Vibration Performance of Bamboo Bundle/Wood Veneer Composite Floor Slabs for Joist-Type Floor Coverings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Testing Equipment

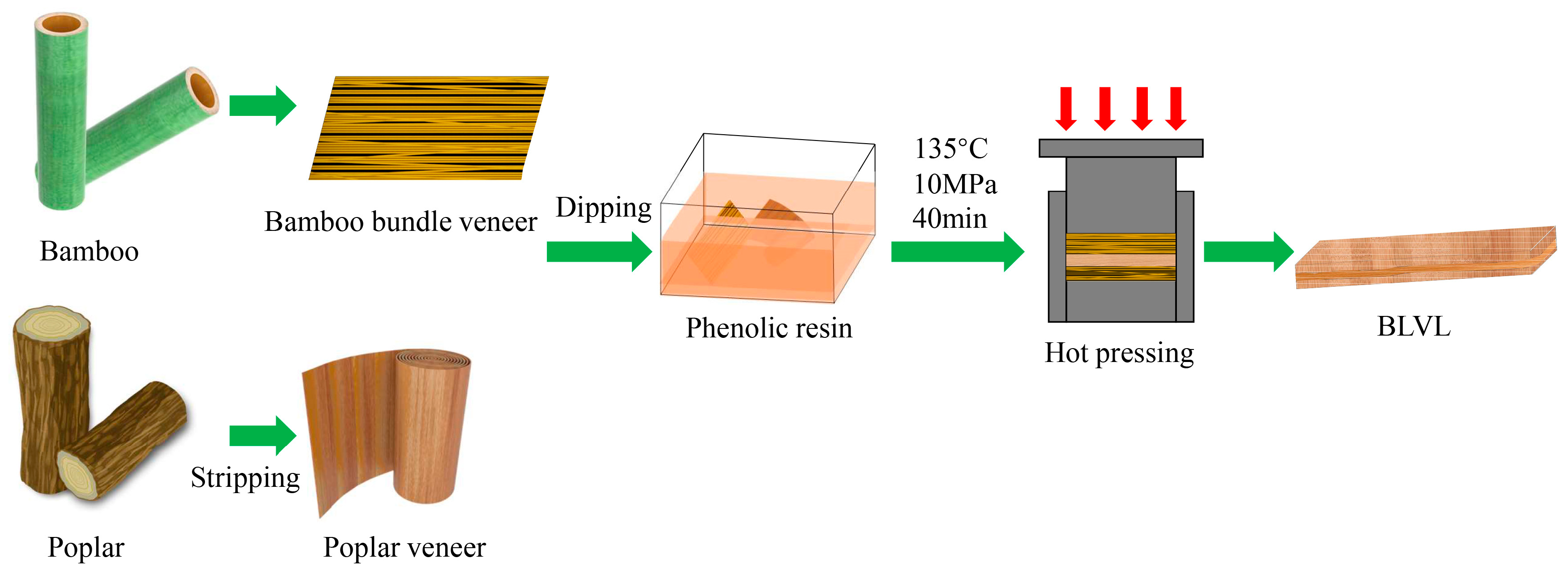

2.2.2. Preparation of Bamboo–Wood Veneer (BLVL) Composite Flooring

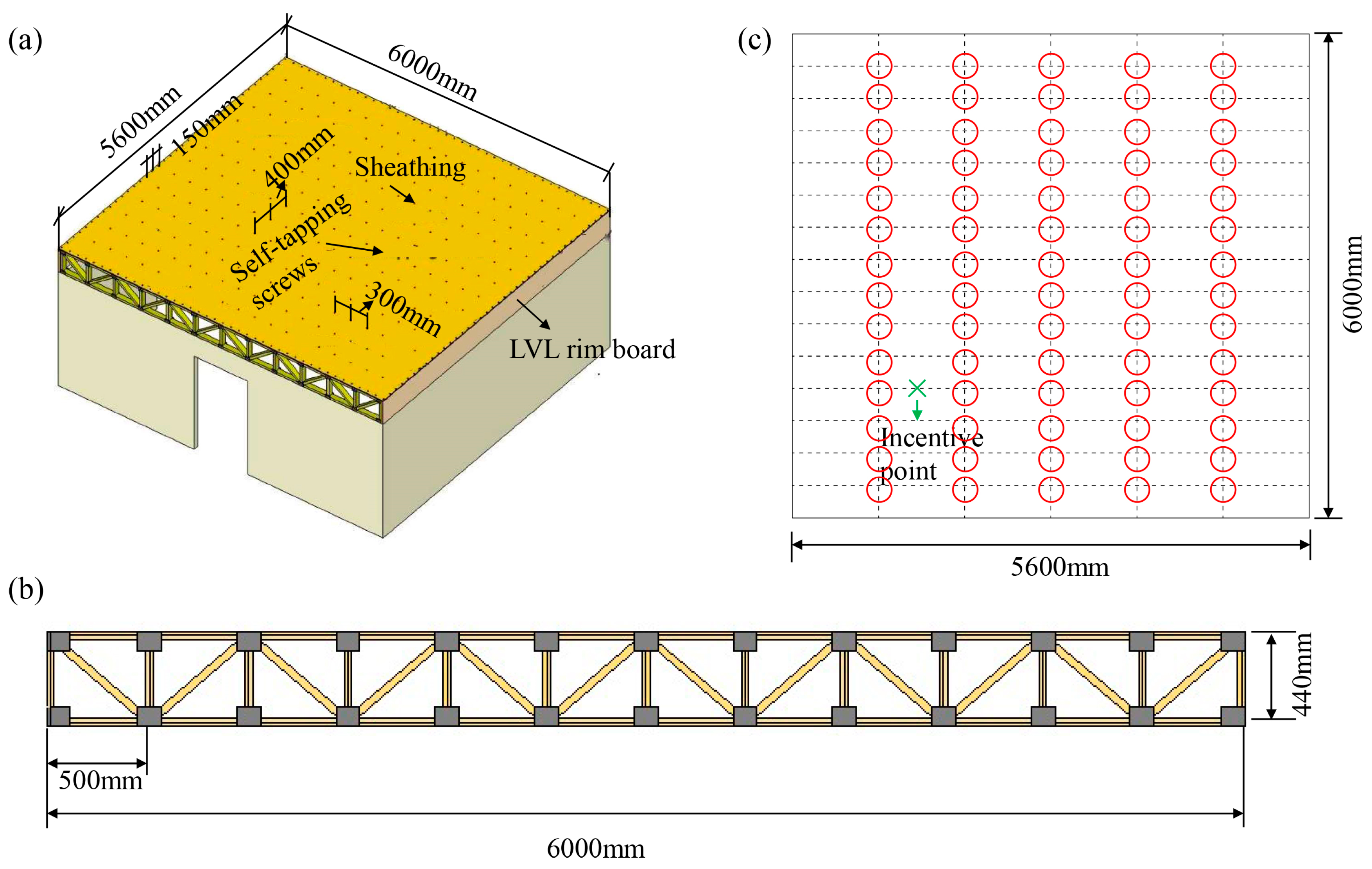

2.2.3. Test Floor Slab Design and Construction

2.2.4. Vibration Performance Test on the Floor Slab

3. Results and Discussion

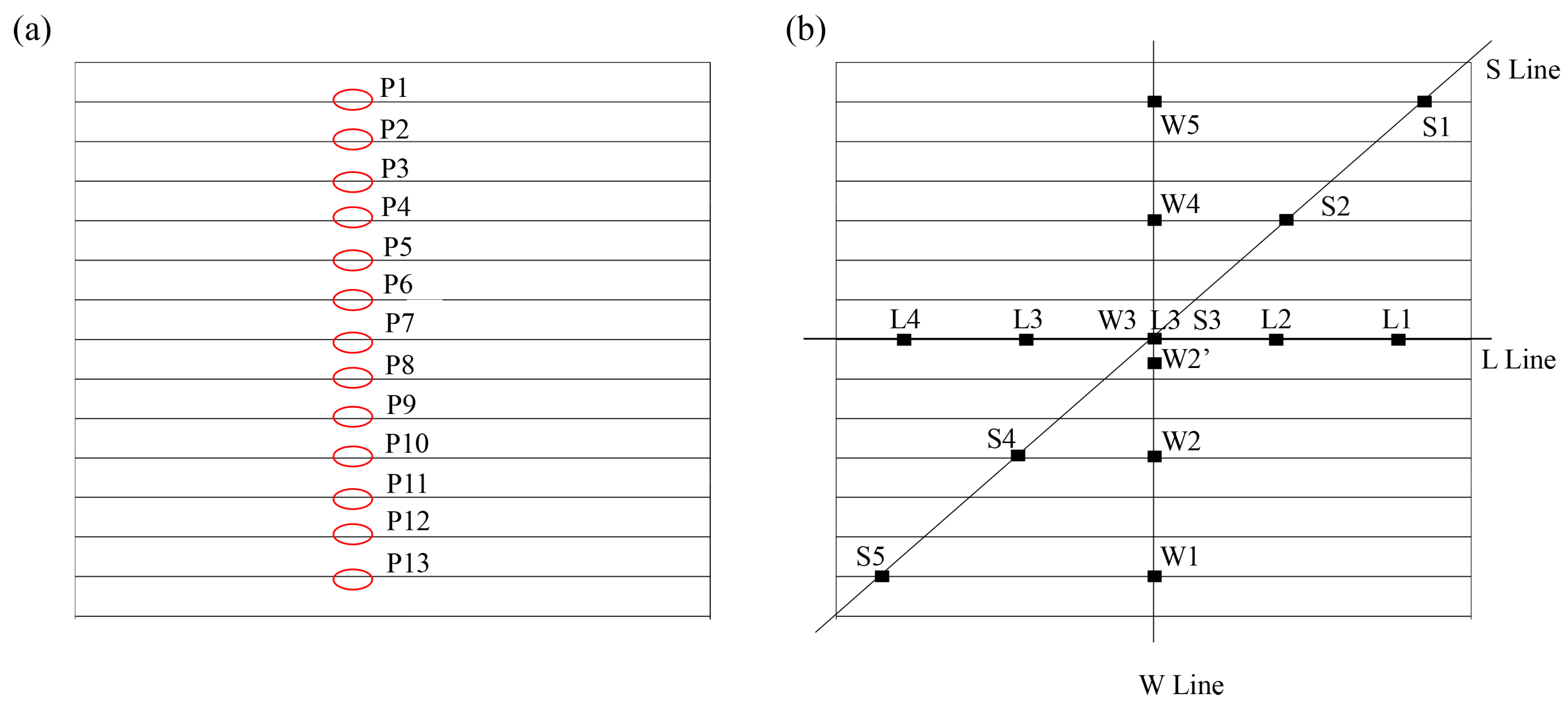

3.1. Vibration Modes

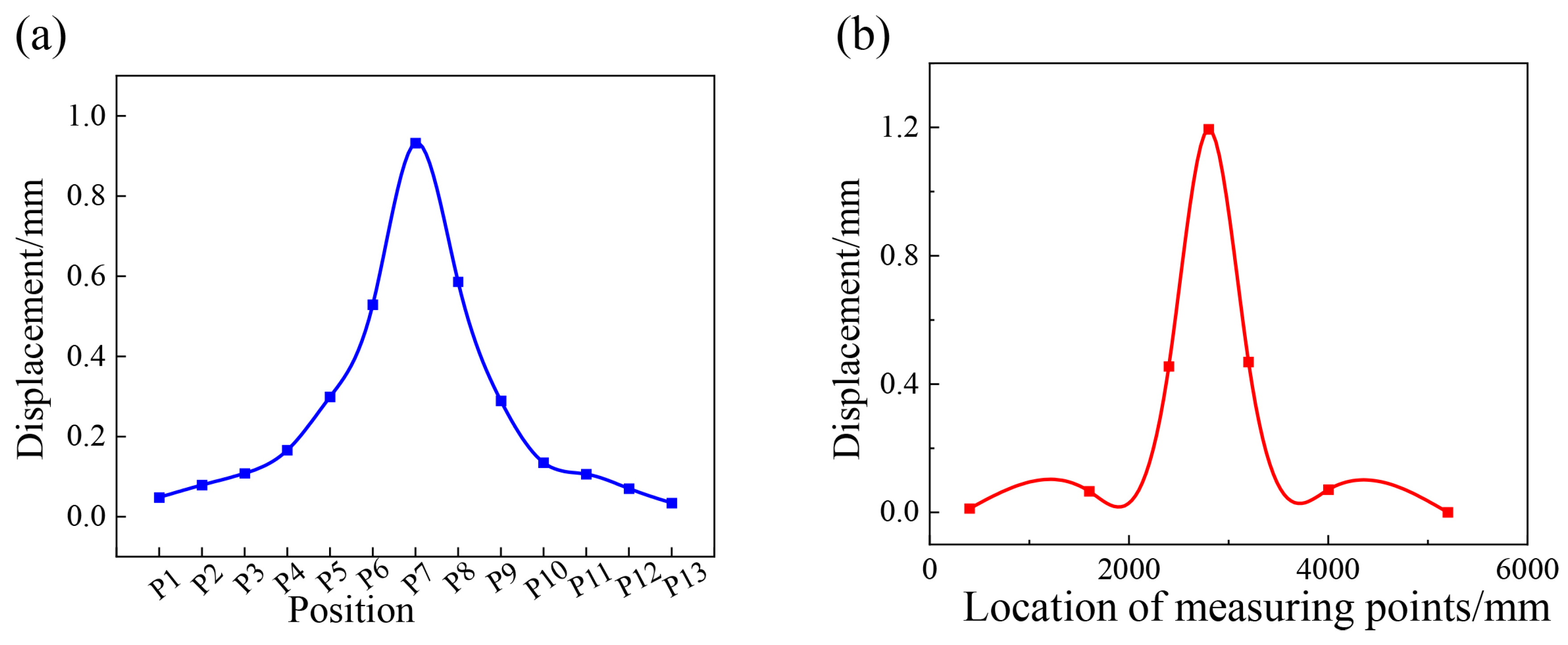

3.2. Static Deflection

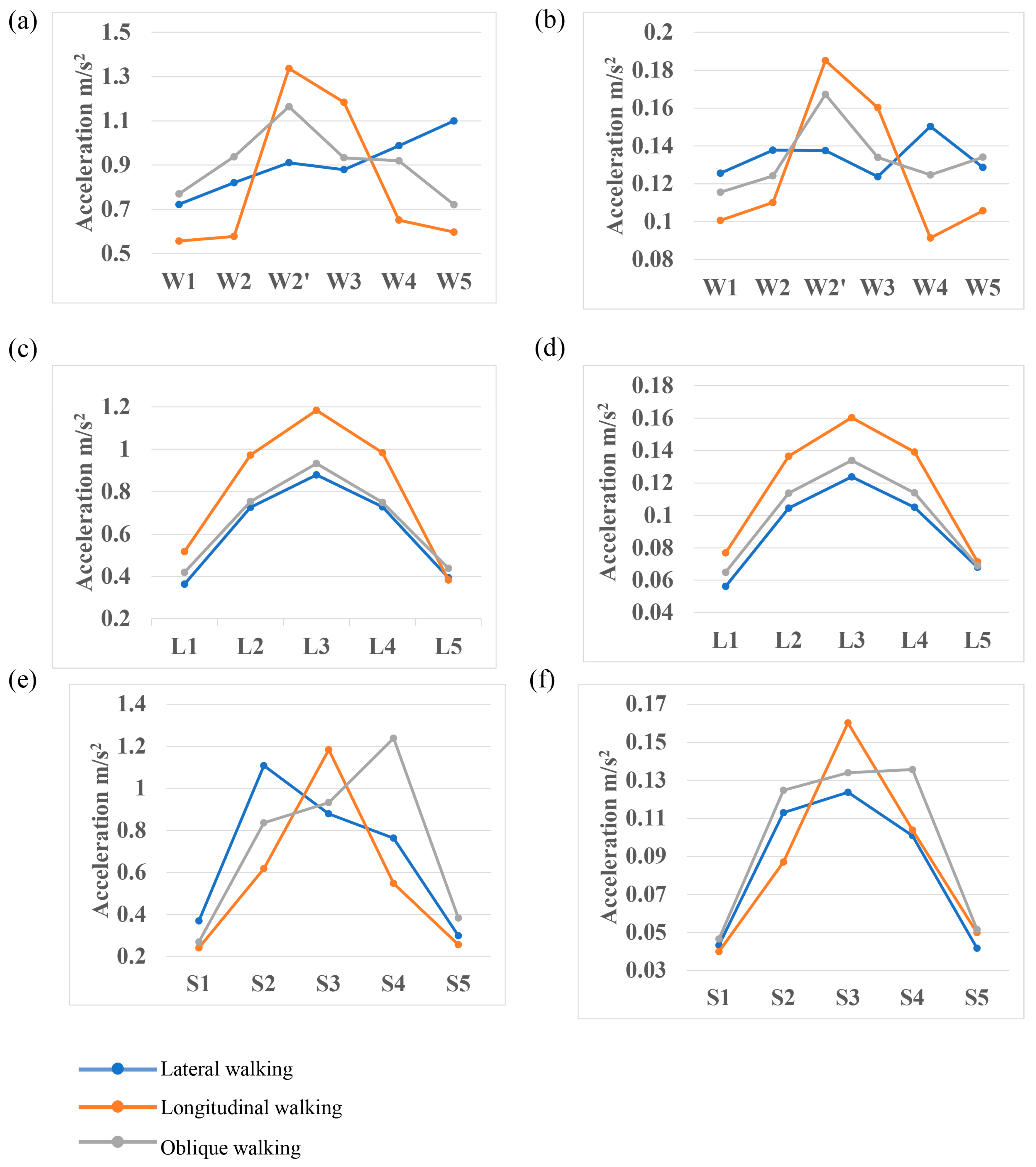

3.3. Single-Person Walking Load

