Feasibility of Using Sugar Cane Bagasse Ash in Partial Replacement of Portland Cement Clinker

Abstract

1. Introduction

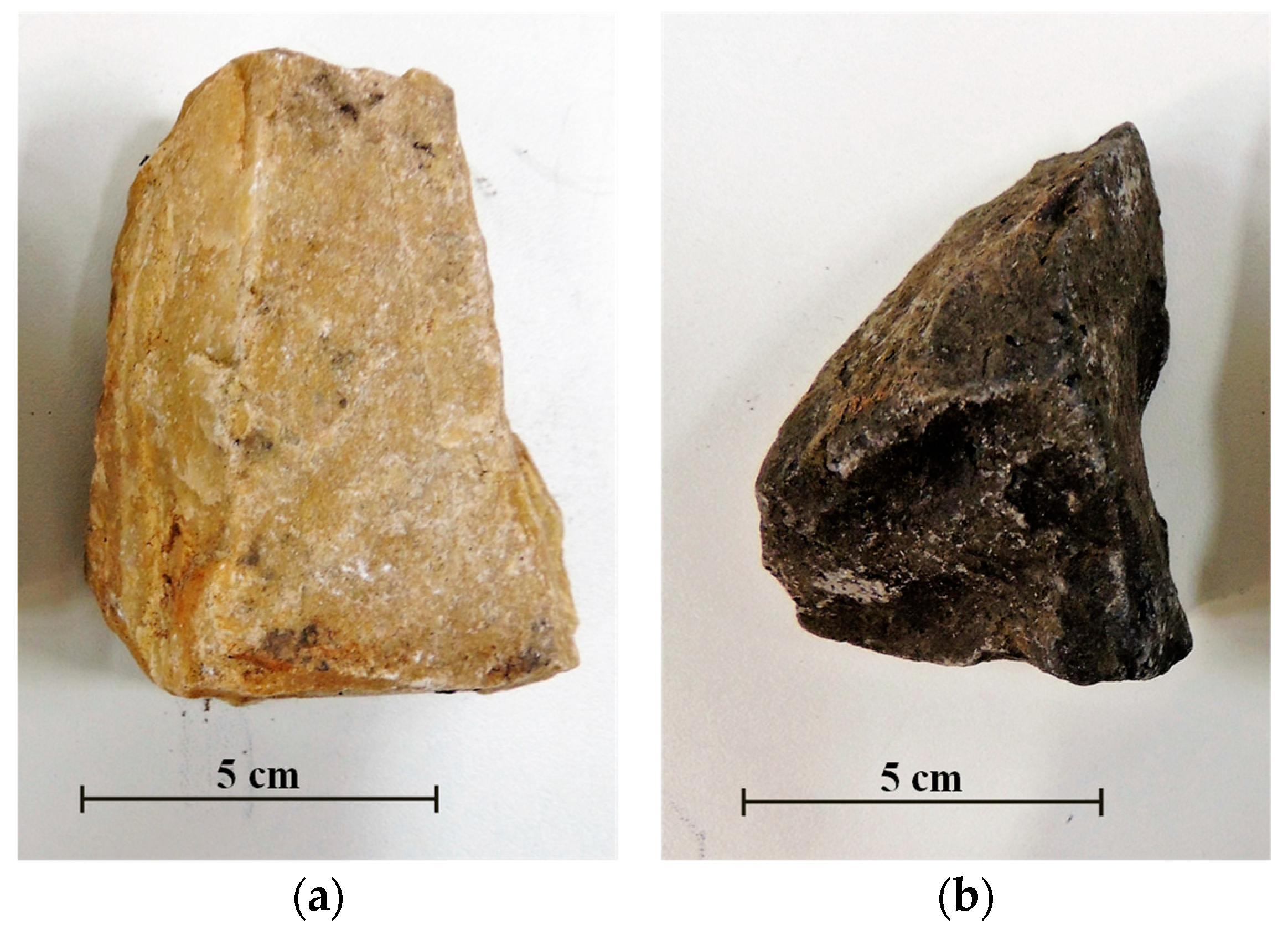

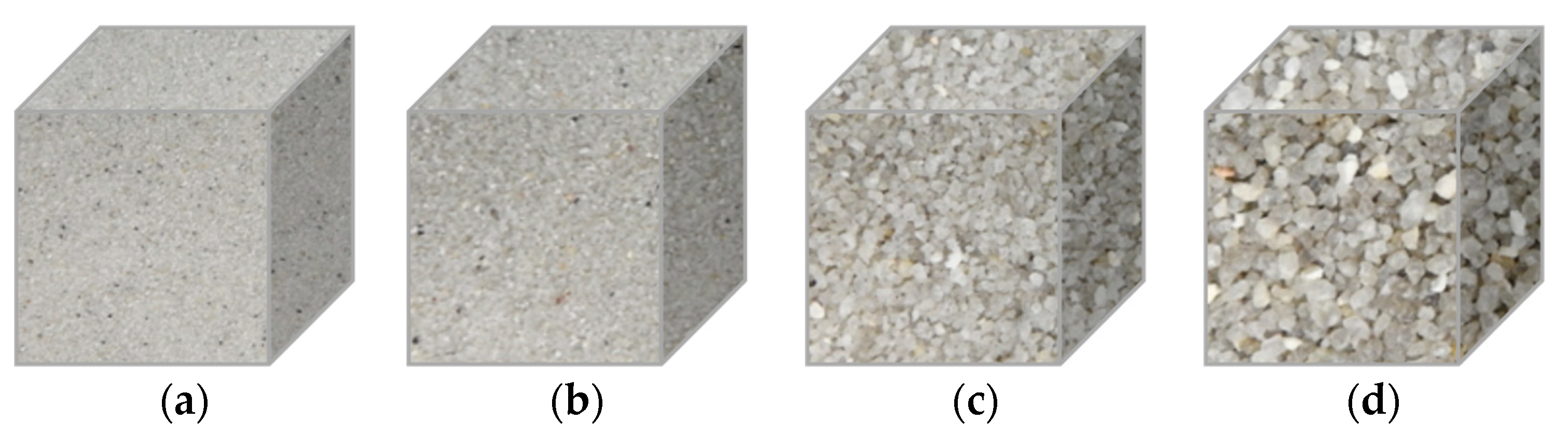

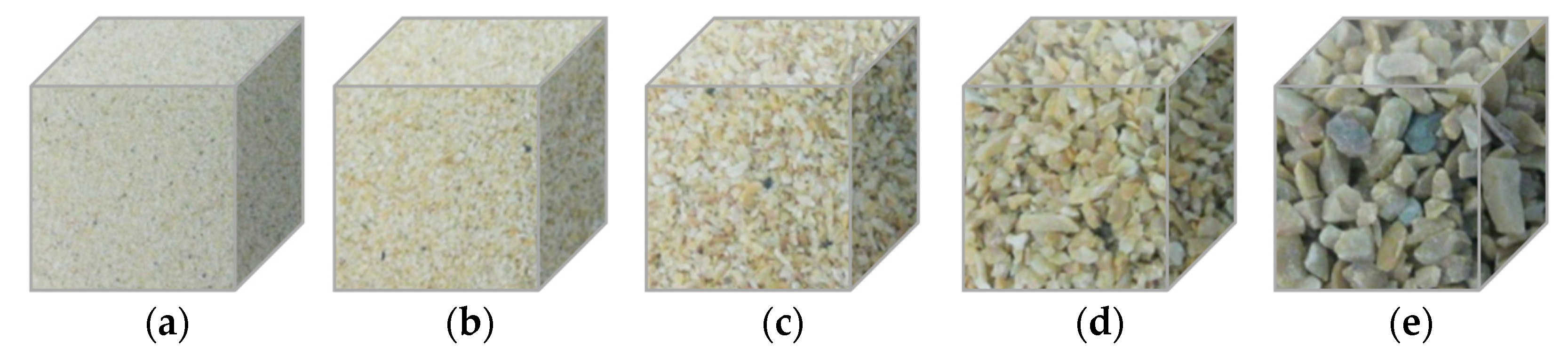

2. Materials and Methods

3. Results

4. Conclusions

- The processing of SCBA by grinding or burning promotes morphological and physical changes. Grinding and burning increased the density and reduced the particle size of SCBA. SCBA AC and SCBA G showed a high loss on ignition. SCBA G and SCBA RG are pozzolanic.

