Fluid Flow Characteristics for Four Lattice Settings in Brick Tunnel Kiln: CFD Simulations

Abstract

1. Introduction

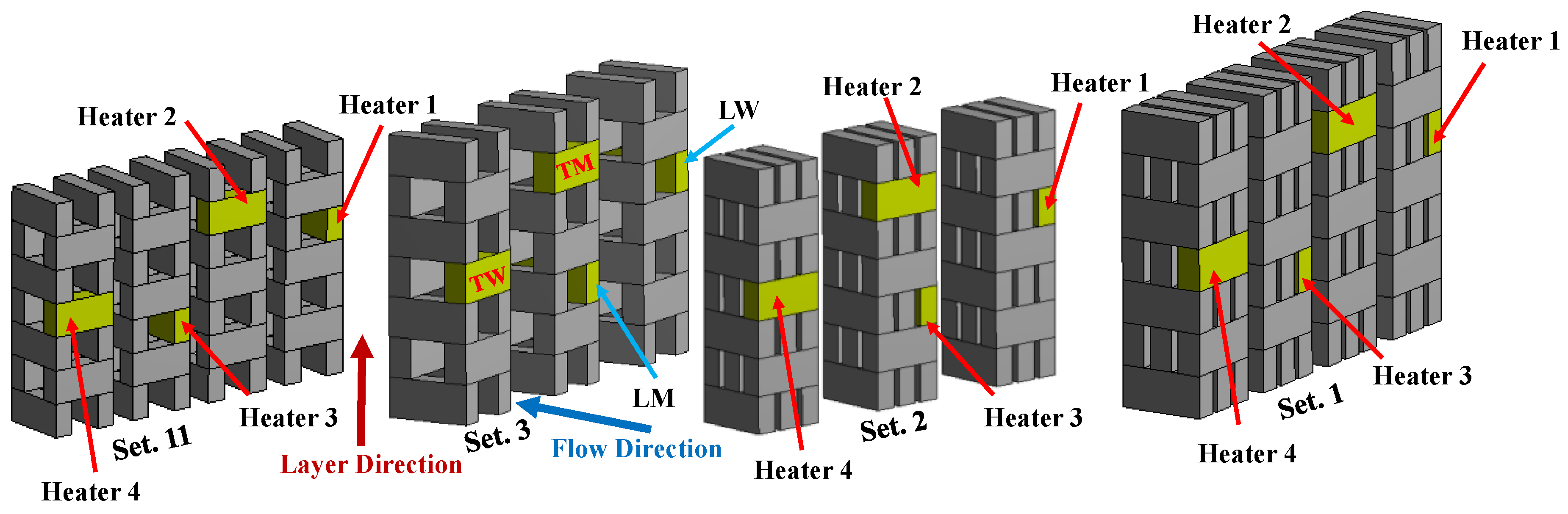

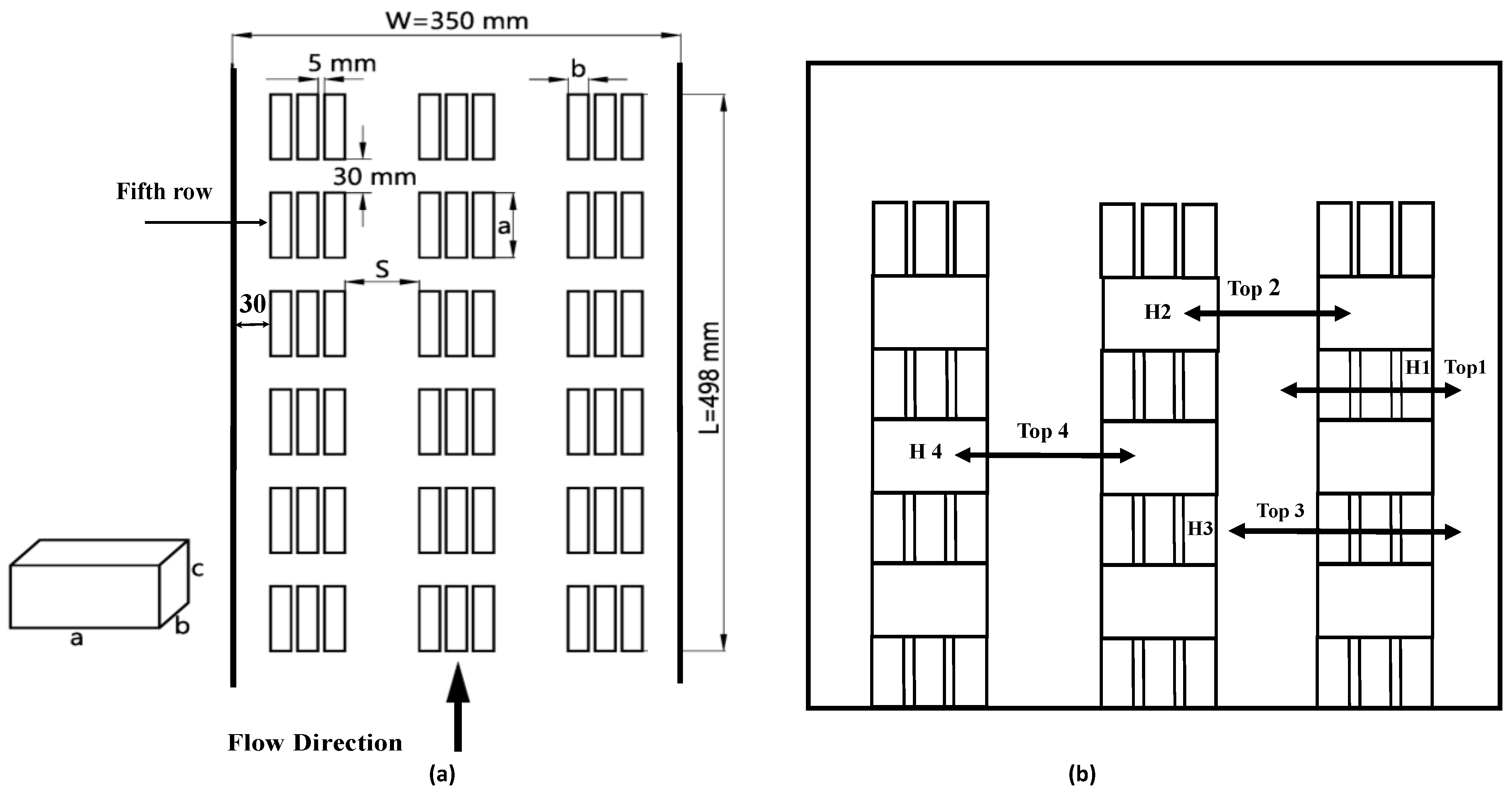

