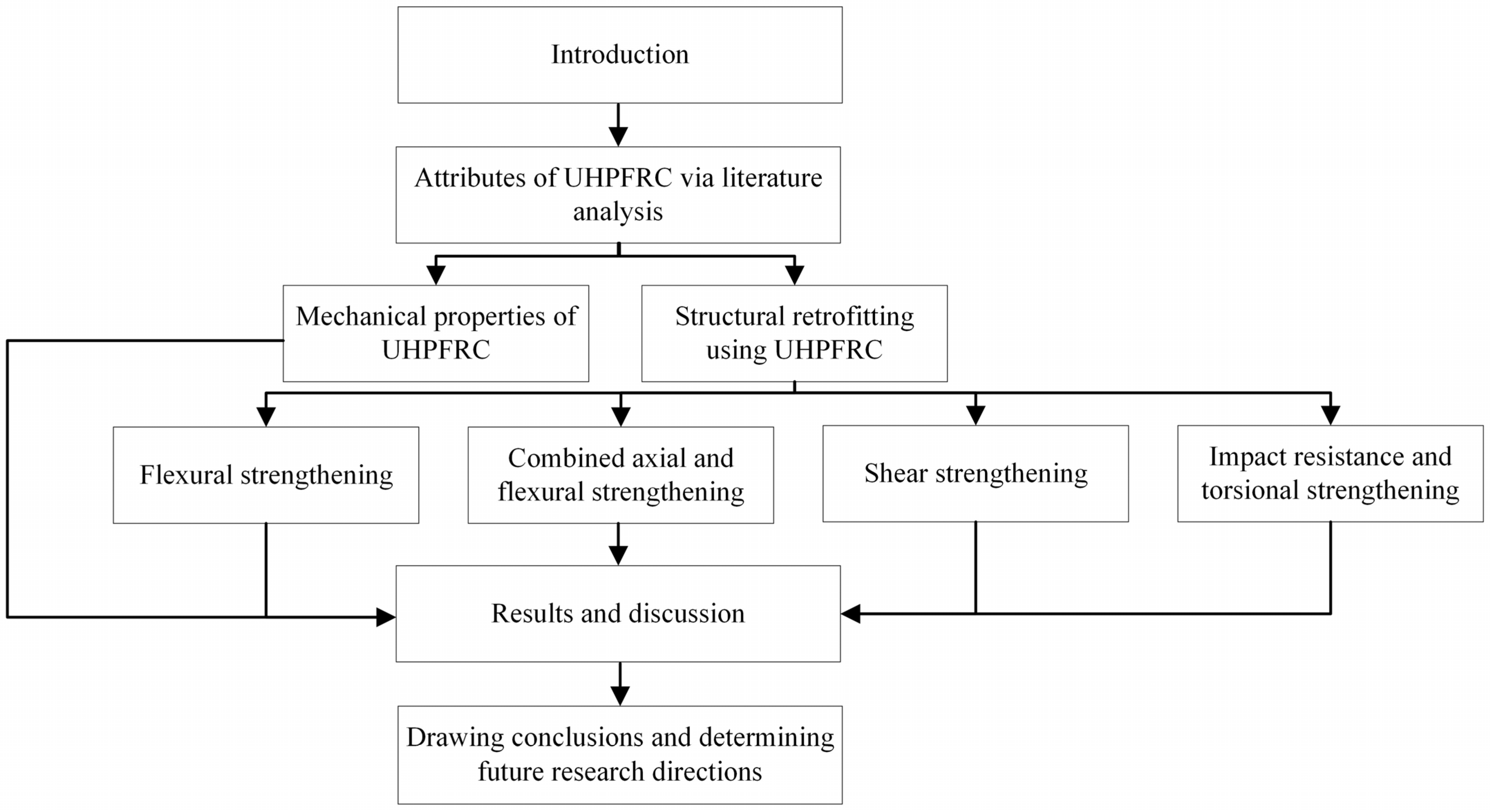

Ultra-High-Performance Fibre-Reinforced Concrete for Rehabilitation and Strengthening of Concrete Structures: A Suitability Assessment

