1. Introduction

Tunnels are defined as underground structures which deliver a space for many purposes, such as storage, transportation, and hydraulic structures [

1]. The use of machinery tunnels is considered the most common tunneling technique, as indicated by its fast progression rate [

2]. Machinery tunnel execution involves four main activities: (A01) thrust and reception shaft installation; (A02) machine Setup and break-in; (A03) machine progression and lining placing; and (A04) machine break-out and removal.

During tunnel construction, shafts are the entrance and departure gates for tunneling tools and materials [

3]. Even after construction, shafts may have further roles to play—they can be used for ventilation or inspection or they can continue their primary job as an access and exit for tunnel users. Shaft design and construction are very specific tasks that consider many parameters: shaft permanent job, groundwater level, geological conditions, tunneling depth, etc. [

4,

5]. One of the most advanced shaft construction techniques, which is considered in this study, is caisson. The technique is feasible for applications in complex soil conditions, in wet ground, or at underground water level. Caissons are usually cast in situ above the ground surface. The shaft’s internal space is excavated, and the caisson sinks under its weight to reach the target depth. Then, forms are added to the top, and concrete is placed to create the next top section of the shaft [

3]. The process is repeated until the shaft depth reaches the target value. For machinery tunnels, thrust and reception shaft successful installation is considered the key to a successful tunneling project.

Break-in/out, also named breakthrough, is the machine transition from the shaft to the ground media and vice versa. It is a critical operation requiring special design considerations and construction procedures [

6]. Special face pressure control is needed when the machine starts its breakthrough (in or out). After the breakthrough, a part of the shaft wall is demolished to offer space for machine passage. Herein, the risk of instability takes place, and the situation of instability can cause the breaking of the ground in the excavation chamber [

7]. This risk seems to be improbable in the case of solid rock media. However, the break-in remains a critical operation that requires particular machine settings for thrust and power to allow for successful penetration [

8]. In the case of fractured rock or soil, it may require extra precaution in addition to face pressure control. Uncontrolled groundwater seepage into the shafts could result in ground collapse with groundwater and soil inflow. In such cases, lowering of groundwater level around the site may be considered. However, ground settlement associated with groundwater drainage can cause structural damage to adjacent buildings. Ground improvement techniques may be utilized to minimize permeability and/or improve the strength of ground media during the breakthrough [

9,

10]. Safe break-in is considered an indicator of a successful machine trip while safe break-out is considered an approval for this success.

Structural analysis and design process are performed for the after-construction phase for most structures, considering the structural system, construction material properties, and applied loads. For tunnels, it is performed for all construction phases with additional special consideration of the surrounding ground media properties and nearby underground and surface structure stability. In the presented tunneling stages, the structural worries are focused on limited construction areas. A machine trip between the shafts from break-in to break-out is the widest range step. The machine moves near or under lots of structures and explores various ground media profiles [

1,

6].

Many factors affect machine progression under the ground surface. The major factors are geological properties, operating conditions, and the machine’s structural characteristics. Thus, mechanics interaction with the ground is analyzed [

11]. The face balancing pressure certifies the ground stability and, thus, controls the surface settlements. Missing the balancing pressure may cause instabilities at the machine face, resulting in surface settlement or even surface collapse if the ground is of poor quality [

7,

12]. Even structures founded on deep foundations may be disturbed by nearby tunneling machine movement and face pressure adjustment. Therefore, an accurate case-study structural analysis is required before construction, depending on the monitoring system records [

13,

14,

15].

In the case of soft ground or weak rock, the tunnel lining is formed by precast concrete segments. These segments are designed to resist the loads from the ground and the temporary production and transportation loads. The tunnel’s inner dimensions are determined according to the intended use of the tunnel [

16]. The precast concrete lining is an efficient and economical system when compared with other cast in situ supporting systems. This lining is suitable for different ground conditions [

17]. Concrete cracks and damage are classified as the most possible defects in machinery tunnels [

18]. Many researchers investigated these defects and their risk effects during the construction stage, and many reasons were assigned to these effects, such as inappropriate transportation and placement and excessive stresses due to the machine jacking forces [

19].

