1. Introduction

The European Council recently set a package of proposals aimed at revising and updating the European Union (EU)’s energy legislation. It is called “Fit for 55” and has the goal to reduce greenhouse gas emissions by 55% by 2030 and reach carbon neutrality by 2050 [

1]. The ongoing energy crisis will worsen, given the current increases in energy demand, if drastic measures are not implemented to improve existing production and consumption practices. In 2021, the operation of buildings accounted for 30% of the world’s global final energy consumption and 27% of total energy sector emissions (8% being direct emissions in buildings and 19% indirect emissions from the production of electricity and heat used in buildings). Both energy consumption and emissions rebounded to above 2019 values, following the drop in 2020 due to COVID-19 restrictions [

2]. In the EU, the building sector is the largest energy consumer, accounting for 40% of the entire EU’s primary energy demand, and is responsible for about 36% of CO

2 emissions [

3].

Since energy is a precious resource with a cost that is recently overgrowing, its excessive and unnecessary use could have dangerous economic and environmental impacts on our society. For this reason, today, thermal comfort conditions and their monitoring represent a central issue that could optimize building energy usage while achieving good building performances in terms of desired indoor environmental conditions.

Although the reduction in building stock emissions and the optimization of building energy performance are great challenges, they cannot be considered independently by the improvement of users’ well-being and health [

4]. The quality of the indoor environment has a relevant influence on people’s physical and mental well-being and health. Therefore, considering that most people spend more than 85% of their time indoors [

5], it is essential to control indoor air quality and thermal comfort for the occupants [

6]. This is strategic when we consider sustainability in a bigger picture with its three pillars: environmental, economic, and social. The literature reports that we have increasingly become an “indoor species” [

4] for whom the built indoor environment represents important issues (commonly known as “sick building syndrome”—SBS or “building-related illnesses”—BRI) [

7,

8].

Moreover, human professional and cognitive performances are closely bound to the built indoor environment. Indoor environmental quality plays a key role in determining occupants’ productivity at work. Many studies have tried to evaluate the effect of indoor environmental conditions by assessing user performance in terms of productivity, mostly focusing on the thermal aspect and indoor air quality [

9,

10]. In [

11], the linkage between the impacts of five IEQ aspects (the quality of indoor temperature, air, natural and electric lighting, and acoustics) and productivity is studied.

Monitoring indoor environmental conditions and assessing building thermal comfort are strategic issues of facility management. This document introduces a workflow that can support the facility manager’s decision making in this field. Starting from the standard measurement system, the developed BIM-centered workflow allows effective data analysis and the following association of comfort levels to each monitored space. Unlike the literature references reported in

Section 2 of this document, this work does not limit the analysis of comfort to Predicted Mean Vote, but also implements local comfort indexes, as prescribed by [

12]. A more complete evaluation based on the environment category is adopted. The proposed methodology, defined in

Section 3 of this document, represents an important contribution to the research because it is able to work with every microclimatic sensor, such as globe thermometers, specifically required by [

12], and is not limited to small smart sensors. Furthermore, the results of comfort evaluation do not need any external platform to be visualized but are provided by easily readable open reports. As shown in

Section 4 of this document, the proposed system is tested in a pilot study hosting the administrative offices of the municipality of Cagliari. As presented in

Section 5 and

Section 6 of this document, the proposed system shows promising results, especially if integrated with building energy consumption data.

2. Background

Thermal comfort in buildings is a function of physical, environmental, and social factors; therefore, its study is multifaceted. The term “thermal comfort” refers to a state of mind in which one is content with one’s thermal surroundings [

13]. Several models have been developed to study thermal comfort.

One of the most widely used methods focuses on the Predicted Mean Vote (PMV) index, based on Fanger’s theoretical basis [

14,

15]. This method is adopted when the building has an active air conditioning or cooling system (mechanical, thermoelectric, etc.) [

8].

The main challenge is achieving thermal comfort for building occupants while reducing energy consumption. Many studies have concluded that using the PMV index in controlling heating, ventilation, and air conditioning (HVAC) systems is efficient for energy saving [

16]; it has been proven that a PMV-based heating system can save up to 33.5% of energy per year [

17].

Exploring the operation of HVAC systems to supply a more satisfactory indoor environment is crucial for human satisfaction and social development [

18]. An analysis of occupant comfort requires specific information and appropriate visualization techniques to identify unsatisfactory problems.

Building Information Modeling (BIM) is one of the emerging technologies in the construction industry. In the past decade, it has been widely used for more efficient facility management (FM) activities [

19,

20,

21,

22]. BIM has been defined as “The digital representation of physical and functional characteristics of a facility. As such, it serves as a shared knowledge resource for information about a facility, forming a reliable basis for decisions during its life cycle from inception onwards” [

23]. BIM deals with different types of building information [

24]: geometric, topological, and semantic information. The integration of FM data and information in BIM allows rapid visualization, queries, and contextualization in the 2D and 3D space [

25], enabling a more efficient decision-making process. Alavi et al. in [

26] present the potential benefits of BIM implementation for maintenance activities to identify and solve the root cause of HVAC problems. A user-centric BIM based-framework was developed to optimize positive interactions between occupants and buildings.