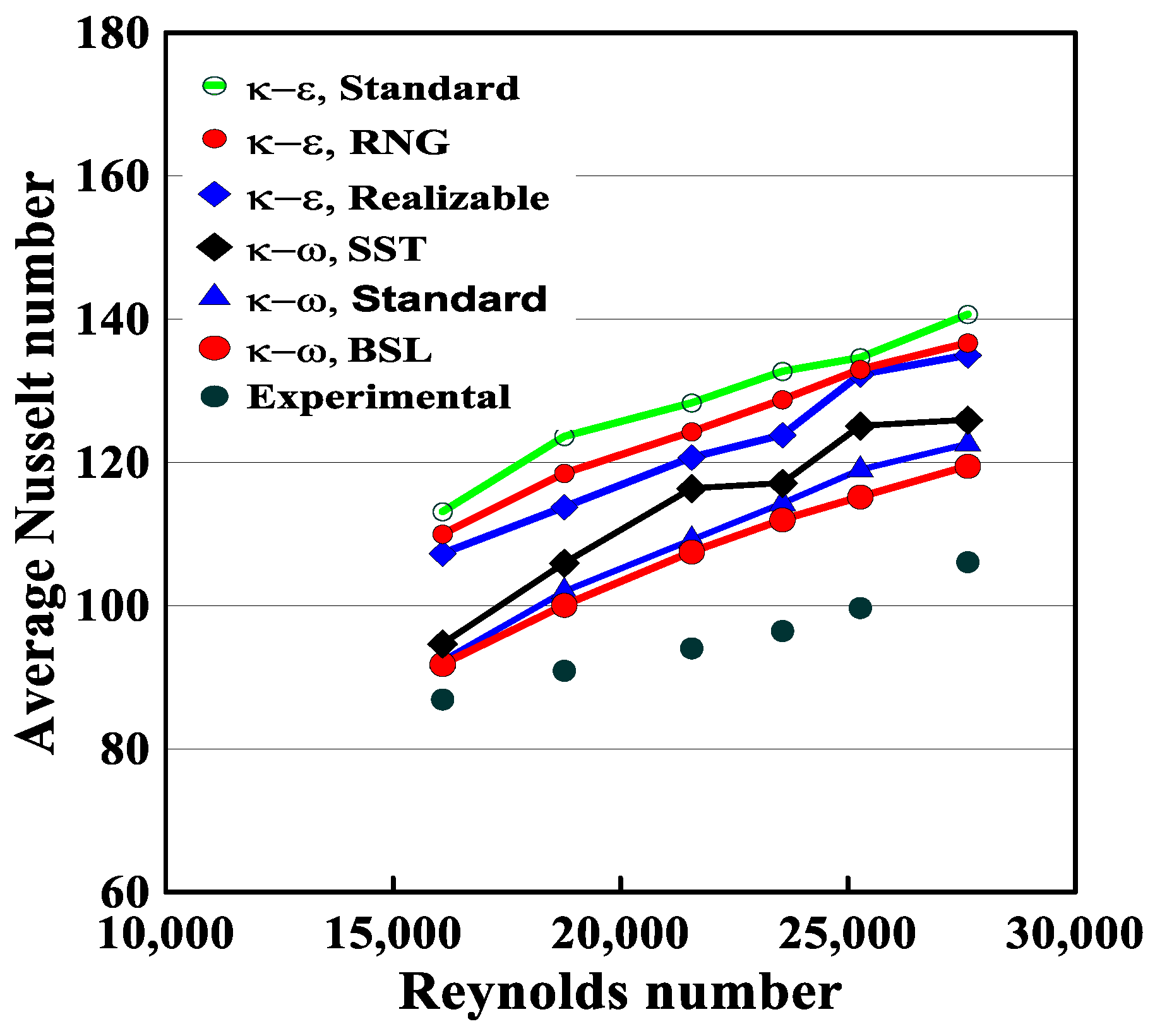

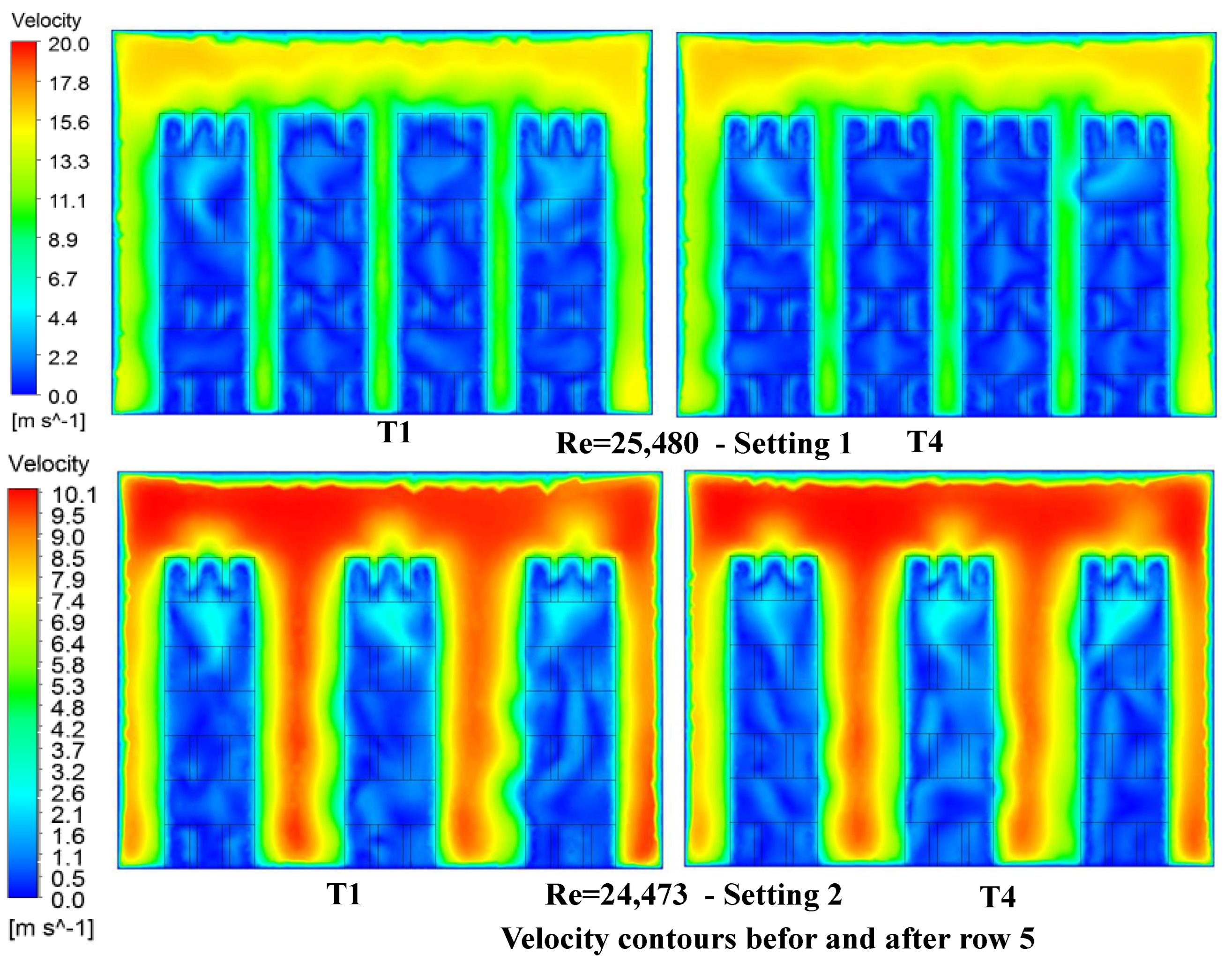

2. Model Description

3. Results and Discussion

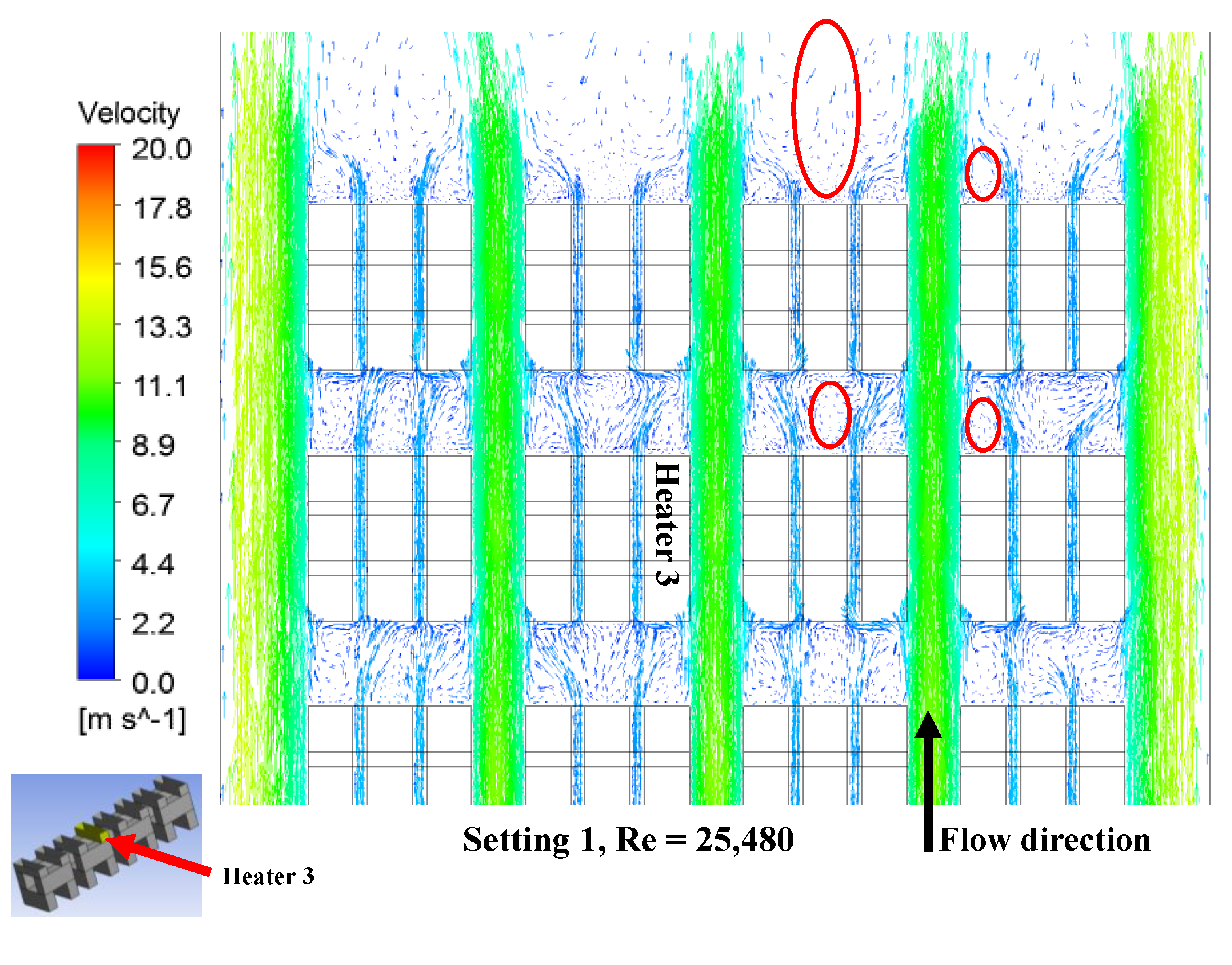

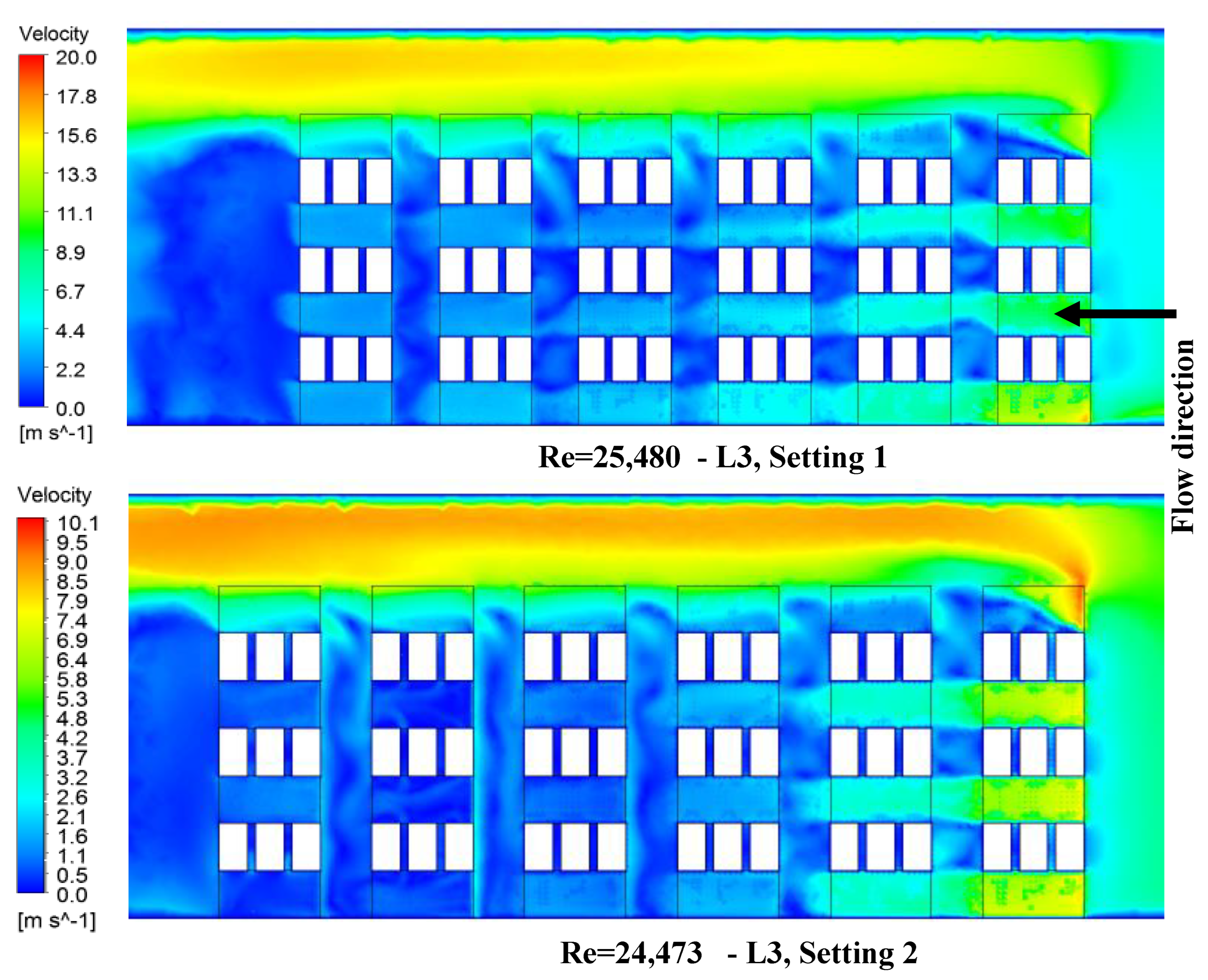

