Valorization of Wheat Crop Waste in Araucanía, Chile: Development of Prototype of Thermal Insulation Material for Blowing Technique and Geographical Analysis

Abstract

:1. Introduction

2. Materials and Methods

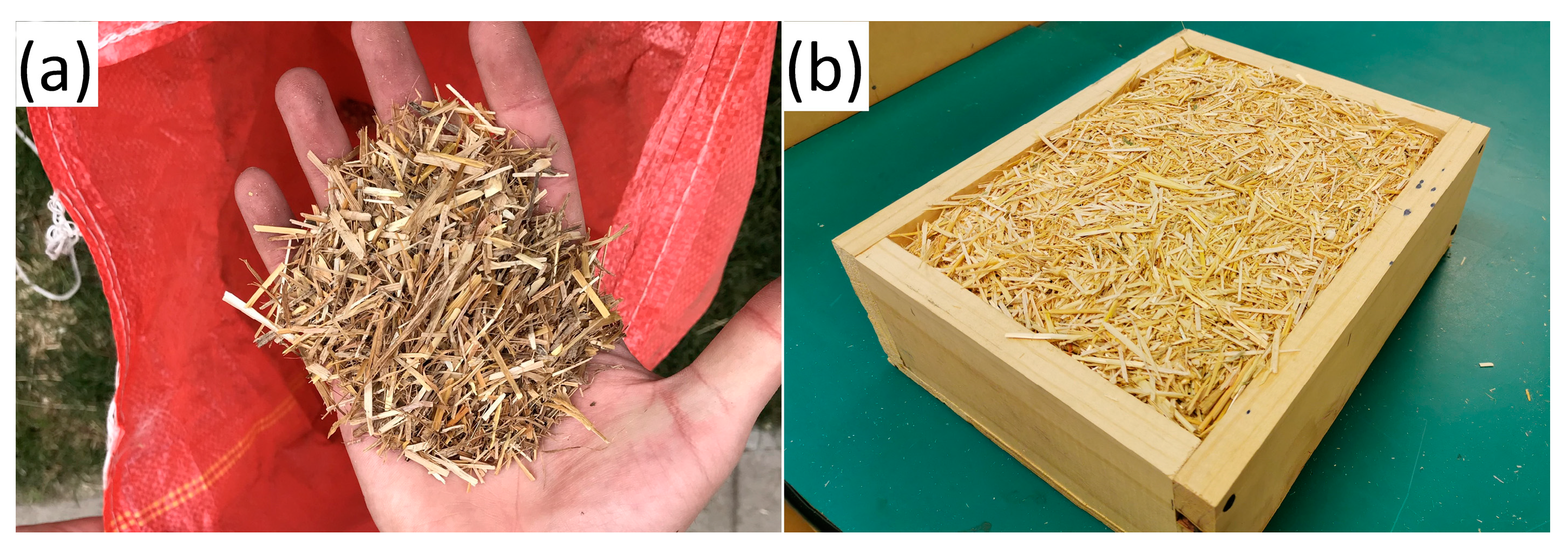

2.1. Feedstock, Analysis, and Processing

2.2. Sample Preparation and Material Application

2.3. Physical Characterization

2.3.1. Thermal Conductivity

2.3.2. Sample Density

2.3.3. Moisture

2.3.4. Fire Behavior

3. Results and Discussion

3.1. Feedstock, Analysis, and Processing

3.2. Samples and Material Application

3.3. Physical Characterization

3.3.1. Thermal Conductivity

3.3.2. Density of the Blowing Material

3.3.3. Moisture

3.3.4. Fire Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Llantoy, N.; Chàfer, M.; Cabeza, L.F. A Comparative Life Cycle Assessment (LCA) of Different Insulation Materials for Buildings in the Continental Mediterranean Climate. Energy Build. 2020, 225, 110323. [Google Scholar] [CrossRef]

- Lausselet, C.; Lund, K.M.; Brattebø, H. LCA and Scenario Analysis of a Norwegian Net-Zero GHG Emission Neighbourhood: The Importance of Mobility and Surplus Energy from PV Technologies. Build. Environ. 2021, 189, 107528. [Google Scholar] [CrossRef]

- Christensen, T.B.; Johansen, M.R.; Buchard, M.V.; Glarborg, C.N. Closing the Material Loops for Construction and Demolition Waste: The Circular Economy on the Island Bornholm, Denmark. Resour. Conserv. Recycl. Adv. 2022, 15, 200104. [Google Scholar] [CrossRef]