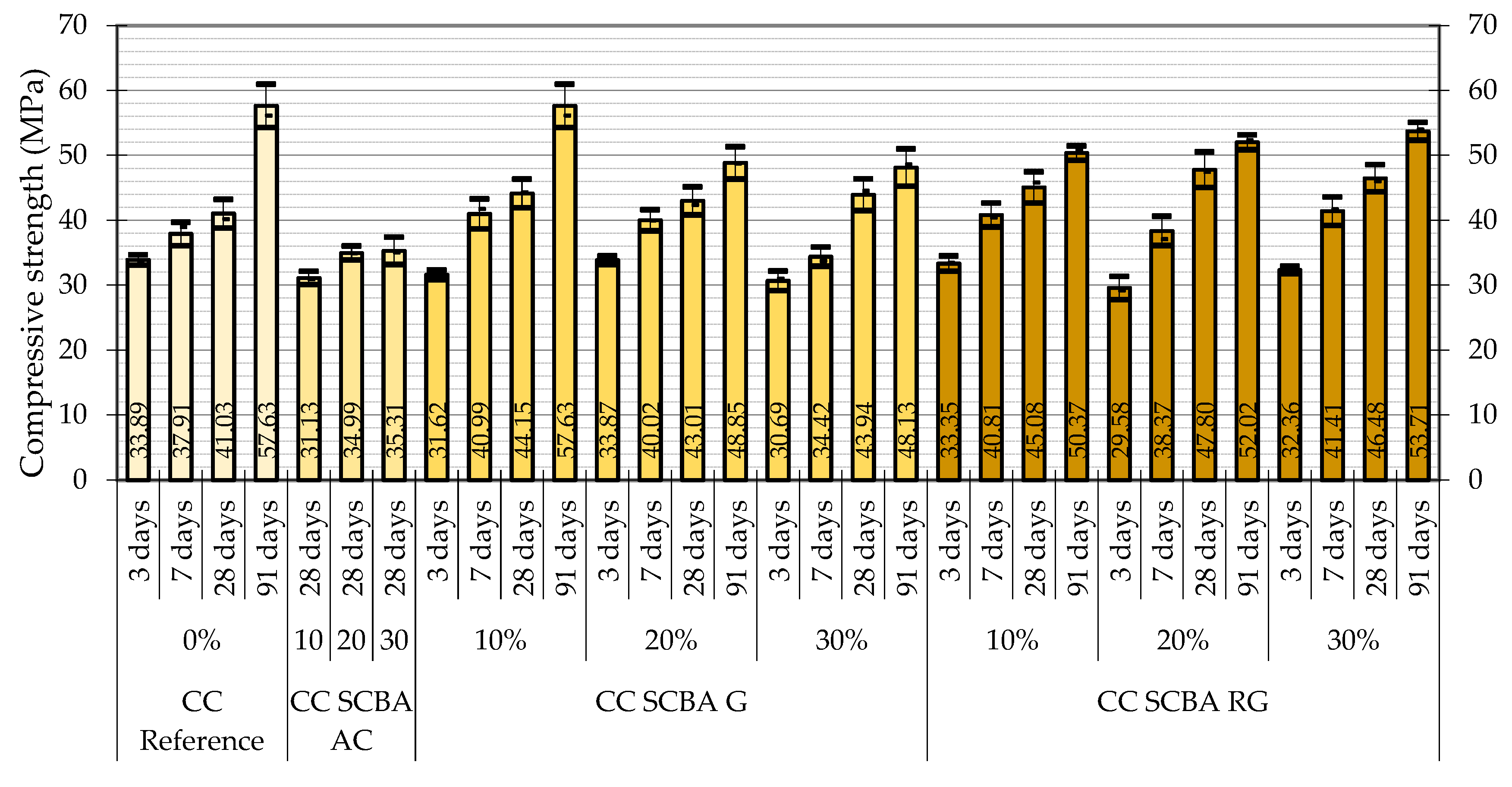

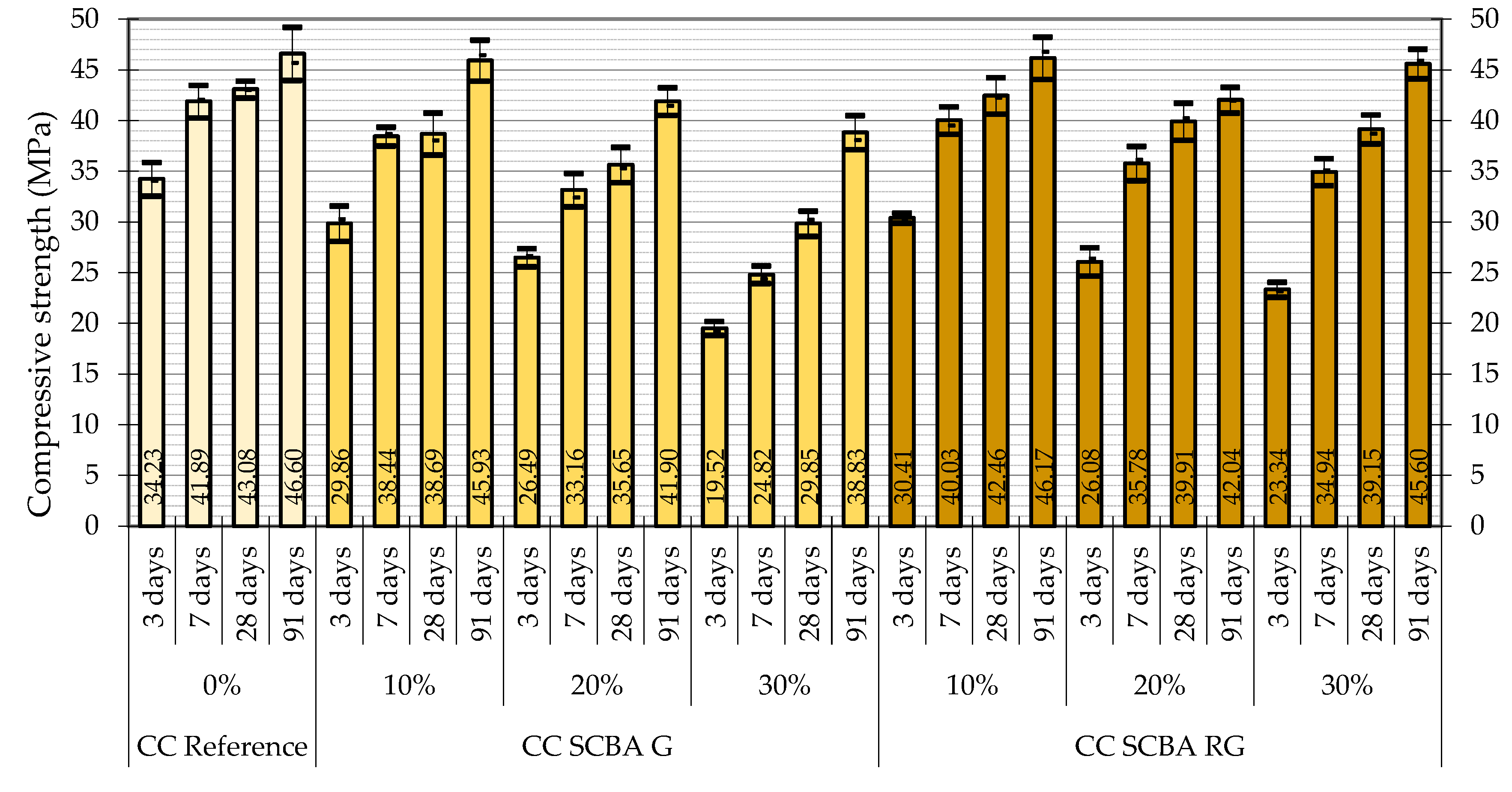

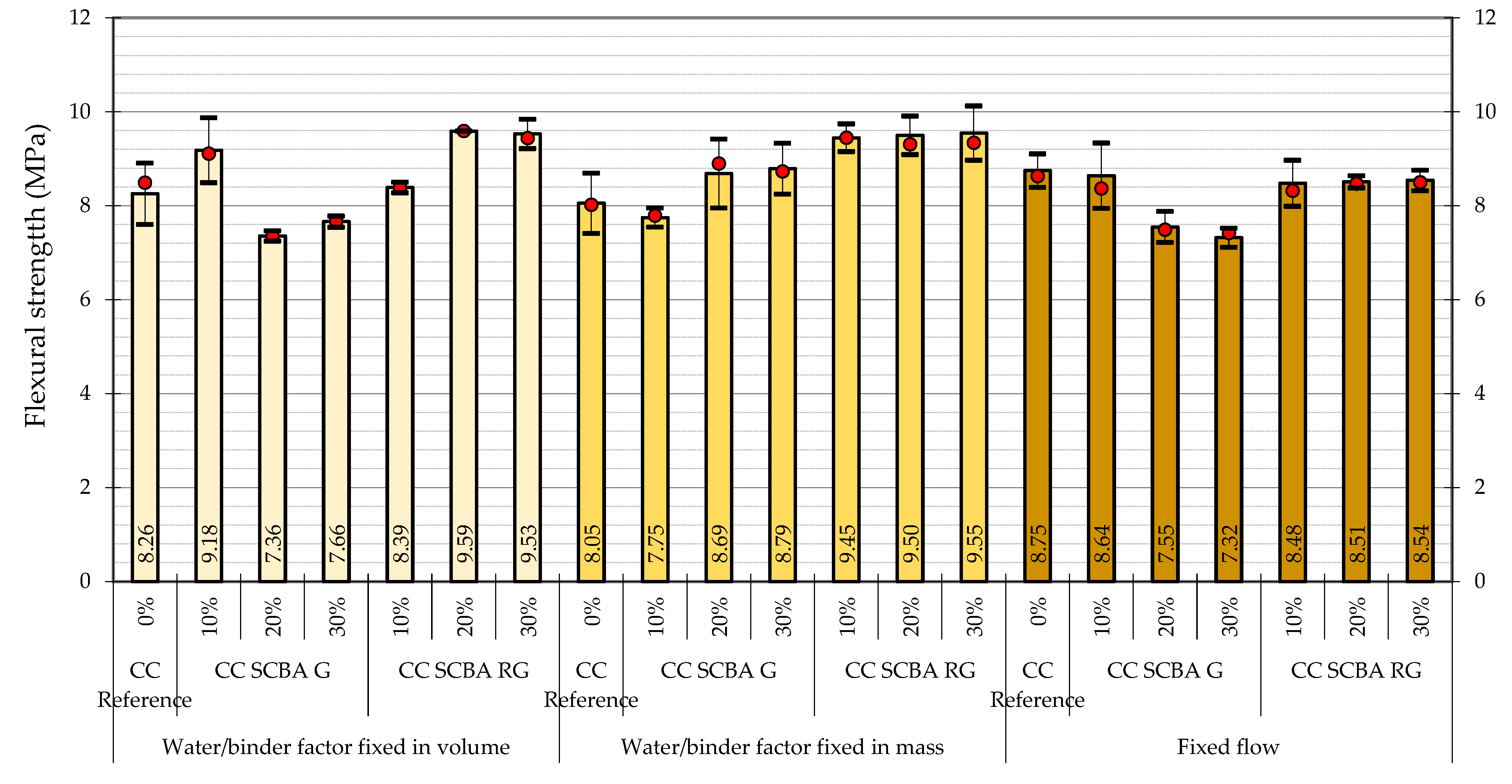

- The cement produced with SCBA AC took the mortar with an inadequate consistency. The cement with SCBA G and SCBA RG did not have its setting time significantly altered. The higher percentage of additions (20% and 30%) of SCBA RG led to mortars with a higher dry bulk density and lower water absorption. The compressive strength of mortars with the cement with SCBA G and SCBA RG were compatible with the results obtained by the reference Portland cement, regardless of the dosage method used.