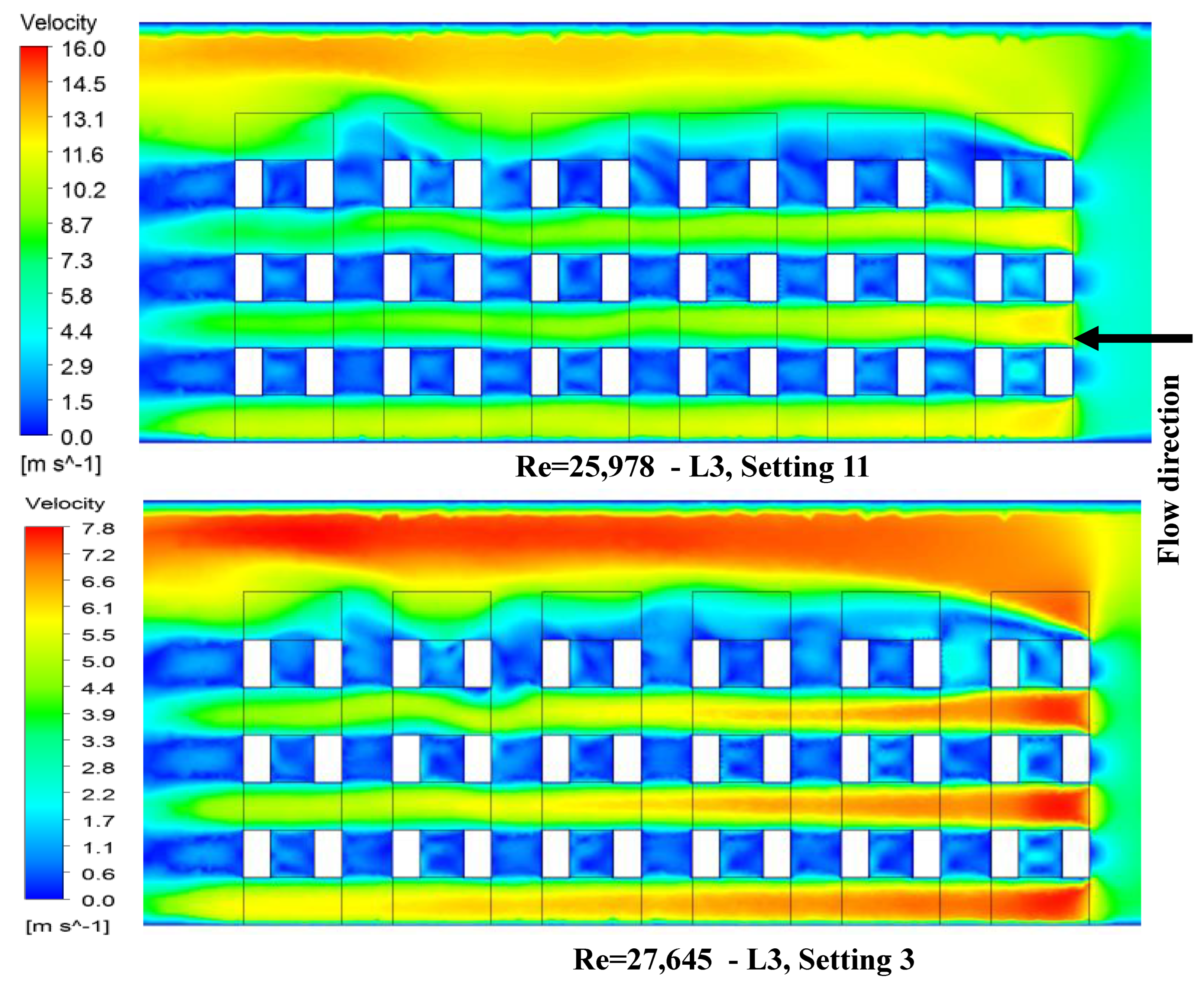

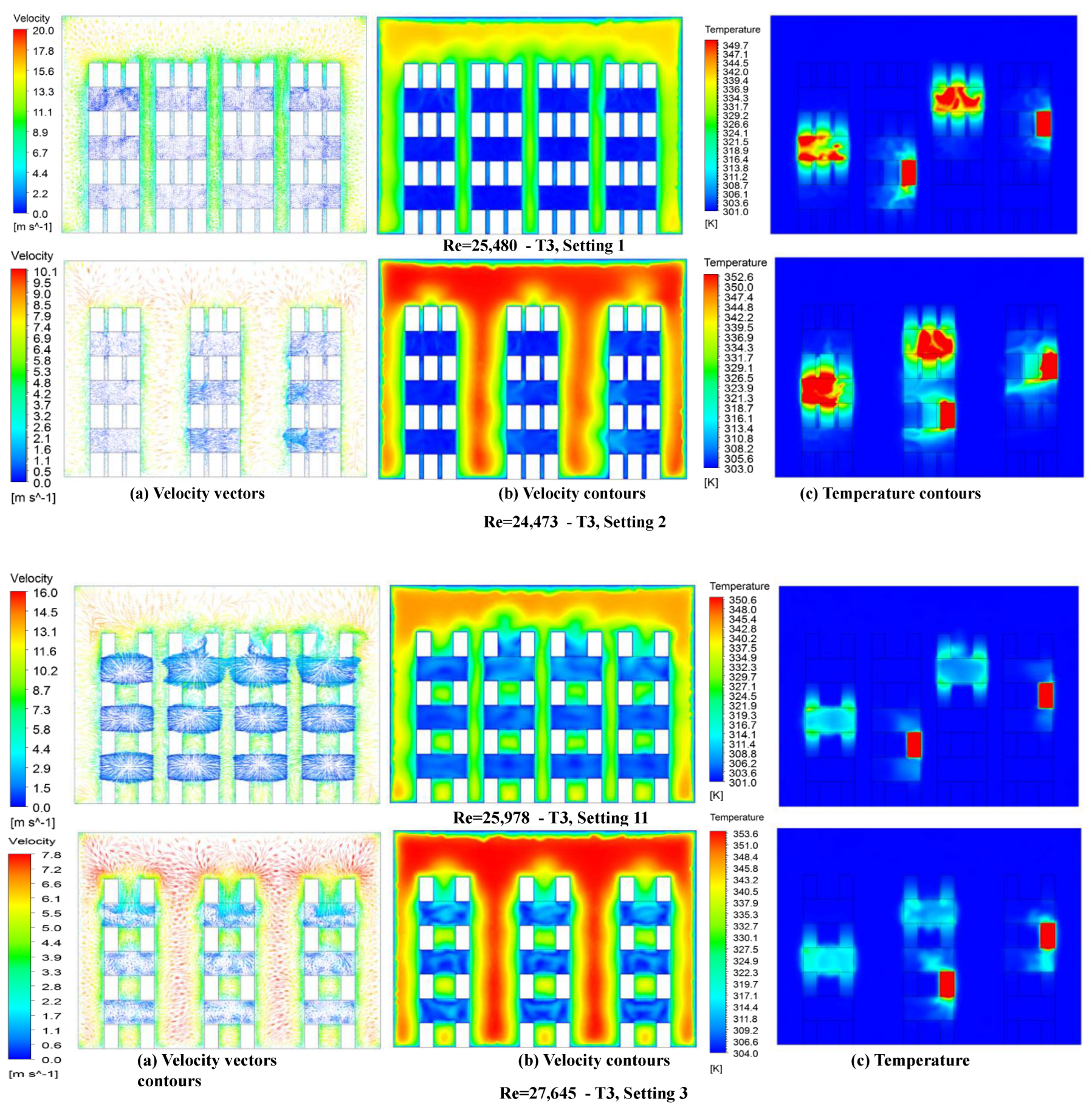

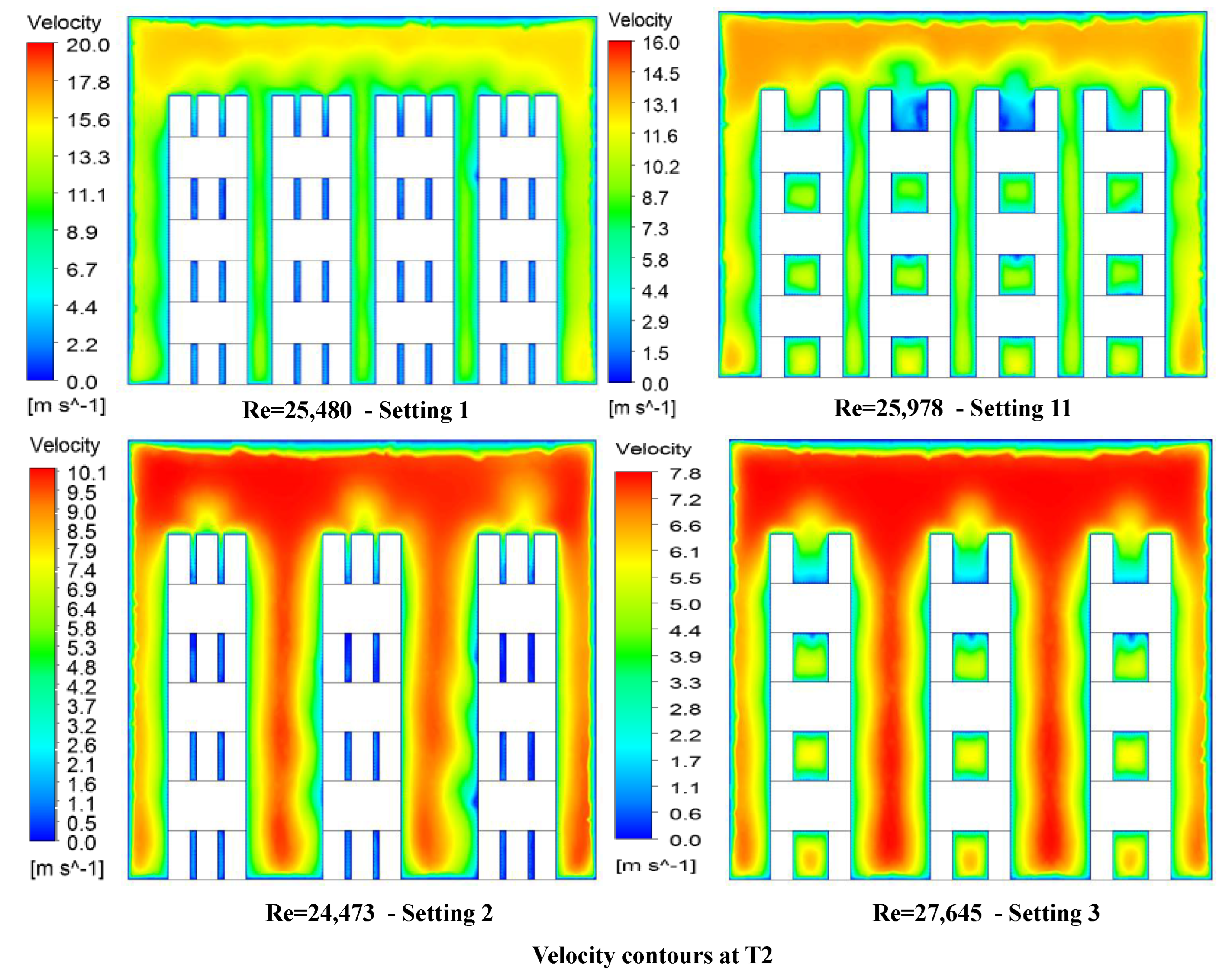

3.1. Effect of Brick Setting Arrangement (Solid Mass Effect) on the Flow Field

