Abstract

Many studies have developed technologies intended to automate the process toward improving sustainability and achieving a circular economy in the construction industry. Despite some research works that have been recently conducted to help construction agents in the management of construction and demolition waste (CDW), developing new CDW monitoring and traceability tools—through a collaborative and integrative approach—is still an urgent challenge. This paper developed a hybrid mobile app for the real-time traceability of construction waste generation and management, where agents involved in CDW management can work together and trace the generation and management of waste. For this, a research method was developed following three stages: (1) planning and design, including identification of the information to be incorporated in the app and the output data; (2) development of the app; and (3) app testing by several construction agents, stressing the benefits and limitations. The developed app allows not only estimating but also tracing the amount of CDW generated in a construction project, ensuring the correct management and control of the waste. In addition, it promotes collaborative work, as the agents involved in CDW management, i.e., construction companies, site managers, truck drivers, waste managers, and management plants, can work together and see in real-time the management of the waste.

1. Introduction

The construction sector is one of the main industries generating great environmental impact. For this, several initiatives have been launched in an attempt to improve this situation. Among these measures, the circular economy principles can be highlighted, which encourage reuse, recycling and recovery of waste. In this sense, many scientific works have been developed to design new building materials incorporating different waste streams [1,2,3].

In addition, since 2008, Europe has incorporated several regulations to manage construction and demolition waste (CDW). For instance, in Spain, the Royal Decree 105/2008 is currently in force [4]. This law regulates the production and management of CDW together with various National Waste Management Plans. These regulations establish several measures to promote CDW recycling and minimization in construction and demolition projects. Among their actions, these regulations require actors to write a CDW report and plan during the design and construction phase of the project as well as to establish an economic fee deposit that will be returned at the end of the project, once the client presents all the needed documents certifying the correct management of the CDW generated.

Despite the legislative advances in CDW management, when it comes to implementing these regulations in the construction industry, there are still many difficulties, such as the difficulty of estimating the CDW generation of a project [5,6,7,8,9] or managing and controlling the waste generated, as there are many agents involved in the process [10,11]. Therefore, it is essential to develop tools that collect data, measure and understand CDW generation, composition, and management, allowing for the collection of data for developing future CDW estimations and allowing the traceability of CDW throughout the entire building process [12].

During the last few years, many research works have been conducted dealing with CDW management issues. In particular, computer-aided tools have been quickly developed to improve CDW management [13,14,15].

In the last few years, these CDW tools have incorporated technological advances to improve their properties. For example, Zainun et al. (2016) used GIS to locate illegal CDW dumping in Kluang, Malaysia [16], and they were able to quantify in volume and weight the amount of CDW that was illegally dumped. Paz et al. (2018) developed a GIS-based planning system for managing CDW in Brazil [17], proving that the GIS system is essential to controlling CDW traceability and final destination.

On the other hand, GIS methods have been also combined with building information modeling (BIM) or the Global Positioning System (GPS) in order to improve CDW management. For example, a combination of the BIM and GIS technologies was used for demolition waste control and management [18]. The key finding of combining both technologies is that it provides information about the spatial data and object-oriented data for the CDW management of a single project [19]. Furthermore, Seror and Portnov [20] used a combination of GIS and GPS to highlight that the distance to the nearest main road, the depth of the ravine, and forest proximity are significant factors influencing illegal CDW dumping [20].

More recently, Hu et al. [21] combined a handheld camera with BIM technology to develop a smart framework for waste management in demolition projects. This smart frame helps to develop not only the BIM model but also to estimate the CDW quantity and management cost.

Another recent study conducted by Lu et al. [22] used computer vision and artificial intelligence to automate the recognition of CDW composition, providing a robust technology for CDW recognition.

Table 1 show recent works dealing with tools for CDW management.

Table 1.

Previous research works dealing with CDW management and quantification tools.

Currently, the development of mobile apps has an exponentially growing market around the world. Kaur and Kaur [23] reviewed the growing use of mobile apps running on smartphones, tablets, laptops, and other mobile devices. In the field of construction waste management, the works of Oliveira et al. from 2019 [24] and Attia et al. from 2021 [25] can be highlighted. In Spain, the Association of Construction Materials Companies (Asemaco, Pontevedra, Spain) has developed a mobile application for the management of construction waste generated in civil construction and demolition works [26]. It is available for Android and incorporates a complementary web app for waste calculation, providing the site agent with an extra tool to estimate the quantities of waste produced on site.

Based on the literature review, no studies were found on developing mobile applications with a collaborative and integrative approach, where the agents involved in CDW management can work together and trace the generation and management of waste. Therefore, this work aims to coordinate the waste management generated in building construction sites by developing a mobile application that allows not only estimating but also tracing the amount of CDW generated in a construction project, ensuring the correct management and control of the waste.

2. Materials and Methods

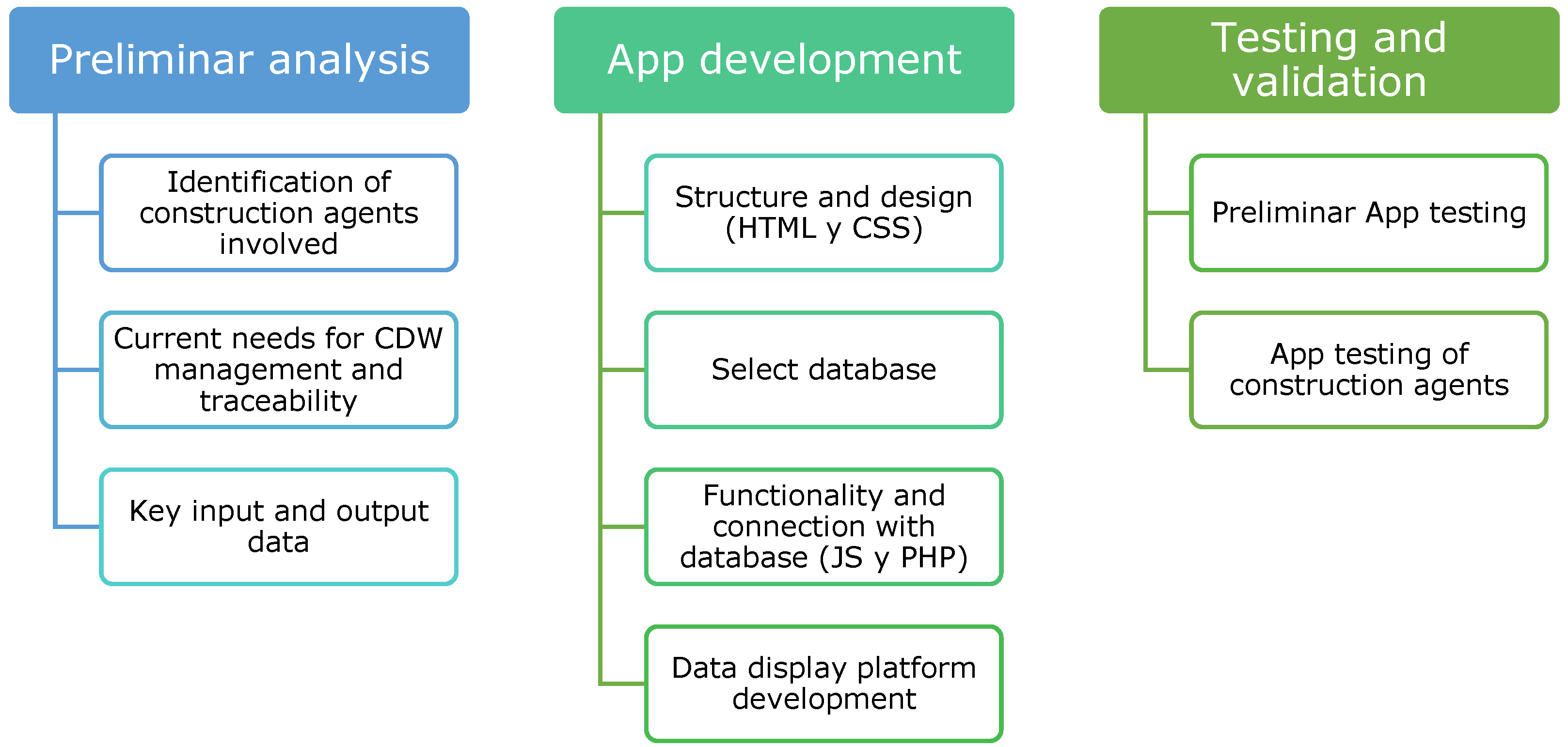

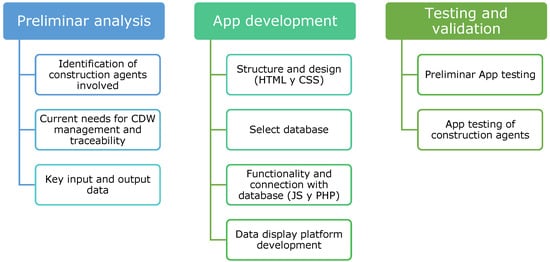

To carry out the development of the application and organize the tasks, a traditional waterfall methodology was followed (Figure 1). It is perfectly suited to small software development projects with specific and clearly defined objectives, since it rigorously orders the different phases of the project. Each phase must wait for the previous phase to finish since, in general, each phase receives as input the output generated in the previous phase.

Figure 1.

Scheme of the methodology followed to develop the app.

As can be seen from the flowchart in Figure 1, the app development consisted of three phases:

- Preliminary analysis: identification of the main information to be incorporated into the app and the output data;

- Development of the app;

- App testing and validation.