Further applications of BIM for FM include integration with other technologies. In [

27], the integration of BIM and sensor technologies to develop a smart lighting maintenance system for university facilities, which is scalable to other building systems, is investigated. Lately, the challenge of bringing building monitoring into BIM has been discussed and designed by many researchers [

28].

The integration of BIM and monitoring systems exploits the geometric and parametric properties of BIM models and the streaming of environmental data (e.g., temperature, humidity, etc.) collected by sensors for the visualization of monitoring data in real time [

29].

Integrating monitoring systems into BIM models can change how we interact with the building environment, making instant data available to users and providing better monitoring, analysis, and management of the building. However, research on integrating these two technologies still needs to be improved and has focused exclusively on the automatic transmission of sensor data to BIM models [

30].

BIM data can be accessed through various mechanisms, including manual interfaces of proprietary systems, programming APIs associated with these applications, potential database connections to the systems, and export via open standards. There has yet to be a single standard. However, several open standards are appearing in both BIM and monitoring systems [

31]. The research on the integration of BIM and sensors is still in the embryonic stages, as most studies only introduce conceptual theoretical proposals [

32]. The processing of data from sensors is usually performed manually using a spreadsheet. This work requires a significant amount of time and can be challenging to execute precisely. The utilization of visual programming platforms, such as Dynamo BIM, enhances the data’s practicality and minimizes the chance of inadvertent mistakes resulting from human manipulation. The utilization of Dynamo in data management for BIM monitoring has proven beneficial, as it can facilitate an automated process, construct a customized data workflow, and expedite the overall timeline [

33].

Currently, the construction industry is showing momentum to transition from a static and closed information environment to a dynamic environment that involves sensor integration and a higher degree of AI implementation [

34].

Lately, the concept of Digital Twin (DT) has been studied. Its definitions are available in various sectors, but the most diffuse concept presents DT as a virtual replica of physical entities to manage, optimize, and control the physical asset supporting the facility manager’s activities. The construction industry is still in its beginning regarding the definition of DT for buildings. A shared definition of DT in the construction sector was provided by [

35], which describes it as “an approach for connecting a physical system to its virtual representation via bidirectional communication using temporally updated Big Data to allow for exploitation of Artificial Intelligence and Big Data Analytics by harnessing this data to unlock value through optimization and prediction of future state”. The main difference between BIM models and DT is the bidirectional communication between the virtual and the physical object since the DT is a dynamic and proactive model either with or without human intervention in the process.

In such a dimension, DT can be seen as an evolution of the integration between BIM and facility management, since DT enables building monitoring and analysis by adding dynamic analysis and simulation capabilities, and the bidirectional communication between the building and the virtual counterpart. Starting from the above definition of DT, it is supported by an acquisition layer, a sensor system that allows continuous physical asset monitoring. Arowoiya et al. [

36] show a growing number of application areas of DT in the O&M phase of the building with a focus on thermal comfort monitoring, energy management, prediction, and optimization for existing buildings. Many efforts have been made using DT in visualization and tracking to understand the comfort of people in indoor environments [

37] and building energy efficiency [

38].

The assessment of thermal comfort is a fundamental part of facility management. Many studies on the application of Building Information Modeling to support its evaluation can be found in the literature. In [

39], a prototype sensor visualization platform is designed to connect in-use performance data to BIM context data to provide actionable advice for landlords and tenants for minimizing repair and maintenance activities. Data are collected by smart sensors for environmental parameters and energy consumption. The informative model is the base to export information regarding the building to a web visualization platform. In [

40], smart sensors are used to monitor indoor environmental quality, of which thermal comfort is an important part. Experimental sensors to evaluate mean radiant temperature are proposed. BIM is again the source of building data. In [

41], a sensor-based alert system is integrated into BIM models for thermal comfort monitoring in buildings during the operational phase and visualizing a building’s thermal condition virtually. In this case, the BIM hosts the virtual objects of the sensors and is also used to provide alerts if comfort thresholds are exceeded. Data are collected by smart temperature and relative humidity wireless sensors. BIM can also be useful to realize 3D maps of comfort values, such as Predicted Mean Vote [

16]. In some other cases, BIM can help to better assess environmental quantities, such as mean radiant, starting from envelope and features, room dimensions, and occupant position [

42]. Finally, BIM can support minimizing the uncertainty of statistical indexes (such as PMV) by comparison with occupant thermal preferences and the implementation of machine learning algorithms [

43].

3. Materials and Methods

This research focuses on the definition of a comprehensive methodology, integrating different methods and tools to perform efficient building monitoring, and data management, and to support the optimization of indoor thermal comfort conditions. This research aims to define a BIM-centered system, enabling data visualization and analytics and integrating building data and indoor comfort monitoring from the sensor network.

As shown in

Figure 1, the proposed methodology is divided into six main tasks: building analysis; BIM updating; thermal comfort assessment; sensor placement; BIM–sensor data integration; report organization.