Tunneling projects, in general, may face unexpected conditions that threaten their continuity [

1]. Machinery tunnel projects particularly suffer from high uncertainty induced mainly by the interaction between the machine and the geological conditions [

20]. Thus, risk analysis and management play essential roles in such projects. However, tunnel risk analysis is still in the development stage [

21].

Fuzzy logic became one of the most popular modeling approaches recently, and its techniques have a wide range of successful applications. When risk analysis needs to consider parameters with quantification complexity, fuzzy logic presents a solid method to model this vagueness [

22]. Fuzzy logic involves many applications in tunneling project execution. A risk assessment model using fuzzy logic to evaluate risk during tunnel construction has been developed [

1]. Fuzzy Bayesian networks have also been used to develop a decision tool for safety assurance and management in tunneling projects [

23]. Fuzzy logic is also used to develop a machinery tunneling utilization predictor, which is applied to planning the projects and estimating the total construction time and cost [

24]. More details for applying fuzzy techniques in tunneling projects will be explained later.

Regarding the demonstrated steps of the tunneling process, many risk factors affect tunnel execution projects. One of the main qualitative risk analysis steps is combining the probability of occurrence with the risk impacts of these factors on the project objectives, which has had limited investigation in tunneling research. Considering the complexity of this combination and associated uncertainties, this type of analysis may be performed only through modeling.

This study aimed to investigate the effect of risks on the most important objectives for tunneling projects—cost, time, quality, and safety—by combining the probability of occurrences and impacts of the risk factors. Thus, developing a new model to analyze risks and assess their effects on tunnel execution objectives was a must. A fuzzy logic-based risk analysis model was presented to evaluate and quantify risk factors’ influence. The proposed model is regarded as a crucial tool for assisting decision-makers in tunnel construction. Further study objectives can be summarized in the following points:

- (1)

To define the main execution activities and risk factors affecting them through the tunnel execution stage;

- (2)

To evaluate the risk factors’ probability of occurrence and their different impacts on the cost, time, quality, and safety;

- (3)

To highlight the risk factors with effective indices that influence the execution of tunnel projects in Egypt;

- (4)

To determine the cost, time, quality, and safety impacts of tunnel execution activities.

2. Research Methodology

The methodology used in this research included identifying the activities of machinery tunnel execution and risk factors affecting these activities. The cost, time, quality, and safety were selected as the most important objectives for these projects. Conducting and verifying a risk analysis model, as a main objective of this study, was considered one of the methodological steps, which depend on combining the probability of occurrences and impacts of the risk factors. In order to apply and test the required model, data based on field surveys were collected using two steps.

In the first step, a comprehensive literature review and brainstorming sessions with professionals in the field of machinery tunnel execution were conducted in order to define the main activities in these projects and effective risks. The number of specialists participating in these sessions was fifteen, with an average of eighteen years of experience in the field of machinery tunnel execution in Egypt. A list of the main activities and risks affecting them was obtained. Based on brainstorming sessions, this stage aimed to affirm the risk factors affecting the tunneling execution process by amending the initial list to match the existing situation in tunneling processes. This step resulted in a final list of risks affecting tunneling activities (thirty-two risk factors) and four activity groups. In this step of data collection, several logical rules in the proposed model were also explained to the participants to confirm these rules and the relations between inputs and outputs. Furthermore, the model outputs represented the significance of a certain risk factor based on conjoining the effects of the associated two inputs.

In the second step of the field survey, the semi-structured interviews were directed to allow respondents to express suggestions for improving survey results [

25]. The main objective of these interviews was to select the most appropriate term for each risk characteristic related to probability and impacts on cost, time, quality, and safety due to their experiences.