3.1.1. Effect of the Number of Bricks

3.1.2. Effect of the Number of Columns

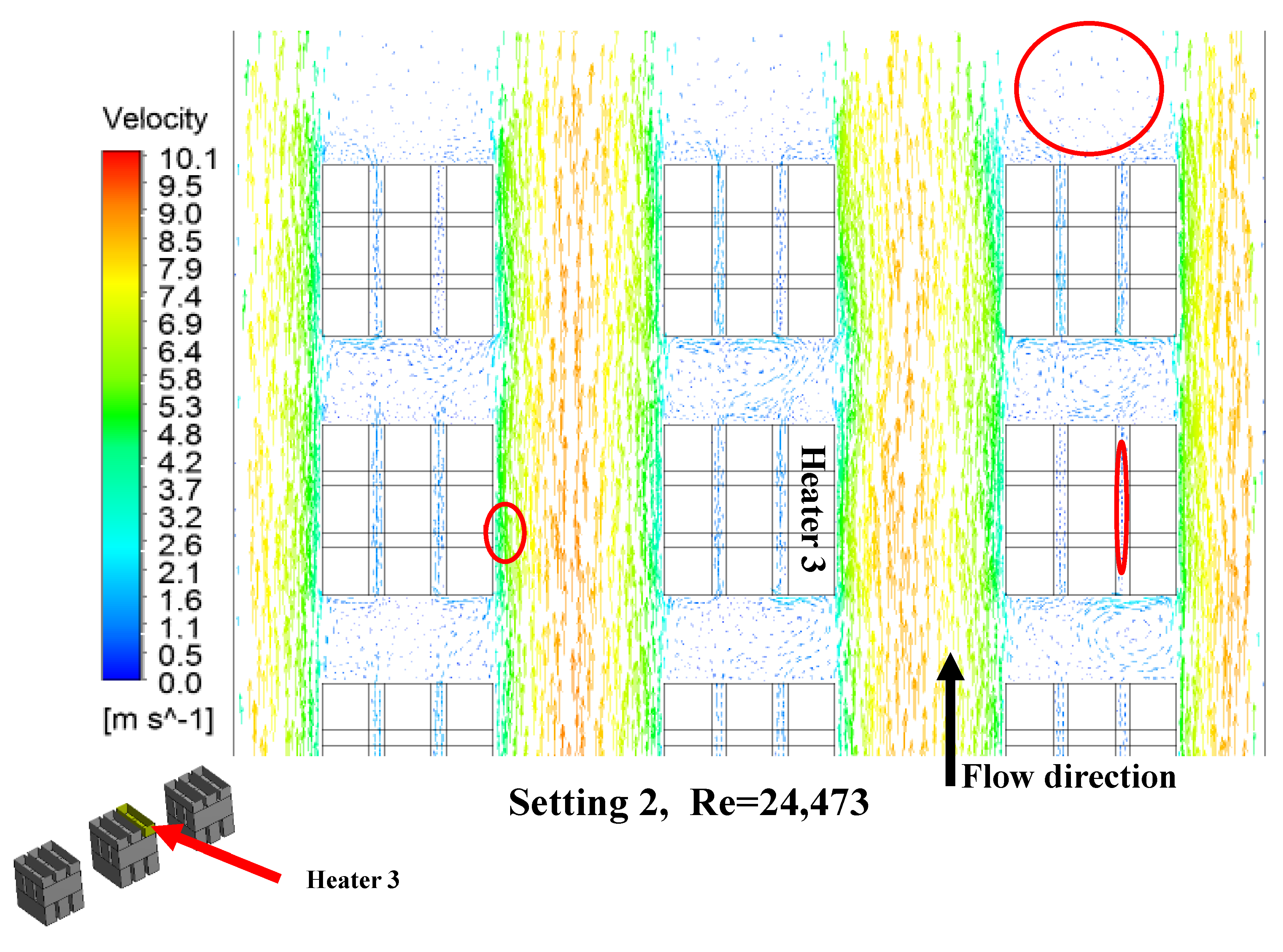

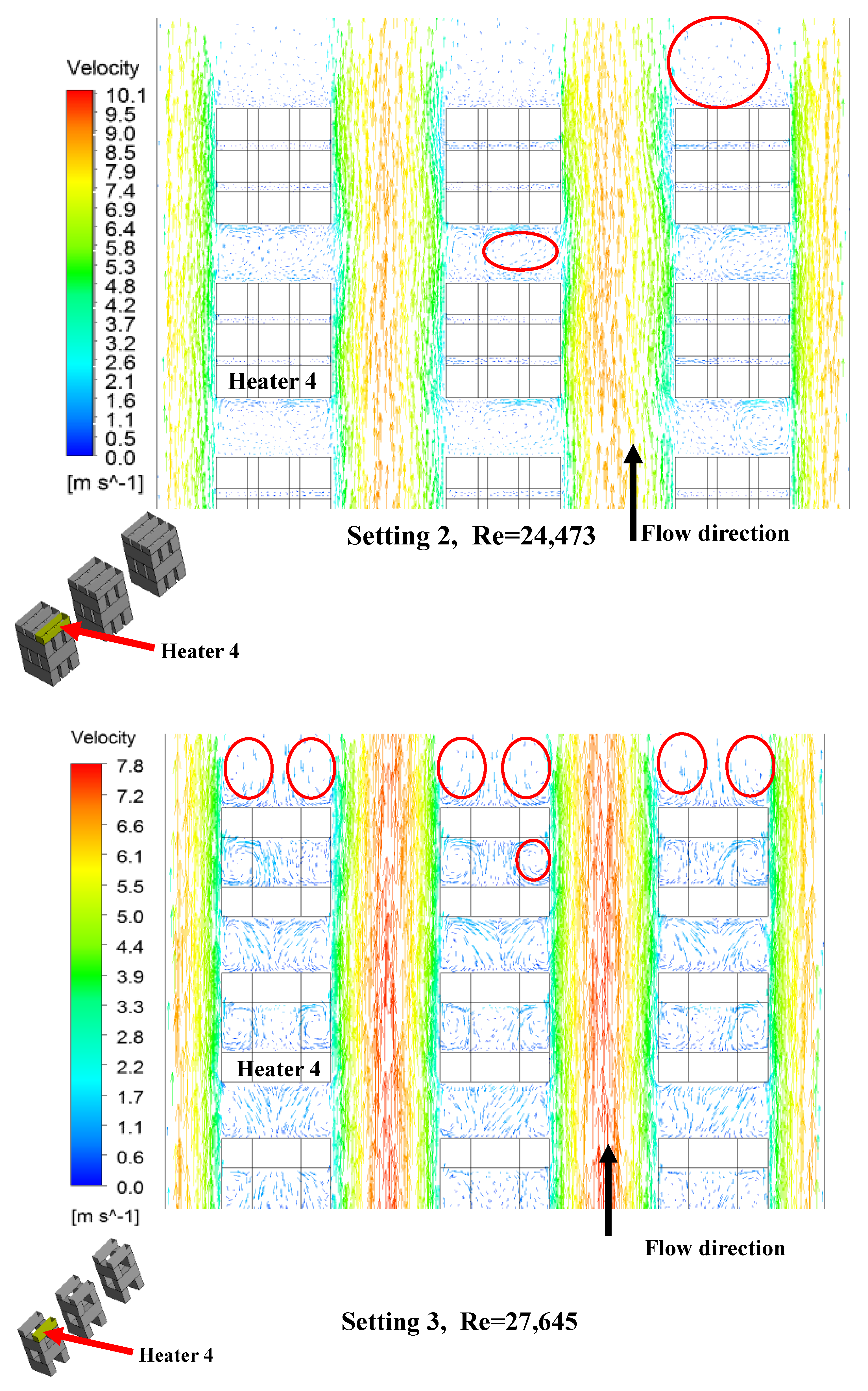

3.2. Wall Effects on the Flow Field

3.3. Flow Uniformity through the Fifth Row