- Zhang, W.; Jia, J.; Zhang, J.; Ding, Y.; Zhang, J.; Lu, K.; Mao, S. Pyrolysis and Combustion Characteristics of Typical Waste Thermal Insulation Materials. Sci. Total Environ. 2022, 834, 155484. [Google Scholar] [CrossRef] [PubMed]

- Brauer, M.; Casadei, B.; Harrington, R.A.; Kovacs, R.; Sliwa, K. Taking a Stand Against Air Pollution—The Impact on Cardiovascular Disease: A Joint Opinion from the World Heart Federation, American College of Cardiology, American Heart Association, and the European Society of Cardiology. J. Am. Coll. Cardiol. 2021, 77, 1684–1688. [Google Scholar] [CrossRef]

- Mardones, C. Ex-Post Evaluation of Residential Insulation Program in the City of Temuco, Chile. Energy Sustain. Dev. 2021, 62, 126–135. [Google Scholar] [CrossRef]

- Karanasiou, A.; Alastuey, A.; Amato, F.; Renzi, M.; Stafoggia, M.; Tobias, A.; Reche, C.; Forastiere, F.; Gumy, S.; Mudu, P.; et al. Short-Term Health Effects from Outdoor Exposure to Biomass Burning Emissions: A Review. Sci. Total Environ. 2021, 781, 146739. [Google Scholar] [CrossRef]

- Hvidtfeldt, U.A.; Sørensen, M.; Geels, C.; Ketzel, M.; Khan, J.; Tjønneland, A.; Overvad, K.; Brandt, J.; Raaschou-Nielsen, O. Long-Term Residential Exposure to PM2.5, PM10, Black Carbon, NO2, and Ozone and Mortality in a Danish Cohort. Environ. Int. 2019, 123, 265–272. [Google Scholar] [CrossRef] [PubMed]

- Abu-jdayil, B.; Mourad, A.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, State-of-the-Art and Renewable Thermal Building Insulation Materials: An Overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Abbara, A.A.; Abdelhalim, A.; Al-Ajamee, M.; Ahmed, O.; Adhikary, S.K.; Ahmed, M. Uniaxial Compressive Stress-Strain Relationship for Rubberized Concrete with Coarse Aggregate Replacement up to 100%. Case Stud. Constr. Mater. 2022, 17, e01336. [Google Scholar] [CrossRef]

- Raimundo, A.M.; Sousa, A.M.; Oliveira, A.V.M. Assessment of Energy, Environmental and Economic Costs of Buildings’ Thermal Insulation–Influence of Type of Use and Climate. Buildings 2023, 13, 279. [Google Scholar] [CrossRef]

- Reif, M.; Zach, J.Ĝ.; Hroudová, J. Studying the Properties of Particulate Insulating Materials on Natural Basis. Procedia Eng. 2016, 151, 368–374. [Google Scholar] [CrossRef]

- Liuzzi, S.; Sanarica, S.; Liuzzi, S.; Stefanizzi, P. Use of Agro-Wastes in Building Materials in the Mediterranean Area: A Review a Review Assessing the Feasibility of Using the Heat Sanarica District Temperatu. Energy Procedia 2017, 126, 242–249. [Google Scholar] [CrossRef]

- Azócar, L.; Hermosilla, N.; Gay, A.; Rocha, S.; Díaz, J.; Jara, P. Brown Pellet Production Using Wheat Straw from Southern Cities in Chile. Fuel 2019, 237, 823–832. [Google Scholar] [CrossRef]

- Instituto Nacional de Estadística (INE) Informe de Cultivos Anuales Esenciales. Superficie Sembrada de Cultivos Anuales, Año Agrícola 2020–2021. Available online: https://www.ine.cl/estadisticas/economia/agricultura-agroindustria-y-pesca/cosecha (accessed on 10 January 2022).

