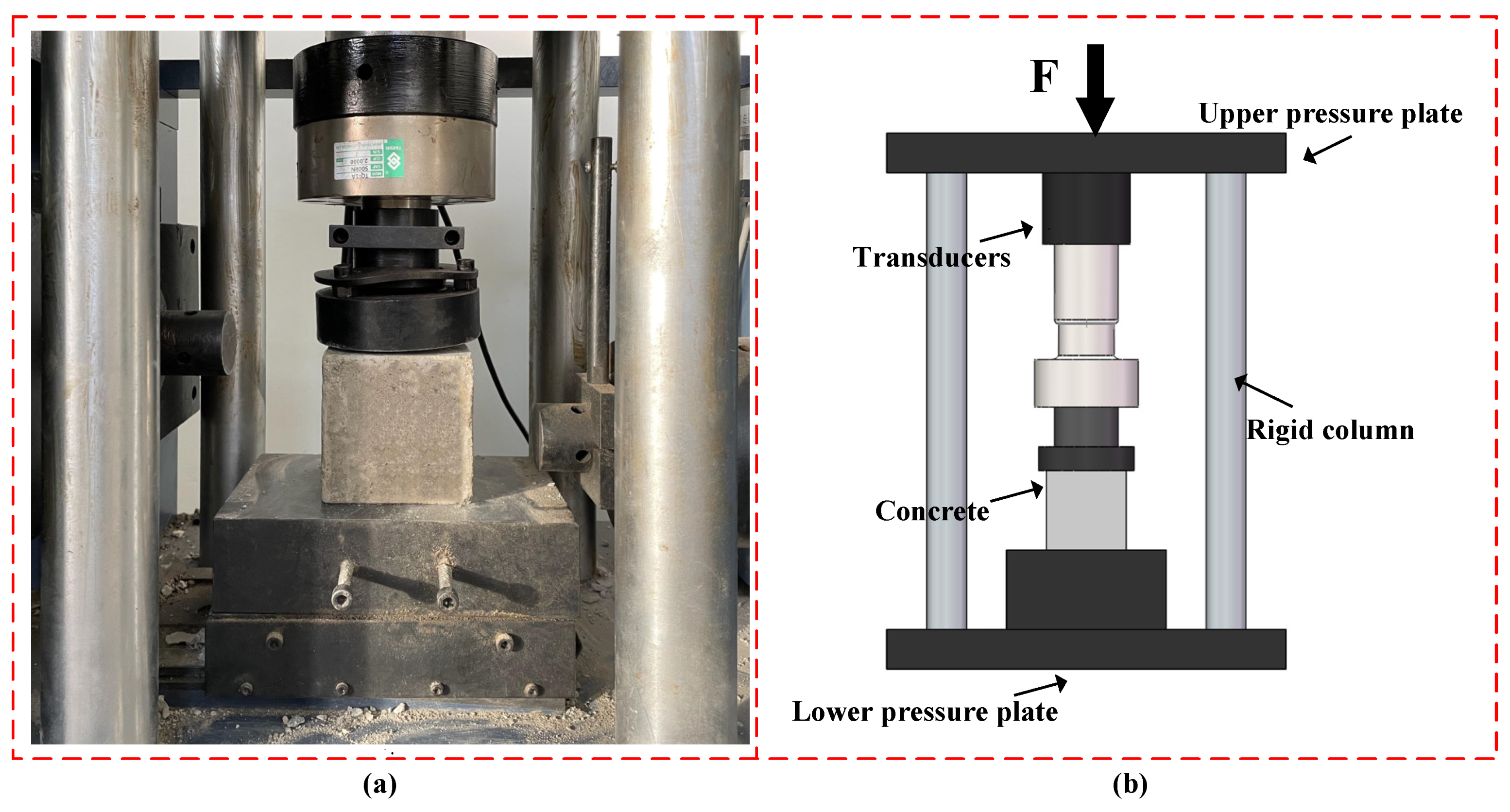

2.3. Loading Device and Test Method

3. Test Process and Failure Mode

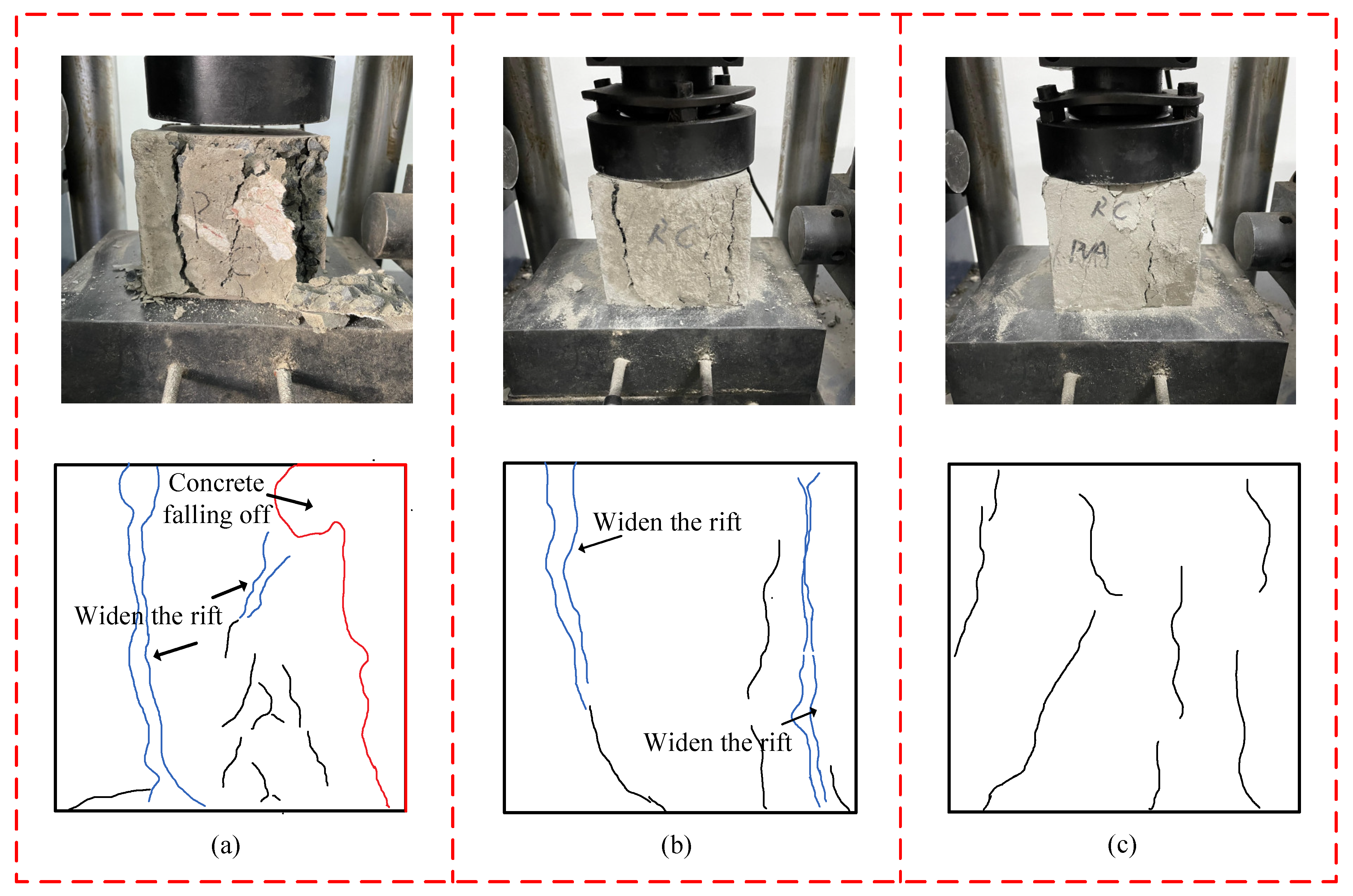

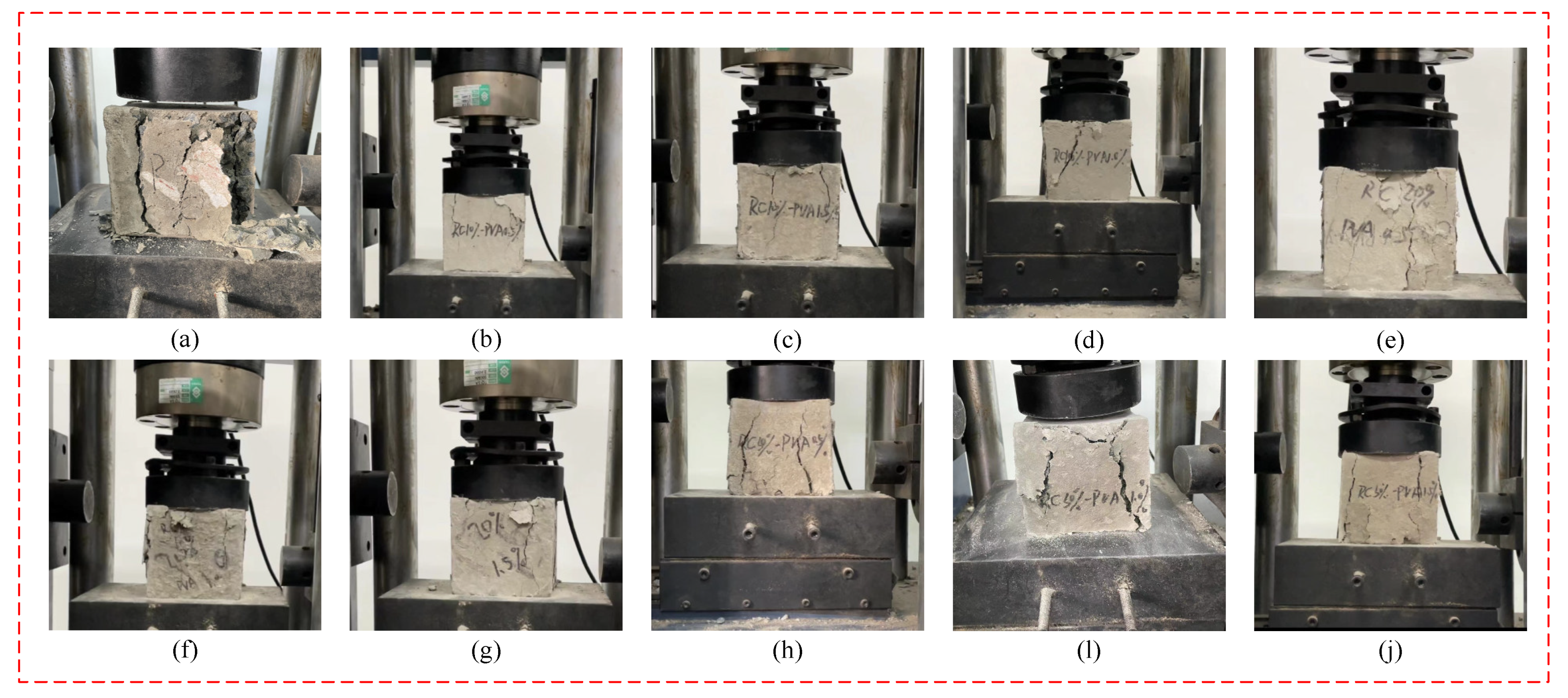

