Abstract

Expansive soils exhibit detrimental swelling and shrinking characteristics in response to variations in water content, posing a threat to engineering safety. Utilizing industrial solid waste for improving the engineering properties of expansive soil presents a promising solution due to its low pollution and high recoverability. This paper reviews the progress of research on various industrial solid wastes in stabilizing expansive soil. The review comprehensively discusses the microscopic characteristics and mechanism of industrial solid waste-stabilized soils, as well as their impact on the compressive strength, shear, compaction characteristics, consistency, swelling and shrinkage properties, and durability of expansive soils. The addition of appropriate curing agents or the combination with other stabilizing materials can enhance the strength of expansive soil, mitigate volume changes, and improve the durability and stability of expansive soils. The mechanisms of stabilization of expansive soils by industrial solid waste involve cation exchange, flocculation-agglomeration, pozzolanic reaction, and carbonation. Additionally, microscopic characterization analysis reveals that the formation of C-S-H and C-A-H is the primary contributor to the improvement of soil geotechnical properties.

1. Introduction

Industrial solid waste refers to the waste residues, dust, and other waste materials that are generated during industrial production and released into the environment. Examples of industrial solid waste include blast furnace slag, steel slag, red mud, cement kiln ash, fly ash, cinder, sulfuric acid slag, and phosphogypsum [1,2,3]. The output of industrial solid waste is increasing annually due to the growth of industrial manufacturing [4]. In China, over 300 million tons of industrial solid waste are generated each year, but only about 60% of it is currently recycled, according to environmental statistics [5]. This waste takes up land resources and pollutes underground water, air, and soil, leading to a decline in environmental quality and long-term environmental risk [6,7,8]. Therefore, it is imperative to find high-value uses for industrial solid waste.

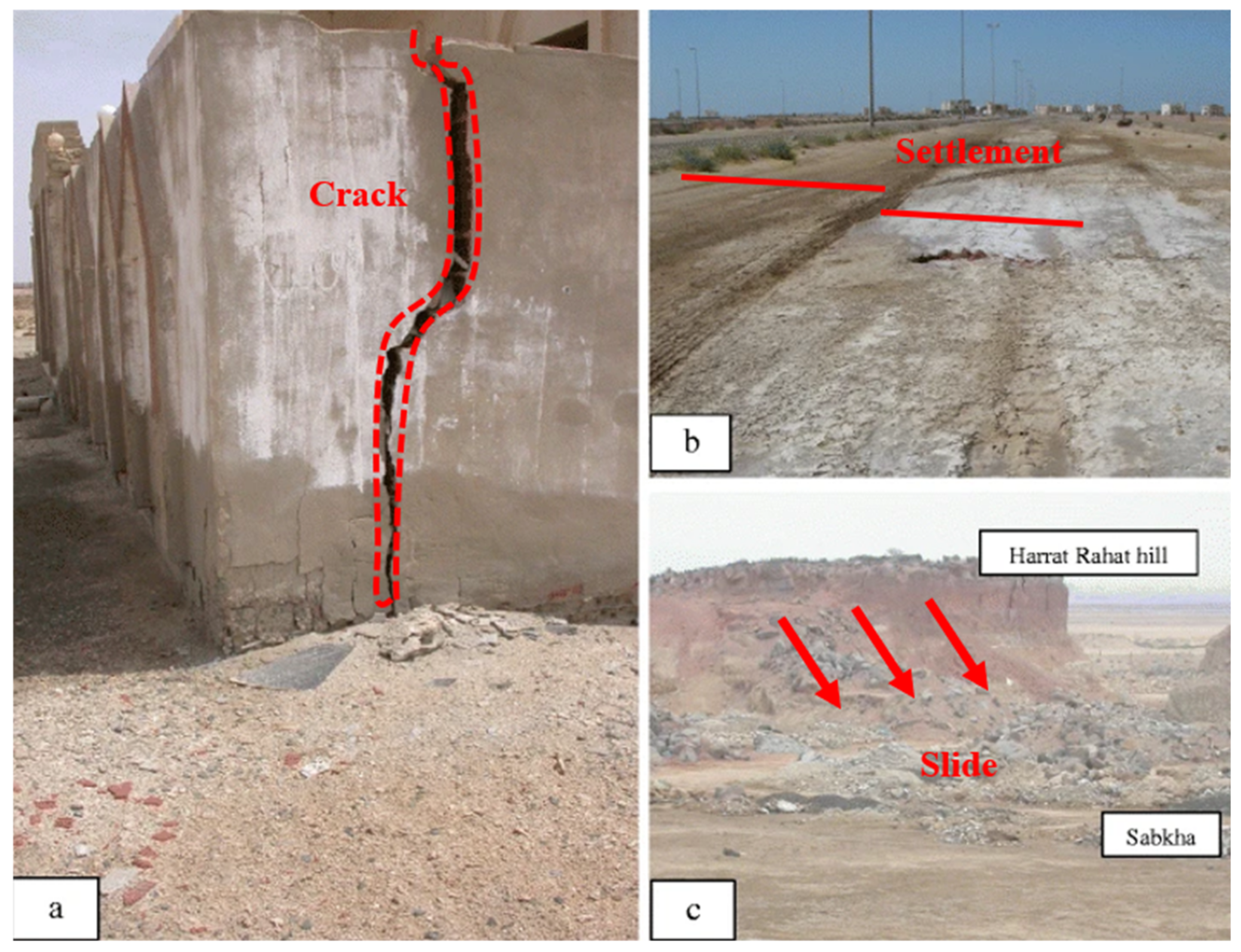

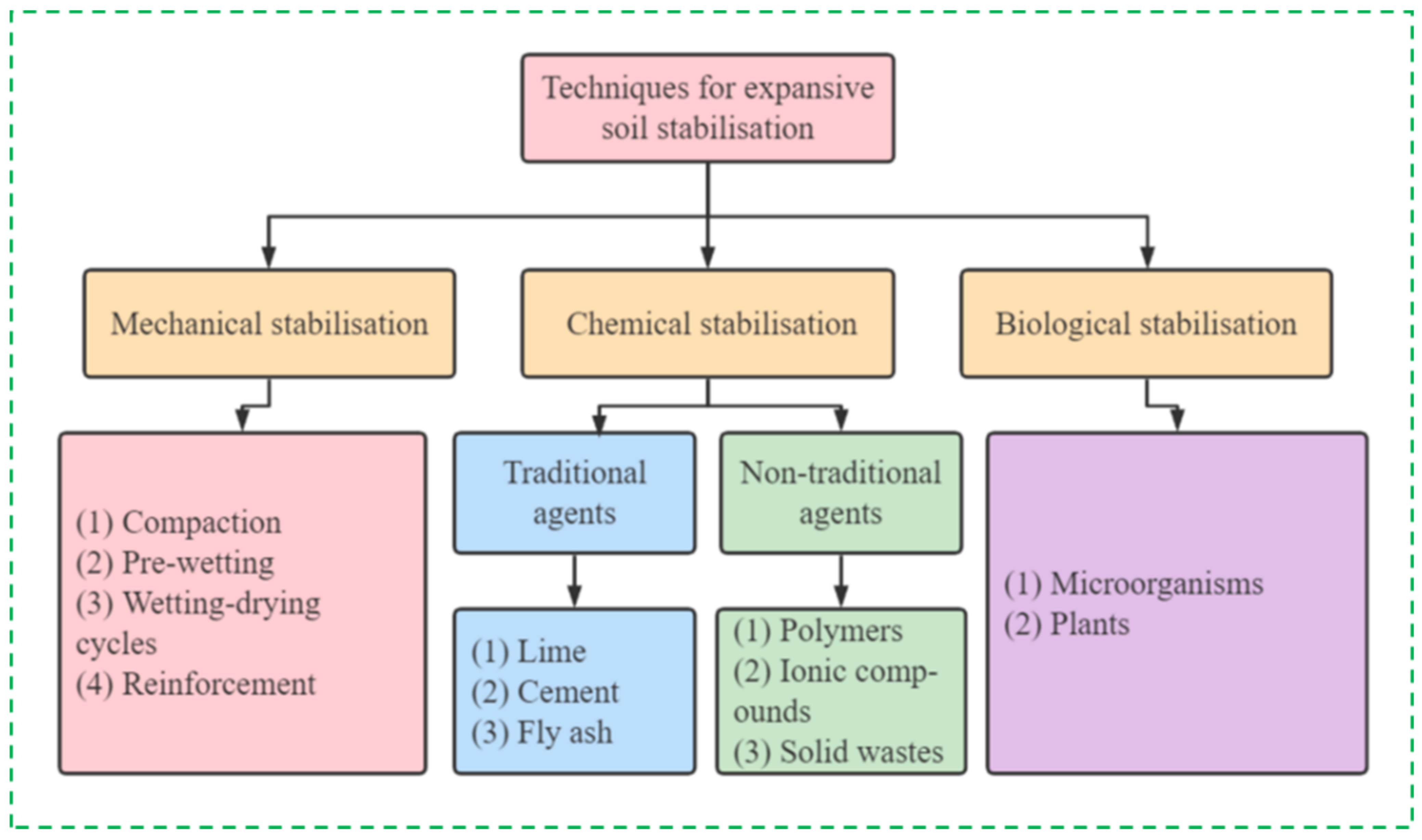

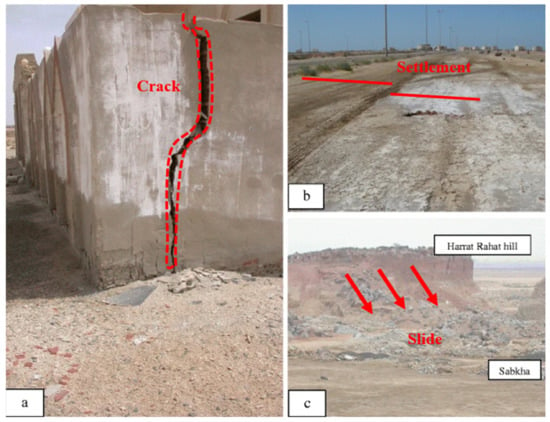

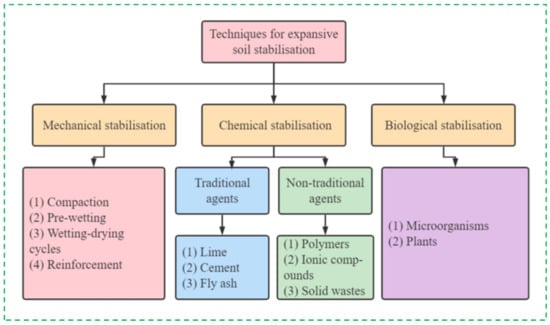

Expansive soil, characterized by its high clay content and mainly composed of minerals such as montmorillonite and illite, poses significant challenges to engineering and geology due to its tendency to swell and shrink during wetting and drying cycles [9,10]. Such soil behavior often leads to adverse effects such as differential settlement in building foundations [9], subgrade settlement [11], and landslides [12], as illustrated in Figure 1. Consequently, practical projects require urgent treatment for expansive soil. Today, the three main stabilization techniques used for expansive soils include mechanical, chemical, and biological stabilization, as shown in Figure 2 [9,13,14,15,16]. Although mechanical stabilization techniques such as compaction and reinforcement have been widely used, they are expensive and prone to instability [17,18]. Biological stabilization techniques, such as microbially induced calcium carbonate precipitation (MICP), have been extensively studied, but their effectiveness in practical applications remains uncertain [19,20]. In contrast, chemical stabilization methods are effective, low-cost, and currently the most commonly used approach for soil stabilization. Traditional chemical curing agents, such as cement and lime, have been shown to significantly improve soil strength [21,22]. However, the use of these agents is not without its drawbacks, such as environmental impacts in terms of CO2 emissions and energy consumption.

