Modeling and Calculation of Improved Centrifuged Reinforced Concrete Columns with Variotropic Structure

Abstract

:1. Introduction

- -

- for the first time we have obtained a picture of the stress–strain state of variotropic centrifuged standard reinforced concrete pillars of industrial buildings with the variatropy coefficient taken into account for the first time, that is, the differentiation of concrete properties over the layers of the structure section [68,69,70,71];

- -

- assessment of the influence of such variotropy and differentiation of properties on the bearing capacity of such columns, not only in the case of central compression, but especially in the case of eccentricity.

- -

- identifying the relationship between the degree of eccentricity and the efficiency and reliability of such a design;

- -

- comparison of approaches, both normative and the authors’, to a general assessment of the bearing capacity of such columns;

- -

- development of a research concept to continue searching for hidden reserves and determine the most effective areas for the work of an unaccounted resource variotropic centrifuged reinforced concrete racks-columns of industrial buildings.

- (1)

- perform a number of numerical experiments;

- (2)

- simulate the stress–strain state of variotropic columns under central compression and eccentricity;

- (3)

- identify the features of work depending on a number of different factors affecting this work.

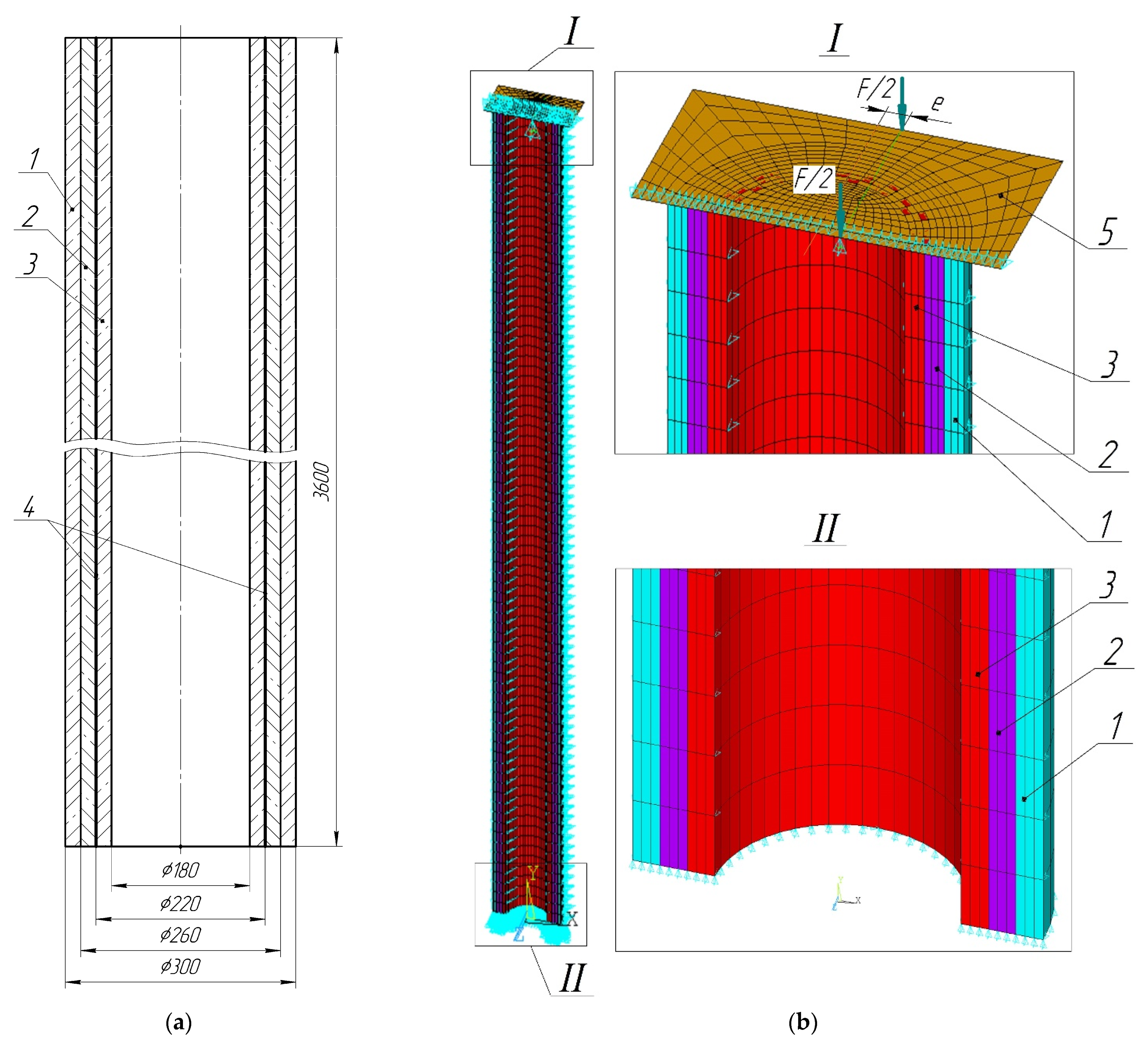

2. Materials and Methods

- -

- all nodes with coordinate z = 0 are fixed along the Oz axis;

- -

- all nodes with coordinates y = 0; x = 0 are fixed along the Ox axis;

- -

- the load is applied by a downward displacement of 2.2 mm to the node with the coordinates x = e; y = l; z = 0 (where e is the load eccentricity; l is the length of the column);

- -

- nodes with coordinates x = e; y = l; z = 0 and x = e; y = l; z = b/2 are connected in the Oy direction (where b is the top width of the plate).

