Real-Time Early Safety Warning for Personnel Intrusion Behavior on Construction Sites Using a CNN Model

Abstract

:1. Introduction

2. Literature Review

2.1. Overview of Early Warning Approaches for Intrusion Behavior

2.2. Overview of the Convolutional Neural Network Model

3. Methodology

3.1. Process of Personnel Intrusion Behavior Early Warning

- (1)

- Start the workstation system. After setting up the camera group and installing the communication wires, the operator can open the camera group and the video identification terminal of the workstation through remote control at the workstation and transmit the real-time video acquired by the camera group in the hazard area of the construction site to the terminal in the form of frame images.

- (2)

- Realize real-time detection of construction site personnel. First, CNN obtained the characteristic map of construction site workers. Then, the classification function of the Softmax function is used to separate the construction personnel in any video frame image, so as to achieve the purpose of detecting the construction site personnel in the video.

- (3)

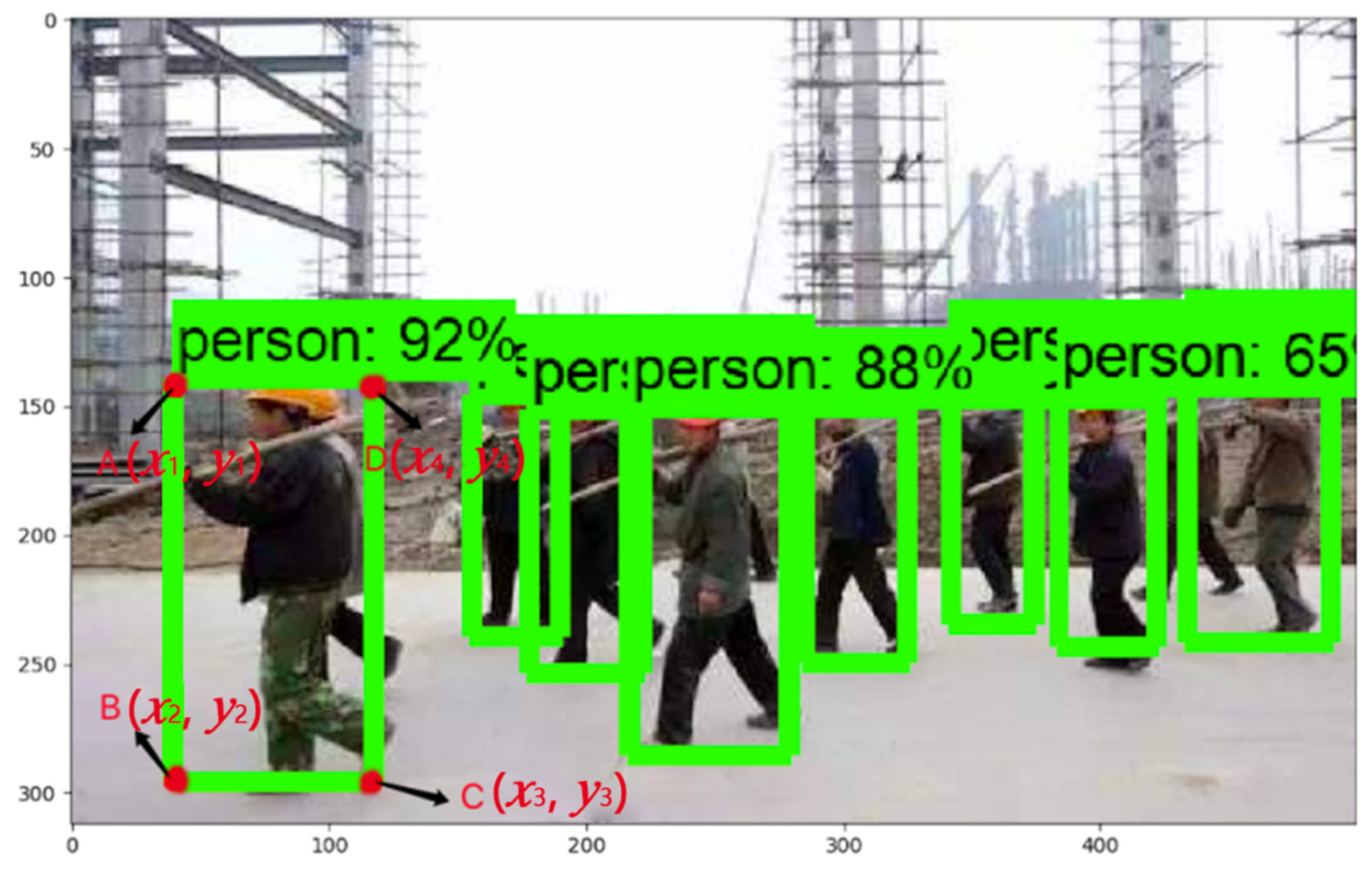

- Real-time measurement of personnel coordinates. After the coordinate recognition of the human body and the drawing of the human body range frame, the coordinate regression function is used to realize the coordinate output of the human body range frame.

- (4)