Figure 1.

Engineering problems and geological disasters by expansive soil: (a) differential settlement of building foundation; (b) subgrade settlement; (c) landslide. Adapted from [9].

Figure 2.

A flow chart of expansive soil stabilization techniques.

Recently, researchers have been seeking new low-carbon and sustainable materials to replace cement and lime as soil stabilization agents [23,24,25]. Additives such as fly ash and silica fume have been used in the treatment of expansive soil due to their physical and chemical properties, which are similar to those of lime and cement. Industrial waste exhibits excellent physical properties, such as small particle size, strong dispersibility, and high water absorption, which contribute to its pozzolanic properties and cementation power [26]. Therefore, the use of industrial waste as a new material for expansive soil stabilization has significant potential for cost savings and promoting a green environment.

This paper presents an introduction to the reaction mechanism of industrial solid waste and provides a comprehensive evaluation of its engineering properties as a reinforcement material for expansive soil. The mechanism, microscopic characteristics, and mineral composition of industrial solid waste-stabilized soils are also discussed. Additionally, the paper highlights the potential for further research on the use of industrial solid waste in stabilizing expansive soil.

2. Mechanism and Microscopic Characteristics

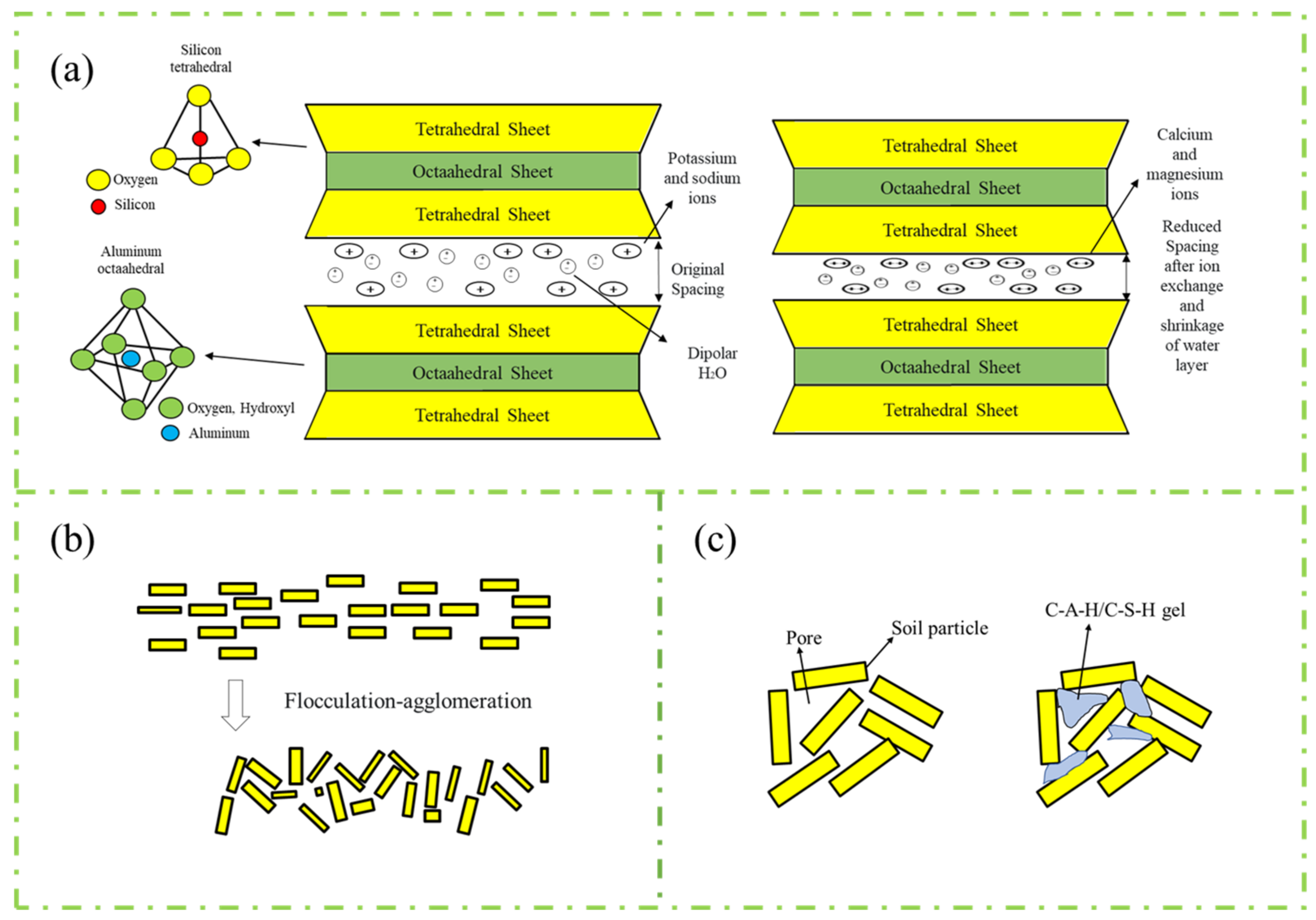

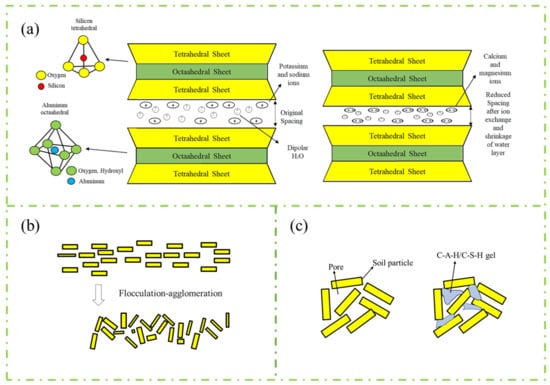

2.1. Cation Exchange

Ion exchange is the primary reaction involved in stabilizing industrial solid wastes, impacting their plasticity and water stability in the short term. As illustrated in Figure 3a, alkaline oxides such as CaO and MgO react with water to form Ca2+ and Mg2+ ions, which replace K+ and Na+ ions in the clay particles via ion exchange. This process reduces the thickness and spacing of the water film between soil particles [27]. Experimental studies conducted have demonstrated that the addition of fly ash effectively reduces plasticity and swelling resulting from cation exchange reactions [28,29]. Furthermore, the alkaline environment produced by fly ash hydration promotes ion exchange, effectively mitigating soil swelling. Additionally, cation exchange facilitates the flocculation-agglomeration of soil particles, thereby enhancing soil strength. However, excessive cation exchange may deplete the Ca2+ and OH− ions required for the volcanic ash reaction, ultimately reducing the production of C-S-H and diminishing soil strength properties [30,31,32].

Figure 3.

Stabilization mechanism: (a) cation exchange; (b) flocculation-agglomeration; (c) pozzolanic reaction. Adapted from [27].

2.2. Flocculation-Agglomeration

Flocculation-agglomeration refers to the transformation of clay particles from a flat, parallel structure to a more random structure with edges in contact with faces, as shown in Figure 3b. This process promotes the formation of larger agglomerates of clay particles, thereby reducing soil plasticity and increasing short-term strength. The flocculation-agglomeration reaction, like the cation exchange reaction, is a short-term reaction [33,34].

Zeta potential can be defined as the electric potential difference between the bulk solution and the surface of a particle when it is surrounded by a diffuse layer of ions [35]. Zeta potential values significantly impact the flocculation-agglomeration of soil particles. A high zeta potential indicates a strong repulsion between soil particles, which can prevent their flocculation-agglomeration and lead to a stable dispersion. Conversely, soils with low zeta potentials are more prone to flocculation-agglomeration. Recent research indicates that the addition of industrial solid waste reduces zeta potential, thereby promoting rapid flocculation-agglomeration. Studies have demonstrated that increasing fly ash admixture leads to a decrease in zeta potential values [36]. This is because a decrease in zeta potential reduces electrostatic repulsion between montmorillonite layers, allowing Van der Waals attraction to dominate.

2.3. Pozzolanic Reaction

The pozzolanic reaction plays a crucial role in the long-term development of soil strength and durability. The incorporation of industrial solid waste elevates soil pH, leading to increased solubility and reactivity of volcanic materials such as silica and alumina [27,37]. The Ca2+ in industrial solid waste reacts with soluble alumina and silica, forming C-S-H and C-A-H [36,38]. These new cementitious compounds fill the pores of soil particles, as illustrated in Figure 3c, thereby densifying the soil’s internal structure and increasing its strength. Additionally, in certain cases, calcium aluminate silicate hydrate (C-A-S-H) may also form, further boosting soil strength and improving geotechnical properties [39,40]. These reactions can be expressed using Equations (1)–(3).

2.4. Carbonation

The carbonation process is crucial for achieving the desired strength of stabilized soil. Volcanic ash reaction results in increased concentrations of Ca2+, Mg2+, and OH− ions in soil pore water [41]. As a part of the zeolite reaction, CO2 from the air penetrates soil pores and reacts with Ca2+, Mg2+, and OH− ions to produce CaCO3 and MgCO3, forming carbonaceous substances [42,43,44]. These solid particles fill and bind the intergranular pores of the soil, a process known as carbonation and denoted by Equations (4) and (5). A prolonged duration of the carbonation process is necessary for developing the desired strength of stabilized soil.