Abstract

1. Introduction

2. Ultra-High-Performance Fibre-Reinforced Concrete (UHPFRC)

3. Mechanical Properties of UHPFRC

3.1. Compressive Strength

3.2. Tensile and Flexural Strengths

3.3. Impact Strength

4. UHPFRC for Structural Retrofitting

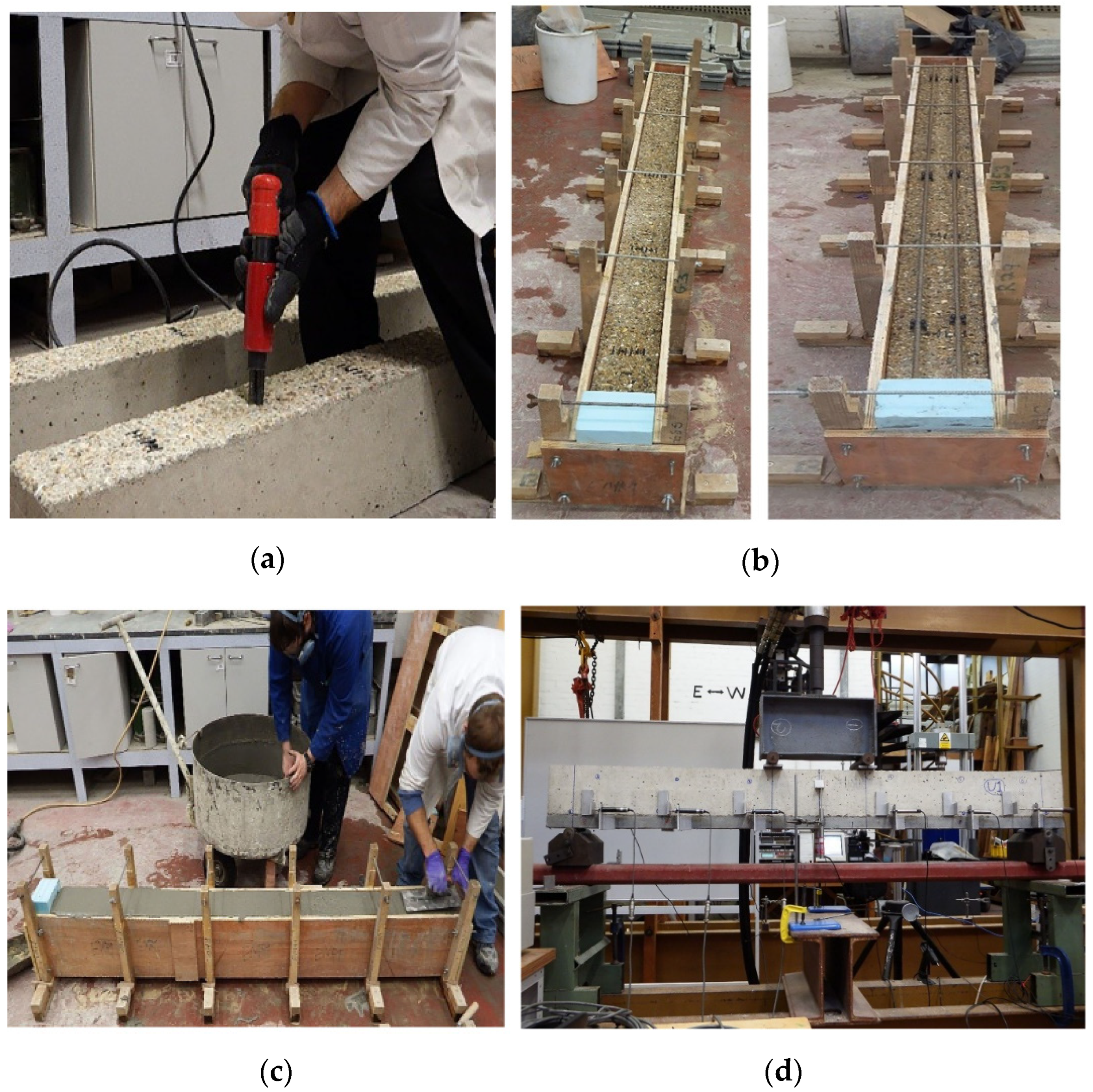

4.1. Flexural Strengthening

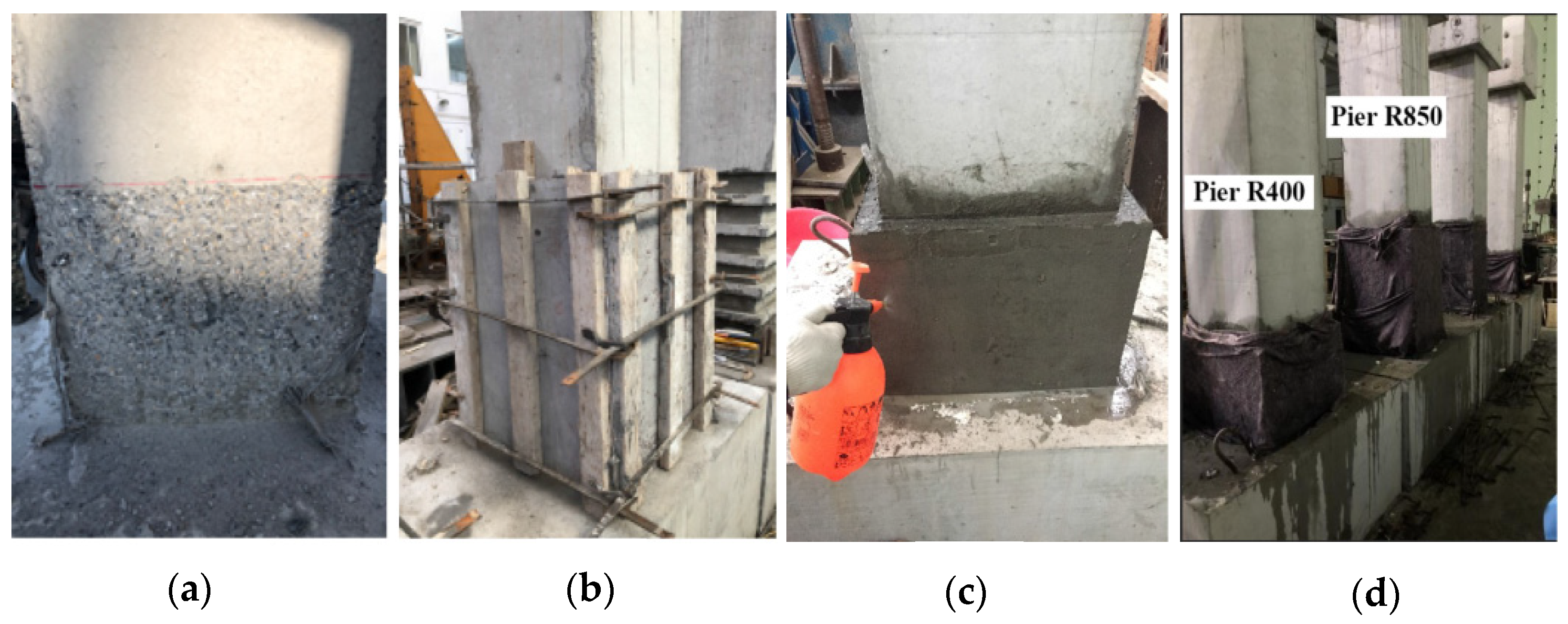

4.2. Combined Axial and Flexural Strengthening

4.3. Shear Strengthening

4.3.1. Beams

4.3.2. Slabs

4.3.3. Columns

4.3.4. Walls

4.4. Impact Resistance and Torsional Strengthening

5. Results and Discussion

5.1. Mechanical Properties

5.2. Structural Retrofitting

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Neville, A. Chloride Attack of Reinforced Concrete: An Overview. Mater. Struct. 1995, 28, 63–70. [Google Scholar] [CrossRef]

- Val, D.V.; Stewart, M.G. Reliability Assessment of Ageing Reinforced Concrete Structures—Current Situation and Future Challenges. Struct. Eng. Int. J. Int. Assoc. Bridge Struct. Eng. (IABSE) 2009, 19, 211–219. [Google Scholar] [CrossRef]

- Kalra, R.; Neubauer, U. Strengthening of the West Gate Bridge with Carbon Fibre Composites—A Proof Engineer’s Perspective. Aust. J. Civ. Eng. 2003, 1, 51–58. [Google Scholar] [CrossRef]

- Raza, S.; Khan, M.K.I.; Menegon, S.J.; Tsang, H.H.; Wilson, J.L. Strengthening and Repair of Reinforced Concrete Columns by Jacketing: State-of-the-Art Review. Sustainability 2019, 11, 3208. [Google Scholar] [CrossRef]

- Santarsiero, G.; Masi, A. Seismic Upgrading of RC Wide Beam–Column Joints Using Steel Jackets. Buildings 2020, 10, 203. [Google Scholar] [CrossRef]

- Chalioris, C.; Kytinou, V.; Voutetaki, M.; Papadopoulos, N. Repair of Heavily Damaged RC Beams Failing in Shear Using U-Shaped Mortar Jackets. Buildings 2019, 9, 146. [Google Scholar] [CrossRef]

- Abbas, H.; Ibrahim, S.M.; Al-Hazmi, N.; Elsanadedy, H.; Almusallam, T.; Al-Salloum, Y. Axial Compression Behavior of Wall-like Reinforced Concrete Columns Retrofitted Using Different FRP Schemes. Buildings 2022, 13, 26. [Google Scholar] [CrossRef]