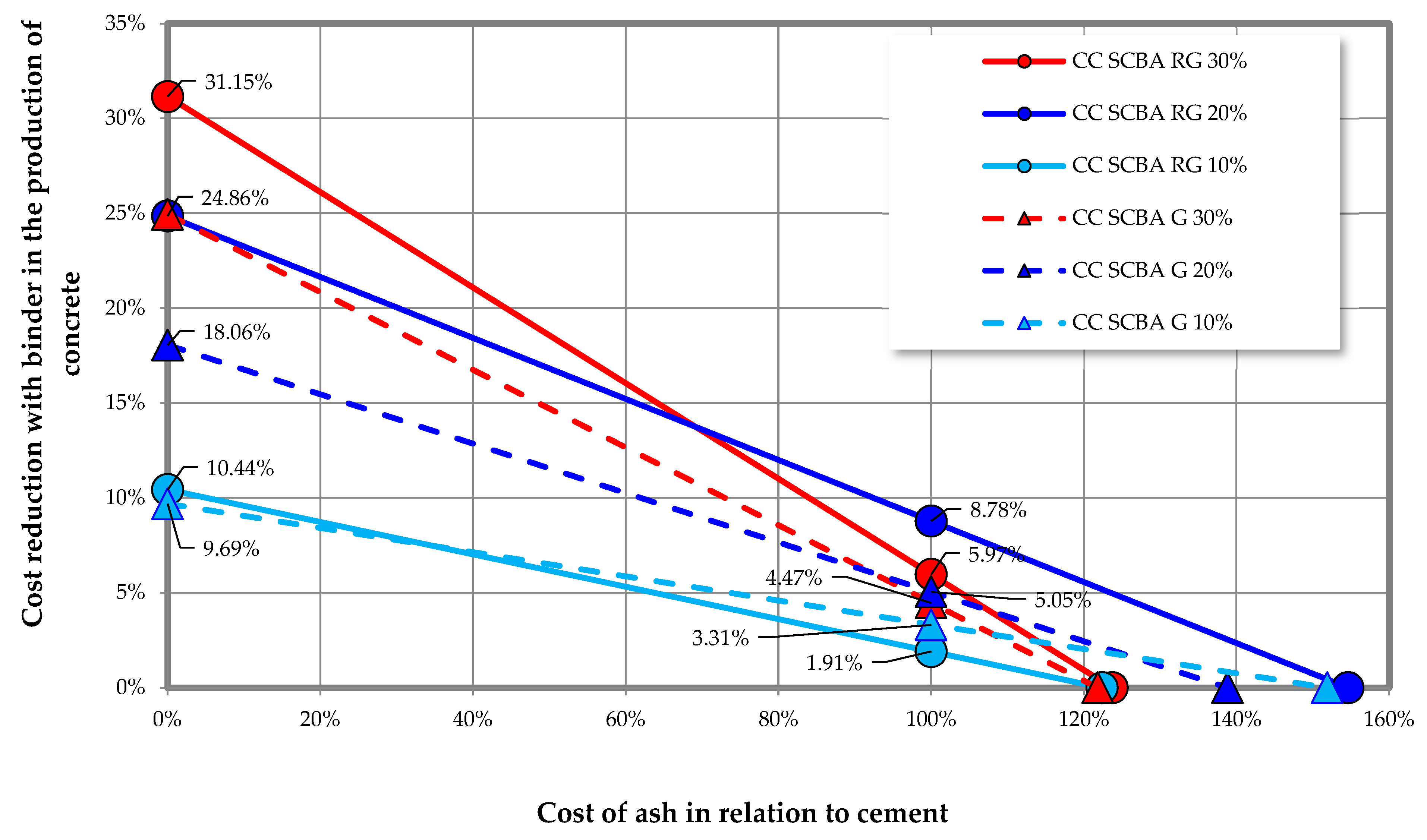

- SCBA RG presented the lowest consumption of the Portland cement reference by compressive strength acquired in the dosing methods: (a) fixed water/binder factor in volume; (b) water/binder factor fixed in weight; and (c) fixed flow.

- Without considering logistical costs, if SCBA’s processing costs are zero, the savings in Portland cement production can reach 31.15%. For replacements of up to 30% of the clinker by SCBA, if the cost of the SCBA is equal to the cost of the clinker, the savings can reach 8.78%. It is worth noting that the temperature adjustment of the boilers of the thermoelectric plants can lead to SCBA being more suitable for the partial replacement of the clinker, without the need for re-firing, and the grinding of the SCBA requires less energy than the grinding of the clinker, mainly due to the size of the SGBA AC being reduced compared to the clinker.