2.5. Microscopic Characteristics

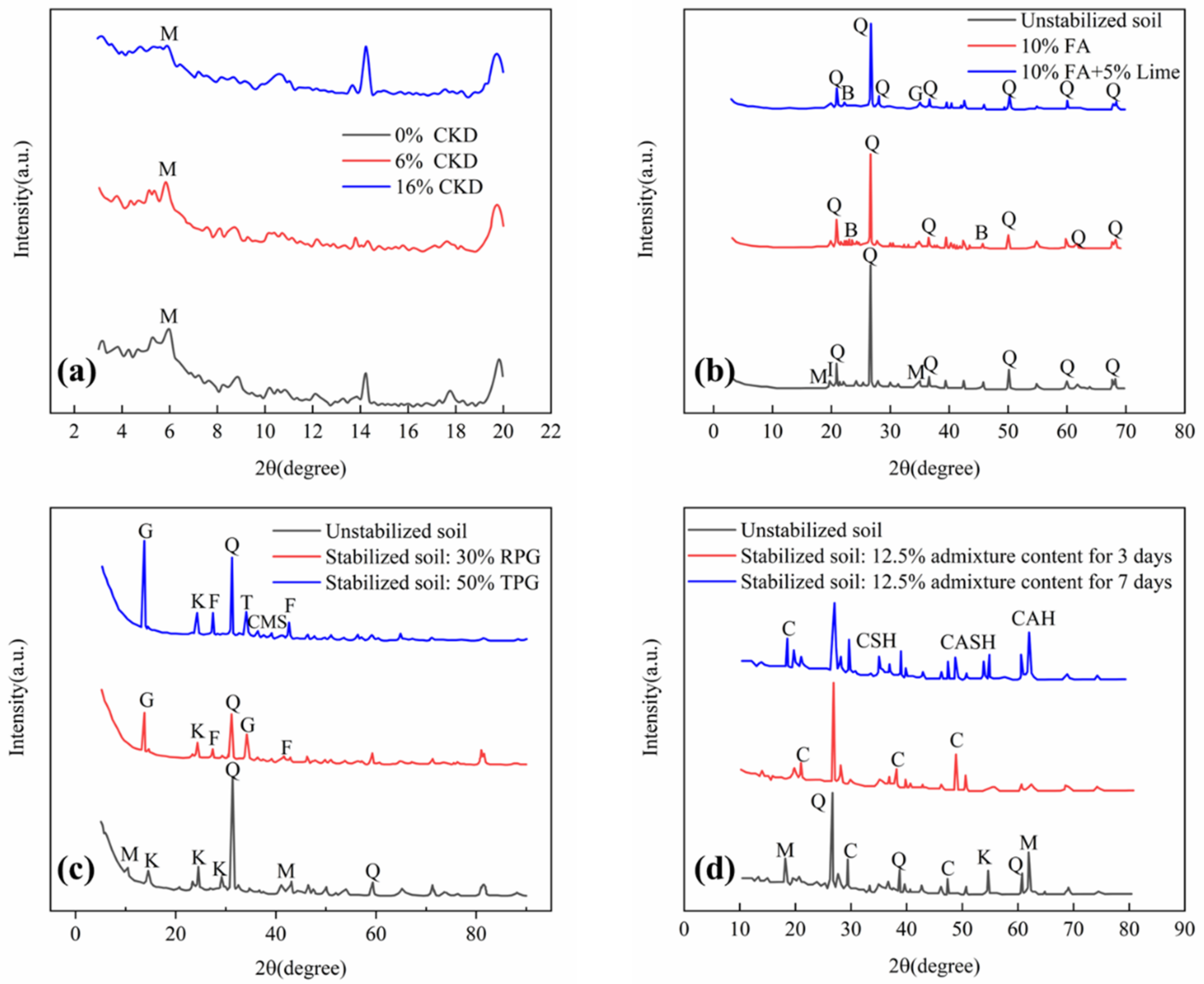

2.5.1. XRD Analysis

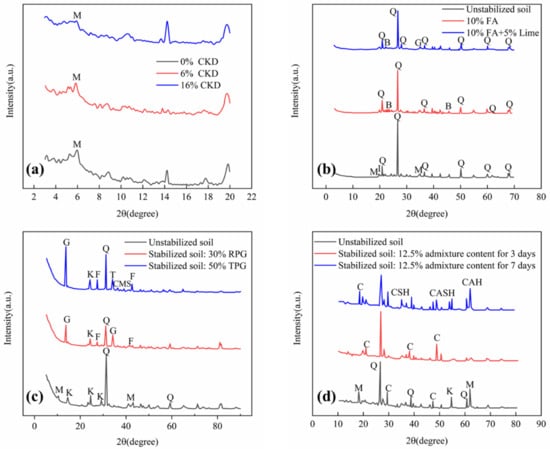

Figure 4a illustrates the X-ray diffraction pattern of expansive soil amended with cement kiln ash. The reflection peak of montmorillonite decreases significantly as the cement kiln ash admixture content increases, indicating a reaction between the admixture and the soil matrix that reduces the hydrophilic mineral content in the soil [45]. Similar observations can be made in fly ash-stabilized expansive soil (Figure 4b). Moreover, it was found that the addition of cement kiln ash led to a reduction in both pore size and number, indicating that the admixture promoted flocculation-agglomeration of soil particles [42].

Figure 4.

XRD pattern of expansive soil by (a) stabilized soil by CKD, (b) stabilized soil by FA, (c) stabilized soil by PG, and (d) stabilized soil by CS. Adapted from [39,42,45,46]. (Note: M: montmorillonite; B: bentonite; C: Calcite; Q: quartz; G: gypsum; K: kaolinite; F: feldspar; I: illite; T: trikalsilite; S: sillimanite; CMS: calcium magnesium silicide; CSH: calcium silicate hydrate; CASH: calcium aluminium silicate hydrate; CAH: calcium aluminium hydrate).

Figure 4c,d display the XRD spectra of different types of stabilized expansive soil. In Figure 4c, the intensity of the montmorillonite reflection peak decreases significantly after curing at 40 °C for 7 days with the addition of two types of PG, indicating a reduction in the hydrophilic mineral content [46]. Additionally, new crystal reflections of calcium magnesium silicide, trikalsilite, and feldspar appear, which contribute to the increased strength of gypsum-stabilized soil. Figure 4d shows the impact of 12.5% copper slag and lime (1:1) on XRD results after curing for 0, 3, and 7 days. The peak in soil samples after 7 days of curing indicates that the zeolite reaction in stabilized copper slag and lime is time-dependent [39]. As curing time increases, new cements such as C-S-H, C-A-H, and C-A-S-H gradually form. By mixing cement kiln ash, copper slag, fly ash, phosphogypsum, and lime, cation exchange can be promoted; expansion and contraction of the expansive soil can be reduced; and the pozzolanic reaction and gelation can be carried out to improve the strength of expansive soil.

2.5.2. SEM Analysis

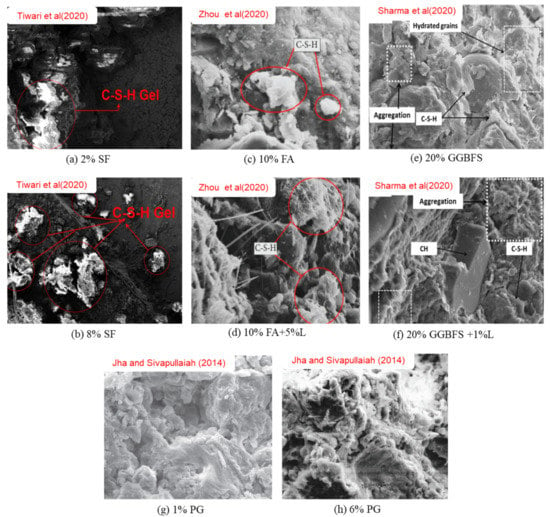

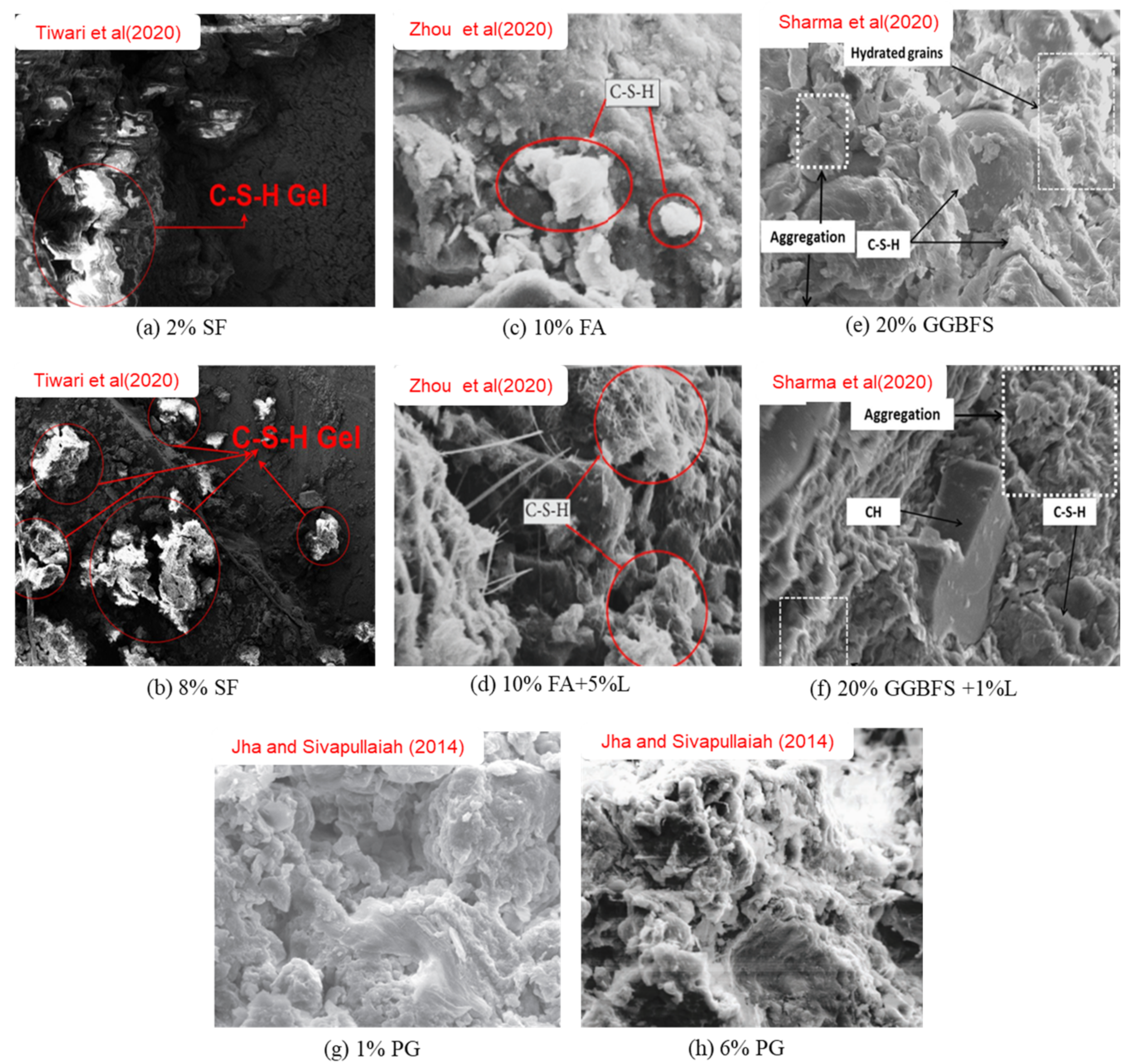

Figure 5 depicts the SEM images of SF, FA, FA + lime, GGBFS + lime, and PG stabilized expansive soil samples that were cured at room temperature. In Figure 5a,b, the SEM images show the soil samples stabilized with 2% and 8% silica fume content, respectively [47]. The presence of C-S-H is observed in the soil samples, which envelops and encapsulates the expansive soil particles, thereby enhancing the soil’s strength. Additionally, the formation of C-S-H is seen to reduce the swelling pressure of the expansive soil, thus effectively restraining soil swelling.

The impact of fly ash addition at 10% and 10% FA + 5% lime on the soil microstructure was analysed by [42], as shown in Figure 5c,d. The modified soil exhibited a more compact structure than the untreated soil, with pores or cracks partially filled with fly ash particles and hydration products. The addition of lime to fly ash enhanced the cementation degree between fly ash and the pores of plain soil, resulting in a finer pore size and closer embedding of fly ash particles in the soil. Figure 5e,f displays SEM micrographs of expansive soil stabilized by 20% GGFBS and 20% GGBFS + 1% lime after 28 days of curing [48]. The micrographs reveal that the soil particles are encased within a compact structure of small aggregates or flocs. The interface properties of the mixture improve with curing time. Samples treated with lime show large aggregates, which contribute to the reduction of swelling in expansive soils. Micrographs also show hydration and chemical reaction products, such as C-S-H and calcium hydroxide (silicate). These products fill the pores between soil particles and enhance soil strength. In another study, Jha and Sivapullaiah [32] employed SEM images to evaluate the improvement of soil strength through microstructural analysis of 1% and 6% gypsum-stabilized soil at 28 days of curing. The strength increase is attributed to the filling of dissolved gypsum, which acts as a cementing and filling agent in the soil.