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Li, H.; Li, Y.; Xiong, Z.; Zhang, N.; Lorenzo, R.; Ashraf, M. Effect of nodes on mechanical properties and microstructure of laminated bamboo lumber units. Constr. Build. Mater. 2021, 304, 124427. [Google Scholar] [CrossRef]

- Prabhudass, J.M.; Palanikumar, K.; Natarajan, E.; Markandan, K. Enhanced thermal stability, mechanical properties and structural integrity of mwcnt filled bamboo/kenaf hybrid polymer nanocomposites. Materials 2022, 15, 506. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Li, J.; Mi, Z.H.R.; Dai, Y.; Xie, J. Rapid processing of whole bamboo with exposed, aligned nanofibrils toward a high-performance structural material. ACS Nano 2020, 14, 5194–5202. [Google Scholar] [CrossRef] [PubMed]

- Perfetto, D.; Lamanna, G.; Sepe, R. Design of a bamboo treadmill bicycle main frame. Macromol. Symp. 2020, 389, 1900101. [Google Scholar] [CrossRef]

- Xu, Q.; Leng, Y.; Chen, X. Experimental study on flexural performance of glued-laminated-timber-bamboo beams. Mater. Struct. 2018, 51, 9. [Google Scholar] [CrossRef]

- Zhao, F.; Xu, Z.; Zhang, Y. Application prospect of bamboo structural materials in the construction field. Constr. Technol. 2012, 3, 47–49. [Google Scholar]

- Wang, G.; Chen, F.; Cheng, H. Characteristic advantages and innovative development of China’s bamboo industry. World Bamboo Ratt. Commun. 2020, 18, 6–13. [Google Scholar]

- Okenwa, U.; Obiozo, E.; Faisa, A. Investigation of molecular and supramolecular assemblies of cellulose and lignin of lignocellulosic materials by spectroscopy and thermal analysis. Int. J. Biol. Macromol. 2020, 5, 916–921. [Google Scholar]