3. Identifying Risk Factors Affecting Machinery Tunnel Execution

There is limited research on handling and identifying challenges and barriers that influence the execution of tunnels. For example, twelve main influencing factors involving subjective and objective factors were identified as well as four actual indices to assess the deformation risk of tunneling in soft rock [

26]. An assessment for delay risk was conducted to predict delays in tunneling boring machine (TBM) projects and to assign the causing critical risk factors [

20]. Using a geological study confirmed by the contribution of experienced technicians, eight levels of risks were considered in mechanized tunneling probability and impact factors in the ideal risk analysis [

27]. Another study introduced the potential risks associated with shield TBM application and categorized them into groups that can systematically assess overall risk levels [

28]. The authors of [

29] concluded the risk analysis of submerged floating tunnels and combined the characteristics of submerged floating tunnels and surrounding environmental risks. The authors of [

30] conducted a study related to deep tunneling projects and proved that the geological and settlement risks were increased proportionally to tunneling depth. They also concluded that unexpected actions had a high impact on machinery projects and unexpected events might have a remarkable delaying effect on such projects.

Differential settlement is considered a high risk that threatens tunnel structure stability. A tunnel settlement monitoring system was developed with intelligent functions to evaluate tunnel structural conditions and guarantee construction sustainability. This monitoring system can help prevent hazards and support decision-making [

31]. A new ground settlement index was presented to evaluate displacement risk during tunneling. The index comprises fifteen parameters affecting induced settlements in tunnel execution. The new index has great significance to ground settlement owing to tunneling [

32].

Regarding the outlined review concerning risks related to the tunneling process, several risk factors were explored and grouped according to tunnel execution activities. The final list of risk factors was established by filtering the initial list, as explained in the

Section 2. This final list included thirty-two risk factors affecting tunnel execution distributed in four activity groups as demonstrated in

Table 1.

4. Risk Analysis and Management in Tunnels

Risk analysis and management approaches made significant contributions to minimizing tunnel construction problems. Risk analysis was introduced to determine tunnel construction time and cost using the decision aids for tunneling concerning factors affecting surface settlement problems [

33]. Risk analysis and management were also introduced through an aeronautics method in tunnels for the purpose of minimizing building and refurbishing costs [

34]. Risk investigation techniques, including qualitative, semi-quantitative, and quantitative approaches, were developed to assess risks in road tunnels [

35]. A pragmatic risk analysis system described in [

36] focused on mortality risks in the case of a road tunnel accident. Another risk analysis was conducted according to technical conditions for the safe operation of road tunnels [

37]. A risk analysis-based methodology was applied to optimize support patterns and advance rates for tunneling in rock. It proved quantitatively that tunnels became more stable and the reliability index was higher if the tunnel support was increased [

38].

Risk assessment and analysis of urban utility tunnels were introduced through dynamic hazard scenario identification for the worst-case scenarios of tunnel accidents; they were modeled using the Bayesian network method. It was verified that the incorporated quantitative risk evaluation can effectively support the safety assessment and planning of such tunneling projects [

39]. An approach that combined building information modeling (BIM), and the Dempster–Shafer (D–S) evidence techniques was presented to aid risk assessment and visualization in tunnels. BIM was applied to conduct three-dimensional models, while the D–S evidence was used to identify the risk presence [

21]. Further, the D–S evidence theory and advanced geological prediction were presented to control the collapse risk of drill-and-blast tunnels [

40]. Using event trees, fault trees, and consequence estimation models, an approach for developing a quantitative risk assessment software tool was applied considering unique road tunnel characteristics [

41].

Different probabilistic models for the prediction of tunnel construction risk were introduced, taking into consideration a simple probabilistic model to estimate tunnel construction failures that induced damage, to aid the decision-making under uncertainty in construction projects, and to create stochastic models for specified tunneling projects problems, such as the influence of tunnel excavation on the surface structure integrity [

42]. A quantified risk assessment for highway tunnel construction was introduced to determine occupational risk at hazard, activity, and job levels, as well as overall company risk [

43].