The SEM micrographs in Figure 5e,f reveal the microstructure of expansive soil stabilized with 20% GGFBS and 20% GGBFS + 1% lime after 28-day curing [48]. The images illustrate a dense structure of small aggregates or flocs surrounding soil particles, indicating improved interface properties with increasing curing time. In contrast, the presence of lime led to the formation of large aggregates. Such aggregations or flocs play a key role in reducing soil swelling [49]. The micrographs also demonstrate the presence of hydration and chemical reaction products, including C-S-H and calcium hydroxide (CH), which fill the pores between soil particles and contribute to increased soil strength [50]. Previous studies have also used SEM images to investigate the microstructure of gypsum-stabilized soil, finding that the strength increase is due to the filling of dissolved gypsum, which acts as a cementing and filling agent in the soil [51].

Figure 5.

SEM of SF, FA, FA + lime, GGBFS, GGBFS + lime, and PG stabilized expansive soil. Adapted from [42,47,48,51].

Figure 5.

SEM of SF, FA, FA + lime, GGBFS, GGBFS + lime, and PG stabilized expansive soil. Adapted from [42,47,48,51].

3. Engineering Properties

3.1. Unconfined Compressive Strength (UCS)

Table 1 demonstrates the effectiveness of industrial solid waste in increasing the unconfined compressive strength (UCS) of expansive soil. Fly ash is a common stabilizer for expansive soil, with the optimal content and curing time being crucial factors. Mahedi et al. [52] found that the UCS of expansive soil increased with 0–25% fly ash admixture, with the highest strength observed in soils solidified with 15% fly ash within 28 days of solidification. The type of fly ash also impacts the UCS of expansive soil, with Class C fly ash being superior to Class F fly ash due to its higher calcium ion content, which promotes pozzolanic reaction and flocculation [53,54,55]. Similar report found that 10% cement kiln dust was the optimal dosage for stabilizing expansive soil, resulting in an increase in UCS from 219 kPa to 354 kPa, or approximately 1.6 times that of untreated soil [45].

Table 2 demonstrates that combining various types of industrial solid waste can more effectively improve the UCS of expansive soil. Yoobanpot et al. [56] found that stabilizing expansive soil with 20% fly ash and 13% cement kiln ash yielded the same improvement in UCS as 10% cement-stabilized expansive soil. Similar studies also found that treating black cotton soil with 16% cement kiln ash and 10% quarry fine increased its UCS from 38 kN/m2 to 820 kN/m2. This effect was attributed to the small particle size of slag powder, which alters the particle size distribution of cement kiln ash, fills gaps between soil particles, and forms a dense mesh structure that enhances the soil’s mechanical properties [33,57,58]. However, excess binder reduces soil strength by not interacting with pozzolanic soil. Additionally, studies have found that an optimal proportion of granulated blast furnace slag and fly ash is necessary for stabilizing expansive soil; beyond this proportion, the UCS of stabilized soil reaches a maximum and then decreases with increases in PG content [59]. Therefore, stabilized expansive soil has an optimal proportion of granulated blast furnace slag and fly ash.

The lime content has a significant impact on the UCS of stabilized soil due to the formation of cementitious compounds through the interaction between the Ca2+ of lime and the SiO2 of industrial solid waste. Muthukkumaran et al. [39] investigated the effect of copper slag and lime on black cotton soil and found that a 1:1 admixture ratio of 12% copper slag and lime improved the soil’s mechanical properties the most. However, increasing the copper slag content reduced the UCS, indicating that lime contributes more to soil strength improvement than copper slag. The addition of lime accelerates the pozzolanic reaction, providing extra strength to the soil–binder mixture by forming a cemented matrix [58]. Optimal lime content for soil stabilization varied in previous studies, with 3%, 5.5%, and 7% lime requiring 0.25%, 0.5%, and 1% PG, respectively. Similar studies also found that 1% PG + 7% lime significantly increased the UCS of expansive soil by tenfold after 28 days of curing [60].

Table 1.

Summary of the UCS of expansive soil stabilized by industrial solid waste.

Table 1.

Summary of the UCS of expansive soil stabilized by industrial solid waste.

| Refs. | Type | Soil Classification | The Optimum Mixture (%) | UCS (MPa) | Rating of Subgrade |

|---|---|---|---|---|---|

| [28] | FA | CH | 9% | 0.45–0.56 (7 d) | Hard |

| [36] | FA-C | CL | 20% | 0.03–0.05 (0 d) | Soft |

| [61] | GGBS | CH | 30% | 0.51–0.95 (3 d) 0.53–1.07 (7 d) 0.67–1.14 (28 d) | Hard |

| [59] | FA + GGBS | CH | 6%FA + 14%GGBS | 0.23–0.29 (7 d) 0.24–0.34 (14 d) 0.27–0.45 (28 d) | Hard |

| [62] | CKD | CL | 12% | 0.37–1.89 (7 d) 0.57–2.07 (14 d) 0.88–2.25 (28 d) 0.89–2.45 (60 d) | Hard |

| [63] | CKD | CL | 10% | 0.59–5.24 (7 d) 1.05–7.52 (14 d) 1.53–10.16 (28 d) | Hard |

| CKD | MH | 10% | 0.68–5.66 (7 d) 1.10–7.86 (14 d) 1.65–10.52 (28 d) | Hard | |

| [64] | SF | CH | 25% | 0.091–0.144 (7 d) | Hard |

| [65] | SF | CH | 20% | 0.2–0.4 (28 d) 0.41–0.70 (90 d) | Hard |

Note: FA: fly ash; GGBS: granulated blast furnace slag; CKD: cement kiln ash; CS: copper slag; RNA: rice husk ash.

Table 2.

Summary of the UCS of expansive soil stabilized by industrial solid waste and lime.

Table 2.

Summary of the UCS of expansive soil stabilized by industrial solid waste and lime.

| Refs. | Soil Classification (USCS) | Type | The Optimum Mixture (%) | Lime Content (%) | UCS(MPa) | Rating of Subgrade |

|---|---|---|---|---|---|---|

| [28] | CH | FA | 9% | 3% | 0.52–0.80 (7 d) | Hard |

| [36] | CL | FA-C | 20% | 8.5% | 0.03–0.11 (0 d) | Stiff |

| [66] | CH | FA | 24% | 3% | 0.66–1.04 (7 d) 1.0–1.42 (28 d) 1.26–1.91 (90 d) | Hard |

| [65] | CH | SF | 10% | 5% | 0.2–0.9 (28 d) 0.41–1.70 (90 d) | Hard |

| [66] | CH | GGBS | 9 | 3% | 0.66–0.99 (7 d) 1.01–1.36 (28 d) 1.28–1.94 (90 d) | Hard |

| [59] | CH | FA + GGBS | 6% FA + 14% GGBS | 1% | 0.31–0.63 (7 d) 0.33–0.72 (14 d) 0.37–0.87 (28 d) | Hard |

| [39] | CH | CS | 12.5% | 12.5 | 0.17–0.92 (28 d) | Hard |

| [67] | MH | FA + RNA | 4% FA + 4% RNA | 6 | 0.07–0.17 (0 d) 0.07–1.20 (7 d) | Hard |

| [68] | PG | 8 | 8 | 0.16–0.47 (3 d) 0.16–0.74 (7 d) 0.16–0.83 (28d) | Hard |

Note: FA: fly ash; SF: silica fume; GGBS: granulated blast furnace slag; CKD: cement kiln ash; CS: copper slag; RNA: rice husk ash.

3.2. Shear Strength

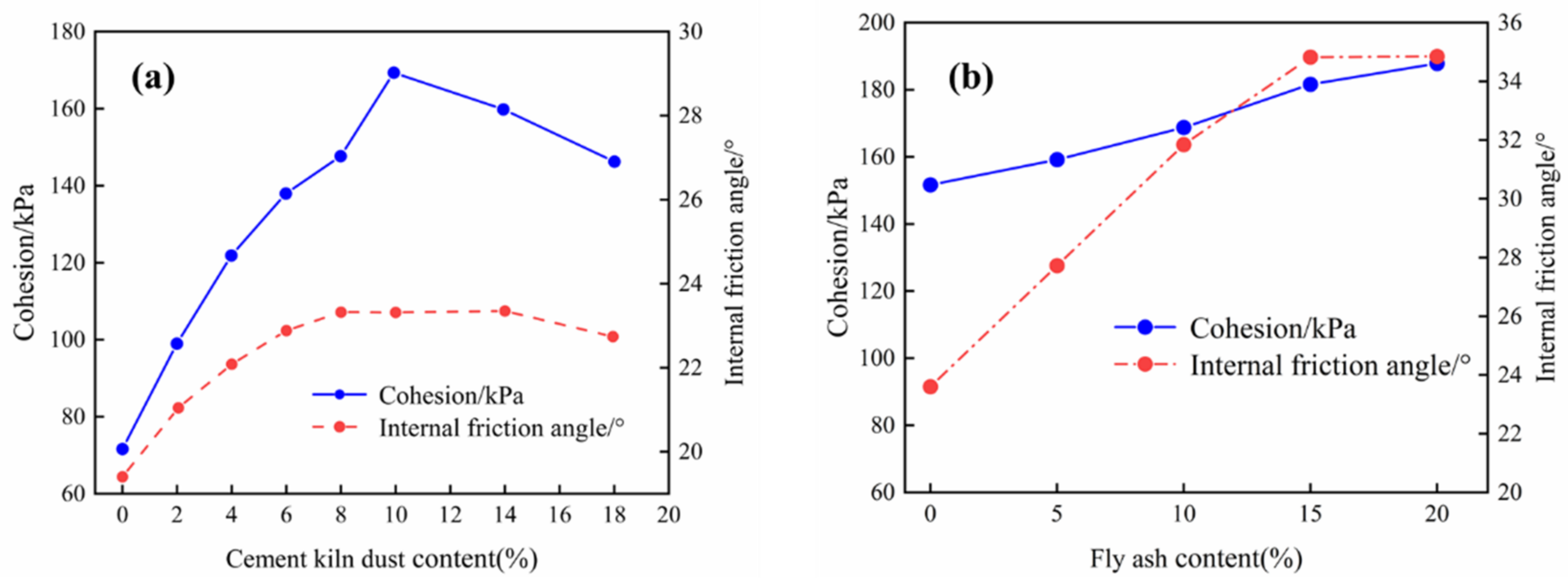

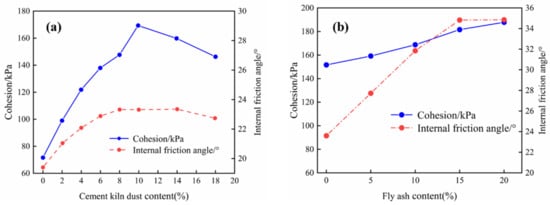

Expansive soil is known to exhibit low shear strength, but this can be improved by incorporating industrial solid wastes. Several studies have investigated the impact of different types and proportions of industrial solid wastes on the shear strength of stabilized expansive soil. For instance, Cui et al. [69] found that the addition of only 12% cement kiln ash significantly improved the internal friction angle and cohesion of the soil (Figure 6a). Another study reported that adding 20% fly ash to expansive soil at a specific moisture level significantly increased its undrained shear strength [70]. The impact of fly ash on the shear strength parameters of modified expansive soil was also investigated by Hasan [71], who found that the internal friction angle varied linearly with fly ash content (Figure 6b). The improved shear strength can be attributed to the initial flocculation-agglomeration and subsequent prolonged pozzolanic reactions between the clay and industrial solid waste, which contribute to changes in the cohesion and internal friction angle.

Figure 6.

Evolution of internal friction angle and cohesion of expansive soil: (a) stabilized soil by cement kiln ash, and (b) stabilized soil by fly ash. Adapted from [69,71].