- -

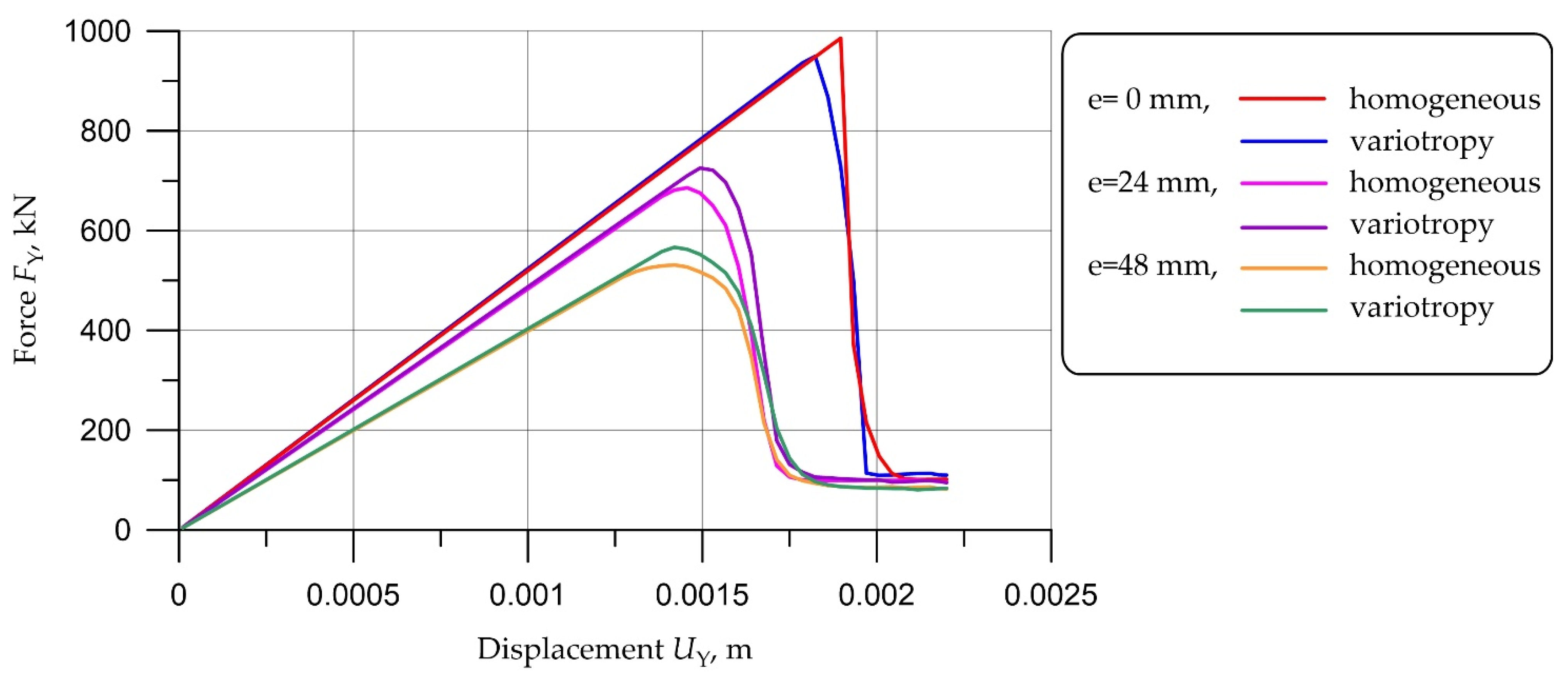

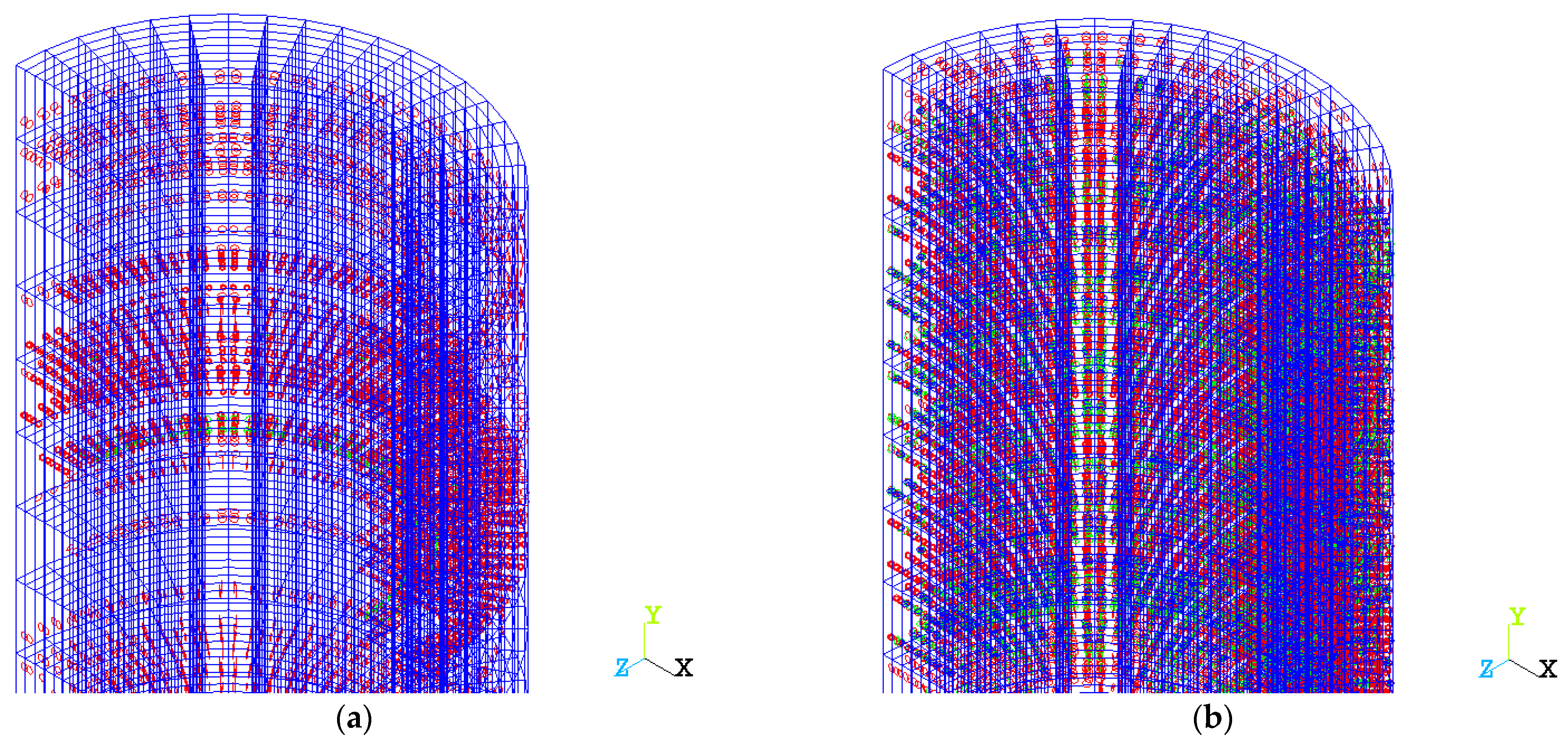

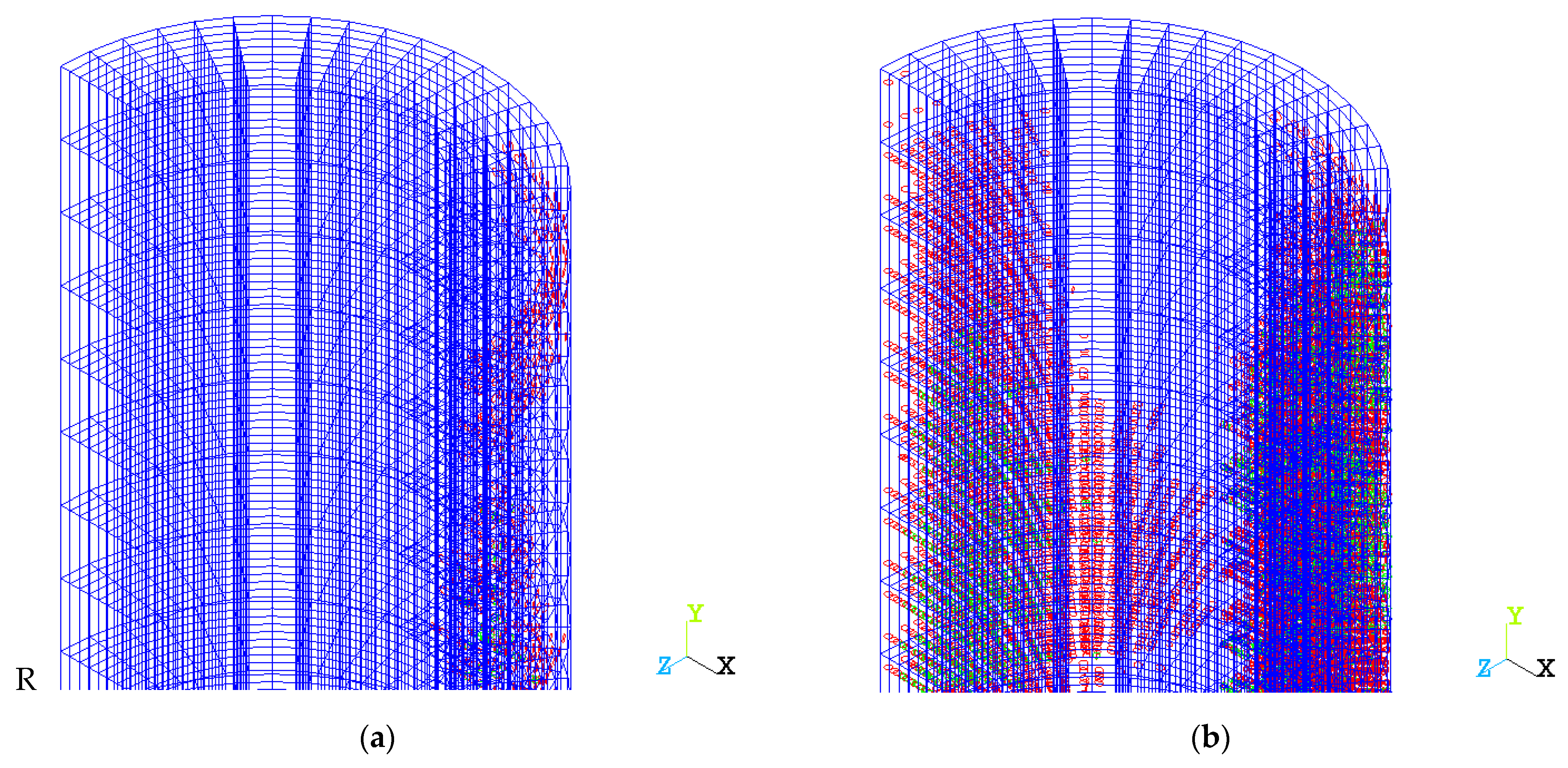

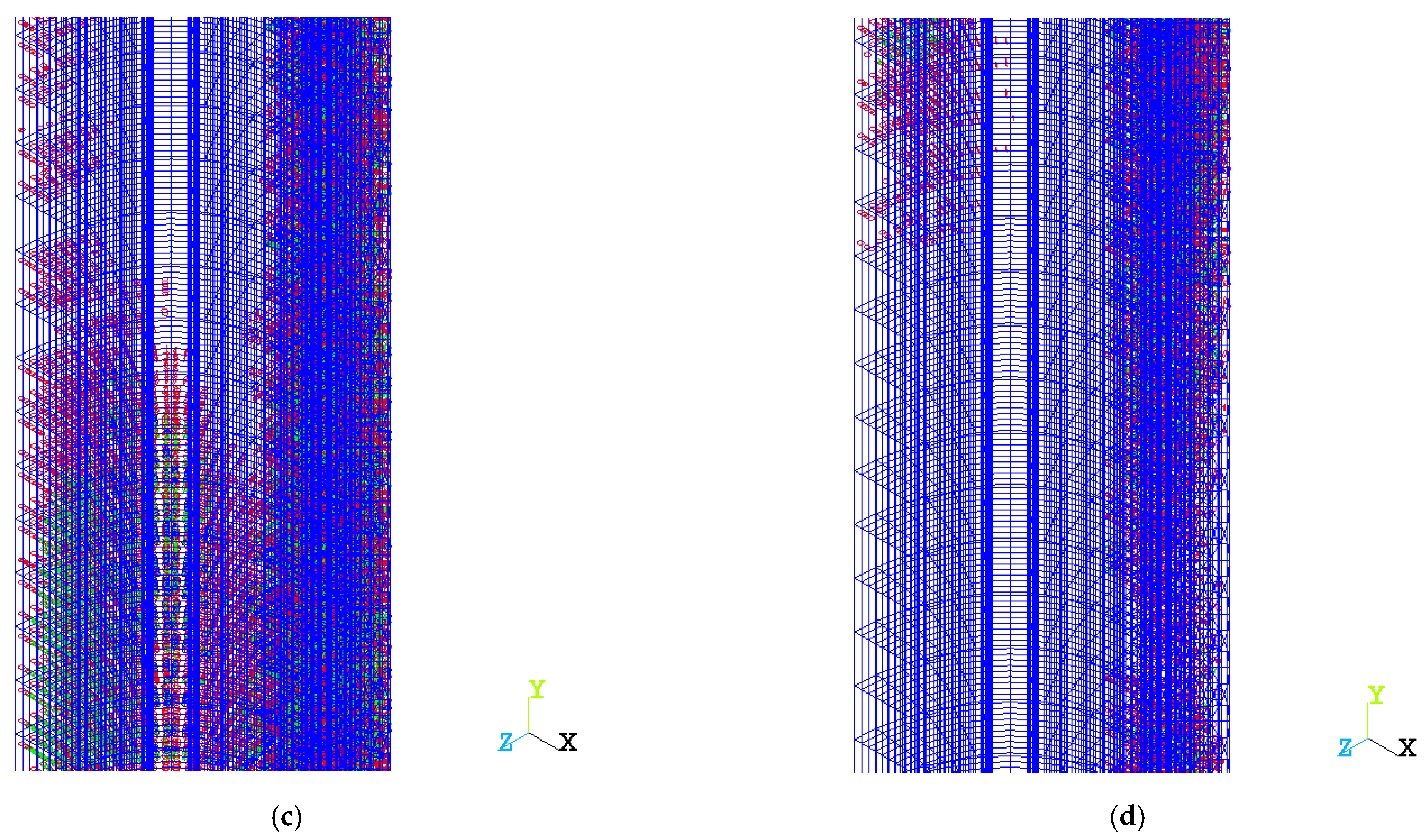

- with homogeneous concrete (homogeneous column) without load eccentricity (e = 0);

- -

- with three-layer concrete (variotropic three-layer column design) without load eccentricity (e = 0);

