Structural Performance of Internally Stiffened Double-Skinned Profiled Composite Walls with Openings

Abstract

:1. Introduction

2. Experimental Approach

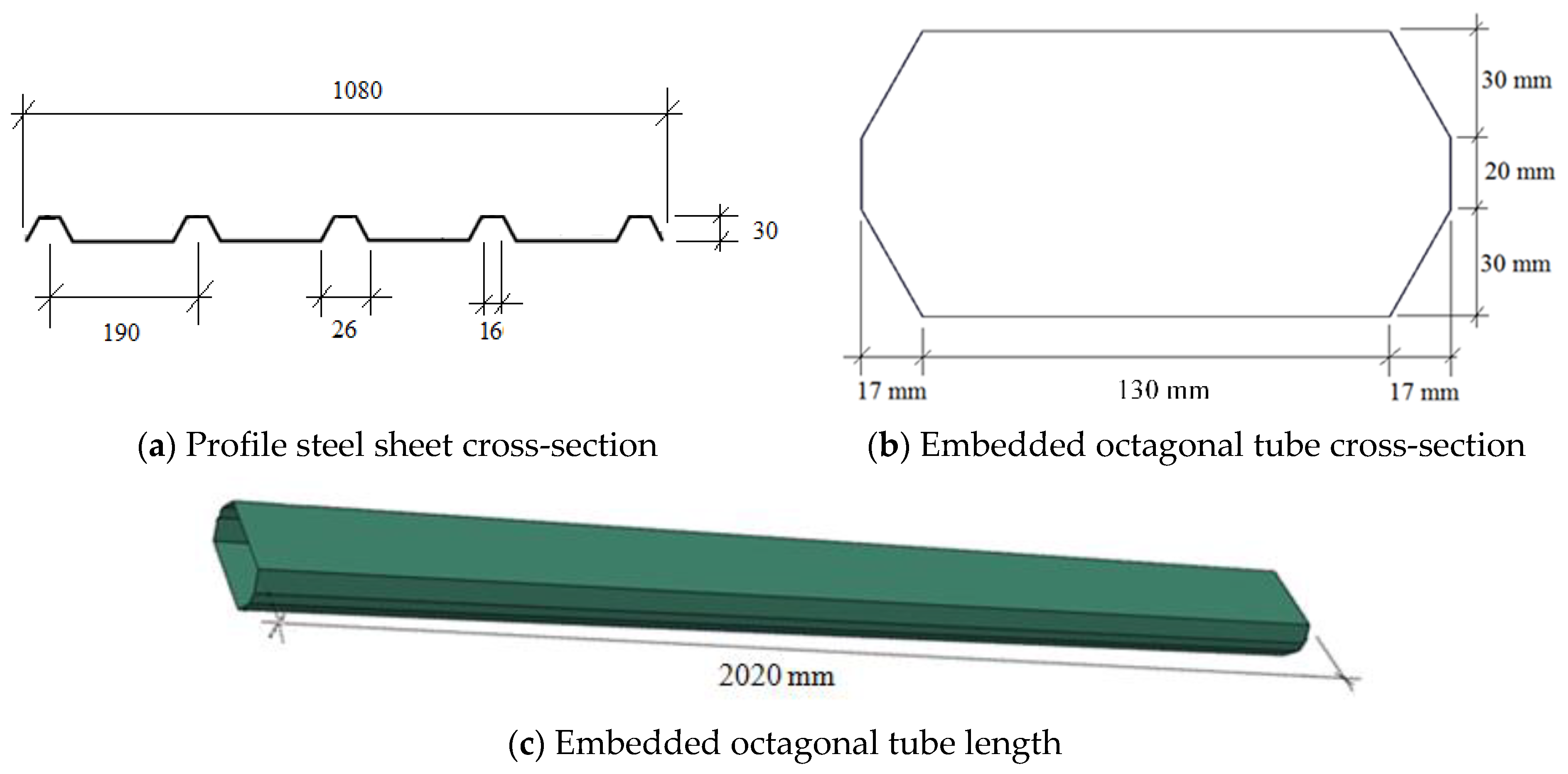

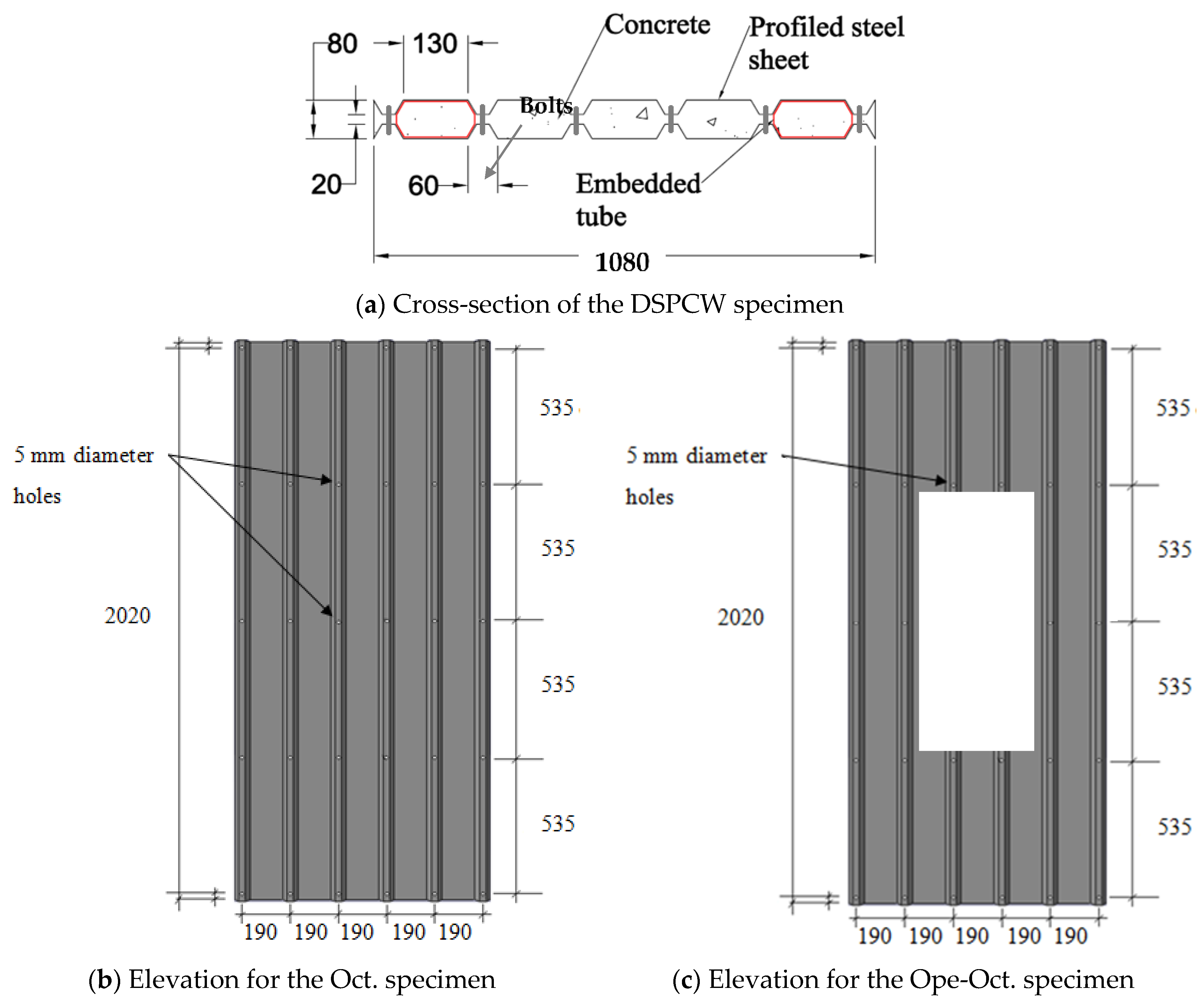

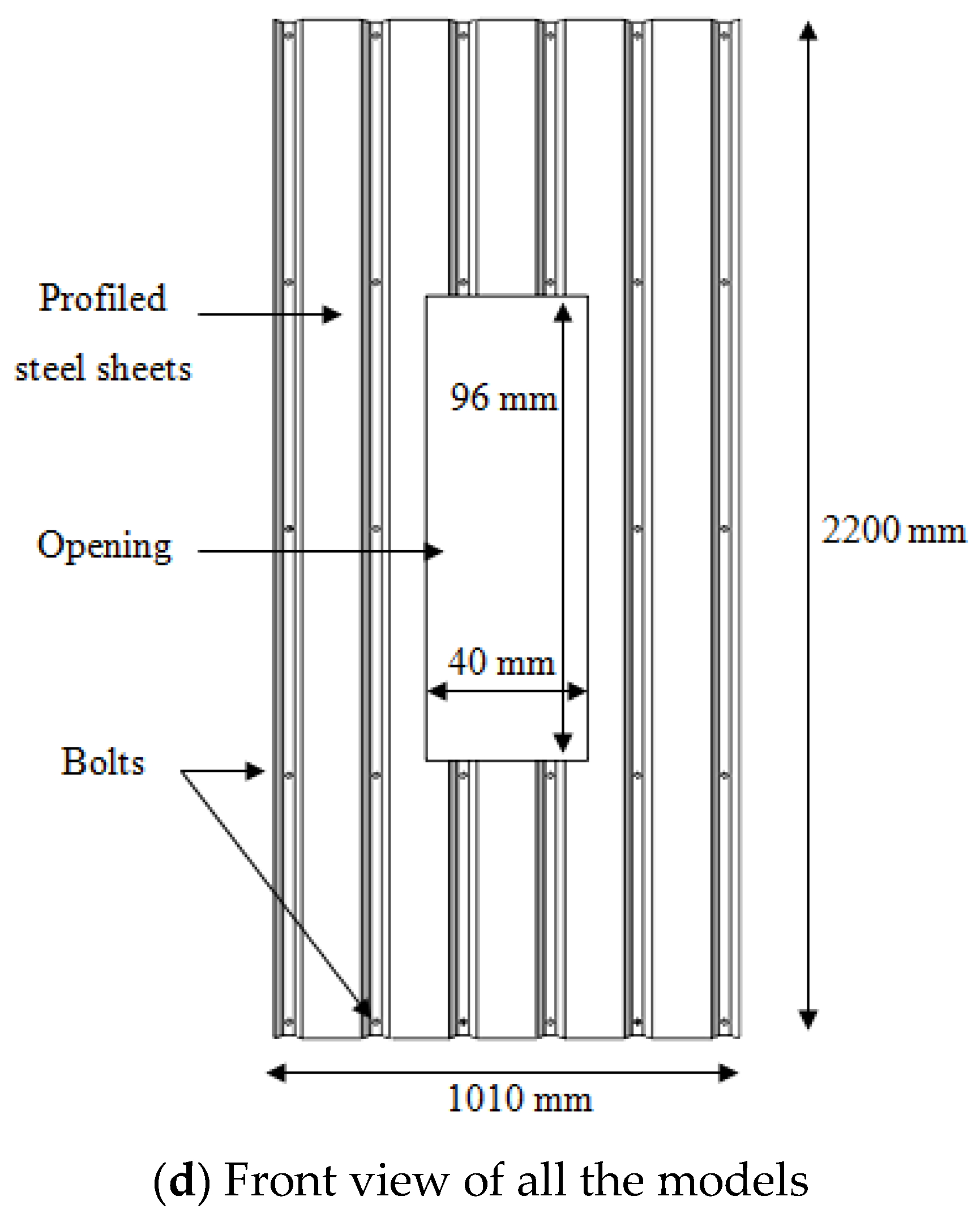

2.1. Specimen Preparation

2.2. Material Properties

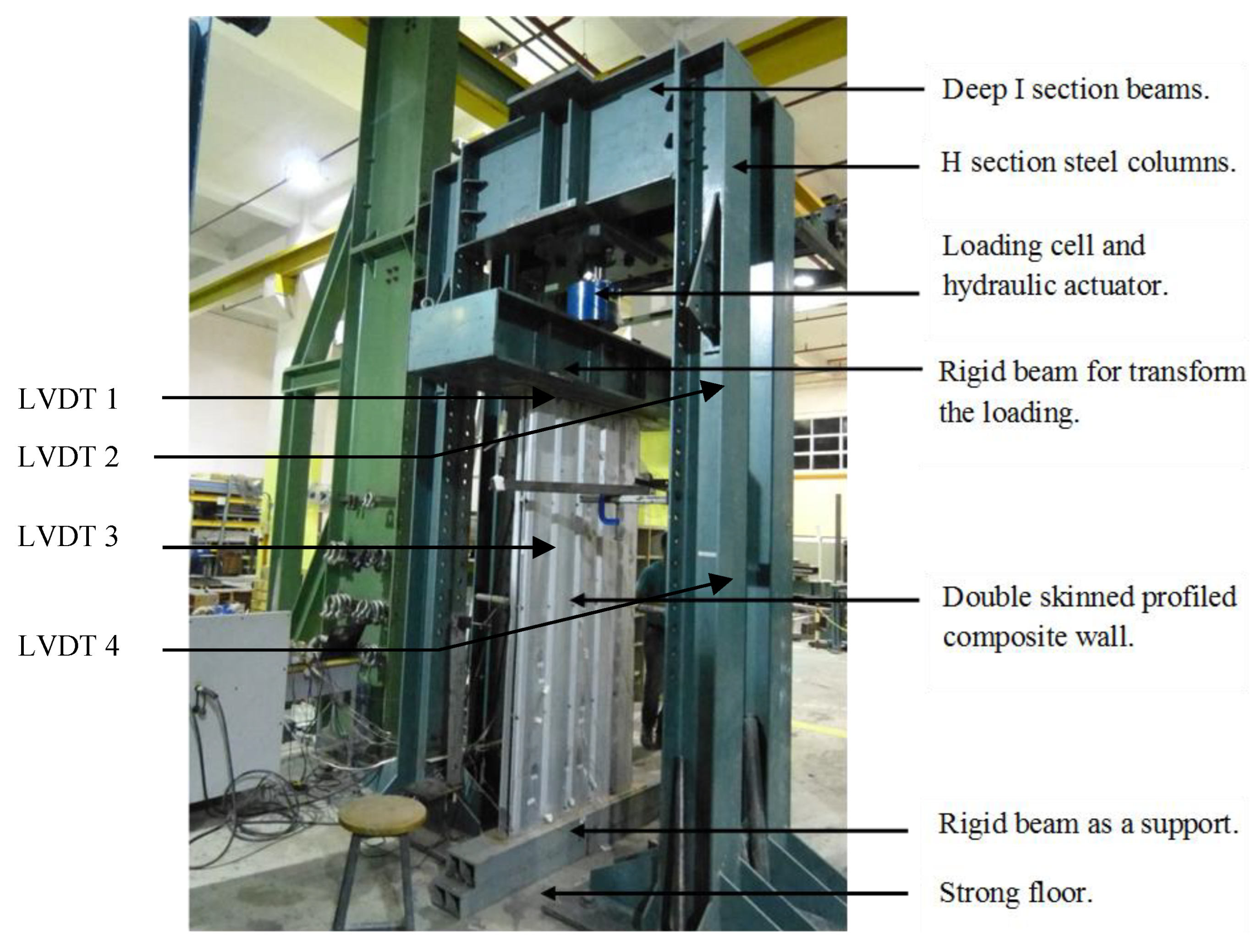

2.3. Test Setup

3. Discussion of the Experimental Results

3.1. Axial Load vs. Displacement Relationship

3.2. Failure Modes

4. Numerical Approach

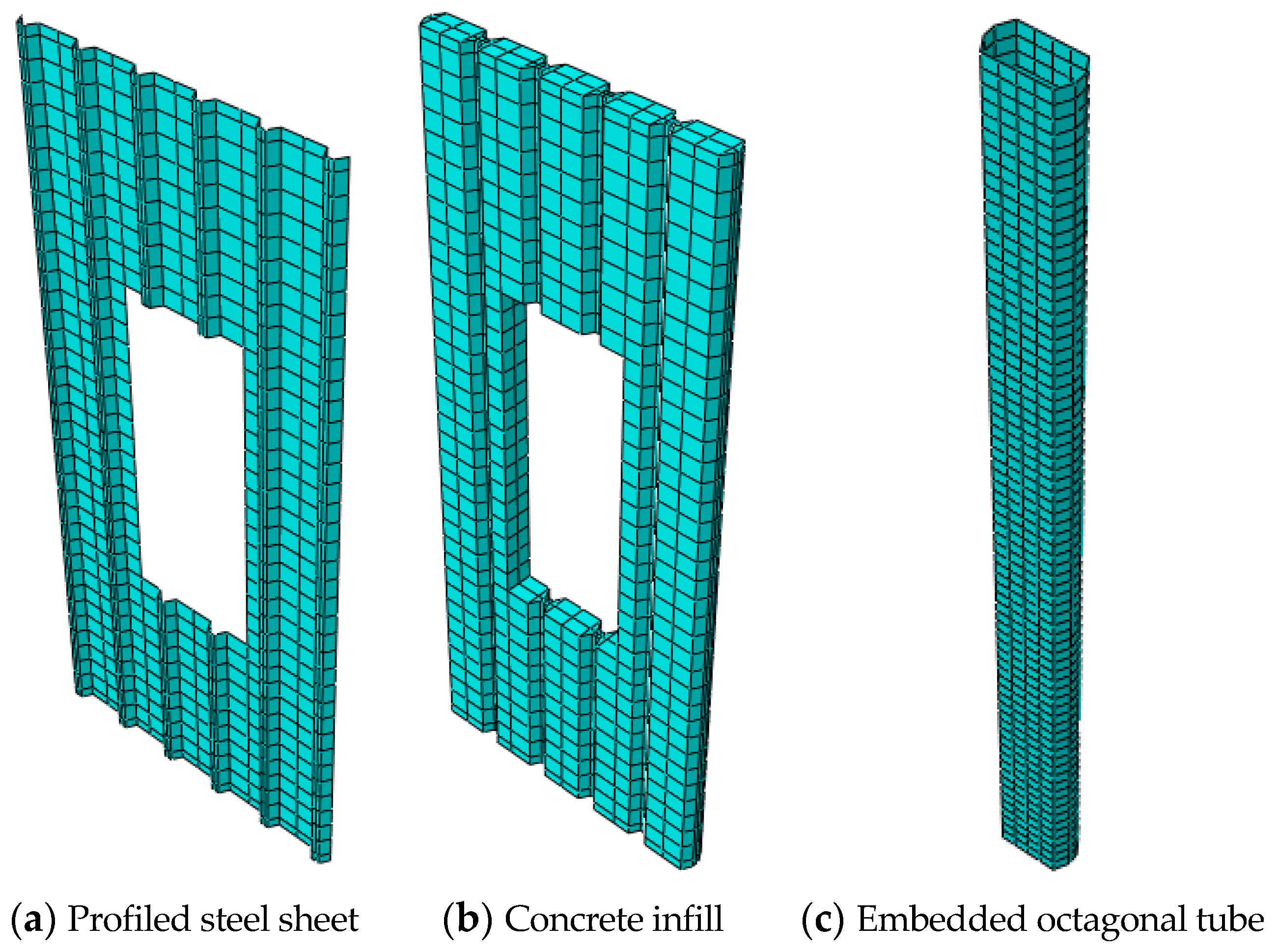

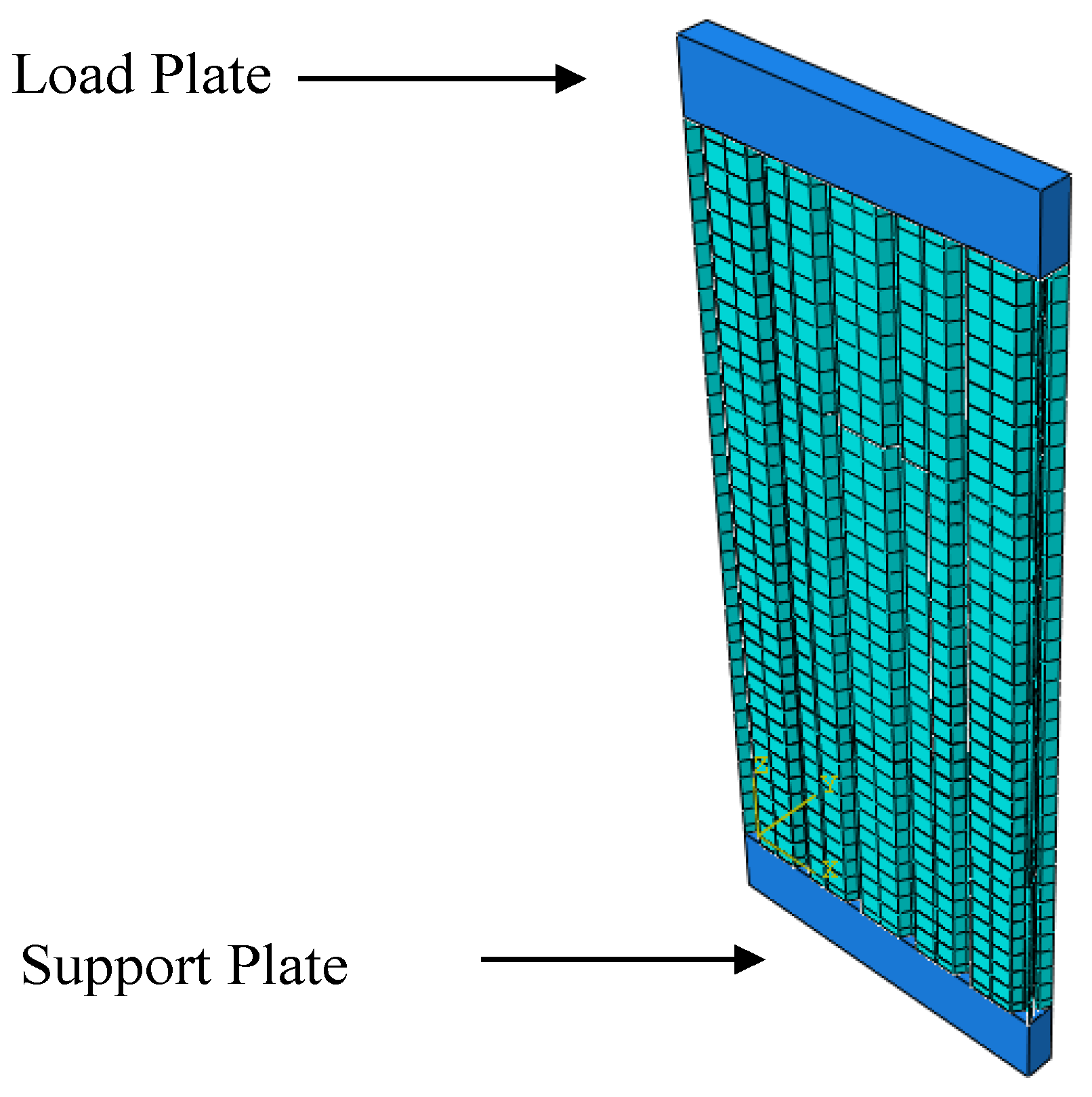

4.1. Description of the FE Model

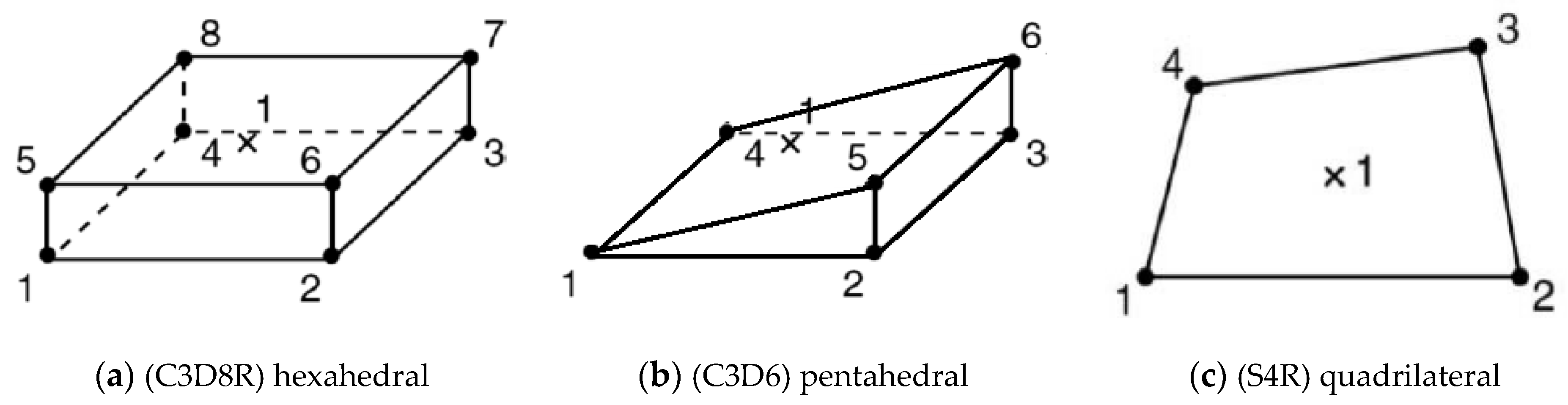

4.2. Elements, Interactions, and Boundary Conditions

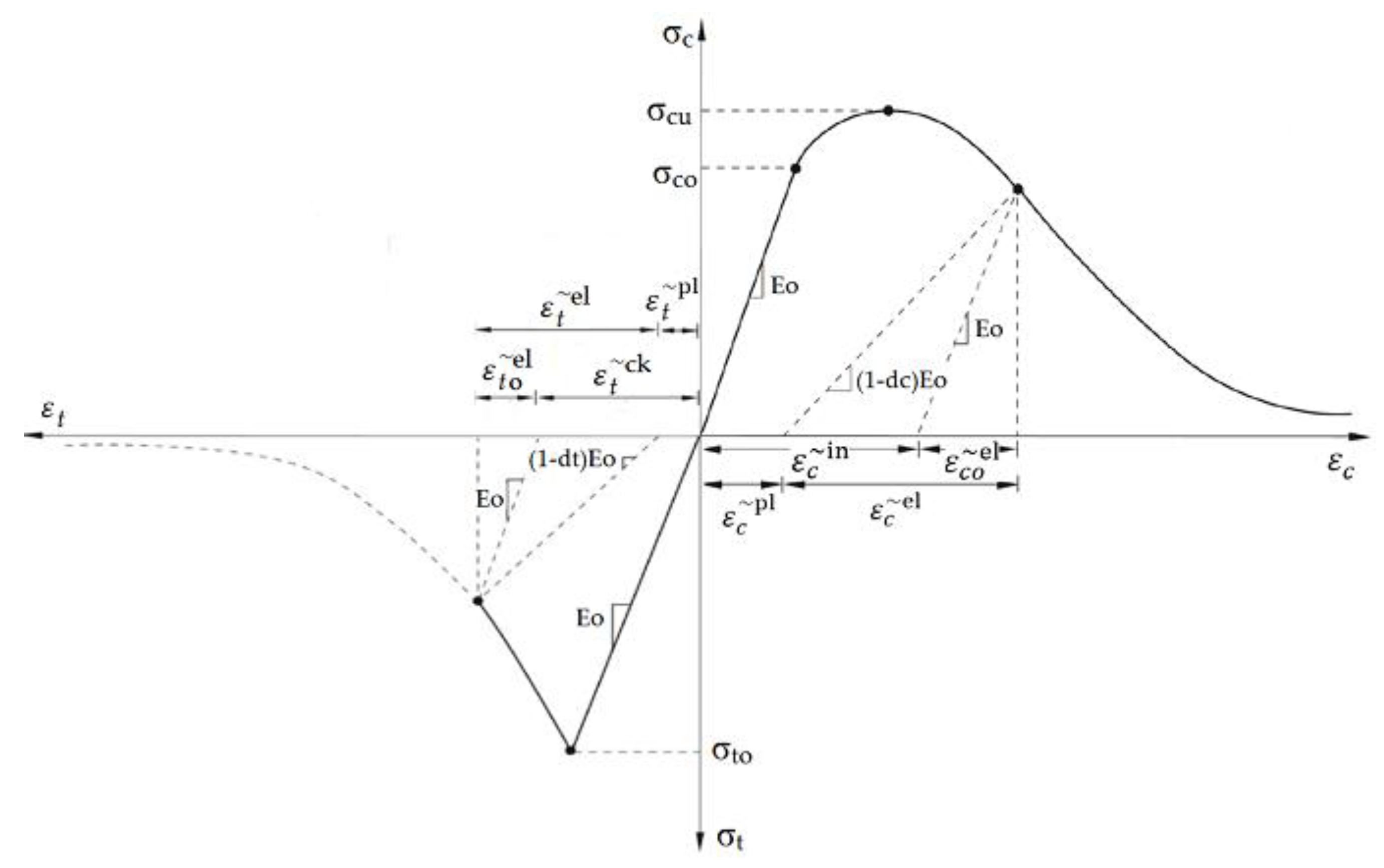

4.3. Modeling of Materials

4.4. Convergence Study

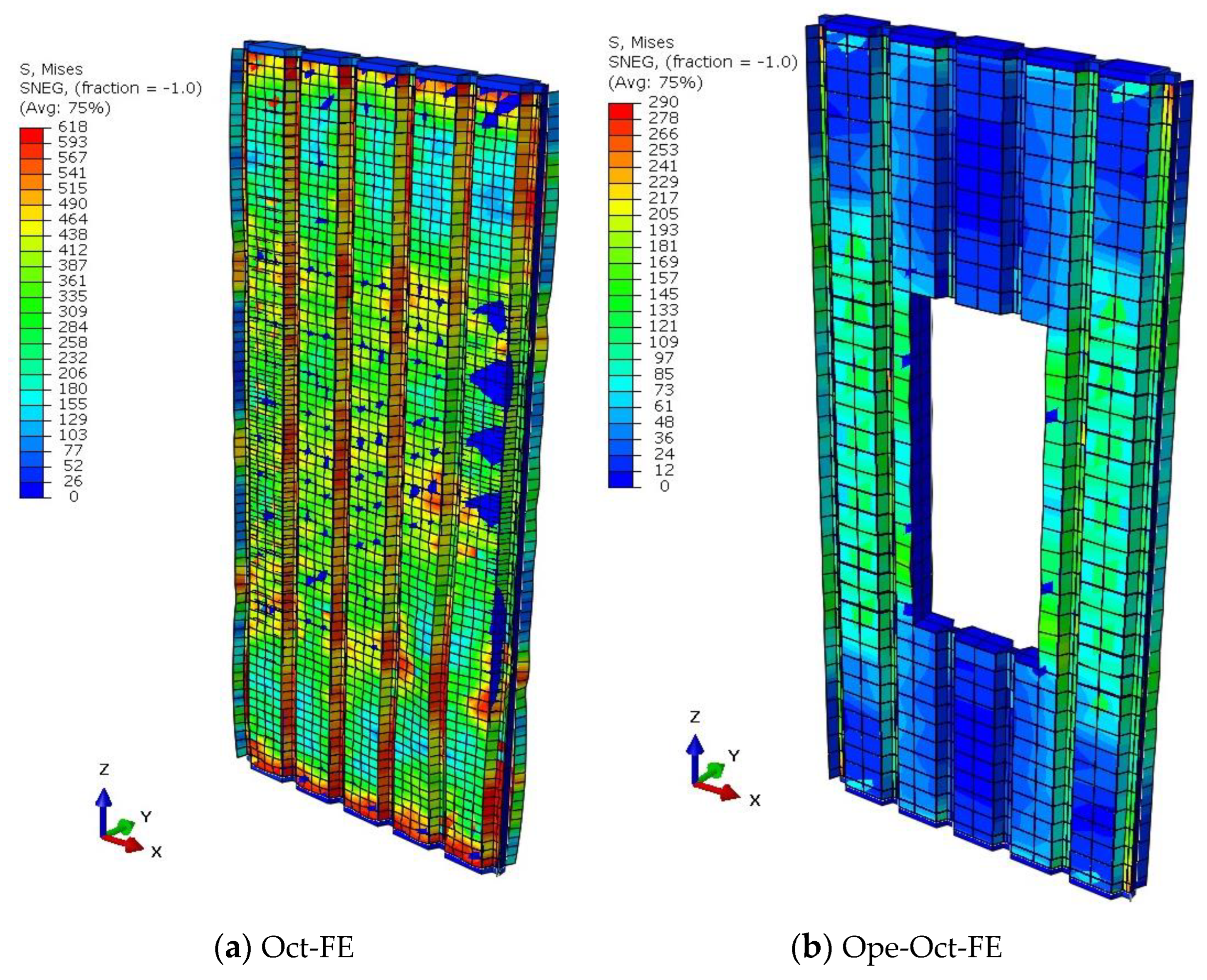

4.5. Verification Study

5. Parametric Study

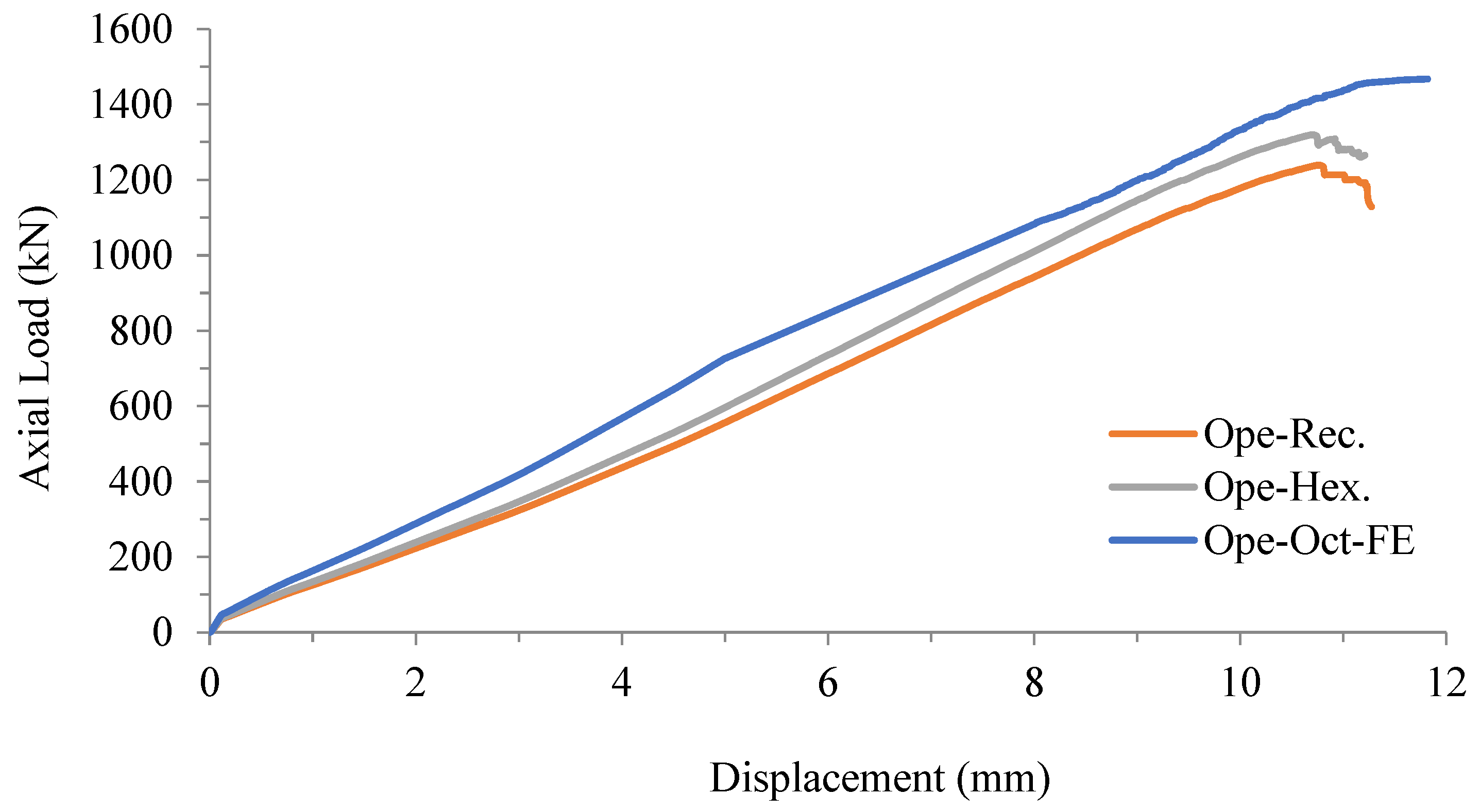

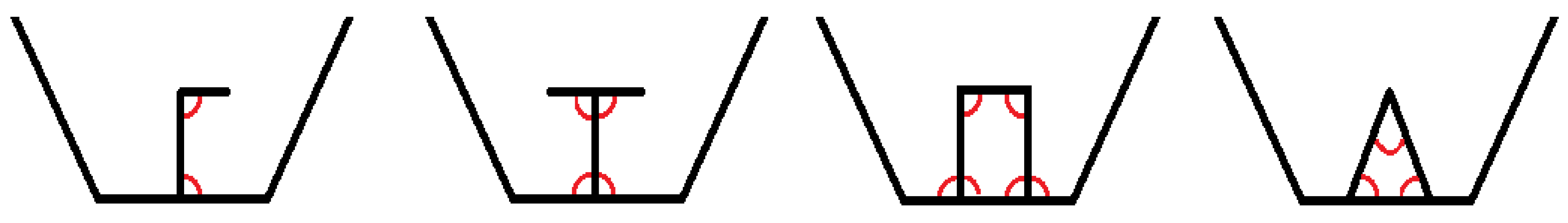

5.1. Effect of the Embedded Tube’s Cross-Section