3.3. Atterberg Limit

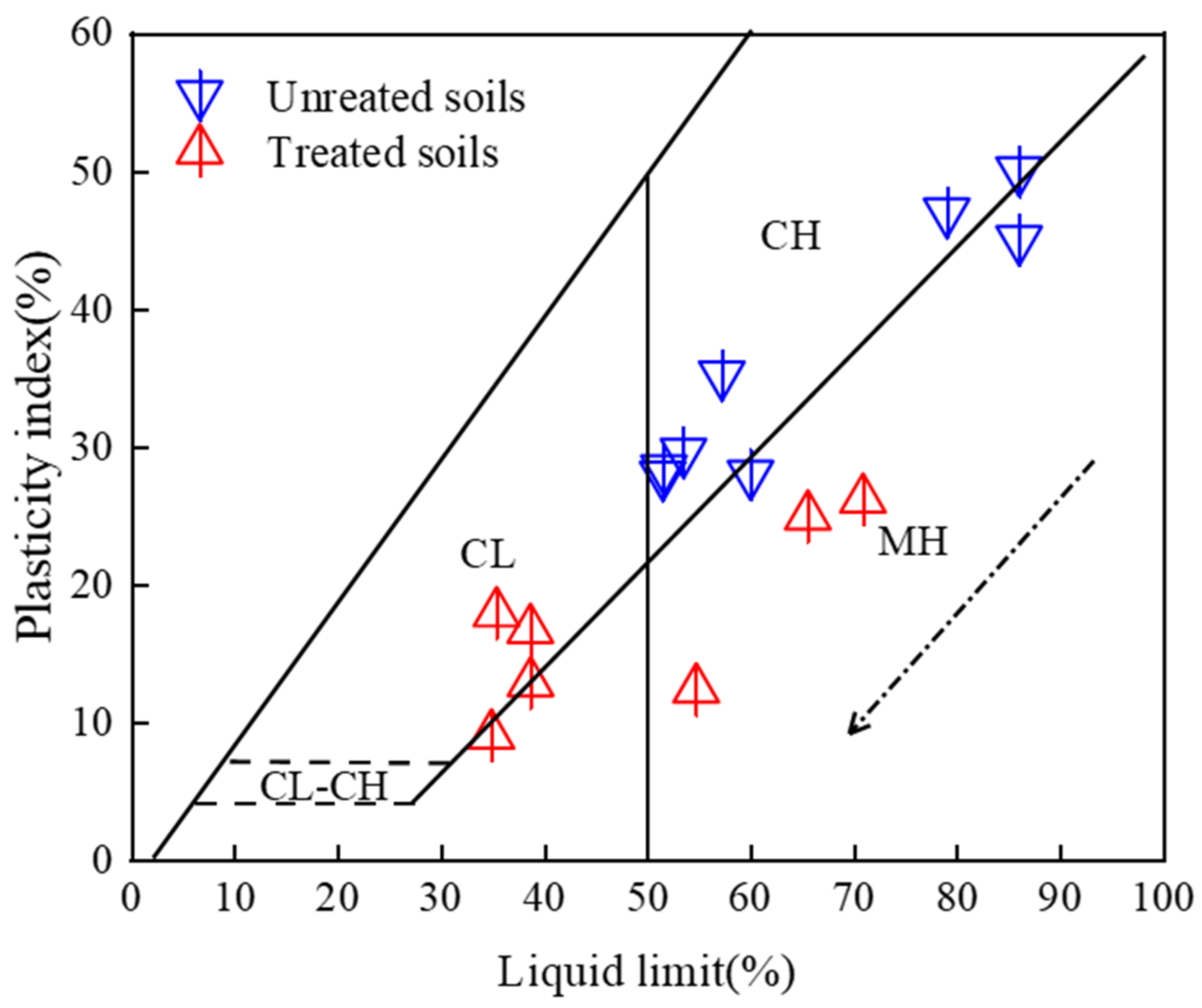

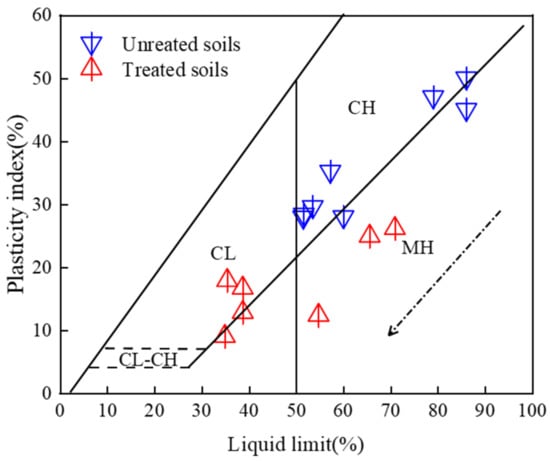

The Atterberg Limit plays a crucial role in predicting soil mechanics and hydrological behaviour, particularly for expansive soils that exhibit a higher liquid limit and plasticity index than other soil types, leading to distinct rheological properties [72]. Figure 7 illustrates that industrial solid waste can impact soil consistency and alter soil classification.

Figure 7.

Classification of stabilized soil by different types of industrial solid waste.

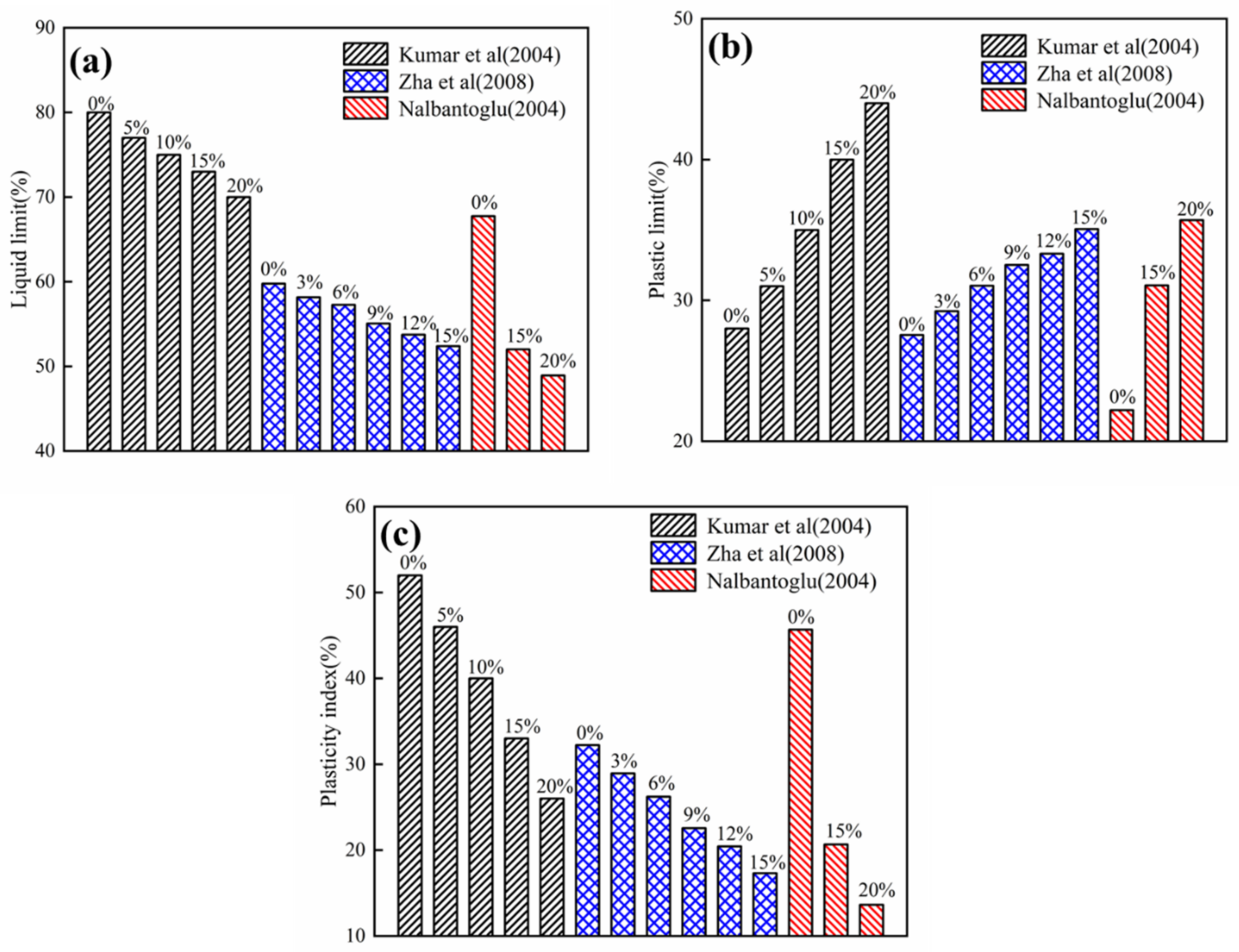

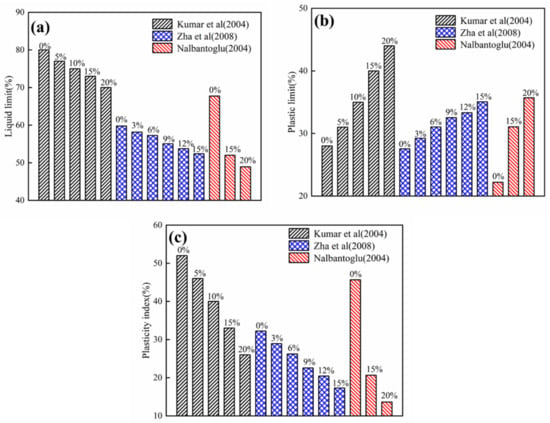

As shown in Figure 8, the addition of fly ash to soil has a significant impact on its liquid and plasticity indices. With increasing fly ash content, the liquid limit decreases while the plasticity index increases. For instance, a 20% application rate of fly ash in expansive soil reduced the liquid limit by 13% to 28%, increased the plasticity index by 47% to 71%, and decreased the plastic limit by 23% to 37% [29,70,73]. Additionally, the same study examined the effects of lime–fly ash stabilization on soil with 0%, 1%, and 2% lime content and found that the addition of lime resulted in a more significant decrease in plasticity [73]. These findings suggest that the addition of industrial solid waste such as fly ash can be an effective method for improving the rheological properties of soil.

Figure 8.

Effect of fly ash on the Atterberg limit of expansive soil (a) liquid limit; (b) plastic limit; (c) plastic index. Adapted from [29,70,73].

Stabilization of expansive soils using cement kiln ash and silica fume produces similar effects. According to Cui et al. [69], a content of 18% CKD has the greatest impact on consistency, resulting in a 34% reduction in liquid limit and a 58% reduction in plasticity index. Another study found that the addition of polypropylene fiber decreased the Atterberg limit [74]. Sabat, A.K [75] found that increasing the ceramic particle content in stabilized expansive soil led to a linear decrease in both liquid limit and plasticity index, as determined by the Atterberg limit test. Therefore, while adding industrial solid waste generally improves the Atterberg limit of soil, the practicality of the application is dependent on the type and amount of waste added.

3.4. Compaction Characteristics

Optimum water content and maximum dry density are critical parameters for soil compaction, affecting permeability, strength, stiffness, and settlement. Previous studies have shown that solidified soil with added industrial wastes had a 1–8% increase in maximum dry density and a 5–23% decrease in optimum water content [59,70,76]. Copper slag was found to affect soil compaction characteristics, with a 12% increase in maximum dry density and a 16% decrease in optimum moisture content observed with a 30% copper slag content [77]. When mixed with expansive soil, copper slag powder can fill the pores in the soil particles and absorb water from the soil.