- Realize early warnings according to detection results. When the body and construction of the danger zone at the edge of the distance is less than the safe distance of construction site rules, under the condition of appropriate comprehensive safety, the personnel access the properties and reminders or warnings for location information are given, and the image is saved automatically. The early safety warning procedure is performed in the next frame image in a row to complete construction hazard area identification.

- (1)

- Ordinary reminder: When personnel enter the hazard area conforming to their own attribute information;

- (2)

- Emergency reminder: When personnel enter the hazard area that does not conform to the information of their own attributes, they will make an emergency reminder and send the information to the security officer for disposal.

3.2. Identification of Hazard Areas at Construction Sites

3.2.1. Division of Hazard Areas

- (1)

- Hazard areas in civil construction. The area may contain hazards such as edges, opening holes, etc. The rules for defining this large category of hazard area draw on previous research, expanding the edge of the construction area by 1 m and using this expansion line as the boundary point for the civil construction hazard area [51].

- (2)

- Hazard area for the movement of machinery. Danger sources include working cranes arms, moving machinery and equipment, etc. Mark the path of the machinery and equipment activity and extend the outermost edge by 1 m as the boundary of the machinery movement hazard area.

- (3)

- Hazard area for power leakage. The main sources are wires and cables. In the direction perpendicular to the main body of the wire, the projection of the wire and cable is expanded by 1 m, which defines the boundary of the leakage hazard area.