- Huang, Z.; Sun, Y.; Musso, F. Assessment on bamboo scrimber as a substitute for timber in building envelope in tropical and humid subtropical climate zones-part 2 performance in building envelope. IOP Conf. Ser. Mater. Sci. Eng. 2017, 264, 012007. [Google Scholar] [CrossRef]

- Li, W.; Long, Y.; Huang, J. Axial load behavior of structural bamboo filled with concrete and cement mortar. Constr. Build. Mater. 2017, 148, 273–287. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Liu, R. Study on bond performance of bamboo-steel interface after long-term loading. J. Build. Struct. 2017, 38, 110–120. [Google Scholar]

- Nguyen, D.; Grillet, A.; Diep, T. Hygric and thermal insulation properties of building materials based on bamboo fibers. In Proceedings of the 4th Congrès International de Géotechnique-Ouvrages-Structures: CIGOS, Ho Chi Minh City, Vietnam, 26–27 October 2017; Springer: Singapore, 2017; pp. 508–522. [Google Scholar]

- Hao, J.; Kou, Y.; Tian, L. Experimental study on the bending resistance of the composite floor with sprayed composite material and dense raw bamboo. J. Xi’an Univ. Archit. Technol. 2018, 50, 471–476. [Google Scholar]

- Xia, Y.; Zheng, X.; Wei, J. Research on vibration and bending performance of plywood—Thin-walled steel composite floor. Wood Ind. 2020, 34, 18–22. [Google Scholar]

- Zhou, X.; Gao, T.; Shi, Y. Experimental study on static deflection and vibration performance of cold-formed thin-walled steel beam-OSB composite floor. Eng. Mech. 2014, 31, 211–217. [Google Scholar]