- Daly, A.F.; Witarnawan, I.W. Strengthening of Bridges Using External Post–Tensioning. In Proceedings of the 2nd Conference of Eastern Asia Society for Transportation Studies, Kuala Lumpur, Malaysia, 4–7 September 1997. [Google Scholar]

- Al-Zu’bi, M.; Fan, M.; Anguilano, L. Advances in Bonding Agents for Retrofitting Concrete Structures with Fibre Reinforced Polymer Materials: A Review. Constr. Build. Mater. 2022, 330, 127115. [Google Scholar] [CrossRef]

- Nayak, A.N.; Kumari, A.; Swain, R.B. Strengthening of RC Beams Using Externally Bonded Fibre Reinforced Polymer Composites. Structures 2018, 14, 137–152. [Google Scholar] [CrossRef]

- Jirawattanasomkul, T.; Likitlersuang, S.; Wuttiwannasak, N.; Ueda, T.; Zhang, D.; Shono, M. Structural Behaviour of Pre-Damaged Reinforced Concrete Beams Strengthened with Natural Fibre Reinforced Polymer Composites. Compos. Struct. 2020, 244, 112309. [Google Scholar] [CrossRef]

- Bisby, L.A. Fire Behaviour of Fibre-Reinforced Polymer (FRP) Reinforced or Confined Concrete; Queen’s University: Kingston, ON, Canada, 2003. [Google Scholar]

- Eide, M.B.; Hisdal, J.M. Ultra High Performance Fibre Reinforced Concrete (UHPFRC)–State of the Art; Blindern: Oslo, Norway, 2012. [Google Scholar]

- Richard, P.; Cheyrezy, M. Composition of Reactive Powder Concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Rossi, P.; Arca, A.; Parant, E.; Fakhri, P. Bending and Compressive Behaviours of a New Cement Composite. Cem. Concr. Res. 2005, 35, 27–33. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Bakar, B.H.; Megat Johari, M.A.; Voo, Y.L. Evaluation of Bond Strength between Normal Concrete Substrate and Ultra High Performance Fiber Concrete as a Repair Material. Proc. Procedia Eng. 2013, 54, 554–563. [Google Scholar] [CrossRef]

- Rossi, P. Ultra-High Performance Fiber-Reinforced Concretes. Concr. Int. 2001, 23, 46–52. [Google Scholar]

- Habel, K. Structural Behaviour of Elements Combining Ultra-High Performance Fibre Reinforced Concretes (Uhpfrc) and Reinforced Concrete; EPEL: Lausanne, Switzerland, 2004; Volume 3036.

- Deeb, R.; Ghanbari, A.; Karihaloo, B.L. Development of Self-Compacting High and Ultra High Performance Concretes with and without Steel Fibres. Cem. Concr. Compos. 2012, 34, 185–190. [Google Scholar] [CrossRef]

- Al-Osta, M.A. Exploitation of Ultrahigh-Performance Fibre-Reinforced Concrete for the Strengthening of Concrete Structural Members. Adv. Civ. Eng. 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-High Performance Concrete: Mechanical Performance, Durability, Sustainability and Implementation Challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- de Larrard, F.; Sedran, T. Mixture-Proportioning of High-Performance Concrete. Cem. Concr. Res. 2002, 32, 1699–1704. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix Design and Properties Assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Ge, Z.; Wang, K.; Sun, R.; Huang, D.; Hu, Y. Properties of Self-Consolidating Concrete Containing Nano-CaCO3. J. Sustain. Cem. Based Mater. 2014, 3, 191–200. [Google Scholar] [CrossRef]

- vande Voort, T.L. Design and Field Testing of Tapered H-Shaped Ultra High Performance Concrete Piles; Iowa State University ProQuest Dissertations Publishing: Iowa, IA, USA, 2008. [Google Scholar]

- Camacho, E.; López, J.Á.; Ros, P.S. Definition of Three Levels of Performance for UHPFRC-VHPFRC with Available Materials. In Proceedings of the Hipermat 2012—3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials, Kassel, German, 7–12 March 2012. [Google Scholar]

- Graybeal, B.; Davis, M. Cylinder or Cube: Strength Testing of 80 to 200 MPa (11.6 to 29 Ksi) Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2008, 105, 603. [Google Scholar] [CrossRef]

- Kazemi, S.; Kazemi, S. Influence of Specimen Size and Fiber Content on Mechanical Properties of Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2012, 109. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Luhar, S.; Arel, H.Ş.; Luhar, I. Performance Evaluation of Ultrahigh Performance Fibre Reinforced Concrete—A Review. Constr. Build. Mater. 2020, 232, 117152. [Google Scholar] [CrossRef]

- Hassan, A.M.T.; Jones, S.W.; Mahmud, G.H. Experimental Test Methods to Determine the Uniaxial Tensile and Compressive Behaviour of Ultra High Performance Fibre Reinforced Concrete(UHPFRC). Constr. Build. Mater. 2012, 37, 874–882. [Google Scholar] [CrossRef]

- Spasojevic, A.; Redaelli, D.; Fernández Ruiz, M.; Muttoni, A. Influence of Tensile Properties of UHPFRC on Size Effect in Bending. In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, German, 5–7 March 2008. [Google Scholar]

- Wille, K.; Parra-Montesinos, G.J. Effect of Beam Size, Casting Method, and Support Conditions on Flexural Behavior of Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2012, 109. [Google Scholar] [CrossRef]

- Mahmud, G.H.; Yang, Z.; Hassan, A.M.T. Experimental and Numerical Studies of Size Effects of Ultra High Performance Steel Fibre Reinforced Concrete (UHPFRC) Beams. Constr. Build. Mater. 2013, 48, 1027–1034. [Google Scholar] [CrossRef]

- Graybeal, B.A. Material Property Characterization of Ultra-High Performance Concrete; FHWA-HRT-06-103; U.S. Federal Highway Administration. Office of Infrastructure Research and Development: Washington, DC, USA, 2006. [Google Scholar]

- Ahlborn, T.M.; Misson, D.L.; Peuse, E.J.; Gilbertson, C.G.; Fehling, E. Durability and Strength Characterization of Ultra-High Performance Concrete under Variable Curing Regimes. In Proceedings of the 2nd International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008. [Google Scholar]

- Reda, M.M.; Shrive, N.G.; Gillott, J.E. Microstructural Investigation of Innovative UHPC. Cem. Concr. Res. 1999, 29, 323–329. [Google Scholar] [CrossRef]

- Schmidt, M.; Fehling, E.; Teichmann, T.; Kai, B.; Roland, B. Ultra-High Performance Concrete: Perspective for the Precast Concrete Industry. Betonw. Und Fert.-Tech./Concr. Precast. Plant. Technol. 2003, 69, 16–29. [Google Scholar]