A maintenance strategy for the tunnel structure was developed to ensure its safe and serviceable operation during its lifespan with the intent to minimize the total risk [

44]. Through a case study, an application of the nonparametric Bayesian networks method, which integrates expert knowledge, was used to assess the risk for common failures in shield tunnel execution [

45]. A discussion was introduced to present a more suitable framework for the assessment and management of risks and uncertainties in the design phase of the world’s longest and deepest undersea road tunnel [

46].

Using the analytic hierarchy process (AHP), the weight values of major risk factors of undersea tunnel area conditions were calculated, and the risk control measures were proposed using a hierarchical structure model of risks for the purpose of providing a reference for decision-makers [

47]. Based on analyzing different impact factors, a risk index system for the public safety of a submerged floating tunnel was determined. Additionally, the construction safety risk was evaluated by the AHP method [

48]. A risk assessment framework combining the Bayesian network and D–S evidence theory was established to evaluate sewer pipeline accidents in a utility tunnel, aiming to prevent and mitigate these accidents [

49]. A general uncertainty analysis utilizing the risk assessment method for damage in hard-rock tunnels was suggested considering risk probability, loss estimation, and risk level evaluation [

50]. Based on a generic bow-tie method, a new risk analysis methodology was presented to assess and manage TBM tunnel risks in difficult ground conditions [

2].

Safety risk management in road tunnels was studied considering the probabilistic approaches associated with dangerous goods transportation and human behavior, safety arrangements, and the varying safety standards among different countries [

51]. Another safety risk assessment approach, which combined the D–S evidence theory and the Monte Carlo simulation technique, was developed to evaluate the safety risk of surface buildings due to tunneling under uncertain conditions [

52]. A risk assessment study presented twenty-five recommendations intending to introduce a system of tunnel safety decision-making and risk assessment [

53]. Finally, a one-dimensional soil–structure interaction model, which integrated an estimation tool for ground movements during tunneling, was used to assess the risks of tunneling-induced building damage [

54].

5. Using Fuzzy Logic Technique in Tunneling Projects

The fuzzy logic technique was introduced to evaluate and solve many problems in tunneling projects. Fuzzy logic was used for developing a TBM utilization predictor in the planning phase. It was applied to planning the machine advance rate and estimating related excavation time and cost [

24]. A fuzzy inference analysis was used in the assessment of lane-changing behavior in undersea tunnels according to the characteristics of traffic flow [

55]. Combining neural, neuro-fuzzy, and analytical solutions, a new strategy was proposed to assess the stability of tunnels during the design and construction phases while its efficiency and validity were verified with two examples of actual tunnels [

56]. Factors affecting rock mass classification were applied as evaluation indices of fuzzy AHP, which was developed with tunnel seismic prediction as a classification method to accurately predict the surrounding rock classification [

57]. The potential applications of fuzzy methodology in geological problems and tunneling problems were discussed taking into account professional expertise and judgment of expert systems, which included many approaches, such as fuzzy decision-making, fuzzy pattern recognition, and fuzzy clustering [

58].

A fuzzy risk assessment model was introduced to evaluate risk events during tunnel construction operations [

1]. A novel integrated risk assessment method that applies multistate fuzzy Bayesian networks was developed to assess the collapse probability of a certain tunnel [

59]. Another multistate fuzzy Bayesian network-based method was proposed to evaluate and control the collapse risk in drill-and-blast tunnels [

60]. A decision tool based on fuzzy Bayesian networks was developed to support safety assurance and management in tunneling projects. The model consisted of risk mechanism analysis, establishing model, fuzzification, model-based inference, defuzzification, and decision-making [

23].