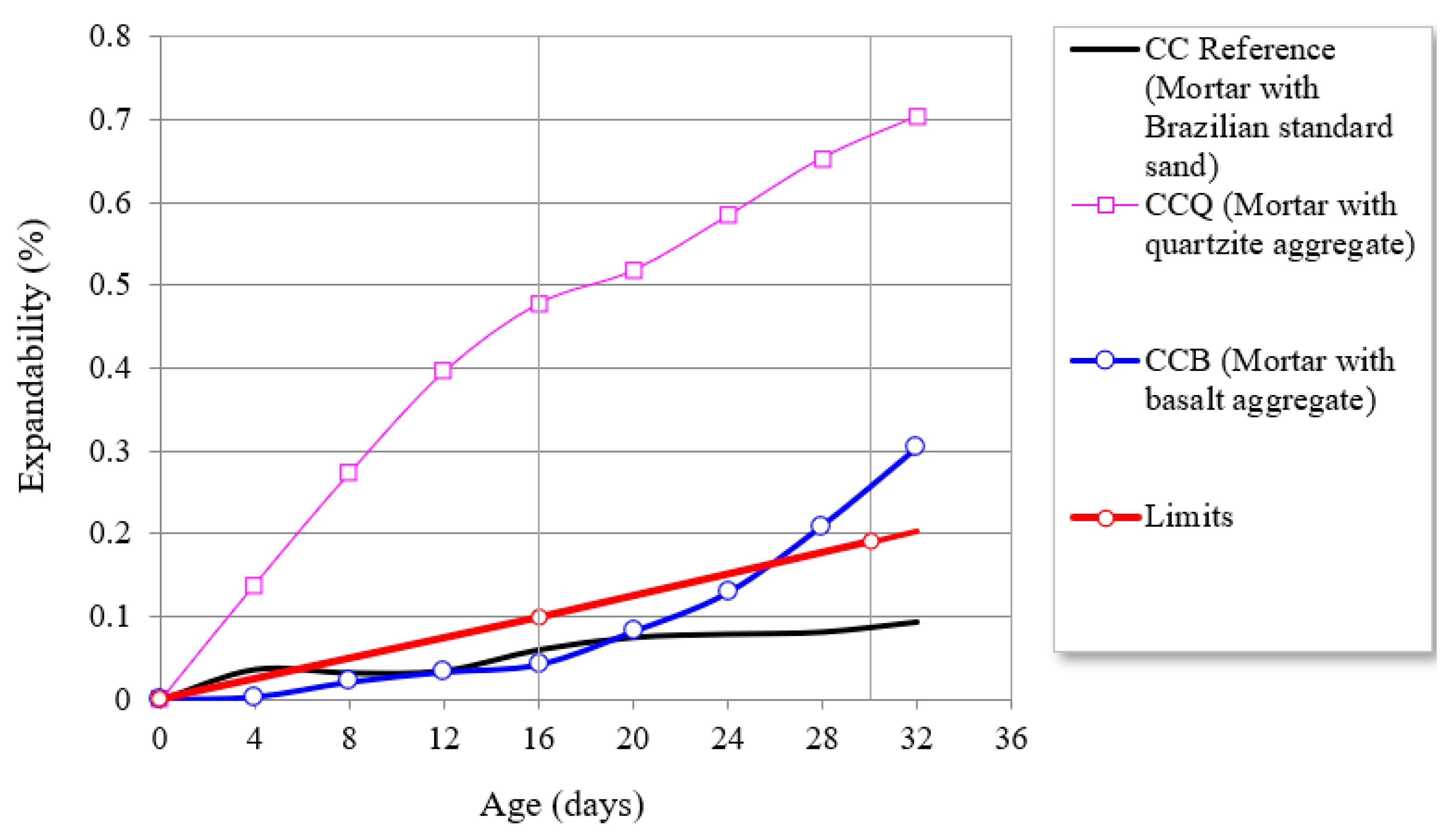

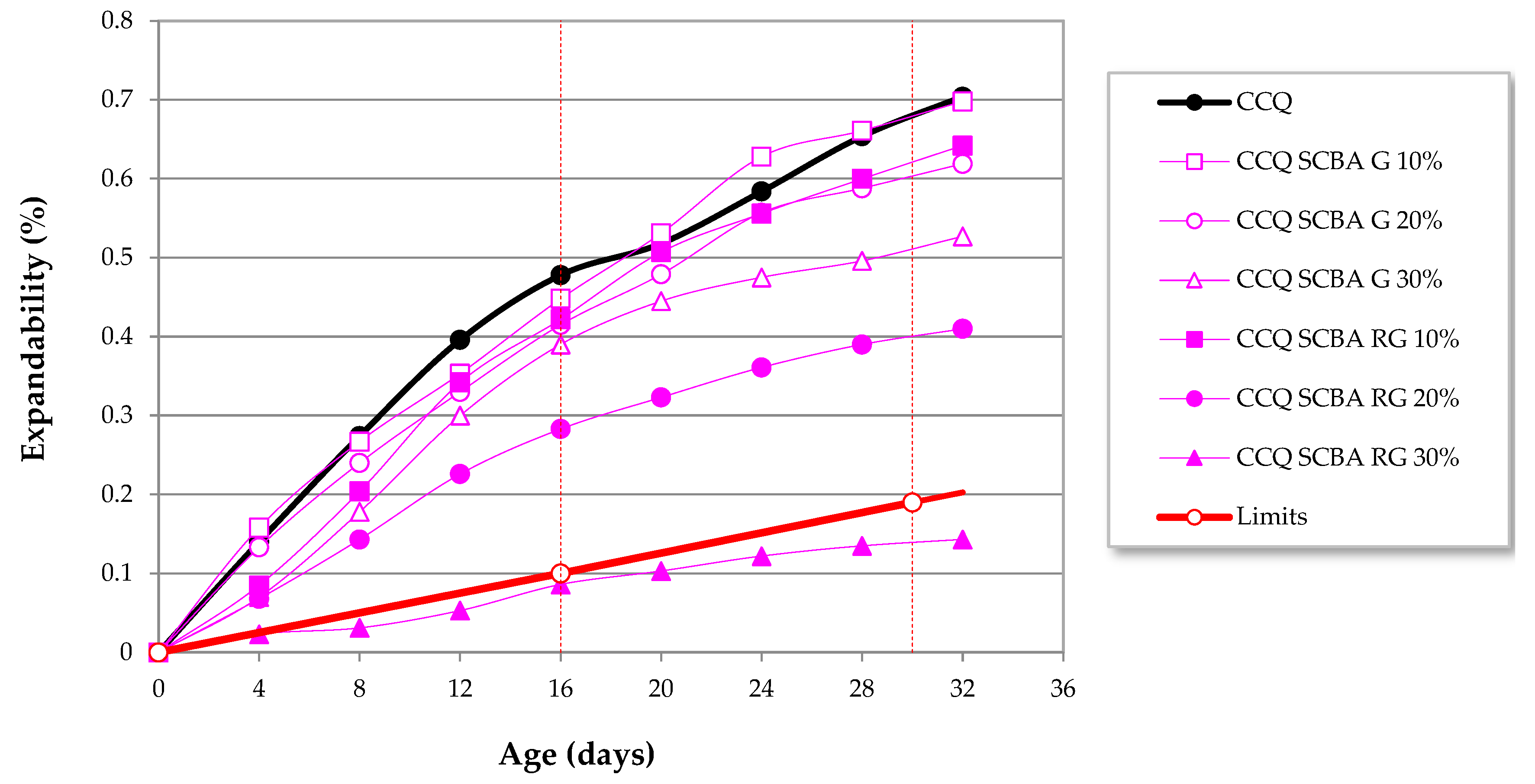

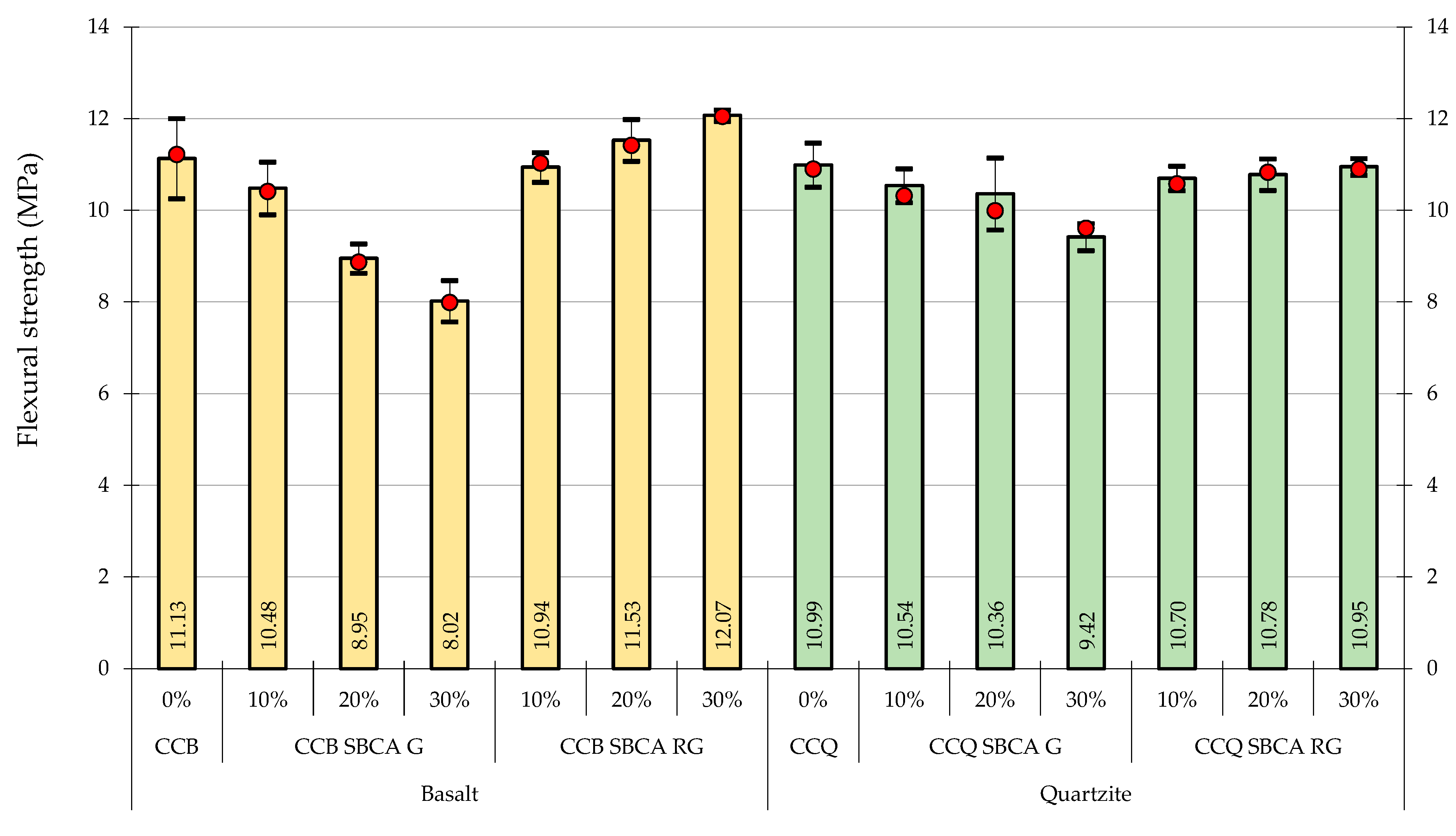

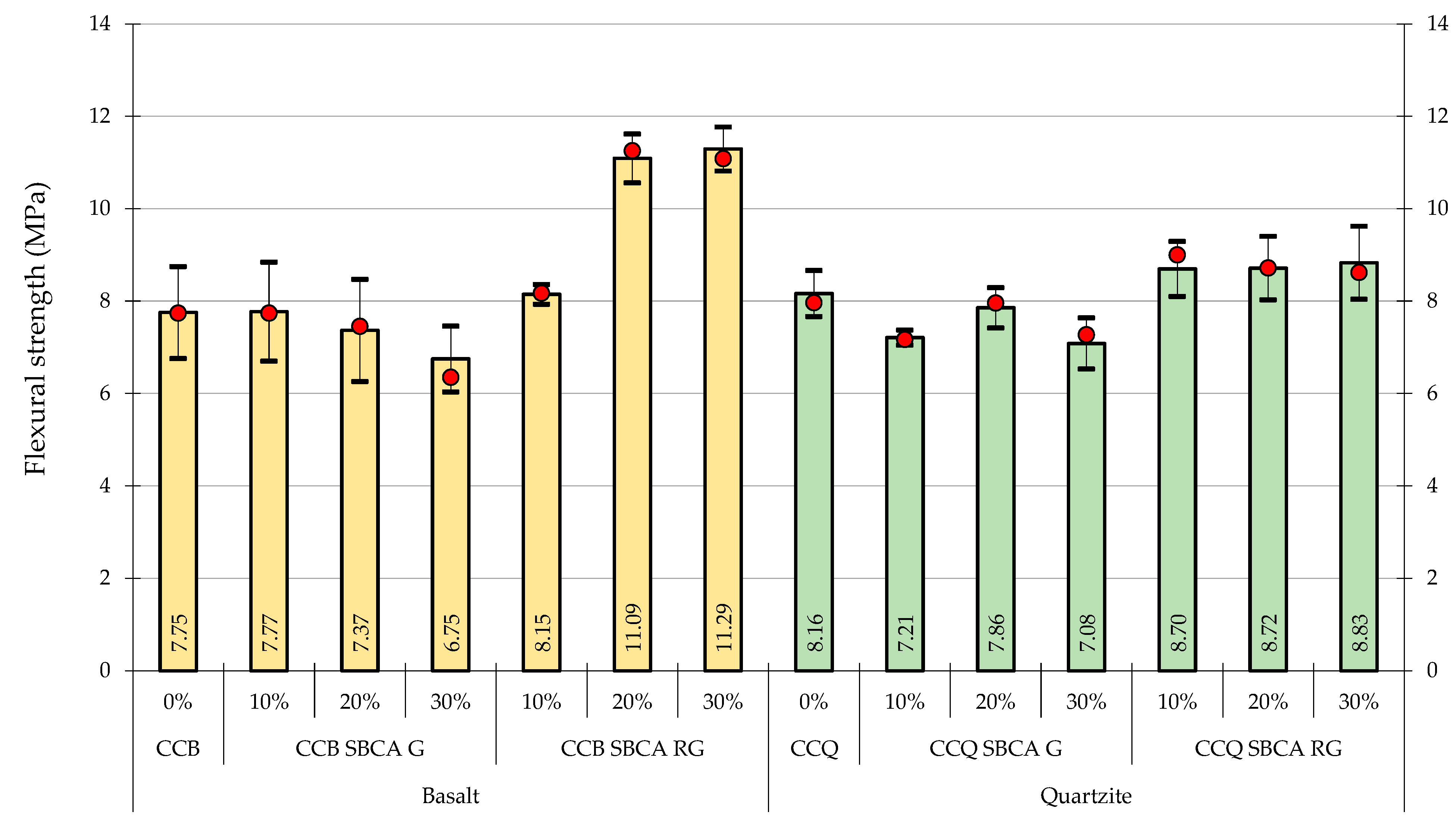

- The clinker’s replacement by SCBA reduces the expansion of mortar prisms with reactive aggregates exposed to aggressive environments (NaOH solution at 80 °C for 28 days). The SCBA RG in the 30% Portland clinker substitution inhibits expansion by ASR with the used aggregates of quartzite and basalt. This fact is confirmed by the flexural strength presented by CC SCBA RG 30% after 900 days of the ASR test.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- United States Geological Survey. Mineral Commodity Summaries 2022; United States Geological Survey: Reston, VA, USA, 2022. [Google Scholar]

- Ali, N.; Mohd Sobri, M.H.A.; Hadipramana, J.; Abdul Samad, A.A.; Mohamad, N. Potential Mixture of POFA and SCBA as Cement Replacement in Concrete—A Review. MATEC Web Conf. 2017, 103, 01006. [Google Scholar] [CrossRef]

- Paris, J.M.; Roessler, J.G.; Ferraro, C.C.; Deford, H.D.; Townsend, T.G. A review of waste products utilized as supplements to Portland cement in concrete. J. Clean. Prod. 2016, 121, 1–18. [Google Scholar] [CrossRef]

- Lorena Figueiredo Martins, M.; Roberto Ribeiro Soares Junior, P.; Henrique da Silva, T.; de Souza Maciel, P.; Peixoto Pinheiro, I.; Cesar da Silva Bezerra, A. Magnesium industry waste and red mud to eco-friendly ternary binder: Producing more sustainable cementitious materials. Constr. Build. Mater. 2021, 310, 125172. [Google Scholar] [CrossRef]

- Gołaszewski, J.; Gołaszewska, M.; Cygan, G. Performance of Ordinary and Self-Compacting Concrete with Limestone after Freeze–Thaw Cycles. Buildings 2022, 12, 2003. [Google Scholar] [CrossRef]

- Khatib, J.; Ramadan, R.; Ghanem, H.; Elkordi, A. Volume stability of cement paste containing limestone fines. Buildings 2021, 11, 366. [Google Scholar] [CrossRef]

- Choi, Y.C.; Park, B. Enhanced autogenous healing of ground granulated blast furnace slag blended cements and mortars. J. Mater. Res. Technol. 2019, 8, 3443–3452. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Pugazhmani, G.; Sripragadeesh, R.; Muthu, D.; Venkatasubramanian, C. Experimental study on the mechanical and durability properties of concrete with waste glass powder and ground granulated blast furnace slag as supplementary cementitious materials. Constr. Build. Mater. 2017, 156, 739–749. [Google Scholar] [CrossRef]

- Zeraoui, A.; Maherzi, W.; Benzerzour, M.; Abriak, N.E.; Aouad, G. Development of Flash—Calcined Sediment and Blast Furnace Slag Ternary Binders. Buildings 2023, 13, 333. [Google Scholar] [CrossRef]

- Ramzi, S.; Hajiloo, H. The Effects of Supplementary Cementitious Materials (SCMs) on the Residual Mechanical Properties of Concrete after Exposure to High Temperatures—Review. Buildings 2022, 13, 103. [Google Scholar] [CrossRef]

- Barboza-Chavez, A.C.; Gómez-Zamorano, L.Y.; Acevedo-Dávila, J.L. Synthesis and characterization of a hybrid cement based on fly ash, metakaolin and portland cement clinker. Materials 2020, 13, 1084. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, J.; Majdi, A.; Arbili, M.M.; Deifalla, A.F.; Naqash, M.T. Mechanical, Durability and Microstructure Analysis Overview of Concrete Made with Metakaolin (MTK). Buildings 2022, 12, 1401. [Google Scholar] [CrossRef]