Industrial solid waste can alter the particle size distribution of soil through ion exchange and flocculation-aggregation effects, thereby impacting the soil’s compaction characteristics and pozzolanic reaction. However, the specific gravity of industrial solid waste may also play a role in compaction characteristics. For instance, the addition of low-specific-gravity fly ash to expansive soil can lead to a decrease in the maximum dry density and an increase in the optimum water content [53,78].

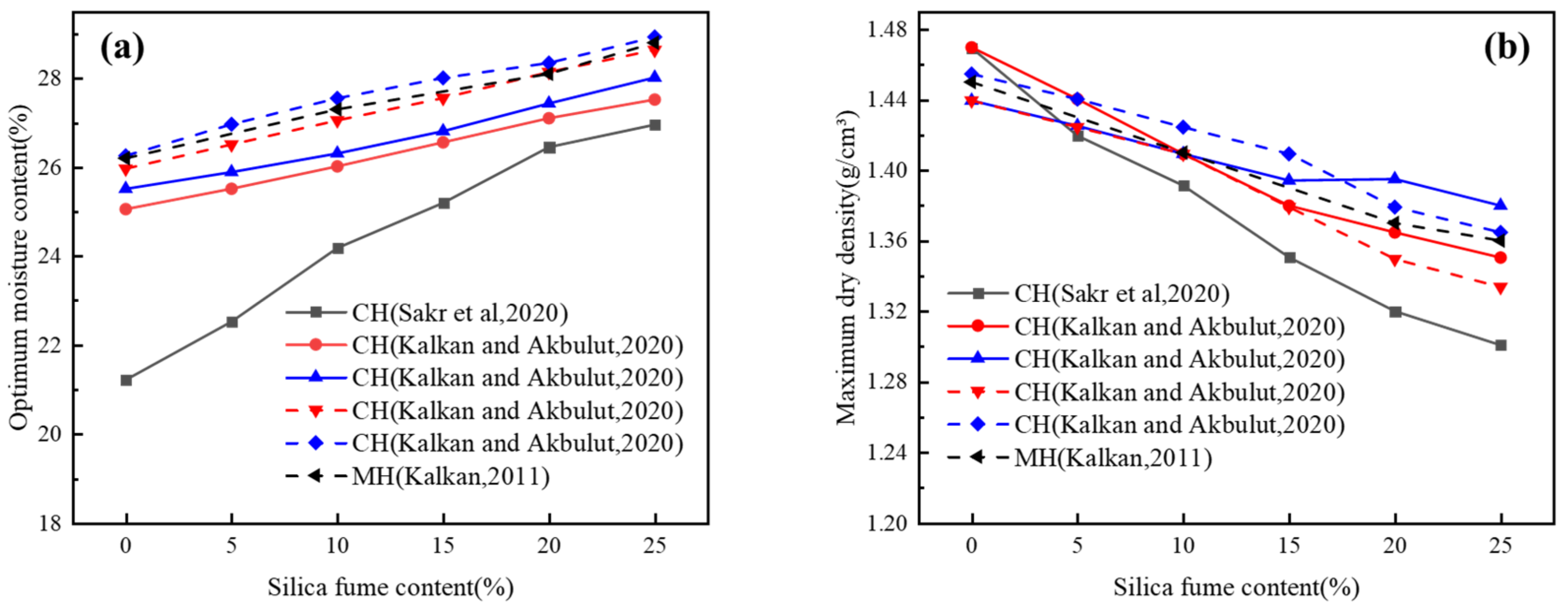

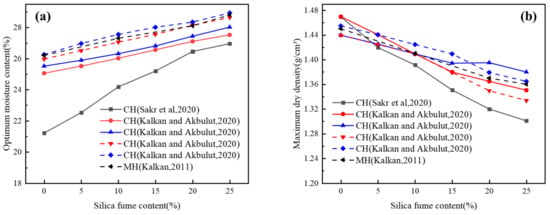

Figure 9 illustrates the compaction characteristic curves of elastic silt [79] and high plasticity clay [64,80] stabilized with silica fume. The maximum dry density decreases as the amount of silica fume increases, while the ideal water content of the silica fume-stabilized soil increases. The maximum dry density and optimum water content of expansive soil stabilized by industrial solid waste may vary depending on the specific gravity and type of waste used.

Figure 9.

Compaction characteristics of expansive soil stabilized by silica fume: (a) optimum moisture content; (b) maximum dry density. Adapted from [64,79,80].

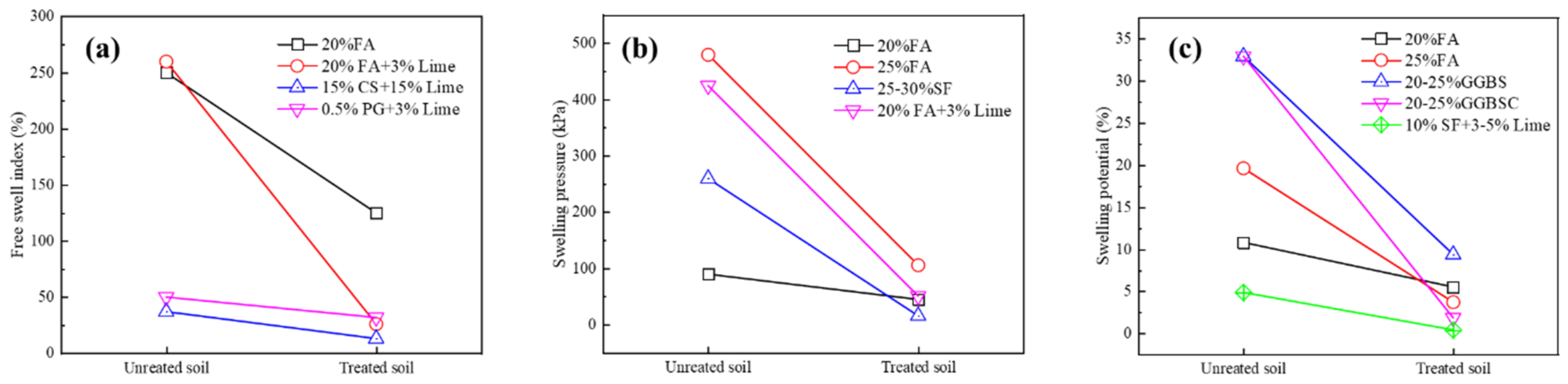

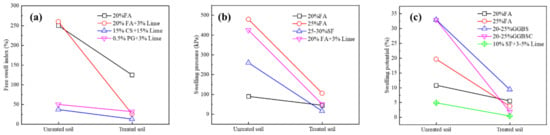

3.5. Swelling and Shrinkage

The swelling and shrinking properties of expansive soils are commonly evaluated using parameters such as free swelling index, swelling potential, and swelling pressure [81]. Figure 10 illustrates that incorporating industrial solid waste can modify these parameters, ultimately reducing the swelling and shrinkage characteristics of expansive soils. Studies indicate that fly ash dosing at 20–25% leads to the most effective improvement in swelling and shrinkage properties of expansive soils [29,70,82]. Moreover, the most significant improvement in the swelling and shrinking properties of expansive soils was observed when the cement kiln dust content was between 10 and 14%, and the curing period was longer than 27 days [83], owing to the slow pozzolanic reaction time. Longer curing times enable the gradual filling and binding of soil particles by substances such as C-S-H and C-A-H, resulting in a denser interior mesh structure of the soil and reduced swelling and shrinking properties [59,84]. Other industrial solid wastes such as red mud [85], polyethylene [86], copper slag [59,84], and silica fume [80,87,88] have also demonstrated the ability to mitigate soil swelling and shrinkage.

Figure 10.

Influence of industrial solid waste on swelling and shrinkage of expansive soil: (a) free swell index; (b) swelling pressure; (c) swelling potential.

The addition of lime or cement to industrial solid waste can improve its expansion properties. This enhancement is attributed to the ability of lime to provide additional cations, which promote cation exchange and flocculation-agglomeration between soil particles. According to Kate et al. [89], the addition of small amounts of lime to fly ash results in a significant reduction in the free expansion index, maximum expansion, and expansion pressure. Cokca et al. [57] conducted a study on the swelling and shrinkage properties of expansive soil using granulated blast furnace slag and granulated blast furnace slag–cement. Their findings revealed that adding 25% blast furnace slag and blast furnace slag–cement reduced the expansion potential from 27.38% to 9.36% and 1.83%, respectively, as well as the expansion rate from 29.4% to 10.9% and 3.1%.

3.6. Durability

Expansive soil undergoes cycles of freeze–thaw and dry and wet weather conditions, resulting in increased pore size and decreased water stability and mechanical properties. This, in turn, reduces the service life of engineering projects, as reported by [90]. The interaction between soil and water can be improved by using industrial solid waste, thereby enhancing the durability of expansive soil. Studies have shown that as the frequency of dry–wet cycles increases, the compressive modulus and UCS of expansive soils treated with 20–30% fly ash significantly decrease [91,92]. Nevertheless, this reduction is less severe than that observed in untreated expansive soil due to the stronger pozzolanic reaction during wetness. According to Rahman et al. [93], the impact of wet–dry cycles on stabilized soils was negligible. However, the strength of fly ash-stabilized soils decreased by up to 40% due to freeze–thaw cycles. Despite this significant decrease, the strength of the stabilized soils remained at least three times higher than that of the unstabilized soils.

Despite a significant reduction in strength, the stabilized soil still maintains a higher strength than untreated soil after undergoing freeze–thaw cycles. A study conducted by Wu Y et al. [94] demonstrated that steel slag–cement modified expansive soil retained its strength, even when exposed to dry–wet and freeze–thaw cycles. Additionally, Kalkan [79] observed that stabilized expansive soil specimens with 25% and 30% silica fume content experienced the highest decrease in swelling pressure and potential after the initial wet and dry cycles. These findings suggest that industrial solid waste stabilization can provide significant benefits in reducing the impact of freeze–thaw cycles on the strength of expansive soils.

4. Knowledge Gaps

Various test methods have been utilized by researchers to optimize the effects of industrial solid waste as stabilizers for expansive soils. Recent studies have shown that replacing cement and lime with industrial solid waste can effectively enhance the properties of expansive soils. Nonetheless, further investigations are required in the following areas:

- ➢

- The use of industrial solid waste as a stabilizer for expansive soils has been extensively studied by researchers, but most studies focus on specific types of expansive soils found in particular areas. This is because expansive soils can vary in their mineral and particle composition, as well as their origin, leading to differences in their properties across different regions. It is important to note that the same stabilizer may not have the same level of effectiveness on expansive soils in other areas. Thus, there is a need for further research on stabilizers that have a wide application and demonstrate better modification effects on expansive soils.

- ➢

- Current research on the durability of expansive soil stabilized by industrial solid waste has focused primarily on mechanical characteristics and the effects of dry–wet and freeze–thaw cycles on soil expansion and contraction. However, other important properties such as consolidation and permeability have received little attention. Furthermore, the performance of these stabilized soils under conditions of high alkalinity, high acidity, continuous high temperature, erosion, and weathering remains largely unknown. Therefore, further research is needed to investigate these areas.

- ➢

- Industrial wastes often contain highly alkaline metal oxides and radioactive elements, which can potentially increase the pH value of soil and cause groundwater pollution if not properly treated. Therefore, it is important to further investigate the environmental impact of using different types of industrial solid waste to solidify expansive soil and develop effective methods for its safe and sustainable utilization.

- ➢

- Existing guidelines for using industrial solid waste as a soil stabilizer may not be fully applicable to expansive soil due to its unique properties. As a result, new evaluation procedures and technical standards need to be developed based on engineering knowledge and previous studies. These new standards will provide technical and theoretical support for the use of industrial solid waste for solidifying expansive soil.