Tunnel ventilation control is to provide a safe and comfortable environment for users [

61]. The tunnel ventilation system aims mainly to keep carbon monoxide pollutant concentration and visibility indicators at a certain level to ensure a comfortable and safe driving environment. Fuzzy logic control methods are usually utilized due to the complexity and nonlinearity of tunnel ventilation systems [

62]. A fuzzy control method for longitudinal ventilation by predicting the number of jet fans of road tunnels to control pollutant levels was presented [

63]. A fuzzy logic control model was applied to the ventilation system in a large road tunnel taking into consideration higher visibility and lower concentration of carbon monoxide. A dynamic equation to describe the air pollution concentration was combined with the fuzzy logic rules [

64]. A predictive fuzzy control was introduced to quantify tunnel ventilation control problems involving many elements; this approach could minimize electric power consumption by maintaining pollution below the allowable limit [

61]. Fuzzy logic control was redesigned using the genetic algorithm to maintain a limited level of pollutants and reduce power consumption in tunnels. Using this approach, the pollutant level was kept within the acceptable limit, and the energy efficiency was enhanced compared with conventional control approaches [

62]. According to mathematical dynamical system theory, a predictive fuzzy control scheme was presented for road tunnels’ ventilation control system using a set of fuzzy dynamical equations to regulate the air quality in the tunnel and reduce the ventilation electrical energy consumption [

65].

The fuzzy logic was also used in solving many problems related to machinery tunnels. A novel hybrid fuzzy decision-making approach was developed to improve construction efficiency as well as decrease the cost of the TBM project [

66]. Fuzzy set theory, fuzzy logic, and neural network techniques showed good performance in geological engineering applications [

67]. An algorithm based on fuzzy c-means, which assesses the alterations among the clusters using the attributes of a data relationship, was applied to real dataset collection from machinery tunnel operation [

68]. On the other hand, fuzzy logic was used for supporting decisions related to machinery tunnels. A fuzzy-based technique for order performance by similarity to ideal solution (TOPSIS) was established to support the TBM tunneling decision-makers in the process of selection [

69]. A new fuzzy-based decision-making technique, which considers the distance between the joint segments, was proposed to determine the proper number of segments [

70].

To overcome the uncertainty of tunnel fire, the fuzzy logic technique was applied to solve several difficulties related to this issue. A model of tunnel fire using fuzzy fault tree analysis was developed for causes of tunnels fire [

71]. A different model based on a fault tree was established for fire accidents in tunnels considering the uncertainty and fuzziness of accidents. It was developed and applied to reduce the occurrence of fire in tunnels [

72]. A fuzzy AHP model that combines the fuzzy consistent matrix and AHP was proposed to assess the subway tunnel fire risk [

73]. A quantitative risk assessment method for road tunnel fire was developed, and a Monte Carlo-based estimation technique was directed to address parameter uncertainty in the risk assessment model depending on event tree analysis and consequence estimation models. The risk indices were very helpful for tunnel operators with distinct risk modes to consider the safety level for road tunnels [

74].