- Yanez, S.; Márquez, C.; Valenzuela, B.; Villamar-Ayala, C.A. A Bibliometric-Statistical Review of Organic Residues as Cementitious Building Materials. Buildings 2022, 12, 597. [Google Scholar] [CrossRef]

- Young, G.; Yang, M. Preparation and characterization of Portland cement clinker from iron ore tailings. Constr. Build. Mater. 2019, 197, 152–156. [Google Scholar] [CrossRef]

- Gou, M.; Zhou, L.; Then, N.W.Y. Utilization of tailings in cement and concrete: A review. Sci. Eng. Compos. Mater. 2019, 26, 449–464. [Google Scholar] [CrossRef]

- Magalhães, L.F.D.; França, S.; Oliveira, M.D.S.; Peixoto, R.A.F.; Bessa, S.A.L.; Bezerra, A.C.D.S. Iron ore tailings as a supplementary cementitious material in the production of pigmented cements. J. Clean. Prod. 2020, 274, 123260. [Google Scholar] [CrossRef]

- ABNT NBR 16697; Cimento Portland—Requisitos. Associação Brasileira de Normas Técnicas (ABNT): São Paulo, Brazil, 2018.

- Teixeira, A.H.C.; Junior, P.R.R.S.; Silva, T.H.; Barreto, R.R.; da Silva Bezerra, A.C. Low-carbon concrete based on binary biomass ash-silica fume binder to produce eco-friendly paving blocks. Materials 2020, 13, 1534. [Google Scholar] [CrossRef]

- Gutiérrez-Orrego, D.A.; Gómez-Botero, M.A.; García, E.F. Alkali-Activated Hybrid Cement from Mineral Wool Fiber Waste and OPC. Buildings 2023, 13, 354. [Google Scholar] [CrossRef]

- De Matos Neto, J.A.; De Resende, D.S.; Da Silva Neto, J.T.; De Gouveia, A.M.C.; De Aguilar, M.T.P.; Da Silva Bezerra, A.C. Sterile clay pozzolans from phosphate mining. Mater. Res. 2015, 18, 230–234. [Google Scholar] [CrossRef]

- Li, J.; Ren, W.; Zhang, A.; Li, S.; Tan, J.; Liu, H. Mechanical Properties and Microstructure Analysis of Cement Mortar Mixed with Iron Ore Tailings. Buildings 2023, 13, 149. [Google Scholar] [CrossRef]

- Kim, J.; Lee, D.; Sičáková, A.; Kim, N. Utilization of Different Forms of Demolished Clay Brick and Granite Wastes for Better Performance in Cement Composites. Buildings 2023, 13, 165. [Google Scholar] [CrossRef]

- de Magalhães, L.F.; de Souza Morais, I.; Lara, L.F.D.S.; de Resende, D.S.; Menezes, R.M.R.O.; Aguilar, M.T.P.; da Silva Bezerra, A.C. Iron ore tailing as addition to partial replacement of portland cement. Mater. Sci. Forum 2018, 930, 125–130. [Google Scholar] [CrossRef]

- de Souza Morais, I.; de Magalhães, L.F.; Lara, L.F.D.S.; Corrêa, E.C.S.; Menezes, R.M.R.O.; Aguilar, M.T.P.; da Silva Bezerra, A.C. Sericitic phyllite as addition in portland cement. Mater. Sci. Forum 2018, 930, 131–136. [Google Scholar] [CrossRef]

- Ye, J.; Liu, S.; Zhao, Y.; Li, Y.; Fang, J.; Zhang, H.; Guan, X. Development of Ultrafine Mineral Admixture from Magnesium Slag and Sequestration of CO2. Buildings 2023, 13, 204. [Google Scholar] [CrossRef]

- Duarte, M.S.; Almada, B.S.; José dos Santos, W.; Lima Bessa, S.A.; Cesar da Silva Bezerra, A.; Paulino Aguilar, M.T. Influence of mechanical treatment and magnetic separation on the performance of iron ore tailings as supplementary cementitious material. J. Build. Eng. 2022, 59, 105099. [Google Scholar] [CrossRef]