2.1. Preliminary Analysis—Identification of Key Input and Output Data

For the first stage of the method (Figure 1), one-to-one interviews were conducted with three experts on CDW management in order to define the needed data to be incorporated and the expected outputs of the app. For this, a CDW manager from a construction company, an authorized waste manager, and an architect from a local authority located in Madrid were approached to participate in a one-to-one interview. The three interviewees were selected because they cover the entire CDW management chain, from the construction company to the waste manager. All of them were working as managers of CDW at the moment of the interview and were chosen randomly based on their experience regarding CDW and their availability to participate in the interview. During the interview, the following open-ended questions were formulated:

- Which are the key factors affecting CDW management and traceability?

- Which construction agents are the ones most directly related to CDW management and traceability and which would be the suitable persons to use the app?

- What would be the input data and expected outcomes of the app? What are your needs?

The answers obtained were analyzed in order to define the needed data to be incorporated into the app as well as the final outcome of the application.

2.2. App Development

There are currently two different types of mobile phone applications: native applications, which are developed for a specific platform, e.g., Android, iOS, Windows Phone, etc., and hybrid applications, which are web applications encapsulated in a native shell given the appearance of the interface user as a mobile application [27]. Despite the native ones allowing developers to make the most of the phone’s operating system and hardware resources, a hybrid mobile application for Android was chosen for this work, since it allows developers to fully manage and optimize the specific management of CDW and the common management of any company.

The second stage of the method, as shown in Figure 1, unfolded in four phases: (1) structure and design; (2) database selection; (3) functionality and connection to the database; and (4) data display platform development.

2.2.1. Structure and Design

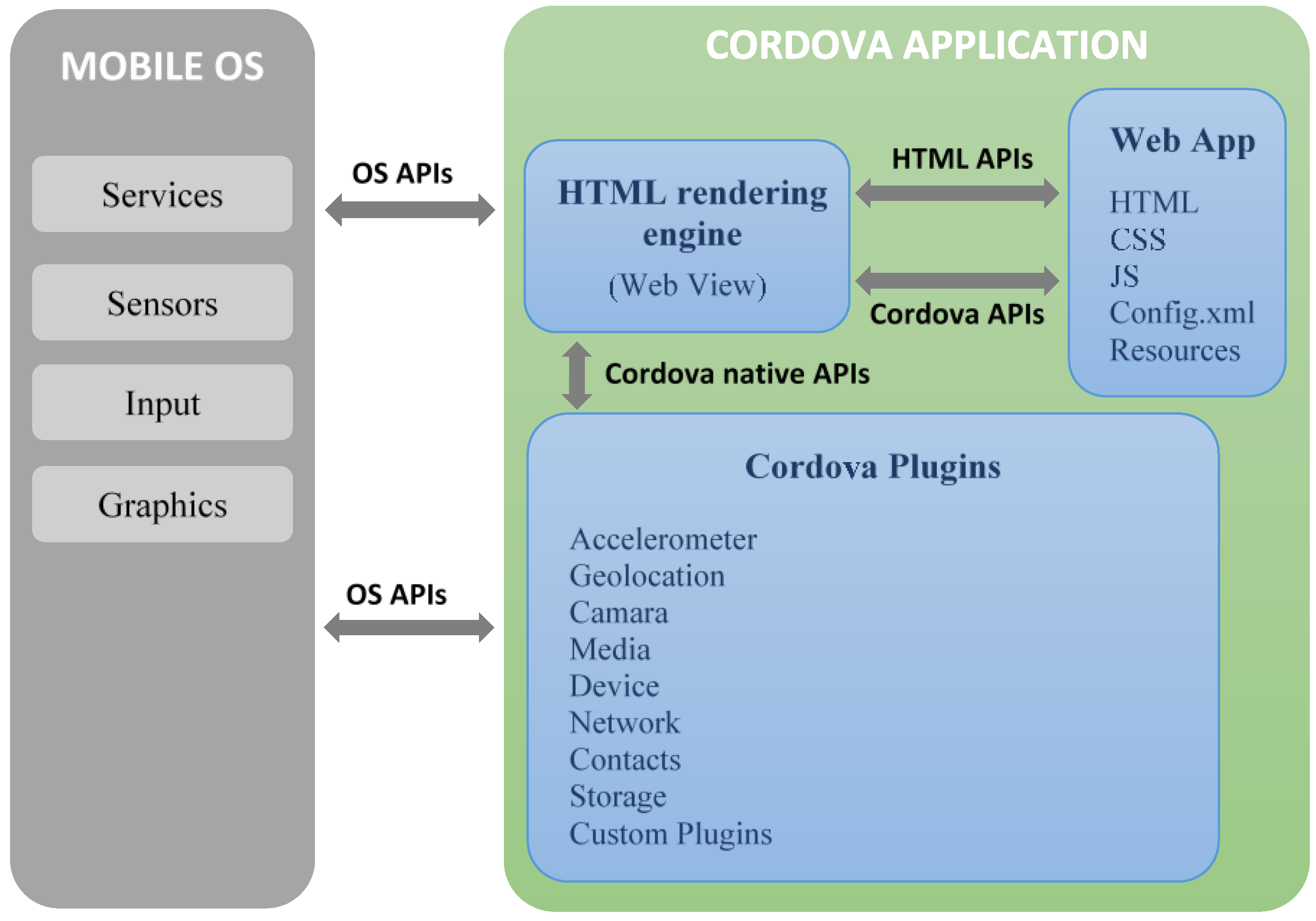

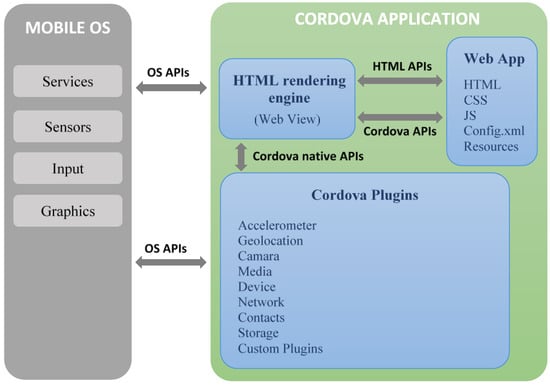

To develop a hybrid application, it is necessary to use a development framework, that is, a set of classes, methods, and libraries that allow agile software development to be carried out and will allow the application to be compatible with the different platforms on which it is deployed. The main hybrid application development frameworks are Apache Cordova [28]/Phonegap [29] and Ionic [30]. Both frameworks offer similar possibilities.

Apache Cordova 9.0.0 has been used in this work because it allows developers to customize the appearance of the application and does not impose any style sheet as occurs in other frameworks. HTML5 [31] has also been used to design the main structure of the application, and JavaScript [32] was used to control the behavior of the different elements of the application. Apache Cordova requires the existence of a home screen that will be the first one to be displayed, and by default its name must be index.html. Its appearance will vary depending on the user, since its content is dynamically generated based on the type of user who has logged in.

ListView and Form were implemented, from which the rest of the three screens were derived: (1) Login, the first screen that the user sees when the application is executed for the first time or the session has been previously closed; (2) ObraView, which shows the relative information of a construction work and (3) MainTransportista, the main screen that the driver of the waste container sees once he logs into the system.

Moreover, CSS3 [33] style sheets—which provide style to HTML elements—and version 4.3.1 of Bootstrap [34]—a multiplatform tool library oriented toward the development of web applications—were used to design the app. The Bootstrap library allows developers to develop applications with a responsive design through a series of predefined styles. This is a key feature due to the large number of screen sizes used by mobile devices and tablets on the market. In addition, it is compatible with most web browsers. For the typography and icons present in the application, those provided by Fontawesome [35] and Flaticon [36] have been used. Once the application was developed, it was encapsulated to be compatible with Android Oreo 8.0.0. [37].

Figure 2 shows the typical architecture of an Apache Cordova application, including three different modules in which the architecture of the application and its communication with the device’s operating system is divided. Apache Cordova creates a directory structure that will house the application files.

Figure 2.

Architecture of a Cordova application [28].

2.2.2. Database Selection

There are various possibilities and technologies that allow developers to add a database to a mobile application. The best option is a relational database manager because it provides persistence to the application’s data in such a way that it will keep the information that is added when you stop using it and will recover it when you want to access it again.

In this work, a centralized open-source database was chosen, MariaDB [38], which has the characteristics of MySQL [39], and in addition, the information generated in the system is stored in it. It will receive the queries generated by the application and send a packet with the corresponding information as a response.

