Changes in Clay Hollow Block Geometry for Energy Efficiency Benefits—Thermal Simulation for Brazil

Abstract

1. Introduction

2. Thermal Analysis in Building Masonries

Heat Transfer and Thermal Properties of Hollow Blocks

- Block configurations are designed by optimizing hollow geometries such as void width, void depth, and the total number of voids. The thermal resistance of blocks can be enhanced by changing the aforesaid parameters;

- The filling of hollow block cavities with insulation materials has a high potential to reduce effective conductivity;

- The lower the coefficient of the thermal conductivity of insulation materials, the stronger the insulation and the higher the cost of the hollow block;

- Engineers should consider developing low-energy residential or office buildings with the use of optimum hollow blocks. Moreover, this improvement is affordable, as there is no need for substantial expenditure on the construction of block models.

3. Materials and Methods

3.1. Changing Hollow Geometry Block in the Brazilian Context

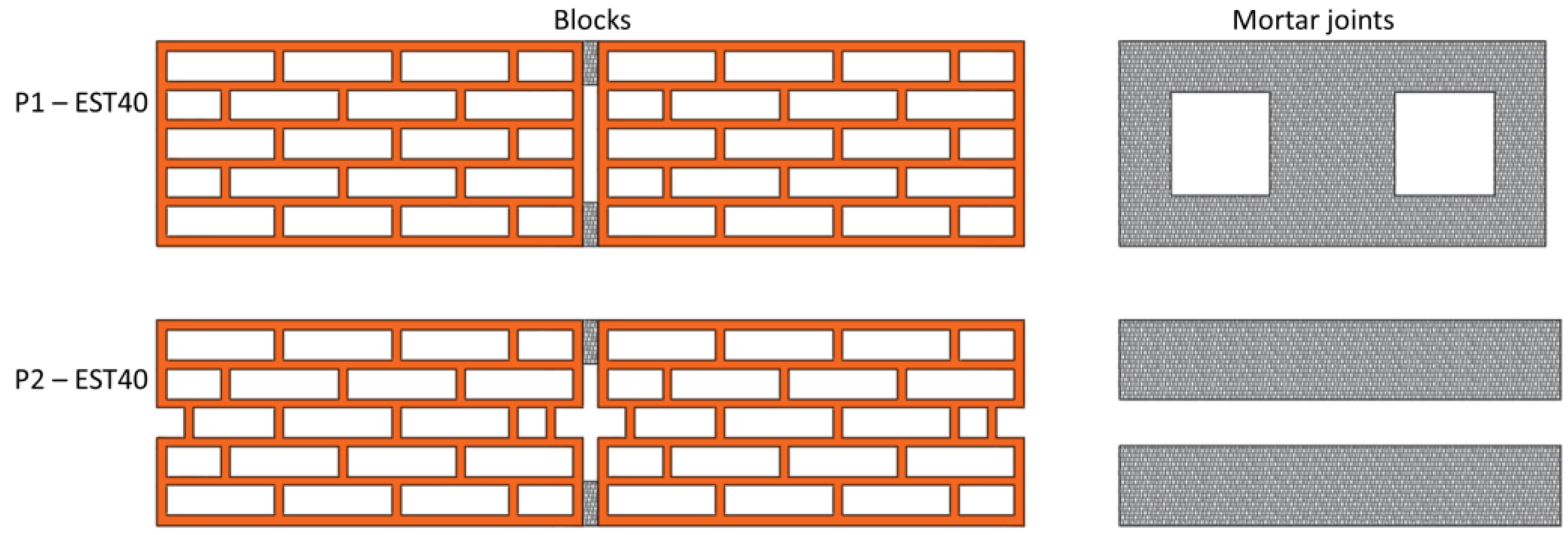

- In the case of block P1-EST40, the minimum wall thickness considered was 7 mm for the external shell and 6 mm for the internal web. In the case of block P1-EST60, the minimum wall thickness considered was 8 mm for the shell and 7 mm for the web. These changes take into account the minimum measures provided by the NBR 15270:2017 standard for clay blocks with vertical voids.

- This geometry sought to increase the number of void rows, respecting the minimum thickness requirements, without significant changes in the relationship between the net area and the gross area of the block. This measure sought to avoid significant cost increases due to higher material consumption.

- Web walls perpendicular to the direction of the masonry were established to provide stability in block resistance but were not evaluated in this work. These walls were arranged without continuity between void rows, to reduce the thermal bridge effect.

- The mortar distribution was maintained using the same format as the reference block.

- In the second stage, the following changes were made:

- A discontinuity was introduced into the side shell of the block, to reduce the thermal bridge effect;

- Horizontal mortar distribution was altered to avoid a thermal bridge through the mortar;

- The vertical joint of the mortar filled the entire height in all cases, with 1 cm thickness and 3 cm depth.