- Pires, M.; de Jesus Andrade Fidelis, R.; de Resende, D.S.; da Silva Bezerra, A.C. Phosphate rock waste in the production of cement tile. Results Eng. 2022, 16, 100701. [Google Scholar] [CrossRef]

- OECD/FAO. OECD-FAO Agricultural Outlook 2020–2029; OECD/FAO: Paris, France, 2020; ISBN 9789264317673. [Google Scholar]

- da Silva Bezerra, A.C.; Saraiva, S.L.C.; dos Silva Lara, L.F.; de Castro, L.W.A.; Gomes, R.C.; de Silva Rodrigues, C.; Ferreira, M.C.N.F.; Aguilar, M.T.P. Effect of partial replacement with thermally processed sugar cane bagasse on the properties of mortars. Rev. Mater. 2017, 22, e11785. [Google Scholar] [CrossRef]

- Rezende, M.F.; Machado, F.C.S.; Gouveia, A.M.C.; Bezerra, A.C.S.; Grillo, R.H.F.; Ortigara, Y.V.B. Substituição parcial do cimento Portland pela cinza de bagaço de cana-de-açúcar em habitações de interesse social. Rev. Agrogeoambiental 2017, 9, 1. [Google Scholar] [CrossRef]

- Soares, M.M.N.S.; Poggiali, F.S.J.; Bezerra, A.C.S.; Figueiredo, R.B.; Aguilar, M.T.P.; Cetlin, P.R. The effect of calcination conditions on the physical and chemical characteristics of sugar cane bagasse ash. Rem Rev. Esc. Minas 2014, 67, 33–39. [Google Scholar] [CrossRef][Green Version]

- Ferreira, R.T.L.; Nunes, F.M.M.P.; Bezerra, A.C.S.; Figueiredo, R.B.; Cetlin, P.R.; Aguilar, M.T.P. Influence of reburning on the pozolanicity of sugar-cane bagasse ashes with different characteristics. Mater. Sci. Forum 2016, 869, 141–146. [Google Scholar] [CrossRef]

- Mohan, R.; Athira, G.; Mali, A.K.; Bahurudeen, A.; Nanthagopalan, P. Systematic Pretreatment Process and Optimization of Sugarcane Bagasse Ash Dosage for Use in Cement-Based Products. J. Mater. Civ. Eng. 2021, 33, 04021045. [Google Scholar] [CrossRef]

- Sousa, L.N.; Figueiredo, P.F.; França, S.; de Moura Solar Silva, M.V.; Borges, P.H.R.; da Silva Bezerra, A.C. Effect of Non-Calcined Sugarcane Bagasse Ash as an Alternative Precursor on the Properties of Alkali-Activated Pastes. Molecules 2022, 27, 1185. [Google Scholar] [CrossRef] [PubMed]

- Silva, T.H.; Lara, L.F.S.; Silva, G.J.B.; Provis, J.L.; Bezerra, A.C.S. Alkali-activated materials produced using high-calcium, high-carbon biomass ash. Cem. Concr. Compos. 2022, 132, 104646. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Fairbairn, E.M.R. Effect of calcination temperature on the pozzolanic activity of sugar cane bagasse ash. Constr. Build. Mater. 2009, 23, 3301–3303. [Google Scholar] [CrossRef]

- ASTM C618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- ABNT NBR 5752; Materiais Pozolânicos—Determinação do Índice Desempenho com Cimento Portland aos 28 Dias. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2014.

- ABNT NBR 15895; Materiais Pozolânicos—Determinação do Teor de Hidróxido de Cálcio Fixado—Método Chapelle Modificado. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2010.

- Moreira, M.A.N.S.; Heitmann, A.P.; Bezerra, A.C.S.; Patrício, P.S.O.; de Oliveira, L.C.A.; Castro, C.S.; de Souza, P.P. Photocatalytic performance of cementitious materials with addition of red mud and Nb2O5 particles. Constr. Build. Mater. 2020, 259, 119851. [Google Scholar] [CrossRef]

- Silva, T.H.; Castro, A.C.M.; Valente Neto, F.C.; Soares, M.M.N.S.; De Resende, D.S.; Bezerra, A.C.S. Recycling ceramic waste as a raw material in sanitary ware production. Ceramica 2019, 65, 426–431. [Google Scholar] [CrossRef]

- Morais, C.F.; Belo, B.R.; Bezerra, A.C.S.; Loura, R.M.; Porto, M.P.; Bessa, S.A.L. Thermal and mechanical analyses of colored mortars produced using Brazilian iron ore tailings. Constr. Build. Mater. 2021, 268, 121073. [Google Scholar] [CrossRef]

- ABNT NM 65; Cimento Portland—Determinação dos Tempos de Pega. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2003.

- ABNT NBR 7215; Cimento Portland—Determinação da Resistência à Compressão de Corpos de Prova Cilíndricos. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2019.

- ABNT NBR 7214; Areia Normal para Ensaio de Cimento (Especificação). Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2015.

- EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization: Brussels, Belgium, 2000.

- ABNT NBR 13279; Argamassa para Assentamento e Revestimento de Paredes e Tetos—Determinação da Resistência à Tração na Flexão e à Compressão. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2005.

- ABNT NBR 9778; Argamassa e Concreto Endurecidos—Determinação da Absorção de Água, Índice de Vazios E Massa Específica. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2005.

- ASTM International (2014) C 1260-14; Standard Test Method Potential Alkali React. Aggregates (Mortar-Bar Method). ASTM International: West Conshohocken, PA, USA, 2014.

- ABNT NBR 15577-5; Agregados—Reatividade Álcali-Agregado Parte 5: Determinação da Mitigação da Expansão em Barras de Argamassa pelo Método Acelerado. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2018.

- ABNT NNBR 15577-4; Agregados—Reatividade Álcali-Agregado Parte 4: Determinação da Expansão em Barras de Argamassa pelo Método Acelerado. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2018; ISBN 978-85-07-07583-7.

- Deepika, S.; Anand, G.; Bahurudeen, A.; Santhanam, M. Construction Products with Sugarcane Bagasse Ash Binder. J. Mater. Civ. Eng. 2017, 29, 04017189. [Google Scholar] [CrossRef]

- Athira, V.S.; Charitha, V.; Athira, G.; Bahurudeen, A. Agro-waste ash based alkali-activated binder: Cleaner production of zero cement concrete for construction. J. Clean. Prod. 2021, 286, 125429. [Google Scholar] [CrossRef]

- Jittin, V.; Minnu, S.N.; Bahurudeen, A. Potential of sugarcane bagasse ash as supplementary cementitious material and comparison with currently used rice husk ash. Constr. Build. Mater. 2020, 273, 121679. [Google Scholar] [CrossRef]

- Yadav, A.L.; Sairam, V.; Srinivasan, K.; Muruganandam, L. Synthesis and characterization of geopolymer from metakaolin and sugarcane bagasse ash. Constr. Build. Mater. 2020, 258, 119231. [Google Scholar] [CrossRef]

- Akbar, A.; Farooq, F.; Shafique, M.; Aslam, F.; Alyousef, R.; Alabduljabbar, H. Sugarcane bagasse ash-based engineered geopolymer mortar incorporating propylene fibers. J. Build. Eng. 2021, 33, 101492. [Google Scholar] [CrossRef]

- Minnu, S.N.; Bahurudeen, A.; Athira, G. Comparison of sugarcane bagasse ash with fly ash and slag: An approach towards industrial acceptance of sugar industry waste in cleaner production of cement. J. Clean. Prod. 2021, 285, 124836. [Google Scholar] [CrossRef]

- Moraes, J.C.B.; Cordeiro, G.C.; Akasaki, J.L.; Vieira, A.P.; Payá, J. Improving the reactivity of a former ground sugarcane bagasse ash produced by autogenous combustion through employment of two different additional grinding procedures. Constr. Build. Mater. 2021, 270, 121471. [Google Scholar] [CrossRef]

- Lyra, G.P.; Borrachero, M.V.; Soriano, L.; Payá, J.; Rossignolo, J.A. Comparison of original and washed pure sugar cane bagasse ashes as supplementary cementing materials. Constr. Build. Mater. 2021, 272, 122001. [Google Scholar] [CrossRef]

- Klathae, T.; Tanawuttiphong, N.; Tangchirapat, W.; Chindaprasirt, P.; Sukontasukkul, P.; Jaturapitakkul, C. Heat evolution, strengths, and drying shrinkage of concrete containing high volume ground bagasse ash with different LOIs. Constr. Build. Mater. 2020, 258, 119443. [Google Scholar] [CrossRef]

- Tavares, L.R.C.; Junior, J.F.T.; Costa, L.M.; da Silva Bezerra, A.C.; Cetlin, P.R.; Aguilar, M.T.P. Influence of quartz powder and silica fume on the performance of Portland cement. Sci. Rep. 2020, 10, 21461. [Google Scholar] [CrossRef]

- ABNT NBR 12653; Materiais pozolânicos—Requisitos. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2014.