- Zhang, Y.; Yu, W.; Kim, N. Mechanical performance and dimensional stability of bamboo fiber-based composite. Polymers 2021, 13, 1732. [Google Scholar] [CrossRef]

- Li, Z.H.; Chen, C.J.; Mi, R.Y.; Gan, W.T.; Hu, L.B. A strong, tough, and scalable structural material from fast-rowing bamboo. Adv. Mater. 2020, 32, 1906308. [Google Scholar] [CrossRef]

- Chen, L.; Han, S.; Li, D.; Chen, F.; Wang, G. The effect of constituent units on the vibration reduction of bamboo engineering materials: The synergistic vibration reduction mechanism of bamboo stiffness and wood damping. Ind. Crops Prod. 2020, 189, 115785. [Google Scholar] [CrossRef]

- Deng, J.; Zhou, H.; Chen, F. Control on gradient adhesive loading of porous laminate: Effects on multiple performance of composites with bamboo bundle and sliver. J. Renew. Mater. 2021, 9, 1555–1570. [Google Scholar] [CrossRef]

- Zhou, H.; Wei, X.; Smith, M.L.; Wang, G.; Chen, F. Evaluation of uniformity of bamboo bundle veneer and bamboo bundle laminated veneer lumber (BLVL). Forests 2019, 10, 921. [Google Scholar] [CrossRef]

- Jain, D.; Zhao, Y.Q. Analysis of three-dimensional bending deformations and failure of wet and dry laminates. Compos. Struct. 2020, 252, 112687. [Google Scholar] [CrossRef]

- Li, J.; Ma, R.; Lu, Y.Z.; Liu, R.M.; Su, X.; Jin, R.; Zhang, Y.; Bao, Y. Bamboo-inspired design of a stable and high-efficiency catalytic capillary microreactor for nitroaromatics reduction. Appl. Catal. B-Environ. 2022, 310, 121297. [Google Scholar] [CrossRef]

- Zhang, C. Hygromechanics and Shape Memory of Wood Cell Wall Investigated with Multiscale Modeling. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2020. [Google Scholar]

- Gamerro, J.; Robeller, C.; Weinand, Y. Rotational mechanical behavior of wood-wood connections with application to double-layered folded timber-plate structure. Constr. Build. Mater. 2018, 165, 434–442. [Google Scholar] [CrossRef]

- Cui, H.X.; Guan, M.J.; Zhu, Y.X. The flexural characteristics of prestressed bamboo slivers reinforced parallel strand lumber (PSL). Key Eng. Mater. 2022, 517, 96–100. [Google Scholar] [CrossRef]

- Duan, Y.; Zhang, J.; Tong, K.; Wu, P. The effect of interfacial slip on the flexural behavior of steel-bamboo composite beams. Structures 2021, 32, 2060–2072. [Google Scholar] [CrossRef]

- Chen, M.; Ye, L.; Semple, K.; Ma, J.; Zhang, J. A new protocol for rapid assessment of bond durability of bio-based pipes: Bamboo winding composite pipe as a case study. Eur. J. Wood Wood Prod. 2022, 80, 947–959. [Google Scholar] [CrossRef]

- Lou, Z.; Han, X.; Liu, J. Nano-Fe3O4/bamboo bundles/phenolic resin oriented recombination ternary composite with enhanced multiple functions. Compos. Part B Eng. 2021, 226, 109335. [Google Scholar] [CrossRef]

- Kulasinski, K.; Derome, D. Impact of hydration on the micromechanical properties of the polymer composite structure of wood investigated with atomistic simulations. J. Mech. Phys. Solids 2017, 103, 221–235. [Google Scholar] [CrossRef]

- Lou, Z.; Yuan, T.C.; Wang, Q.Y. Fabrication of Crack-Free Flattened Bamboo and Its Macro-/MicroMorphological and Mechanical Properties. J. Renew. Mater. 2021, 9, 959–977. [Google Scholar] [CrossRef]

- Califano, A.; Zanola, A.; Terlizzi, I. Preliminary evaluation of the climate-induced fatigue in wood: A physical and computational approach. Forces Mech. 2023, 11, 100168. [Google Scholar] [CrossRef]

- Habibi, M.K.; Tam, L.H.; Lau, D.; Lu, Y. Viscoelastic damping behavior of structural bamboo material and its microstructural origins. Mech. Mater. 2016, 97, 184–198. [Google Scholar] [CrossRef]

- Kazemi, N.S.; Kiaefar, A. Effect of bark flour content on the hygroscopic characteristics of wood–polypropylene composites. J. Appl. Polym. Sci. 2018, 110, 3116–3120. [Google Scholar] [CrossRef]

- ISO 18324:2016; Timber Structures—Test Methods—Floor Vibration Performance. International Organization for Standardization: Beijing, China, 2016.