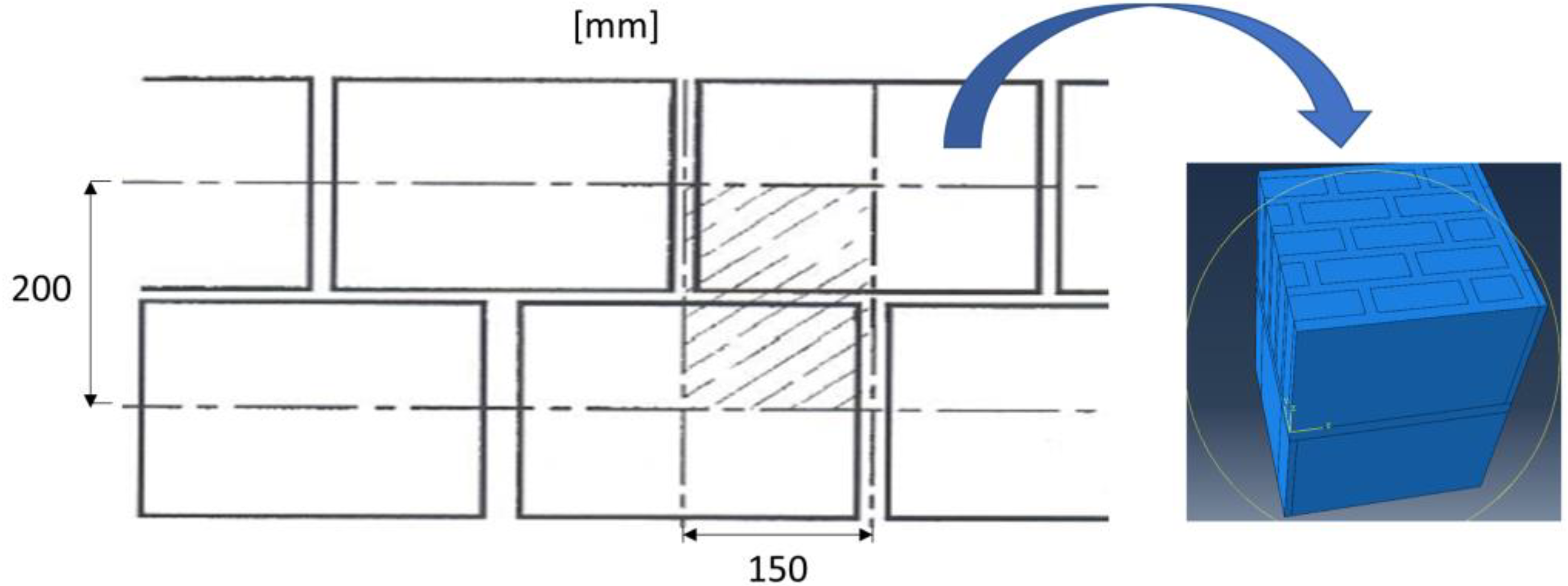

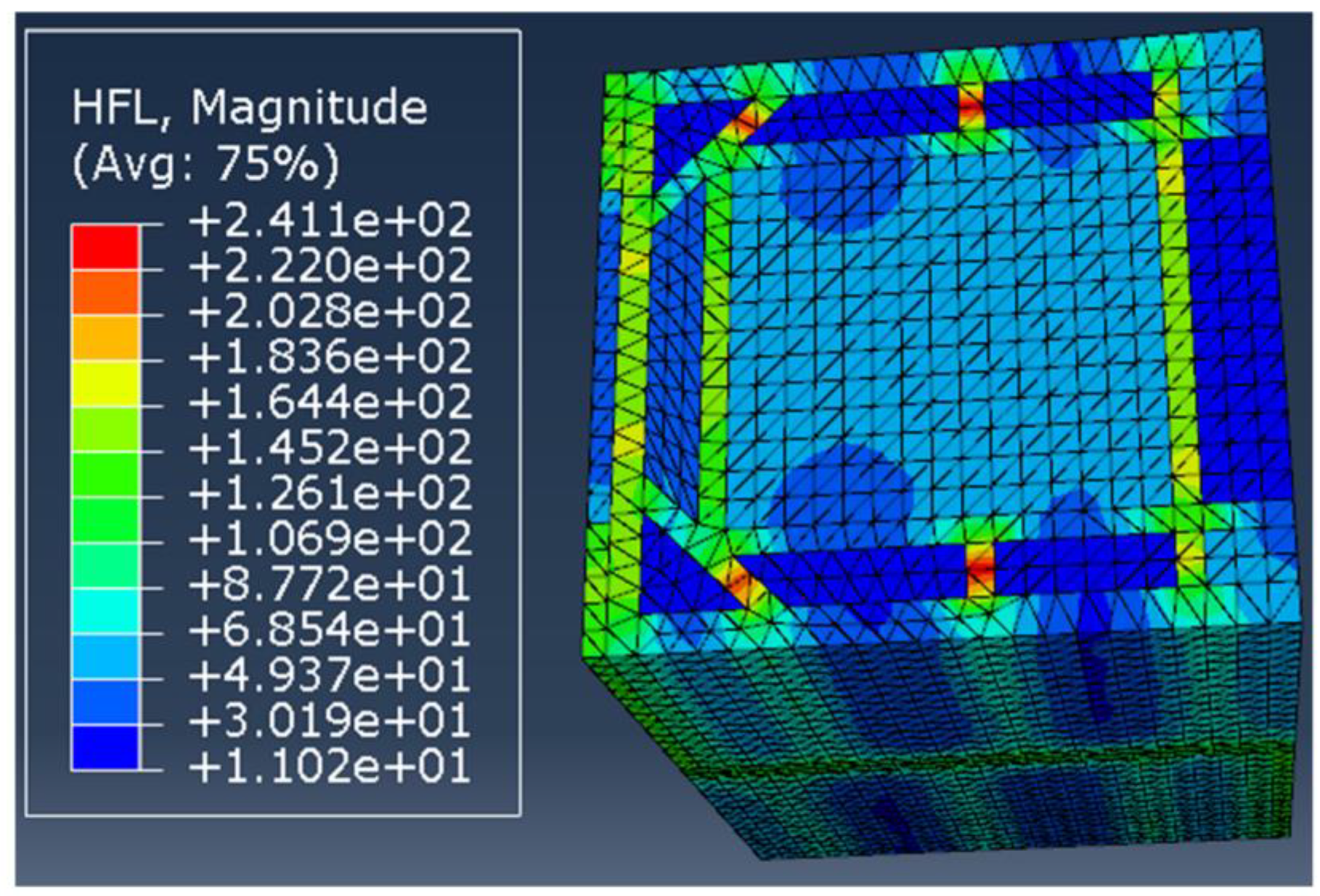

3.2. Numerical Simulation Procedure Using Finite Elements

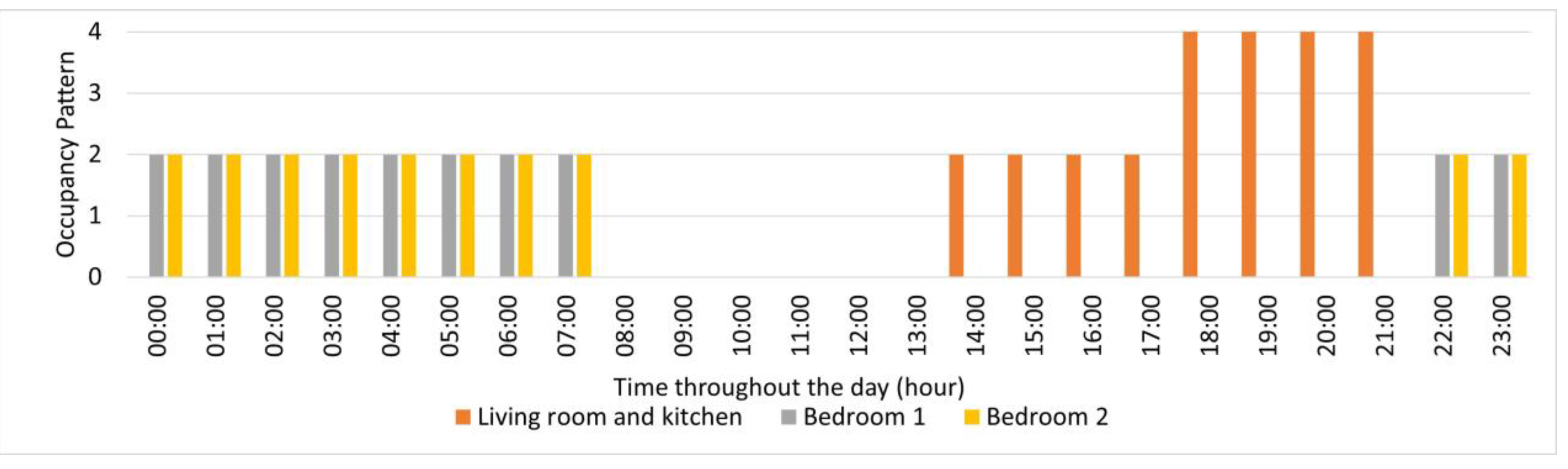

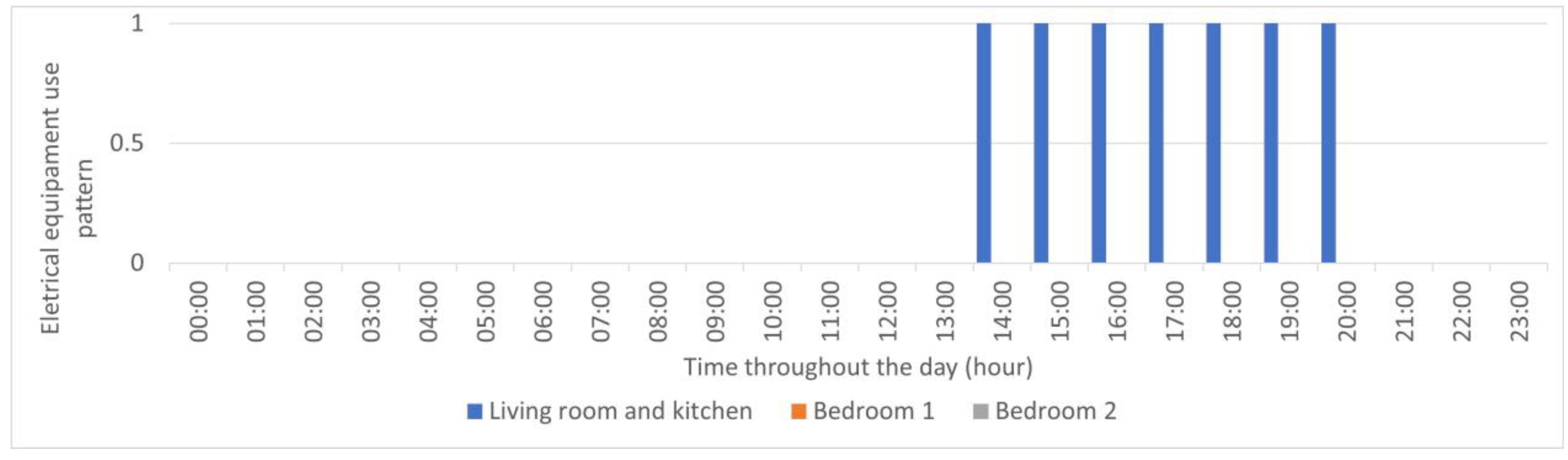

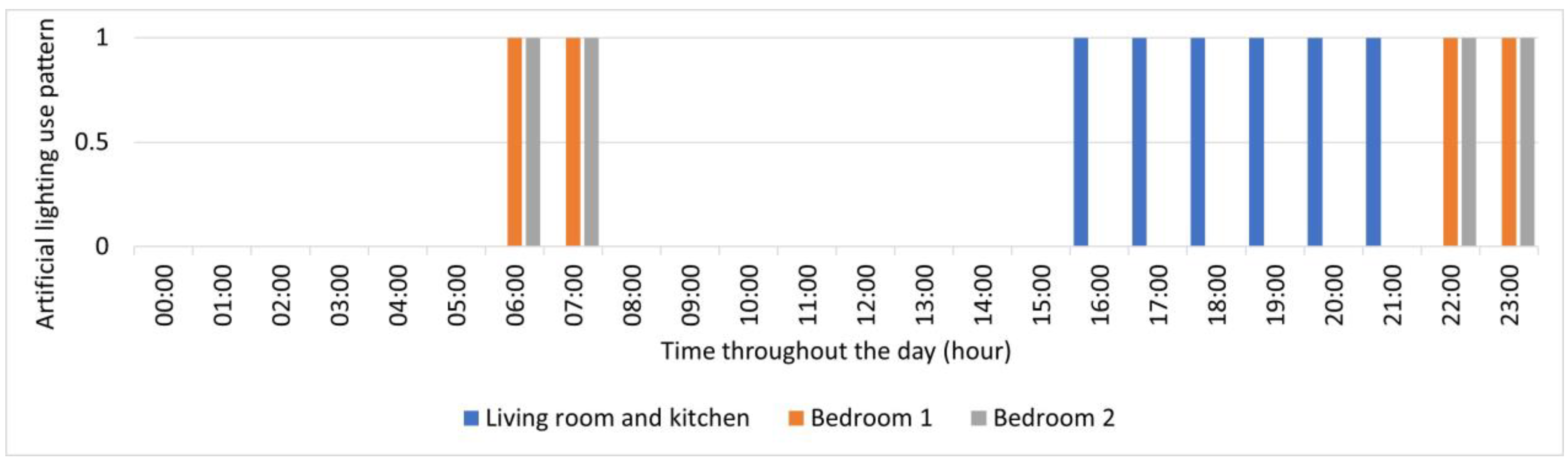

3.3. Energy Efficiency Numerical Analysis in Housing Buildings

- Lighting power of 100 W for the living room/kitchen, and 60 W for each room;

- Metabolic rate of 108 W/person in the living room and 81 W/person in the bedrooms;

- Equipment power level of 120 W for the living room/kitchen;

- A ventilation model configured by the airflow network object, present in the EnergyPlus software, which considers natural ventilation according to the climatic file;

- No air renewal between roof and ceiling (slab);

- Openings (glass windows) corresponding to 5.61% of the area of the south façade, 7.5% of the area of the west façade, 5.61% of the north façade area, and 9.77% of the east façade area.

