Hot Water Generation for Domestic Use in Residential Buildings via PCM Integrated U-Tube Based Solar Thermal Collector: A 4-E Analysis

Abstract

1. Introduction

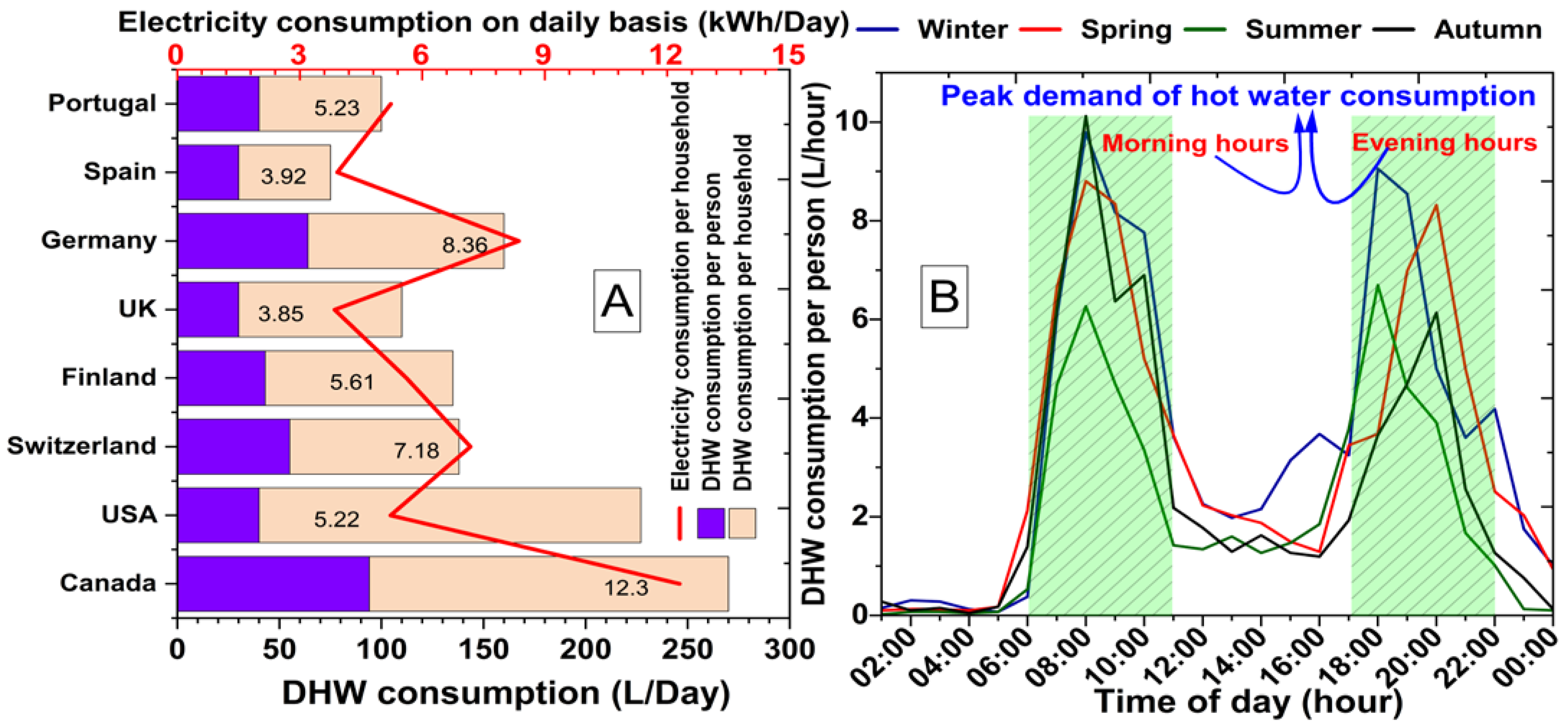

1.1. Hot Water Consumption in Buildings

1.2. Research Gaps and Objective of the Study

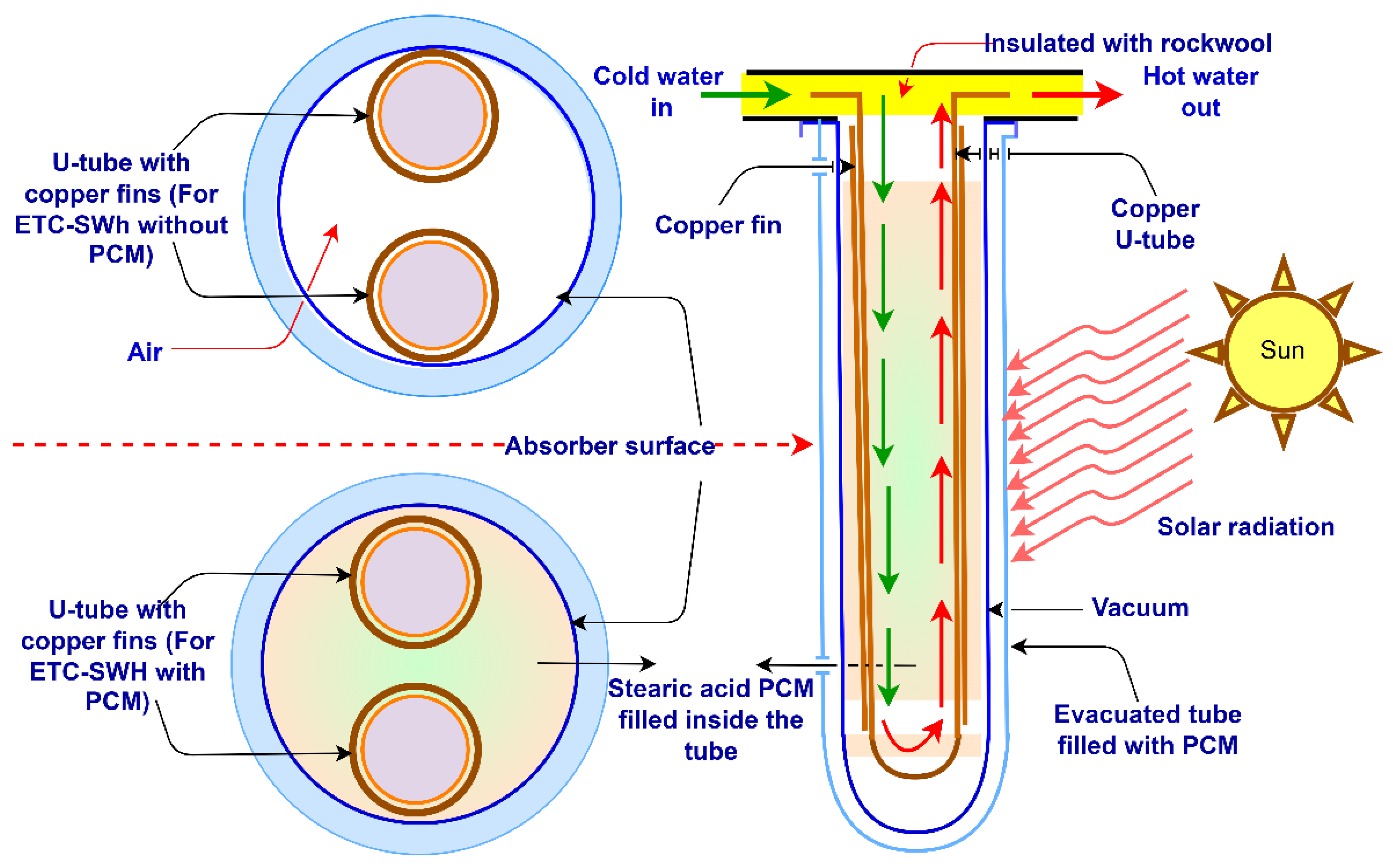

2. Selection and Addition of PCM with Proposed ETC-SWH

3. Experimental Setup and Methodology

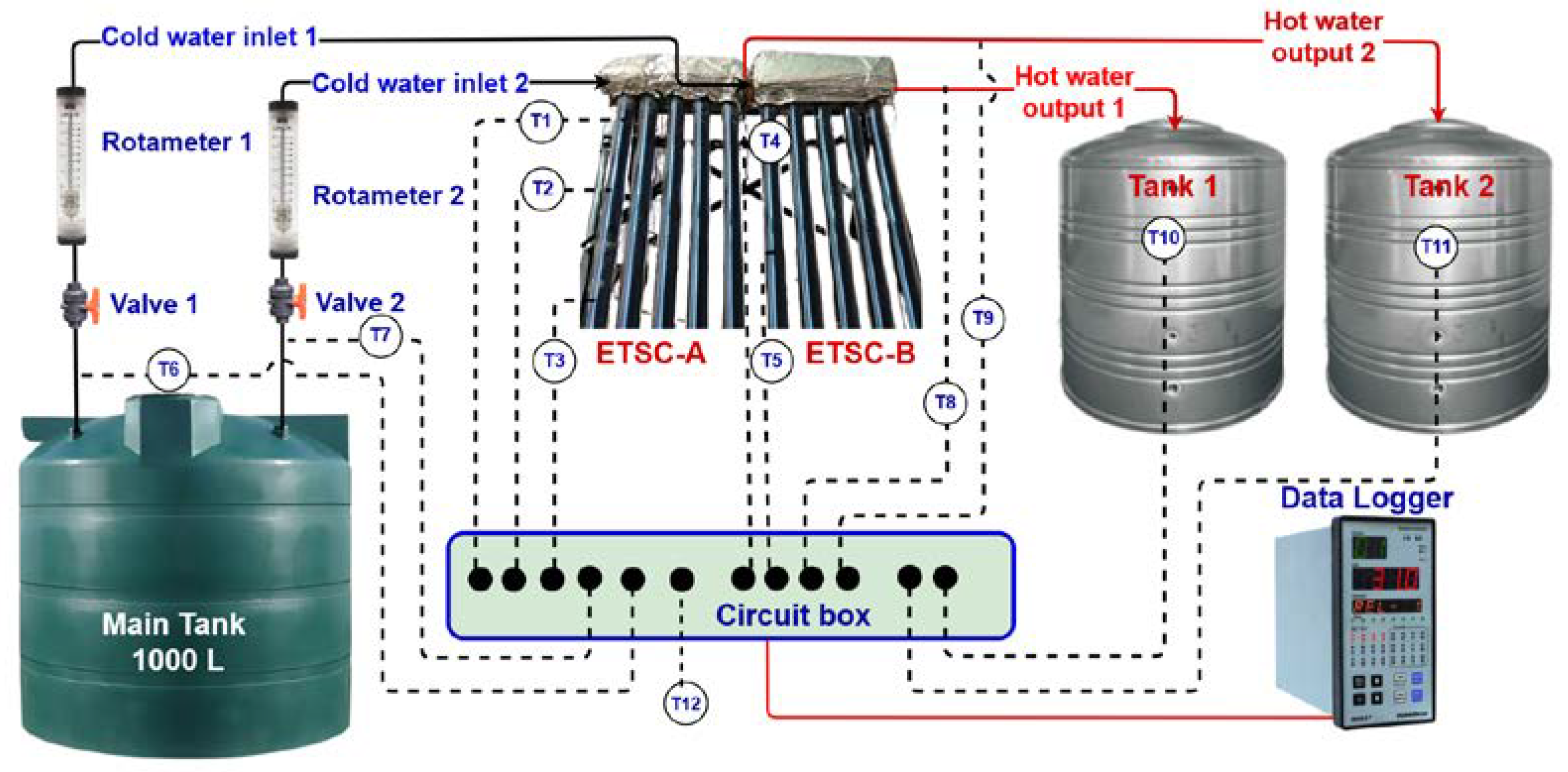

3.1. Test Setup

3.2. Research Methodology

4. Thermodynamic Analysis of U-Tube Based ETSC

4.1. Energy Analysis

4.2. Exergy Analysis

4.3. Numerical Models for the Generation of Energy and Exergy

4.4. Economic and Environmental Analysis

4.5. Experimental Error Analysis

5. Results and Discussion

5.1. Effect of Low Mass Flow Rate (0.167 LPM) on Various Parameters

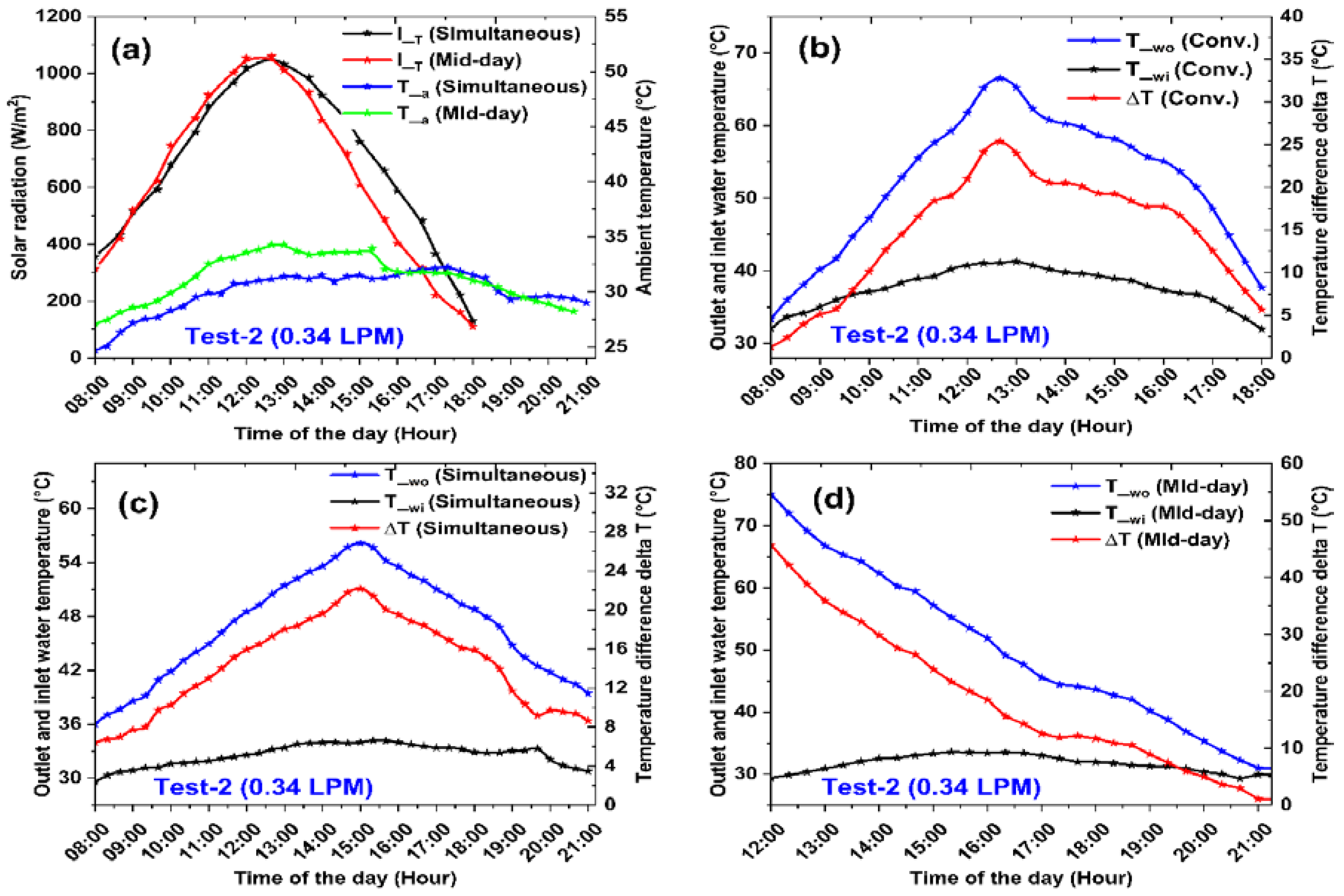

5.2. Effect of Medium Mass Flow Rate (0.34 LPM) on Various Parameters

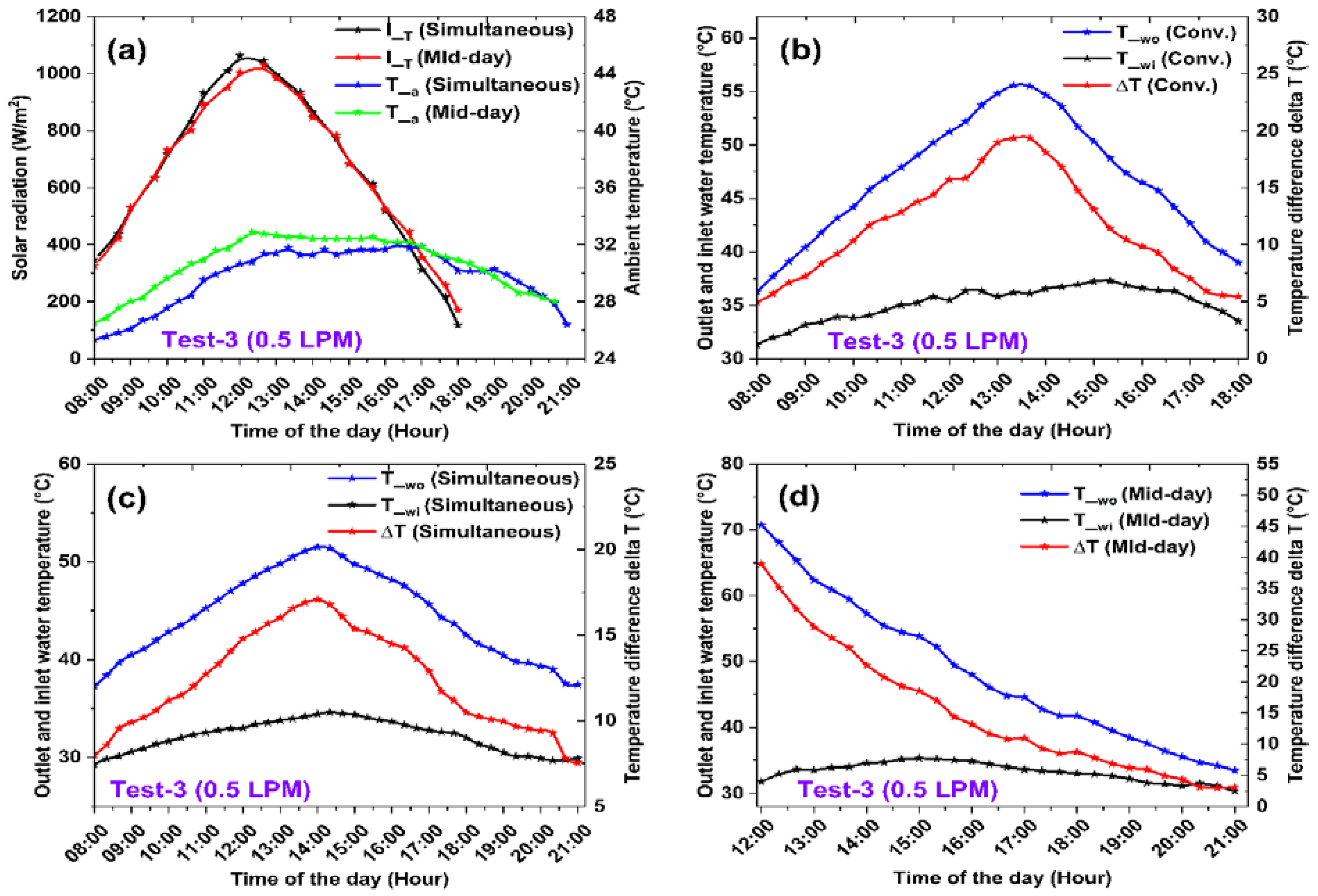

5.3. Effect of High Mass Flow Rate (0.5 LPM) on Various Parameters