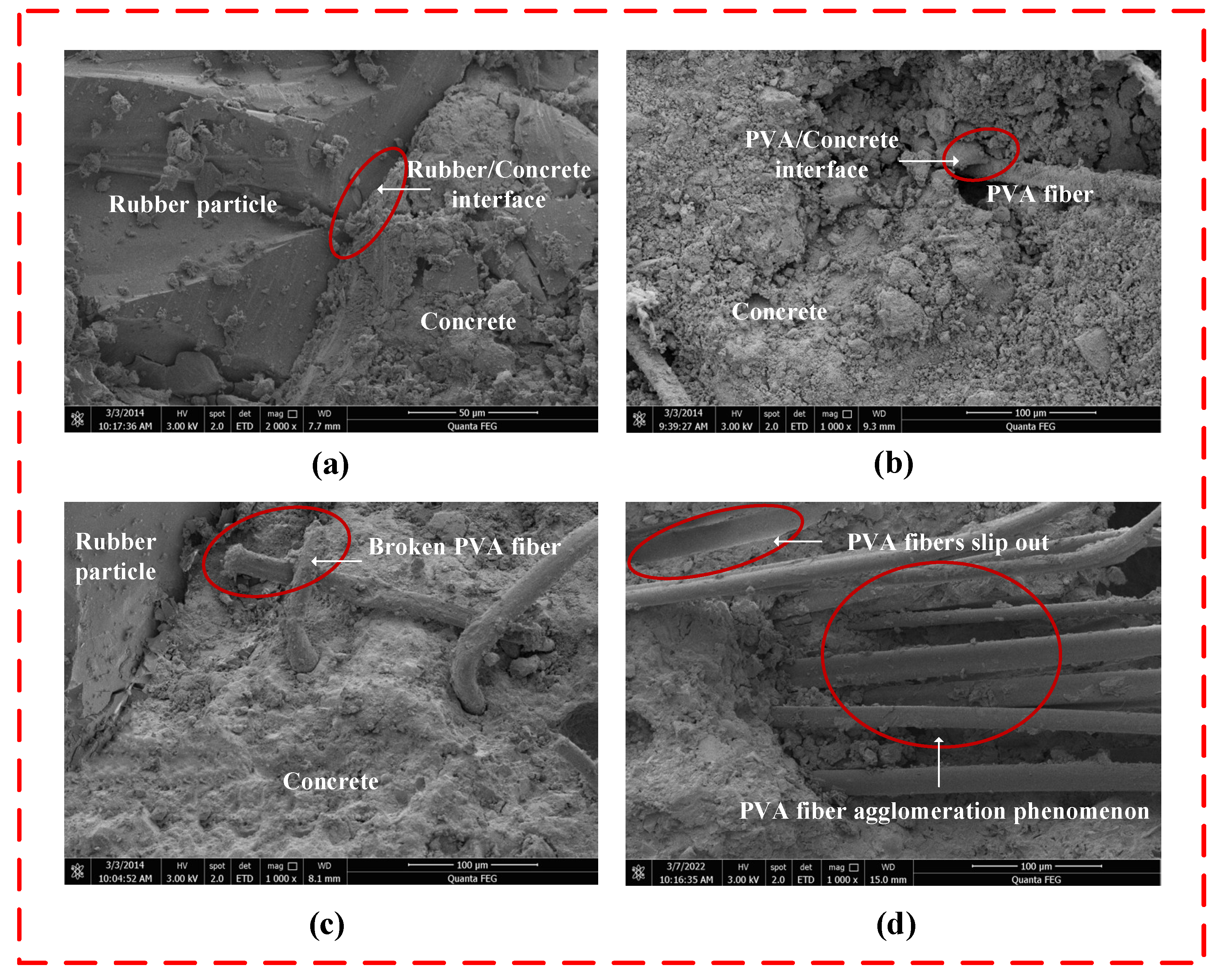

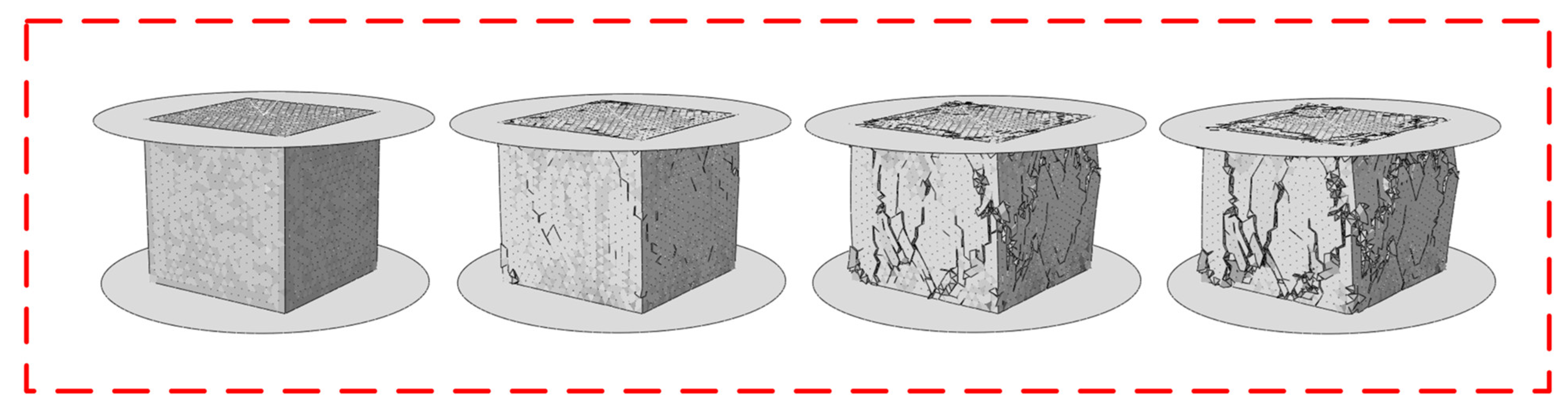

3.1. PVA Rubber/Concrete Failure Process and Morphology

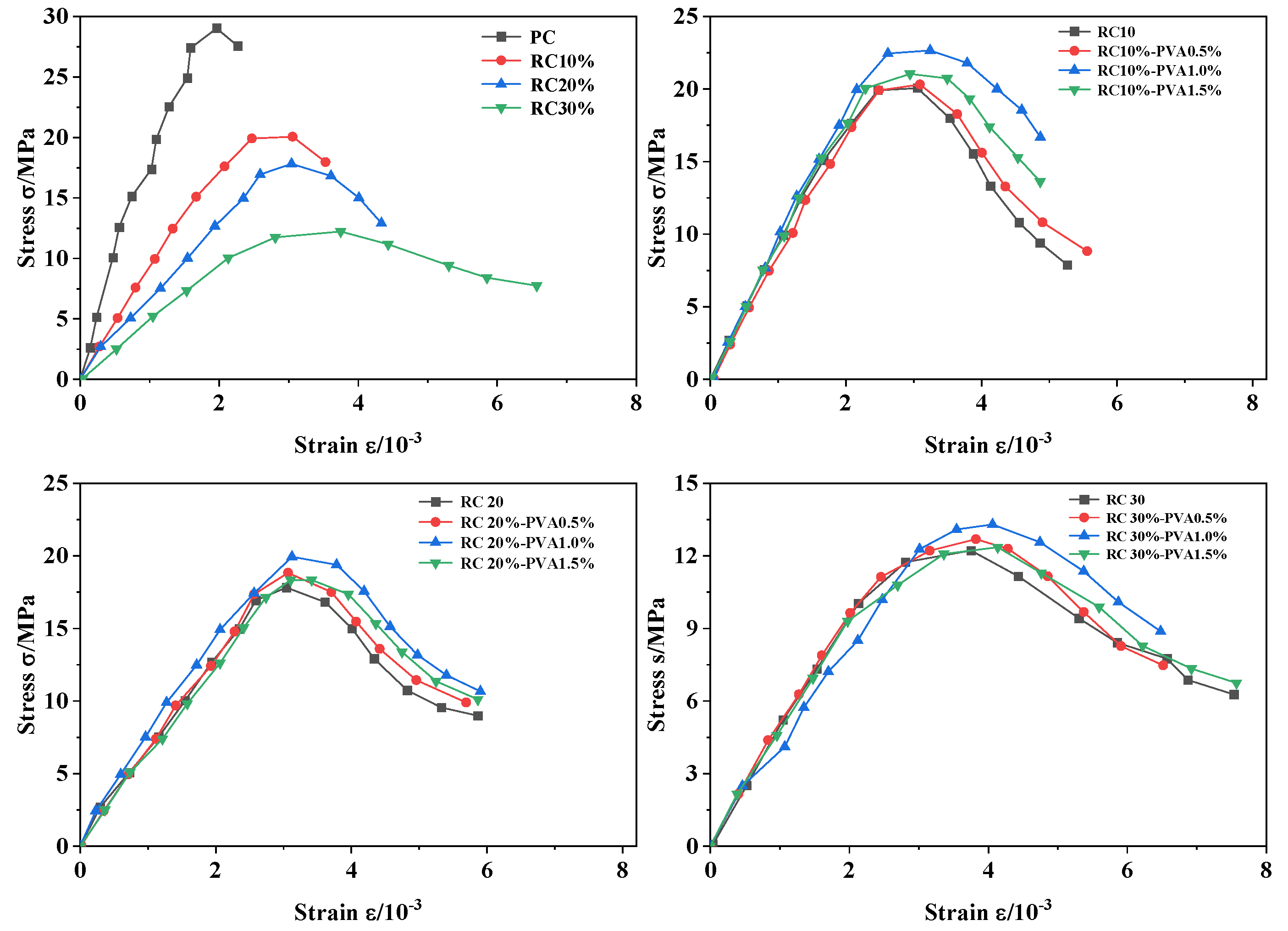

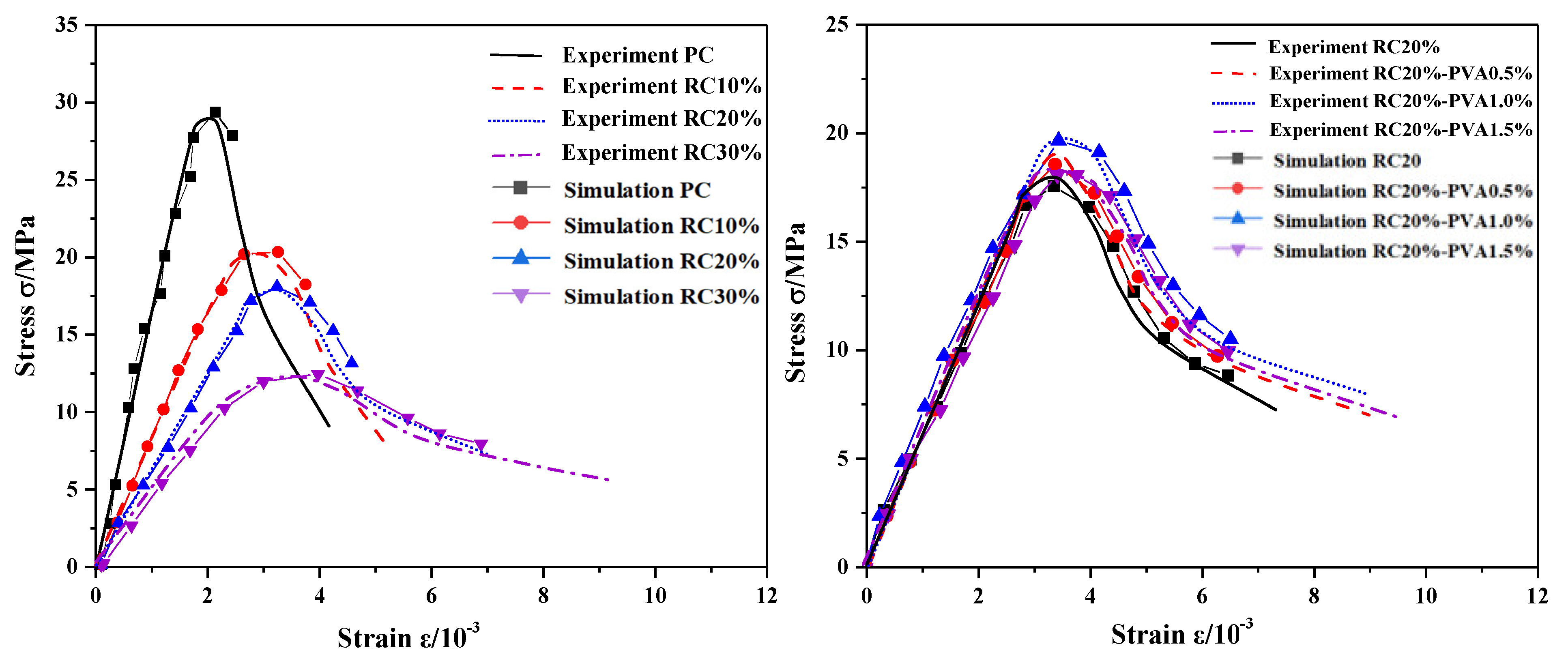