5. Conclusions

The use of industrial solid wastes for stabilizing expansive soils offers several potential benefits, including improved engineering properties of the soil and positive environmental impacts. This paper has reviewed the current status of research on industrial solid wastes, such as fly ash, cement kiln ash, silica fume, copper slag, granulated blast furnace slag, phosphogypsum, and red mud, in the stabilization of expansive soils in recent decades. The following conclusions can be drawn:

(1) Industrial solid waste exhibits several positive engineering properties when used as a reinforcement material for expansive soil. Specifically, the addition of 8–25% industrial solid waste can effectively enhance the shear and compressive strength of expansive soil, increase its resistance to adverse environmental conditions such as freeze–thaw or dry–wet cycles, reduce its volume instability and expansion potential, and decrease its shrinkage and plasticity index.

(2) The stabilization mechanism of industrial solid waste involves four distinct reactions: cation exchange, flocculation and coagulation, pozzolanic reaction, and carbonization. Short-term reactions, such as cation exchange, flocculation, and coagulation, can enhance the water stability of expansive soil by reducing its shrinkage and expansion characteristics. In contrast, the long-term responses of the pozzolanic reaction and carbonization can significantly improve the mechanical properties of the soil.

(3) The microscopic characteristics of industrial solid waste reveal that the formation of C-S-H, C-A-H, C-A-S-H, silicate, calcite, and aluminate compounds are the primary reasons for the improvement in soil geotechnical properties.

Author Contributions

Conceptualization, S.M.I.B.S.Z.A. and Q.H.; Software, J.W. (Jianmeng Wei); Data curation, J.W. (Jianmeng Wei); Investigation, J.W. (Jianhu Wei); Writing—original draft, Z.Z.; Writing—review & editing, J.W. (Jianhu Wei); Supervision, S.M.I.B.S.Z.A. and Z.Z.; Funding acquisition, Q.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Plan of Guangzhou, grant number 201904010251 and the Natural Science Foundation of Guangdong General Project, grant number 2020A1515011583).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Geng, Y.; Zhu, Q.; Haight, M. Planning for integrated solid waste management at the industrial Park level: A case of Tianjin, China. Waste Manag. 2007, 27, 141–150. [Google Scholar] [CrossRef] [PubMed]

- Pirani, S.I.; Arafat, H.A. Solid waste management in the hospitality industry: A review. J. Environ. Manag. 2014, 146, 320–336. [Google Scholar] [CrossRef] [PubMed]

- Sabat, A.K.; Pati, S. A review of literature on stabilization of expansive soil using solid wastes. Electron. J. Geotech. Eng. 2014, 19, 251–256. [Google Scholar]

- Barbuta, M.; Bucur, R.D.; Cimpeanu, S.M.; Paraschiv, G.; Bucur, D.; Agroecology, C. Wastes in building materials industry. Agroecology 2015, 1, 81–99. [Google Scholar]

- Xu, S. The situation of generation, treatment and supervision of common industrial solid wastes in China. IOP Conf. Ser. Earth Environ. Sci. 2018, 113, 012154. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, X.; Li, Y.; Li, X. Waste incineration industry and development policies in China. Waste Manag. 2015, 46, 234–241. [Google Scholar] [CrossRef]

- Zhou, B.; Sun, C.; Yi, H. Solid waste disposal in Chinese cities: An evaluation of local performance. Sustainability 2017, 9, 2234. [Google Scholar] [CrossRef]

- Tan, K.; Qin, Y.; Wang, J. Evaluation of the properties and carbon sequestration potential of biochar-modified pervious concrete. Constr. Build. Mater. 2022, 314, 125648. [Google Scholar] [CrossRef]

- Aqeel, A. Investigation of expansive soils in Obhor Sabkha, Jeddah-Saudi Arabia. Arab. J. Geosci. 2016, 9, 1–14. [Google Scholar] [CrossRef]

- Asuri, S.; Keshavamurthy, P. Expansive Soil Characterisation: An Appraisal. INAE Lett. 2016, 1, 29–33. [Google Scholar] [CrossRef]

- Zha, F.; Liu, S.; Du, Y.; Cui, K. Evaluation of physicochemical process in stabilized expansive soils using electrical resistivity method. Rock Soil Mech. 2009, 30, 1711–1718. [Google Scholar]

- Syed, M.; GuhaRay, A.; Kar, A. Stabilization of Expansive Clayey Soil with Alkali Activated Binders. Geotech. Geol. Eng. 2020, 38, 6657–6677. [Google Scholar] [CrossRef]

- Das, B.M. Geotechnical Engineering Handbook; J. Ross publishing: Fort Lauderdale, FL, USA, 2010. [Google Scholar]

- Ikeagwuani, C.C.; Nwonu, D.C. Emerging trends in expansive soil stabilisation: A review. J. Rock Mech. Geotech. Eng. 2019, 11, 423–440. [Google Scholar] [CrossRef]

- Bo, M.; Na, Y.; Arulrajah, A.; Chang, M.-F. Densification of granular soil by dynamic compaction. Proc. ICE-Ground Improv. 2009, 162, 121–132. [Google Scholar] [CrossRef]

- Kanchi, G.M.; Neeraja, V.; Sivakumar Babu, G. Effect of anisotropy of fibers on the stress-strain response of fiber-reinforced soil. Int. J. Geomech. 2015, 15, 06014016. [Google Scholar] [CrossRef]

- Morsy, A.M.; Zornberg, J.G.; Han, J.; Leshchinsky, D. A new generation of soil-geosynthetic interaction experimentation. Geotext. Geomembr. 2019, 47, 459–476. [Google Scholar] [CrossRef]

- Amakye, S.Y.; Abbey, S.J. Understanding the performance of expansive subgrade materials treated with non-traditional stabilisers: A review. Clean. Eng. Technol. 2021, 4, 100159. [Google Scholar] [CrossRef]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Jiang, N.J.; Tang, C.S.; Hata, T.; Courcelles, B.; Dawoud, O.; Singh, D.N. Bio-mediated soil improvement: The way forward. Soil Use Manag. 2020, 36, 185–188. [Google Scholar] [CrossRef]

- Zhang, X.-P.; Shi, B.; Lu, X.-C. Experimental study on micro-pore structure of expansive soil improved by lime. Chin. J. Geotech. Eng. Chin. Ed. 2003, 25, 761–763. [Google Scholar]

- Khajeh, A.; Jamshidi Chenari, R.; Payan, M. A simple review of cemented non-conventional materials: Soil composites. Geotech. Geol. Eng. 2020, 38, 1019–1040. [Google Scholar] [CrossRef]

- James, J.; Pandian, P.K. Industrial Wastes as Auxiliary Additives to Cement/Lime Stabilization of Soils. Adv. Civ. Eng. 2016, 2016, 1267391. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Parthiban, D. Effect of Solid waste based stabilizing material for strengthening of Expansive soil—A review. Environ. Technol. Innov. 2020, 20, 101108. [Google Scholar] [CrossRef]

- Tan, K.; Wang, J. Substrate modified with biochar improves the hydrothermal properties of green roofs. Environ. Res. 2023, 216, 114405. [Google Scholar] [CrossRef]

- Zhao, H.-X.; Zhou, F.-S.; Evelina, L.M.A.; Liu, J.-L.; Zhou, Y. A review on the industrial solid waste application in pelletizing additives: Composition, mechanism and process characteristics. J. Hazard. Mater. 2022, 423, 127056. [Google Scholar] [CrossRef]

- Prusinski, J.R.; Bhattacharja, S. Effectiveness of Portland cement and lime in stabilizing clay soils. Transp. Res. Rec. 1999, 1652, 215–227. [Google Scholar] [CrossRef]

- Zha, F.; Liu, S.; Du, Y. Experiment on improvement of expansive clays with lime-fly ash. J. Southeast Univ. Nat. Sci. Ed. 2007, 37, 339–344. [Google Scholar]

- Nalbantoğlu, Z. Effectiveness of Class C fly ash as an expansive soil stabilizer. Constr. Build. Mater. 2004, 18, 377–381. [Google Scholar] [CrossRef]

- Akbulut, S.; Arasan, S. The variations of cation exchange capacity, pH, and zeta potential in expansive soils treated by additives. Int. J. Civ. Struct. Eng. 2010, 1, 139–154. [Google Scholar]

- Nalbantoglu, Z.; Gucbilmez, E. Improvement of calcareous expansive soils in semi-arid environments. J. Arid. Environ. 2001, 47, 453–463. [Google Scholar] [CrossRef]

- Jha, A.; Sivapullaiah, P. Gypsum-induced volume change behavior of stabilized expansive soil with fly ash-lime. Geotech. Test. J. 2016, 39, 391–406. [Google Scholar] [CrossRef]

- Cokca, E. Use of class C fly ashes for the stabilization of an expansive soil. J. Geotech. Geoenviron. Eng. 2001, 127, 568–573. [Google Scholar] [CrossRef]

- Arasan, S. Investigation of the Effect of Cement, Lime, Silica Fume and Fly Ash on Swelling Pressure and Cation Exchange Capacity of Fine Grained Soils. Master’s Thesis, Ataturk University, Erzurum, Turkey, 2005. [Google Scholar]

- İlhan, M.; Gültekin, H.E.; Rençber, S.; Şenyiğit, Z.; Aydın, H.H. Chapter 12-Aquasomes: A novel platform for drug delivery. In Systems of Nanovesicular Drug Delivery; Nayak, A.K., Hasnain, M.S., Aminabhavi, T.M., Torchilin, V.P., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 191–206. [Google Scholar] [CrossRef]

- Sharma, N.K.; Swain, S.K.; Sahoo, U.C. Stabilization of a Clayey Soil with Fly Ash and Lime: A Micro Level Investigation. Geotech. Geol. Eng. 2012, 30, 1197–1205. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Guney Olgun, C.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo-Eng. 2017, 8, 26. [Google Scholar] [CrossRef]

- Shen, W.; Zhou, M.; Zhao, Q. Study on lime–fly ash–phosphogypsum binder. Constr. Build. Mater. 2007, 21, 1480–1485. [Google Scholar] [CrossRef]

- Muthukkumaran, K.; Anusudha, V. Study on Behavior of Copper Slag and Lime–Treated Clay under Static and Dynamic Loading. J. Mater. Civ. Eng. 2020, 32, 04020230. [Google Scholar] [CrossRef]

- Tastan, E.O.; Edil, T.B.; Benson, C.H.; Aydilek, A.H. Stabilization of organic soils with fly ash. J. Geotech. Geoenviron. Eng. 2011, 137, 819–833. [Google Scholar] [CrossRef]

- Boardman, D.; Glendinning, S.; Rogers, C. Development of stabilisation and solidification in lime–clay mixes. Geotechnique 2001, 51, 533–543. [Google Scholar] [CrossRef]

- Zhou, S.; Zhou, D.; Zhang, Y.; Wang, W. Study on Physical-Mechanical Properties and Microstructure of Expansive Soil Stabilized with Fly Ash and Lime. Adv. Civ. Eng. 2019, 2019, 4693757. [Google Scholar] [CrossRef]

- Metelková, Z.; Boháč, J.; Přikryl, R.; Sedlářová, I. Maturation of loess treated with variable lime admixture: Pore space textural evolution and related phase changes. Appl. Clay Sci. 2012, 61, 37–43. [Google Scholar] [CrossRef]

- Al-Mukhtar, M.; Khattab, S.; Alcover, J.-F. Microstructure and geotechnical properties of lime-treated expansive clayey soil. Eng. Geol. 2012, 139–140, 17–27. [Google Scholar] [CrossRef]