- House 1: two-bedroom house with flat roof and glass windows;

- House 2: two-bedroom house with ceramic tile roof and glass windows;

- Apartment: two-bedroom apartment with glass windows and two façades.

4. Results and Discussion

4.1. Thermal Transmittance (U)

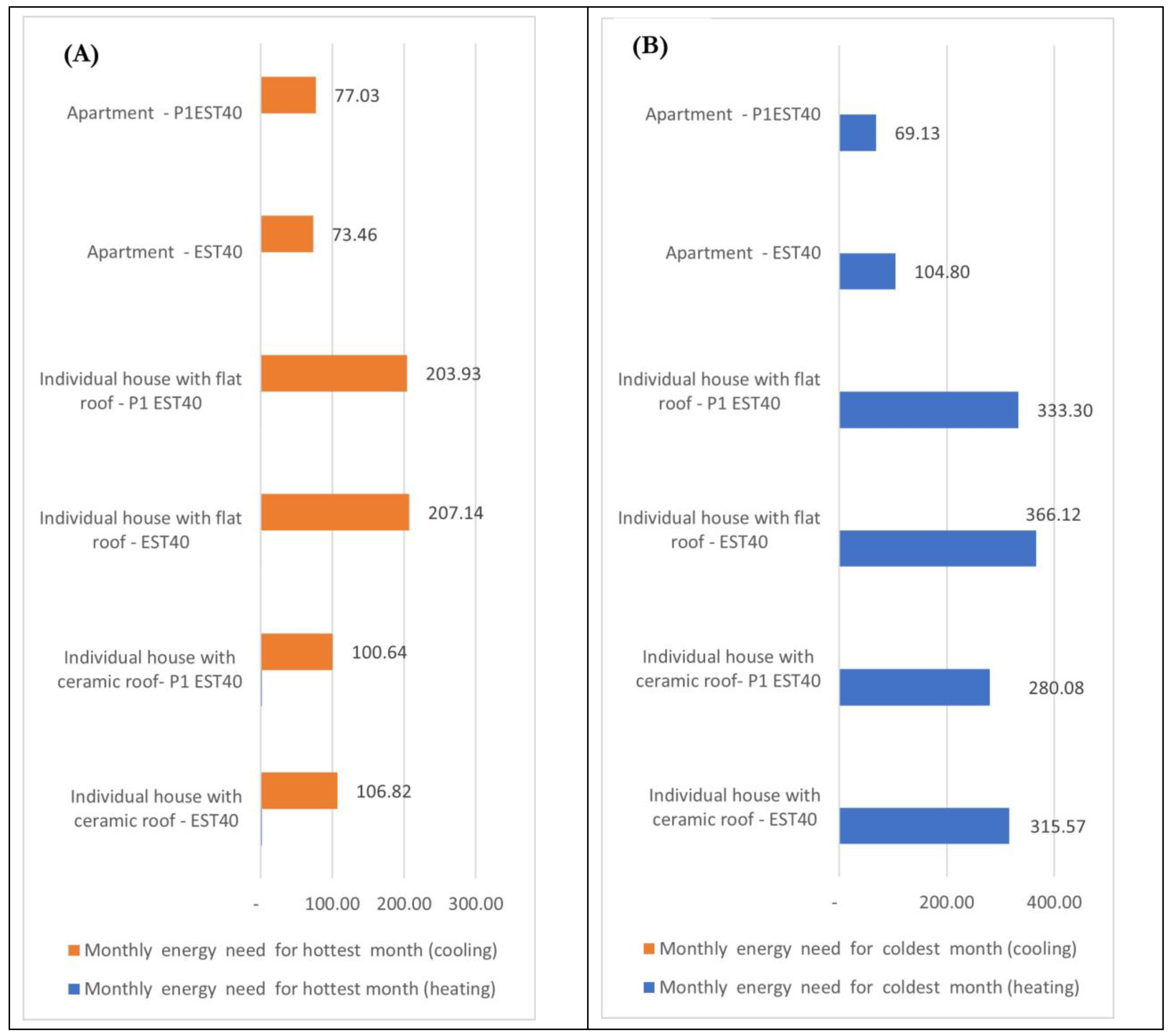

4.2. Energy Simulation Results

5. Conclusions

- Development of masonry block systems (common and complementary blocks) that can achieve better thermal resistance without significant hollow ratio variation.

- Development of architectural typologies that allow, associated with these new blocks, greater energy efficiency in the warmer months.

- Evaluation of the impact of changes in the blocks on their mechanical characteristics.

- Energy consumption and internal temperatures simulation with different occupation patterns and with the use of HVAC systems.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. Electricity Information: Overview; IEA: Paris, France, 2021. [Google Scholar]

- ISO 7730:2005; Ergonomics of the Thermal Environment: Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. ISO: Geneva, Switzerland, 2005.

- ANSI/ASHRAE Standard 55-2010; ASHRAE Thermal Environmental Conditions for Human Occupancy. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.: Peachtree Corners, GA, USA, 2010; Volume 2.