3.1. Building Analysis

Building analysis starts from building inspection, document mapping, and “as built” BIM study. The current state of the building and its critical issues in terms of indoor comfort can be reviewed through an interview with the facility manager. Evaluating the actual use of the building and its levels of occupancy will be a necessary step.

This task is strategic also to select the monitoring sensor’s location to be sure to check the most critical spaces, those in which the users are present for extended periods and which, therefore, must be kept under close observation. Obtaining and mapping the information associated with the management of the systems for indoor thermal comfort conditions (cooling and heating systems) will be necessary.

The monitoring spaces which are the most representative of the entire building must be selected, based on criteria such as the following:

Different exposure, to evaluate the effects due to the sun and prevailing winds;

Location on several floors, to evaluate the effects deriving from the upper (e.g., roof) and lower floors;

Dimensions of glass surfaces.

3.2. BIM Updating

In this task, the as-built BIM provided by the facility manager has been updated and integrated with the information collected in the previous task: the actual type of activity carried out, areas, and occupancy levels of users. It will also be essential to integrate BIM with all the necessary documents for the subsequent task of choosing and placing the sensor network. The creation of a virtual model for the sensors located inside the building was not considered necessary. It was considered much faster as well as more sustainable to associate the monitoring data with the “room” object of BIM. It is nothing more than a “smart object” to which a variety of data and information, including data from sensors, can be linked. The “room” object is a space delimited by the virtual objects of BIM such as walls, floors, and ceilings. With this type of “object”, various data and information such as constraints, dimensions (area, volume, and perimeter), number, name, destination, occupancy level, etc., will be associated. The “virtual” room must be named with the same code as the “real” room. Finally, it will be associated with the “room” object the parameters needed to collect comfort data from the sensor network used to monitor indoor comfort conditions. They must be able to create a “bridge” between the monitoring system and BIM.

3.3. Thermal Comfort Model

Thermal comfort is the psychophysical state in which the subject expresses satisfaction with the thermal environment under examination. The technical reference standard for evaluating moderate environments is UNI EN ISO 7730:2006: Ergonomics of thermal environments—Analytical determination and interpretation of thermal comfort by calculation [

13].

The model aims to estimate the average thermal sensation of the population in each indoor space by relating four environmental parameters (air temperature, average radiant temperature, relative humidity, and relative wind speed) and two individual parameters (clothing insulation and metabolic heat capacity).

After collecting all the necessary data, the results of the thermal comfort test are obtained by applying mathematical equations.

To assess the thermal comfort of a building objectively, continuous measurements are required to obtain profiles of air temperature and main radiance temperature (°C), relative humidity (RH in %), and air velocity (m/s) using metering devices in the selected zones at planned-minute intervals for the suitable period.

Regular calibration of sensors is needed to ensure an adequate degree of accuracy of the measurements.

The air temperature sensors are located at 1.1 m and 0.1 m above ground level, and the remaining instruments are located at 1.1 m. Such positions help to obtain as much information as possible on the conditions that office workers are typically subjected to, in terms of global and local thermal comfort [

12].

3.3.1. Global Assessment: Determination of PMV and PPD

The most important indices, known as Fanger indices, are Predicted Mean Vote (PMV), which expresses a predicted mean vote for the feeling of thermal well-being, and Predicted Percentage of Dissatisfied (PPD), which is the predicted percentage of dissatisfied people. The formulation of the index is based on the integrated use of the heat balance equation and statistical analysis. The PMV is defined on a seven-point thermal sensation scale, from −3 to +3, where PMV = 0 corresponds to thermal neutrality. On the other hand, the PPD can range from 5% to 100%. These comfort values will vary depending on the position of the occupant in the building. For comfort ranges to comply with standards, no occupied point in space should be above 15% PPD. There is a correlation between PMV and PPD, with PPD being a function of PMV [

13].

3.3.2. Assessment of Local Discomfort

Thermal comfort is obtained when an individual is thermally neutral in the environment, which means that the skin temperature and perspiration rate are within specific limits compatible with the activity performed. Nonetheless, the individual may experience local thermal discomforts, such as a sensation of a cold or warm floor, vertical air temperature difference, radiant temperature asymmetry, or drafts. Ref. [

11] proposes indexes to describe these discomfort causes: the draught rate (DR; depending on the air temperature, its velocity, and turbulence) and the percentages of dissatisfaction (PD), which are due to the radiant asymmetry, the warm ceiling and the floor temperature. As shown in

Table 1, three categories of acceptable PD are defined according to [

13]. Indexes are estimated one by one and without any indication of the mutual interactions and the possible influence on the overall judgment. The draught phenomenon is mainly felt by people who are sedentary, and it involves localized cooling of a part of the body. Normally, the most critical areas are the ankles (0.1 m from the floor) and the neck (1.1 m for seated people and 1.7 m for standing people, from the floor). The acceptable value of the vertical gradient of the air temperature must lead to a maximum difference of 3 °C between the level of the ankles (0.1 m from the floor) and that of the neck (1.1 m from the floor for a seated person), with a gradient of 1.9 °C/m. Asymmetry in plane radiant temperature measures the difference in the perceived radiation and is defined as the difference between the plane radiant temperature of the two opposite sides of a small horizontal or vertical plane element. To avoid a feeling of discomfort, the floor temperature must be within the range of 18–29 °C. To safeguard conditions of acceptable comfort, the PPD, referring to people who complain of this phenomenon, must be a maximum of 15% according to [

11].