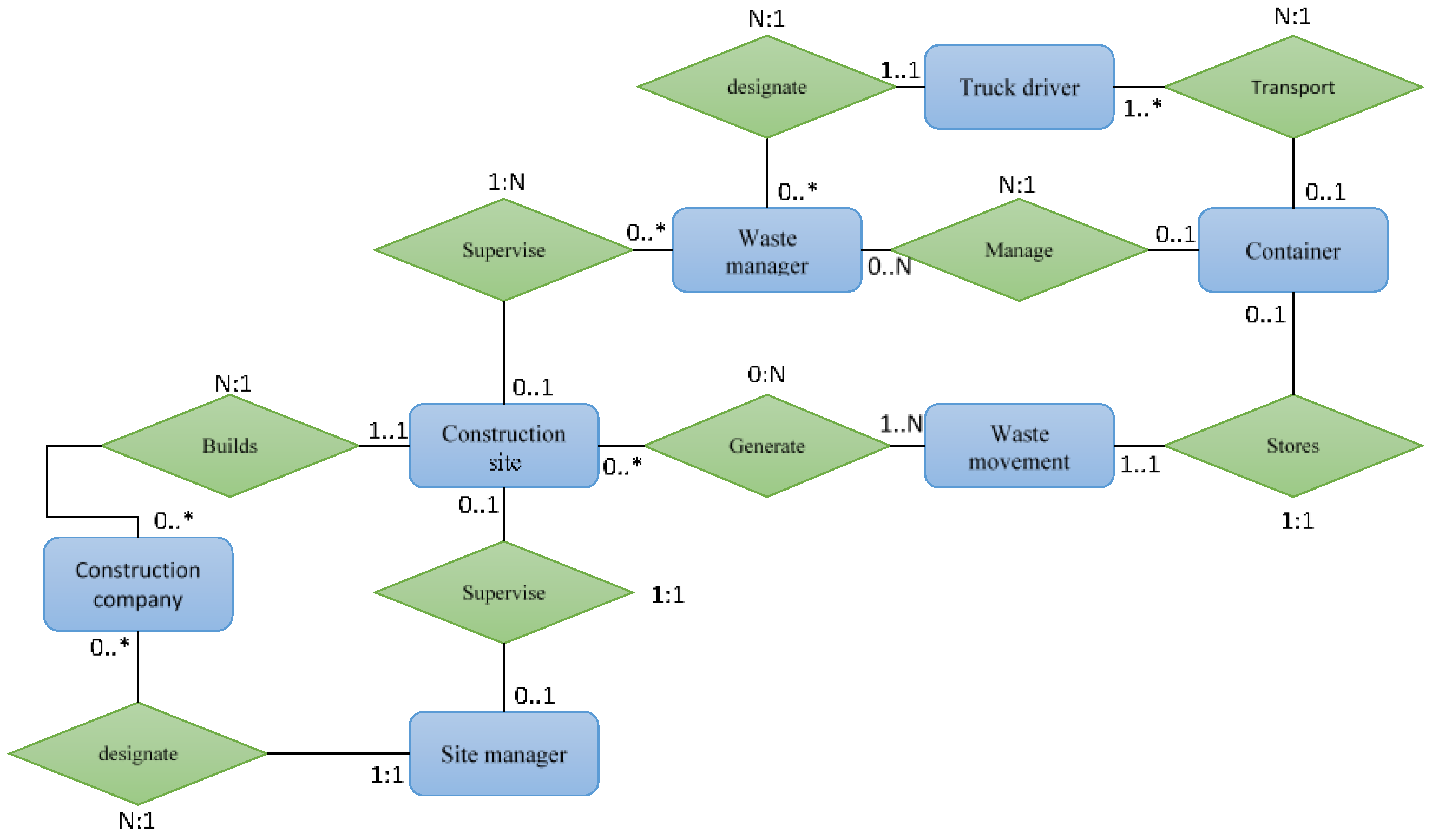

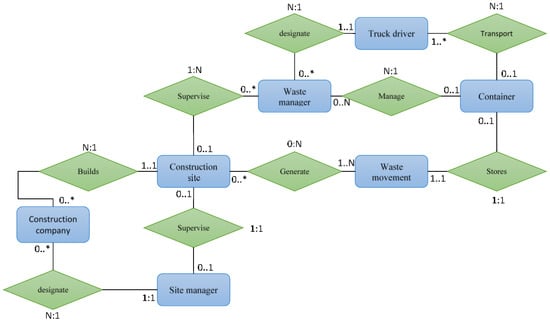

In this way, all users operate on the same data, being able to consult in real time the data that other users have been able to modify. Figure 3 shows the entity/relationship diagram using a flowchart [40] in which the relationships and interactions between the entities involved in the process are observed.

Figure 3.

Entity/relationship diagram.

As can be seen, the resources that are part of the process have also been defined:

- Works/projects carried out by construction companies.

- CDW containers where the waste is stored and transported. They are the key to carrying out the traceability of CDW, since the waste will be identified by the identifier of the container in which it is stored.

- Container movements, that is, exchanges of waste containers that occur at the construction site. There are two types: deposit of container or collection of container. Each of them records different information in the system.

Four types of users or roles involved in the management of CDW, as based on the results of Section 2.1, have been defined in the system:

- Construction company: registers the construction sites or projects in the system and provides the information related to them. The construction company can also select the CDW manager who is going to carry out the waste management of the work, provided the manager is already registered in the system. In addition, if the site manager is already known, the construction company role can select and assign the site manager at this point (if there they are registered and available, i.e., they are not assigned to any other site).

- Site manager: who should be an employee of the construction company and is in charge of supervising the CDW management of the work.

- CDW managers or recycling plant: they can consult the information concerning the projects that have been assigned to them by the construction companies. They can register and consult the movements of the containers.

- Drivers of CDW trucks: they transport the waste to an authorized plant and they record in the system the movements of containers that occur in the construction sites.

Each of the users registered in the system must be classified in one of these roles, and their activity within the system will be restricted according to what is established in their role.

2.2.3. Functionality and Connection with Database

JavaScript [32] has been used to provide functionality to the different elements of the application, such as buttons and drop-down menus, to prepare calls to the database and to use the local storage of the phone’s browser. JavaScript has a series of methods grouped under the name of Ajax [41] that are included in the JQuery [42] library, which allows information to be exchanged with a server through asynchronous HTTP requests.

The data transfer between client and server was encapsulated in the JSON [43] format to ensure effective communication between them. Version 2.2.4 of JQuery has been used to enable the use of Ajax methods to encapsulate HTTP requests to the database and version 1.4.5 of JQuery mobile to add some animation effects, such as transition effects during navigation through the application screens.

The information generated in the system is stored in a centralized database so that all users operate on the same data, being able to consult in real time the data that other users may have modified. To manage the database, the server language PHP [44] has been used, which is very suitable for managing databases in web development. These files are executed on the server and attend the HTTP requests generated by the client to perform CRUD operations on the data. In case the client wants to obtain data, it is encapsulated in the JSON format by the server before sending the response.

2.2.4. Data Display Platform Development

The procedure was as follows:

- The WebApp was developed, which is the www directory in which the application’s HTML, CSS, and JavaScript files are located. It includes a global configuration file, config.xml, to configure certain global application parameters that are independent of the operating system, such as the name of the app and the description of the application that will be displayed on the application marketplace, for example, in the Play Store for Android. In addition, it allows developers to set some preferences, such as the orientation with which the application should be displayed during its execution, the background color, and the appearance of the loading screen before the application starts.

- It was encapsulated in the platform using its framework, a directory that stores folders oriented toward the encapsulation of the application. This code is generated in the native language of the platform, Java for Android.

- The plugins were added. A directory in which the source files of the installed Cordova plugins are stored and which are necessary to access the phone’s native functionalities.

- The WebView (the rendering engine that Apache Cordova uses to view the application on mobile devices) was implemented so that some CSS styles do not vary. For this, the webkit for Android was used.

- Java 1.8.0, Android SDK Tools 26.1.1 [45] and Android SDK Platform-Tools 25.0.1 [46] were also used. In this way, the mobile app can be installed and used on most of the available mobile platforms.

2.3. App Testing and Validation

The third stage of the methodology (Figure 1) consisted of the validation of the developed app. For this, a first testing was conducted by the authors in order to test the performance, fix potential bugs, and improve operation.

Later, the app was presented to different construction agents (one construction company, seven site managers, and two truck drivers/waste managers), who tested and accessed the app considering their role. Ten construction agents were contacted in Madrid based on their experience regarding CDW management and their willingness to test the developed app. The contributions that the users of the application can make in this phase are very valuable. They belong to the group of users, so their opinions and proposals for improvement must be taken into account. In addition, they are people who have been completely unrelated to the development of the software, so it is possible that they will find a bug or vulnerability that the developers have overlooked.

In this phase, personal one-to-one interviews were conducted with the ten users. The interviews consisted of two parts. First, the users were trained regarding the use of the app, and then the following open-ended questions were asked in order to obtain their feedback:

- In your opinion, what are the strengths of the app? Was it easy to use?

- What are the limitations of the app? Would you add any other functionality? How do you think we could improve the app?

The answers were collected and the strengths and limitations were identified, discussed, and further analyzed, and their feedback will be taken into account in successive life cycles of the software.

3. Results and Discussion

This section shows the results and discussion of the main findings reached for each stage of the methodology.

3.1. Results of the Preliminary Analysis—Key Input and Output Data

Based on the results of the interviews, several problems that usually exist in the management of CDW were highlighted by the respondents. The great amount of red tape was highlighted by the environmental manager of the construction company, which indicated that the amount of CDW generated is usually recorded manually.

Another limitation raised during the interviews was the great difficulty in estimating the volume of CDW that will be produced on site, as there are multiple agents involved in the process and it is difficult to carry out proper CDW traceability. This problem was highlighted by both the construction company and the local authority.

Furthermore, the following agents were identified by the respondents as the most directly related to CDW management and traceability:

- Site managers, who are the site employees in charge of supervising the movement of CDW containers on site.

- CDW managers or recycling plant, who are responsible for collecting, weighing, and storing the CDW.

- Drivers of CDW trucks, who provide and/or remove the waste containers to the construction site.