3.2. PVA-Rubber/Concrete Compressive Stress Strain

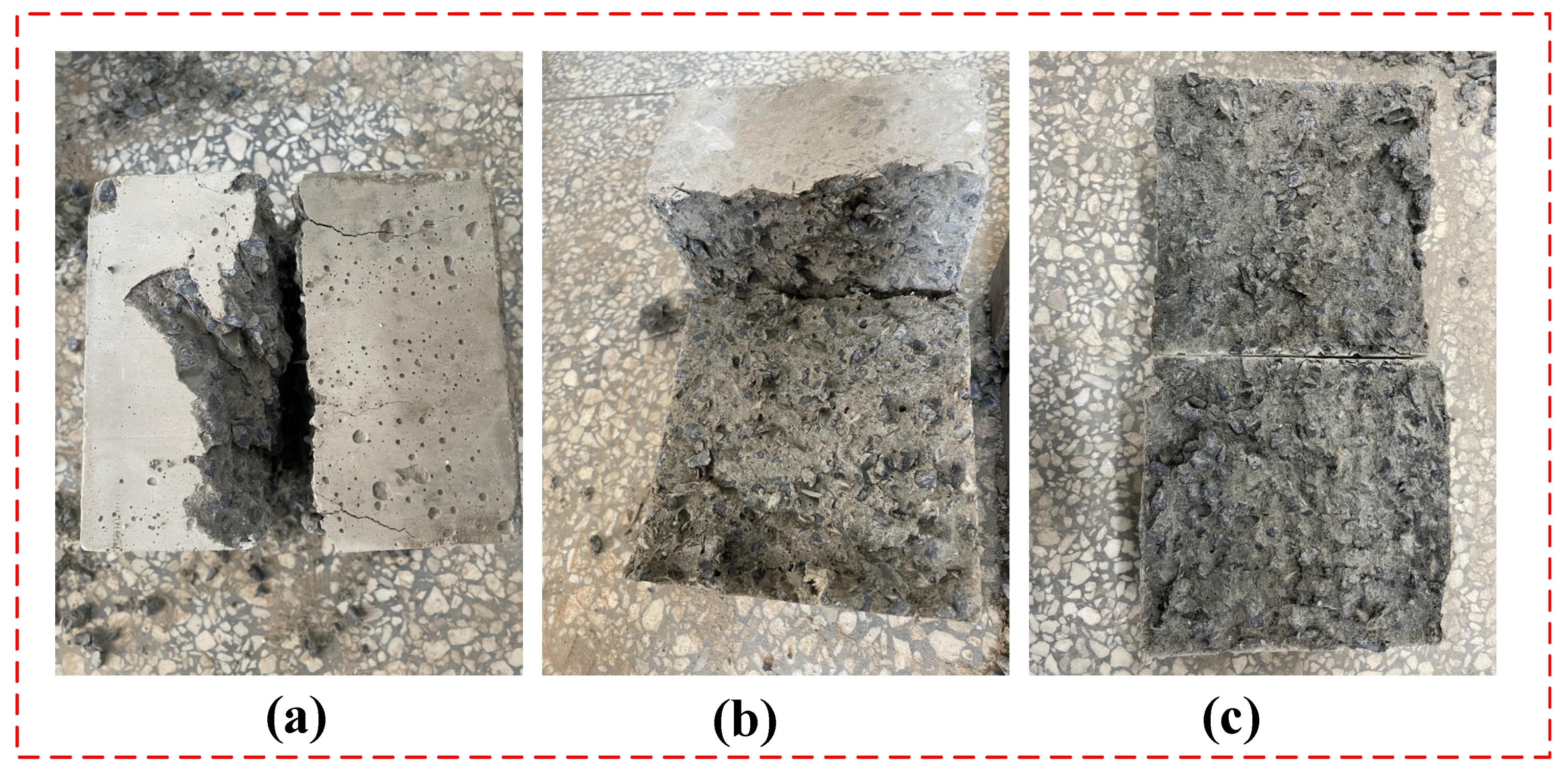

3.3. Failure Mechanism of PVA Fiber Pull-Out Rubber Concrete Interface

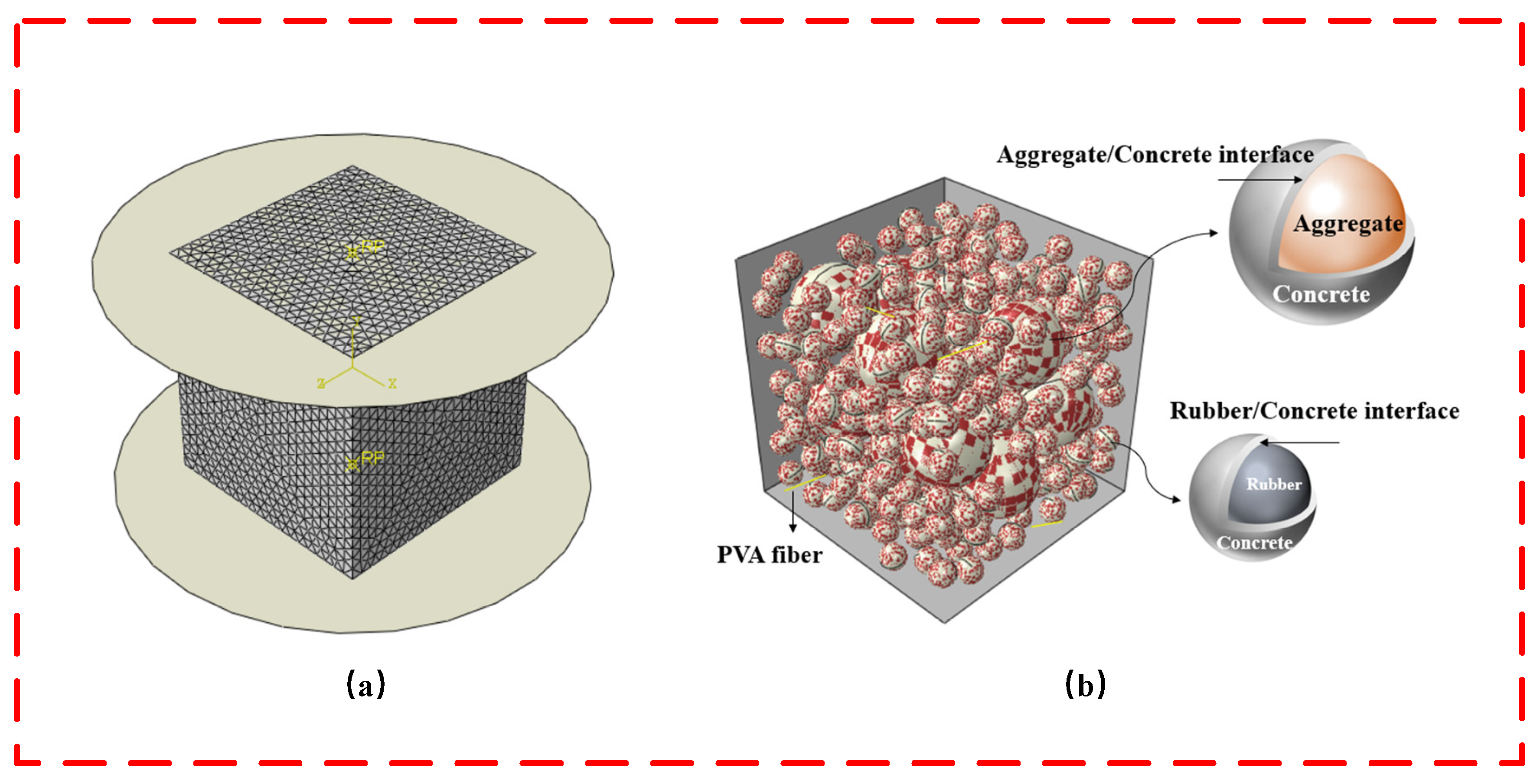