3.2.2. Modeling of Construction Site

3.3. Quantification of Construction Personnel Information

3.3.1. Collection of Personnel Attribute Information

3.3.2. Quantification of Personnel Behavior

3.4. CNN Model of Intrusions in Hazard Area

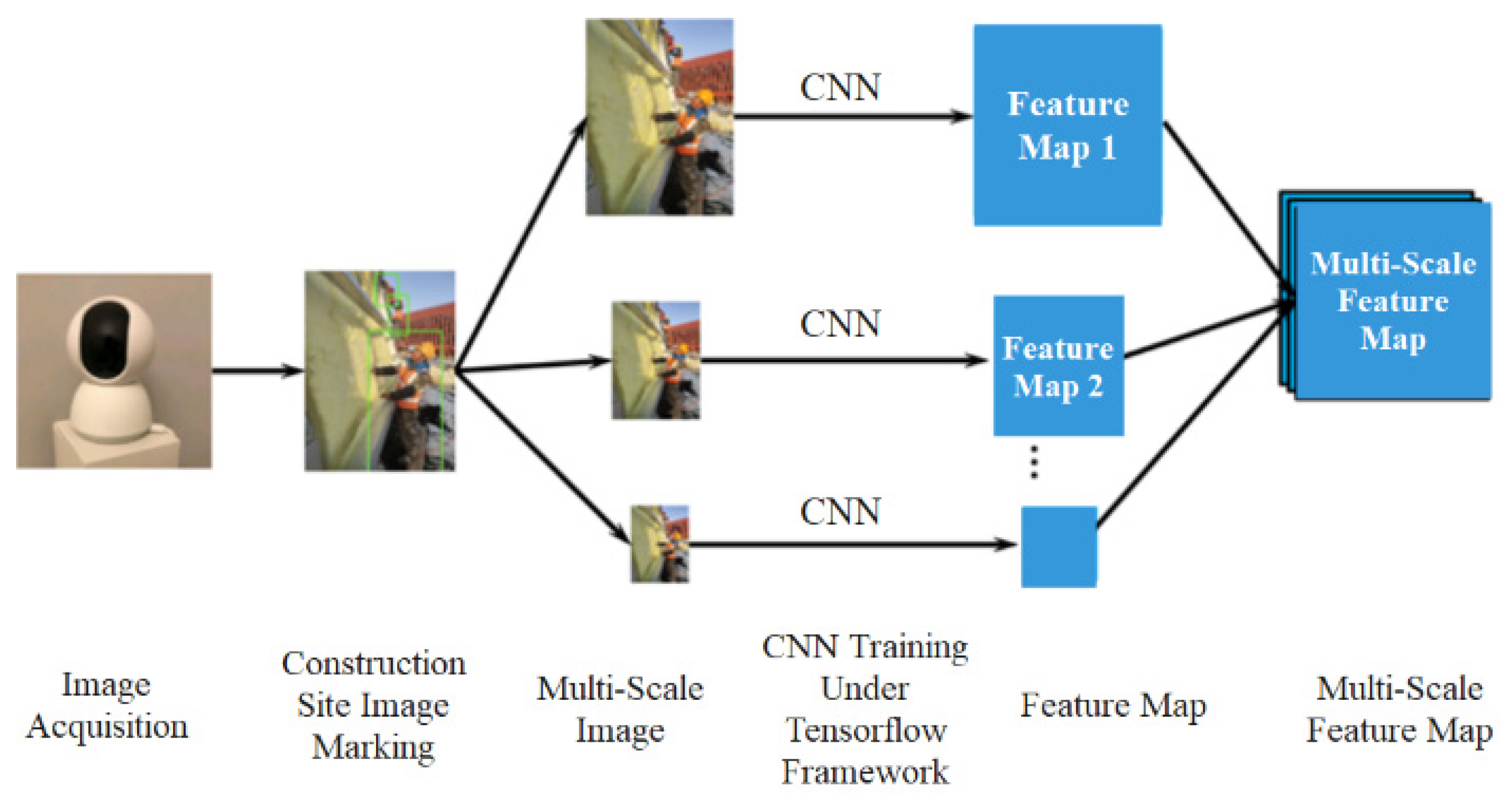

3.4.1. Personnel Image Acquisition and Marking

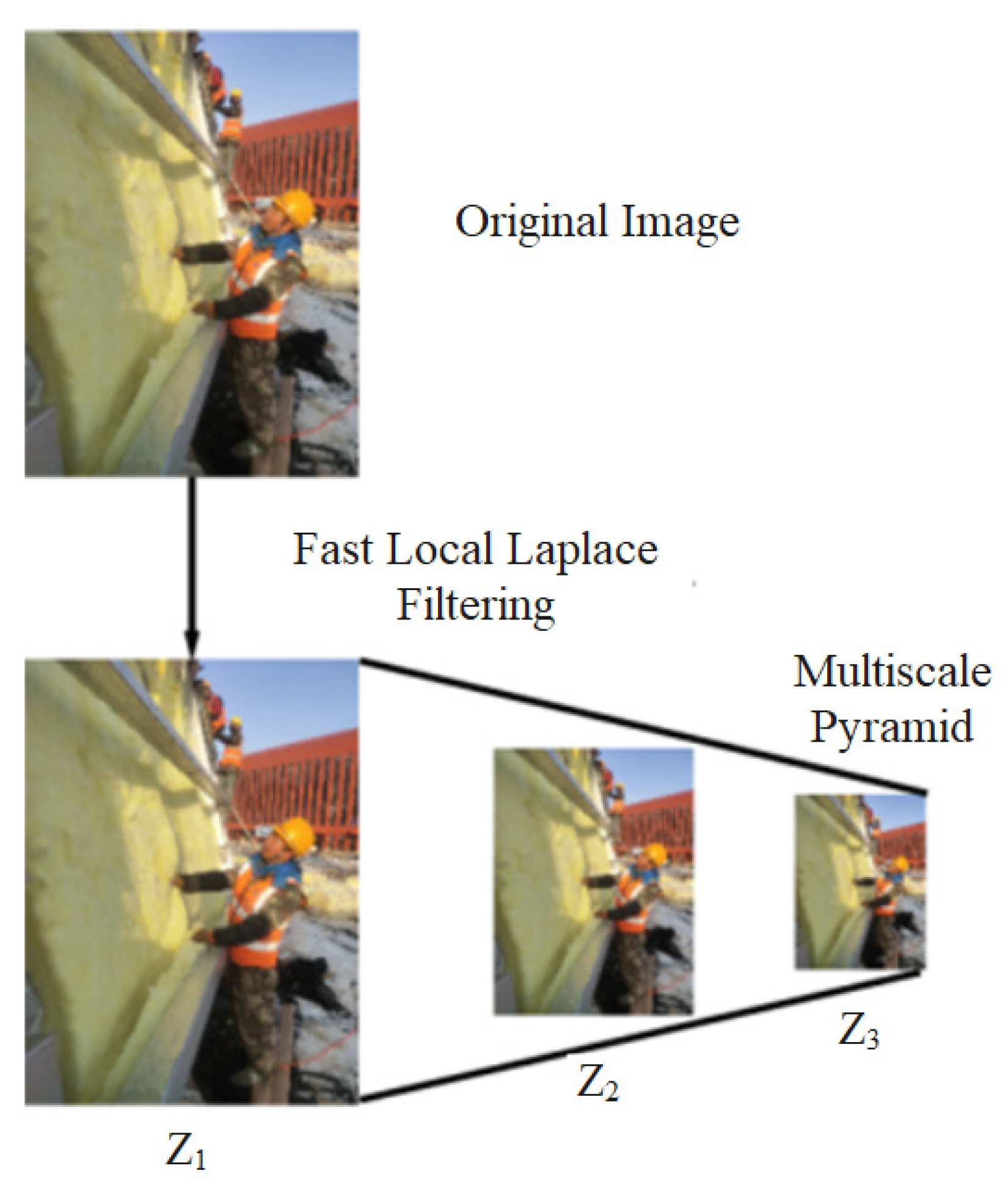

3.4.2. Personnel Image Feature Mapping Acquisition

3.4.3. Personnel Identification and Classification Model Construction

4. Results

4.1. Test and Analysis Based on the CNN Model

4.2. Early Warning of Intrusion Behavior Based on CNN

5. Discussion

- (1)

- A construction site personnel management system based on BIM-RFID was adopted to realize real-time detection of personnel attribute information on the construction site. According to industry norms and operating time characteristics, construction personnel were classified into three categories: civil construction personnel, mechanical operation personnel, and electrical engineering personnel. In combination with the safe operation scope of each professional construction personnel, three types of construction hazard areas, including civil construction hazard areas, machinery moving hazard areas, and power leakage hazard areas, were established.

- (2)

- Based on personnel attributes and hazard area division, the rationale for construction intrusion behavior was elaborated. The center coordinates were determined according to the posture of the construction personnel, and the safety threshold was then compared with the linear distance (the distance between the personnel center coordinate point and the hazard area) and the personnel work area for a two-level differential warning.

- (3)

- The method of multi-scale hierarchical feature extraction was used to obtain the feature map of construction personnel, and then the Softmax classification function and argmax function were employed to establish the recognition model. The model was applied to a specific project for empirical research, which shows that its determination of intrusion behavior of construction site personnel is relatively accurate and can achieve the function of prior warning.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- National Engineering Quality and Safety Supervision Information Platform. Ministry of Housing and Urban-Rural Development of the People’s Republic of China (MOHURD). Available online: https://zlaq.mohurd.gov.cn/fwmh/bjxcjgl/fwmh/pages/default/index.html (accessed on 1 January 2023).

- Heinrich, H.W. Industrial Accident Prevention: A Scientific Approach, 2nd ed.; McGraw-Hill Book Company: New York, NY, USA, 1941; pp. 354–396. [Google Scholar]

- Wang, C. Research on the Subway Construction Safety Management Based on Worker’s Unsafe Behavior. Master’s Thesis, Tianjin University of Technology, Tianjin, China, 2014. [Google Scholar]

- Gao, H.; Luo, H.B.; Fang, W.L. Methods of intrusion identification in hazardous areas based on computer vision. J. Civ. Eng. Manag. 2019, 36, 123–128. [Google Scholar] [CrossRef]