- El-Dieb, A.S. Mechanical, Durability and Microstructural Characteristics of Ultra-High-Strength Self-Compacting Concrete Incorporating Steel Fibers. Mater. Des. 2009, 30, 4286–4292. [Google Scholar] [CrossRef]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring Mechanical and Durability Properties of Ultra-High Performance Concrete Incorporating Various Steel Fiber Lengths and Dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Magureanu, C.; Sosa, I.; Negrutiu, C.; Heghes, B. Mechanical Properties and Durability of Ultra-High-Performance Concrete. ACI Mater. J. 2012, 109, 177–183. [Google Scholar]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of Steel Fiber Content and Shape on Mechanical Properties of Ultra High Performance Concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile Behavior of Ultra High Performance Hybrid Fiber Reinforced Concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- van Tuan, N.; Ye, G.; van Breugel, K.; Fraaij, A.L.A.; Bui, D.D. The Study of Using Rice Husk Ash to Produce Ultra High Performance Concrete. Constr. Build. Mater. 2011, 25, 2030–2035. [Google Scholar] [CrossRef]

- van Tuan, N.; Ye, G.; van Breugel, K.; Copuroglu, O. Hydration and Microstructure of Ultra High Performance Concrete Incorporating Rice Husk Ash. Cem. Concr. Res. 2011, 41, 1104–1111. [Google Scholar] [CrossRef]

- Vejmelková, E.; Keppert, M.; Rovnaníková, P.; Ondráček, M.; Keršner, Z.; Černý, R. Properties of High Performance Concrete Containing Fine-Ground Ceramics as Supplementary Cementitious Material. Cem. Concr. Compos. 2012, 34, 55–61. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an Eco-Friendly Ultra-High Performance Concrete (UHPC) with Efficient Cement and Mineral Admixtures Uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Yang, S.L.; Millard, S.G.; Soutsos, M.N.; Barnett, S.J.; Le, T.T. Influence of Aggregate and Curing Regime on the Mechanical Properties of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Constr. Build. Mater. 2009, 23, 2291–2298. [Google Scholar] [CrossRef]

- Aldahdooh, M.A.A.; Muhamad Bunnori, N.; Megat Johari, M.A. Evaluation of Ultra-High-Performance-Fiber Reinforced Concrete Binder Content Using the Response Surface Method. Mater. Des. 2013, 52, 957–965. [Google Scholar] [CrossRef]

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of Strain Hardening Ultra High Performance Fiber Reinforced Concrete (UHP-FRC) under Direct Tensile Loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- Magureanu, C.; Sosa, I.; Negrutiu, C.; Heghes, B. Physical and Mechanical Properties of Ultra High Strength Fiber Reinforced Cementitious Composites. Korea Concr. Inst. 2010, 1491–1497. [Google Scholar]

- Yoo, D.Y.; Lee, J.H.; Yoon, Y.S. Effect of Fiber Content on Mechanical and Fracture Properties of Ultra High Performance Fiber Reinforced Cementitious Composites. Compos. Struct. 2013, 106, 742–753. [Google Scholar] [CrossRef]

- Kang, S.T.; Lee, Y.; Park, Y.D.; Kim, J.K. Tensile Fracture Properties of an Ultra High Performance Fiber Reinforced Concrete (UHPFRC) with Steel Fiber. Compos. Struct. 2010, 92, 61–71. [Google Scholar] [CrossRef]

- Eldin, H.K.S.; Mohamed, H.A.; Khater, M.; Ahmed, S. Mechanical Properties of Ultra-High Performance Fiber Reinforced Concrete. Int. J. Eng. Innov. Technol. 2014, 4. [Google Scholar]

- Kang, S.T.; Lee, B.Y.; Kim, J.K.; Kim, Y.Y. The Effect of Fibre Distribution Characteristics on the Flexural Strength of Steel Fibre-Reinforced Ultra High Strength Concrete. Constr. Build. Mater. 2011, 25, 2450–2457. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, S.T.; Yoon, Y.S. Effect of Fiber Length and Placement Method on Flexural Behavior, Tension-Softening Curve, and Fiber Distribution Characteristics of UHPFRC. Constr. Build. Mater. 2014, 64, 67–81. [Google Scholar] [CrossRef]

- Nguyen, D.L.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Size Effect on Flexural Behavior of Ultra-High-Performance Hybrid Fiber-Reinforced Concrete. Compos. B Eng. 2013, 45, 1104–1116. [Google Scholar] [CrossRef]

- Frettlöhr, B.; Reineck, K.H.; Reinhardt, H.W. Size and Shape Effect of Uhpfrc Prisms Tested under Axial Tension and Bending. RILEM Bookseries 2012, 6, 365–372. [Google Scholar] [CrossRef]

- Yang, I.H.; Joh, C.; Kim, B.S. Structural Behavior of Ultra High Performance Concrete Beams Subjected to Bending. Eng. Struct. 2010, 32, 3478–3487. [Google Scholar] [CrossRef]

- Habel, K.; Gauvreau, P. Response of Ultra-High Performance Fiber Reinforced Concrete (UHPFRC) to Impact and Static Loading. Cem. Concr. Compos. 2008, 30, 938–946. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N.; Kim, S.W.; Yoon, Y.S. Response of Ultra-High-Performance Fiber-Reinforced Concrete Beams with Continuous Steel Reinforcement Subjected to Low-Velocity Impact Loading. Compos. Struct. 2015, 126, 233–245. [Google Scholar] [CrossRef]

- Máca, P.; Sovják, R.; Konvalinka, P. Mix Design of UHPFRC and Its Response to Projectile Impact. Int. J. Impact Eng. 2014, 63, 158–163. [Google Scholar] [CrossRef]

- Nicolaides, D.; Kanellopoulos, A.; Savva, P.; Petrou, M. Experimental Field Investigation of Impact and Blast Load Resistance of Ultra High Performance Fibre Reinforced Cementitious Composites (UHPFRCCs). Constr. Build. Mater. 2015, 95, 566–574. [Google Scholar] [CrossRef]

- Sovják, R.; Vavřiník, T.; Zatloukal, J.; Máca, P.; Mičunek, T.; Frydrýn, M. Resistance of Slim UHPFRC Targets to Projectile Impact Using In-Service Bullets. Int. J. Impact Eng. 2015, 76, 166–177. [Google Scholar] [CrossRef]

- Feng, J.; Sun, W.; Liu, Z.; Cui, C.; Wang, X. An Armour-Piercing Projectile Penetration in a Double-Layered Target of Ultra-High-Performance Fiber Reinforced Concrete and Armour Steel: Experimental and Numerical Analyses. Mater. Des. 2016, 102, 131–141. [Google Scholar] [CrossRef]

- Charron, J.P.; Denarié, E.; Brühwiler, E. Permeability of Ultra High Performance Fiber Reinforced Concretes (UHPFRC) under High Stresses. Mater. Struct. /Mater. Et Constr. 2007, 40, 269–277. [Google Scholar] [CrossRef]