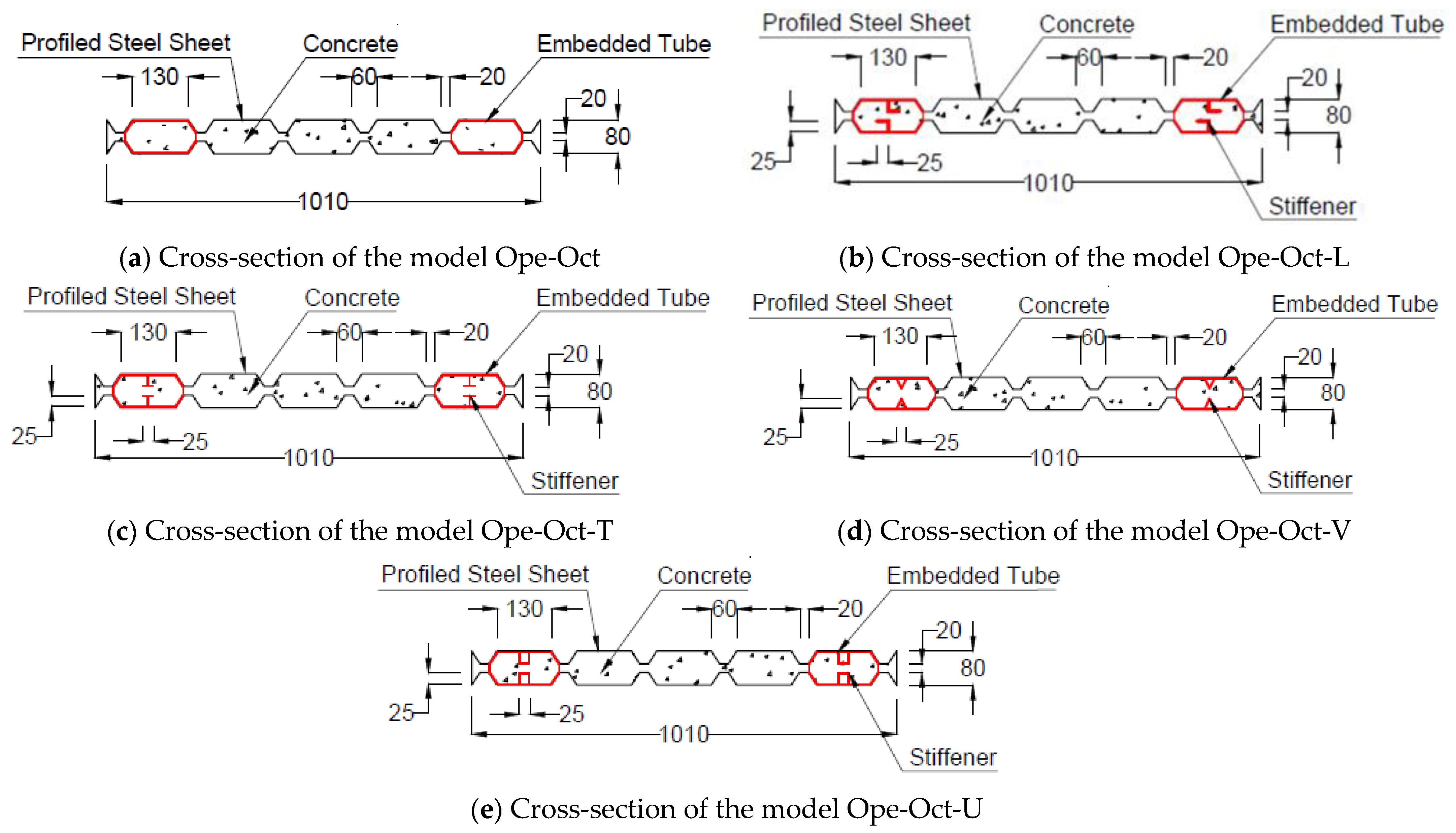

5.2. Effect of the Embedded Octagonal Tubes Stiffened with Steel Stiffeners

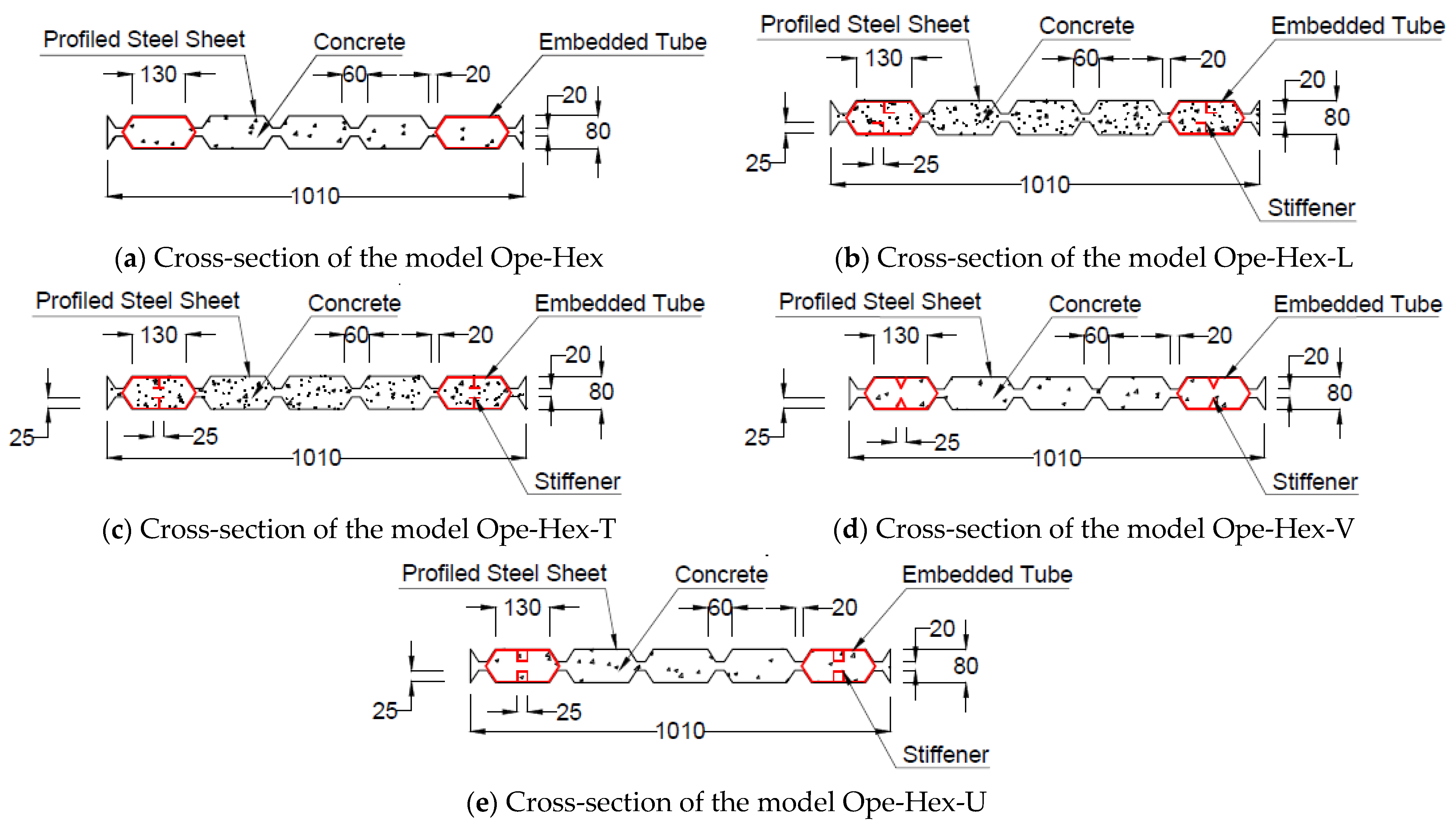

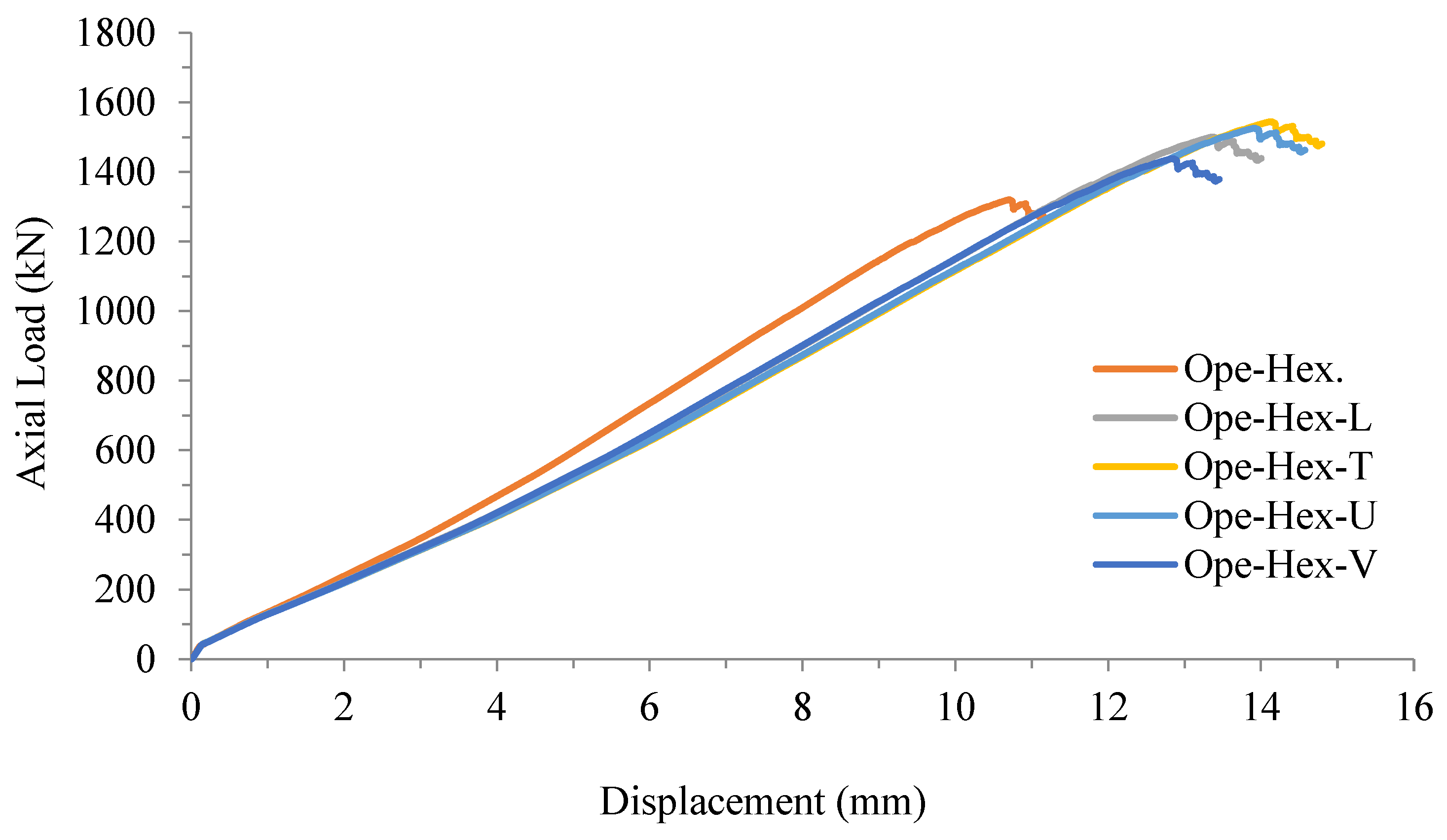

5.3. Effect of the Embedded Hexagon Tubes Stiffened with Steel Stiffeners

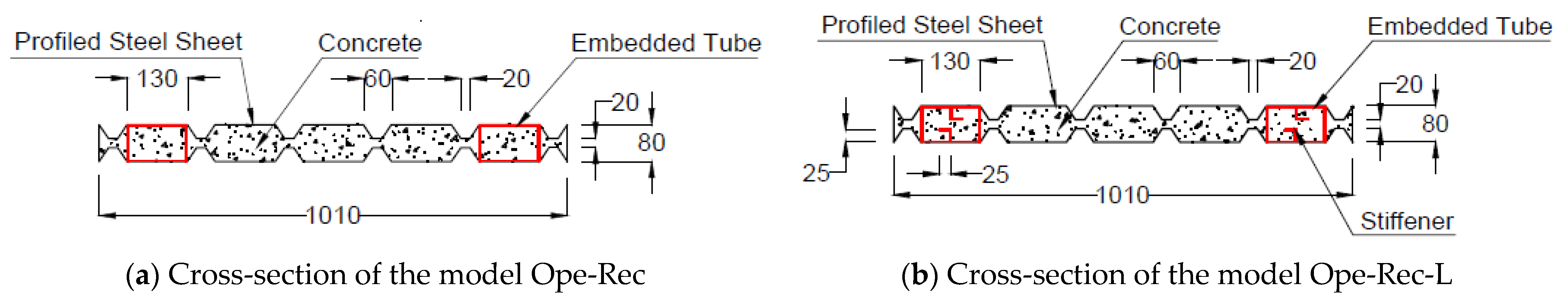

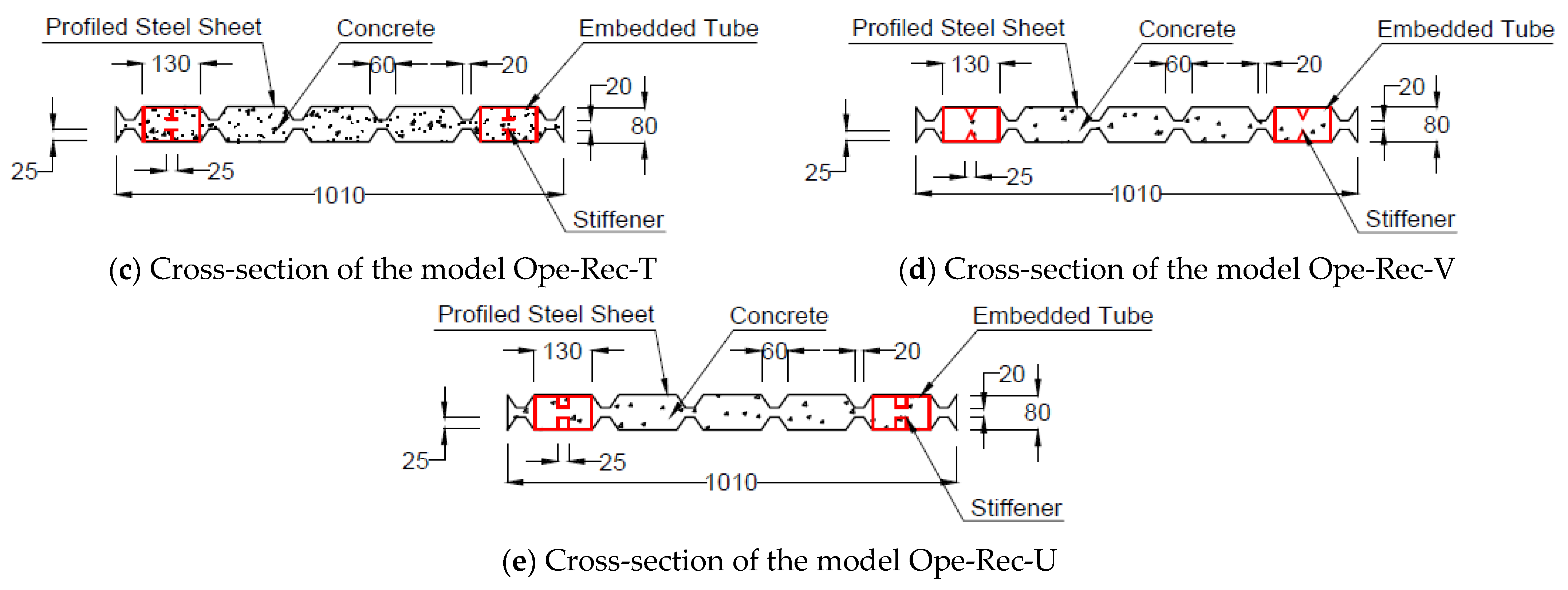

5.4. Effect of the Embedded Rectangular Tubes Stiffened with Steel Stiffeners

6. Discussion

7. Conclusions

- Firstly, the presence of openings in DSPCWs resulted in a reduction of approximately 10% in their axial capacity compared to control walls without openings. Specifically, the axial load capacity of the control wall was recorded as 1473 kN, while the wall with an opening (Ope-Oct.) had an axial load capacity of 1338 kN.

- Secondly, the currently adopted numerical approach effectively simulates the experimental results of the ultimate loading capacity and axial behavior of DSPCWs strengthened with embedded CFST columns. The FE models of both walls with and without openings reasonably overestimated the actual results