- Fouda, M.; Taleb, T.; Guizani, M.; Nemoto, Y.; Kato, N. On supporting P2P-based VoD services over mesh overlay networks. In Proceedings of the GLOBECOM 2009—2009 IEEE Global Telecommunications Conference, Honolulu, HI, USA, 30 November–4 December 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Kim, K.; Kim, M. RFID-based location-sensing system for safety management. Pers. Ubiquitous Comput. 2012, 16, 235–243. [Google Scholar] [CrossRef]

- Navon, R.; Kolton, O. Model for automated monitoring of fall hazards in building construction. J. Constr. Eng. Manag. 2006, 132, 733–740. [Google Scholar] [CrossRef]

- Zheng, X.Z.; Wang, X.L.; Liu, H.L.; Sun, Z.G.; Guo, J. Real-time monitoring and early warning system for near-miss incidents of subway station construction. J. Xi’an Univ. Sci. Technol. 2019, 39, 589–596. [Google Scholar] [CrossRef]

- Shuang, Q.; Zhang, Z. Determining critical cause combination of fatality accidents on construction sites with machine learning techniques. Buildings 2023, 13, 345. [Google Scholar] [CrossRef]

- Nnaji, C.; Karakhan, A.A. Technologies for safety and health management in construction: Current use, implementation benefits and limitations, and adoption barriers. J. Build. Eng. 2020, 29, 101–212. [Google Scholar] [CrossRef]

- Altman, E.I. Financial ratios, discriminant analysis and the prediction of corporate bankruptcy. J. Finance 1968, 23, 589–609. [Google Scholar] [CrossRef]

- Gu, H.B. Macroeconomic early warning research: Theory, method and history. Econ. Theor. Bus. Manag. 1997, 4, 1–7. [Google Scholar]

- Guo, H.L.; Liu, W.P.; Zhang, W.S. A BIM-PT-integrated warning system for on-site workers’ unsafe behavior. Chin. Saf. Sci. J. 2014, 24, 104–109. [Google Scholar] [CrossRef]

- Zhao, T.S.; Xu, K.; Zhou, W. Graded management of hazardous area in construction site. Ind. Saf. Environ. Prot. 2018, 44, 43–46. [Google Scholar]

- Teizer, J.; Cheng, T. Proximity hazard indicator for workers-on-foot near miss interactions with construction equipment and georeferenced hazard areas. Autom. Constr. 2015, 60, 58–73. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H.S.; Park, M.; Chung, B.; Hwang, S. Automated hazardous area identification using laborers’ actual and optimal routes. Autom. Constr. 2016, 65, 21–32. [Google Scholar] [CrossRef]

- Maalek, R.; Sadeghpour, F. Accuracy assessment of ultra-wide band technology in locating dynamic resources in indoor scenarios. Autom. Constr. 2016, 63, 12–26. [Google Scholar] [CrossRef]

- Vahdatikhaki, F.; Hammad, A. Risk-based look-ahead workspace generation for earthwork equipment using near real-time simulation. Autom. Constr. 2015, 58, 207–220. [Google Scholar] [CrossRef]

- Li, H.; Dong, S.; Skitmore, M.; He, Q.H.; Yin, Q. Intrusion warning and assessment method for site safety enhancement. Saf. Sci. 2016, 84, 97–107. [Google Scholar] [CrossRef]

- Dong, S.; Li, H.; Skitmore, M.; Yin, Q. An experimental study of intrusion behaviors on construction sites: The role of age and gender. Saf. Sci. 2019, 115, 425–434. [Google Scholar] [CrossRef]

- Guo, H.L.; Yu, Y.T.; Skitmore, M. Visualization technology-based construction safety management: A review. Autom. Constr. 2017, 73, 135–144. [Google Scholar] [CrossRef]

- Xing, Z.X.; Gu, H.L.; Wei, Z.G.; Qian, H.; Zhang, Y.; Wang, L.J. Contrastive Study of the Pedestrian Head Detection Method Based on Convolutional Neural Network. Saf. Environ. Eng. 2019, 26, 77–82. [Google Scholar] [CrossRef]

- Guo, Y.; Su, P.F.; Wu, Y.F.; Guo, J. Object detection and location of robot based on Faster R-CNN. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2018, 46, 55–59. [Google Scholar] [CrossRef]