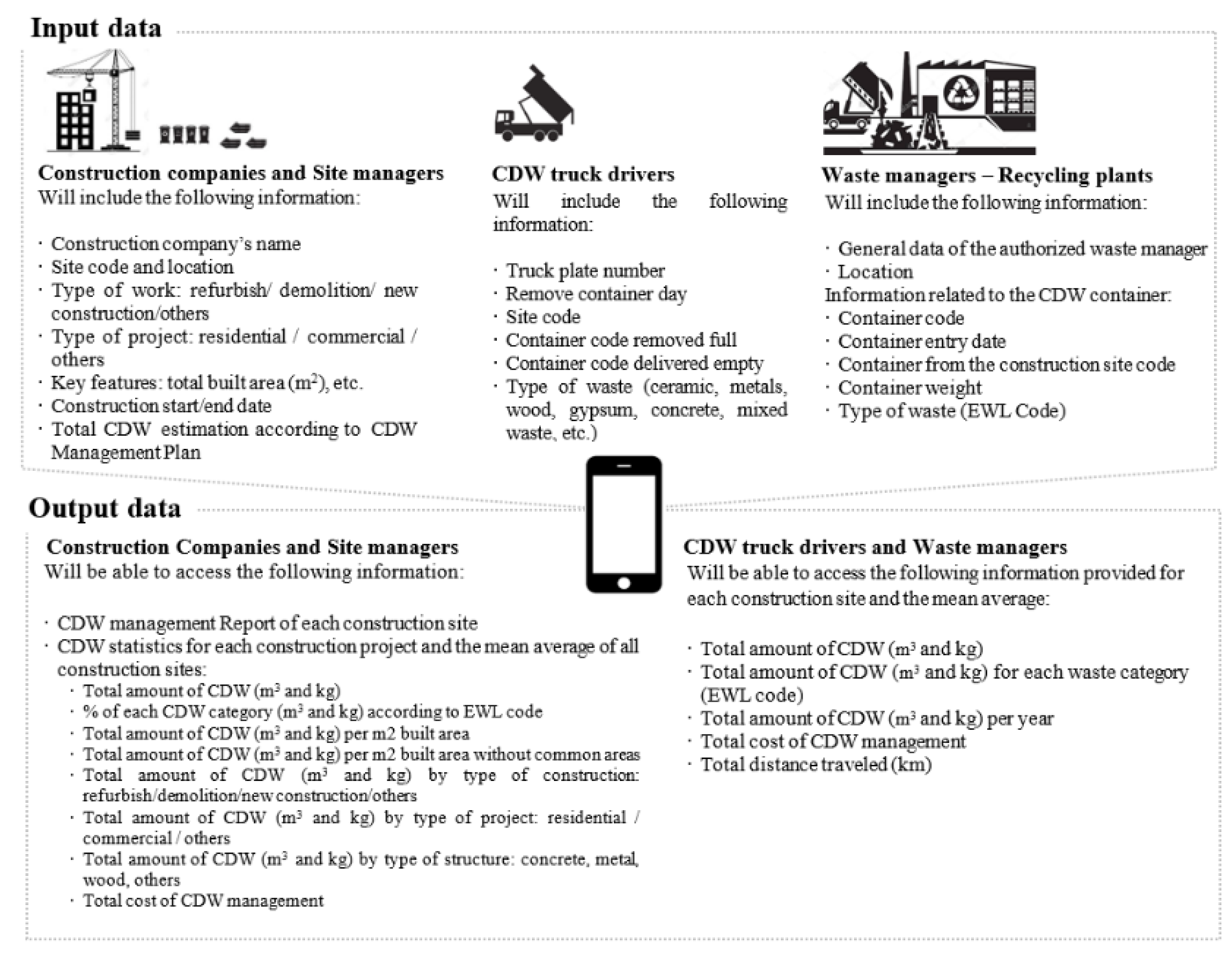

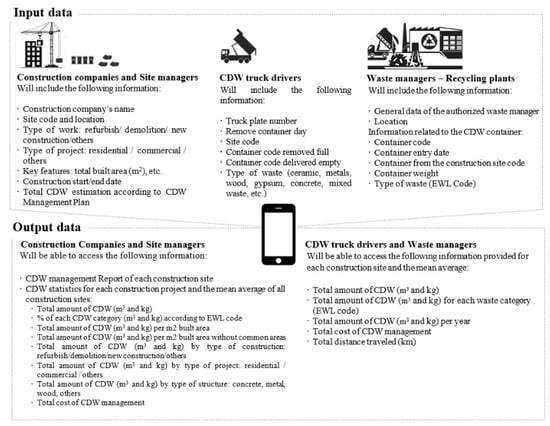

In addition, the input data and expected outcomes of the app were also asked about during the interviews and were all collected. Figure 4 shows the needed information to be incorporated into the app as well as the expected results for each construction agent.

Figure 4.

Key input and output information of the app tool.

3.2. Operation of the App

The operation of the developed app is explained and detailed in the next sections.

3.2.1. Login and Registration

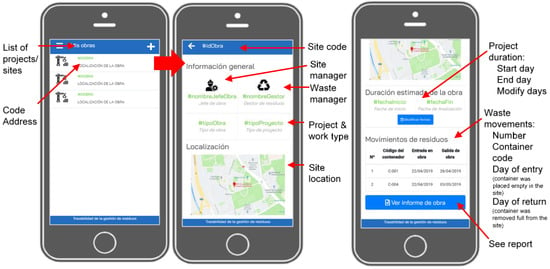

The app was developed so that on an initial page were the different agents managing CDW are to be registered and to login. Each construction agent can access the app and include information regarding CDW management, depending on their role: construction company, CDW site manager, CDW waste manager, and CDW truck driver. The construction company and the waste managers must include their login details to access the system, while the site managers and truck drivers must be previously registered in the system by the construction company or the waste managers (Figure 5).

Figure 5.

Login and new registrations.

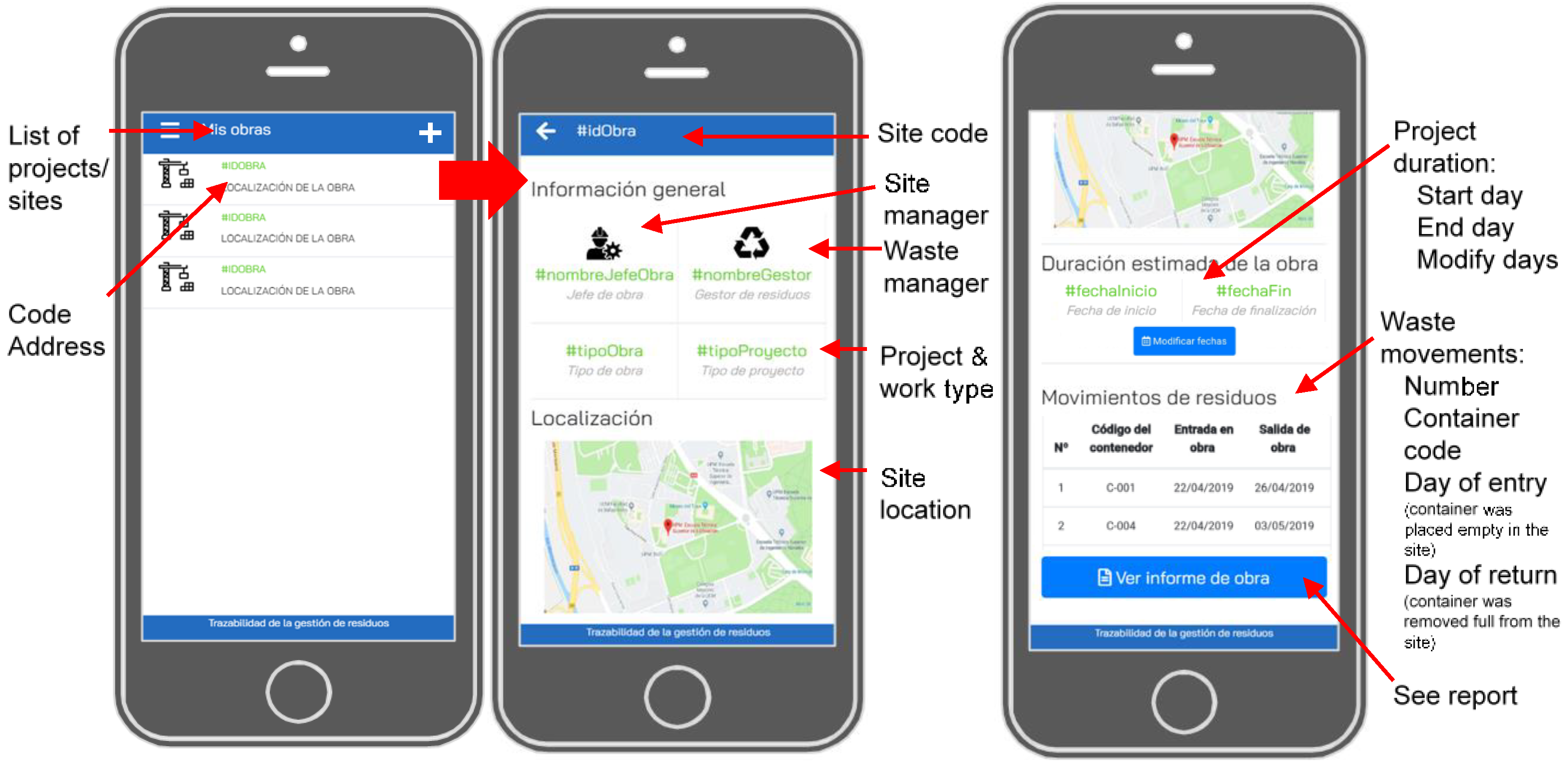

3.2.2. Construction Company: Information and Registration of a Construction Site

The construction company must enter the information related to the construction site: location, name of construction site manager, name of the waste manager, type of construction and project, estimated project duration, CDW containers, and CDW report (Figure 6). There is a search tab for the list of construction sites assigned to the different construction companies in the system. Each site will be identified by a unique code and location. The general information of each site is shown and the data allows users to consult the information related to the work. In addition, the construction company can also generate a PDF report to have a detailed relation of the waste generated at a specific construction site. However, this feature of the app is currently under development.