- Cordeiro, G.C.; Barroso, T.R.; Toledo Filho, R.D. Enhancement the Properties of Sugar Cane Bagasse Ash with High Carbon Content by a Controlled Re-calcination Process. KSCE J. Civ. Eng. 2018, 22, 1250–1257. [Google Scholar] [CrossRef]

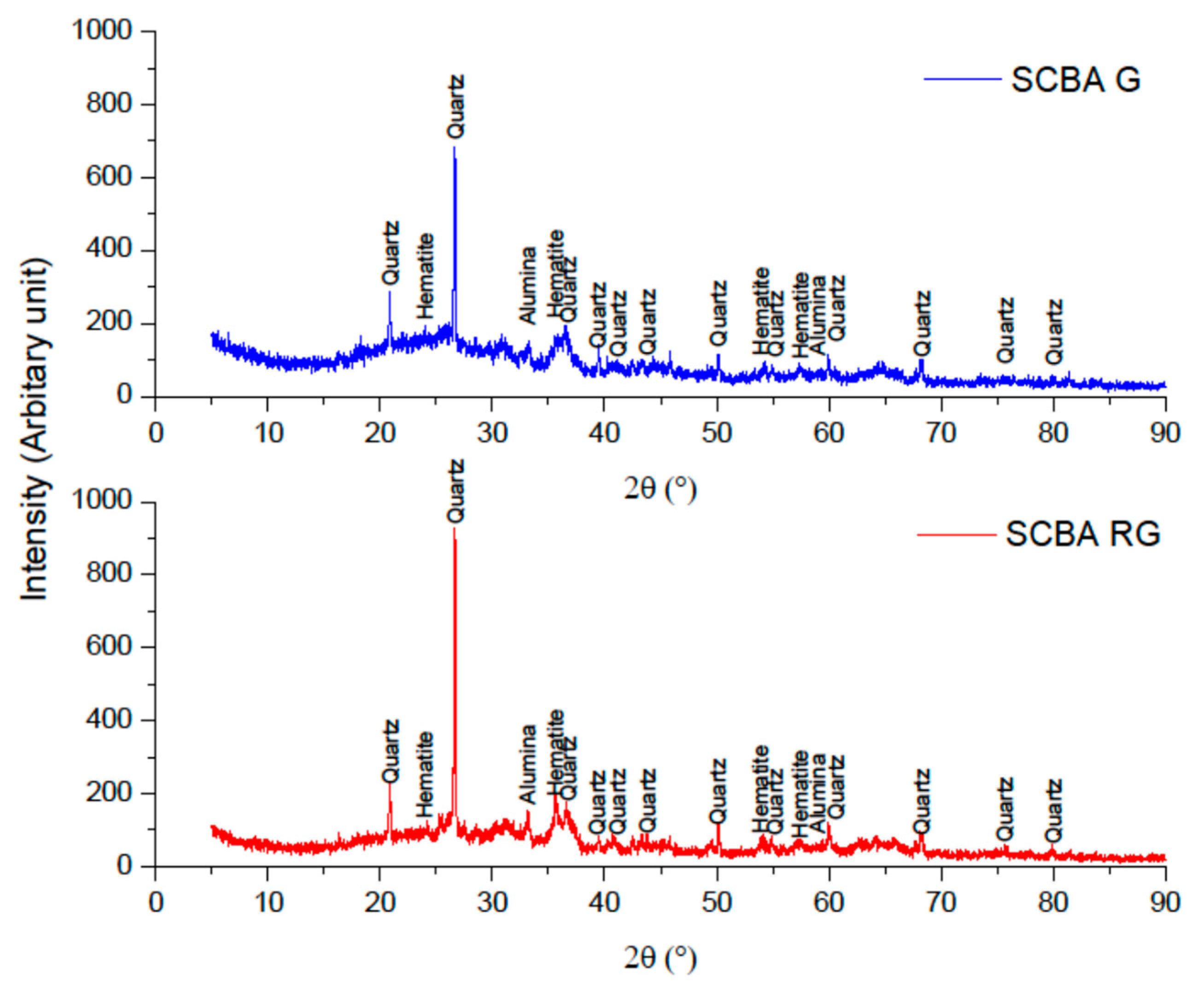

- Antao, S.M.; Hassan, I.; Wang, J.; Lee, P.L.; Toby, B.H. State-of-the-art high-resolution powder X-ray diffraction (HRPXRD) illustrated with rietveld structure refinement of quartz, sodalite, tremolite, and meionite. Can. Mineral. 2008, 46, 1501–1509. [Google Scholar] [CrossRef]

- Dan’ko, A.J.; Rom, M.A.; Sidelnikova, N.S.; Nizhankovskiy, S.V.; Budnikov, A.T.; Grin, L.A.; Kaltaev, K.S.O. Transformation of the corundum structure upon high-temperature reduction. Crystallogr. Rep. 2008, 53, 1112–1118. [Google Scholar] [CrossRef]

- Pauling, L.; Hendricks, S.B. The crystal structures of hematite and corundum. J. Am. Chem. Soc. 1925, 47, 781–790. [Google Scholar] [CrossRef]

- Andreão, P.V.; Suleiman, A.R.; Cordeiro, G.C.; Nehdi, M.L. Beneficiation of Sugarcane Bagasse Ash: Pozzolanic Activity and Leaching Behavior. Waste Biomass Valorization 2020, 11, 4393–4402. [Google Scholar] [CrossRef]

- Martins Torres, S.; Estolano de Lima, V.; de Azevedo Basto, P.; de Araújo Júnior, N.T.; de Melo Neto, A.A. Assessing the pozzolanic activity of sugarcane bagasse ash using X-ray diffraction. Constr. Build. Mater. 2020, 264, 120684. [Google Scholar] [CrossRef]

- Figueiredo, R.L.; Pavía, S. A study of the parameters that determine the reactivity of sugarcane bagasse ashes (SCBA) for use as a binder in construction. SN Appl. Sci. 2020, 2, 1515. [Google Scholar] [CrossRef]

- Katare, V.D.; Madurwar, M.V. Use of processed biomass ash as a sustainable pozzolana. Curr. Sci. 2019, 116, 741–750. [Google Scholar] [CrossRef]

- Praveenkumar, S.; Sankarasubramanian, G. Synergic Effect of Sugarcane Bagasse Ash Based Cement on High Performance Concrete Properties. Silicon 2021, 13, 2357–2367. [Google Scholar] [CrossRef]

- Bonfim, W.B.; de Paula, H.M. Characterization of different biomass ashes as supplementary cementitious material to produce coating mortar. J. Clean. Prod. 2021, 291, 125869. [Google Scholar] [CrossRef]

- Raverdy, M.; Brivot, F.; Paillére, A.M.; Dron, R. Assessment of the pozzolanic activity of the secondary constituents (in French: Appreciation de l’actvite pouzzolanique des constituants secondaires). In Proceedings of the 7th International Congress on the Chemistry of Cement, Paris, France, 1 January 1980; Volume 3, pp. 36–41. [Google Scholar]

- Jahanzaib Khalil, M.; Aslam, M.; Ahmad, S. Utilization of sugarcane bagasse ash as cement replacement for the production of sustainable concrete—A review. Constr. Build. Mater. 2021, 270, 121371. [Google Scholar] [CrossRef]

- Barbosa, F.L.; Cordeiro, G.C. Partial cement replacement by different sugar cane bagasse ashes: Hydration-related properties, compressive strength and autogenous shrinkage. Constr. Build. Mater. 2021, 272, 8–11. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Kroehong, W.; Damrongwiriyanupap, N.; Suriyo, W.; Jaturapitakkul, C. Mechanical properties, chloride resistance and microstructure of Portland fly ash cement concrete containing high volume bagasse ash. J. Build. Eng. 2020, 31, 101415. [Google Scholar] [CrossRef]

- da Silva Andrade Neto, J.; de França, M.J.S.; de Amorim Júnior, N.S.; Ribeiro, D.V. Effects of adding sugarcane bagasse ash on the properties and durability of concrete. Constr. Build. Mater. 2021, 266, 120959. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Patnaikuni, I.; Wu, Y.F. Pozzolanic reaction of sugarcane bagasse ash and its role in controlling alkali silica reaction. Constr. Build. Mater. 2017, 148, 231–240. [Google Scholar] [CrossRef]

- Abbas, S.; Sharif, A.; Ahmed, A.; Abbass, W.; Shaukat, S. Prospective of sugarcane bagasse ash for controlling the alkali-silica reaction in concrete incorporating reactive aggregates. Struct. Concr. 2020, 21, 781–793. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Pozzolanic activity and filler effect of sugar cane bagasse ash in Portland cement and lime mortars. Cem. Concr. Compos. 2008, 30, 410–418. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Tavares, L.M.; Toledo Filho, R.D. Improved pozzolanic activity of sugar cane bagasse ash by selective grinding and classification. Cem. Concr. Res. 2016, 89, 269–275. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Bahrami, N. Microstructure, strength, and durability of eco-friendly concretes containing sugarcane bagasse ash. Constr. Build. Mater. 2018, 184, 258–268. [Google Scholar] [CrossRef]

| CC = Cementitious Composite B = Basalt Q = Quartzite | Replacement (%) | Consumption of Materials (g) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Cement | Ash | Fine Aggregate (Basalt or Quartzite) | Water | ||||||