4. Conclusions

- The flow patterns of velocity vectors are predicted and plotted along the transversal and longitudinal bricks in the studied lattice brick settings for the same values of Reynolds number.

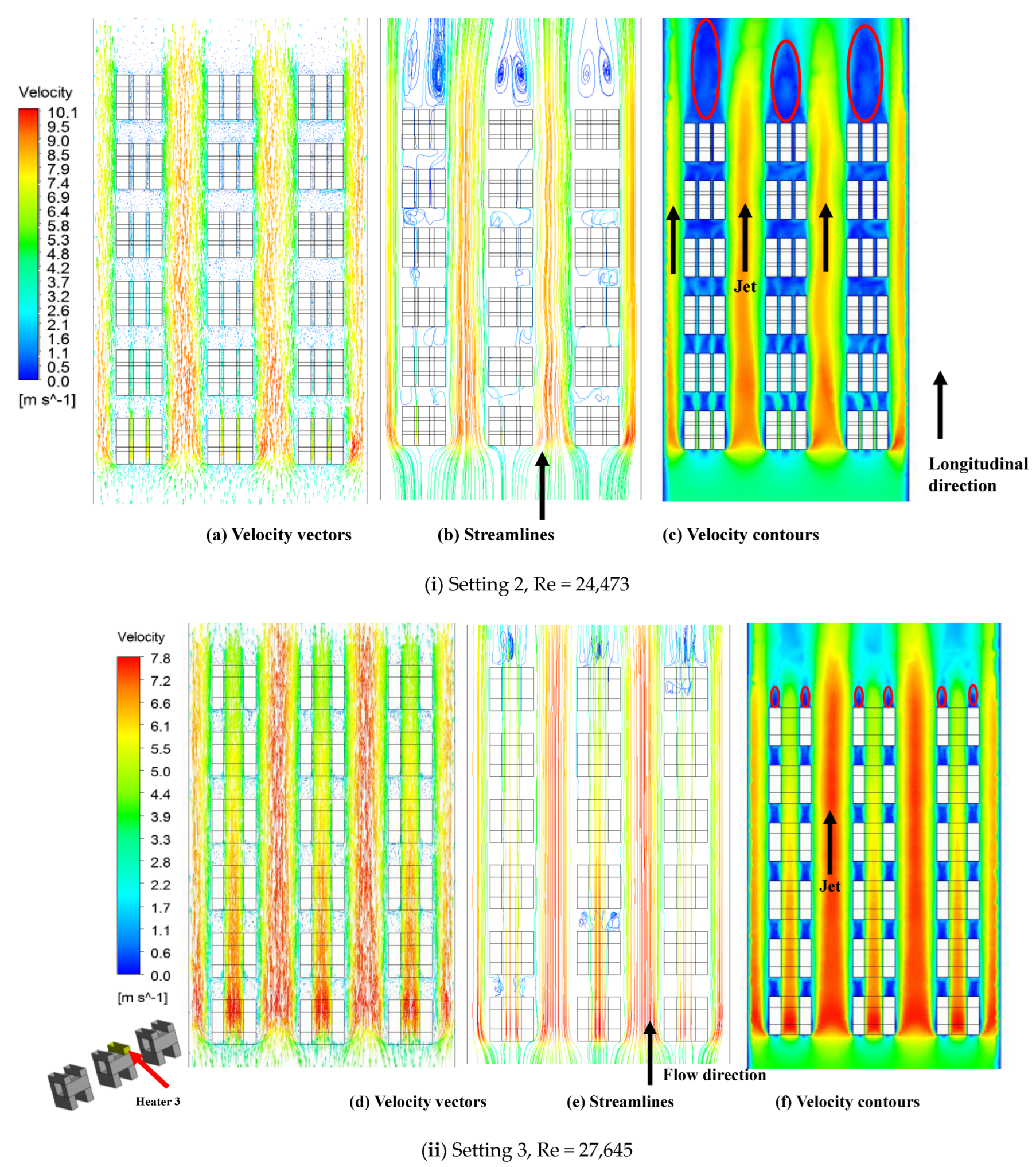

- The present BSL k-ω turbulent model predicts that vortex shedding will play an important role in heat transfer enhancement through the lattice brick settings.