- ABNT.NBR 15220; Desempenho Térmico de Edificações. Parte 1: Definições, Símbolos e Unidades. Associação Brasileira de Normas Técnicas: São Paulo, Brasil, 2005.

- ABNT.NBR 15220; Desempenho Térmico de Edificações—Parte 2: Métodos de Cálculo Da Transmitância Térmica, Da Capacidade Térmica, Do Atraso Térmico e Do Fator Solar de Elementos e Componentes de Edificações. Associação Brasileira de Normas Técnicas: São Paulo, Brasil, 2008.

- ABNT.NBR 15575; Edificações Habitacionais—Desempenho Parte 1: Requisitos Gerais. Associação Brasileira de Normas Técnicas: São Paulo, Brasil, 2021.

- Turgut, P.; Yesilata, B. Physico-Mechanical and Thermal Performances of Newly Developed Rubber-Added Bricks. Energy Build. 2008, 40, 679–688. [Google Scholar] [CrossRef]

- Krstić, H.; Miličević, I.; Markulak, D.; Domazetović, M. Thermal Performance Assessment of a Wall Made of Lightweight Concrete Blocks with Recycled Brick and Ground Polystyrene. Buildings 2021, 11, 584. [Google Scholar] [CrossRef]

- Sutcu, M.; Del Coz Díaz, J.J.; Álvarez Rabanal, F.P.; Gencel, O.; Akkurt, S. Thermal Performance Optimization of Hollow Clay Bricks Made up of Paper Waste. Energy Build. 2014, 75, 96–108. [Google Scholar] [CrossRef]

- Sutcu, M. Influence of Expanded Vermiculite on Physical Properties and Thermal Conductivity of Clay Bricks. Ceram. Int. 2015, 41, 2819–2827. [Google Scholar] [CrossRef]

- Koçyiğit, F. Thermo-Physical and Mechanical Properties of Clay Bricks Produced for Energy Saving. Int. J. Thermophys. 2022, 43, 18. [Google Scholar] [CrossRef]

- Kočí, V.; Bažantová, Z.; Černý, R. Computational Analysis of Thermal Performance of a Passive Family House Built of Hollow Clay Bricks. Energy Build. 2014, 76, 211–218. [Google Scholar] [CrossRef]

- Sousa, H.; Sousa, R.; Sousa, L. Influence of Enclosure Masonry Walls on Energy Consumption of Buildings. In Proceedings of the Brick and Block Masonry: Trends, Innovations and Challenges: Proceedings of the 16th Inter-national Brick and Block Masonry Conference (IBMAC 2016), Padova, Italy, 26–30 June 2016; p. 405.

- Sousa, H.; Sousa, F.; Sousa, R.M.; Silva, L.C.; Sousa, G.N. Thermal Performance of Light Blocks in a Mediterranean Climate. Rev. Int. De Métodos Numéricos Para Cálculo Y Diseño En Ing. 2020, 36, 13. [Google Scholar] [CrossRef]

- Cheng, L.; Zhuang, C.; Li, S.; Huang, G.; Zhang, H.; Gan, F.; Xu, N.; Hou, S. Thermal Performance Optimization Simulation Study of a Passive Solar House with a Light Steel Structure and Phase Change Walls. Energies 2023, 16, 3725. [Google Scholar] [CrossRef]

- Ahmad, A.; Al-Hadhrami, L. Thermal Performance and Economic Assessment of Masonry Bricks. Therm. Sci. 2009, 13, 221–232. [Google Scholar] [CrossRef]

- Morales, M.P.; Juárez, M.C.; Muñoz, P.; Gómez, J.A. Study of the Geometry of a Voided Clay Brick Using Non-Rectangular Perforations to Optimise Its Thermal Properties. Energy Build. 2011, 43, 2494–2498. [Google Scholar] [CrossRef]

- Morales, M.P.; Juárez, M.C.; López-Ochoa, L.M.; Doménech, J. Study of the Geometry of a Voided Clay Brick Using Rectangular Perforations to Optimize Its Thermal Properties. Appl. Therm. Eng. 2011, 31, 2063–2065. [Google Scholar] [CrossRef]

- Sousa, H.; Sousa, R. Sensibility Analysis of the Thermal Resistance of Masonry through Numerical Simulations of Laboratory Tests. In Proceedings of the 9th International Masonry Conference, Guimarães, Portugal, 7–9 July 2014. [Google Scholar]

- Cuce, P.M.; Cuce, E.; Sudhakar, K. A Systematic Review of Thermal Insulation Performance of Hollow Bricks as a Function of Hollow Geometry. Int. J. Ambient. Energy 2022, 43, 4406–4415. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Besir, A.B. Improving Thermal Resistance of Lightweight Concrete Hollow Bricks: A Numerical Optimisation Research for a Typical Masonry Unit. J. Energy Syst. 2020, 4, 121–144. [Google Scholar] [CrossRef]

- Pinterić, M. Heat Transfer in Building Components. Build. Phys. 2021, 71–116. [Google Scholar] [CrossRef]

- ISO. ISO 6946; Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation. International Organization for Standardization: Geneva, Switzerland, 1996.