- Zúñiga, F.; Jaime, M.; Salazar, C. Crop Farming Adaptation to Droughts in Small-Scale Dryland Agriculture in Chile. Water Resour. Econ. 2021, 34, 100176. [Google Scholar] [CrossRef]

- Palumbo, M.; Avellaneda, J.; Lacasta, A.M. Availability of Crop By-Products in Spain: New Raw Materials for Natural Thermal Insulation. Resour. Conserv. Recycl. 2015, 99, 1–6. [Google Scholar] [CrossRef]

- Azzouzi, D.; Rabahi, W.; Seddiri, F.; Hemis, M. Experimental Study of the Fibres Content Effect on the Heat Insulation Capacity of New Vegetable Composite Plaster-Pea Pod Fibres. Sustain. Mater. Technol. 2020, 23, e00144. [Google Scholar] [CrossRef]

- Ntimugura, F.; Vinai, R.; Harper, A.; Walker, P. Mechanical, Thermal, Hygroscopic and Acoustic Properties of Bio-Aggregates–Lime and Alkali-Activated Insulating Composite Materials: A Review of Current Status and Prospects for Miscanthus as an Innovative Resource in the South West of England. Sustain. Mater. Technol. 2020, 26, e00211. [Google Scholar] [CrossRef]

- Zhou, Y.; Trabelsi, A.; El Mankibi, M. A Review on the Properties of Straw Insulation for Buildings. Constr. Build. Mater. 2022, 330, 127215. [Google Scholar] [CrossRef]

- Janowska-renkas, E.; Król, A.; Pochwała, S.; Pałubski, D.; Adamska, M.; Klementowski, I. The Fire Resistance and Heat Conductivity of Natural Construction Material Based on Straw and Numerical Simulation of Building Energy Demand. Energies 2022, 15, 1155. [Google Scholar] [CrossRef]

- Bakatovich, A.; Gaspar, F.; Boltrushevich, N. Thermal Insulation Material Based on Reed and Straw Fibres Bonded with Sodium Silicate and Rosin. Constr. Build. Mater. 2022, 352, 129055. [Google Scholar] [CrossRef]

- Khoukhi, M.; Dar Saleh, A.; Mohammad, A.F.; Hassan, A.; Abdelbaqi, S. Thermal Performance and Statistical Analysis of a New Bio-Based Insulation Material Produced Using Grain Puffing Technique. Constr. Build. Mater. 2022, 345, 128311. [Google Scholar] [CrossRef]

- Lopez Hurtado, P.; Rouilly, A.; Vandenbossche, V.; Raynaud, C. A Review on the Properties of Cellulose Fibre Insulation. Build. Environ. 2016, 96, 170–177. [Google Scholar] [CrossRef]

- Böck, A.; Treml, S.; Engelhardt, M. Long-Term Settlement Behavior of Loose-Fill Cellulose Insulation under Different Types of Exposure. Eur. J. Wood Wood Prod. 2015, 73, 705–707. [Google Scholar] [CrossRef]

- Palumbo, M.; Formosa, J.; Lacasta, A.M. Thermal Degradation and Fire Behaviour of Thermal Insulation Materials Based on Food Crop By-Products. Constr. Build. Mater. 2015, 79, 34–39. [Google Scholar] [CrossRef]

- Gnanachelvam, S.; Ariyanayagam, A.; Mahendran, M. Effects of Insulation Materials and Their Location on the Fire Resistance of LSF Walls. J. Build. Eng. 2021, 44, 103323. [Google Scholar] [CrossRef]

- Kumar, D.; Morshed, A.; Doshi, A. Investigating the Influence of Thermal Conductivity and Thermal Storage of Lightweight Concrete Panels on the Energy and Thermal Comfort in Residential Buildings. Buildings 2023, 13, 720. [Google Scholar] [CrossRef]

- Agustín Taladriz & Andrés Schwember Cereales En Las Zonas Centro-Sur y Sur de Chile, ¿Qué Hacer Con Los Rastrojos? Agronomía y Forestal N°46. 2012, pp. 25–27. Available online: https://agronomia.uc.cl/component/com_sobipro/Itemid,232/pid,920/sid,926 (accessed on 14 July 2022).

- Román-Figueroa, C.; Montenegro, N.; Paneque, M. Bioenergy Potential from Crop Residue Biomass in Araucania Region of Chile. Renew. Energy 2017, 102, 170–177. [Google Scholar] [CrossRef]

- Mishra, A.K.; Shinjo, H.; Jat, H.S.; Jat, M.L.; Jat, R.K.; Funakawa, S.; Sutaliya, J.M. Farmers’ Perspectives as Determinants for Adoption of Conservation Agriculture Practices in Indo-Gangetic Plains of India. Resour. Conserv. Recycl. Adv. 2022, 15, 200105. [Google Scholar] [CrossRef]

- Carlos, R.; Instituto de Investigaciones Agropecuarias (INIA)–Centro Regional de Investigación Quilamapu. Rastrojo de Cultivos y Residuos Forestales. Programa de Transferencia de Prácticas Alternativas Al Uso Del Fuego En La Región Del Biobío. Boletín INIA N°308. 2015. Consulted on 11 October 2022. Available online: https://biblioteca.inia.cl/handle/20.500.14001/7856 (accessed on 14 July 2022).