Figure 6.

Construction companies: site data and information.

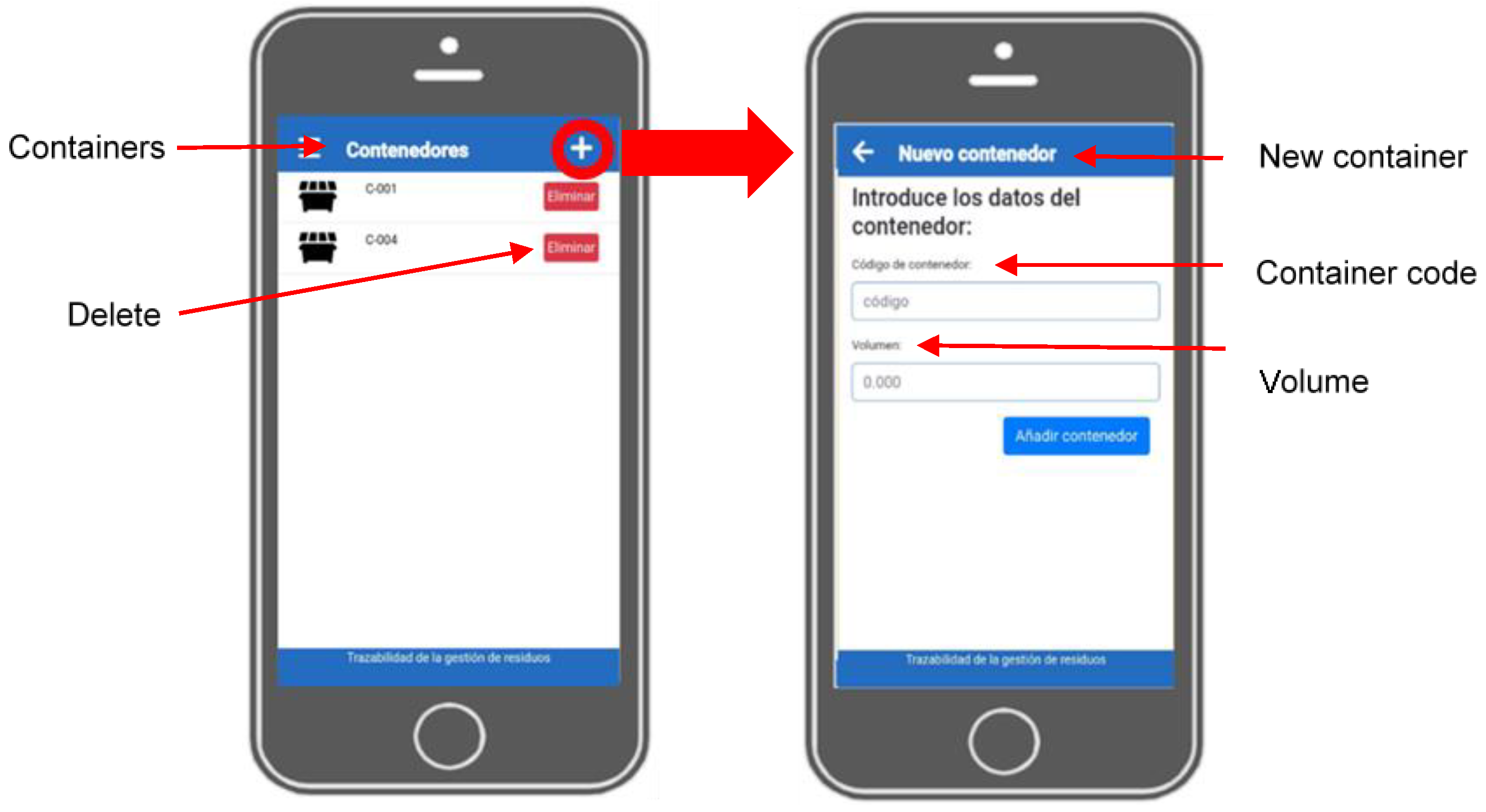

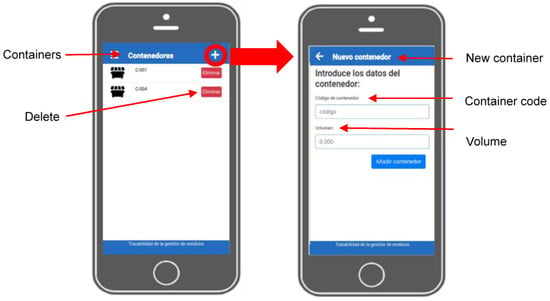

3.2.3. Waste Manager: Register Waste Containers and Truck Drivers

The authorized manager must enter the information concerning the waste containers into the application (Figure 7). To register a new container in the system, you must click on the button located at the top right of the list of containers and introduce the required data: container code and volume (m3). This is a key step to identify the waste and carry out its traceability.

Figure 7.

Register a waste container.

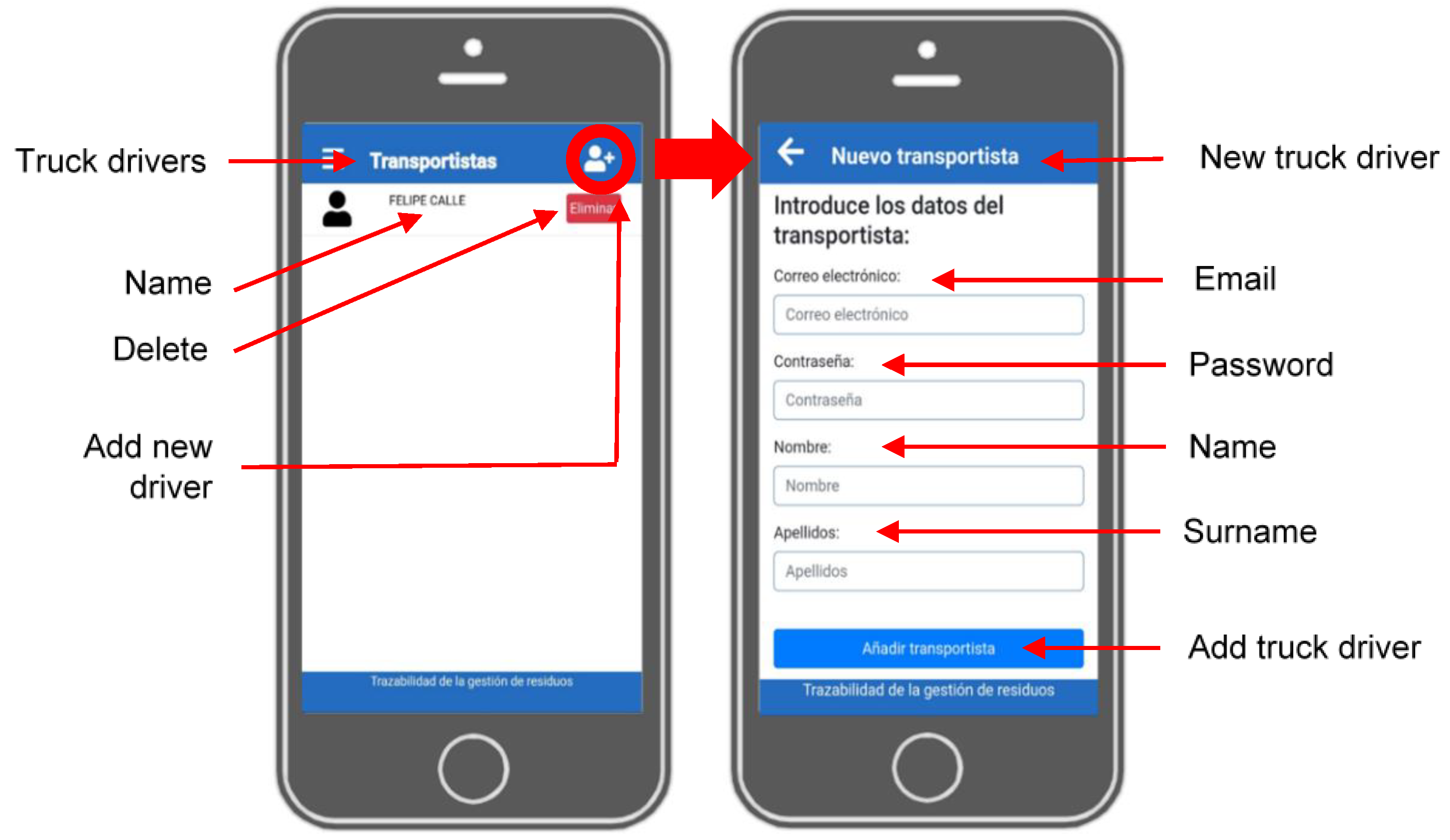

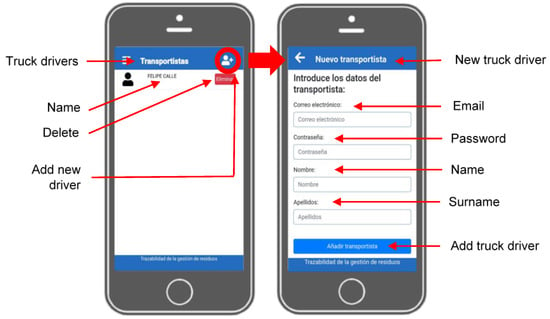

Waste managers must also register authorized truck drivers to collect CDW containers (Figure 8). The CDW truck drivers, once registered by the waste manager, must register the movement of the containers produced at the construction sites. To register a new CDW truck driver in the system, you must click on the button located at the top right of the list of drivers and introduce the required data: name, surname, email, and password. To consult the list of registered drivers, waste managers must go to the main screen, display the menu on the left, and click ‘CDW truck drivers’.