- Wang, W.; Liu, J.; Agostini, F.; Davy, C.A.; Skoczylas, F.; Corvez, D. Durability of an Ultra High Performance Fiber Reinforced Concrete (UHPFRC) under Progressive Aging. Cem. Concr. Res. 2014, 55, 1–13. [Google Scholar] [CrossRef]

- Matos, A.M.; Chaves Figueiredo, S.; Nunes, S.; Schlangen, E.; Barroso-Aguiar, J.L. Durability of an UHPFRC under Mechanical and Chloride Loads. Constr. Build. Mater. 2021, 311, 125223. [Google Scholar] [CrossRef]

- Kang, S.T.; Kim, J.H.; Lee, B.Y. Effects of Water Reducing Admixture on Rheological Properties, Fiber Distribution, and Mechanical Behavior of UHPFRC. Appl. Sci. 2018, 9, 29. [Google Scholar] [CrossRef]

- Farzad, M.; Shafieifar, M.; Azizinamini, A. Experimental and Numerical Study on Bond Strength between Conventional Concrete and Ultra High-Performance Concrete (UHPC). Eng. Struct. 2019, 186, 297–305. [Google Scholar] [CrossRef]

- Jafarinejad, S.; Rabiee, A.; Shekarchi, M. Experimental Investigation on the Bond Strength between Ultra High Strength Fiber Reinforced Cementitious Mortar & Conventional Concrete. Constr. Build. Mater. 2019, 229, 116814. [Google Scholar] [CrossRef]

- Alaee, F.J.; Karihaloo, B.L. Retrofitting of Reinforced Concrete Beams with CARDIFRC. J. Compos. Constr. 2003, 7, 174–186. [Google Scholar] [CrossRef]

- Habel, K.; Denarié, E.; Brühwiler, E. Structural Response of Elements Combining Ultrahigh-Performance Fiber-Reinforced Concretes and Reinforced Concrete. J. Struct. Eng. 2006, 132, 1793–1800. [Google Scholar] [CrossRef]

- Habel, K.; Denarié, E.; Brühwiler, E. Experimental Investigation of Composite Ultra-High-Performance Fiber-Reinforced Concrete and Conventional Concrete Members. ACI Struct. J. 2007, 104, 93. [Google Scholar] [CrossRef]

- Noshiravani, T.; Brühwiler, E. Experimental Investigation on Reinforced Ultra-High-Performance Fiber-Reinforced Concrete Composite Beams Subjected to Combined Bending and Shear. ACI Struct. J. 2013, 110, 251–261. [Google Scholar] [CrossRef]

- Lampropoulos, A.P.; Paschalis, S.A.; Tsioulou, O.T.; Dritsos, S.E. Strengthening of Existing Reinforced Concrete Beams Using Ultra High Performance Fibre Reinforced Concrete. In Proceedings of the 4th International Conference on Concrete Repair, Rehabilitation and Retrofitting, ICCRRR, Leipzig, Germany, 5–7 October 2015. [Google Scholar]

- Safdar, M.; Matsumoto, T.; Kakuma, K. Flexural Behavior of Reinforced Concrete Beams Repaired with Ultra-High Performance Fiber Reinforced Concrete (UHPFRC). Compos. Struct. 2016, 157, 448–460. [Google Scholar] [CrossRef]

- Aldahdooh, M.A.A.; Muhamad Bunnori, N.; Megat Johari, M.A.; Jamrah, A.; Alnuaimi, A. Retrofitting of Damaged Reinforced Concrete Beams with a New Green Cementitious Composites Material. Compos. Struct. 2016, 142, 27–34. [Google Scholar] [CrossRef]

- Tanarslan, H.M. Flexural Strengthening of RC Beams with Prefabricated Ultra High Performance Fibre Reinforced Concrete Laminates. Eng. Struct. 2017, 151, 337–348. [Google Scholar] [CrossRef]

- Tanarslan, H.M.; Alver, N.; Jahangiri, R.; Yalçınkaya; Yazıcı, H. Flexural Strengthening of RC Beams Using UHPFRC Laminates: Bonding Techniques and Rebar Addition. Constr. Build. Mater. 2017, 155, 45–55. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Isa, M.N.; Baluch, M.H.; Rahman, M.K. Flexural Behavior of Reinforced Concrete Beams Strengthened with Ultra-High Performance Fiber Reinforced Concrete. Constr. Build. Mater. 2017, 134, 279–296. [Google Scholar] [CrossRef]

- Dagenais, M.-A.; Massicotte, B. Cyclic Behavior of Lap Splices Strengthened with Ultrahigh Performance Fiber-Reinforced Concrete. J. Struct. Eng. 2017, 143, 04016163. [Google Scholar] [CrossRef]

- Sadouki, H.; Denarié, E.; Brühwiler, E. Validation of a FEA Model of Structural Response of RC-Cantilever Beams Strengthened with a (R-) UHPFRC Layer. Constr. Build. Mater. 2017, 140, 100–108. [Google Scholar] [CrossRef]

- Paschalis, S.A.; Lampropoulos, A.P.; Tsioulou, O. Experimental and Numerical Study of the Performance of Ultra High Performance Fiber Reinforced Concrete for the Flexural Strengthening of Full Scale Reinforced Concrete Members. Constr. Build. Mater. 2018, 186, 351–366. [Google Scholar] [CrossRef]

- Ramachandra Murthy, A.; Karihaloo, B.L.; Priya, D.S. Flexural Behavior of RC Beams Retrofitted with Ultra-High Strength Concrete. Constr. Build. Mater. 2018, 175, 815–824. [Google Scholar] [CrossRef]

- Ramachandra Murthy, A.; Karihaloo, B.L.; Vindhya Rani, P.; Shanmuga Priya, D. Fatigue Behaviour of Damaged RC Beams Strengthened with Ultra High Performance Fibre Reinforced Concrete. Int. J. Fatigue 2018, 116, 659–668. [Google Scholar] [CrossRef]