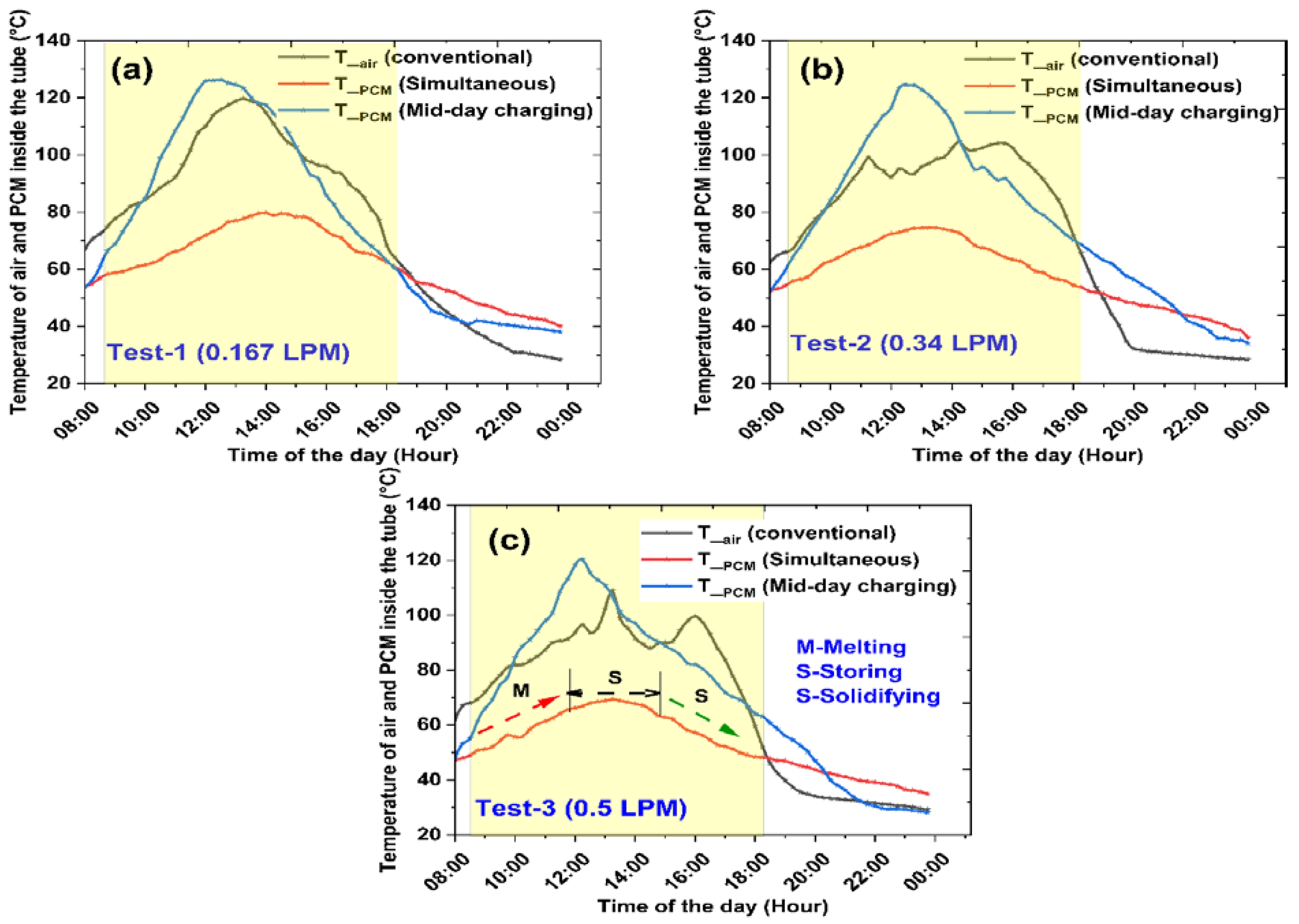

5.4. Effect of Mass Flow Rates on the Temperature of Air and PCM Inside the Tubes of Collectors

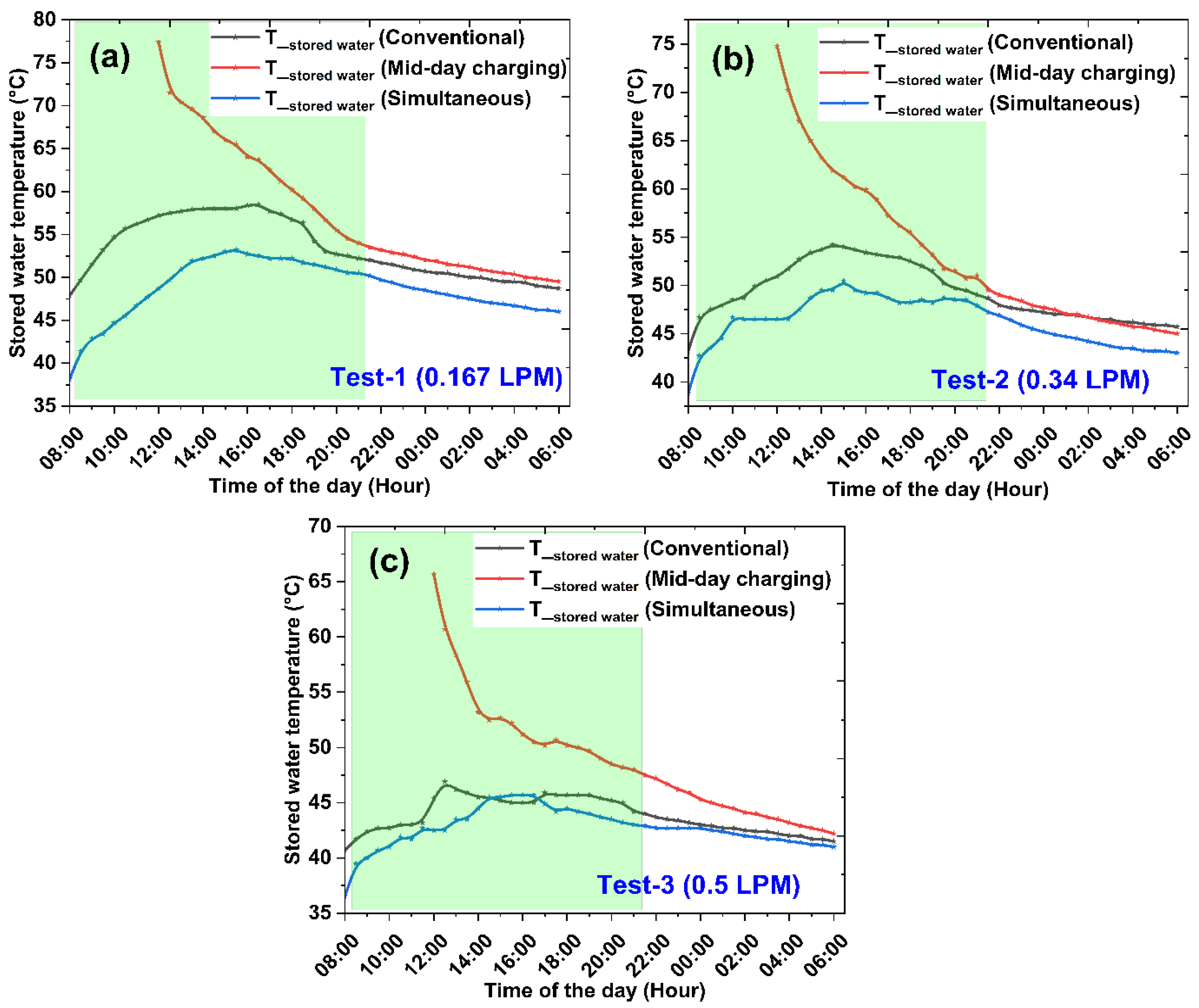

5.5. Effect of Mass Flow Rates on the Temperature of Stored Water in Both Collectors

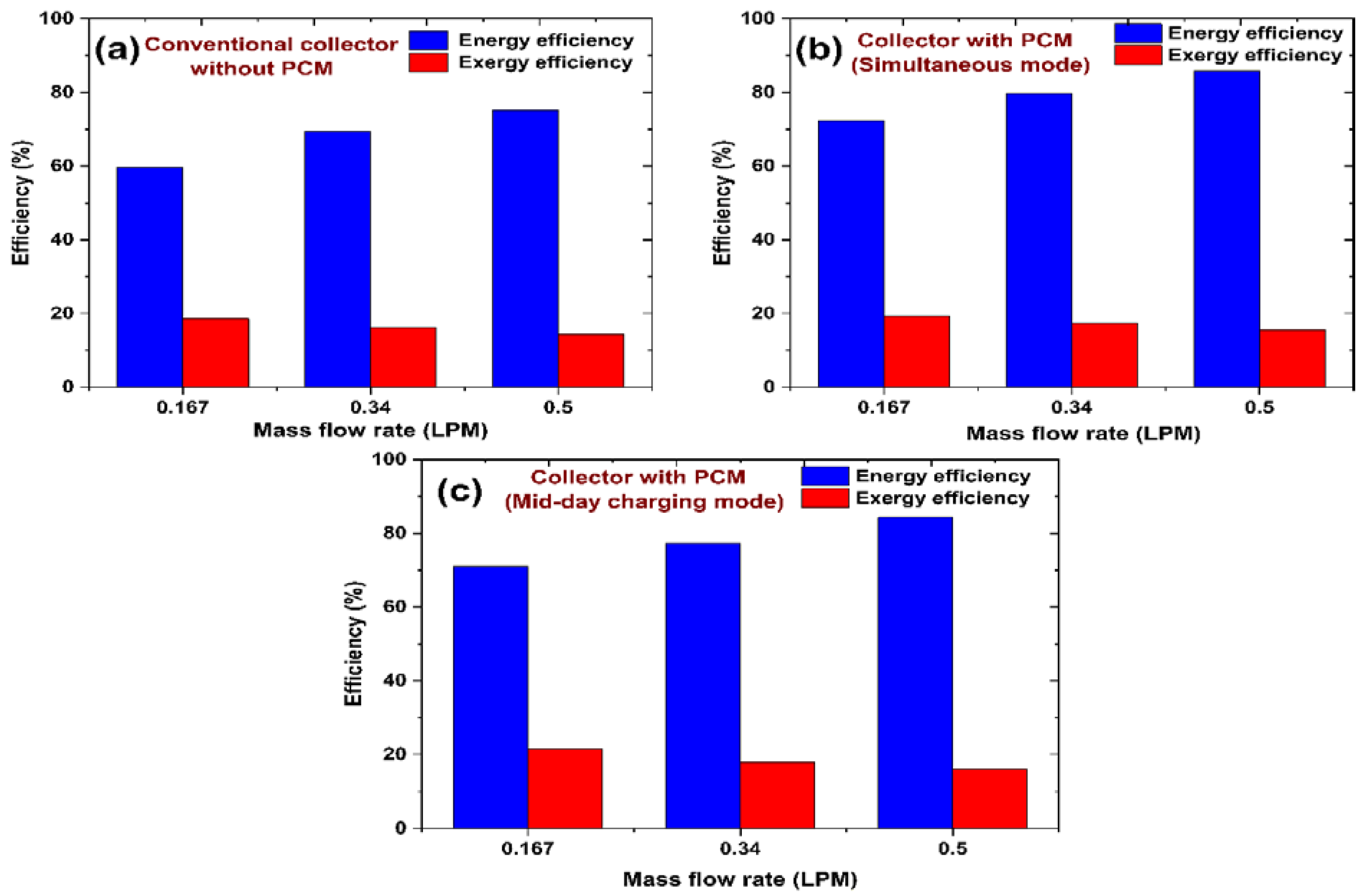

5.6. Effect of Mass Flow Rates on Average Daily Energy and Exergy Output of Both Collectors

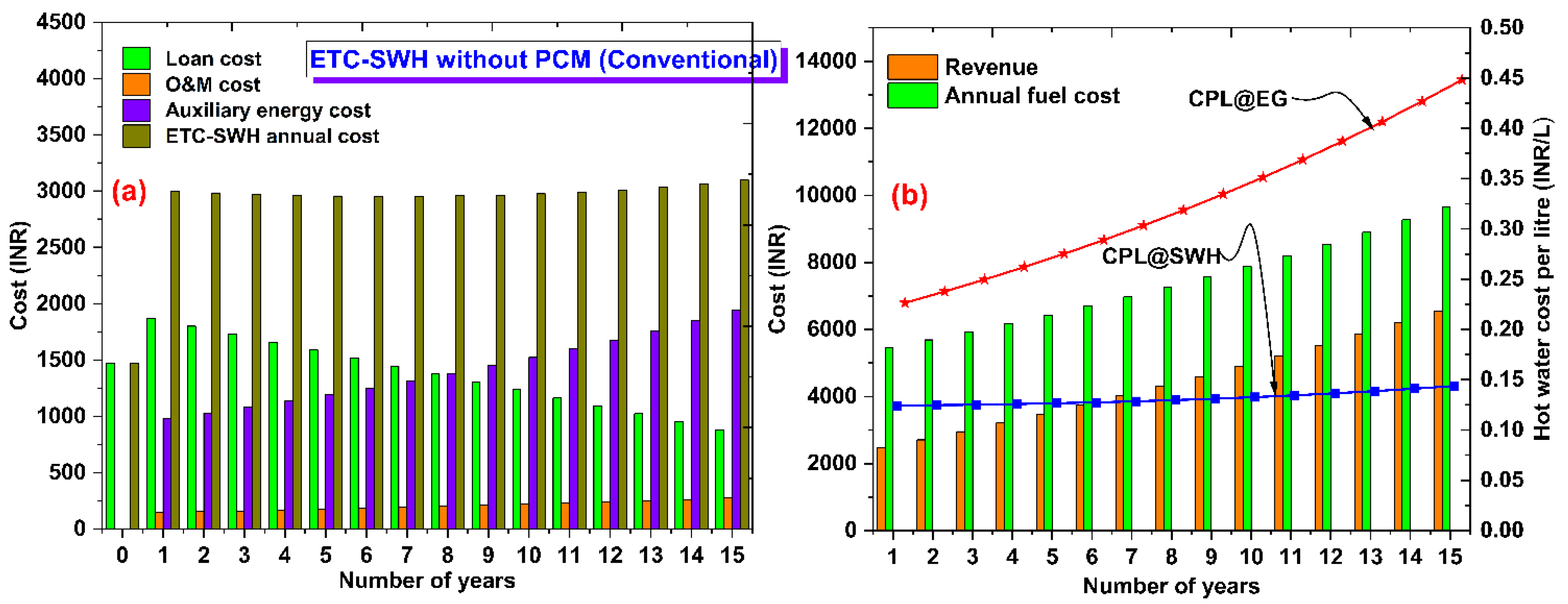

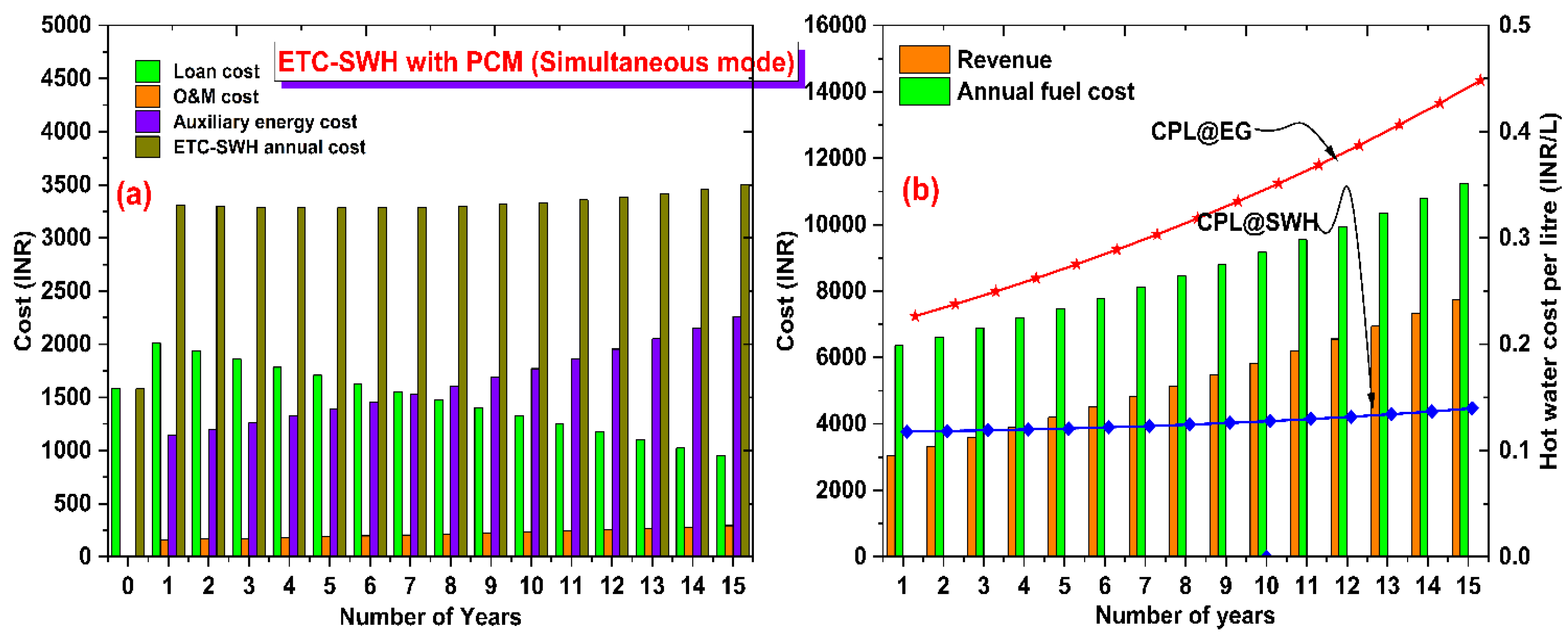

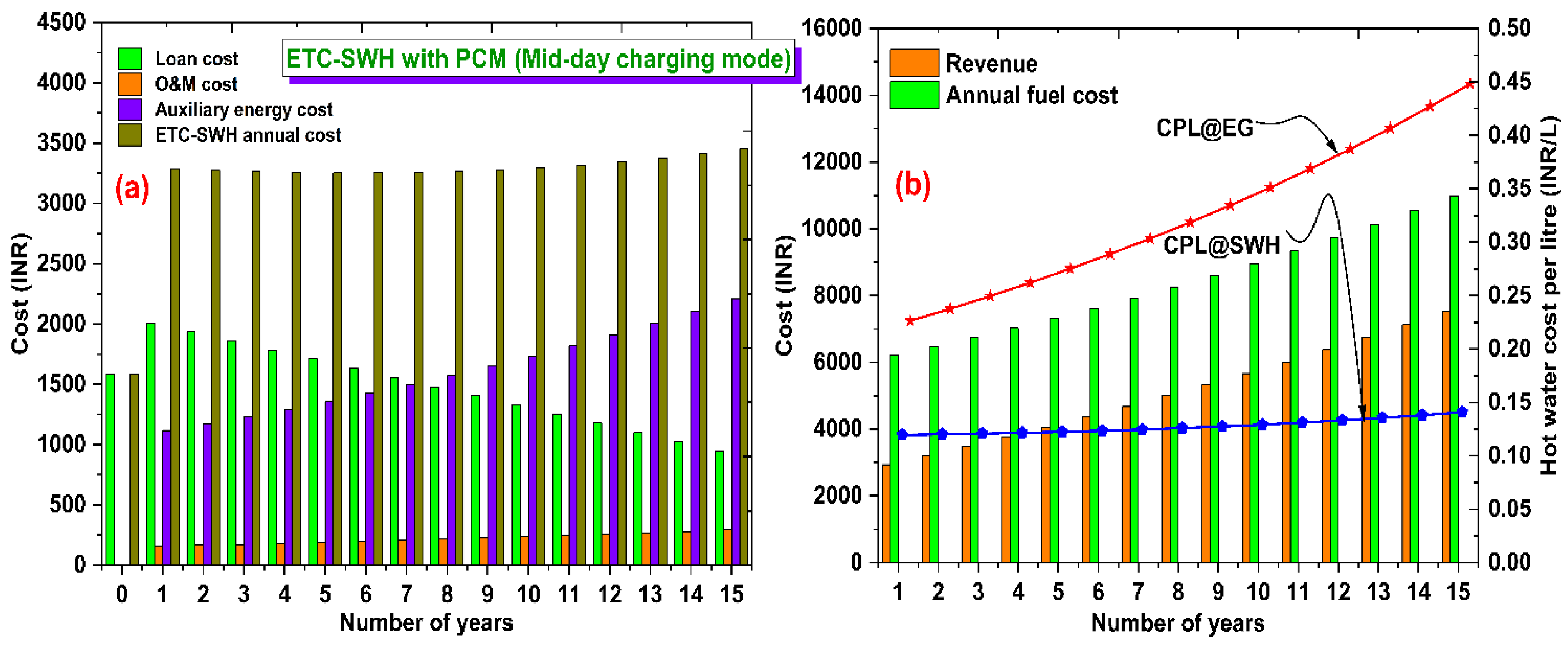

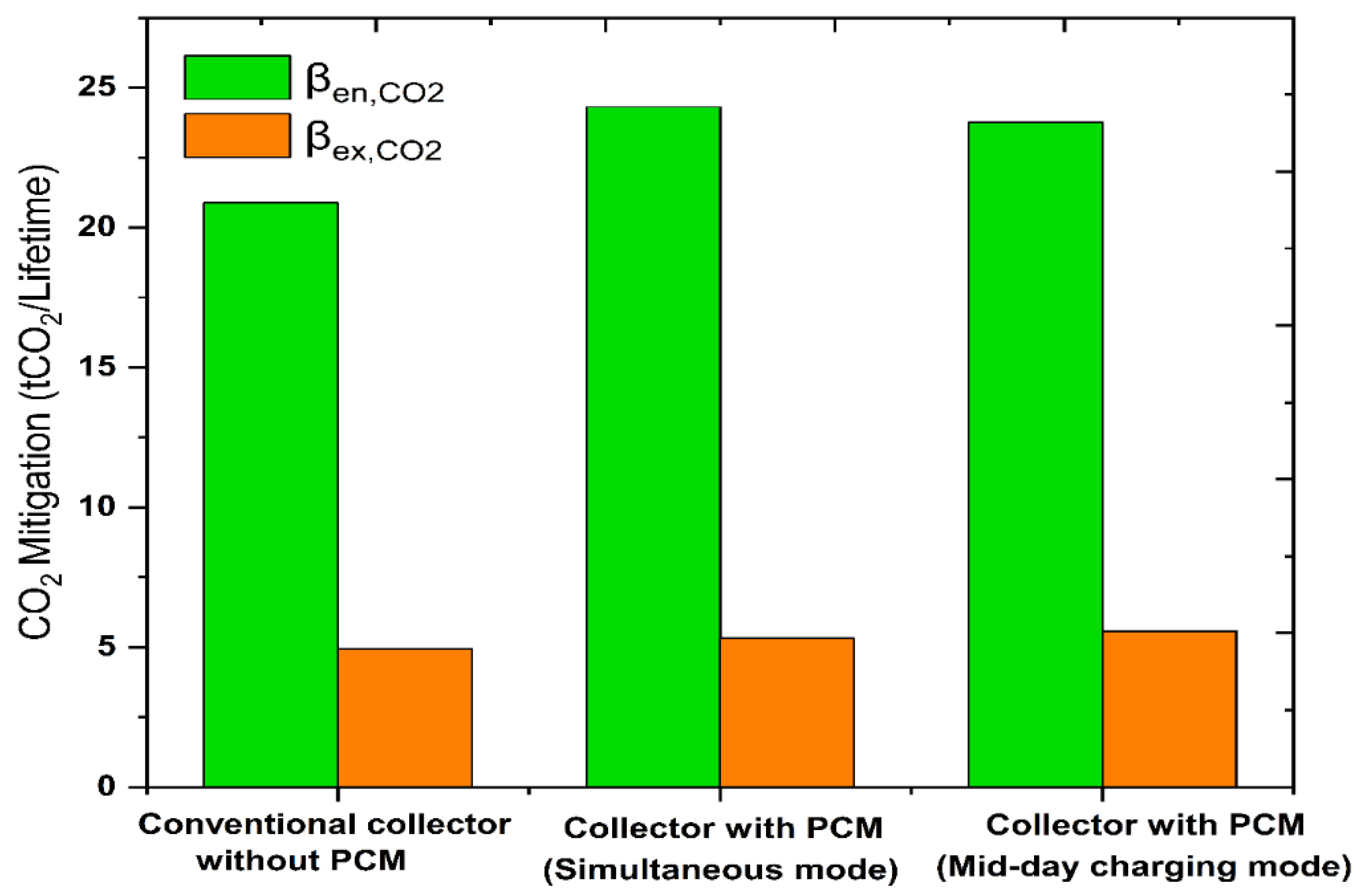

5.7. Effect on Economic, Enviro- and Exergoeconomic Outputs with and without Use of PCM

6. Conclusions and Future Recommendations

6.1. Conclusions

- Integrating copper fin with U-tube of collector A would increase the heat transfer rate between the U-tube and phase change material;

- The energy and exergy outputs of collector A, operated under dual modes, were higher than collector B;