6. Risk Analysis Model for Tunnel Execution (RAMTE)

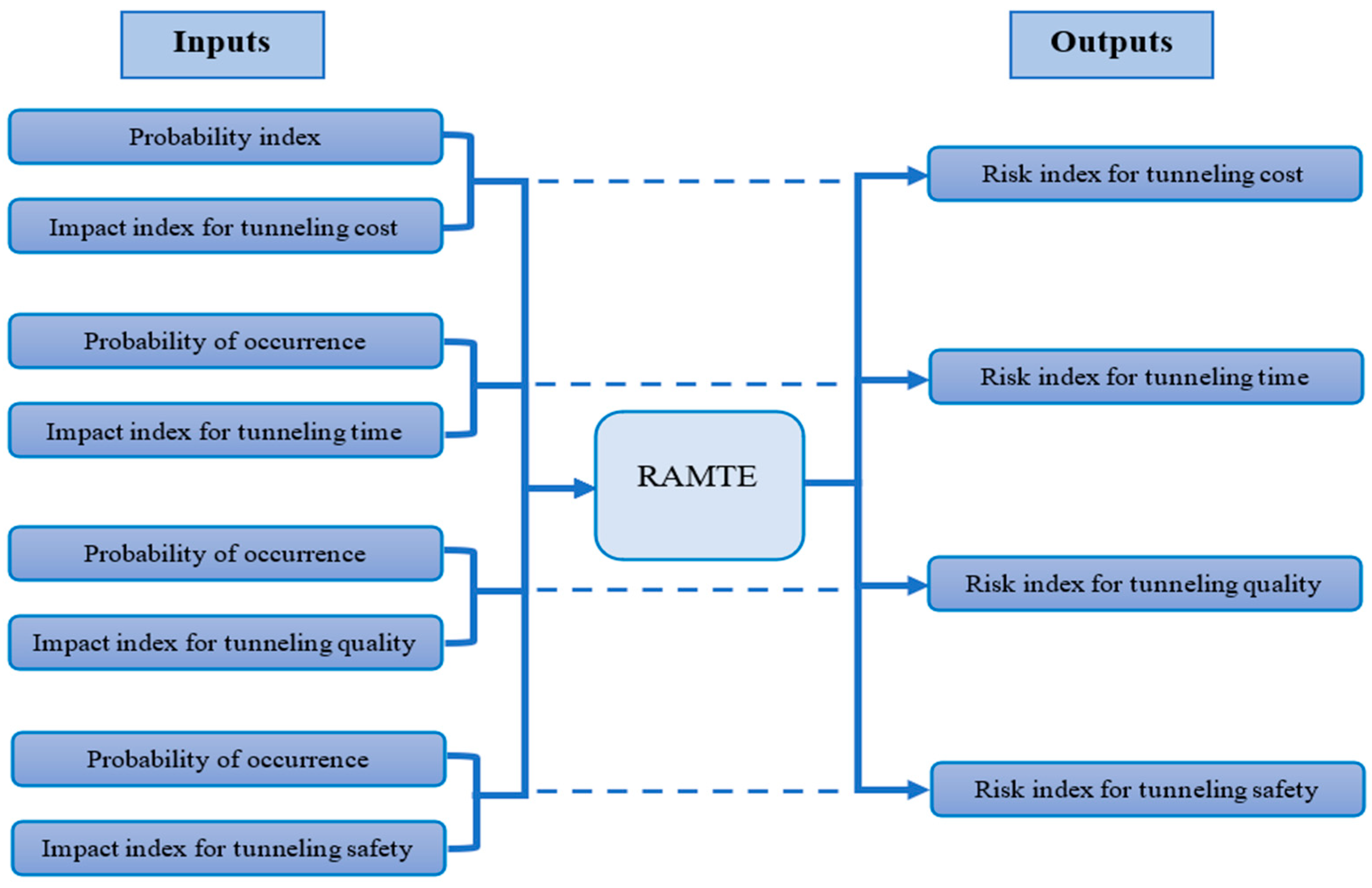

A proposed new risk analysis model was developed for addressing the main activities of tunneling processes and the associated risks using the fuzzy logic technique. It was created in three stages, including selecting the appropriate membership function, defining the rule base, and determining the inference mechanism. The crisp inputs in the current fuzzy logic model contained five indices: risk factor probability of occurrence (PI), impact index for tunneling cost (IITC), impact index for tunneling time (IITT), impact index for tunneling quality (IITQ), and finally, impact index for tunneling safety (IITS). For assessing the risk factors affecting tunnel execution activities, four new risk indices were created as the model outputs. Each index combined the probability of occurrence of each risk factor with an impact index. For example, the risk index for tunneling cost (RITC) combined the effect of both PI and IITC. The new index specified the overall importance related to cost. In the same way, the remaining three indices—risk index for tunneling time (RITT), risk index for tunneling quality (RITQ), and risk index for tunneling safety (RITS—represented the combined effect for the probability of occurrence with IITT, IITQ, and IITS, respectively. The layout for the proposed model is shown in

Figure 1.

For each case (cost, time, quality, and safety), there were two inputs and one output, and twenty-five logical rules were introduced to associate the model inputs with outputs. The selected linguistic terms to express the probability of occurrence are presented in

Table 2 and range from rare to very likely, while the impacts are described from very low to very high, and the output is determined by a range from trivial to extreme. The proposed logical rules correlating RAMTE inputs and outputs are recognized based on the fuzzy associated memories (FAMs), as shown in

Table 3.