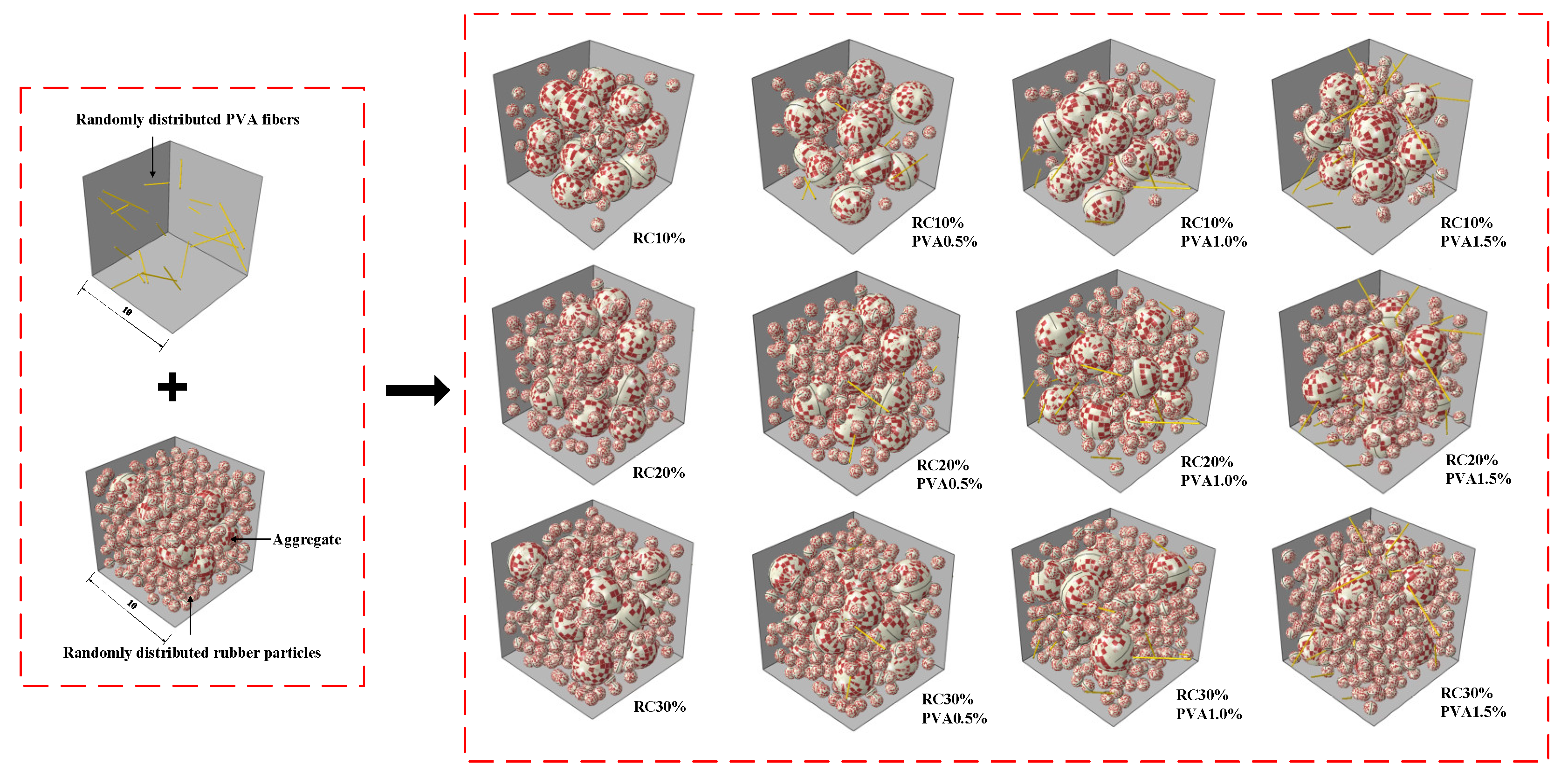

4. Numerical Analysis

4.1. 3D Geometry Model Creation

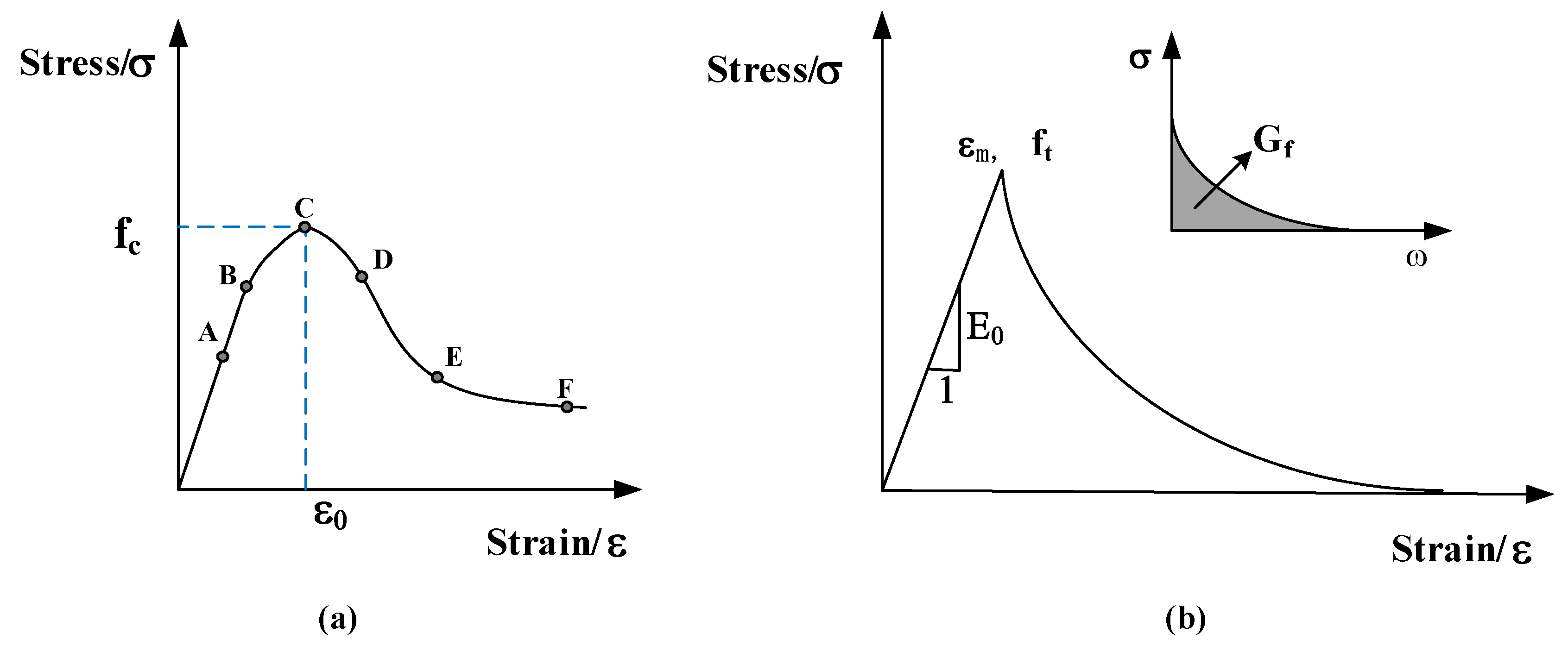

4.2. Material Constitutive Model

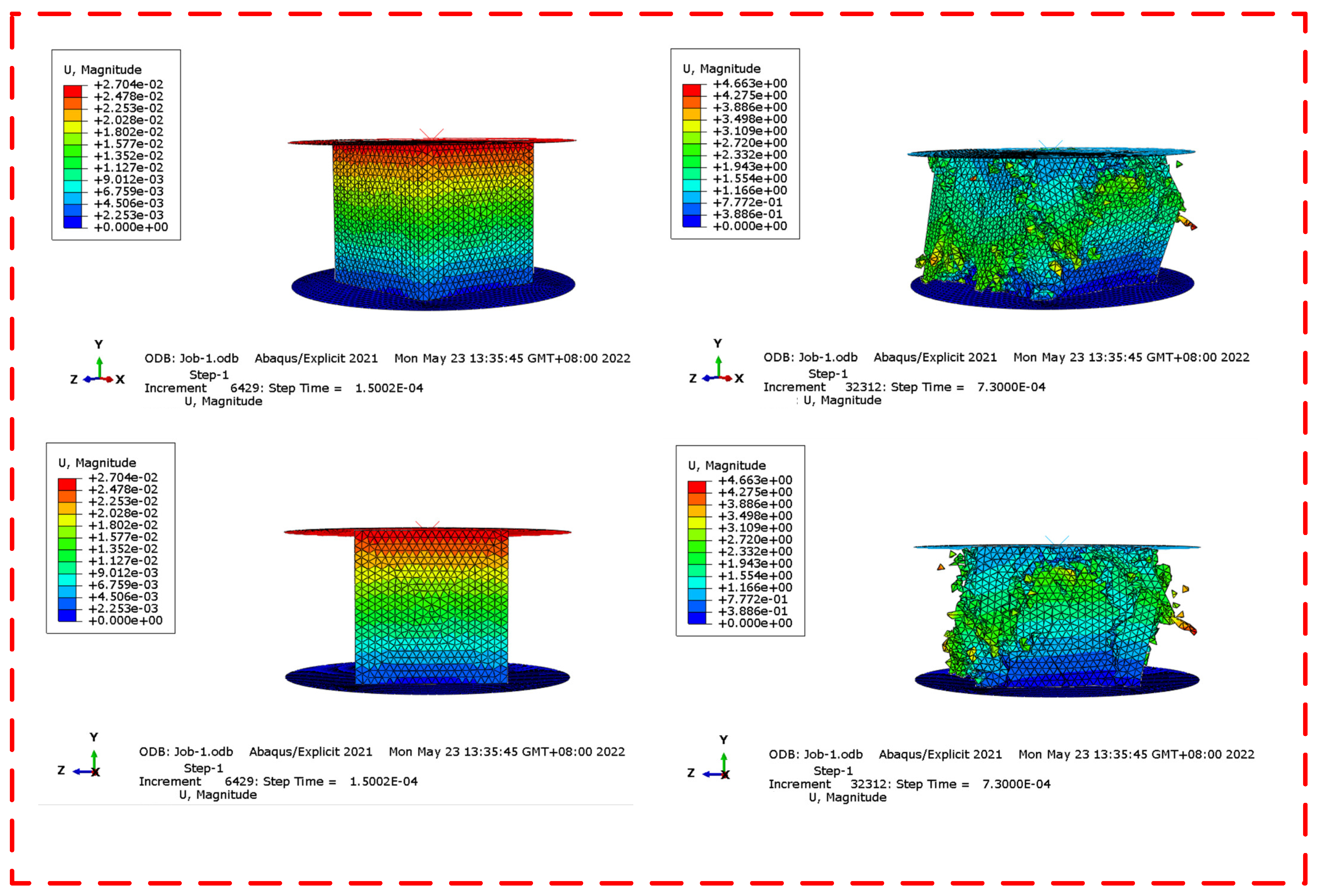

4.3. Finite Element Analysis Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Segre, N.; Joekes, I. Use of tire rubber particles as addition to cement paste. Cem. Concr. Res. 2000, 30, 1421–1425. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Li, G.; Stubblefield, M.A.; Garrick, G.; Eggers, J.; Abadie, C.; Huang, B. Development of waste tire modified concrete. Cem. Concr. Res. 2004, 34, 2283–2289. [Google Scholar] [CrossRef]