- Instituto de Investigaciones Agropecuarias (INIA). Carlos Ruiz Costos Del Manejo de Rastrojos de Trigo En La Precordillera de Ñub. leInformativo N°137. 2018. Consulted on 11 October 2022. Available online: https://biblioteca.inia.cl/bitstream/handle/20.500.14001/4833/NR40904.pdf?sequence=1&isAllowed=y (accessed on 11 October 2022).

- SICAM Diagnóstico Para La Impementación de Planes de Descontaminación Atmosférica de La Zona Centro-Sur de Chile; 2017. Servicios Inte-grales de Calidad Ambiental de Chile. Report Code: 108-IMP16v.2. Available online: www.sicam.cl (accessed on 3 March 2022).

- Zhao, Y.; Feng, D.; Yu, L.; Wang, X.; Chen, Y.; Bai, Y.; Hernández, H.J.; Galleguillos, M.; Estades, C.; Biging, G.S.; et al. Detailed Dynamic Land Cover Mapping of Chile: Accuracy Improvement by Integrating Multi-Temporal Data. Remote Sens. Environ. 2016, 183, 170–185. [Google Scholar] [CrossRef]

- Hernández, H.J.; Galleguillos, M.; Estades, C. Mapa de Cobertura de Suelos de Chile 2014: Descripción Del Producto; Laboratorio de Geomática y Ecología del Paisaje (GEP), Facultad de Ciencias Forestales y Conservación de la Naturaleza, Universidad de Chile: Santiago, Chile, 2016; pp. 1–4. [Google Scholar]

- IEEE Std 442-1981; IEEE Guide for Soil Thermal Resistivity Measurements. IEEE: Piscataway, NJ, USA, 1980; pp. 1–16. [CrossRef]

- ASTM D5334-00; Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure. ASTM: West Conshohocken, PA, USA, 2017. [CrossRef]

- UNE 23-725-90; Ensayos de Reacción Al Fuego de Los Materiales de Construcción. Ensayo de Goteo Aplicable a Los Materiales Fusibles. Ensayo Complementario. Asociación Española de Normalización y Certificación: Madrid, Spain, 1990; p. 725.

- Soto, M.; Rojas, C.; Cárdenas-Ramírez, J.P. Characterization of a Thermal Insulating Material Based on a Wheat Straw and Recycled Paper Cellulose to Be Applied in Buildings by Blowing Method. Sustainability 2023, 15, 58. [Google Scholar] [CrossRef]

- Hetz, H.E.; De La Cerda, A.J.; López, R.M. Straw Availability in the Wheat Stubbles of Three Provinces of Chile. Agric. Técnica 2006, 66, 393–401. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, State-of-the-Art and Future Thermal Building Insulation Materials and Solutions-Properties, Requirements and Possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Yoo, J.; Chang, S.J.; Yang, S.; Wi, S.; Kim, Y.U.; Kim, S. Performance of the Hygrothermal Behavior of the CLT Wall Using Different Types of Insulation; XPS, PF Board and Glass Wool. Case Stud. Therm. Eng. 2021, 24, 100846. [Google Scholar] [CrossRef]

- Ahmed, A.; Qayoum, A.; Mir, F.Q. Investigation of the Thermal Behavior of the Natural Insulation Materials for Low Temperature Regions. J. Build. Eng. 2019, 26, 100849. [Google Scholar] [CrossRef]

- Florea, I.; Manea, D.L. Analysis of Thermal Insulation Building Materials Based on Natural Fibers. Procedia Manuf. 2019, 32, 230–235. [Google Scholar] [CrossRef]

- Soto, M.; Vera, M.; Parra, K.; Rojas, C.; Cárdenas, J.P. Potential of the Residual Fibers of Pisum Sativum (PS), for Use in a Development of a Thermal Insulator Material. IOP Conf. Ser. Earth Environ. Sci. 2020, 503, 012084. [Google Scholar] [CrossRef]

- Rojas, C.; Cea, M.; Iriarte, A.; Valdés, G.; Navia, R.; Cárdenas-r, J.P. Thermal Insulation Materials Based on Agricultural Residual Wheat Straw and Corn Husk Biomass, for Application in Sustainable Buildings. Sustain. Mater. Technol. 2019, 17, e00102. [Google Scholar] [CrossRef]