3.4. Sensors Placement

To obtain the values of the four physical quantities required for the estimation of comfort and discomfort indexes, calibrated instruments compliant with the requirements of UNI EN ISO 7726:2002 Standard [

12] must be used. The reference standard reports characteristics required in terms of accuracy and calibration according to the purpose of the monitoring (thermal comfort, thermal stress).

Within the office room, the positioning of devices is performed based on the office layout, taking care to avoid direct exposure to sunlight and proximity to heat or cold sources.

The facility manager’s feedback on spaces with critical comfort conditions is valuable input to define the best placement of the selected sensors. As an additional source of building information, BIM can provide significant support for efficient planning and installation of sensors, selecting critical areas to be monitored, and optimizing spatial distribution.

3.5. BIM–Sensor Data Integration

Once the informative model is updated and the sensor network set, an algorithm is structured to process the monitoring data from sensors.

This algorithm can support data exchange between BIM and the selected sensor network. For this aim, Dynamo Visual Programming is used to extend the power of the Revit Autodesk platform by providing access to the Revit API (Application Programming Interface) more effectively and efficiently. Dynamo is an excellent tool. Its limits are the boundaries beyond which the Python sphere is necessary. Python is an easy-to-learn, powerful programming language. It has efficient high-level data structures and a simple but effective approach to object-oriented programming [

44]. Excessive use of Dynamo nodes often results in a severe slowdown of data processing, but with Python code, these issues are significantly reduced. One of its greatest strengths is its extensive standard library that provides tools suitable for many tasks, including modules for creating graphical user interfaces or connecting to relational databases. The latest innovation is the possibility of installing Python packages within Dynamo. The Pandas package to standardize the process [

45] is strategic.

While all the algorithms found in the literature can process only global comfort indices, the algorithm developed in our work can also process local discomfort indices [

41,

46]. Furthermore, it can collect information on the type of building to be monitored, homogenizes the data from the different sensing instruments, and exports them in a format that allows the results to be easily read. It must receive parameters from the model and sensors with unique names. The algorithm can be run either from Dynamo Sunbox or from the interface defined as “Dynamo Player” in Revit. The operator can start the script and import the data for analysis in the information model.

The Dynamo script processing provides two results. The first result is a summary, i.e., the room’s color scheme. The function of the color scheme is to identify rooms with criticalities using a visual approach. However, in the case of criticality, more detail is needed to identify the problem. For this reason, the second result is a more in-depth analysis.

3.6. Report Organization

One of the most critical issues for facility managers is that they must make decisions from the processed monitoring data, which are not always visually accessible and transparent [

25,

47]. A report could accurately visualize, analyze, and share data through descriptive analytics to effectively support facility managers in defining strategies to optimize indoor comfort conditions.

To accomplish this goal, in this task, a report that can support the visualization of collected data in the building must be created. It must include graphs, statistical analysis, and time series.

Dynamo’s processed images are kept in a designated folder on the web page, formatted in HTML. Within the HTML code, the “relative URL” of each image to be incorporated can be specified. After importing the images, it is necessary to print the page in PDF format.

The BIM information model in the first section of the report highlights rooms with critical issues, and below, the graphs for the comfort summary of specific rooms are reported.

The subsequent section of the report showcases the monitoring data collected in a graphical format. It provides a visual representation of the raw data obtained during the monitoring activity. This section is divided into two parts, with the second part offering more comprehensive details than the first. In the first section of the report, there are summary graphs representing the overall comfort data. These graphs provide an overview of the comfort levels in the building without specific details.

In the second part of the document, on the other hand, there are more in-depth graphs that present both global and local comfort.

4. Case Study Implementation

The case study on which the experimentation phase was carried out is an office building of Cagliari Municipality. Recently, the municipality and an Energy Service Company (ESCO) signed an Energy Performance Contract (EPC) to improve the energy efficiency of the administrative office building. The interventions carried out have been the installation of automated sunshades with remote control, the replacement of all the external windows and doors, and putting in a remote-control system for the heating and air conditioning system. Despite these interventions, some users complained of discomfort in the building’s interior rooms. Monitoring was carried out in some offices to understand the causes of the discomfort.

4.1. Building Analysis

The first phase was collecting information about the building. The energy manager provided all the documentation on the building components, focusing on the HVAC systems. He provided insight into spatial data, such as occupancy density and user feedback. The in-depth control of the documentation and the “as-built” model made clear the first criticality: the information model still needed to be updated with the latest ESCO works.