Figure 8.

Register a CDW truck driver.

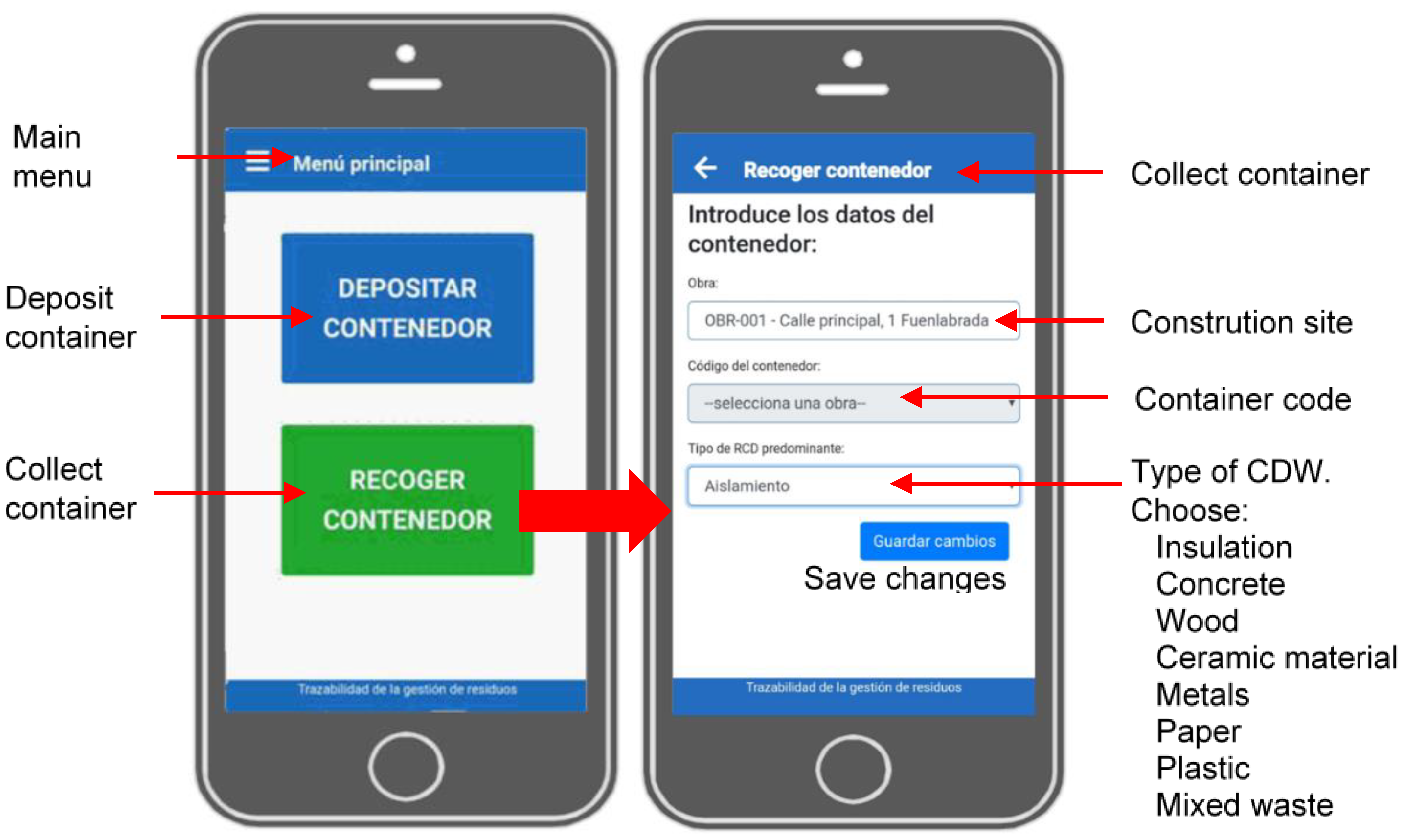

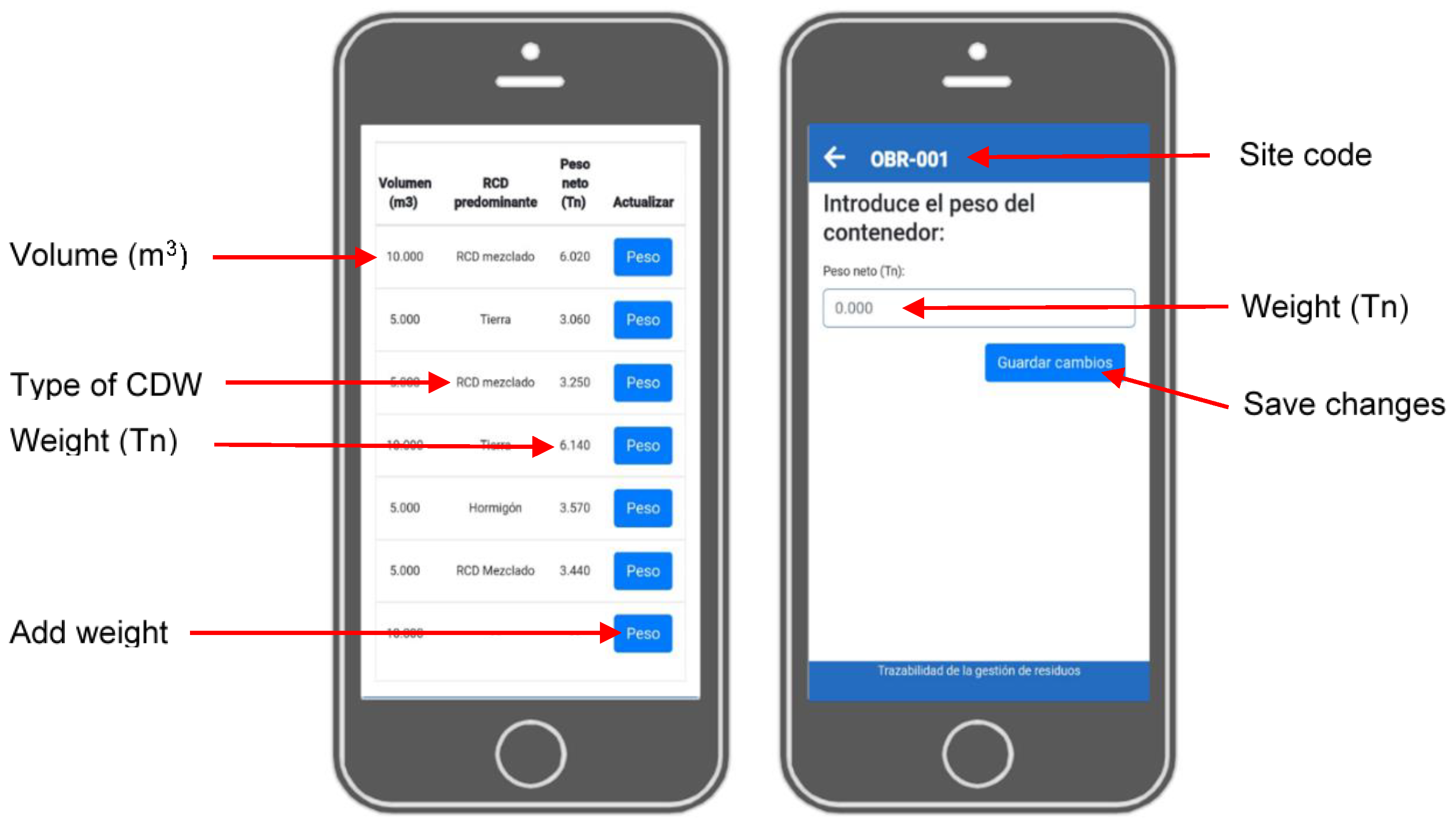

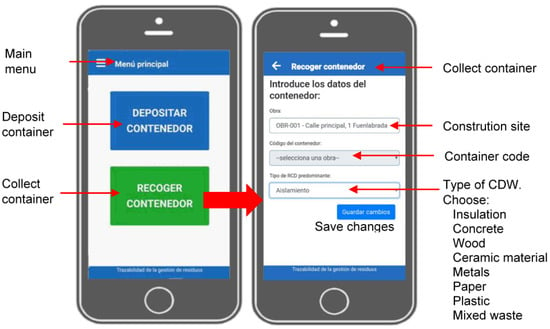

3.2.4. Truck Driver: Collect/Deposit a Container to/from the Construction Site

The driver must deposit an empty container at the construction site and register it in the application by entering the container code, site and date on which the deposit is made. If the driver collects a container full of waste from the construction site, it should be also registered in the app. For this, you must click on the ‘Pick up container’ button and complete the information related to the construction site code, the container code, and choosing the predominant type of CDW based on the list displayed. Once these data have been entered, changes must be saved using the ‘Save changes’ button (Figure 9).

Figure 9.

Collect a waste container from the construction site.