by about 2.6% and 12.4%, respectively. Additionally, unlike the overall buckling failure observed in the tested specimens, which occurred at the extreme loading stage, the corresponding FE models accurately simulated the local buckling failure mode of the PSS parts.

- Thirdly, among the different cross-sectional shapes of CFST columns, octagonal shapes demonstrated superior performance, achieving an increase in loading capacity of 11% and 18.4% compared to hexagonal and rectangular CFST columns, respectively. For example, the octagonal CFST columns increased the axial load capacity of the DSPCW system to 1642 kN.

- Additionally, the introduction of internal steel stiffeners to reinforce the embedded CFST columns led to further enhancements in the axial loading capacity of DSPCWs. Specifically, T-shaped stiffeners exhibited superior performance compared to L-shaped, V-shaped, and U-shaped stiffeners, resulting in increased capacity for DSPCWs with openings. For instance, the T-shaped stiffeners increased the axial load capacity of the DSPCW system by 19.2% compared to the control wall without stiffeners.

- The current study confirms that embedded CFST columns are effective in improving the axial loading capacity of DSPCWs, even in the presence of openings. The choice of CFST column shape and the use of steel stiffeners significantly influence the performance of DSPCWs. Future research is required to explore additional parameters that have not yet been investigated and develop analytical models to accurately predict the axial capacity of the suggested composite wall system. Additionally, efforts should be made to suggest and develop a simplified fabrication process scenario.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Cassese, P.; Riascos, C.; Rainieri, C.; De Luca, G.; Pavese, A.; Bonati, A. Experimental Study on the in-Plane Response of Cast-in-Situ Reinforced Concrete Sandwich Walls under Combined Vertical and Horizontal Load. Procedia Struct. Integr. 2023, 44, 774–781. [Google Scholar] [CrossRef]