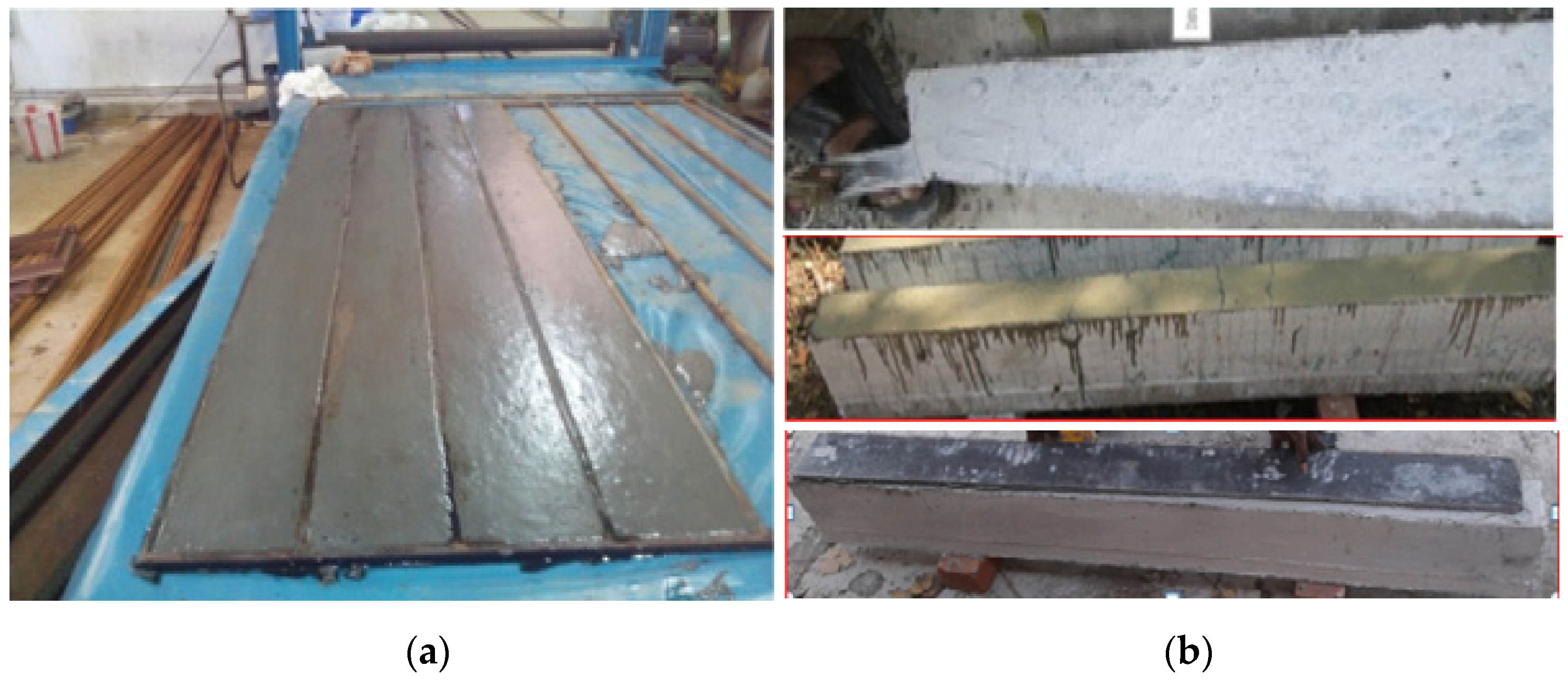

- Yin, H.; Teo, W.; Shirai, K. Experimental Investigation on the Behaviour of Reinforced Concrete Slabs Strengthened with Ultra-High Performance Concrete. Constr. Build. Mater. 2017, 155, 463–474. [Google Scholar] [CrossRef]

- Brühwiler, E. UHPFRC Technology to Enhance the Performance of Existing Concrete Bridges. Struct. Infrastruct. Eng. 2020, 16, 94–105. [Google Scholar] [CrossRef]

- Brühwiler, E.; Bastien-Masse, M.; Mühlberg, H.; Houriet, B.; Fleury, B.; Cuennet, S.; Schär, P.; Boudry, F.; Maurer, M. Strengthening the Chillon Viaducts Deck Slabs with Reinforced UHPFRC. In Proceedings of the IABSE Conference, Geneva 2015: Structural Engineering: Providing Solutions to Global Challenges—Report, Geneva, Switzerland, 23–25 September 2015. [Google Scholar]

- Moreillon, L.; Menétrey, P. Rehabilitation and Strengthening of Existing RC Structures with UHPFRC: Various Applications. In Proceedings of the RILEM-fib-AFGC International Symposium on Ultra-High Performance Fibre-Reinforced Concrete, Montpellier, France, 2–4 October 2017; RILEM Publication SARL: Montpellier, France, 2013; pp. 127–136. [Google Scholar]

- Tong, T.; Yuan, S.; Zhuo, W.; He, Z.; Liu, Z. Seismic Retrofitting of Rectangular Bridge Piers Using Ultra-High Performance Fiber Reinforced Concrete Jackets. Compos. Struct. 2019, 228, 111367. [Google Scholar] [CrossRef]

- Massicotte, B.; Dagenais, M.A.; Garneau, J.F. Bridge Pier Seismic Strengthening Using UHPFRC Cover. In Proceedings of the 9th International Conference on Short and Medium Span Bridges, Calgary, AB, Canada, 15–18 July 2014. [Google Scholar]

- Dagenais, M.-A.; Massicotte, B.; Boucher-Proulx, G. Seismic Retrofitting of Rectangular Bridge Piers with Deficient Lap Splices Using Ultrahigh-Performance Fiber-Reinforced Concrete. J. Bridge. Eng. 2018, 23, 04017129. [Google Scholar] [CrossRef]

- Lavorato, D.; Bergami, A.V.; Nuti, C.; Briseghella, B.; Xue, J.; Tarantino, A.M.; Marano, G.C.; Santini, S. Ultra-High-Performance Fibre-Reinforced Concrete Jacket for the Repair and the Seismic Retrofitting of Italian and Chinese RC Bridges. In Proceedings of the COMPDYN 2017—6th International Conference on Computational Methods in Structural Dynamics and Earthquake Engineering, Rhodes Island, Greece, 15–17 June 2017; Volume 1. [Google Scholar]

- Zhou, M.; Lu, W.; Song, J.; Lee, G.C. Application of Ultra-High Performance Concrete in Bridge Engineering. Constr. Build. Mater. 2018, 186, 1256–1267. [Google Scholar] [CrossRef]

- Tong, T.; Lei, H.; Yuan, S.; Liu, Z. Experimental Investigation and Seismic Vulnerability Assessment of Low Flexural Strength Rectangular Bridge Piers Retrofitted with Ultrahigh-Performance Concrete Jackets. Eng. Struct. 2020, 206, 110132. [Google Scholar] [CrossRef]

- Sakr, M.A.; el Korany, T.M.; Osama, B. Analysis of RC Columns Strengthened with Ultra-High Performance Fiber Reinforced Concrete Jackets under Eccentric Loading. Eng. Struct. 2020, 220, 111016. [Google Scholar] [CrossRef]

- Li, S.; Zhao, T.; Chu, C.; Wang, J.Q.; Shahria Alam, M.; Tong, T. Lateral Cyclic Response Sensitivity of Rectangular Bridge Piers Confined with UHPFRC Tube Using Fractional Factorial Design. Eng. Struct. 2021, 235, 111883. [Google Scholar] [CrossRef]

- Elsayed, M.; Tayeh, B.A.; Elmaaty, M.A.; Aldahshoory, Y. Behaviour of RC Columns Strengthened with Ultra-High Performance Fiber Reinforced Concrete (UHPFRC) under Eccentric Loading. J. Build. Eng. 2022, 47, 103857. [Google Scholar] [CrossRef]