- The maximum energy efficiency of collector A was 85.86% (simultaneous mode) and 84.27% (midday charging mode), whereas for collector B it was 75.08% at 0.5 LPM. In contrast, the exergy efficiencies were found to be 19.41% and 21.35% for collector A, and 18.52% for collector B at a low flow rate (0.167 LPM) for the same modes;

- The energy enhancement ratio of collector A was obtained in the 14.35–21.01% range compared with collector B. In contrast, the exergy enhancement ratio of collector A was obtained in the range of 7.2–15.25% compared with collector B;

- The CPL of collector A was found to be INR 0.1261 for simultaneous mode and INR 0.1276 for midday charging mode, which is much less than the CPL of EG (INR 0.325);

- The levelized energy cost, net present worth, and the payback time of collector A were found to be 4.61 INR/kWh, INR 49710, and 4.49 years (S), and 4.67 INR/kWh, INR 48130, and 4.64 years (M), respectively;

- The amount of CO2 mitigation from the energy and exergy perspectives for collector A was 24.30 for simultaneous mode, 23.76 tCO2/lifetime for midday charging mode, and 5.31 and 5.58 tCO2/lifetime for the same modes, respectively.

6.2. Future Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Aperture area of the collector (m2) | Saving on CO2 emission from energy |

| Specific heat of working fluid (J/kg·K) | Saving on CO2 emission from exergy |

| Cash flow cost (INR) | Initial expenditure cost (INR) |

| Initial cost (INR) | and Velocity at inlet and outlet (m/s) |

| Debt–equity ratio | and Energy function at inlet and outlet |

| Depreciation rate (%) | Loan cost for a particular financial year |

| Exergy at the inlet (J) | |

| Exergy at the outlet (J) | |

| Exergy loss (J) | |

| Exergy incident on aperture area (J) | |

| Incident solar radiation (W/m2) | |

| Useful amount of heat (J) | |

| Useful exergy from predicted model | |

| Useful energy from predicted model | |

| Mass flow rate of working fluid (LPM) | |

| Payback period (years) | |

| iInterest (%) | |

| iRReverse interest rate (%) | |

| nNumber of years | |

| Working fluid inlet temperature (°C) | |

| Working fluid outlet temperature (°C) | |