The significance of a risk factor as a model output resulted in a combined influence of two inputs. The authors introduced the rules according to the relations shown in

Table 3, which were validated by the specialists in the brainstorming session. Two examples of the suggested logical rules are as follows:

Example 1. If the risk factor probability of occurrence is Unlikely and its impact on cost is Medium, then the risk factor significance related to cost is Minor.

Example 2. If the risk factor probability of occurrence is Moderate and its impact on safety is Very high, then the risk factor significance related to safety is Major.

Linguistic variables used in fuzzy logic can represent the fuzziness degree through several membership functions. These membership functions represent a numerical meaning for each linguistic term, and researchers should select the most suitable one according to the problem [

75]. The membership functions signify input and output value ranges associated with each label. The triangular membership function was proposed to be applied in RAMTE for inputs and outputs. This selection is supported due to several uses of this membership function in risk management and civil engineering projects in several situations similar to the presented study [

76]. The proposed membership function is depicted in

Figure 2.

6.1. Model Application

To assess risk factors affecting the tunneling process by applying RAMTE, many field surveys were conducted as explained in the

Section 2 to collect data on five characteristics concerning the identified thirty-two risk factors in Egypt (PI, IITC, IITT, IITQ, and IITS). The inputs of the model are briefed in the first five columns in

Table 4 as outputs of the field survey. These indices were calculated according to the following equations using linguistic terms. The probability of occurrence is represented in Equation (1) while the impact indices are represented by Equations (2) to (5). These new indices were applied for rating risk factors as introduced based on the participant’s opinion.

PI: the probability of accuracy;

Pi: the probability weight;

Ni: number of participants who reacted to option i;

IITC: the impact index for tunneling cost;

Iitci: the impact weight;

IITT: the impact index for tunneling time;

Iitti: the impact weight;

IITQ: the impact index for tunneling quality;

Iitqi: the impact weight;

IITS: the impact index for tunneling safety; and

Iitsi: the impact weight.

The weight of Pi, Iitci, Iitti, Iitqi, and Iitsi was represented as 0.1, 0.3, 0.5, 0.7, and 0.9 for (i = 1, 2, 3, 4, and 5, respectively).

The four model outputs (RITC, RITT, RITQ, and RITS) were determined and are summarized in

Table 4. All factors are also ranked in the same table. It can be noted from this table that RF21 (conflict between technical geological report and the ground nature) was regarded as the most significant risk factor based on its important effect on both cost and safety and represented the third and eighth orders due to its significant effect on time and quality, respectively. Furthermore, this factor, RF21, had the highest value of probability of occurrence (PI = 0.78). RF15 (groundwater or soil inflow during break-in) was ranked first due to its significant effect on time. On the other hand, RF28 (shaft wall damage during break-out) was considered the most important risk factor due to its significant effect on quality.

6.2. Verification of RAMTE

The defined risk factors can be classified according to the values of severity indices, which can be determined by applying the following equations [

77]:

where SIC, SIT, SIQ, and SIS are the severity indices for tunneling cost, time, quality, and safety, respectively. The RAMTE was applied to all risk factors affecting tunneling in Egypt, resulting in IITC, IITT, IITQ, and IITS. Spearman’s test was applied and the correlation coefficient was calculated to rank the factors in the four cases. The values of the correlation coefficient are summarized in

Table 5. It can be noted that all values are positive and above 95%, which verifies the model results.

The proposed model can be applied to other risk analysis cases associated with execution activities using the same methodology explained in this research, which includes the following: (1) collecting data concerning the execution of main activities and risk factors affecting them; (2) determining the most important objectives related to the case study, such as cost, safety, sustainability, etc.; (3) developing the risk model based on available data, which may include some risk characteristics, such as the probability of existence and the influence of each risk factor on the selected objectives; the model can relate these characteristics to determine the overall significance of each risk factor by using suggested logical rules; (4) applying the model for each case study according to the collected data.