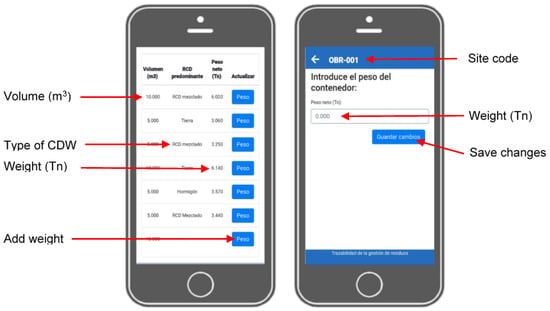

3.2.5. Waste Manager: Receiving the Container at the Plant

The CDW truck driver takes the container to the installation of the waste manager and the weight of the container is recorded. In order to complete the traceability of the waste in the system, the waste manager incorporates the data concerning the weight into the app. To do this, the waste manager needs to login and scroll to the bottom of the screen, Figure 10, where the site/project information is shown. This table shows information about the container’s movements, such as the container code, the date of deposit/return at/from the site, etc. The weight can be incorporated by clicking the ‘Weight’ button located on the right side of the table.

Figure 10.

The CDW manager adds the weight of the container once it arrives at the plant.

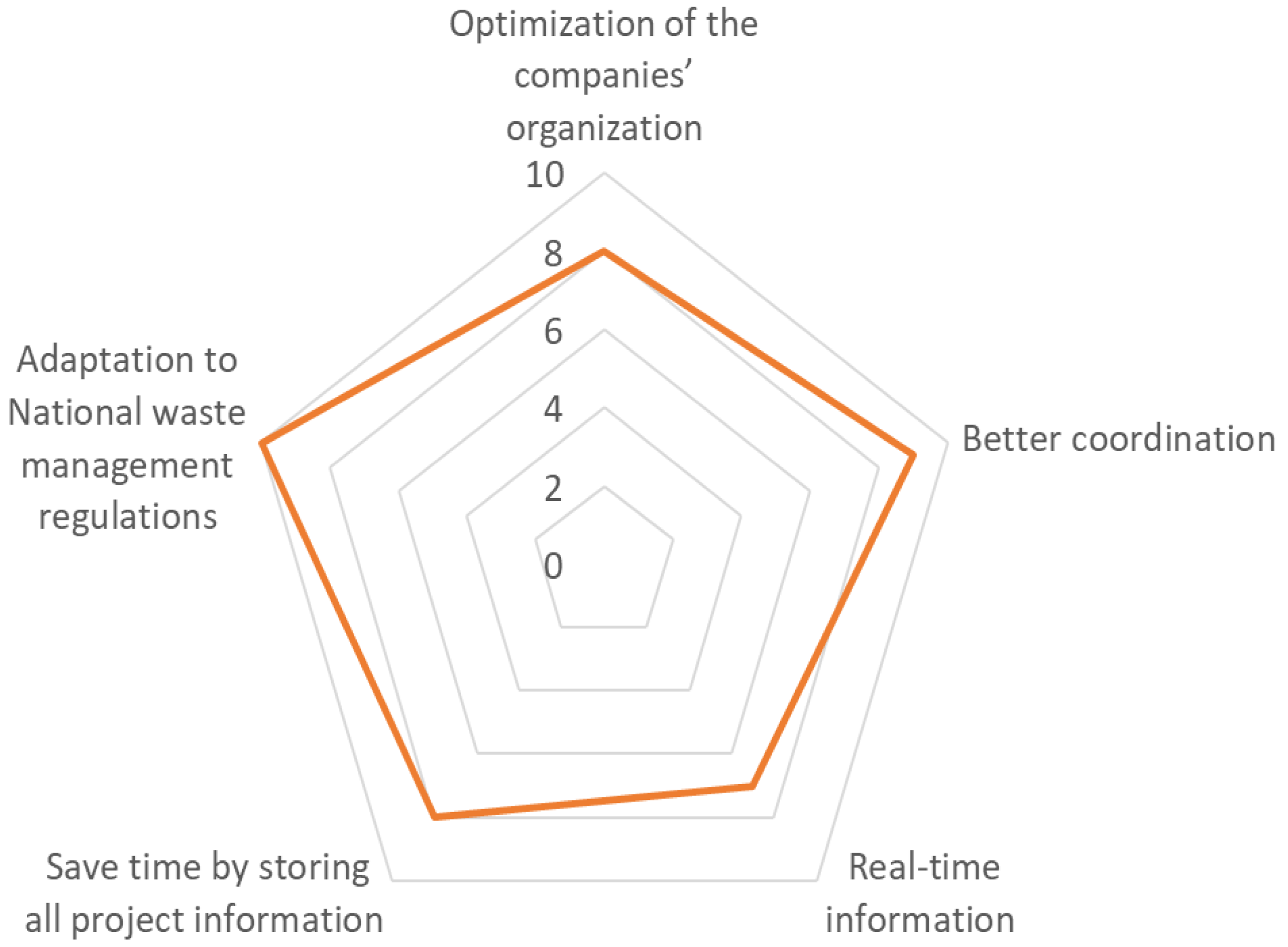

3.3. Strengths and Limitations of the Proposed App

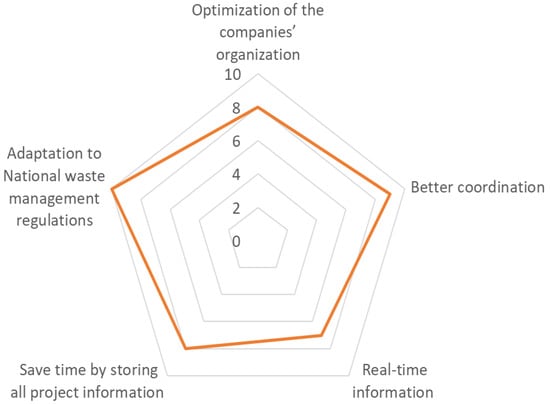

From the conducted interviews, the five strengths shown in Figure 11 were highlighted.

Figure 11.

Number of respondents who agreed on the same strength.

All the interviewees agreed that the developed app can help waste managers and construction companies to meet the requirements of the current regulations regarding CDW management. For instance, CDW managers have access to the CDW containers’ movements and therefore are able to monitor what occurs during the waste logistics, speeding up the process, and construction companies can access the list of their construction sites to supervise CDW management. In addition, construction companies will have a record of the amount of CDW generated in each of their projects and the amount of waste generated per construction activity, and therefore, they will have the needed data to obtain their own CDW generation ratios to develop the future documents ‘CDW Report’ and ‘CDW Plan’ established by the law.

The interviewees pointed out the following benefits of the proposed mobile application (Figure 11):

- Optimization of the companies’ organization was highlighted by 80% of the respondents, the construction company, and site managers.

- Better coordination between the different agents involved in CDW management, promoting a collaborative working method, was highlighted by 90% of the respondents.

- Real-time information, knowing at all times the place where the waste is generated and what is its final destination, thus guaranteeing a complete traceability and offering information on a map. This was raised by 70% of the respondents.

- Save time by storing all project information, waste quantities and their management in a safe place to have instant access whenever and wherever you want, which was highlighted by 80% of the users.

- Adaptation to national waste management regulations was raised by all the respondents.

Furthermore, the interviewees also detected several limitations or improvements and additional functionalities that would complete the operation of the current application. For example, three site managers recommended the possibility of using the app offline, without an internet connection. This was raised because in some locations of the worksite, it was difficult to reach the internet connection, especially in underground floors. This could be enabled by including a local database installed together with the application, and the data stored in the system could be accessed without an internet connection. This would allow the user of the application to be able to work offline.

Two interviewees, a truck driver and the construction company, suggested being able to upload a picture of the container once the truck driver removes it from the site, which would be perfect visual proof of the waste, providing veracity to the information that the driver is registering and avoiding fraud in CDW management. This image could be available for construction companies, waste managers, and drivers, and it could appear in the table of container movements (Figure 11).

Other recommendations raised by the respondents were ‘using push notifications’ to notify users about new events or information. For instance, to notify the site manager that the truck driver has arrived and taken a container with specific characteristics, or notify the site manager when the container reaches the waste management plant and include the weight in the app. Finally, the use of QR codes in the containers was a measure proposed by the truck drivers and site manager. This way, the truck driver will be able to scan the QR code and directly complete the type of container, volume, etc., without needing to complete it in the app. This will help to improve the recording of each container’s movement and speed up the process.

Finally, despite previous research works having claimed the difficulties of users’ participation and engagement in app implementation [47], no comments were received about this issue. Therefore, further research and exploration could be performed in this way.

4. Conclusions

The following conclusions can be drawn from this study:

- A mobile technology applied directly to manage the waste generated in the construction sector was developed and can be used by construction companies, site managers, waste truck drivers, and waste disposal companies for the traceability of CDW following a collaborative working method.

- The mobile application will favor the adequate environmental management of CDW and will contribute to sustainability since it traces CDW generation and reduces the problems currently associated with the red tape of both public and private construction works.

- Local governments can also benefit from the app as they can control CDW generation in their area, facilitating the monitoring of waste disposal to avoid the use of non-controlled landfills that harm the environment.

- With the development of this application, the objectives set have been achieved and the construction agents will be able to speed up the current red tape to carry out CDW management.

- Finally, some limitations were also found from the work performed, which could improve the developed technology, such as the possibility of using the app offline—without an internet connection—or the use of QR codes in the containers to improve the recording of each container’s movement and speed up the process. In addition, future in-depth analyses should be performed to explore the user’s participation and engagement in the use of apps for building construction, considering different workers’ profiles, such as prior work experience, education or age.