| Atmospheric temperature (°C) | |

| Time strap (sec) | |

| Temperature of sun (°C) | |

| Overall heat transfer loss | |

| Daily energy efficiency (%) | |

| Daily exergy efficiency (%) |

Abbreviations

| CFD—Computational fluid dynamics |

| HTF—Heat transfer fluid |

| INR—Indian rupees |

| LCWH—Levelized cost of water heating |

| NPV—Net present worth |

| EER—Efficiency enhancement ratio |

| LHS—Latent heat storage |

| SWH—Solar water heater |

| ETC—Evacuated tube collector |

| ETSC—Evacuated tube solar collector |

| FPC—Flat plate collector |

| PCM—Phase change material |

| TES—Thermal energy storage |

References

- Soares, N.; Costa, J.J.; Gaspar, A.R.; Santos, P. Review of passive PCM latent heat thermal energy storage systems towards buildings’ energy efficiency. Energy Build. 2013, 59, 82–103. [Google Scholar] [CrossRef]

- Yao, S.; Yang, L.; Shi, S.; Zhou, Y.; Long, M.; Zhang, W.; Cai, S.; Huang, C.; Liu, T.; Zou, B. A Two-in-One Annealing Enables Dopant Free Block Copolymer Based Organic Solar Cells with over 16% Efficiency. Chin. J. Chem. 2023, 41, 672–678. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.-H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Fan, R.; Li, Y.; Bu, T.; Sun, K.; Zhou, Y.; Shi, J.; Zhang, X. Comparative study of solar hot air heating systems with phase change materials in plateau areas. Energy Build. 2020, 224, 110265. [Google Scholar] [CrossRef]

- Aoul, K.T.; Hasan, A.; Riaz, H. Solar water heating systems for different buildings under a hot climate; parametric optimization and economic analysis. Sustain. Build. 2018, 3, 3. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Pathak, A.K.; Pandey, A.; Sari, A. Experimental performance evaluation of a novel designed phase change material integrated manifold heat pipe evacuated tube solar collector system. Energy Convers. Manag. 2019, 198, 111896. [Google Scholar] [CrossRef]

- Pathak, S.K.; Tyagi, V.; Chopra, K.; Sharma, R.K. Recent development in thermal performance of solar water heating (SWH) systems. Mater. Today Proc. 2022, 63, 778–785. [Google Scholar] [CrossRef]