4.2. BIM Updating

The as-built model was updated with all the efficiency improvements brought by the ESCO. All the new installation documents were linked to the components of the updated model. The essential parameters for the monitoring phase were integrated into the informative model. For example, the comfort category parameter has been introduced for each room to define the predicted percentage of dissatisfied occupants for global or local comfort parameters. The model includes everything about spaces, the number of people in each room, and how each room is used. Specifically, the rooms have been updated with a unique code. The “virtual” room has been named with the same code as the “real” room. Within BIM, one preset table for each level of the building was created and stored in the “sheets” section. Starting from these tables, in the following steps, Dynamo can produce and insert into the report images with a color scheme that represents thermal comfort in the building.

4.3. Sensor Placement

To understand the causes of the indoor thermal discomfort of the occupants, an accurate monitoring activity is required. The microclimatic control units allow a much more precise and faster monitoring task of indoor environmental comfort than small building automation systems.

The monitored rooms were selected to represent the whole building. The spaces were chosen with different exposures and dimensions of the glass surfaces.

The control unit was situated close to the workstations in an office. The height of monitoring temperature probes was leveled at two heights (0.1 m and 1.1 m from floor), as mentioned in

Section 3.4, while the remaining probes were leveled at 1.0 m during the entire experiment.

Thermal environment measurements were carried out using a microclimatic station, produced by Tecno El, with the GRILLO data logger. The unit complied with UNI EN ISO 7726 [

12] and included the following probes: a 150 mm diameter globe thermometer (0.01 °C resolution and ±0.01 °C accuracy), an omnidirectional ultrasonic anemometer (velocity measurement range: 0–30 m/s, resolution: 1 cm/s, accuracy: +/− 2% of the measurement range, direction measurement range: 0–359°, resolution: 1°, accuracy: +/− 3%), and a dry-bulb temperature, relative humidity sensor, and radiant asymmetry probe (5% accuracy). The dataloggers Tinytag used to measure air temperature at 0.1 m level have the following features:

Integrated temperature and humidity sensors (−25 to +85 °C or 0 to 95% RH) for low-humidity indoor (IP53) environments;

Internally mounted temperature sensor of the 10K NTC Thermistor type with a reading resolution of 0.01 °C or better;

Externally mounted capacitive humidity sensor with an accuracy of ±3.0% RH at 25 °C and reading resolution of 0.3% RH or better.

The microclimate station and the data logger shown in

Figure 2 acquire the measurements every 10 min. They transmit the data to the platform every 30 min. These settings were made during the installation of the control units inside the building.

The Grillo Multi Microclimate Test System (GRILLO MMTS) data acquisition system uses Wi-Fi, GPS, or GPRS technology to transmit data to the OLINDA WEB platform, a Web Application developed by the company Tecno El. It allows the user to visualize remotely and in real time the measured quantities but is not able to elaborate comfort parameters. This system can accept the electrical signal of the most-used transducers as input; this feature, combined with the autonomous battery, solar panel, or local power supply, makes it a unit of rapid installation and immediate use.

The data stored by Tinytag can be transferred by cable to a central unit (a personal computer) through the software provided with the instrument. The software manages the start and stop of the instrument, deals with alarm thresholds, and displays and processes data, as shown in

Figure 3.

The OLINDA platform allows access to monitor system data via any browser and download the data in *CSV format. CSV data, on the other hand, are not structured using standard protocols. This is one of the crucial, critical issues that underpin our work: a unique code for imported data is necessary, as better described in the following section.

4.4. BIM–Sensor Data Integration

The operation of recording, uploading, and processing microclimatic parameters requires considerable computation time. The workflow in

Figure 4, developed in Dynamo, enables more efficient and faster data management from microclimatic stations. An operator can start the script through Dynamo Sunbox or the interface defined as “Dynamo Player” in Revit.

The proposed procedure creates the dynamic process of integrating data from the BIM and monitoring systems. The input data (room use, comfort category) for the algorithm are read from the BIM of the building, through nodes called “Input Parameter”. With the “Expected Category” group of nodes, the algorithm can identify the expected category for each room, again according to [

13], as shown in

Figure 5.

The script uploads data from the monitoring systems. These are in a CSV format and not codified. The script converts the original code of CSV fields to a unique label for both OLINDA and Tinytag files.

These are uploaded through a simplified interface of the Dynamo script (Dynamo Player), as indicated in

Figure 6.