- Dong, Q.; Huang, B.; Shu, X. Rubber modified concrete improved by chemically active coating and silane coupling agent. Constr. Build. Mater. 2013, 48, 116–123. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B. Recycling of waste tire rubber in asphalt and portland cement concrete: An overview. Constr. Build. Mater. 2014, 67, 217–224. [Google Scholar] [CrossRef]

- Topçu, I.B. The properties of rubberized concretes. Cem. Concr. Res. 1995, 25, 304–310. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, D.; Li, G.; Yao, Y.; Ou, Y.; Shi, C.; Du, Y. Flexural response of basalt textile reinforced concrete with pre-tension and short fibers under low-velocity impact loads. Constr. Build. Mater. 2018, 169, 859–876. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, D. Tensile behavior of glass fiber reinforced composite at different strain rates and temperatures. Constr. Build. Mater. 2015, 96, 648–656. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, D.; Li, H. Strain Rate and Temperature Effects on the Dynamic Tensile Behaviors of Basalt Fiber Bundles and Reinforced Polymer Composite. J. Mater. Civ. Eng. 2016, 28, 04016101. [Google Scholar] [CrossRef]

- Li, K.; Liu, W.; Zhang, K.; Wang, X.; Zhu, J.; Sheikh, S. Bond behavior of stainless steel wire ropes embedded in engineered cementitious composites. Constr. Build. Mater. 2021, 281, 122622. [Google Scholar] [CrossRef]

- Zhang, K.; Yuan, Q.; Zhu, J. Analytical model for the bonding performance between HSSWM-ECC and concrete. Cem. Concr. Compos. 2022, 132, 104632. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, K.; Wang, X.; Li, K.; Zou, X.; Feng, H. Bond-Slip Performance between High-Strength Steel Wire Rope Meshes and Engineered Cementitious Composites. J. Mater. Civ. Eng. 2022, 34, 04022048. [Google Scholar] [CrossRef]

- Li, V.C.; Wu, C.; Wang, S.X.; Ogawa, A.; Saito, T. Interface tailoring for strain-hardening polyvinyl alcohol-engineered cementitious composite (PVA-ECC). Aci Mater. J. 2002, 99, 463–472. [Google Scholar]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Investigation of properties and performances of Polyvinyl Alcohol (PVA) fiber-reinforced rubber concrete. Constr. Build. Mater. 2018, 193, 631–642. [Google Scholar] [CrossRef]

- Yuan, B.; Chen, W.; Zhao, J.; Li, L.; Liu, F.; Guo, Y.; Zhang, B. Addition of alkaline solutions and fibers for the reinforcement of kaolinite-containing granite residual soil. Appl. Clay Sci. 2022, 228, 106644. [Google Scholar] [CrossRef]

- Yuan, B.; Chen, W.; Zhao, J.; Yang, F.; Luo, Q.; Chen, T. The Effect of Organic and Inorganic Modifiers on the Physical Properties of Granite Residual Soil. Adv. Mater. Sci. Eng. 2022, 2022, 1–13. [Google Scholar] [CrossRef]

- Yuan, B.; Chen, M.; Chen, W.; Luo, Q.; Li, H. Effect of Pile-Soil Relative Stiffness on Deformation Characteristics of the Laterally Loaded Pile. Adv. Mater. Sci. Eng. 2022, 2022, 1–13. [Google Scholar] [CrossRef]

- Yuan, B.; Li, Z.; Chen, W.; Zhao, J.; Lv, J.; Song, J.; Cao, X. Influence of Groundwater Depth on Pile–Soil Mechanical Properties and Fractal Characteristics under Cyclic Loading. Fractal Fract. 2022, 6, 198. [Google Scholar] [CrossRef]

- Si, R.; Guo, S.; Dai, Q. Durability performance of rubberized mortar and concrete with NaOH-Solution treated rubber particles. Constr. Build. Mater. 2017, 153, 496–505. [Google Scholar] [CrossRef]

- Han, Q.; Yang, G.; Xu, J.; Fu, Z.; Lacidogna, G.; Carpinteri, A. Acoustic emission data analyses based on crumb rubber concrete beam bending tests. Eng. Fract. Mech. 2019, 210, 189–202. [Google Scholar] [CrossRef]

- Masad, N.; Zollinger, D.; Kim, S.-M.; Grasley, Z. Meso-scale model for simulations of concrete subjected to cryogenic temperatures. Mater. Struct. 2015, 49, 2141–2159. [Google Scholar] [CrossRef]

- Chen, H.; Xu, B.; Wang, J.; Zhou, T.; Mo, Y.L. Parametric analysis on compressive strain rate effect of concrete using mesoscale modeling approach. Constr. Build. Mater. 2020, 246, 118375. [Google Scholar] [CrossRef]

- Jin, L.; Yu, W.; Du, X. Effect of Initial Static Load and Dynamic Load on Concrete Dynamic Compressive Failure. J. Mater. Civ. Eng. 2020, 32, 04020351. [Google Scholar] [CrossRef]

- Maleki, M.; Rasoolan, I.; Khajehdezfuly, A.; Jivkov, A.P. On the effect of ITZ thickness in meso-scale models of concrete. Constr. Build. Mater. 2020, 258, 119639. [Google Scholar] [CrossRef]

- Fuller, W.B.; Thompson, S.E. The Laws of Proportioning, Concrete. Trans. Am. Soc. Civ. Eng. 1907, 59, 67–143. [Google Scholar] [CrossRef]

- Jin, L.; Yu, W.; Du, X.; Yang, W. Mesoscopic numerical simulation of dynamic size effect on the splitting-tensile strength of concrete. Eng. Fract. Mech. 2019, 209, 317–332. [Google Scholar] [CrossRef]

- Wang, Z.M.; Kwan, A.K.H.; Chan, H.C. Mesoscopic study of concrete I: Generation of random aggregate structure and finite element mesh. Comput. Struct. 1999, 70, 533–544. [Google Scholar] [CrossRef]

- Park, S.-M.; Lim, J.H.; Seong, M.R.; Sohn, D. Efficient generator of random fiber distribution with diverse volume fractions by random fiber removal. Compos. Part B Eng. 2019, 167, 302–316. [Google Scholar] [CrossRef]