- Cui, S.; Wang, A.; Tian, M.; Yan, K. Laboratory test on compaction properties of expansive soils reinforced with Cement kiln dust(CKD) content. J. Northwest Univ. Nat. Sci. Ed. 2016, 46, 256–260. [Google Scholar]

- Mashifana, T.P.; Okonta, F.N.; Ntuli, F. Geotechnical Properties and Microstructure of Lime-Fly Ash-Phosphogypsum-Stabilized Soil. Adv. Civ. Eng. 2018, 2018, 3640868. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Singh, K. Effect of Curing on Micro-Physical Performance of Polypropylene Fiber Reinforced and Silica Fume stabilized Expansive Soil Under Freezing Thawing Cycles. Sci Rep 2020, 10, 7624. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.K.; Sivapullaiah, P.V. Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soils Found. 2016, 56, 205–212. [Google Scholar] [CrossRef]

- Al-Rawas, A.A. Microfabric and mineralogical studies on the stabilization of an expansive soil using cement by-pass dust and some types of slags. Can. Geotech. J. 2002, 39, 1150–1167. [Google Scholar] [CrossRef]

- Diamond, S. The microstructure of cement paste and concrete––A visual primer. Cem. Concr. Compos. 2004, 26, 919–933. [Google Scholar] [CrossRef]

- Jha, A.K.; Sivapullaiah, P.V. Role of gypsum on microstructure and strength of soil. Environ. Geotech. 2014, 3, 78–89. [Google Scholar] [CrossRef]

- Mahedi, M.; Cetin, B.; White, D.J. Cement, Lime, and Fly Ashes in Stabilizing Expansive Soils: Performance Evaluation and Comparison. J. Mater. Civ. Eng. 2020, 32, 04020177. [Google Scholar] [CrossRef]

- Mir, B.A.; Sridharan, A. Physical and Compaction Behaviour of Clay Soil–Fly Ash Mixtures. Geotech. Geol. Eng. 2013, 31, 1059–1072. [Google Scholar] [CrossRef]

- Hakari, U.D.; Puranik, S.C. Stabilisation of black cotton soils using fly ash, Hubballi-Dharwad Municipal Corporation Area, Karnataka, India. Glob. J. Res. Eng 2012, 12, E2. [Google Scholar]

- Tan, K.; Qin, Y.; Du, T.; Li, L.; Zhang, L.; Wang, J. Biochar from waste biomass as hygroscopic filler for pervious concrete to improve evaporative cooling performance. Constr. Build. Mater. 2021, 287, 123078. [Google Scholar] [CrossRef]

- Yoobanpot, N.; Jamsawang, P.; Horpibulsuk, S. Strength behavior and microstructural characteristics of soft clay stabilized with cement kiln dust and fly ash residue. Appl. Clay Sci. 2017, 141, 146–156. [Google Scholar] [CrossRef]

- Cokca, E.; Yazici, V.; Ozaydin, V. Stabilization of Expansive Clays Using Granulated Blast Furnace Slag (GBFS) and GBFS-Cement. Geotech. Geol. Eng. 2008, 27, 489–499. [Google Scholar] [CrossRef]

- Sharma, A.; Puvvadi, S. Improvement of Strength of Expansive Soil with Waste Granulated Blast Furnace Slag. In Proceedings of the GeoCongress, Oakland, CA, USA, 25–29 March 2012. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sivapullaiah, P.V. Swelling behaviour of expansive soil treated with fly ash–GGBS based binder. Geomech. Geoengin. 2016, 12, 191–200. [Google Scholar] [CrossRef]

- James, J.; Pandian, P.K. Effect of phosphogypsum on strength of lime stabilized expansive soil. Građevinar 2015, 66, 1109–1116. [Google Scholar]

- Mujtaba, H.; Aziz, T.; Farooq, K.; Sivakugan, N.; Das, B.M. Improvement in Engineering Properties of Expansive Soils using Ground Granulated Blast Furnace Slag. J. Geol. Soc. India 2018, 92, 357–362. [Google Scholar] [CrossRef]

- Phanikumar, B.; Nagaraju, T. Effect of fly ash and rice husk ash on index and engineering properties of expansive clays. Geotech. Geol. Eng. 2018, 36, 3425–3436. [Google Scholar] [CrossRef]

- Rimal, S.; Poudel, R.K.; Gautam, D. Experimental study on properties of natural soils treated with cement kiln dust. Case Stud. Constr. Mater. 2019, 10, e00223. [Google Scholar] [CrossRef]

- Kalkan, E.; Akbulut, S. The positive effects of silica fume on the permeability, swelling pressure and compressive strength of natural clay liners. Eng. Geol. 2004, 73, 145–156. [Google Scholar] [CrossRef]

- GhavamShirazi, S.; Bilsel, H. Characterization of volume change and strength behavior of micro-silica and lime-stabilized Cyprus clay. Acta Geotech. 2020, 16, 827–840. [Google Scholar] [CrossRef]

- McCarthy, M.J.; Csetenyi, L.J.; Sachdeva, A.; Dhir, R.K. Engineering and durability properties of fly ash treated lime-stabilised sulphate-bearing soils. Eng. Geol. 2014, 174, 139–148. [Google Scholar] [CrossRef]

- Rama Subbarao, G.V.; Siddartha, D.; Muralikrishna, T.; Sailaja, K.S.; Sowmya, T. Industrial Wastes in Soil Improvement. ISRN Civ. Eng. 2011, 2011, 138149. [Google Scholar] [CrossRef]

- Kumar, S.; Dutta, R.K.; Mohanty, B. Engineering Properties of Bentonite Stabilized with Lime and Phosphogypsum. Slovak J. Civ. Eng. 2014, 22, 35–44. [Google Scholar] [CrossRef]

- Cui, S.L.; Wang, J.D.; Wang, X.D.; Du, Y.F.; Wang, X.P. Mechanical behavior and micro-structure of cement kiln dust-stabilized expensive soil. Arab. J. Geosci. 2018, 11, 521. [Google Scholar] [CrossRef]

- Kumar, B.; Sharma, R. Effect of Fly Ash on Engineering Properties of Expansive Soils. J. Geotech. Geoenviron. Eng. 2004, 130, 764–767. [Google Scholar] [CrossRef]

- Hasan, H.A. Effect of fly ash on geotechnical properties of expansive soil. J. Eng. Sustain. Dev. 2012, 16, 306–316. [Google Scholar]

- Blanco-Canqui, H. Biochar and soil physical properties. Soil Sci. Soc. Am. J. 2017, 81, 687–711. [Google Scholar] [CrossRef]

- Zha, F.; Liu, S.; Du, Y.; Cui, K. Behavior of expansive soils stabilized with fly ash. Nat. Hazards 2008, 47, 509–523. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Patva, J. Engineering Characteristics and Performance of Polypropylene Fibre and Silica Fume Treated Expansive Soil Subgrade. Int. J. Geosynth. Ground Eng. 2020, 6, 18. [Google Scholar] [CrossRef]

- Sabat, A.K. Stabilization of expansive soil using waste ceramic dust. Electron. J. Geotech. Eng. 2012, 17, 3915–3926. [Google Scholar]

- Pathak, A.K.; Pandey, V.; Murari, K.; Singh, J. Soil stabilisation using ground granulated blast furnace slag. Int. J. Eng. Res. Appl. 2014, 4, 164–171. [Google Scholar]

- Qureshi, M.A.; Mistry, H.M.; Patel, V.D. Improvement in soil properties of expansive soil by using copper slag. Int. J. Adv. Res. Eng. Sci. Technol. 2015, 2, 125–130. [Google Scholar]

- Choudari, S.; Krishna, Y.B.G. Effect of FlyAsh on Compaction Characteristics of Expansive Soils, Near Anandapuram, Visakhapatnam, Andhra Pradesh, India. Int. J. Eng. Res. Technol. 2015, 4, 28. [Google Scholar]

- Kalkan, E. Impact of wetting–drying cycles on swelling behavior of clayey soils modified by silica fume. Appl. Clay Sci. 2011, 52, 345–352. [Google Scholar] [CrossRef]

- Mugahed Sakr, M.; Azzam, W.R.; Meguid, M.A.; Ghoneim, H. Improvement of Expansive Soil by Using Micro Silica Fume. J. Eng. Res. 2020, 4, 26–30. [Google Scholar] [CrossRef]

- Ito, M.; Azam, S. Determination of swelling and shrinkage properties of undisturbed expansive soils. Geotech. Geol. Eng. 2010, 28, 413–422. [Google Scholar] [CrossRef]

- Hardaha, R.P.; Agrawal, M.L.; Agrawal, A. Study about swelling behaviour of black cotton soil with fly ash. Int. J. Sci. Res. 2015, 4, 1514–1517. [Google Scholar]

- Cui, S.; Yan, K.; Wang, A.; Tian, M. An experimental study of expansion-shrinkage characteristics of cement-kiln-dust-treated expansive soil. Hydrogeol. Eng. Geol. 2015, 42, 102–106. [Google Scholar]

- Nelson, J.; Miller, D.J. Expansive Soils: Problems and Practice in Foundation and Pavement Engineering; John Wiley & Sons: Hoboken, NJ, USA, 1997. [Google Scholar]

- Kalkan, E. Utilization of red mud as a stabilization material for the preparation of clay liners. Eng. Geol. 2006, 87, 220–229. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Lu, Y.; Feng, Q.; Zhang, F.; Qi, C.; Wei, J.; Kanungo, D.P. Effect of Polyvinyl Acetate Stabilization on the Swelling-Shrinkage Properties of Expansive Soil. Int. J. Polym. Sci. 2017, 2017, 1–8. [Google Scholar] [CrossRef]

- Singh, P.; Kumar Dash, H.; Samantaray, S. Effect of silica fume on engineering properties of expansive soil. Mater. Today Proc. 2020, 33, 5035–5040. [Google Scholar] [CrossRef]

- Al-Gharbawi, A.S.; Najemalden, A.M.; Fattah, M.Y. Expansive Soil Stabilization with Lime, Cement, and Silica Fume. Appl. Sci. 2022, 13, 436. [Google Scholar] [CrossRef]

- Kate, J. Strength and volume change behavior of expansive soils treated with fly ash. In Innovations in Grouting and Soil Improvement; American Society of Civil Engineers: Reston, VA, USA, 2005; pp. 1–15. [Google Scholar]

- Yarbaşı, N.; Kalkan, E.; Akbulut, S. Modification of the geotechnical properties, as influenced by freeze–thaw, of granular soils with waste additives. Cold Reg. Sci. Technol. 2007, 48, 44–54. [Google Scholar] [CrossRef]

- Wang, D.; Zentar, R.; Abriak, N.E. Durability and swelling of solidified/stabilized dredged marine soils with class-F fly ash, cement, and lime. J. Mater. Civ. Eng. 2018, 30, 04018013. [Google Scholar] [CrossRef]

- Meiguo, F.; Shanxiong, C.; Song, Y.U.; Jia, M.A. Laboratory study on water stability of flyash-treated expansive soil. Rock Soil Mech. 2007, 28, 1889–1893. [Google Scholar]

- Bin-Shafique, S.; Rahman, K.; Yaykiran, M.; Azfar, I. The long-term performance of two fly ash stabilized fine-grained soil subbases. Resour. Conserv. Recycl. 2010, 54, 666–672. [Google Scholar] [CrossRef]

- Wu, Y.; Qiao, X.; Yu, X.; Yu, J.; Deng, Y. Study on properties of expansive soil improved by steel slag powder and cement under freeze-thaw cycles. KSCE J. Civ. Eng. 2021, 25, 417–428. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).