- Wei, R.; Love, P.; Fang, W.; Luo, H.; Xu, S. Recognizing people’s identity in construction sites with computer vision: A spatial and temporal attention pooling network. Adv. Eng. Inform. 2019, 42, 21–29. [Google Scholar] [CrossRef]

- Ding, L.; Fang, W.; Luo, H.; Love, P.E.; Zhong, B.; Ouyang, X. A deep hybrid learning model to detect unsafe behavior: Integrating convolution neural networks and long short-term memory. Autom. Constr. 2018, 86, 118–124. [Google Scholar] [CrossRef]

- Wang, W.; Liu, S.K.; Zhang, Y.G.; Zhao, C.N.; He, H.G. Research on early warning of intrusion into hazardous construction area based on bim and machine vision technology. Saf. Environ. Eng. 2020, 27, 196–203. [Google Scholar] [CrossRef]

- Awolusi, I.; Marks, E.D. Active Work Zone Safety: Preventing accidents using intrusion sensing technologies. Front. Built Environ. 2019, 5, 21. [Google Scholar] [CrossRef]

- Teizer, J.; Allread, B.S.; Fullerton, C.E.; Hinze, J. Autonomous pro-active real-time construction worker and equipment operator proximity safety alert system. Autom. Constr. 2010, 19, 630–640. [Google Scholar] [CrossRef]

- Forsythe, P. Proactive construction safety systems and the human factor. Proc. Inst. Civ. Eng. Geotech. Eng. Manag. Procure. Law 2014, 167, 242–252. [Google Scholar] [CrossRef]

- Arslan, M.; Cruz, C.; Ginhac, D. Visualizing intrusions in dynamic building environments for worker safety. Saf. Sci. 2019, 120, 428–446. [Google Scholar] [CrossRef]

- Huang, Y.; Hammad, A.; Zhu, Z. Providing proximity alerts to workers on construction sites using Bluetooth low energy RTLS. Autom. Constr. 2021, 132, 103928. [Google Scholar] [CrossRef]

- Sakhakarmi, S.; Park, J. Improved intrusion accident management using haptic signals in roadway work zone. J. Saf. Res. 2022, 80, 320–329. [Google Scholar] [CrossRef] [PubMed]

- Hubel, D.H.; Wiesel, T.N. Receptive fields, binocular interaction and functional architecture in the cat’s visual cortex. J. Physiol. 1962, 160, 106–154. [Google Scholar] [CrossRef]

- Li, H.M.; Duan, P.S.; Meng, H.; Guo, H.D. Study on safety early-warning assessment of damaged steel structure reconstruction based on ipso-bp. J. Saf. Sc. Technol. 2019, 15, 174–180. [Google Scholar] [CrossRef]

- Xiao, H.H.; Shi, J.L. Video captioning based on C3D and visual elements. J. South Chin. Univ. Technol. (Nat. Sci. Ed.) 2018, 46, 88–95. [Google Scholar] [CrossRef]

- Yang, L.Q.; Cai, L.Q.; Gu, S. Detection on wearing behavior of safety helmet based on machine learning method. J. Saf. Sci. Technol. 2019, 15, 152–157. [Google Scholar] [CrossRef]

- Albawi, S.; Mohammed, T.A.; Al-Zawi, S. Understanding of a convolutional neural network. In Proceedings of the 2017 International Conference on Engineering and Technology (ICET), Antalya, Turkey, 21–23 August 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Chauhan, R.; Ghanshala, K.K.; Joshi, R.C. Convolutional neural network (CNN) for image detection and recognition. In Proceedings of the 2018 First International Conference on Secure Cyber Computing and Communication (ICSCCC), Jalandhar, India, 15–17 December 2018; pp. 278–282. [Google Scholar] [CrossRef]

- Agarap, A.F. An architecture combining convolutional neural network (CNN) and support vector machine (SVM) for image classification. arXiv 2017, arXiv:1712.03541. [Google Scholar] [CrossRef]

- Jahanshahi, M.R.; Masri, S.F.; Padgett, C.W.; Sukhatme, G.S. An innovative methodology for detection and quantification of cracks through incorporation of depth perception. Mach. Vis. Appl. 2013, 24, 227–241. [Google Scholar] [CrossRef]