- Pathak, S.K.; Tyagi, V.; Chopra, K.; Rejikumar, R.; Pandey, A. Integration of emerging PCMs and nano-enhanced PCMs with different solar water heating systems for sustainable energy future: A systematic review. Sol. Energy Mater. Sol. Cells 2023, 254, 112237. [Google Scholar] [CrossRef]

- Baneshi, M.; Bahreini, S.A. Impacts of hot water consumption pattern on optimum sizing and techno-economic aspects of residential hybrid solar water heating systems. Sustain. Energy Technol. Assess. 2018, 30, 139–149. [Google Scholar] [CrossRef]

- Fuentes, E.; Arce, L.; Salom, J. A review of domestic hot water consumption profiles for application in systems and buildings energy performance analysis. Renew. Sustain. Energy Rev. 2018, 81, 1530–1547. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.V.; Pandey, A.K. Thermodynamic and techno-economic analysis of heat pipe ETC water heating system for Indian composite climate. J. Therm. Anal. Calorim. 2019, 139, 1395–1407. [Google Scholar] [CrossRef]

- Naghavi, M.; Ong, K.; Badruddin, I.; Mehrali, M.; Metselaar, H. Thermal performance of a compact design heat pipe solar collector with latent heat storage in charging/discharging modes. Energy 2017, 127, 101–115. [Google Scholar] [CrossRef]

- Xue, H.S. Experimental investigation of a domestic solar water heater with solar collector coupled phase-change energy storage. Renew. Energy 2016, 86, 257–261. [Google Scholar] [CrossRef]

- Abokersh, M.H.; El-Morsi, M.; Sharaf, O.; Abdelrahman, W. On-demand operation of a compact solar water heater based on U-pipe evacuated tube solar collector combined with phase change material. Sol. Energy 2017, 155, 1130–1147. [Google Scholar] [CrossRef]

- O’neil, T.J.; Sobhansarbandi, S. Thermal performance investigation of energy storage based U-pipe evacuated tube solar collector: An experimental study. Sustain. Energy Technol. Assess. 2022, 52, 102146. [Google Scholar] [CrossRef]

- Li, Y.; Liang, X.; Song, W.; Li, T.; Wang, D.; Liu, Y. Optimization and thermal performance of U-type evacuated tube solar collector filled with phase change material. Energy Rep. 2022, 8, 6126–6138. [Google Scholar] [CrossRef]

- Huang, K.; Feng, G.; Zhang, J. Experimental and numerical study on phase change material floor in solar water heating system with a new design. Sol. Energy 2014, 105, 126–138. [Google Scholar] [CrossRef]

- Essa, M.A.; Asal, M.; Saleh, M.A.; Shaltout, R. A comparative study of the performance of a novel helical direct flow U-Tube evacuated tube collector. Renew. Energy 2020, 163, 2068–2080. [Google Scholar] [CrossRef]

- Nemati, H.; Souriaee, V.; Habibi, M.; Vafai, K. Design and Taguchi-based optimization of the latent heat thermal storage in the form of structured porous-coated pipe. Energy 2023, 263, 125947. [Google Scholar] [CrossRef]

- Ao, C.; Yan, S.; Zhao, S.; Hu, W.; Zhao, L.; Wu, Y. Stearic acid/expanded graphite composite phase change material with high thermal conductivity for thermal energy storage. Energy Rep. 2022, 8, 4834–4843. [Google Scholar] [CrossRef]

- Chopra, K.; Pathak, A.K.; Tyagi, V.; Pandey, A.; Anand, S.; Sari, A. Thermal performance of phase change material integrated heat pipe evacuated tube solar collector system: An experimental assessment. Energy Convers. Manag. 2019, 203, 112205. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Pandey, A.; Popli, S.; Singh, G.; Sharma, R.; Sari, A. Effect of simultaneous & consecutive melting/solidification of phase change material on domestic solar water heating system. Renew. Energy 2022, 188, 329–348. [Google Scholar] [CrossRef]

- Pathak, S.K.; Tyagi, V.; Chopra, K.; Kalidasan, B.; Pandey, A.; Goel, V.; Saxena, A.; Ma, Z. Energy, exergy, economic and environmental analyses of solar air heating systems with and without thermal energy storage for sustainable development: A systematic review. J. Energy Storage 2023, 59, 106521. [Google Scholar] [CrossRef]

- Essa, M.A.; Rofaiel, I.Y.; Ahmed, M.A. Experimental and Theoretical Analysis for the Performance of Evacuated Tube Collector Integrated with Helical Finned Heat Pipes using PCM Energy Storage. Energy 2020, 206, 118166. [Google Scholar] [CrossRef]

- Pandey, A.; Laghari, I.A.; Kumar, R.R.; Chopra, K.; Samykano, M.; Abusorrah, A.M.; Sharma, K.; Tyagi, V. Energy, exergy, exergoeconomic and enviroeconomic (4-E) assessment of solar water heater with/without phase change material for building and other applications: A comprehensive review. Sustain. Energy Technol. Assess. 2021, 45, 101139. [Google Scholar] [CrossRef]

- Petela, R. Exergy of undiluted thermal radiation. Sol. Energy 2003, 74, 469–488. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Pathak, S.K.; Tripathi, P.A.; Sharma, R.; Singh, G.; Pandey, A. Thermal and chemical reliability of paraffin wax and its impact on thermal performance and economic analysis of solar water heater. Energy Sustain. Dev. 2023, 73, 39–53. [Google Scholar] [CrossRef]

- Rezvani, S.; Bahri, P.; Urmee, T.; Baverstock, G.; Moore, A. Techno-economic and reliability assessment of solar water heaters in Australia based on Monte Carlo analysis. Renew. Energy 2017, 105, 774–785. [Google Scholar] [CrossRef]

- Tewari, K.; Dev, R. Exergy, Environmental and Economic Analysis of Modified Domestic Solar Water Heater with Glass-to-Glass PV Module; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; Volume 170. [Google Scholar] [CrossRef]

- Hossain, M.S.; Pandey, A.K.; Tunio, M.A.; Selvaraj, J.; Hoque, K.E.; Rahim, N.A. Thermal and economic analysis of low-cost modified flat-plate solar water heater with parallel two-side serpentine flow. J. Therm. Anal. Calorim. 2015, 123, 793–806. [Google Scholar] [CrossRef]

- Abo-Elfadl, S.; Yousef, M.S.; Hassan, H. Energy, exergy, and enviroeconomic assessment of double and single pass solar air heaters having a new design absorber. Process. Saf. Environ. Prot. 2020, 149, 451–464. [Google Scholar] [CrossRef]

- Alwaeli, A.H.A.; Kazem, H.A.; Chaichan, M.T.; Sopian, K. Experimental investigation of using nano-PCM/nanofluid on a photovoltaic thermal system (PVT): Technical and economic study. Therm. Sci. Eng. Prog. 2019, 11, 213–230. [Google Scholar] [CrossRef]

- Murali, G.; Mayilsamy, K.; Arjunan, T.V. An Experimental Study of PCM-Incorporated Thermosyphon Solar Water Heating System. Int. J. Green Energy 2014, 12, 978–986. [Google Scholar] [CrossRef]

- Mellouli, S.; Alqahtani, T.; Algarni, S. Parametric Analysis of a Solar Water Heater Integrated with PCM for Load Shifting. Energies 2022, 15, 8741. [Google Scholar] [CrossRef]

- Azari, P.; Lavasani, A.M.; Rahbar, N.; Yazdi, M.E. Performance enhancement of a solar still using a V-groove solar air collector—Experimental study with energy, exergy, enviroeconomic, and exergoeconomic analysis. Environ. Sci. Pollut. Res. 2021, 28, 65525–65548. [Google Scholar] [CrossRef] [PubMed]