- Eshaghi-Milasi, S.; Mostofinejad, D.; Saljoughian, A.; Bahmani, H. Behavior of RC Columns Strengthened with UHPFRC Jackets through Grooving Method under Eccentric Loading: A Comparative Evaluation of Steel and Synthetic Macro Fibers in UHPFRC. Struct. Concr. 2022, 23, 187–206. [Google Scholar] [CrossRef]

- Noshiravani, T.; Brühwiler, E. Behaviour of UHPFRC-RC Composite Beams Subjected to Combined Bending and Shear. In Proceedings of the 8th fib PhD Symposium. fib Symposium, Copenhagen, Denmark, 20–23 June 2010. [Google Scholar]

- Meda, A.; Mostosi, S.; Riva, P. Shear Strengthening of Reinforced Concrete Beam with High-Performance Fiber-Reinforced Cementitious Composite Jacketing. ACI Struct. J. 2014, 111, 1059. [Google Scholar] [CrossRef]

- Aghani, K.; Afshin, H. Experimental and Numerical Investigation on Shear Retrofitting of RC Beams by Prefabricated UHPFRC Sheets. Civ. Eng. J. 2016, 2, 168–179. [Google Scholar] [CrossRef]

- Garg, V.; Bansal, P.P.; Sharma, R. Retrofitting of Shear-Deficient RC Beams Using UHP-FRC. Iran. J. Sci. Technol.—Trans. Civ. Eng. 2019, 43, 419–428. [Google Scholar] [CrossRef]

- Zohrevand, P.; Yang, X.; Jiao, X.; Mirmiran, A. Punching Shear Enhancement of Flat Slabs with Partial Use of Ultrahigh-Performance Concrete. J. Mater. Civ. Eng. 2015, 27, 04014255. [Google Scholar] [CrossRef]

- Bastien-Masse, M.; Brühwiler, E. Contribution of R-UHPFRC Strengthening Layers to the Shear Resistance of RC Elements. Struct. Eng. Int. 2016, 26, 365–374. [Google Scholar] [CrossRef]

- Wu, X.; Yu, S.; Xue, S.; Kang, T.H.K.; Hwang, H.J. Punching Shear Strength of UHPFRC-RC Composite Flat Plates. Eng. Struct. 2019, 184, 278–286. [Google Scholar] [CrossRef]

- Koo, I.-Y.; Hong, S.-G. Strengthening RC Columns with Ultra High Performance Concrete. In Proceedings of the 2016 Structures Congress, Jeju Island, Korea, 28 August–1 September 2016. [Google Scholar]

- Hong, S.-G.; Lee, J.-H.; Choi, Y.; Gu, I.-Y. Seismic Strengthening of Concrete Columns by Ultrahigh-Performance Fiber-Reinforced Concrete Jacketing. J. Struct. Eng. 2021, 147, 04021157. [Google Scholar] [CrossRef]

- Sakr, M.A.; El-khoriby, S.R.; Khalifa, T.M.; Nagib, M.T. Modeling of RC Shear Walls Strengthened with Ultra-High Performance Fiber Reinforced Concrete (UHPFRC) Jackets. Eng. Struct. 2019, 200, 109696. [Google Scholar] [CrossRef]

- Franssen, R.; Courard, L.; Mihaylov, B.I. Shear Behavior of Concrete Walls Retrofitted with Ultra- High-Performance Fiber-Reinforced Concrete Jackets. ACI Struct. J. 2021, 118. [Google Scholar] [CrossRef]

- Fan, W.; Shen, D.; Yang, T.; Shao, X. Experimental and Numerical Study on Low-Velocity Lateral Impact Behaviors of RC, UHPFRC and UHPFRC-Strengthened Columns. Eng. Struct. 2019, 191, 509–525. [Google Scholar] [CrossRef]

- Lee, J.Y.; Aoude, H.; Yoon, Y.S.; Mitchell, D. Impact and Blast Behavior of Seismically-Detailed RC and UHPFRC-Strengthened Columns. Int. J. Impact Eng. 2020, 143, 103628. [Google Scholar] [CrossRef]

- Wei, J.; Li, J.; Wu, C.; Liu, Z.X.; Fang, J. Impact Resistance of Ultra-High Performance Concrete Strengthened Reinforced Concrete Beams. Int. J. Impact Eng. 2021, 158, 104023. [Google Scholar] [CrossRef]

- Mohammed, T.J.; Abu Bakar, B.H.; Muhamad Bunnori, N. Torsional Improvement of Reinforced Concrete Beams Using Ultra High-Performance Fiber Reinforced Concrete (UHPFC) Jackets—Experimental Study. Constr. Build. Mater. 2016, 106, 533–542. [Google Scholar] [CrossRef]

| Material | Mix Proportion (kg/m3) | ||

|---|---|---|---|

| Typical Range | Ductal ® | CEMTEC® | |

| Cement | 610–1080 | 746 | 1050 |

| Silica fume | 50–334 | 242 | 275 |

| Crushed quartz | 0–410 | 224 | - |

| Sand | 490–1390 | 1066 | 730 |

| Water | 126–261 | 142 | 190 |

| Superplasticizer | 9–71 | 9 | 35 |

| Steel fibres | 40–250 | 161 | 470 |

| Study | Type of Structural Member, Strengthening and Testing Method | Results/Remarks |

|---|---|---|

| [71] | Retrofitting damaged RC beams by adhesively bonding precast UHPFRC strips; Testing using four-point bending setup. | Increase in the ultimate load with the increase in UHPFRC strip thickness. |

| [72] | Strengthening damaged RC beams by reinforced and unreinforced UHPFRC layers; Investigation using an analytical cross-sectional model. | Retrofitting configurations lead to higher stiffness and increased resistance, while delaying crack propagation. |

| [73] | Four-point bending test of full-size RC beams strengthened with UHPFRC layers. | The addition of reinforcing bars in the UHPFRC layer significantly increased the composite members’ flexural capacity and delayed the formation of localised macro-cracks. |

| [74] | Testing of UHPFRC-strengthened beams using a cantilever beam setup by varying span length, ratio and type of reinforcement. | Strengthened beams failed in flexure at a force about 2 to 2.8 times higher than the failure load of reference RC specimens. |

| [75] | Four-point bending test of existing RC beams strengthened with UHPFRC layers (tension side, compression side and three-side-jacketing configurations). | Three-side-jacketed beams complimented with additional reinforcement exhibited the highest flexural capacity enhancement. |

| [76] | Four-point bending test for RC beams repaired in the tension and compression zone with UHPFRC layers of varying thicknesses. | Significant increase in the cracking and ultimate load for strengthened beams with higher UHPFRC layer thickness. Concrete crushing and rebar fracture failure modes were observed. |

| [77] | Retrofitting damaged RC beams with prefabricated strips of UHPFRC containing up to 50% palm oil fuel ash. Testing using four-point bending setup. | Increase in the average failure load within the range of 21 to 37% compared to refence RC beams. |