- Alghamdi, A.A.; Alqarni, A.M.; AlZahrani, A.A. Numerical Investigation of Effects of Camlock System on Thermal Conductivity of Structural Insulated Panels. Buildings 2023, 13, 413. [Google Scholar] [CrossRef]

- Tajuddeen, I.; Sajjadian, S.M.; Jafari, M. Regression Models for Predicting the Global Warming Potential of Thermal Insulation Materials. Buildings 2023, 13, 171. [Google Scholar] [CrossRef]

- Zach, J.; Novák, V.; Peterková, J.; Bubeník, J.; Košir, M.; Božiček, D.; Krejza, Z. The Use of Advanced Environmentally Friendly Systems in the Insulation and Reconstruction of Buildings. Buildings 2023, 13, 404. [Google Scholar] [CrossRef]

- Rojas, C.; Cea, M.; Rosas-Díaz, F.; Cárdenas-R, J. Physical, Chemical and Mechanical Characterization of a Prototype Insulating Material Based on Eucalyptus Bark Fiber. IEEE Lat. Am. Trans. 2018, 16, 2441–2446. [Google Scholar] [CrossRef]

- Cárdenas-R, J.P.; Cea, M.; Santín, K.; Valdés, G.; Hunter, R.; Navia, R. Characterization and Application of a Natural Polymer Obtained from Hydrangea Macrophylla as a Thermal Insulation Biomaterial. Compos. Part B Eng. 2018, 132, 10–16. [Google Scholar] [CrossRef]

- Mehrzad, S.; Taban, E.; Soltani, P.; Samaei, S.E.; Khavanin, A. Sugarcane Bagasse Waste Fibers as Novel Thermal Insulation and Sound-Absorbing Materials for Application in Sustainable Buildings. Build. Environ. 2022, 211, 108753. [Google Scholar] [CrossRef]

- Wang, X.; Qin, D.H.; Ren, J.W.; Wang, F.T. Numerical Estimation of Thermal Insulation Performance of Different Coverage Schemes at Three Places for Snow Storage. Adv. Clim. Chang. Res. 2021, 12, 903–912. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An Overview of Factors Influencing Thermal Conductivity of Building Insulation Materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Lu, J.; Wang, D.; Jiang, P.; Zhang, S.; Chen, Z.; Bourbigot, S.; Fontaine, G.; Wei, M. Design of Fire Resistant, Sound-Absorbing and Thermal-Insulated Expandable Polystyrene Based Lightweight Particleboard Composites. Constr. Build. Mater. 2021, 305, 124773. [Google Scholar] [CrossRef]

- Bovo, M.; Giani, N.; Barbaresi, A.; Mazzocchetti, L.; Barbaresi, L.; Giorgini, L.; Torreggiani, D.; Tassinari, P. Contribution to Thermal and Acoustic Characterization of Corn Cob for Bio-Based Building Insulation Applications. Energy Build. 2022, 262, 111994. [Google Scholar] [CrossRef]

- Pontinha, A.D.R.; Mäntyneva, J.; Santos, P.; Durães, L. Thermomechanical Performance Assessment of Sustainable Buildings’ Insulating Materials under Accelerated Ageing Conditions. Gels 2023, 9, 241. [Google Scholar] [CrossRef]

- Mawardi, I.; Aprilia, S.; Faisal, M.; Rizal, S. Investigation of Thermal Conductivity and Physical Properties of Oil Palm Trunks/Ramie Fiber Reinforced Biopolymer Hybrid Composites as Building Bio-Insulation. Mater. Today Proc. 2022, 60, 373–377. [Google Scholar] [CrossRef]

- Liu, Y.; Dong, M.; Wang, T.; Xiong, L.; Hang, T.; Ling, H.; Hu, A.; Gao, L.; Li, M. Design of Thermally Stable Insulation Film by Radical Grafting Poly(Methylacrylic Acid) on Silicon Surface. Appl. Surf. Sci. 2019, 464, 627–635. [Google Scholar] [CrossRef]

- Zhao, W.; Yan, W.; Zhang, Z.; Gao, H.; Zeng, Q.; Du, G.; Fan, M. Development and Performance Evaluation of Wood-Pulp/Glass Fibre Hybrid Composites as Core Materials for Vacuum Insulation Panels. J. Clean. Prod. 2022, 357, 131957. [Google Scholar] [CrossRef]