- Konstandakopoulou, F.; Tsimirika, M.; Pnevmatikos, N.; Hatzigeorgiou, G.D. Optimization of Reinforced Concrete Retaining Walls Designed according to European Provisions. Infrastructures 2020, 5, 46. [Google Scholar] [CrossRef]

- Hilo, S.J.; Wan Badaruzzaman, W.H.; Osman, S.A.; Al Zand, A.W.; Samir, M.; Hasan, Q.A. A State-of-the-Art Review on Double-Skinned Composite Wall Systems. Thin-Walled Struct. 2015, 97, 74–100. [Google Scholar] [CrossRef]

- Senthilkumar, R.; Karunakaran, P.; Chandru, U. Progress and Challenges in Double Skin Steel–Concrete Composite Walls: A Review. Innov. Infrastruct. Solut. 2023, 8, 32. [Google Scholar] [CrossRef]

- Qin, Y.; Shu, G.P.; Fan, S.G.; Lu, J.Y.; Cao, S.; Han, J.H. Strength of Double Skin Steel-Concrete Composite Walls. Int. J. Steel Struct. 2017, 17, 535–541. [Google Scholar] [CrossRef]

- Le, Q.X.; Dao, V.T.N.; Torero, J.L.; Ngo, T.D. Experimental Study into the Behaviour of Profiled Composite Walls under Combined Axial and Thermal Loadings. Eng. Struct. 2020, 210, 110354. [Google Scholar] [CrossRef]