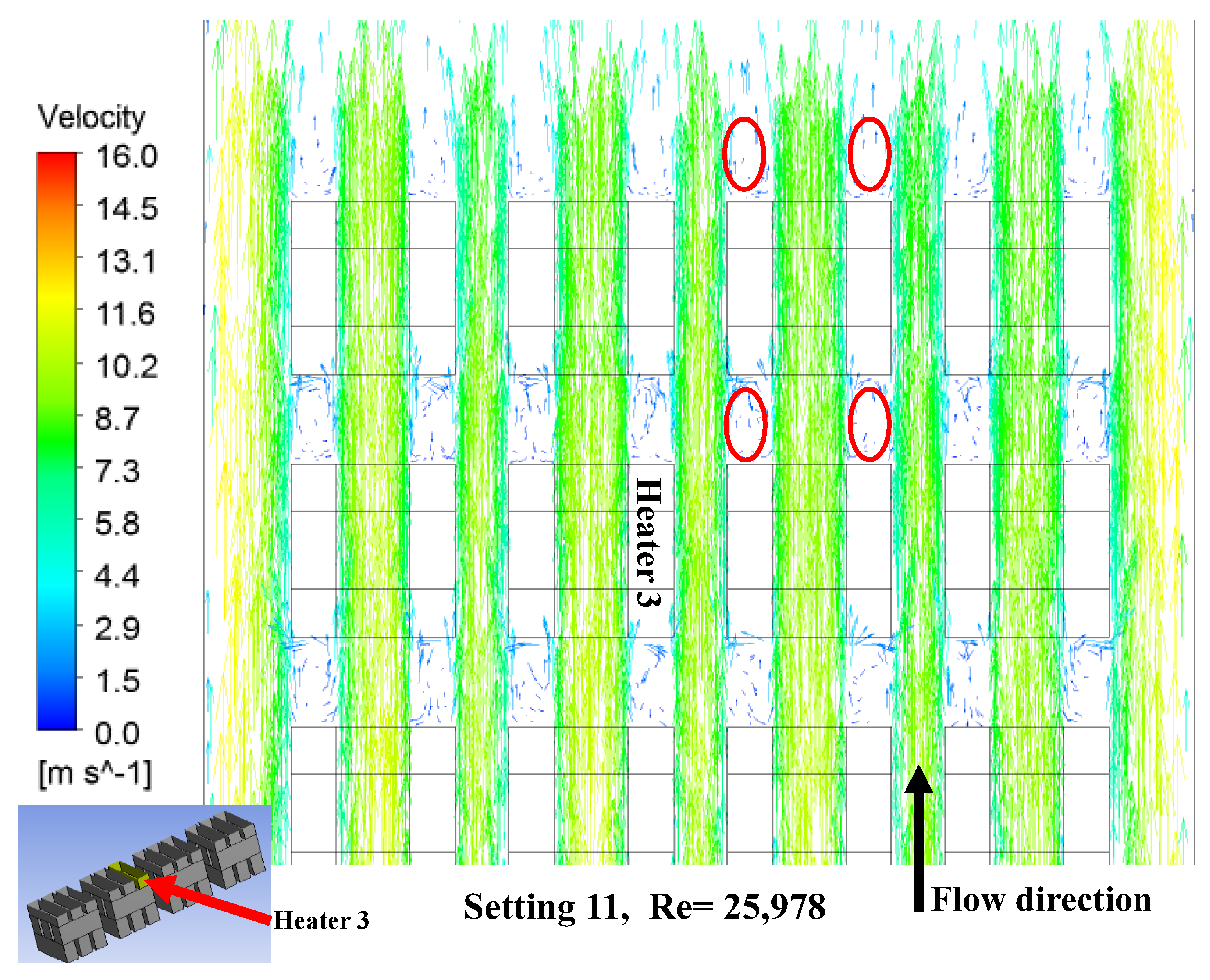

- A large recirculation zone (dead zone) is formed in setting 11, and reversed flow patterns are found upstream of the high brick density setting.

- The recirculating flow appears to have a low velocity, so a low heat transfer rate is expected in the wake region.

- The dense arrangements of bricks in settings 1 and 2 and the limited gap space between bricks hinder the small-scale eddies’ growth.

- The vortices formed inside the brick columns improve the heat transfer through the brick’s side walls, which are not perpendicular to the main flow.

- A secondary flow is observed in setting 3, and the flow velocity increases in the gap between bricks compared to other settings. The lowest secondary flow velocity is observed in the wake region in setting 11.

- The findings give a clear vision of the fluid flow and a comparison between the four lattice brick settings, which will be beneficial to the brick tunnel kiln designers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |

| a | Brick length, mm |

| Ab | Brick surface area, m2 |

| Aw | Wet area, m2, |

| Aw,b | Brick wet area, m2 |

| Ad,w | Duct wet area, m2 |

| b | Brick width, mm |

| c | Brick height, mm |

| Cp | Specific heat |

| Dh | Hydraulic diameter, m, |

| f | Friction factor |

| Convective heat transfer coefficient, | |

| k | Fluid thermal conductivity, |

| L | Length of brick setting, mm |

| P | Pressure, Pa |

| Q | Heat transfer rate, W |

| S | Spacing between columns, m |

| u | Superficial velocity, m/s |

| U | Interstitial velocity, , |

| Re | Reynolds number |

| Vb | Brick volume, m3 |

| Vd | Duct volume, m3 |

| Vf | Volume of flow, m3, |

| Greek letters | |

| ε | Void fraction = Vf/Vd |

| ρ | Density, |

| ρs | Brick setting density = Vb/Vd |

| Dynamic viscosity, kg/m·s | |

| Subscript | |

| avg | |

| i | Local value |

| Abbreviations | |

| H | Heater |

| L | Longitudinal |

| LM | Longitudinal middle |

| LW | Longitudinal wall |

| T | Transverse |

| TM | Transversal middle |

| Top | Top plane |

| TW | Transversal wall |

References

- Refaey, H.A. Mathematical Model to Analyze the Heat Transfer in Tunnel Kilns for Burning of Ceramics. Ph.D. Dissertation, Otto-von-Guericke University, Magdeburg, Germany, 2013. [Google Scholar]

- Tehzeeb, H.; Bhuiyan, M.; Jayasuriya, N. Evaluation of brick kiln performances using computational fluid dynamics (CFD). Energy Environ. Eng. J. 2012, 1, 86–93. [Google Scholar]