- LY/T 3218-2020; Testing Methods for Vibration Performance of Wood Structure Floors. China Industry Standard Forestry: Beijing, China, 2020.

- Lin, S. Accurate Calculation Theory of Internal Force Envelope Diagram of Bar System Structure under Moving Load. Ph.D. Thesis, Tsinghua University, Beijing, China, 2018. [Google Scholar]

- AISC/CISC. Design Guidelines for Steel Structures in the United States; AISC/CISC: Chicago, IL, USA, 1997. [Google Scholar]

- Li, J.P.; Li, X.D.; Zhang, L.X. Discussion on Eurocode 8-structural seismic design. World Earthq. Eng. 2006, 3, 53–59. [Google Scholar]

- Fu, W.G. Introduction to the Canadian National Building Code NBC-2010. Build. Struct. 2018, 4, 34–39. [Google Scholar]

- CECS261:2009; Code for Design of Steel Structure Residential Buildings. China Engineering Construction Standardization Association: Beijing, China, 2009.

- Yang, Y.; Bai, S.L. Relevant issues in the evaluation of seismic design safety level in China from the comparison of national codes. J. Chongqing Jianzhu Univ. 2000, 1, 192–200. [Google Scholar]

- Yu, Z.; Shi, S.H.; Shen, J. A comparative study of seismic design response spectra in China, the United States, and Europe. Earthq. Disaster Prev. Technol. 2008, 2, 136–144. [Google Scholar]

- Du, X.; Mao, K.; Lin, C. Analysis of the architecture of Canadian building technical regulations system. Eng. Constr. Stand. 2019, 4, 47–56. [Google Scholar]

- Zhou, H. Study on Manufacture and Deformation of Thin Bamboo Bundle Veneer Laminated Composites. Ph.D. Thesis, Chinese Academy of Forestry, Beijing, China, 2020. [Google Scholar]

| Type | Order | Frequency (Hz) | Damping Ratio (%) |

|---|---|---|---|

| BLVL | 1 | 13.769 | 2.728 |

| 2 | 19.533 | 1.337 | |

| 3 | 22.321 | 1.262 | |

| OSB | 1 | 14.812 | 7.037 |

| 2 | 17.801 | 7.302 | |

| 3 | 21.034 | 5.511 |

| Building Cover Types | RMS Acceleration (m·s−2) | Peak Acceleration (m·s−2) | ||||

|---|---|---|---|---|---|---|

| S | W | L | S | W | L | |

| OSB | - | 0.138 | 0.263 | - | 1.62 | 2.13 |

| BLVL | 0.134 | 0.124 | 0.16 | 0.933 | 0.879 | 1.184 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, L.; Han, S.; Li, D.; Deng, J.; Chen, F.; Wang, G. Vibration Performance of Bamboo Bundle/Wood Veneer Composite Floor Slabs for Joist-Type Floor Coverings. Buildings 2023, 13, 1265. https://doi.org/10.3390/buildings13051265

Chen L, Han S, Li D, Deng J, Chen F, Wang G. Vibration Performance of Bamboo Bundle/Wood Veneer Composite Floor Slabs for Joist-Type Floor Coverings. Buildings. 2023; 13(5):1265. https://doi.org/10.3390/buildings13051265

Chicago/Turabian StyleChen, Linbi, Shanyu Han, Deyue Li, Jianchao Deng, Fuming Chen, and Ge Wang. 2023. "Vibration Performance of Bamboo Bundle/Wood Veneer Composite Floor Slabs for Joist-Type Floor Coverings" Buildings 13, no. 5: 1265. https://doi.org/10.3390/buildings13051265

APA StyleChen, L., Han, S., Li, D., Deng, J., Chen, F., & Wang, G. (2023). Vibration Performance of Bamboo Bundle/Wood Veneer Composite Floor Slabs for Joist-Type Floor Coverings. Buildings, 13(5), 1265. https://doi.org/10.3390/buildings13051265