- Zou, S.; Li, H.; Liu, L.; Wang, S.; Zhang, X.; Zhang, G. Experimental Study on Fire Resistance Improvement of Wheat Straw Composite Insulation Materials for Buildings. J. Build. Eng. 2021, 43, 103172. [Google Scholar] [CrossRef]

- Zhou, J.; Peng, Y.; Xu, J.; Wu, Y.; Huang, Z.; Xiao, X.; Cui, Y. Vacuum Insulation Arrays as Damage-Resilient Thermal Superinsulation Materials for Energy Saving. Joule 2022, 6, 2358–2371. [Google Scholar] [CrossRef]

| Cereals | Surface [ha] | [%] With Respect to Chile |

|---|---|---|

| Wheat | 93,797 | 41.45 |

| Flour wheat | 92,781 | 45.26 |

| Wheat candeal | 1016 | 4.77 |

| Corn | 53 | 0.08 |

| Corn consumption | 53 | 0.09 |

| Seed corn | - | - |

| Barley | 11,113 | 41.54 |

| Malting barley | 7646 | 44.22 |

| Feed barley | 3467 | 36.63 |

| Rice | - | - |

| Oat | 60,851 | 54.02 |

| Triticale | 9127 | 83.63 |

| Other cereals | 1494 | 36.23 |

| TOTAL | 176,435 | -- |

| Thermal Conductivity [W/mK] | AVG | SD | ||||

|---|---|---|---|---|---|---|

| M1 | M2 | M3 | M4 | |||

| Sample 1 | 0.034 | 0.033 | 0.033 | 0.034 | 0.034 | 0.0006 |

| Sample 2 | 0.034 | 0.032 | 0.034 | 0.035 | 0.034 | 0.0013 |

| Sample 3 | 0.035 | 0.033 | 0.033 | 0.032 | 0.033 | 0.0013 |

| 0.034 | 0.001 | |||||

| Repetition | Ignition | Extinction | Total | ||

|---|---|---|---|---|---|

| Minute | Second | Minute | Second | Duration [s] | |

| 1 | 0 | 2.94 | 0 | 5.90 | 2.96 |

| 2 | 0 | 9.73 | 0 | 14.18 | 4.45 |

| 3 | 0 | 17.59 | 0 | 21.60 | 4.01 |

| 4 | 0 | 25.57 | 0 | 29.05 | 3.48 |

| 5 | 0 | 32.74 | 0 | 34.32 | 1.58 |

| 6 | 0 | 38.44 | 0 | 42.19 | 3.75 |

| 7 | 0 | 45.28 | 0 | 57.85 | 12.57 |

| 8 | 1 | 4.78 | 1 | 6.40 | 1.62 |

| 9 | 1 | 10.61 | 1 | 14.23 | 3.62 |

| 10 | 1 | 18.35 | 1 | 22.58 | 4.23 |

| 11 | 1 | 26.63 | 1 | 29.71 | 3.08 |

| 12 | 1 | 33.54 | 1 | 38.40 | 4.86 |

| 13 | 1 | 42.42 | 1 | 48.33 | 5.91 |

| 14 | 1 | 49.27 | 1 | 52.00 | 2.73 |

| 15 | 1 | 56.74 | 2 | 10.51 | 13.77 |

| 16 | 2 | 19.05 | 2 | 23.25 | 4.20 |

| 17 | 2 | 32.00 | 2 | 36.18 | 4.18 |

| 18 | 2 | 49.04 | 2 | 54.26 | 5.22 |

| Total | 86.22 | ||||

| Average | 4.79 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carlos Javier, R.H.; Karin, R.N.; Juan Pablo, C.-R. Valorization of Wheat Crop Waste in Araucanía, Chile: Development of Prototype of Thermal Insulation Material for Blowing Technique and Geographical Analysis. Buildings 2023, 13, 1152. https://doi.org/10.3390/buildings13051152

Carlos Javier RH, Karin RN, Juan Pablo C-R. Valorization of Wheat Crop Waste in Araucanía, Chile: Development of Prototype of Thermal Insulation Material for Blowing Technique and Geographical Analysis. Buildings. 2023; 13(5):1152. https://doi.org/10.3390/buildings13051152

Chicago/Turabian StyleCarlos Javier, Rojas Herrera, Rodríguez Neira Karin, and Cárdenas-Ramírez Juan Pablo. 2023. "Valorization of Wheat Crop Waste in Araucanía, Chile: Development of Prototype of Thermal Insulation Material for Blowing Technique and Geographical Analysis" Buildings 13, no. 5: 1152. https://doi.org/10.3390/buildings13051152