| Particle Size | |||||||||

| 0.15 mm | 0.30 mm | 0.60 mm | 1.20 mm | 2.40 mm | |||||

| CCB or CCQ | 0 | 440.0 | 0.0 | 148.5 | 247.5 | 247.5 | 247.5 | 99.0 | 206.8 |

| CCB SCBA G or CCQ SCBA G | 10 | 396.0 | 28.0 | 148.5 | 247.5 | 247.5 | 247.5 | 99.0 | 206.8 |

| 20 | 352.0 | 56.0 | 148.5 | 247.5 | 247.5 | 247.5 | 99.0 | 206.8 | |

| 30 | 308.0 | 84.0 | 148.5 | 247.5 | 247.5 | 247.5 | 99.0 | 206.8 | |

| CCB SCBA RG or CCQ SCBA RG | 10 | 396.0 | 37.6 | 148.5 | 247.5 | 247.5 | 247.5 | 99.0 | 206.8 |

| 20 | 352.0 | 75.2 | 148.5 | 247.5 | 247.5 | 247.5 | 99.0 | 206.8 | |

| 30 | 308.0 | 112.8 | 148.5 | 247.5 | 247.5 | 247.5 | 99.0 | 206.8 | |

| Portland Cement | SCBA G | SCBA RG | |

|---|---|---|---|

| Chemical composition by XRF (wt%) | |||

| SiO2 | 6.8 | 21.1 | 40.5 |

| Al2O3 | 4.9 | 13.0 | 24.8 |

| Fe2O3 | 4.5 | 7.7 | 15.0 |

| CaO | 78.3 | 2.0 | 3.8 |

| MgO | 1.5 | 1.2 | 2.3 |

| TiO2 | 0.2 | 2.3 | 4.4 |

| P2O5 | 0.0 | 1.0 | 1.6 |

| Na2O | 0.1 | 0.2 | 0.4 |

| K2O | 0.4 | 2.2 | 3.7 |

| MnO | 0 | 0.1 | 0.1 |

| LOI | 3.4 | 49.2 | 3.3 |

| Particle density (g/cm3) | 3.106 | 1.977 | 2.653 |

| Particle size distribution | |||

| D10 (µm) | 2.46 | 2.12 | 1.39 |

| D50 (µm) | 11.70 | 9.58 | 8.47 |

| D90 (µm) | 27.50 | 32.29 | 28.62 |

| Daverage (µm) | 13.66 | 13.53 | 11.88 |

| Mortar | Flow (mm) | Water (g) | Compressive Strength (MPa) | Pozzolanic Activity (%) |

|---|---|---|---|---|

| Type I “A” (Portland cement) | 225.0 | 162.7 | 43.08 | 100.0 |

| Type II “B” (SCBA G 35%) | 225.0 | 168.1 | 35.93 | 83.4 |

| Type II “C” (SCBA RG 35%) | 225.0 | 179.4 | 38.17 | 88.6 |

| Addition | Substitution (%) | Flow (mm) 1 | Cement Setting Times (min) 2 | Dry Bulk Density (g/cm³) 1 | Water Absorption (%) 1 | |

|---|---|---|---|---|---|---|

| Start | End | |||||

| CC Reference | 0 | 172.5 (0.5) 3 | 142 | 191 | 2.168 (0.003) | 6.65 (0.08) |

| CC SCBA AC | 10 | Dry mix (Disaggregated) | 139 | 183 | 2.156 (0.013) | 7.12 (0.17) |

| 20 | Dry mix (Disaggregated) | 135 | 183 | 2.133 (0.007) | 7.51 (0.25) | |

| 30 | Dry mix (Disaggregated) | 129 | 181 | 2.129 (0.008) | 7.72 (0.15) | |

| CC SCBA G | 10 | 168.0 (0.9) | 146 | 196 | 2.162 (0.005) | 7.03 (0.13) |

| 20 | 169.0 (0.0) | 143 | 195 | 2.142 (0.006) | 7.17 (0.14) | |

| 30 | 176.0 (0.5) | 141 | 191 | 2.141 (0.005) | 6.90 (0.24) | |

| CC SCBA RG | 10 | 166.5 (0.9) | 141 | 188 | 2.169 (0.010) | 6.79 (0.47) |

| 20 | 166.5 (0.0) | 143 | 191 | 2.171 (0.008) | 6.24 (0.28) | |

| 30 | 166.0 (0.0) | 143 | 190 | 2.178 (0.006) | 6.10 (0.14) | |

| Method | Mortar | Subst. (%) | Clinker Consumption per Volume (kg/m³) | SCBA Consumption per Volume (kg/m³) | Water/Binder in Volume | Water/Binder in Weight | Clinker Consumption per Strength (kg/MPa) | Binder Consumption per Strength (kg/MPa) |

|---|---|---|---|---|---|---|---|---|

| Water/binder factor fixed in volume | CC reference | 0% | 513.8 | 0.0 | 1.49 | 0.48 | 12.07 | 12.07 |

| CC SCBA AC | 10% | 462.4 | 28.5 | 1.49 | 0.50 | 11.60 | 12.31 | |

| 20% | 411.0 | 56.9 | 1.49 | 0.53 | 12.11 | 13.79 | ||

| 30% | 359.6 | 85.4 | 1.49 | 0.56 | 11.10 | 13.73 | ||

| CC SCBA G | 10% | 462.4 | 32.7 | 1.49 | 0.50 | 10.90 | 11.67 | |

| 20% | 411.0 | 65.4 | 1.49 | 0.52 | 9.89 | 11.46 | ||

| 30% | 359.6 | 98.1 | 1.49 | 0.54 | 9.06 | 11.53 | ||

| CC SCBA RG | 10% | 462.4 | 43.9 | 1.49 | 0.49 | 10.81 | 11.84 | |

| 20% | 411.0 | 87.8 | 1.49 | 0.50 | 9.07 | 11.01 | ||

| 30% | 359.6 | 131.6 | 1.49 | 0.50 | 8.31 | 11.35 |

| Method | Mortar | Subst. (%) | Clinker Consumption per Volume (kg/m³) | SCBA Consumption per Volume (kg/m³) | Water/Binder in Volume | Water/Binder in Weight | Clinker Consumption per Strength (kg/MPa) | Binder Consumption per Strength (kg/MPa) |

|---|---|---|---|---|---|---|---|---|

| Water/binder factor fixed in weight | CC reference | 0% | 514.0 | 0.0 | 1.49 | 0.48 | 12.53 | 12.53 |

| CC SCBA AC | 10% | 467.7 | 28.8 | 1.42 | 0.48 | 15.02 | 15.95 | |

| 20% | 420.4 | 58.2 | 1.36 | 0.48 | 12.02 | 13.68 | ||

| 30% | 372.0 | 88.3 | 1.29 | 0.48 | 10.54 | 13.04 | ||

| CC SCBA G | 10% | 466.8 | 33.0 | 1.44 | 0.48 | 10.57 | 11.32 | |

| 20% | 418.7 | 66.6 | 1.38 | 0.48 | 9.73 | 11.28 | ||

| 30% | 369.7 | 100.9 | 1.33 | 0.48 | 8.41 | 10.71 | ||

| CC SCBA RG | 10% | 464.2 | 44.1 | 1.47 | 0.48 | 10.30 | 11.27 | |

| 20% | 414.1 | 88.4 | 1.45 | 0.48 | 8.66 | 10.51 | ||

| 30% | 363.7 | 133.1 | 1.43 | 0.48 | 7.82 | 10.69 |

| Method | Mortar | Subst. (%) | Clinker Consumption per Volume (kg/m³) | SCBA Consumption per Volume (kg/m³) | Water/Binder in Volume | Water/Binder in Weight | Clinker Consumption per Strength (kg/MPa) | Binder Consumption per Strength (kg/MPa) |

|---|---|---|---|---|---|---|---|---|

| Fixed flow | CC reference | 0% | 503.2 | 0.0 | 1.62 | 0.52 | 11.68 | 11.68 |

| CC SCBA G | 10% | 448.0 | 31.7 | 1.69 | 0.56 | 11.58 | 12.40 | |

| 20% | 395.4 | 62.9 | 1.73 | 0.60 | 11.09 | 12.86 | ||

| 30% | 342.4 | 93.4 | 1.80 | 0.65 | 11.47 | 14.60 | ||

| CC SCBA RG | 10% | 447.5 | 42.5 | 1.70 | 0.55 | 10.54 | 11.54 | |

| 20% | 394.3 | 84.2 | 1.75 | 0.58 | 9.88 | 11.99 | ||

| 30% | 343.4 | 125.7 | 1.78 | 0.60 | 8.77 | 11.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

França, S.; Sousa, L.N.; Saraiva, S.L.C.; Ferreira, M.C.N.F.; Silva, M.V.d.M.S.; Gomes, R.C.; Rodrigues, C.d.S.; Aguilar, M.T.P.; Bezerra, A.C.d.S. Feasibility of Using Sugar Cane Bagasse Ash in Partial Replacement of Portland Cement Clinker. Buildings 2023, 13, 843. https://doi.org/10.3390/buildings13040843

França S, Sousa LN, Saraiva SLC, Ferreira MCNF, Silva MVdMS, Gomes RC, Rodrigues CdS, Aguilar MTP, Bezerra ACdS. Feasibility of Using Sugar Cane Bagasse Ash in Partial Replacement of Portland Cement Clinker. Buildings. 2023; 13(4):843. https://doi.org/10.3390/buildings13040843

Chicago/Turabian StyleFrança, Sâmara, Leila Nóbrega Sousa, Sérgio Luiz Costa Saraiva, Maria Cecília Novaes Firmo Ferreira, Marcos Vinicio de Moura Solar Silva, Romero César Gomes, Conrado de Souza Rodrigues, Maria Teresa Paulino Aguilar, and Augusto Cesar da Silva Bezerra. 2023. "Feasibility of Using Sugar Cane Bagasse Ash in Partial Replacement of Portland Cement Clinker" Buildings 13, no. 4: 843. https://doi.org/10.3390/buildings13040843

APA StyleFrança, S., Sousa, L. N., Saraiva, S. L. C., Ferreira, M. C. N. F., Silva, M. V. d. M. S., Gomes, R. C., Rodrigues, C. d. S., Aguilar, M. T. P., & Bezerra, A. C. d. S. (2023). Feasibility of Using Sugar Cane Bagasse Ash in Partial Replacement of Portland Cement Clinker. Buildings, 13(4), 843. https://doi.org/10.3390/buildings13040843