- Zhu, Z.; Park, M.W.; Koch, C.; Soltani, M.; Hammad, A.; Davari, K. Predicting movements of onsite workers and mobile equipment for enhancing construction site safety. Autom. Constr. 2016, 68, 95–101. [Google Scholar] [CrossRef]

- Kolar, Z.; Chen, H.; Luo, X. Transfer learning and deep convolutional neural networks for safety guardrail detection in 2D images. Autom. Constr. 2018, 89, 58–70. [Google Scholar] [CrossRef]

- Lin, P.; Wei, P.C.; Fan, Q.X.; Chen, W.Q. CNN model for mining safety hazard data from a construction site. J. Tsinghua Univ. (Sci. Technol.) 2019, 59, 628–634. [Google Scholar] [CrossRef]

- Xiong, W.; Xu, X.; Chen, L.; Yang, J. Sound-based construction activity monitoring with deep learning. Buildings 2022, 12, 1947. [Google Scholar] [CrossRef]

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich feature hierarchies for accurate object detection and semantic segmentation. In Proceedings of the 2014 IEEE Conference on Computer Vision and Pattern Recognition, Columbus, OH, USA, 23–28 June 2014; pp. 580–587. [Google Scholar] [CrossRef]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards real-time object detection with region proposal networks. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1137–1149. [Google Scholar] [CrossRef]

- Nath, N.D.; Behzadan, A.H.; Paal, S.G. Deep learning for site safety: Real-time detection of personal protective-equipment. Autom. Constr. 2020, 112, 103085. [Google Scholar] [CrossRef]

- Shahverdy, M.; Fathy, M.; Berangi, R. Driver behavior detection and classification using deep convolutional neural networks. Expert Syst. Appl. 2020, 149, 122290. [Google Scholar] [CrossRef]

- Lung, L.W.; Wang, Y.R. Applying deep learning and single shot detection in construction site image recognition. Buildings 2023, 13, 1074. [Google Scholar] [CrossRef]

- Lai, X.Y.; Zhang, M.G.; Xu, S. Influence of safety attitude and its components on construction workers’ safety behaiour. J. Civ. Eng. Manag. 2019, 36, 74–80. [Google Scholar] [CrossRef]

- Liu, W.P. The Schematic Studies of Construction Accident Warning System Based on BIM and Positioning Technology. Master’s Thesis, Tsinghua University, Beijing, China, 2015. [Google Scholar]

- Zhao, J.; Zhao, J.Y.; Zhang, S.K. Research on construction site personnel management system based on BIM-RFID. Value Eng. 2019, 38, 12–14. [Google Scholar] [CrossRef]

- Paris, S.; Hasinoff, S.W.; Kautz, J. Local laplacian filters: Edge-aware image processing with a laplacian pyramid. ACM Trans. Graph. 2011, 30, 68. [Google Scholar] [CrossRef]

| Confusion Matrix | Predicted Value | Precision | Recall | F1 Score | ||

|---|---|---|---|---|---|---|

| Positive | Negative | |||||

| True value | Positive | 2809 | 423 | 0.8691 | 0.9314 | 0.8992 |

| Negative | 207 | 1411 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Xu, Y.; Zhu, W.; Liu, M.; Zhao, J. Real-Time Early Safety Warning for Personnel Intrusion Behavior on Construction Sites Using a CNN Model. Buildings 2023, 13, 2206. https://doi.org/10.3390/buildings13092206

Zhao J, Xu Y, Zhu W, Liu M, Zhao J. Real-Time Early Safety Warning for Personnel Intrusion Behavior on Construction Sites Using a CNN Model. Buildings. 2023; 13(9):2206. https://doi.org/10.3390/buildings13092206

Chicago/Turabian StyleZhao, Jinyu, Yinghui Xu, Weina Zhu, Mei Liu, and Jing Zhao. 2023. "Real-Time Early Safety Warning for Personnel Intrusion Behavior on Construction Sites Using a CNN Model" Buildings 13, no. 9: 2206. https://doi.org/10.3390/buildings13092206

APA StyleZhao, J., Xu, Y., Zhu, W., Liu, M., & Zhao, J. (2023). Real-Time Early Safety Warning for Personnel Intrusion Behavior on Construction Sites Using a CNN Model. Buildings, 13(9), 2206. https://doi.org/10.3390/buildings13092206