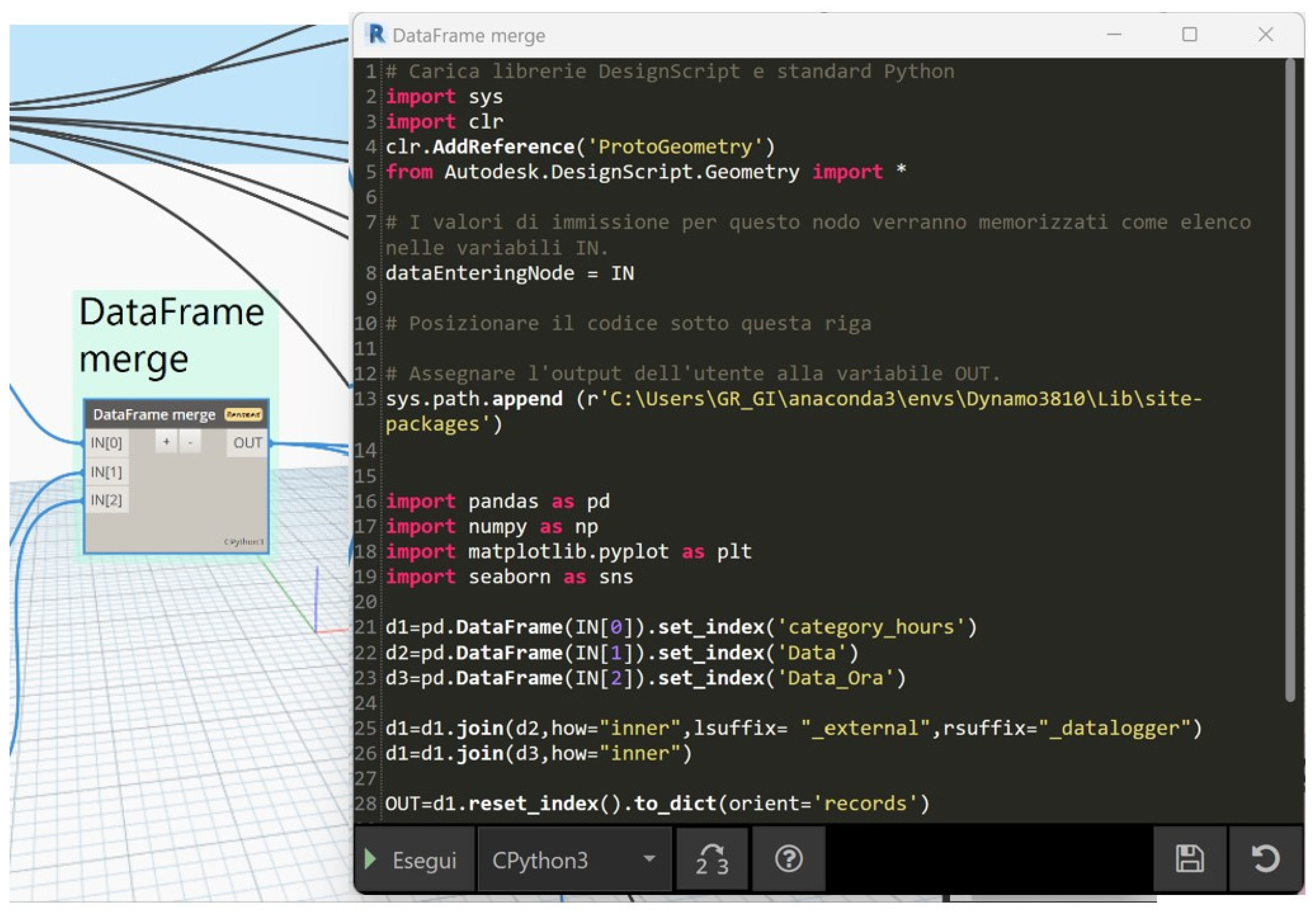

As microclimatic stations must be moved to detect conditions in different parts of the building, the start and end of monitoring must be written down manually. Often, the transcription is carried out on a paper document. A new node is introduced to overcome this criticality. The new node can automatically find the shared time value between the three data frames imported from the dataloggers and the microclimatic controllers. The node named “Data Frame merge” automatically detects the start and end of monitoring. As indicated in

Figure 7, the integration of Python into Dynamo makes this task possible. Python allows the exploitation of rich open-source libraries through integration with Anaconda (Python’s distribution platform), which were also used to calculate PMV and local comfort indexes and to create the graphs presented in the report.

The following libraries were implemented:

Matplotlib, a comprehensive library for static, animated, and interactive visualizations [

48];

Seaborn, to facilitate Python data visualization based on matplotlib [

49];

NumPy, for being able to work with arrays and matrices [

50];

Pandas, a fast, powerful, flexible, and easy-to-use open-source data analysis and manipulation tool [

51]. It standardizes and automates data processing and allows a clear reading of data from any microclimate controller or sensor.

As shown in

Figure 8, the last part of the script allows the calculation and processing of global and local comfort data, again according to [

13], and checks the expected category. Within these nodes, the comfort equations are transcribed into Python code.

In the case of running the script through Dynamo Player in Revit, the last block of Python code assigns the results to the corresponding rooms, as indicated in

Figure 9, then produces a color scheme using the preset sheets, described in

Section 4.2, and exports the latter and every graph on comfort conditions to be used in the report described below. In the case of running the script through Dynamo SandBox, the node simply produces the graphs that are exported to the report.

The purpose of the color scheme is to find rooms with critical problems using a visual approach. However, to visualize the detected issue more in depth, it is necessary to visualize the report. For each room, a dedicated report is created by the script. For Revit users, it is accessible by the link highlighted in the model. As indicated in

Figure 10, it is a parameter specifically associated with each room instance. For SandBox users, the report is saved in a dedicated folder.