- Ismaiel, M.; Chen, Y.; Cruz-Noguez, C.; Hagel, M. Thermal Resistance of Masonry Walls: A Literature Review on Influence Factors, Evaluation, and Improvement. J. Build. Phys. 2022, 45, 528–567. [Google Scholar] [CrossRef]

- EN 1745; Masonry and Masonry Products—Methods for Determining Thermal Properties. CEN: Brussels, Belgium, 2012.

- Al-Tamimi, A.S.; Al-Osta, M.A.; Al-Amoudi, O.S.B.; Ben-Mansour, R. Effect of Geometry of Holes on Heat Transfer of Concrete Masonry Bricks Using Numerical Analysis. Arab. J. Sci. Eng. 2017, 42, 3733–3749. [Google Scholar] [CrossRef]

- Dias, A.; Ferraz, E.; Sousa, H.; Sousa, L.; Sousa, R.; Lourenço, P.; Vasconcelos, P.; Medeiros, P. Development of Ceramic Block for a Sustainable Construction. In Proceedings of the Sustainability of Constructions—Integrated Approach to Life-Time, Dresden, Germany, 6–7 October 2008. [Google Scholar]

- ABNT.ABNT 15270; Componentes Cerâmicos—Blocos e Tijolos Para Alvenaria—Parte 1: Requisitos. Associação Brasileira de Normas Técnicas: São Paulo, Brasil, 2017.

- ABAQUS Abaqus User’s Manual Version 2019; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2019.

- Energyplus QuickStart—Welcome to the Energy Plus Quick Start Guide! Available online: https://energyplus.net/quick-start (accessed on 11 July 2022).

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Buhl, W.F.; Huang, Y.J.; Pedersen, C.O.; Strand, R.K.; Liesen, R.J.; Fisher, D.E.; Witte, M.J.; et al. EnergyPlus: Creating a New-Generation Building Energy Simulation Program. Energy Build. 2001, 33, 319–331. [Google Scholar] [CrossRef]

- Schaefer, A.; Ghisi, E. Method for Obtaining Reference Buildings. Energy Build. 2016, 128, 660–672. [Google Scholar] [CrossRef]

- ASHRAE ANSI/ASHRAE Standard 169-2013; Climatic Data for Building Design Standards. ASHRAE: Peachtree Corners, GA, USA, 2013; Volume 8400.

| Parameter that influences thermal resistance | How to increase thermal resistance |

|---|---|

| Number of void rows | Increase the number of void rows [18,19,26]. |

| Void thickness in the block section | Increase the thickness of the void, based on the standard ISO 6946 [23], to improve thermal resistance up to a limit value that depends on the void format. |

| Web width in the direction of the heat flow | Reduce the thickness of internal web walls [19,26]. |

| Staggered or ‘in-line’ voids | Avoid thermal bridges in the block by arranging void perforations in quincunx [18]. For blocks with the same proportion of voids, the use of a staggered arrangement for rectangular holes has a considerable effect [26]. |

| Void shape | Modify the vertical holes of rectangular shapes to a rumbroid or rhomboid shape, which reduced thermal transmittance in simulation studies by finite elements performed by [27] and [17]. For blocks with the same proportion of voids, rectangular void shapes achieved more efficient results than circular ones [26]. |

| Hollow ratio | Increase hollow ratio (HR), which tends to significantly decrease heat transfer from the outside to the inner side of the block [26]. |

| Unit length | Increase unit length [19]. |

| Thermal bridge in the vertical joint region | Prolong hole perforations in the tongue and grooved area, to avoid a tongue and groove thermal bridge [17]. |

| Mortar distribution in the joints | Use thin-layer mortar joints [19]. Use discontinuous horizontal joints, although no significant increase is expected when the ratio between the length of mortar filling and the block width is less than 0.4 [19]. Use dry vertical joints or partially filled mortar joints with mechanical locking (voids must be placed near joints to reduce heat flow) [19]. |

| Block Model | Size (mm) | Weight (kg) | Mechanical Resistance (MPa) | Prism Resistance with Mortar of 4.0 (MPa) | Net Area/Gross Area (Percentage of Voids) (%) | U Value (Thermal Transmittance) (2.5 cm Mortar Layer + Masonry Unit + 2.0 cm Mortar Layer) (W/m2·K) |

|---|---|---|---|---|---|---|

| EST40 | 140 × 190 × 290 | 4.90 | 4.0 | 2.5 | 33 | Not reported |

| EST60 | 140 × 190 × 290 | 6.10 | 7.0 | 3.5 | 41 | 2.1 |

| Model | External Dimensions (cm) | Net Area/Gross Area (%) | Shell/Web Thickness (mm) |