- Pawar, V.R.; Sobhansarbandi, S. Heat transfer enhancement of a PCM-porous metal based heat pipe evacuated tube solar collector: An experimental study. Sol. Energy 2023, 251, 106–118. [Google Scholar] [CrossRef]

| Component | Properties | Value |

|---|---|---|

| Evacuated tube | Outer/inner diameters | 58 mm and 47 mm |

| Thickness of tube | 1800 mm | |

| Length of tube | 1800 m | |

| Specific heat | 980 (J/kg K) | |

| Thermal conductivity | 1.14 (W/m K) | |

| Transmissivity | 0.92 | |

| Absorber coating | Thickness of coating | 0.1 mm |

| Three target ALN/SS/Cu | Absorptivity | 0.92 |

| Emissivity | 0.08 | |

| Heat exchanger | Length of tube | 1700 mm |

| (U-tube of copper) | Outer/inner dia. of tube | 8 mm and 7.5 mm |

| Fin material | Copper | |

| Fin thickness | 0.5 mm | |

| Fin length | 1600 mm | |

| Thermal conductivity | 385 W/m K | |

| Density of copper | 8830 kg/m3 | |

| Collector | Aperture area | 0.490 m2 |

| Type of System | Flow Rate (LPM) | Daily Energy Efficiency (%) | Error (%) | Daily Exergy Efficiency (%) | Error (%) |

|---|---|---|---|---|---|

| Collector B (reference system) | 0.167 | 59.62 ± 1.91 | 1.13 | 18.52 ± 0.0113 | 1.13 |

| 0.34 | 69.40 ± 2.18 | 1.51 | 16.12 ± 0.0144 | 1.44 | |

| 0.50 | 75.08 ± 3.01 | 2.26 | 14.43 ± 0.0197 | 1.97 | |

| Collector A with PCM (simultaneous mode) | 0.167 | 72.15 ± 1.84 | 1.32 | 19.41 ± 0.0122 | 1.21 |

| 0.34 | 79.64 ± 2.44 | 1.94 | 17.40 ± 0.0153 | 1.53 | |

| 0.50 | 85.75 ± 2.85 | 2.45 | 15.48 ± 0.0193 | 1.93 | |

| Collector A with PCM (midday charging mode) | 0.167 | 70.93 ± 1.51 | 1.07 | 21.35 ± 0.0101 | 1.01 |

| 0.34 | 77.86 ± 1.93 | 1.51 | 17.83 ± 0.0143 | 1.43 | |

| 0.50 | 84.27 ± 2.42 | 2.03 | 16.06 ± 0.0175 | 1.75 |

| Type of the Collector | Mass Flow Rate (LPM) | Daily Incident Energy (MJ) | Daily Useful Energy (MJ) | Daily Energy Efficiency (%) | Daily Exergy Efficiency (%) |

|---|---|---|---|---|---|

| Collector B without PCM (reference collector) | 0.167 | 11.69 | 6.97 | 59.62 | 18.52 |

| 0.34 | 12.68 | 8.81 | 69.4 | 16.12 | |

| 0.5 | 12.40 | 9.31 | 75.08 | 14.43 | |

| Collector A with PCM (simultaneous mode) | 0.167 | 11.69 | 8.44 | 72.15 | 19.41 |

| 0.34 | 12.68 | 10.10 | 79.64 | 17.4 | |

| 0.5 | 12.40 | 10.65 | 85.56 | 15.48 | |

| Collector A with PCM (midday charging mode) | 0.167 | 12.42 | 8.82 | 70.97 | 21.35 |

| 0.34 | 12.04 | 9.31 | 77.35 | 17.83 | |

| 0.5 | 12.33 | 10.39 | 84.27 | 16.06 |

| Input Economic Parameters | Value |

|---|---|

| Total aperture area (m2) | 0.49 |

| Capital cost of collector per unit collector area (Rs/m2-aperture area) | 32,000 |

| Total initial cost of solar collectors (Rs) | 15,810.6 |

| Debt–equity ratio | 90% |

| Nominal interest rate | 8% |

| Debt term (years) | 15 |

| Percentage of O&M cost | 1.00% |

| Electricity price in first year (Rs/kWh) | 6.50 |

| Inflation rate in electricity | 5.0% |

| Inflation rate | 4.5% |

| Rate of discount | 5.0% |

| Rate of degradation | 1.00% |

| N (Years) | Interest Rate | Uniform Annual Cost (INR) | Energoeconomic Factor Based on Energy (kJ/INR) | Exergoeconomic Factor Based on Energy (kJ/INR) | |||

|---|---|---|---|---|---|---|---|

| Proposed ETC | EG | Proposed ETC | EG | Proposed ETC | EG | ||

| 10 | 6 | 3097 | 6604 | 809.81 | 379.76 | 192.28 | 90.17 |

| 7 | 3156 | 794.67 | 188.68 | ||||

| 8 | 3216 | 779.85 | 185.16 | ||||

| 12 | 6 | 2959 | 6899 | 847.58 | 363.53 | 201.25 | 86.31 |

| 7 | 3019 | 830.73 | 197.25 | ||||

| 8 | 3080 | 814.28 | 193.34 | ||||

| 15 | 6 | 2869 | 7373 | 874.17 | 340.16 | 207.56 | 80.76 |

| 7 | 2930 | 855.97 | 203.24 | ||||

| 8 | 2992 | 838.23 | 199.03 | ||||

| N (Years) | Interest Rate | Uniform Annual Cost (INR) | Energoeconomic Factor Based on Energy (kJ/INR) | Exergoeconomic Factor Based on Energy (kJ/INR) | |||

|---|---|---|---|---|---|---|---|

| Proposed ETC | EG | Proposed ETC | EG | Proposed ETC | EG | ||

| 10 | 6 | 3437 | 7687 | 849.28 | 379.73 | 184.78 | 82.62 |

| 7 | 3501 | 833.76 | 181.40 | ||||

| 8 | 3565 | 818.79 | 178.14 | ||||

| 12 | 6 | 3294 | 8030 | 886.15 | 363.51 | 192.80 | 79.09 |

| 7 | 3360 | 868.75 | 189.01 | ||||

| 8 | 3426 | 852.01 | 185.37 | ||||

| 15 | 6 | 3208 | 8582 | 909.91 | 340.13 | 197.97 | 74.00 |

| 7 | 3275 | 891.29 | 193.92 | ||||

| 8 | 3341 | 873.69 | 190.09 | ||||

| N (Years) | Interest Rate | Uniform Annual Cost (INR) | Energoeconomic Factor Based on Energy (kJ/INR) | Exergoeconomic Factor Based on Energy (kJ/INR) | |||

|---|---|---|---|---|---|---|---|

| Proposed ETC | EG | Proposed ETC | EG | Proposed ETC | EG | ||

| 10 | 6 | 3405 | 7512 | 837.88 | 379.79 | 196.38 | 89.01 |

| 7 | 3470 | 822.19 | 192.70 | ||||

| 8 | 3534 | 807.30 | 189.21 | ||||

| 12 | 6 | 3261 | 7848 | 874.88 | 363.53 | 205.05 | 85.20 |

| 7 | 3327 | 857.52 | 200.99 | ||||

| 8 | 3392 | 841.09 | 197.14 | ||||

| 15 | 6 | 3172 | 8388 | 899.43 | 340.12 | 210.81 | 79.72 |

| 7 | 3238 | 881.09 | 206.51 | ||||

| 8 | 3304 | 863.49 | 202.39 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pathak, S.K.; Tyagi, V.V.; Chopra, K.; Pandey, A.K.; Sari, A. Hot Water Generation for Domestic Use in Residential Buildings via PCM Integrated U-Tube Based Solar Thermal Collector: A 4-E Analysis. Buildings 2023, 13, 1212. https://doi.org/10.3390/buildings13051212

Pathak SK, Tyagi VV, Chopra K, Pandey AK, Sari A. Hot Water Generation for Domestic Use in Residential Buildings via PCM Integrated U-Tube Based Solar Thermal Collector: A 4-E Analysis. Buildings. 2023; 13(5):1212. https://doi.org/10.3390/buildings13051212

Chicago/Turabian StylePathak, Sudhir Kumar, V. V. Tyagi, K. Chopra, A. K. Pandey, and Ahmet Sari. 2023. "Hot Water Generation for Domestic Use in Residential Buildings via PCM Integrated U-Tube Based Solar Thermal Collector: A 4-E Analysis" Buildings 13, no. 5: 1212. https://doi.org/10.3390/buildings13051212

APA StylePathak, S. K., Tyagi, V. V., Chopra, K., Pandey, A. K., & Sari, A. (2023). Hot Water Generation for Domestic Use in Residential Buildings via PCM Integrated U-Tube Based Solar Thermal Collector: A 4-E Analysis. Buildings, 13(5), 1212. https://doi.org/10.3390/buildings13051212