4.5. Report Organization

The last step of the methodology includes report planning and its configuration setting up. The report, which represents the significant process output, visualizes data processing from the sensors and the information model.

One of the most critical aspects of building monitoring is the visualization, analysis, and sharing of collected data, information, and knowledge derived from data analysis. The report allows us to accurately visualize, analyze, and share data through descriptive analytics to effectively represent a starting point and support for defining strategies to optimize building management. The advantage of using this representation is understanding, as it allows the user to focus on issues and opportunities. The objective is to provide informative insights, enabling the user to keep track of the building and make informed decisions. The proposed report, shown in

Figure 11, is organized into macro-sections.

Section 1 of

Figure 11 provides information on the instrumentation used and on the start and end date and time of the monitoring. Furthermore, values for clothing insulation, metabolic rate, and information on the expected category are reported, as indicated in blue box 1 of

Figure 11.

The information model occupies an essential part of the report, as indicated in red in Section 2 of

Figure 11. It indicates the immediate location of the room under study.

In Section 3 of

Figure 11, the visualization of the PMV index is provided via pie charts. They include a summary of the 24-hour or 8–18-hour percentage of time in which PMV is higher or lower than the limit of the fixed category. In this section, there are also two pie charts representing the percentage of time in which the environmental parameters provide a room category that is better than, equal to, or worse than the fixed one, as shown in yellow box 3 of

Figure 11. Section 4 of

Figure 11 shows raw data on outdoor, indoor, and radiant temperature, followed by indoor humidity and air speed, as indicated in the green box of

Figure 11. Finally, the last section of

Figure 11 allows access to global and local comfort indexes, as shown in orange box 5.

5. Results and Discussion

The following paragraph focuses on analyzing and discussing the thermal conditions measured within the building using the monitoring system. As the building falls into category B, and considering the sampling period, the system automatically defines the Met and Clo values. The first, which is evaluated for sedentary activity, is set at 1. The latter, which is determined based on the winter sampling period, is set at 1.2.

Room 216: A continuous comfort condition is noted for office 216. Global comfort is always within the class B range. The local indexes are also within the acceptable range, except for the draft, which exceeds the threshold at certain times. Exceeding the threshold occurs mainly in the evening/afternoon period and may be associated with open windows, unlikely due to the HVAC fan coil.

Room 253: As shown in

Figure 12, air temperatures exceed the acceptable range, which means that comfort limits are exceeded throughout the day and during working hours. Since the monitoring was carried out during the winter season, the excess temperature cannot be seen as a lack of perceived comfort because, presumably, the occupants will adopt adaptive behavior, such as light clothing. However, keeping the heating system operating may constitute an unnecessary waste of energy. The cause of overheating is to be found in the southwest exposure of a glazed surface. It will require the checking of the automatic sunscreens installed in the building. There are no instances of local discomfort.

Room 259: No global or local discomfort conditions are observed in this office.

Room 405: As shown in

Figure 13, discomfort conditions are observed at certain times, mainly outside working hours. The low temperature also results in incomplete compliance with local discomfort PD% caused by a warm or cold floor, leading to a change in classification from category B to C.

Room 409: As shown in

Figure 14, the most critical conditions are found in this room. The indexes also fall outside the acceptable range for class C. There is overheating in the afternoon and underheating is primarily concentrated in the non-working period. Overheating is probably due to the solar radiation that hits the workstation in the afternoon through the southwest-facing glazing. This exposition could have altered the measurements, not necessarily reflecting an actual discomfort condition. The operation of the solar shading must also be verified in this case. An excessive draft is also detected at one point during the measurement period.

Room 657: As shown in

Figure 15, there is substantial variability in the thermal parameters, which leads to an overshoot of the comfort indexes even compared to the class C limits. On the first three days of monitoring, temperatures in the afternoon/evening period decrease below acceptable values, resulting in a negative PMV. However, this occurs in the period after working hours. On the last day, an opposite trend is observed. The increase in temperature leads to an overshoot in the opposite direction of the class limits. Values above the local discomfort threshold for a cold floor are also noted.

Room 661: As shown in

Figure 16, most of the time, especially at night, the temperature is much lower than what is allowed for class C. As far as local discomfort is concerned, the floor temperature and the present draft values are above the threshold of class B.

According to [

13], even a single piece of data outside the limits identified for a class causes the environment to be downgraded to the class below.

However, this rule must be interpreted in various specific cases, which are different in the case of the municipality of Cagliari.

First, the measurement period is discriminating. Since it is an office, the time when values above or below the threshold occur without staff is not problematic. For this reason, the algorithm was programmed to divide the fields in the 8–18-hour time slot, which is the most important one.