- Dugwell, D.R.; Oakley, D.E. A model of heat transfer in tunnel kilns used for firing refractories. Int. J. Heat Mass Transf. 1988, 31, 2381–2390. [Google Scholar] [CrossRef]

- Refaey, H.A.; Specht, E. Flow Field Visualization to Simulate the burning of sanitaryware in tunnel Kilns. In Proceedings of the ICFD11: Eleventh International Conference of Fluid Dynamics, Alexandria, Egypt, 19–21 December 2013. [Google Scholar]

- Kaya, S.; Kucukada, K.; Mancuhan, E. Model-based optimization of heat recovery in the cooling zone of a tunnel kiln. Appl. Therm. Eng. 2008, 28, 633–641. [Google Scholar] [CrossRef]

- Naccache, M.F.; Gomes, M.S.P.; Nieckele, A.O. Numerical simulation of flow and heat transfer through a tunnel Kiln. In Proceedings of the 18th International Congress of Mechanical Engineering, Ouro Preto, Brazil, 6–11 November 2005. [Google Scholar]

- Al-Hasnawi, A.G.T.; Refaey, H.A.; Redemann, H.A.T.; Attalla, M.; Specht, E. Computational Fluid Dynamics Simulation of Flow Mixing in Tunnel Kilns by Air Side Injection. J. Therm. Sci. Eng. Appl. 2018, 10, 031007. [Google Scholar] [CrossRef]

- Refaey, H.A.; Abdel-Aziz, A.A.; Ali, R.K.; Abdelrahman, H.E.; Salem, M.R. Augmentation of convective heat transfer in the cooling zone of brick tunnel kiln using guide vanes: An experimental study. Int. J. Therm. Sci. 2017, 122, 172–185. [Google Scholar] [CrossRef]

- Refaey, H.A.; Abdel-Aziz, A.A.; Salem, M.R.; Abdelrahman, H.E.; Al-Dosoky, M.W. Thermal performance augmentation in the cooling zone of brick tunnel kiln with two types of guide vanes. Int. J. Therm. Sci. 2018, 130, 264–277. [Google Scholar] [CrossRef]

- Refaey, H.A.; Karali, M.A.; Al-Hasnawi, A.G.; Specht, E. Mathematical model to simulate the heat transfer in vitrified clay pipes kiln. In Proceedings of the International Conference on Applied Mechanics and Mechanical Engineering, AMME-18, Cairo, Egypt, 3–5 April 2018. [Google Scholar]

- Almutairi, J.H.; Alrahmani, M.A.; Almesri, I.F.; Abou-Ziyan, H.Z. Effect of fluid channels on flow uniformity in complex geometry similar to lattice brick setting in tunnel kilns. Int. J. Mech. Sci. 2017, 134, 28–40. [Google Scholar] [CrossRef]

- Beyene, A.; Ramayya, V.; Shunki, G. CFD Simulation of Biogas Fired Clay Brick Kiln. Am. J. Eng. Appl. Sci. 2018, 11, 1045–1061. [Google Scholar] [CrossRef]

- Gomez, R.S.; Porto, T.R.N.; Magalhães, H.L.F.; Moreira, G.; André, A.M.M.C.N.; Melo, R.B.F.; Lima, A.G.B. Natural Gas Intermittent Kiln for the Ceramic Industry: A Transient Thermal Analysis. Energies 2019, 12, 1568. [Google Scholar] [CrossRef]

- Refaey, H.A.; Alharthi, M.A.; Salem, M.R.; Abdel-Aziz, A.A.; Abdelrahman, H.E.; Karali, M. Numerical investigations of convective heat transfer for lattice settings in brick Tunnel Kiln: CFD simulation with experimental validation. Therm. Sci. Eng. Prog. 2021, 24, 100934. [Google Scholar] [CrossRef]

- Ngom, M.; Thiam, A.; Balhamri, A.; Sambou, V.; Raffak, T.; Refaey, H.A. Transient study during clay bricks cooking in the traditional kiln; CFD numerical study. Case Stud. Therm. Eng. 2021, 28, 101672. [Google Scholar] [CrossRef]

- Refaey, H.; Almohammadi, B.A.; Abdel-Aziz, A.A.; Abdelrahman, H.; El-Ghany, H.A.; Karali, M.A.; Al-Dosoky, M. Transient thermal behavior in brick tunnel kiln with guide vanes: Experimental study. Case Stud. Therm. Eng. 2022, 33, 101959. [Google Scholar] [CrossRef]

| Setting | No. of Bricks | ε | Dh (mm) | Aw,b (m2) | Aw,b/Aw,b1 (%) | ρs = Vb/Vd | S (mm) | S/a | S/b |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 504 | 0.6995 | 43.17 | 2.2936 | 100.0 | 0.3005 | 19.3 | 0.3333 | 1.2083 |

| 2 | 378 | 0.7746 | 59.54 | 1.7202 | 75.0 | 0.2254 | 58.0 | 1.0000 | 3.6250 |

| 3 | 252 | 0.8497 | 81.31 | 1.2574 | 54.8 | 0.1503 | 58.0 | 1.0000 | 3.6250 |

| 11 | 336 | 0.7996 | 59.3 | 1.7964 | 78.3 | 0.2004 | 19.3 | 0.3333 | 1.2083 |

| Mass Flow Rate | Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | |

|---|---|---|---|---|---|---|---|

| Setting | |||||||

| 1 | 0.365 | 0.435 | 0.504 | 0.556 | 0.592 | 0.646 | |

| 2 | 0.277 | 0.339 | 0.392 | 0.428 | 0.458 | 0.499 | |

| 3 | 0.263 | 0.307 | 0.353 | 0.386 | 0.414 | 0.452 | |

| 11 | 0.310 | 0.369 | 0.428 | 0.471 | 0.502 | 0.548 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Refaey, H.A.; Alharthi, M.A.; Abdel-Aziz, A.A.; Elattar, H.F.; Almohammadi, B.A.; Abdelrahman, H.E.; Karali, M.A.; Attia, E.-A.; Al-Dosoky, M.W. Fluid Flow Characteristics for Four Lattice Settings in Brick Tunnel Kiln: CFD Simulations. Buildings 2023, 13, 733. https://doi.org/10.3390/buildings13030733

Refaey HA, Alharthi MA, Abdel-Aziz AA, Elattar HF, Almohammadi BA, Abdelrahman HE, Karali MA, Attia E-A, Al-Dosoky MW. Fluid Flow Characteristics for Four Lattice Settings in Brick Tunnel Kiln: CFD Simulations. Buildings. 2023; 13(3):733. https://doi.org/10.3390/buildings13030733

Chicago/Turabian StyleRefaey, Hassanein A., Mathkar A. Alharthi, Ali A. Abdel-Aziz, Hassan F. Elattar, Bandar Awadh Almohammadi, Hany E. Abdelrahman, Mohamed A. Karali, El-Awady Attia, and Mamdouh W. Al-Dosoky. 2023. "Fluid Flow Characteristics for Four Lattice Settings in Brick Tunnel Kiln: CFD Simulations" Buildings 13, no. 3: 733. https://doi.org/10.3390/buildings13030733

APA StyleRefaey, H. A., Alharthi, M. A., Abdel-Aziz, A. A., Elattar, H. F., Almohammadi, B. A., Abdelrahman, H. E., Karali, M. A., Attia, E.-A., & Al-Dosoky, M. W. (2023). Fluid Flow Characteristics for Four Lattice Settings in Brick Tunnel Kiln: CFD Simulations. Buildings, 13(3), 733. https://doi.org/10.3390/buildings13030733