- -

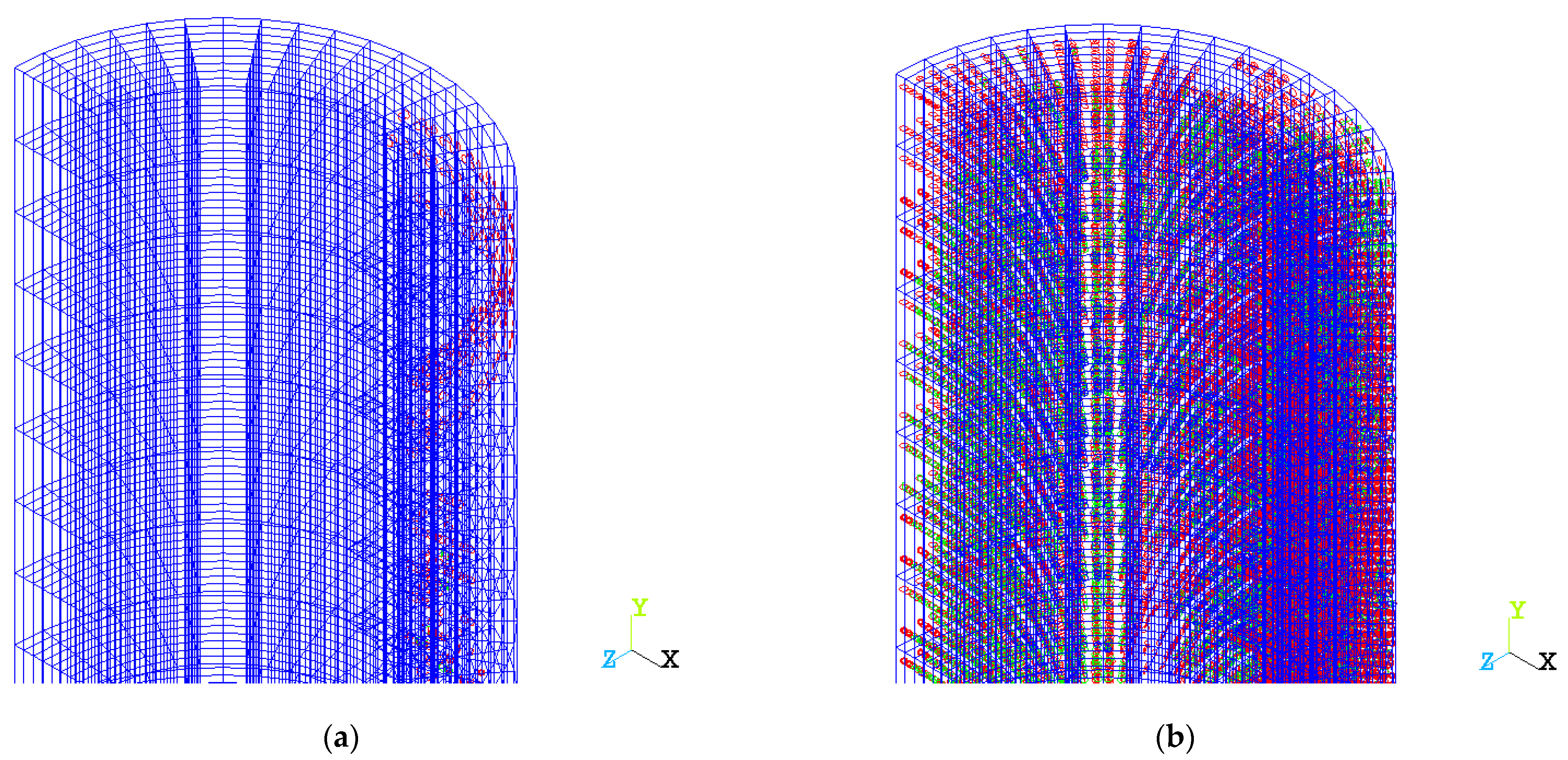

- with homogeneous concrete (homogeneous column) with load eccentricity (e = 24 mm);

- -

- with three-layer concrete (three-layer column design) with load eccentricity (e = 24 mm);

- -

- with homogeneous concrete (homogeneous column) with load eccentricity (e = 48 mm);

- -

- with three-layer concrete (three-layer column design) with load eccentricity (e = 48 mm).

3. Results and Discussion

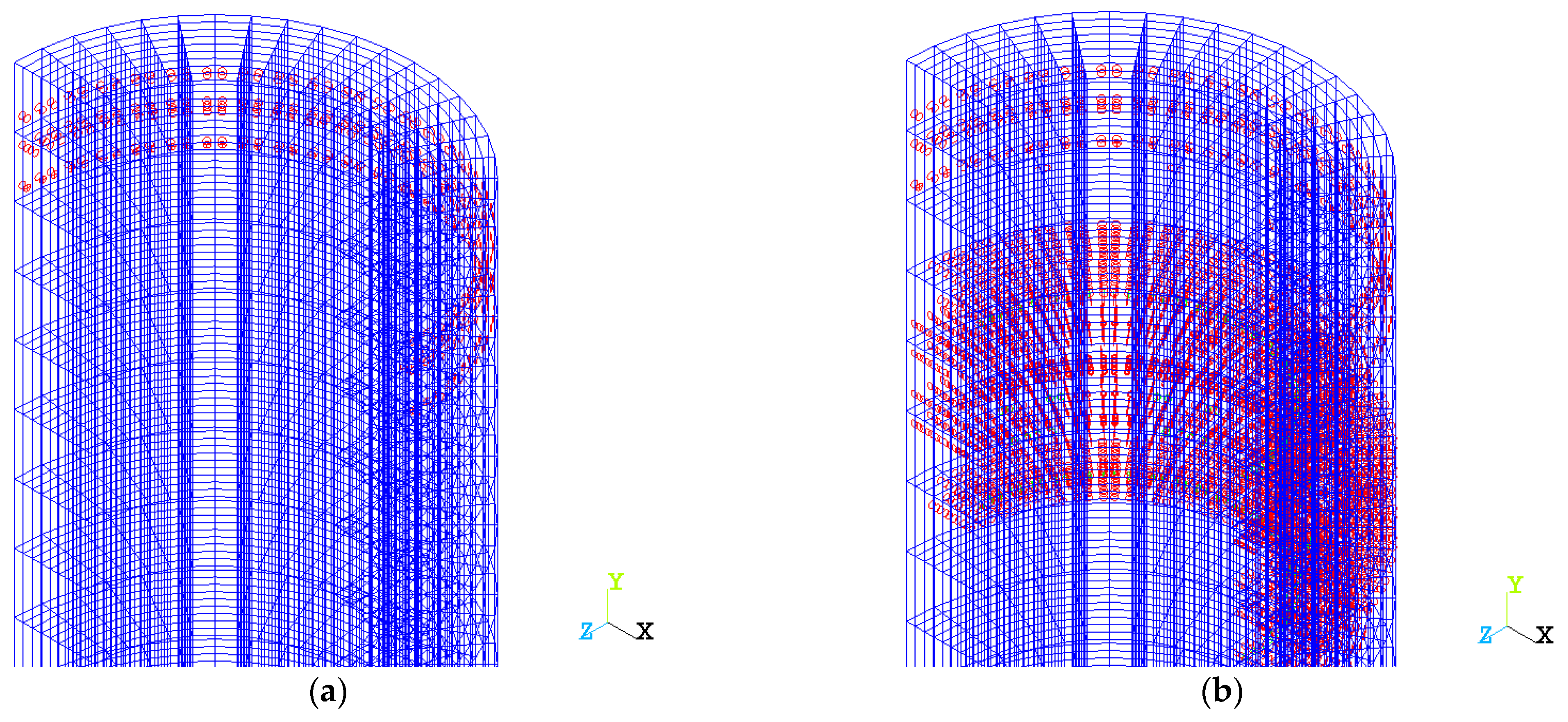

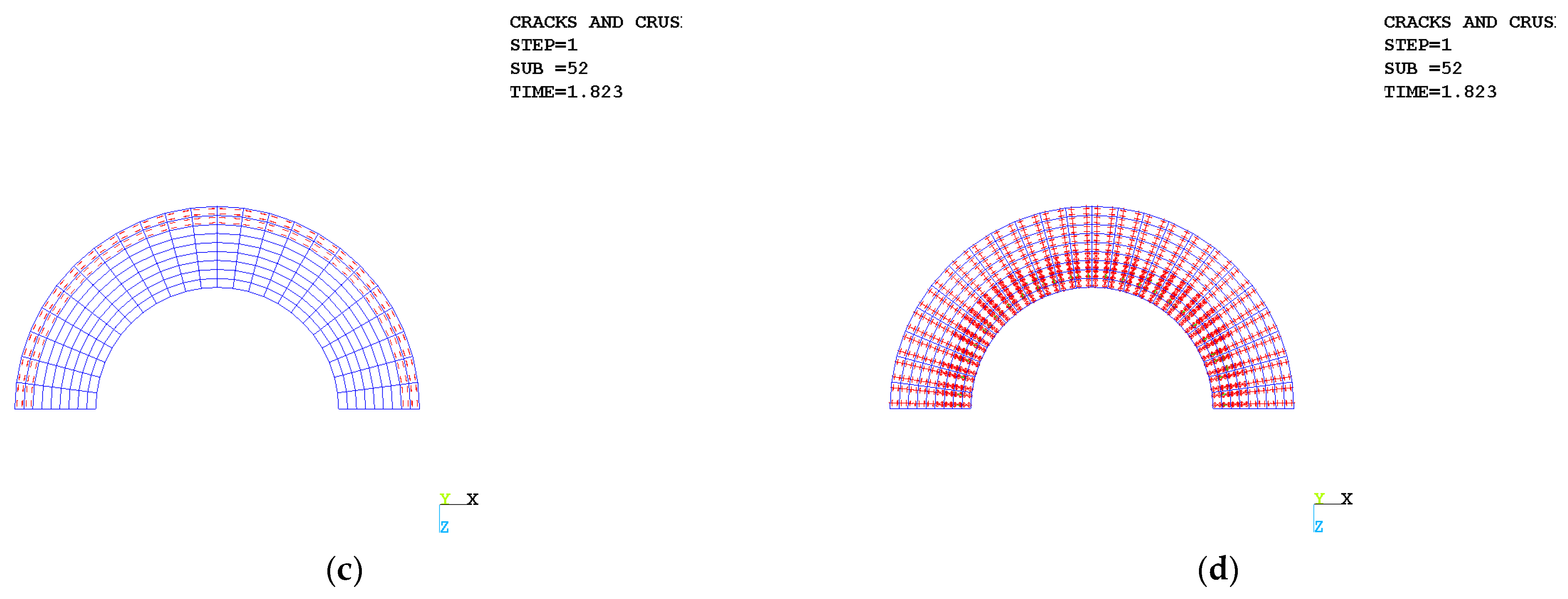

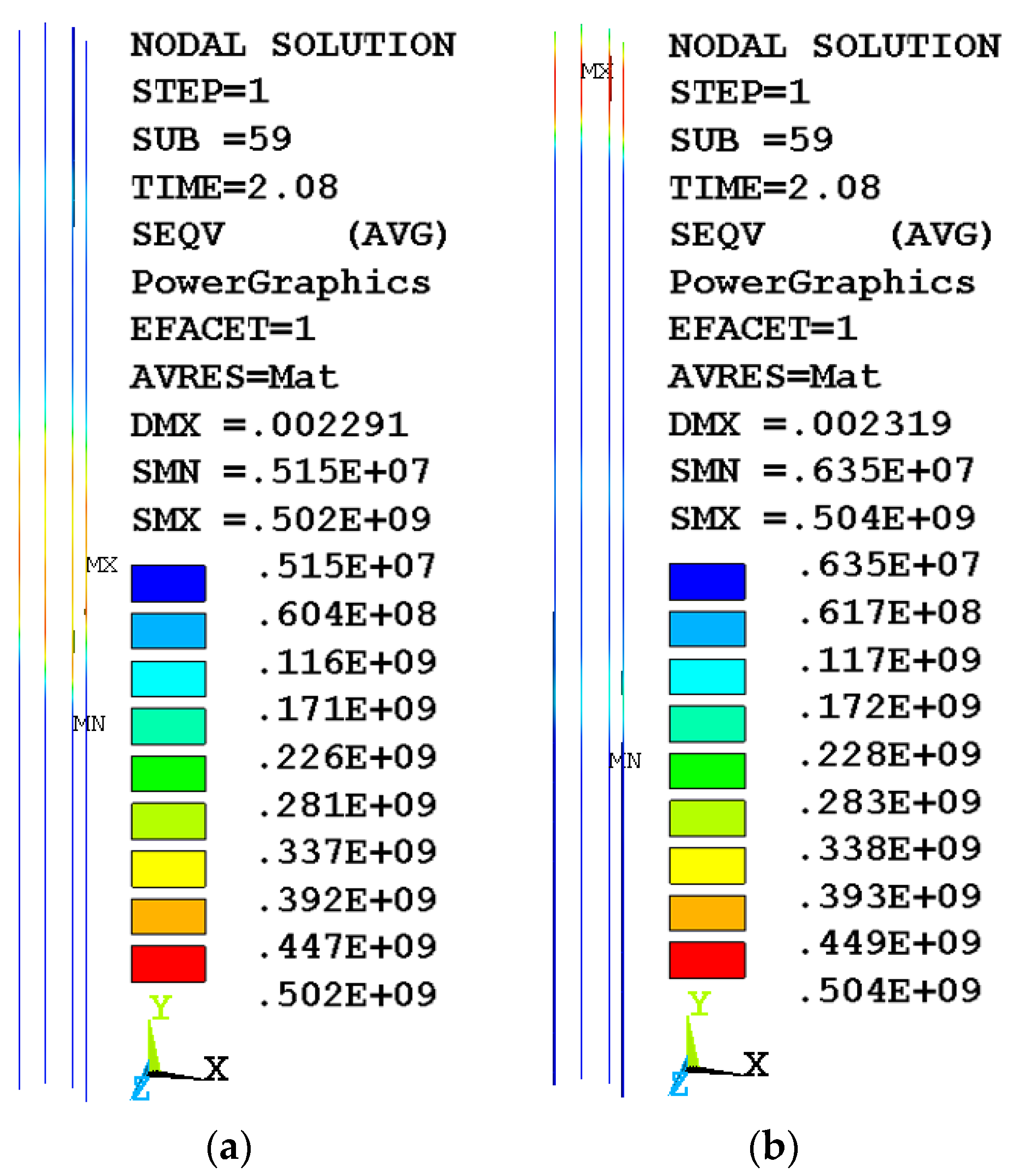

3.1. Numerical Analysis of the Central Compression of the Column (e = 0)

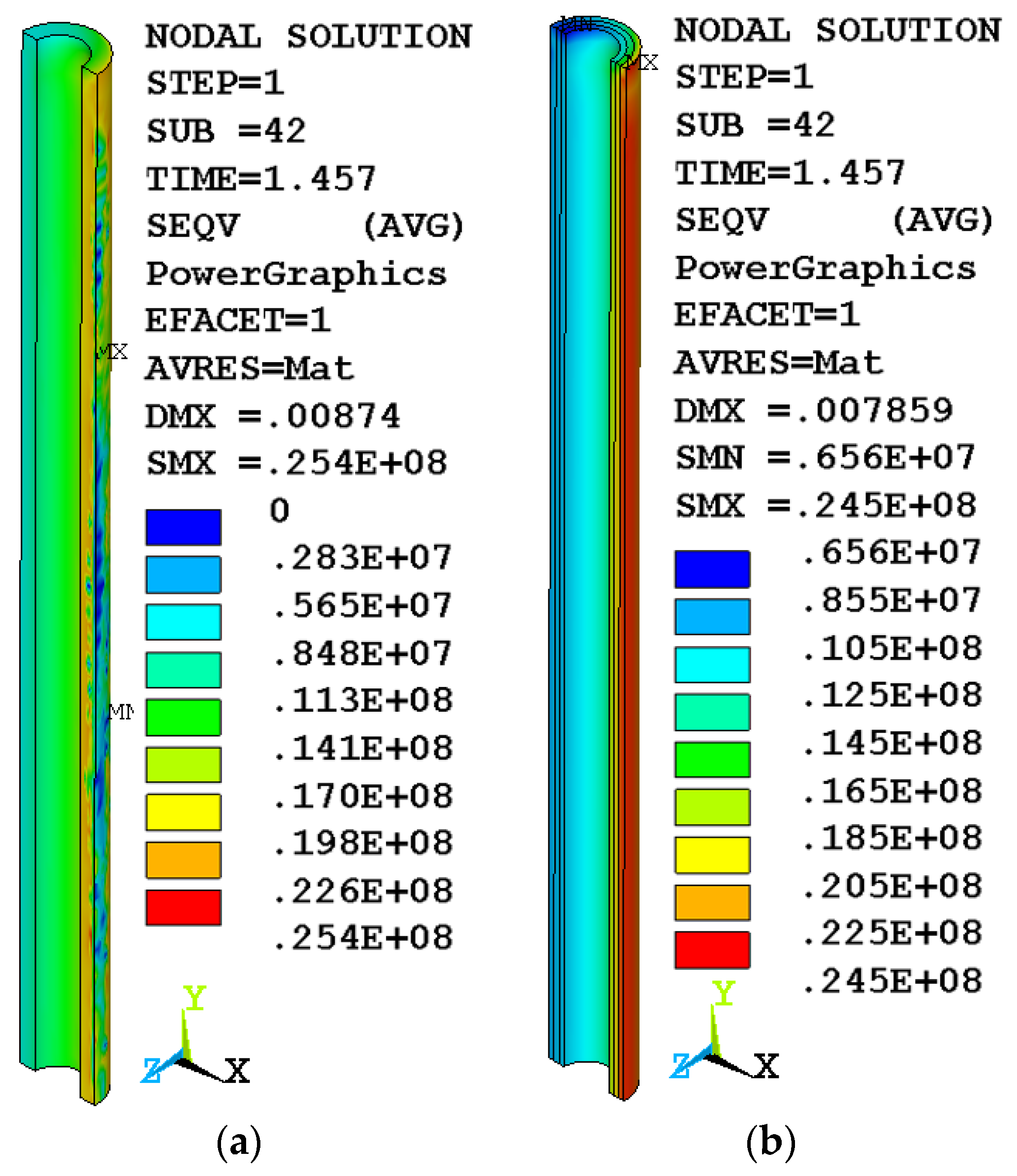

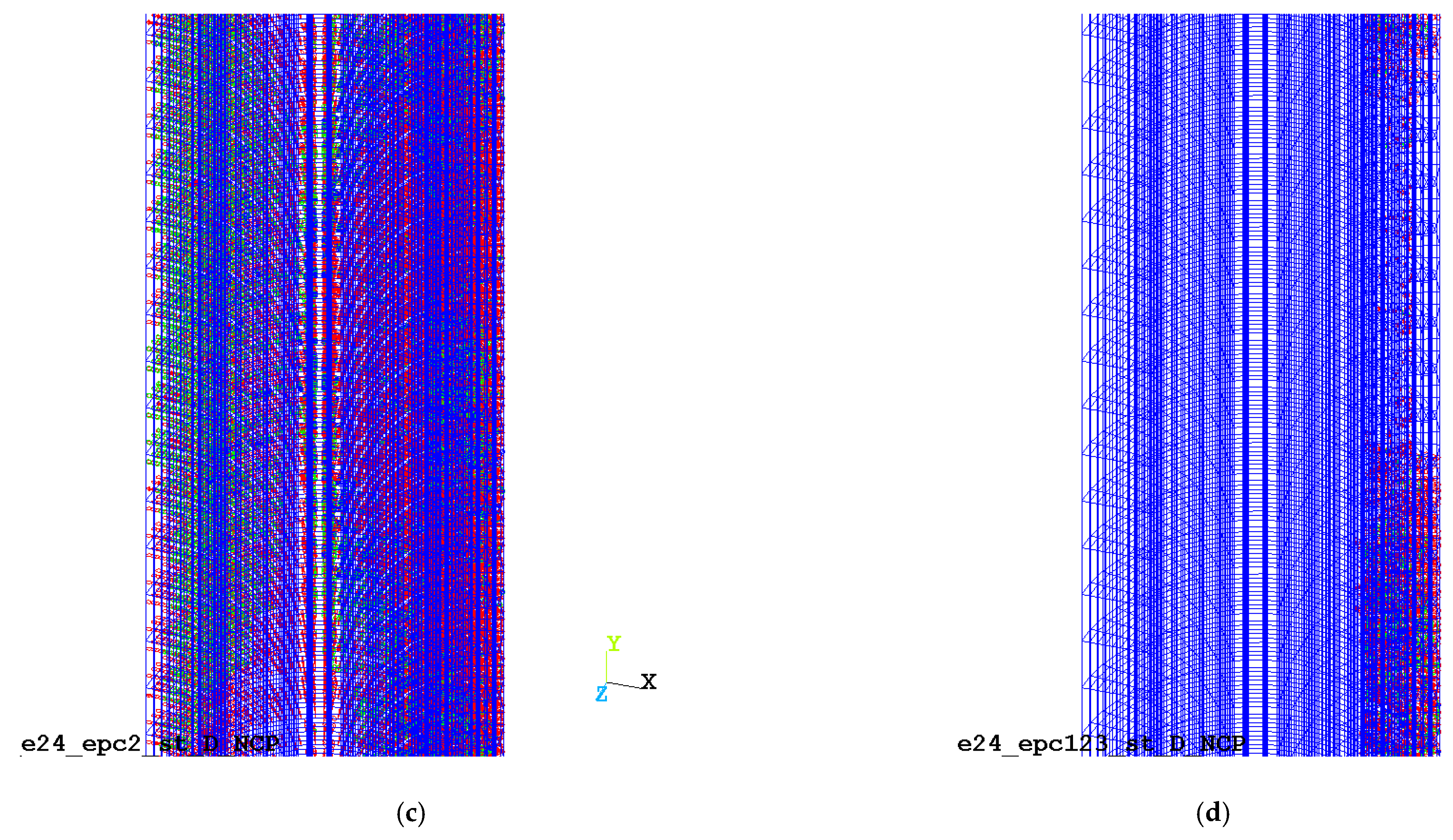

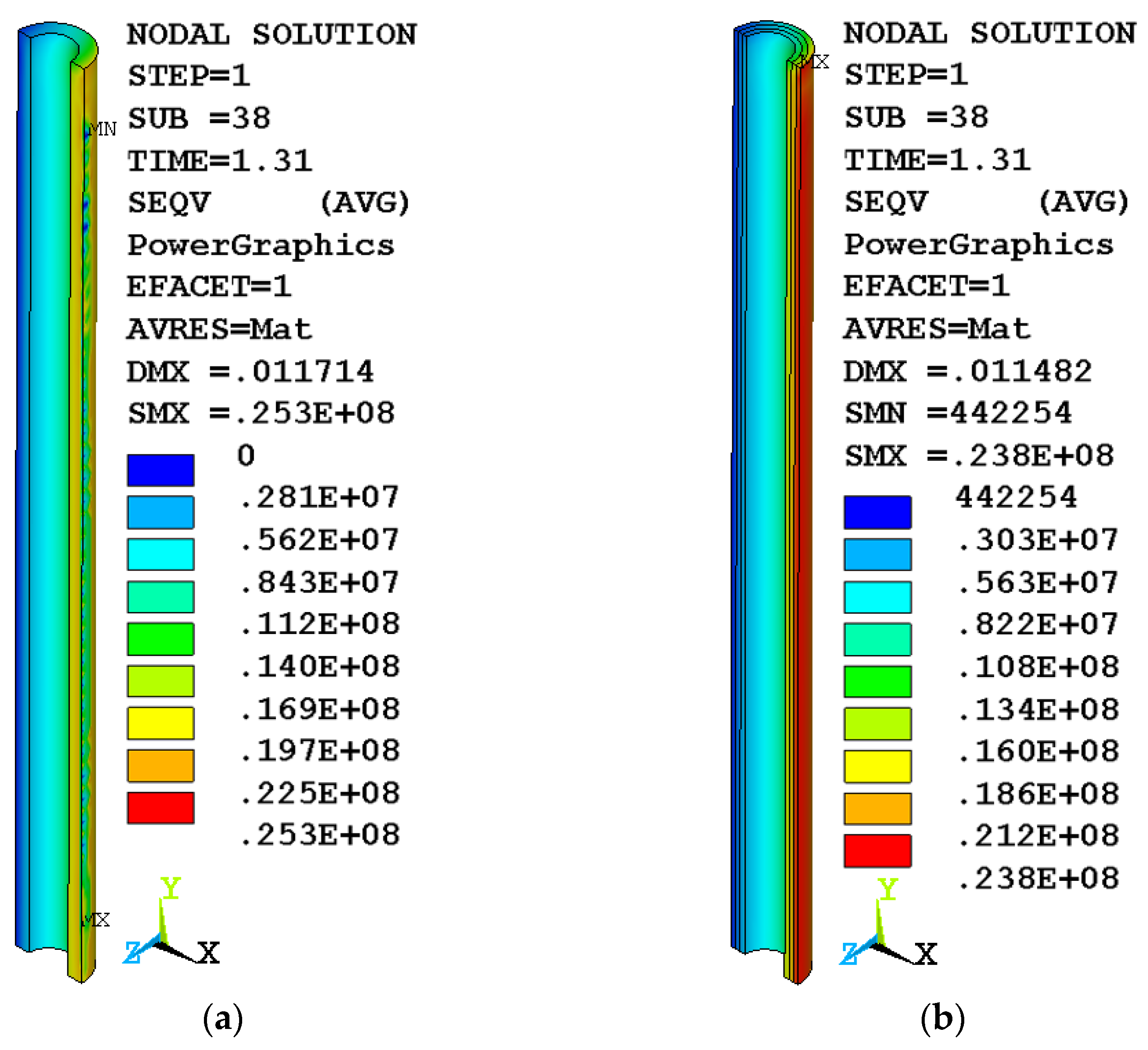

3.2. Numerical Analysis of Compression of a Column with Eccentricity e = 24 mm

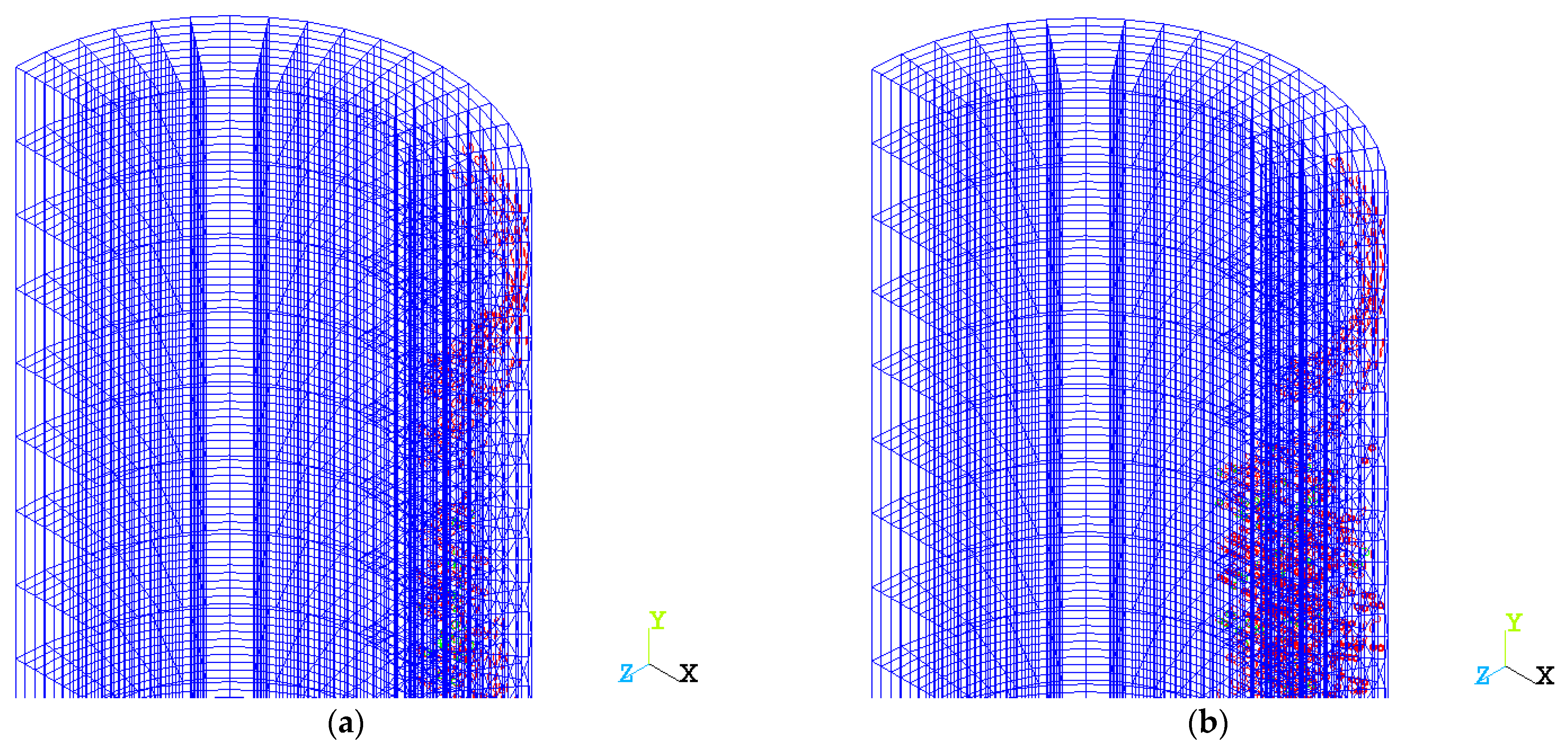

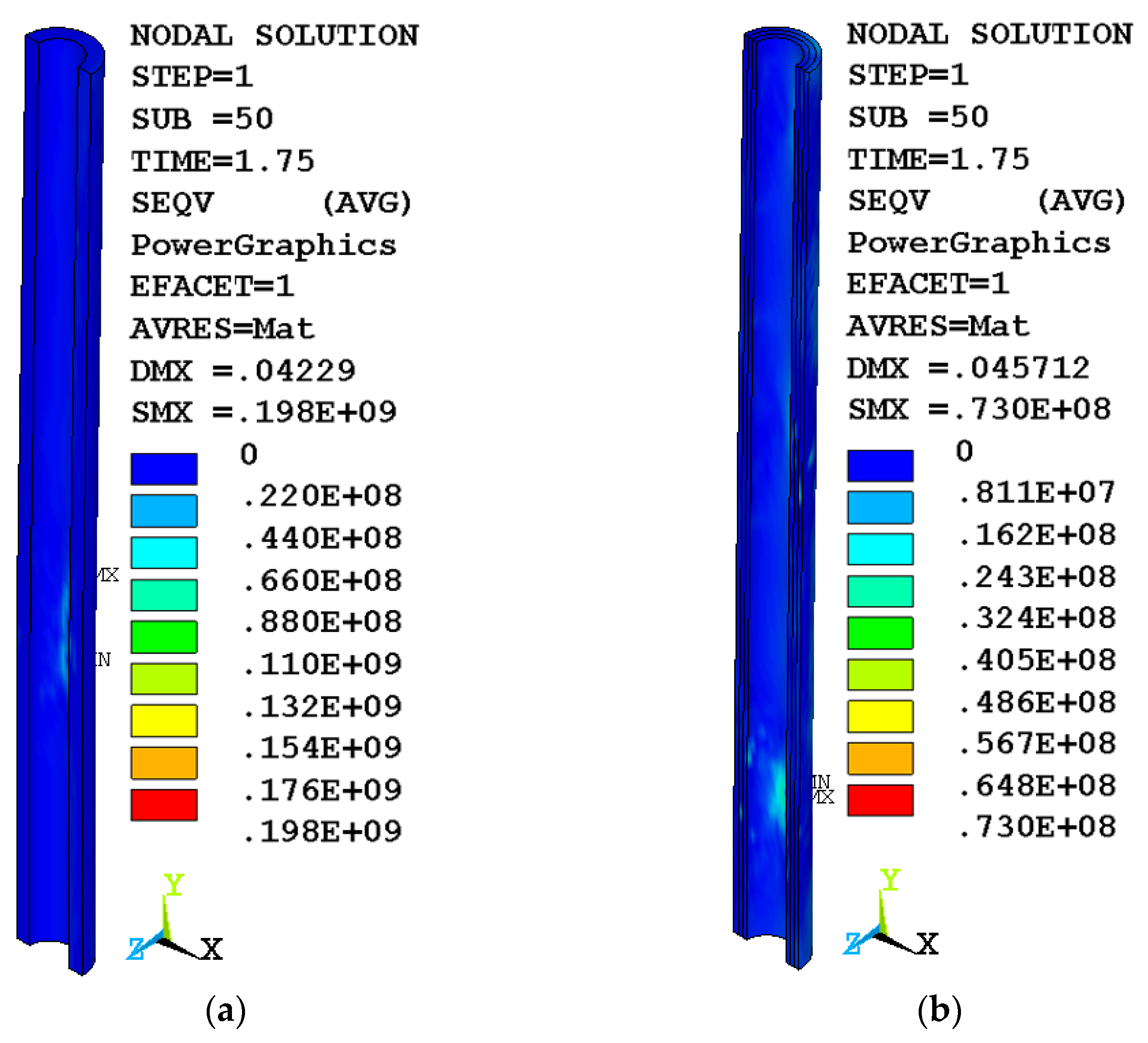

3.3. Numerical Analysis of Column Compression with Eccentricity e = 48 mm

4. Conclusions

- (1)

- It is shown that under central compression, a homogeneous column has a 3.6% higher bearing capacity than a variotropic one.

- (2)

- Eccentric compression with eccentricity e/r = 0.16; 0.32 changes the stress–strain state of the column and the variotropic column has a 5.5% and 6.2% higher bearing capacity, respectively, than a homogeneous one.

- (3)

- It is shown that the nature of the stress–strain state changes and the zone of the beginning of destruction near the variotropic column shifts upward to the zone of application of the load.

- (4)

- The obtained results show that the variotropic column design has an advantage in the bearing capacity of eccentrically compressed columns and can be implemented in practice.

- (5)

- The revealed positive effect of the variotropy of the concrete structure of eccentrically compressed reinforced concrete columns develops the previously known theory of the advantages of such columns in the case of central compression. This relationship proves the high efficiency and the possibility of using variotropic columns in technically complex structures with increased responsibility.

- (6)

- The research recommendation is to propose to develop the study of the work of variotropic structures in non-trivial problems. In particular, these are other types of stress–strain states other than the compressed state, other types of compressed structures in terms of geometry and design solutions, and the continuation of work on studying the effect of eccentricity on them.

- (7)

- Prospects for the development of research lie in the direction of studying the relationship between the geometric and design parameters of variotropic columns and their bearing capacity under central and eccentric loading. The scope of future work is to assess the effect of the heterogeneity of the structure of variotropic reinforced concrete beams on their performance under dynamic loads.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aksoylu, C.; Özkılıç, Y.O.; Arslan, M.H. Mechanical Steel Stitches: An innovative approach for strengthening shear deficiency in undamaged reinforced concrete beams. Buildings 2022, 12, 1501. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, W.; Yang, J. Analysis of stochastic process to model safety risk in construction industry. J. Civ. Eng. Manag. 2021, 27, 87–99. [Google Scholar] [CrossRef]

- Gemi, L.; Alsdudi, M.; Aksoylu, C.; Yazman, Ş.; Özkılıç, Y.O.; Arslan, M.H. Optimum amount of CFRP for strengthening shear deficient reinforced concrete beams. In Steel and Composite Structures; Techno-Press: Daejeon, Republic of Korea, 2022. [Google Scholar]

- Korkmaz, H.H.; Dere, Y.; Özkılıç, Y.O.; Bozkurt, M.B.; Ecemiş, A.S.; Özdoner, N. Excessive snow induced steel roof failures in Turkey. Eng. Fail. Anal. 2022, 141, 106661. [Google Scholar] [CrossRef]

- Abdal, S.; Mansour, W.; Agwa, I.; