An Overview of the Application of Fiber-Reinforced Cementitious Composites in Spray Repair of Drainage Pipes

Abstract

1. Introduction

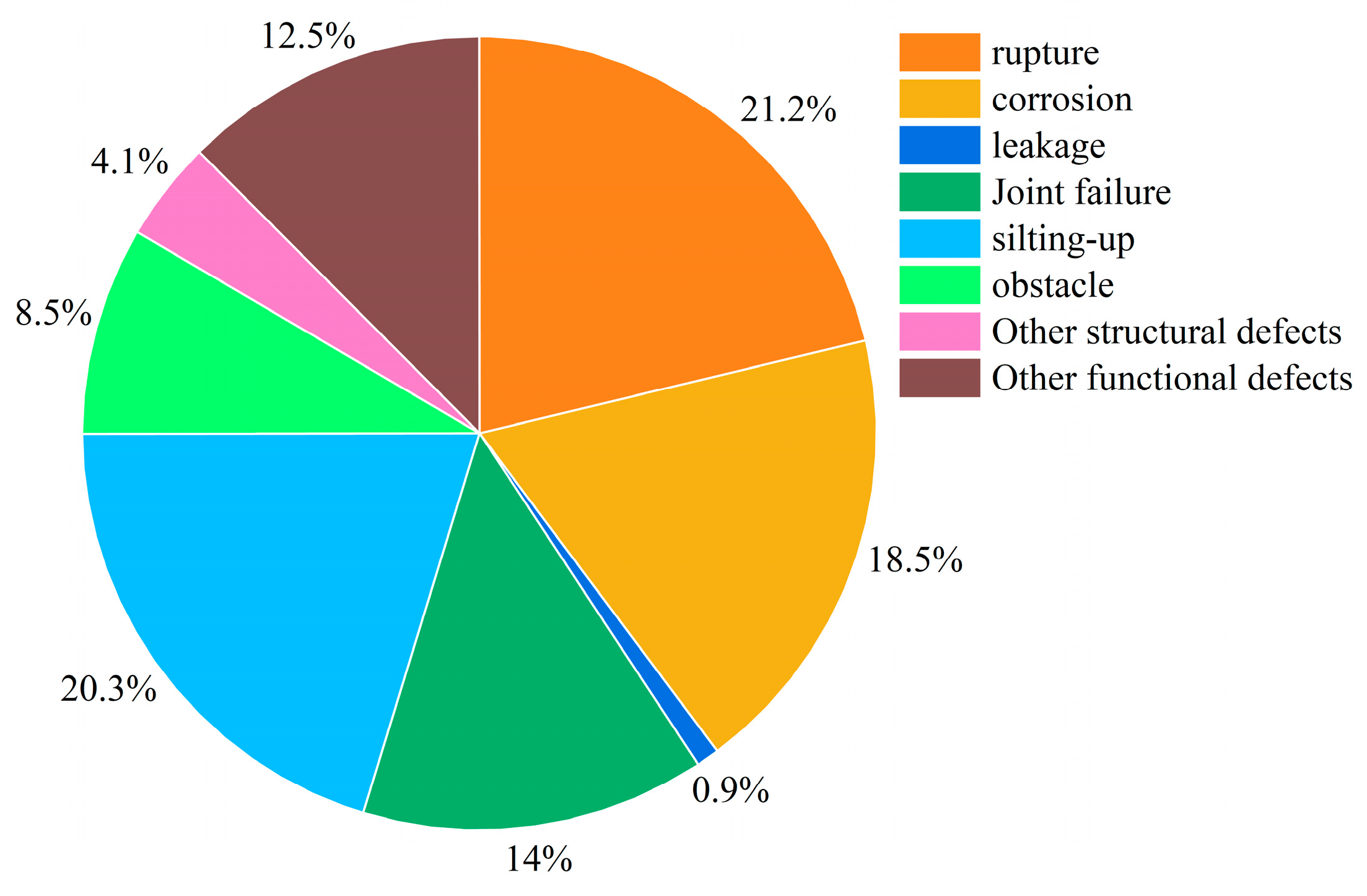

2. Survey of Drainage Pipe Defects and Repair Requirements

2.1. Service Environment and Defect Types of Drainage Pipes

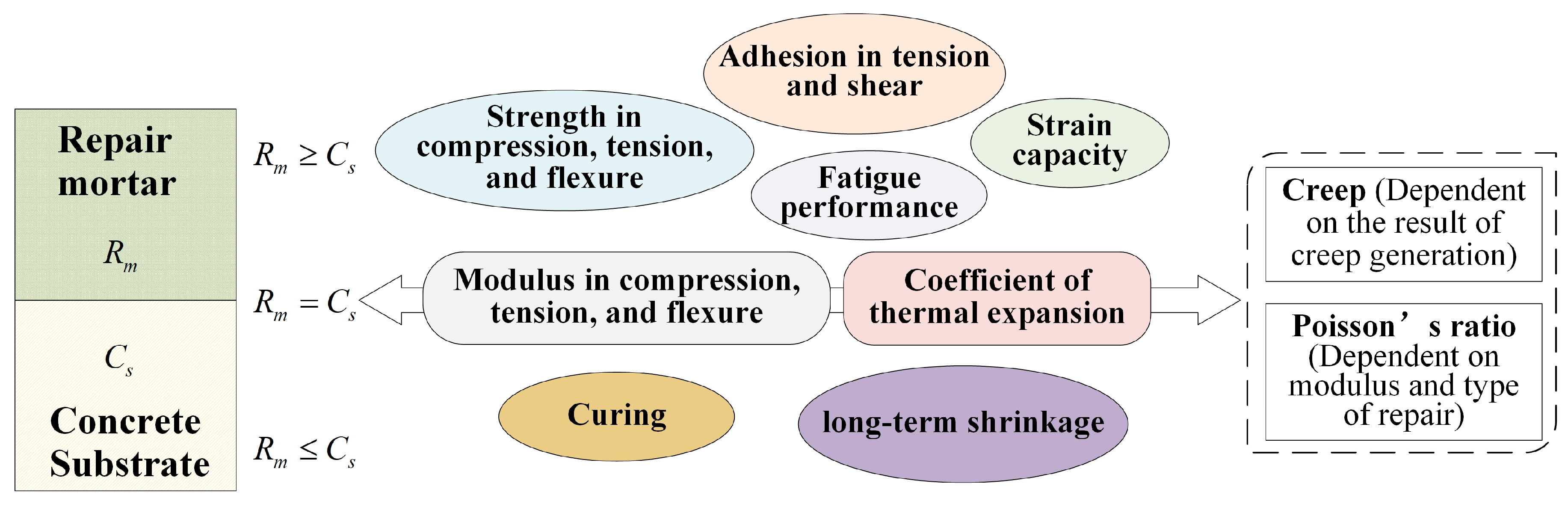

2.2. Requirements for Material Properties of Cementitious Material Spraying Method

- (1)

- Strength of materials

- (2)

- Durability

- (3)

- Interfacial bonding performance

- (4)

- Sprayability

- (5)

- Impermeability

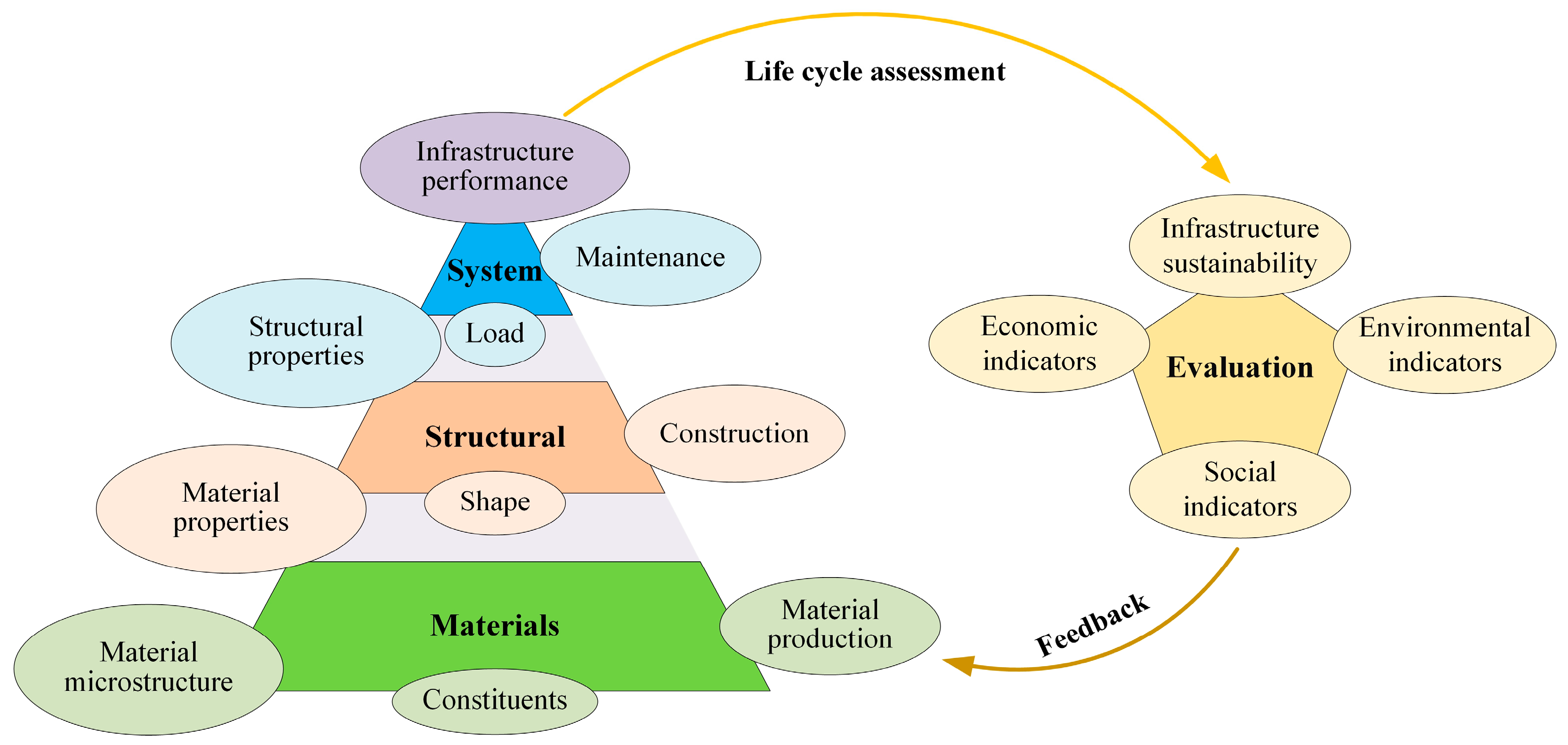

3. Research Progress of Fiber-Reinforced Cementitious Composites

3.1. Introduction to Fiber-Reinforced Cementitious Composites

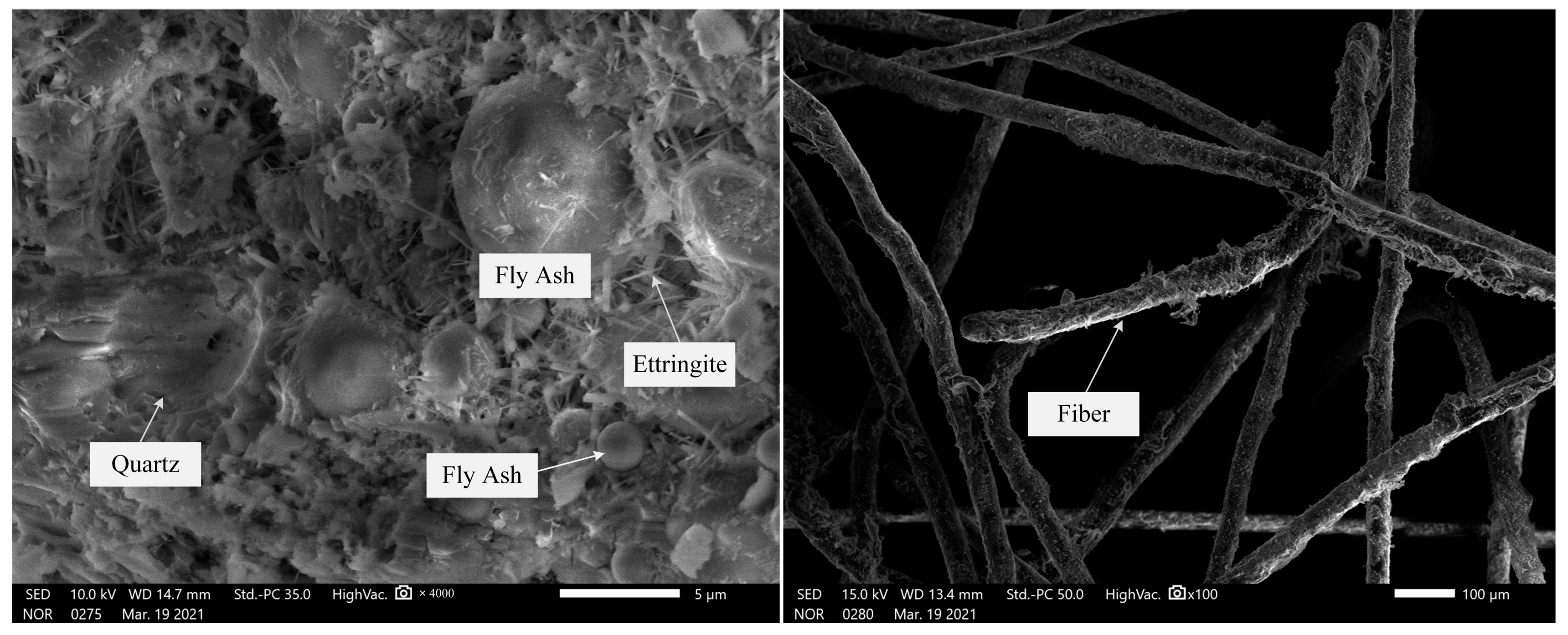

3.2. Matrix Materials

3.3. Fibers for Reinforcement

- (1)

- Improve the tensile and flexural strength, etc.

- (2)

- Improve the anticracking ability, effectively reduce cracks caused by the plastic shrinkage and dry shrinkage of the material, prevent the appearance of microcracks in the material, and delay the development of new cracks.

- (3)

- Improve the toughness and impact resistance of the material, bear the tensile stress at the location of the crack so that the material has good toughness.

- (4)

- Improve the seepage resistance, durability, etc. of the material.

3.4. Fiber–Matrix Interface

4. Performance of Repaired Structures

4.1. Structural Performance Testing of Combined Beams

4.2. Three-Edge Bearing Test

4.3. Soil–Pipe–Liner Structural Performance

5. Wall Thickness Design of Liner

6. Lining with Sprayed Cementitious Materials

7. Conclusions

- (1)

- When the method of lining with sprayed cementitious materials is used for drainage pipe repair, the repair effect is closely related to the performance of the lining material. The lining material for rehabilitation should have excellent structural strength, durability, impermeability, sprayability, etc., and can be firmly bonded and synergistically stressed with the original pipe.

- (2)

- Research on fiber-reinforced cementitious composites for spray repair should be conducted in terms of three aspects: matrix material, reinforcing fiber, and the role of the fiber–matrix interface. It is also necessary to design the material properties in conjunction with the structural stresses of the lined pipe and according to the actual needs of the structure.

- (3)

- Ultra-high-toughness cementitious composites with excellent toughness, structural strength, and durability in the drainage pipe spray repair have gradually begun to be applies. The use of ultra-high-toughness cementitious composites is conducive to the repair of the structure to bear the load and improve the overall service life of the structure.

- (4)

- Although there have been a large number of structural performance tests and theoretical pieces of research, there is no fully unified lining wall thickness design method. A buried pipeline–nonexcavation repair lining system is a secondary force structure; there has been no research in this area and so further theoretical and experimental work is needed.

- (5)

- Fiber-reinforced cementitious composite spraying technology can be used for the repair of drainage pipes of various section shapes and sizes, with flexible construction and reliable repair results, and can lay reinforcement mesh and design wall thicknesses as required, which has obvious advantages when used for the nonexcavation repair of urban drainage pipes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, B.; Yu, W.; Xie, Y.; Fang, H.; Du, X.; Wang, N.; Zhai, K.; Wang, D.; Chen, X.; Du, M.; et al. Trenchless Rehabilitation of Sewage Pipelines from the Perspective of the Whole Technology Chain: A State-of-the-Art Review. Tunn. Undergr. Space Technol. 2023, 134, 105022. [Google Scholar] [CrossRef]

- Najafi, M.; Gokhale, S.; Calderón, D.R.; Ma, B. Trenchless Technology: Pipeline and Utility Design, Construction, and Renewal; McGraw-Hill Education: New York, NY, USA, 2021; ISBN 1-260-45873-3. [Google Scholar]

- Zhao, Y.; Ma, B.; Ariaratnam, S.T.; Yan, X.; Xiang, W.; Zhu, Z.; Li, Z.; Moghbel Esfahani, M. Buckling Behaviour of Internal Stiffened Thin-Walled Stainless Steel Liners under External Constraints. Tunn. Undergr. Space Technol. 2022, 129, 104685. [Google Scholar] [CrossRef]

- He, C.; Yan, X.; Ma, B.; Zhao, Y. Experimental and numerical simulation of formed-in-place pipe liner for repairing water mains with void. Tunn. Undergr. Space Technol. 2022, 130, 104752. [Google Scholar] [CrossRef]

- Zeng, Z.; Yan, X.; Xiang, W.; Zhao, Y.; Ariaratnam, S.T. Buckling Behavior of Loosely Fitted Formed-In-Place Pipe Liner in Circular Host Pipe under External Pressure. Appl. Sci. 2023, 13, 679. [Google Scholar] [CrossRef]

- Ma, B.S. Trenchless Pipeline Rehabilitation and Renewal Technology; China Communications Press: Beijing, China, 2014; ISBN 978-7-114-11364-2. [Google Scholar]

- Zhu, Z.; Zhang, P.; Ma, B.; Zeng, C.; Zhao, Y.; Wang, F.; Li, Z.; Xiang, W.; Ariaratnam, S.T.; Yan, X. Quantitative model for residual bearing capacity of corroded reinforced concrete pipe based on failure mode. Tunn. Undergr. Space Technol. 2022, 129, 104675. [Google Scholar] [CrossRef]

- Yahong, Z.; Sheng, H.; Baosong, M.; Cong, Z.; Xuefeng, Y.; Zhongsen, T.; Han, L.; Caiying, D. Experiment and Evaluation Model of Liner Design for Renewal of Deteriorated Reinforced Concrete Pipes Utilizing Cured-in-Place-Pipe Technology. Tunn. Undergr. Space Technol. 2023, 132, 104866. [Google Scholar] [CrossRef]

- Ma, B.S.; Najafi, M. Development and Applications of Trenchless Technology in China. Tunn. Undergr. Space Technol. 2008, 23, 476–480. [Google Scholar] [CrossRef]

- Serajiantehrani, R.; Najafi, M.; Malek Mohammadi, M.; Kaushal, V.; Jalalediny Korky, S. Construction Cost Analysis of Trenchless Cured-in-Place Pipe and Spray-Applied Pipe Linings Rehabilitation Methods in Gravity Conveyance Conduits. In Proceedings of the Pipelines 2021, virtually, 3–6 August 2021; pp. 210–220. [Google Scholar]

- Yan, X.; Deng, C.; Zhao, Y.; Liu, H.; Mei, S. Mechanical Performance Study of Pipe-Liner Composite Structure Based on the Digital Image Correlation Method. IEEE Trans. Instrum. Meas. 2022, 72, 1–12. [Google Scholar] [CrossRef]

- Walker, K.R. Five Trenchless Rehab Projects Save Failing Large Diameter Combined Sewer Structures in Albany, NY. In Proceedings of the Pipelines 2020, San Antonio, TX, USA, 6 August 2020; American Society of Civil Engineers: Reston, VA, USA; pp. 427–432. [Google Scholar]

- Shook, W.E.; Arold, R.M.; Shepherd, R.M. Trenchless Rehabilitation Saves Grottoes, VA, Culverts—And Money—Without Disrupting Traffic. In Proceedings of the Pipelines 2015, Baltimore, ML, USA, 17 August 2015; American Society of Civil Engineers: Reston, VA, USA; pp. 171–179. [Google Scholar]

- Zhao, Y.H.; Ma, B.S.; Ariaratnam, S.T.; Zeng, C.; Yan, X.F.; Wang, F.Z.; Wang, T.Y.; Zhu, Z.H.; He, C.L.; Shi, G.P.; et al. Structural Performance of Damaged Rigid Pipe Rehabilitated by Centrifugal Spray on Mortar Liner. Tunn. Undergr. Space Technol. 2021, 116, 104117. [Google Scholar] [CrossRef]

- Wang, F.Z.; Zeng, C.; Ma, B.S.; Gong, C.K.; Liao, B.Y.; Zhao, Y.H.; Ma, C.; Kong, Y.Z. Experimental Investigations of a Tunnel Lining Segment Strengthened by In Situ Spraying Mortar. Appl. Sci. 2022, 12, 3722. [Google Scholar] [CrossRef]

- Wang, T.; Zeng, C. Study of Cement-Based Superhydrophobic Composite Coating: New Option for Water Drainage Pipeline Rehabilitation. Materials 2020, 13, 5004. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Wang, T.; Wang, Y.; Li, V.C. Trenchless Rehabilitation for Concrete Pipelines of Water Infrastructure: A Review from the Structural Perspective. Cem. Concr. Compos. 2021, 123, 104193. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, D.; Li, V.C. Centrifugally Sprayed Engineered Cementitious Composites: Rheology, Mechanics, and Structural Retrofit for Concrete Pipes. Cem. Concr. Compos. 2022, 129, 104473. [Google Scholar] [CrossRef]

- Spiesz, P.; Hunger, M. Structural Ultra-Lightweight Concrete–from Laboratory Research to Field Trials. In Proceedings of the 11th High Performance Concrete Conference, Tromsø, Norway, 6–8 March 2017; pp. 1–10. [Google Scholar]

- Valikhani, A.; Jahromi, A.J.; Mantawy, I.M.; Azizinamini, A. Experimental Evaluation of Concrete-to-UHPC Bond Strength with Correlation to Surface Roughness for Repair Application. Constr. Build. Mater. 2020, 238, 117753. [Google Scholar] [CrossRef]

- Kong, Y.Z. Study and Application of Cast In-Situ Method for Pipeline and Manhole Trenchless Rehabilitation. Doctoral Thesis, China University of Geosciences, Wuhan, China, 2017. [Google Scholar]

- Zhao, Y.; Ma, B.; Zhang, H.F. Mechanical Behavior and Calculation Method of Interface between Host Pipeline and Lining. J. Harbin Inst. Technol. 2020, 52, 167–174. [Google Scholar] [CrossRef]

- Morgan, D.R. Compatibility of Concrete Repair Materials and Systems. Constr. Build. Mater. 1996, 10, 57–67. [Google Scholar] [CrossRef]

- Kosednar, J.; Mailvaganam, N.P. Selection and Use of Polymer-Based Materials in the Repair of Concrete Structures. J. Perform. Constr. Facil. 2005, 19, 229–233. [Google Scholar] [CrossRef]

- Pattnaik, R. Investigation into Compatibility between Repair Material and Substrate Concrete Using Experimental and Finite Element Methods. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2006. [Google Scholar]

- Su, N.; Lou, L.; Amirkhanian, A.; Amirkhanian, S.N.; Xiao, F. Assessment of Effective Patching Material for Concrete Bridge Deck -A Review. Constr. Build. Mater. 2021, 293, 123520. [Google Scholar] [CrossRef]

- Zhang, H.F. Theoretical and Experimental Study on Structural Performance of the Sprayed-On Cement Mortor Liners Rehabilitaing Precast Concrete Drainage Pipe. Ph.D. Thesis, China University of Geosciences, Wuhan, China, 2019. [Google Scholar]

- Piratla, K.R.; Jin, H.; Yazdekhasti, S. A Failure Risk-Based Culvert Renewal Prioritization Framework. Infrastruct. Base 2019, 4, 43. [Google Scholar] [CrossRef]

- Najafi, M.; Bhattachar, D.V. Development of a Culvert Inventory and Inspection Framework for Asset Management of Road Structures. J. King Saud Univ. Sci. 2011, 23, 243–254. [Google Scholar] [CrossRef]

- Tang, Y.; Cai, Y.; Feng, D. Full-Scale Experiment and Ultimate Bearing Capacity Assessment of Reinforced Concrete Drainage Culverts with Defects. KSCE J. Civ. Eng. 2021, 25, 4348–4358. [Google Scholar] [CrossRef]

- Huang, F.; Wang, N.; Fang, H.; Liu, H.; Pang, G. Research on 3D Defect Information Management of Drainage Pipeline Based on BIM. Buildings 2022, 12, 228. [Google Scholar] [CrossRef]

- Trott, J. Buried Rigid Pipes: Structural Design of Pipelines; Taylor & Francis: Abingdon, UK, 1984; ISBN 1-280-40637-2. [Google Scholar]

- Ballinger, C.A.; Drake, P.G. Culvert Repair Practices Manual: Volume I; Federal Highway Administration, Office of Engineering and Highway Operations R&D: McLean, VA, USA, 1995; Volume 1.

- Parker, C.D. Mechanics of Corrosion of Concrete Sewers by Hydrogen Sulfide. Sewage Ind. Wastes 1951, 23, 1477–1485. [Google Scholar]

- Grengg, C.; Mittermayr, F.; Ukrainczyk, N.; Koraimann, G.; Kienesberger, S.; Dietzel, M. Advances in Concrete Materials for Sewer Systems Affected by Microbial Induced Concrete Corrosion: A Review. Water Res. 2018, 134, 341–352. [Google Scholar] [CrossRef]

- Wu, M.; Wang, T.; Wu, K.; Kan, L. Microbiologically Induced Corrosion of Concrete in Sewer Structures: A Review of the Mechanisms and Phenomena. Constr. Build. Mater. 2020, 239, 117813. [Google Scholar] [CrossRef]

- Li, V.C. Engineered Cementitious Composites (ECC): Bendable Concrete for Sustainable and Resilient Infrastructure; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 978-3-662-58437-8. [Google Scholar]

- T/CECS 717-2020; The Specification for Construction and Acceptance of Trenchless Repair Engineering of Urban Drainage Pipeline. China Architecture and Building Press: Beijing, China, 2020.

- Emberson, N.K.; Mays, G.C. Significance of Property Mismatch in the Patch Repair of Structural Concrete Part 1: Properties of Repair Systems. Mag. Concr. Res. 1990, 42, 147–160. [Google Scholar] [CrossRef]

- McAlpine, G. Structural Rehabilitation of Semi Elliptical Concrete Sewers. In Pipelines 2006: Service to the Owner; American Society Civil Engineers: Reston, VA, USA, 2006; pp. 1–7. [Google Scholar]

- Wang, T.; Zhao, Y.; Ma, B.; Zeng, C. Durability Study on High-Performance Fiber-Reinforced Mortar under Simulated Wastewater Pipeline Environment. Materials 2021, 14, 3781. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, X.; Li, Y.; Yang, H.; Tang, S. Influences of MgO and PVA fiber on the abrasion and cracking resistance, pore structure and fractal features of hydraulic concrete. Fractal Fract. 2022, 6, 674. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Yang, H.; Wang, Y.; Tang, S. Comparison of fly ash, PVA fiber, MgO and shrinkage-reducing admixture on the frost resistance of face slab concrete via pore structural and fractal analysis. Fractals 2021, 29, 2140002. [Google Scholar] [CrossRef]

- Wang, L.; He, T.; Zhou, Y.; Tang, S.; Tan, J.; Liu, Z.; Su, J. The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr. Build. Mater. 2021, 282, 122706. [Google Scholar] [CrossRef]

- Xie, Q.; Li, H.B.; Wang, H.M. Effect of Mineral Admixtures on the Performance of Cement Mortar. J. China Foreign Highw. 2021, 41, 291–294. [Google Scholar] [CrossRef]

- Lepech, M.D.; Li, V.C. Water Permeability of Engineered Cementitious Composites. Cem. Concr. Compos. 2009, 31, 744–753. [Google Scholar] [CrossRef]

- Li, V.C.; Kong, H.; Chan, Y.-W. Development of Self-Compacting Engineered Cementitious Composites. ASCE Mater. Civ. Eng. 1998, 2, 46–59. [Google Scholar]

- Kim, Y.Y.; Fischer, G.; Lim, Y.M.; Li, V.C. Mechanical Performance of Sprayed Engineered Cementitious Composite Using Wet-Mix Shotcreting Process for Repair Applications. ACI Mater. J. 2004, 101, 42–49. [Google Scholar]

- Azmee, N.M.; Shafiq, N. Ultra-High Performance Concrete: From Fundamental to Applications. Case Stud. Constr. Mater. 2018, 9, e00197. [Google Scholar] [CrossRef]

- Akeed, M.H.; Qaidi, S.; Ahmed, H.U.; Faraj, R.H.; Mohammed, A.S.; Emad, W.; Tayeh, B.A.; Azevedo, A.R.G. Ultra-High-Performance Fiber-Reinforced Concrete. Part I: Developments, Principles, Raw Materials. Case Stud. Constr. Mater. 2022, 17, e01290. [Google Scholar] [CrossRef]

- Li, V.C. Engineered Cementitious Composites–Tailored Composites through Micromechanical Modeling. In Fiber Reinforced Concrete: Present and the Future; Canadian Society of Civil Engineers: Montreal, QC, Canada, 1998. [Google Scholar]

- Wu, H.-L.; Zhang, D.; Ellis, B.R.; Li, V.C. Development of Reactive MgO-Based Engineered Cementitious Composite (ECC) through Accelerated Carbonation Curing. Constr. Build. Mater. 2018, 191, 23–31. [Google Scholar] [CrossRef]

- Herbert, E.; Li, V. Self-Healing of Microcracks in Engineered Cementitious Composites (ECC) Under a Natural Environment. Materials 2013, 6, 2831–2845. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q.; Gu, C.; Su, H.; Li, V. Self-Healing of Microcracks in Engineered Cementitious Composites under Sulfate and Chloride Environment. Constr. Build. Mater. 2017, 153, 948–956. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q.; Gu, C.; Su, H.; Li, V. Influence of Microcrack Self-Healing Behavior on the Permeability of Engineered Cementitious Composites. Cem. Concr. Compos. 2017, 82, 14–22. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, D.; Zhu, H.; Ma, B.; Li, V.C. Durability and Self-Healing of Engineered Cementitious Composites Exposed to Simulated Sewage Environments. Cem. Concr. Compos. 2022, 129, 104500. [Google Scholar] [CrossRef]

- Li, Q.; Yin, X.; Huang, B.; Zhang, Y.; Xu, S. Strengthening of the Concrete Face Slabs of Dams Using Sprayable Strain-Hardening Fiber-Reinforced Cementitious Composites. Front. Struct. Civ. Eng. 2022, 16, 145–160. [Google Scholar] [CrossRef]

- Rokugo, K.; Kunieda, M.; Lim, S.C.; Co, D. Patching Repair with ECC on Cracked Concrete Surface. Proc. ConMat 2005, 5, 22–24. [Google Scholar]

- Huang, B.T.; Li, Q.H.; Xu, S.L.; Zhou, B. Strengthening of Reinforced Concrete Structure Using Sprayable Fiber-Reinforced Cementitious Composites with High Ductility. Compos. Struct. 2019, 220, 940–952. [Google Scholar] [CrossRef]

- Li, V.C. Integrated Structures and Materials Design. Mater. Struct. 2007, 40, 387–396. [Google Scholar] [CrossRef]

- Committee, J.-D. DFRCC Terminology and Application Concepts. J. Adv. Concr. Technol. 2003, 1, 335–340. [Google Scholar] [CrossRef]

- Wang, T. Study on Engineered Cementitious Composites Used in Trenchless Pipeline Rehabilitation. Ph.D. Thesis, China University of Geosciences, Wuhan, China, 2022. [Google Scholar]

- Chindaprasirt, P.; Homwuttiwong, S.; Sirivivatnanon, V. Influence of Fly Ash Fineness on Strength, Drying Shrinkage and Sulfate Resistance of Blended Cement Mortar. Cem. Concr. Res 2004, 34, 1087–1092. [Google Scholar] [CrossRef]

- Yang, E.-H. Designing Added Functions in Engineered Cementitious Composites. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2008. [Google Scholar]

- Zheng, Y.; Cui, Y.; Wang, W.; Zhang, Y.; Liu, S. Study on optimal mix proportion and mechanical property experiment of PVA-ECC. J. Hunan Inst. Eng. Nat. Sci. Ed. 2014, 24, 69–72. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Kong, H.J.; Li, V.C. Design of Engineered Cementitious Composite Suitable for Wet-Mixture Shotcreting. ACI Mater. J. 2003, 100, 511–518. [Google Scholar] [CrossRef]

- Zhu, H.; Yu, K.Q.; Li, V.C. Sprayable Engineered Cementitious Composites (ECC) Using Calcined Clay Limestone Cement (LC3) and PP Fiber. Cem. Concr. Comp. 2021, 115, 103868. [Google Scholar] [CrossRef]

- Izadifar, M.; Ukrainczyk, N.; Salah Uddin, K.M.; Middendorf, B.; Koenders, E. Dissolution of Portlandite in Pure Water: Part 2 Atomistic Kinetic Monte Carlo (KMC) Approach. Materials 2022, 15, 1442. [Google Scholar] [CrossRef] [PubMed]

- Izadifar, M.; Ukrainczyk, N.; Salah Uddin, K.M.; Middendorf, B.; Koenders, E. Dissolution of β-C2S Cement Clinker: Part 2 Atomistic Kinetic Monte Carlo (KMC) Upscaling Approach. Materials 2022, 15, 6716. [Google Scholar] [CrossRef] [PubMed]

- Abrishambaf, A.; Pimentel, M.; Nunes, S. Influence of Fibre Orientation on the Tensile Behaviour of Ultra-High Performance Fibre Reinforced Cementitious Composites. Cem. Concr. Res. 2017, 97, 28–40. [Google Scholar] [CrossRef]

- Huang, H.H.; Gao, X.J.; Teng, L. Fiber Alignment and Its Effect on Mechanical Properties of UHPC: An Overview. Constr. Build. Mater. 2021, 296, 123741. [Google Scholar] [CrossRef]

- Liu, J.; Tang, J.; Han, F. Toughening and crack prevention of modern concrete: Mechanisms and applications. China Civ. Eng. J. 2021, 54, 47–54+63. [Google Scholar] [CrossRef]

- Lai, Y.Y.; Zhang, Q.B.; Tang, J.W. Experimental Study on the Effect of Polypropylene Fiber on the Flow of Cement Mortar. Sichuan Cem. 2017, 3, 12–13. [Google Scholar]

- Pereira, E.B.; Fischer, G.; Barros, J.A.O. Direct Assessment of Tensile Stress-Crack Opening Behavior of Strain Hardening Cementitious Composites (SHCC). Cem. Concr. Res. 2012, 42, 834–846. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, X.; Ji, H.; Zhang, C. Carbonation Model and Prediction of Polyvinyl Alcohol Fiber Concrete with Fiber Length and Content Effects. Int. J. Concr. Struct. Mater. 2022, 16, 9. [Google Scholar] [CrossRef]

- Li, V.C.; Stang, H. Interface Property Characterization and Strengthening Mechanisms in Fiber Reinforced Cement Based Composites. Adv. Cem. Based Mater. 1997, 6, 1–20. [Google Scholar] [CrossRef]

- Wölfel, E.; Brünig, H.; Curosu, I.; Mechtcherine, V.; Scheffler, C. Dynamic Single-Fiber Pull-Out of Polypropylene Fibers Produced with Different Mechanical and Surface Properties for Concrete Reinforcement. Materials 2021, 14, 722. [Google Scholar] [CrossRef]

- Li, V.C.; Wu, C.; Wang, S.; Ogawa, A.; Saito, T. Interface Tailoring for Strain-Hardening Polyvinyl Alcohol-Engineered Cementitious Composite (PVA-ECC). Mater. J. 2002, 99, 463–472. [Google Scholar]

- Wu, H.-C.; Li, V.C. Fiber/Cement Interface Tailoring with Plasma Treatment. Cem. Concr. Compos. 1999, 21, 205–212. [Google Scholar] [CrossRef]

- Tosun, K.; Felekoglu, B.; Baradan, B. Multiple Cracking Response of Plasma Treated Polyethylene Fiber Reinforced Cementitious Composites under Flexural Loading. Cem. Concr. Compos. 2012, 34, 508–520. [Google Scholar] [CrossRef]

- Stang, H.; Li, Z.; Shah, S.P. Pullout Problem: Stress versus Fracture Mechanical Approach. J. Eng. Mech. 1990, 116, 2136–2150. [Google Scholar] [CrossRef]

- Lin, Z.; Kanda, T.; Li, V.C. On Interface Property Characterization and Performance of Fiber Reinforced Cementitious Composites. Concrete Sci. Eng. 1999, 1, 173–184. [Google Scholar]

- Becerril García, D.; Moore, I.D. Performance of Deteriorated Corrugated Steel Culverts Rehabilitated with Sprayed-on Cementitious Liners Subjected to Surface Loads. Tunn. Undergr. Space Technol. 2015, 47, 222–232. [Google Scholar] [CrossRef]

- Riahi, E.; Yu, X.; Najafi, M.; Sever, V.F. D-Load Strength of Concrete Pipes with Epoxy Linings. J. Pipeline Syst. Eng. Pract. 2019, 10, 04019030. [Google Scholar] [CrossRef]

- Lim, Y.M.; Li, V.C. Durable Repair of Aged Infrastructures Using Trapping Mechanism of Engineered Cementitious Composites. Cem. Concr. Compos. 1997, 19, 373–385. [Google Scholar] [CrossRef]

- Wang, N.; Xu, S. Flexural response of reinforced concrete beams strengthened with post-poured ultra high toughness cementitious composites layer. J. Cent. South Univ. Technol. 2011, 18, 932–939. [Google Scholar] [CrossRef]

- Kamada, T.; Li, V.C. The Effects of Surface Preparation on the Fracture Behavior of ECC/Concrete Repair System. Cem. Concr. Compos. 2000, 22, 423–431. [Google Scholar] [CrossRef]

- Hui-cai, X.; Geng-ying, L.; Guang-jing, X. Microstructure Model of the Interfacial Zone between Fresh and Old Concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2002, 17, 64–68. [Google Scholar] [CrossRef]

- Qian, J.S.; You, C.; Wang, Q.Z.; Wang, H.T.; Jia, X.W. A Method for Assessing Bond Performance of Cement-Based Repair Materials. Constr. Build. Mater. 2014, 68, 307–313. [Google Scholar] [CrossRef]

- Xu, S.L.; Mu, F.J.; Wang, J.Y.; Li, W.P. Experimental Study on the Interfacial Bonding Behaviors between Sprayed UHTCC and Concrete Substrate. Constr. Build. Mater. 2019, 195, 638–649. [Google Scholar] [CrossRef]

- Cheng, H. Experimental Research on Adherence Property of Fresh Fiber Reinforced Concrete to Old Concrete. Ph.D. Thesis, Zhengzhou University, Zhengzhou, China, 2007. [Google Scholar]

- Wang, B.; Xu, S.L.; Liu, F. Evaluation of Tensile Bonding Strength between UHTCC Repair Materials and Concrete Substrate. Constr. Build. Mater. 2016, 112, 595–606. [Google Scholar] [CrossRef]

- Yang, J.; Chen, R.; Zhang, Z.; Zou, Y.; Zhou, J.; Wang, W. Effects of planting bar parameters on the shear resistance of UHPC-stone interface. China Civ. Eng. J. 2022, 55, 62–78. [Google Scholar] [CrossRef]

- Najafi, M.; Sever, F. Structural Capabilities of No-Dig Manhole Rehabilitation Products; WERF Report INFR1R12. 2015. Available online: https://cfpub.epa.gov/si/si_public_record_report.cfm?Lab=NRMRL&dirEntryId=332730 (accessed on 10 February 2023).

- Kang, J.S.; Davidson, J.S. Structural Effects of Concrete Lining for Concrete-Lined Corrugated Steel Pipes. Struct. Infrastruct. Eng. 2013, 9, 130–140. [Google Scholar] [CrossRef]

- Fan, W.; Zhuge, Y.; Ma, X.; Chow, C.W.K.; Gorjian, N.; Li, D.D. Retrofitting of Damaged Reinforced Concrete Pipe with CAC-GGBFS Blended Strain Hardening Cementitious Composite (SHCC). Thin Wall Struct. 2022, 176, 109351. [Google Scholar] [CrossRef]

- Entezarmahdi, A.; Najafi, M.; Sever, F. Testing and Analysis of No-Dig Structural Manhole Rehabilitation Materials. In Pipelines 2014: From Underground to the Forefront of Innovation and Sustainability; ASCE: Reston, VA, USA, 2014; pp. 1680–1693. [Google Scholar]

- Law, T.M.; Moore, I.D. Laboratory Investigation on the Static Response of Repaired Sewers. In Pipelines 2002: Beneath Our Feet: Challenges and Solutions; ASCE: Reston, VA, USA, 2002; pp. 1–13. [Google Scholar]

- ASCE Emerging Concepts for the Design of Pipeline Renewal Systems; ASCE: Reston, VA, USA, 2007.

- Moore, I.D.; García, B.D. Measured Response of Two Deteriorated Metal Culverts Repaired with Sprayed Cementitious Liners; Report on Performance of the GeoSpray Liner System for the 407 ETR; 407 ETR: Reston, VA, USA, 2013. [Google Scholar]

- Moore, I.D.; Garcia, D.B. Ultimate Strength Testing of Two Deteriorated Metal Culverts Repaired with Spray-On Cementitious Liners. Transp. Res. Rec. 2015, 2522, 139–147. [Google Scholar] [CrossRef]

- Zhang, X.J.; Fang, H.Y.; Hu, Q.F.; Ma, B.S.; Hu, S.W.; Du, M.R.; Du, X.M.; Yang, K.J.; Li, B.; Shi, M.S. Mechanical Performance of Corroded Reinforced Concrete Pipelines Rehabilitated with Sprayed-on Cementitious Liners Subjected to Combined Loads. Tunn. Undergr. Space Technol. 2022, 120, 104266. [Google Scholar] [CrossRef]

- Zhang, X.J.; Fang, H.Y.; Shi, M.S.; Du, M.R.; Yang, K.J.; Li, B.; Zhang, Z.Y. Structural Performance of Corroded Concrete Pipes after Mortar Spraying Rehabilitation under Traffic Load. Tunn. Undergr. Space Technol. 2022, 128, 104620. [Google Scholar] [CrossRef]

- Tetreault, J.; Hoult, N.A.; Moore, I.D. Pre- and Post-Rehabilitation Behaviour of a Deteriorated Horizontal Ellipse Culvert. Can. Geotech. J. 2018, 55, 329–342. [Google Scholar] [CrossRef]

- Spasojevic, A.D.; Mair, R.J.; Gumbel, J.E. Centrifuge Modelling of the Effects of Soil Loading on Flexible Sewer Liners. Geotechnique 2007, 57, 331–341. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Cao, Z. Size Effect in Brittle Failure of Unreinforced Pipes. J. Proc. 1986, 83, 369–373. [Google Scholar]

- Matthews, J.C.; Condit, W.; Vaidya, S.; Stowe, R. Performance Evaluation of an Innovative Fiber Reinforced Geopolymer Spray-Applied Mortar for Large Diameter Wastewater Main Rehabilitation in Houston, Texas; US Environmental Protection Agency: Washington, DC, USA, 2014.