- Wright, H.D.; Evans, H.R.; Harding, P.W. The Use of Profiled Steel Sheeting in Floor Construction. J. Constr. Steel Res. 1987, 7, 279–295. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Youssf, O.; Mills, J.E.; Xiao, J.; Singh, A. Structural Performance of Composite Panels Made of Profiled Steel Skins and Foam Rubberised Concrete under Axial Compressive Loads. Eng. Struct. 2020, 211, 110448. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Xiao, J.; Youssf, O. Composite Walls Composed of Profiled Steel Skin and Foam Rubberized Concrete Subjected to Eccentric Compressions. J. Build. Eng. 2022, 46, 103715. [Google Scholar] [CrossRef]

- Qiao, W.; Zhang, X.; Xu, Q.; Wang, G. Seismic Performance of Thin-Walled Steel and Concrete Composite Column-Corrugated Steel Shear Wall Structure. J. Constr. Steel Res. 2023, 201, 107745. [Google Scholar] [CrossRef]

- Li, W.; Chen, H.; Li, F. Performance of Concrete-Filled Double-Skin Shallow-Corrugated Steel Plate Composite Walls under Compression-Bending Load. J. Constr. Steel Res. 2023, 201, 107701. [Google Scholar] [CrossRef]

- Sharda, A.; Manalo, A.; Ferdous, W.; Bai, Y.; Nicol, L.; Mohammed, A.; Benmokrane, B. Flexural Behaviour of Composite Modular Wall Systems under Uniformly Distributed and Concentrated Loads. Compos. Struct. 2023, 303, 116346. [Google Scholar] [CrossRef]

- Ali, M.M.; Osman, S.A.; Aw, A.Z.; Yatim, M.Y.M.; Alatshana, F.; Hilo, S.J. Concrete-Filled Twin-Layer Steel-Sheet Cws System: A Systematic Review of the Literature. Lat. Am. J. Solids Struct. 2021, 18, 1–43. [Google Scholar] [CrossRef]

- An, G.; Wang, R.; Zhao, H.; Chen, W.; Li, T.; Liu, Y. Response of Axial-Loaded Steel-Concrete Composite Walls under Low-Velocity Impact. J. Constr. Steel Res. 2023, 203, 107829. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Youssf, O.; Mills, J.E.; Xiao, J. Structural Behaviour of Composite Panels Made of Profiled Steel Sheets and Foam Rubberised Concrete under Monotonic and Cyclic Shearing Loads. Thin-Walled Struct. 2020, 151, 106726. [Google Scholar] [CrossRef]

- Tong, J.-Z.; Pan, W.-H.; Shen, M.-H. Performance of Double-Skin Composite Walls with Re-Entrant Profiled Faceplates under Eccentric Compression. J. Build. Eng. 2020, 28, 101010. [Google Scholar] [CrossRef]