Global comfort conditions prevail over discomfort conditions in the rooms monitored. Some of them have specific exceedances of the limits due to peculiar situations, such as essential openings on the southwest side. These lead to an increase in comfort indexes above the hot threshold. In rooms 253 and 409, the C or N is due to a PMV above 0.5 or 0.7. This means that given the exposure, the solar radiation increases the global temperature to 30 °C, with an air temperature (shielded sensor) around 25 °C. These values would be more acceptable in summer (with a different clothing index). A quick survey of room occupants will probably confirm that, in some cases, they solve the problem by “taking off their jackets or jumpers and staying in their shirtsleeves”. The important thing for the facility manager to check is that the heating thermostat, in these situations, intervenes and turns off the fan coil unit. The only somewhat “delicate” environments are rooms 405, 409, and 661, where the PMV is below 0.5 (class B).

It is crucial to verify the results acquired considering two fundamental variables: the set-point temperature of the system and the position of the automatic screens. In the first case, assessing whether underheating conditions, which are increasingly common at night, persist even when the system is in operation is necessary. In the second case, on the other hand, it must be verified whether the shading can mitigate overheating where necessary. If it is possible to adopt adaptive behaviors to solve the problem during winter; this will be reflected in a marked discomfort condition or a noticeable aggravation for the air conditioning system during summer.

Monitoring thermal comfort quality is critical for building supervisors and facility managers. To evaluate the effectiveness of the proposed system, it was presented to the supervisors and energy managers of the municipal building selected as a case study. The feedback confirmed that BIM integrated with sensors systems facilitates data processing and interpretation. In addition, the proposed report can be understood even by people without in-depth technical skills. Tables and graphs allow users to interpret values immediately. Furthermore, such representations can maximize user participation and consequently improve comfort conditions. It should be noted that the application is easily accessible to energy managers even without using Autodesk Revit Software. The algorithm is developed both to use the Dynamo version built into the Autodesk platform and the less-friendly Dynamo Sandbox version. Sandbox is Dynamo’s “Core” functionality, distributed in a way that does not interfere with other Dynamo installations and does not require any other applications (except for a few window components and some optional extras). The system allows records produced by any sensor to be imported. It is an essential advantage as it saves time developing customized scripts for each device. The use of Dynamo avoids the extra time and potential errors created by manual processing in a spreadsheet. The report generation process was completed in two hours compared to a spreadsheet’s manual processing, which would have taken several days.

6. Conclusions

One of the key objectives of the European 2030 climate and energy framework focuses on making the building stock efficient to reduce the environmental impact (decreasing climate change effects). However, the optimization of the energy performance of a building cannot be considered independently by the improvement of the users’ well-being and health in the indoor spaces (increasing comfort and indoor environmental quality, IEQ) if a bigger picture of overall sustainability is concerned (social, environmental, and economic levels). Therefore, the interventions on the existing building stock must focus on the integrated analysis of these highly complementary aspects, but first require an in-depth process of knowledge of the buildings. From these premises, this paper shows the primary results of ongoing research focused on the integration of Building Information Modeling tools and sensor technology through Dynamo Visual Programming to provide a common data platform for gathering, analyzing, and visualizing data about building indoor conditions that would enable facility operators to obtain important information. The literature shows that the Building Information Modeling methodology is strategic; it is increasingly driving innovation in the asset management of existing buildings. BIM can define a virtual replica of the buildings from which to acquire the first useful information set. Moreover, the additional value that can be exploited with the deployment of sensor networks in the spaces to gather information about indoor conditions could provide the creation of a Digital Twin for facility management and planning of refurbishment activities. In this scenario, the evolution of the building towards a customized service provider for users is central. The possibility to mark out a digital framework to rule the existing buildings opens new perspectives and introduces a paradigm shift from a static document-based model of asset management to a controlled and customized system with fine granularity that results in economic, environmental, and social benefits. Starting from the development of an Asset Information Model enriched by data from sensors (known as a Digital Twin), the research aims at defining a monitoring system for different aspects such as internal comfort, human well-being, and health (which affect productivity) alongside the energy behaviors and energy consumption of the existing buildings. The first step presented in this contribution focuses on a workflow that allows rapid and effective gathering and elaborating of data about thermal comfort levels. The use of a color scheme can help highlight building areas where comfort conditions are not met for an unacceptable amount of time. The reports produced could be of more help to facility managers to attain better knowledge of an existing building and its HVAC systems to assure their best operative status or plan suitable interventions to achieve it. The future developments of the research will include the integration of CO

2 sensors to provide data and information about indoor air quality. Moreover, the collection and representation of energy consumption data through dedicated sensors will complete the instrument designed to allow facility managers to balance different aspects such as human well-being and health with the energy behavior and consumption of the buildings. The workflow proposed could also be the framework for comfort evaluation with models other than the PMV one. In particular, personal comfort models require the elaboration of a large amount of data from several users and are strictly correlated with buildings spaces features [

52]. Building information models can be a valid support for their application. They can be more relevant in those cases in which personal comfort indexes are the basis for setting personal conditioning systems [

53] that require even more detailed information on buildings, including the MEP (mechanical, electrical, and plumbing) ones. Since managing diffuse real estate stock is a great challenge, scaling up through BIM/GIS integration will be a future research development.