Author Contributions

Conceptualization, P.V.S., M.Á.A. and C.P.-A.; methodology, P.V.S., M.Á.A. and Á.G.T.; software, Á.G.T.; validation, P.V.S.; formal analysis, P.V.S.; writing—original draft preparation, P.V.S., C.P.-A. and M.A.B.-Á.; writing—review and editing, P.V.S., M.Á.A., C.P.-A. and M.A.B.-Á.; supervision, P.V.S. and M.Á.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created.

Acknowledgments

The authors would like to acknowledge the company that kindly agreed to test the app and provide valuable opinion and comments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ma, Z.; Shen, J.; Wang, C.; Wu, H. Characterization of sustainable mortar containing high-quality recycled manufactured sand crushed from recycled coarse aggregate. Cem. Concr. Compos. 2022, 132, 104629. [Google Scholar] [CrossRef]

- Del Río-Merino, M.; Vidales-Barriguete, A.; Piña-Ramírez, C.; Vitiello, V.; Santa Cruz-Astorqui, J.; Castelluccio, R. A review of the research about gypsum mortars with waste aggregates. J. Build. Eng. 2022, 45, 103338. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rubio-de-Hita, P. Reuse of CD and DVD Wastes as Reinforcement in Gypsum Plaster Plates. Materials 2020, 13, 989. [Google Scholar] [CrossRef]

- Spanish Government. Real Decreto 105/2008, de 1 de Febrero, por el que se Regula la Producción y Gestión de los Residuos de Construcción y Demolición; (Royal Decree 105/2008, of February 1, on the Production and Management of Construction and Demolition Waste), Official state bulletin (BOE); Spanish Government: Barcelona, Spain, 2008; pp. 7724–7730.

- Villoria Sáez, P.; Santa Cruz Astorqui, J.; del Río Merino, M.; Mercader Moyano, M.d.P.; Rodríguez Sánchez, A. Estimation of construction and demolition waste in building energy efficiency retrofitting works of the vertical envelope. J. Clean. Prod. 2018, 172, 2978–2985. [Google Scholar] [CrossRef]

- Kern, A.P.; Dias, M.F.; Kulakowski, M.P.; Gomes, L.P. Waste generated in high-rise buildings construction: A quantification model based on statistical multiple regression. Waste Manag. 2015, 39, 35–44. [Google Scholar] [CrossRef] [PubMed]

- Mália, M.; de Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. 2013, 31, 241–255. [Google Scholar] [CrossRef] [PubMed]

- Villoria Sáez, P.; Porras Amores, C.; del Rio Merino, M. Chapter 3: Estimation of construction and demolition waste. In Advances in Construction and Demolition Waste Recycling: Management, Processing and Environmental Assessment; Pacheco-Torgal, F., Ed.; Elsevier: London, UK, 2020; pp. 13–27. [Google Scholar]

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Osmani, M.; Villoria Sáez, P. Current and Emerging Construction Waste Management Status, Trends and Approaches, Waste, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Adams, K.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. Proc. Inst. Civ. Eng. Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X. Web-based construction waste estimation system for building construction projects. Autom. Constr. 2013, 35, 142–156. [Google Scholar] [CrossRef]

- Akinade, O.O.; Oyedele, L.O.; Munir, K.; Bilal, M.; Ajayi, S.O.; Owolabi, H.A.; Alaka, H.A.; Bello, S.A. Evaluation criteria for construction waste management tools: Towards a holistic BIM framework. Int. J. Sustain. Build. Technol. Urban Dev. 2016, 7, 3–21. [Google Scholar] [CrossRef]

- Zhang, X.; Ahmed, R.R. A queuing system for inert construction waste management on a reverse logistics network. Autom. Constr. 2022, 137, 104221. [Google Scholar] [CrossRef]

- Oliveira, M.d.P.S.L.; Oliveira, E.A.d.; Wanderley, A.; Campos, A.; Fonseca, A.M. Smart management of waste from construction sites: Mobile application technology in the city Manaus, Amazonas, Brazil. In Proceedings of the XIII International Conference on Virtual City and Territory: Challenges and Paradigms of the Contemporary City, Barcelona, Spain, 2–4 October 2019; pp. 1–14. [Google Scholar]

- Zainun, N.Y.; Rahman, I.A.; Rothman, R.A. Mapping of construction waste illegal dumping using geographical information system (GIS). IOP Conf. Ser. Mater. Sci. Engineering. IOP Publ. 2016, 160, 12049. [Google Scholar] [CrossRef]

- Paz, D.H.F.d.; Lafayette, K.P.V.; Sobral, M.d.C. GIS-based planning system for managing the flow of construction and demolition waste in Brazil. Waste Manag. Res. 2018, 36, 541–549. [Google Scholar] [CrossRef]

- Irizarry, J.; Karan, E.P.; Jalaei, F. Integrating BIM and GIS to improve the visual monitoring of construction supply chain management. Autom. Constr. 2013, 31, 241–254. [Google Scholar] [CrossRef]

- Al-Saggaf, A.; Jrade, A. Benefits of integrating BIM and GIS in construction management and control. In Proceedings of the CSCE International Construction Specialty Conference, Vancouver, BC, Canada, 7–10 June 2015. [Google Scholar]

- Seror, N.; Portnov, B.A. Identifying areas under potential risk of illegal construction and demolition waste dumping using GIS tools. Waste Manag. 2018, 75, 22–29. [Google Scholar] [CrossRef]

- Hu, X.; Zhou, Y.; Vanhullebusch, S.; Mestdagh, R.; Cui, Z.; Li, J. Smart building demolition and waste management frame with image-to-BIM. J. Build. Eng. 2022, 49, 104058. [Google Scholar] [CrossRef]

- Lu, W.; Chen, J.; Xue, F. Using computer vision to recognize composition of construction waste mixtures: A semantic segmentation approach. Resources. Conserv. Recycl. 2022, 178, 106022. [Google Scholar] [CrossRef]

- Kaur, A.; Kaur, K. Investigation on test effort estimation of mobile applications: Systematic literature review and survey. Inf. Softw. Technol. 2019, 110, 56–77. [Google Scholar] [CrossRef]

- Oliveira, M.; Arantes De Oliveira, E.; Freitas, R.d.R.; Campos, A.M.; Fonseca, A. Waste Management at Construction Sites in the Municipality of Manaus, Amazonas, Brazil: Characterization of the Current Situation. Curr. World Environ. J. 2019, 14, 326–335. [Google Scholar] [CrossRef]

- Attia, T.; Elshaboury, N.; Hesham, A.; Elhadary, M. Quantifying construction and demolition waste using slam-based mobile mapping system: A case study from Kafr El Sheikh, Egypt. In Proceedings of the 2021 International Conference on Data Analytics for Business and Industry (ICDABI), Sakheer, Bahrain, 25–26 October 2021; pp. 459–463. [Google Scholar]

- ASEMACO. Asociación de Empresarios de Materiales para la Construccion de Galicia, 2022. Available online: https://asemaco.com/ (accessed on 16 July 2023).

- Litayem, N.; Dhupia, B.; Rubab, S. Review of cross-platforms for mobile learning application development. Int. J. Adv. Comput. Sci. Appl. 2015, 6, 31–39. [Google Scholar] [CrossRef]

- Apache Cordova. Available online: https://cordova.apache.org/ (accessed on 16 July 2023).

- Phonegap. Available online: https://phonegap-desktop.software.informer.com/ (accessed on 16 July 2023).

- Ionic. Available online: https://ionicframework.com/ (accessed on 16 July 2023).

- HTML5. Available online: https://developer.mozilla.org/es/docs/Glossary/HTML5 (accessed on 16 July 2023).

- Java Script. Available online: https://developer.mozilla.org/es/docs/Web/JavaScript (accessed on 16 July 2023).

- CSS3. Available online: https://web.archive.org/web/20160310025511/http://www.w3schools.com/Css/css3_intro.asp (accessed on 16 July 2023).

- BootStrap. Available online: https://getbootstrap.com/docs/5.1/getting-started/introduction/ (accessed on 16 July 2023).

- Fontawesome. Available online: https://fontawesome.com/ (accessed on 16 July 2023).

- Flaticon. Available online: https://www.flaticon.es/ (accessed on 16 July 2023).

- Android Oreo. Available online: https://www.android.com/versions (accessed on 16 July 2023).

- MariaDB. Available online: https://mariadb.org/ (accessed on 16 July 2023).

- MySQL. Available online: https://www.mysql.com/ (accessed on 16 July 2023).

- Hayes, A.L.; Das, M.; Odom, P.; Natarajan, S. User friendly automatic construction of background knowledge: Mode construction from er diagrams. In Proceedings of the Knowledge Capture Conference, Austin, TX, USA, 4–6 December 2017; pp. 1–8. [Google Scholar]

- Ajax. Available online: https://dotnet.microsoft.com/en-us/apps/aspnet (accessed on 16 July 2023).

- JQuery. Available online: https://jquery.com/ (accessed on 16 July 2023).

- JSON. Available online: https://www.json.org/json-en.html (accessed on 16 July 2023).

- PHP. Available online: https://www.php.net (accessed on 16 July 2023).

- Android SDK Tools. Available online: https://android-sdk.en.uptodown.com (accessed on 16 July 2023).

- Android SDK Platform-Tools. Available online: https://androidsdkmanager.azurewebsites.net (accessed on 16 July 2023).

- Yang, C.; Lai, D.W.; Sun, Y.; Ma, C.-Y.; Chau, A.K.C. Mobile application use and loneliness among older adults in the digital age: Insights from a survey in Hong Kong during the COVID-19 pandemic. Int. J. Environ. Res. Public Health 2022, 19, 7656. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).