- Yu, C.Q.; Tong, J.Z. Compressive Behavior of Slender Profiled Double-Skin Composite Walls. J. Constr. Steel Res. 2021, 182, 106657. [Google Scholar] [CrossRef]

- Tong, J.Z.; Yu, C.Q.; Zhang, L. Sectional Strength and Design of Double-Skin Composite Walls Withre-Entrant Profiled Faceplates. Thin-Walled Struct. 2021, 158, 107196. [Google Scholar] [CrossRef]

- Li, W.; Li, F.; Chen, H. Performance of Concrete-Filled Double-Skin Shallow-Corrugated Steel Plate Composite Walls under Axial Compression. J. Constr. Steel Res. 2022, 196, 107374. [Google Scholar] [CrossRef]

- Wang, S.; Wang, W.; Xie, S.; Chen, Y. Behavior and Design Method of Double Skin Composite Wall under Axial Compression. J. Build. Eng. 2023, 64, 105554. [Google Scholar] [CrossRef]

- Wang, M.Z.; Guo, Y.L.; Zhu, J.S.; Yang, X. Flexural-Torsional Buckling and Design Recommendations of Axially Loaded Concrete-Infilled Double Steel Corrugated-Plate Walls with T-Section. Eng. Struct. 2020, 208, 110345. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Mol, L.K.; Anwar, M.S. Axial Load Behaviour of Pierced Profiled Composite Walls with Strength Enhancement Devices. J. Constr. Steel Res. 2015, 110, 48–64. [Google Scholar] [CrossRef]

- Al Zand, A.W.; Wan Badaruzzaman, W.H.; Ali, M.M.; Hasan, Q.A.; Al-Shaikhli, M.S. Flexural Performance of Cold-Formed Square CFST Beams Strengthened with Internal Stiffeners. Steel Compos. Struct. 2020, 34, 123–139. [Google Scholar] [CrossRef]

- Bahrami, A.; Badaruzzaman, W.H.W.; Osman, S.A. Nonlinear Analysis of Concrete-Filled Steel Composite Columns Subjected to Axial Loading. Struct. Eng. Mech. 2011, 39, 383–398. [Google Scholar] [CrossRef]

- ASTM-E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2009.

- Zhang, M.; Ding, J.; Pang, L.; Ding, K. Numerical Study on the Influence of In-Plane Damage on the out-of-Plane Seismic Performance of Masonry Infill Walls with Opening in Reinforced Concrete Frames. Adv. Struct. Eng. 2023, 26, 344–359. [Google Scholar] [CrossRef]

- Wen, C.B.; Guo, Y.L.; Sun, H.J.; Tian, Z.H.; He, X. Experimental and Numerical Study on Seismic Performance of Concrete-Infilled Double Steel Corrugated-Plate Walls. J. Build. Eng. 2023, 68, 106171. [Google Scholar] [CrossRef]

- Le Minh, H.; Khatir, S.; Abdel Wahab, M.; Cuong-Le, T. A Concrete Damage Plasticity Model for Predicting the Effects of Compressive High-Strength Concrete under Static and Dynamic Loads. J. Build. Eng. 2021, 44, 103239. [Google Scholar] [CrossRef]

- Cuong-Le, T.; Minh, H.L.; Sang-To, T. A Nonlinear Concrete Damaged Plasticity Model for Simulation Reinforced Concrete Structures Using ABAQUS. Frat. Ed Integrità Strutt. 2022, 16, 232–242. [Google Scholar] [CrossRef]

- Abdualrahman, S.Q.; Al-Zuhairi, A.H. A Comparative Study of the Performance of Slender Reinforced Concrete Columns with Different Cross-Sectional Shapes. Fibers 2020, 8, 35. [Google Scholar] [CrossRef]

- Al-Zuhairi, A.H.; Al-Ahmed, A.H.; Abdulhameed, A.A.; Hanoon, A.N. Calibration of a New Concrete Damage Plasticity Theoretical Model Based on Experimental Parameters. Civ. Eng. J. 2022, 8, 225–237. [Google Scholar] [CrossRef]

- Hilo, S.J.; Sabih, S.M.; Faris, M.M.; Al-Zand, A.W. Numerical Investigation on the Axial Load Behaviour of Polygonal Steel Tube Columns. Int. Rev. Civ. Eng. 2022, 13, 397. [Google Scholar] [CrossRef]

- Wang, M.Z.; Guo, Y.L.; Yang, X.; Zhu, J.S. Compressive Buckling Behaviour of Steel Corrugated-Plates in Contact with a Rigid Medium. Compos. Struct. 2021, 262, 113356. [Google Scholar] [CrossRef]

| Specimens | Ultimate Axial Load (Pu) (kN) | Displacement at Ultimate Load (mm) | Load Capacity Reduction (%) |

|---|---|---|---|

| Oct | 1473 | 11 | - |

| Ope-Oct | 1338 | 11 | −9.4 |

| Model | Ultimate Axial Load (PExp.) kN | Ultimate Axial Load (PFE) kN | PFE/PExp |

|---|---|---|---|

| Oct-FE | 1473 | 1512 | 0.974 |

| Ope-Oct-FE | 1338 | 1467 | 0.912 |

| Models | Cross-Sectional Shape of Tube | Axial Load (kN) | Displacement (mm) | Load Deviation (%) |

|---|---|---|---|---|

| Ope-Oct-FE | Octagonal | 1467 | 11.0 | - |

| Ope-Hex-FE | Hexagonal | 1320 | 10.7 | −11.0 |

| Ope-Rec-FE | Rectangular | 1239 | 10.8 | −18.4 |

| Models | Stiffeners Shape | Load (kN) | Displacement (mm) | Load Deviation |

|---|---|---|---|---|

| (%) | ||||

| Ope-Oct-FE | - | 1467 | 11.0 | - |

| Ope-Oct-L | L | 1536 | 15.5 | +4.7 |

| Ope-Oct-T | T | 1649 | 15.3 | +12.4 |

| Ope-Oct-U | U | 1620 | 14.7 | +10.4 |

| Ope-Oct-V | V | 1507 | 14.7 | +2.7 |

| Models | Stiffeners Shape | Load (kN) | Displacement (mm) | Load Deviation (%) |

|---|---|---|---|---|

| Ope-Hex. | - | 1320 | 10.7 | - |

| Ope-Hex-L | L | 1501 | 13.4 | +13.7 |

| Ope-Hex-T | T | 1545 | 14.1 | +17.0 |

| Ope-Hex-U | U | 1526 | 13.9 | +15.6 |

| Ope-Hex-V | V | 1438 | 12.9 | +8.9 |

| Models | Stiffeners Shape | Load (kN) | Displacement (mm) | Load Deviation (%) |

|---|---|---|---|---|

| Ope-Rec. | - | 1239 | 10.8 | - |

| Ope-Rec-L | L | 1405 | 12.9 | +13.4 |

| Ope-Rec-T | T | 1477 | 12.4 | +19.2 |

| Ope-Rec-U | U | 1441 | 12.5 | +16.3 |

| Ope-Rec-V | V | 1345 | 12.9 | +8.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hilo, S.J.; Hamood, M.J.; Al-Zuhairi, A.H.; Zand, A.W.A.; Kaish, A.B.M.A.; Ali, M.M.; Faris, M.M.; Badaruzzaman, W.H.W. Structural Performance of Internally Stiffened Double-Skinned Profiled Composite Walls with Openings. Buildings 2023, 13, 1499. https://doi.org/10.3390/buildings13061499

Hilo SJ, Hamood MJ, Al-Zuhairi AH, Zand AWA, Kaish ABMA, Ali MM, Faris MM, Badaruzzaman WHW. Structural Performance of Internally Stiffened Double-Skinned Profiled Composite Walls with Openings. Buildings. 2023; 13(6):1499. https://doi.org/10.3390/buildings13061499

Chicago/Turabian StyleHilo, Salam J., Mohammed J. Hamood, Alaa Hussein Al-Zuhairi, Ahmed W. Al Zand, A. B. M. A. Kaish, Mustafa M. Ali, Marwah M. Faris, and Wan Hamidon W. Badaruzzaman. 2023. "Structural Performance of Internally Stiffened Double-Skinned Profiled Composite Walls with Openings" Buildings 13, no. 6: 1499. https://doi.org/10.3390/buildings13061499

APA StyleHilo, S. J., Hamood, M. J., Al-Zuhairi, A. H., Zand, A. W. A., Kaish, A. B. M. A., Ali, M. M., Faris, M. M., & Badaruzzaman, W. H. W. (2023). Structural Performance of Internally Stiffened Double-Skinned Profiled Composite Walls with Openings. Buildings, 13(6), 1499. https://doi.org/10.3390/buildings13061499