- Royer, J.R.; Allouche, E. Laboratory Testing and Analysis of Geopolymer Pipe-Lining Technology for Rehabilitation of Sewer & Stormwater Conduits; NASTT: Bothell, WA, USA, 2016. [Google Scholar]

- Watkins, R.K.; Anderson, L.R. Structural Mechanics of Buried Pipes; CRC Press: Boca Raton, FL, USA, 1999; ISBN 978-0-429-12977-3. [Google Scholar]

- Young, W.C.; Budynas, R.G.; Sadegh, A.M. Roark’s Formulas for Stress and Strain; McGraw-Hill Education: New York, NY, USA, 2012; ISBN 0-07-174247-6. [Google Scholar]

- ASTM F1216; Standard Practice for Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube. ASTM International: West Conshohocken, PA, USA, 2016; Volume ASTM F1216.

- Zihai, S.; Masaaki, N.; Yoshifumi, T. Structural Analysis and Renovation Design of Ageing Sewers: Design Theories and Case Studies; De Gruyter Open Poland: Berlin, Germany, 2016; ISBN 978-3-11-047174-8. [Google Scholar]

| Parameter | H-70 | MS-10000 | PL-8000 | |

|---|---|---|---|---|

| Compressive strength (MPa) | 24 h | ≥25 | 20.68 | 20.7 |

| 28 d | ≥65 | 70 | 55 | |

| Flexural strength (MPa) | 24 h | ≥3.5 | 2.76 | 4.1 |

| 28 d | ≥9.5 | 10.34 | 7.4 | |

| Elastic modulus (GPa) | ≥30 | 36 | 36 | |

| Tensile strength (MPa) | - | 5.52 | 4.7 | |

| Setting time (min) | Initial setting | ≤120 | ≤120 | ≤120 |

| Final setting | ≤360 | ≤240 | ≤240 | |

| Parameter | Specifications | |

|---|---|---|

| Setting time (min) | Initial setting | ≤120 |

| Final setting | ≤360 | |

| Compressive strength (MPa) | 24 h | ≥25 |

| 28 d | ≥65 | |

| Flexural strength (MPa) | 24 h | ≥3.5 |

| 28 d | ≥9.5 | |

| Elastic modulus (GPa) | 28 d | ≥30 |

| Adhesion in tension | 28 d | ≥1.2 |

| Impermeability | 28 d | ≥1.5 MPa |

| Shrinkage performance | 28 d | ≤0.1% |

| Acid resistance | Corrosion for 24 h (5% sulfuric acid) | No spalling, no cracking |

| Corrosion for 48 h (10% citric acid; 10% lactic acid; 10% acetic acid) | ||

| Cement | Water | Sand | Fly Ash | Hydroxypropyl Methyl Cellulose | High-Efficiency Water-Reducing Agent | Aluminate Cement | Fiber (Volume Fraction)/% |

|---|---|---|---|---|---|---|---|

| 0.95 | 0.46 | 0.80 | 0.30 | 0.0005 | 0.0075 | 0.05 | 0.02 1 |

| Types of Fibers | Length (mm) | Diameter (µm) | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|---|---|

| Polypropylene fiber (PP) | 8~20 | 12 | 0.91~0.97 | 850 | 6.0 | 21 |

| Polyvinyl alcohol fiber (PVA) | 8~12 | 39 | 1.3 | 1600 | 42.8 | 6~8 |

| Polyethylene fiber (PE) | 8~18 | 20~38 | 0.97 | 3000 | 100 | 2~3 |

| Steel Fiber | 6~15 | 100~1000 | 7.8 | 350~3000 | 210 | 2~4 |

| Alkali-resistant glass fiber | 5~20 | 13~15 | 2.4~2.76 | 2000~4000 | 70~80 | 2~3.5 |

| Basalt fiber | 15~30 | 6~20 | 2.6~2.8 | 2230~4840 | 85.8~89 | 2.8~3.1 |

| Carbon Fiber | 3~6 | 5~10 | 1.57~1.8 | 525~4660 | 33~268 | 0.8~2.4 |

| Type of Fiber | Fiber Content (%) | Initial Cracking Tensile Strength (MPa) | Ultimate Tensile Strength (MPa) | Ultimate Strain (%) | Crack Width (μm) |

|---|---|---|---|---|---|

| PVA | 0.75~2.5 | 2.6~4.0 | 3.9~5.0 | 1.4~4.6 | 42~71 |

| PP | 1.4~3.2 | 2.3~4.3 | 0.8~3.9 | 63~258 | |

| PE | 4.4~8.3 | 6.6~11.9 | 3.4~9.6 | 50~150 |

| References | Calculation Equation | Parameter |

|---|---|---|

| [106] | is the direct tensile strength of the liner. N is the safety factor. C is the ovality reduction factor. | |

| [107] | is the long-term elastic modulus of the liner. | |

| [108,109] | is the normal stress of a beam in plane bending. | |

| [108,109] | w is the crack width. | |

| [108,110] | The symbols’ meaning is as above. | |

| [111] | is the coefficient of elastic support. is the modulus of the soil reaction. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, S.; Wang, D.; Hui, E.; Gao, C.; Zhang, H.; Tan, Y. An Overview of the Application of Fiber-Reinforced Cementitious Composites in Spray Repair of Drainage Pipes. Buildings 2023, 13, 1119. https://doi.org/10.3390/buildings13051119

Dong S, Wang D, Hui E, Gao C, Zhang H, Tan Y. An Overview of the Application of Fiber-Reinforced Cementitious Composites in Spray Repair of Drainage Pipes. Buildings. 2023; 13(5):1119. https://doi.org/10.3390/buildings13051119

Chicago/Turabian StyleDong, Shun, Dianchang Wang, Erqing Hui, Chao Gao, Han Zhang, and Yaosheng Tan. 2023. "An Overview of the Application of Fiber-Reinforced Cementitious Composites in Spray Repair of Drainage Pipes" Buildings 13, no. 5: 1119. https://doi.org/10.3390/buildings13051119

APA StyleDong, S., Wang, D., Hui, E., Gao, C., Zhang, H., & Tan, Y. (2023). An Overview of the Application of Fiber-Reinforced Cementitious Composites in Spray Repair of Drainage Pipes. Buildings, 13(5), 1119. https://doi.org/10.3390/buildings13051119