| [78] | Four-point bending test of RC beams strengthened with prefabricated UHPFRC laminates. Epoxy bonding and anchorage bonding were implemented. | A maximum load-carrying capacity increase of 208% was observed for reinforced UHPFRC-strengthened beams. Higher quality control and workmanship required. |

| [79] | Four-point bending test of RC beams strengthened with UHPFRC laminates. Compared epoxy bonding and mechanical anchorage. | Both anchoring mechanisms showed similar ultimate loads. The glued specimen had lower ultimate deflection. |

| [80] | Comparison of the performance of beams strengthened by bonding UHPFRC strips and casting UHPFRC layers in situ; Testing using four-point bending setup. | No significant difference in the results for flexural testing using both techniques. However, the sandblasting/UHPFRC cast in situ technique showed an overall better performance. |

| [81] | Investigated the cyclic behaviour of lap splices of RC beams strengthened with UHPFRC with varying fibre contents and reinforcement arrangements; Tested with reverse cyclic loading. | UHPFRC with appropriate fibre content can provide the continuity of lapped bars, ensuring better ductile performance under cyclic loading. |

| [82] | Numerical simulation of the structural response of RC cantilever beams retrofitted with UHPFRC. | Strengthened beams using UHPFRC and reinforced UHPFRC increased the flexural capacity of beams by 40% and 53%, respectively, compared to the reference beam. |

| [83] | Experimental and numerical investigation of the performance of UHPFRC-strengthened RC beams; Four-point bending and push-off testing. | A better bond between the UHPFRC layer and concrete substrate was observed. Average maximum load increase of 87% for the retrofitted beams compared to control beams. |

| [84] | Four-point bending test of damaged RC beams restored with thin UHPFRC strips. Finite element models were developed to predict the flexural response of retrofitted beams. | No debonding/delamination of UHPFRC strips was observed. Preloaded and retrofitted RC beams had a slightly higher load carrying capacity than the undamaged control beams. |

| [85] | Investigated the fatigue behaviour of damaged RC beams restored with thin UHPFRC strips by conducting fatigue testing. | The maximum number of cycles to failure of all pre-loaded and retrofitted RC beams was found to be substantially higher than that of the control beams. |

| [86] | Experimental investigation of the behaviour of composite RC slabs strengthened with UHPFRC; Tested using three-point bending setup. | Strengthened slab panels showed improved ultimate load. Post cracking range exhibited excellent energy absorption with excessive deflection hardening and ductility. |

| Study | Type of Structural Member, Strengthening and Testing Method | Results/Remarks |

|---|---|---|

| [91] | Explored the behaviour of UHPFRC-strengthened bridge pier specimens (originally with deficient lap splices) subjected to constant axial load and increasing lateral displacement. | Splitting cracks were eliminated, exhibiting ductile behaviour, and progressive failure was caused by the dowel bar’s tensile rupture in the footing. |

| [92] | Conducted unidirectional reverse cyclic tests for RC column specimens with deficient lap splices strengthened with a UHPFRC cover. | The concrete damage failure modes of crushing and spalling were avoided by the UHPFRC cover integrity. The failure of all retrofitted specimens was ductile and progressive. |

| [93] | Investigated the seismic behaviour of bridge piers with insufficient seismic durability which were retrofitted with UHPFRC. Cyclic tests were carried out on repaired and retrofitted 1:6 scale pier specimens. | Strengthened piers showed an increased moment capacity, eliminating failure by shear rupture. |

| [94] | Reviewed the applications of UHPFRC retrofitting in bridge engineering. | UHPFRC retrofitting improved the issues related to deformation and cracking of bridge pavements while enhancing the connection integrity of joints. The primary limitations of UHPFRC retrofitting were identified as corrosion of the surface steel fibre and the possibility of cracking. |

| [90] | Conducted pseudo-static cyclic loading tests on as-built and UHPFRC jacket retrofitted full scale bridge pier specimens. | Jackets enhanced the RC piers’ lateral load carrying capacity, improved the piers’ self-centring capability and mitigated the residual lateral drift. |

| [95] | Compared the performance of two different UHPFRC jacket configurations (single wide strip jacket and multi-narrow strip jackets) for seismic retrofitting of bridge piers by conducting cyclic tests. | Both techniques mitigated the residual drift and concrete damage, leading to the improved seismic resilience of piers. Piers with a single wide strip UHPFRC jacket exhibited higher lateral strength; however, they were prone to plastic hinge relocation. |

| [96] | Developed finite element and analytical models to investigate the behaviour of UHPFRC retrofitted RC columns under axial or eccentric loading. | The results illustrated that a monolithic behaviour of the strengthened columns can be obtained by using an adequate number of dowels, reducing the jacket thickness and improving the core surface texture. |

| [97] | Investigated the cyclic response of UHPFRC tube-confined piers using 3D finite element models. | Predictive equations were proposed to foresee the response of UHPFRC tube-confined columns through regression analysis. |

| [98] | Conducted an extensive experimental programme to investigate the performance of UHPFRC-strengthened columns under eccentric loading by varying the load eccentricity ratio, volume ratio of fibres, thickness of UHPFRC and strengthening scheme. | The results indicated that the gain in moment capacity, axial load capacity and stiffness is inversely proportional to the eccentricity ratio and proportional to the UHPFRC jacket thickness. |

| [99] | Examined the behaviour of circular RC columns retrofitted with UHPFRC jackets under concentric and eccentric loading. | The enhancement in the load-carrying capacity of RC columns under eccentric loading was attributed to UHPFRC jackets. Furthermore, the ductility and energy dissipation were enhanced. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bandara, S.; Wijesundara, K.; Rajeev, P. Ultra-High-Performance Fibre-Reinforced Concrete for Rehabilitation and Strengthening of Concrete Structures: A Suitability Assessment. Buildings 2023, 13, 614. https://doi.org/10.3390/buildings13030614

Bandara S, Wijesundara K, Rajeev P. Ultra-High-Performance Fibre-Reinforced Concrete for Rehabilitation and Strengthening of Concrete Structures: A Suitability Assessment. Buildings. 2023; 13(3):614. https://doi.org/10.3390/buildings13030614

Chicago/Turabian StyleBandara, Sahan, Kushan Wijesundara, and Pat Rajeev. 2023. "Ultra-High-Performance Fibre-Reinforced Concrete for Rehabilitation and Strengthening of Concrete Structures: A Suitability Assessment" Buildings 13, no. 3: 614. https://doi.org/10.3390/buildings13030614

APA StyleBandara, S., Wijesundara, K., & Rajeev, P. (2023). Ultra-High-Performance Fibre-Reinforced Concrete for Rehabilitation and Strengthening of Concrete Structures: A Suitability Assessment. Buildings, 13(3), 614. https://doi.org/10.3390/buildings13030614