|---|---|---|---|

| EST40 | 14 × 19 × 29 cm | 33 | 7 and 9/6 |

| P1-EST40 | 14 × 19 × 29 cm | 35 | 7/6 |

| P2-EST40 | 14 × 19 × 29 cm | 35 | 7/6 |

| EST60 | 14 × 19 × 29 cm | 41 | 9/8 |

| P1-EST60 | 14 × 19 × 29 cm | 42 | 8/7 |

| P2-EST60 | 14 × 19 × 29 cm | 42 | 8/7 |

| Features | Curitiba | Fortaleza |

|---|---|---|

| Climate zone according to [33] | 3A | 0A |

| Latitude | −49.18° | −3.78° |

| Longitude | −25.52° | −38.53° |

| Elevation (m) | 910 | 25.0 |

| Dry Bulb Temperature (DBT) average (°C) | 16.6 | 26.5 |

| Wet Bulb Temperature (WBT) average (°C) | 14.7 | 23.4 |

| Relative Humidity (RH) average | 85% | 78% |

| Wind speed (m/s) | 3.2 | 3.8 |

| Construction elements | Layers | Thickness (m) | Conductivity λ(W/(m·K)) | Density (kg/m3) | Cp J/kg·K | U (W/(m2·K)) |

|---|---|---|---|---|---|---|

| Concrete | 0.1 | 1.15 | 2400 | 1000 | ||

| Floors | Mortar subfloor | 0.03 | 1.15 | 2000 | 1000 | 8.32 |

| Ceramic tile | 0.0075 | 1.05 | 2000 | 920 | ||

| Mortar | 0.025 | 1.15 | 2000 | 1000 | ||

| External and internal walls (EST 40 block) | Clay block | 0.14 | 0.450 | 688 | 932 | 2.82 |

| Coating mortar | 0.025 | 1.15 | 2000 | 1000 | ||

| Mortar | 0.025 | 1.15 | 2000 | 1000 | ||

| External and internal walls (P1 EST 40 block) | Clay block | 0.14 | 0.290 | 723 | 932 | 1.90 |

| Coating mortar | 0.025 | 1.15 | 2000 | 1000 | ||

| Roof, made with a slope layer of ceramic tiles and a horizontal reinforced concrete slab (beam and block system—only for house example) | Ceramic tile | 0.01 | 1.05 | 2000 | 920 | |

| Air gap (R = 0.21 m2·k/W) | variable | - | - | - | 3.80 | |

| Concrete | 0.05 | 1.15 | 2400 | 1000 | ||

| Flat roof—concrete waterproofing | Concrete | 0.1 | 1.15 | 2400 | 1000 | |

| Bitumen sheet (waterproofing) | - | - | - | - | 8.85 | |

| Plastering mortar | 0.03 | 1.15 | 2000 | 1000 |

| Masonry Unit Model | Net Area/Gross Area (Block) (%) | U Masonry Unit (W/m2·K) | Reduction in U Masonry Unit (%) | Thermal Resistance (m2·K/W) | U Wall (W/m2·K) | Reduction (U Wall) (%) |

|---|---|---|---|---|---|---|

| EST 40 | 33 | 3.212 | - | 0.311 | 1.921 | - |

| P1 EST 40 | 35 | 2.067 | 35.6 | 0.484 | 1.443 | 24.9 |

| P2 EST 40 | 35 | 2.054 | 36.1 | 0.487 | 1.437 | 25.2 |

| EST 60 | 41 | 3.398 | - | 0.294 | 1.987 | - |

| P1 EST 60 | 42 | 2.321 | 31.7 | 0.431 | 1.562 | 21.3 |

| P2 EST 60 | 42 | 2.310 | 32.0 | 0.433 | 1.558 | 21.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gondim, I.A.; Sousa, H.; Bertini, A. Changes in Clay Hollow Block Geometry for Energy Efficiency Benefits—Thermal Simulation for Brazil. Buildings 2023, 13, 1594. https://doi.org/10.3390/buildings13071594

Gondim IA, Sousa H, Bertini A. Changes in Clay Hollow Block Geometry for Energy Efficiency Benefits—Thermal Simulation for Brazil. Buildings. 2023; 13(7):1594. https://doi.org/10.3390/buildings13071594

Chicago/Turabian StyleGondim, Ivo Almino, Hipólito Sousa, and Alexandre Bertini. 2023. "Changes in Clay Hollow Block Geometry for Energy Efficiency Benefits—Thermal Simulation for Brazil" Buildings 13, no. 7: 1594. https://doi.org/10.3390/buildings13071594

APA StyleGondim, I. A., Sousa, H., & Bertini, A. (2023). Changes in Clay Hollow Block Geometry for Energy Efficiency Benefits—Thermal Simulation for Brazil. Buildings, 13(7), 1594. https://doi.org/10.3390/buildings13071594