- Vaughan, T.J.; McCarthy, C.T. A combined experimental–numerical approach for generating statistically equivalent fibre distributions for high strength laminated composite materials. Compos. Sci. Technol. 2010, 70, 291–297. [Google Scholar] [CrossRef]

- Xu, W.X.; Chen, H.S.; Lv, Z. An overlapping detection algorithm for random sequential packing of elliptical particles. Phys. A Stat. Mech. Appl. 2011, 390, 2452–2467. [Google Scholar] [CrossRef]

- Yang, L.; Yan, Y.; Ran, Z.; Liu, Y. A new method for generating random fibre distributions for fibre reinforced composites. Compos. Sci. Technol. 2013, 76, 14–20. [Google Scholar] [CrossRef]

- Zhu, C.; Zhu, P.; Liu, Z.; Tao, W. Numerical investigation of fiber random distribution on the mechanical properties of yarn in-plain woven carbon fiber-reinforced composite based on a new perturbation algorithm. J. Compos. Mater. 2017, 52, 755–771. [Google Scholar] [CrossRef]

- Carreira, D.J.; Chu, K.H. Stress-strain relationship for plain concrete in compression. J. Am. Concr. Inst. 1985, 82, 797–804. [Google Scholar] [CrossRef]

- Li, D.; Zhuge, Y.; Gravina, R.; Mills, J.E. Compressive stress strain behavior of crumb rubber concrete (CRC) and application in reinforced CRC slab. Constr. Build. Mater. 2018, 166, 745–759. [Google Scholar] [CrossRef]

- Li, L.; Ruan, S.; Zeng, L. Mechanical properties and constitutive equations of concrete containing a low volume of tire rubber particles. Constr. Build. Mater. 2014, 70, 291–308. [Google Scholar] [CrossRef]

- Naderi, S.; Tu, W.; Zhang, M. Meso-scale modelling of compressive fracture in concrete with irregularly shaped aggregates. Cem. Concr. Res. 2021, 140, 106317. [Google Scholar] [CrossRef]

- Popovics, S. A numerical approach to the complete stress-strain curve of concrete. Cem. Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

- Xiong, Q.; Wang, X.; Jivkov, A.P. A 3D multi-phase meso-scale model for modelling coupling of damage and transport properties in concrete. Cem. Concr. Compos. 2020, 109, 103545. [Google Scholar] [CrossRef]

- Haifeng, L.; Ping, W. Dynamic characteristics of concrete with different interfacial phase thicknesses. Chin. J. High Press. Phys. 2017, 31, 249–260. [Google Scholar] [CrossRef]

- Li, M.; Hao, H.; Shi, Y.; Hao, Y. Specimen shape and size effects on the concrete compressive strength under static and dynamic tests. Constr. Build. Mater. 2018, 161, 84–93. [Google Scholar] [CrossRef]

| Composition | Other | ||||||

|---|---|---|---|---|---|---|---|

| Content/% | 63.11 | 22.60 | 5.03 | 4.38 | 1.46 | 2.24 | 0.21 |

| Specific Surface Area/(m2 kg−1) | Standard Consistency/% | Coagulation Time/min | Flexural Strength/MPa | Compressive Strength/MPa | |||

|---|---|---|---|---|---|---|---|

| Initial Setting Time | Final Setting Time | 3 d | 28 d | 3 d | 28 d | ||

| 370 | 27 | 150 | 205 | 4.8 | 8.0 | 29.2 | 49 |

| Particle Size Range /mm | Apparent Density /kg/m3 | Bulk Density /kg/m3 | Elastic Modulus /GPa | Poisson Ratio |

|---|---|---|---|---|

| 1~3 | 1.03 | 610 | 0.07 | 0.449 |

| Density /kg/m3 | Diameter /μm | Elastic Modulus /GPa | Length /mm | Tensile Strength/MPa | Break Elongation/% | Poisson Ratio |

|---|---|---|---|---|---|---|

| 1.3 | 15 | 39 | 6 | 1704 | 12 | 0.3 |

| Name | Fine Aggregate | Rubber Particles /kg/m3 | ||||

|---|---|---|---|---|---|---|

| PC | 400 | 160 | 799 | 1106 | ||

| RC10% | 400 | 160 | 719 | 1106 | 32.6 | |

| RC20% | 400 | 160 | 639 | 1106 | 65.4 | |

| RC30% | 400 | 160 | 559 | 1106 | 97.7 | |

| RC10%-PVA0.5% | 400 | 160 | 719 | 1106 | 32.6 | 19.4 |

| RC10%-PVA1.0% | 400 | 160 | 719 | 1106 | 32.6 | 38.6 |

| RC10%-PVA1.5% | 400 | 160 | 719 | 1106 | 32.6 | 57.8 |

| RC20%-PVA0.5% | 400 | 160 | 639 | 1106 | 65.4 | 19.4 |

| RC20%-PVA1.0% | 400 | 160 | 639 | 1106 | 65.4 | 38.6 |

| RC20%-PVA1.5% | 400 | 160 | 639 | 1106 | 65.4 | 57.8 |

| RC30%-PVA0.5% | 400 | 160 | 559 | 1106 | 97.7 | 19.4 |

| RC30%-PVA1.0% | 400 | 160 | 559 | 1106 | 97.7 | 38.6 |

| RC30%-PVA1.5% | 400 | 160 | 559 | 1106 | 97.7 | 57.8 |

| Parameters | Elastic Modulus/(GPa) | Poisson Ratio | Compressive Strength/(MPa) | Tensile Strength/(MPa) |

|---|---|---|---|---|

| Aggregate phase | 50 | 0.2 | 80 | 8 |

| Mortar phase | 30 | 0.2 | 49 | 3.9 |

| Rubber particles | 0.07 | 0.499 | 25 | 2.5 |

| PVA fiber | 39 | 0.3 | / | 1704 |

| Aggregate/Mortar Interface | 21.6 | 0.2 | 35.3 | 2.8 |

| Rubber/Mortar Interface | 6 | 0.2 | 1.0 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Niu, Z.; Zhao, C.; Li, L. Compressive Test Investigation and Numerical Simulation of Polyvinyl-Alcohol (PVA)-Fiber-Reinforced Rubber Concrete. Buildings 2023, 13, 431. https://doi.org/10.3390/buildings13020431

Feng Y, Niu Z, Zhao C, Li L. Compressive Test Investigation and Numerical Simulation of Polyvinyl-Alcohol (PVA)-Fiber-Reinforced Rubber Concrete. Buildings. 2023; 13(2):431. https://doi.org/10.3390/buildings13020431

Chicago/Turabian StyleFeng, Yong, Zijuan Niu, Chen Zhao, and Lijuan Li. 2023. "Compressive Test Investigation and Numerical Simulation of Polyvinyl-Alcohol (PVA)-Fiber-Reinforced Rubber Concrete" Buildings 13, no. 2: 431. https://doi.org/10.3390/buildings13020431

APA StyleFeng, Y., Niu, Z., Zhao, C., & Li, L. (2023). Compressive Test Investigation and Numerical Simulation of Polyvinyl-Alcohol (PVA)-Fiber-Reinforced Rubber Concrete. Buildings, 13(2), 431. https://doi.org/10.3390/buildings13020431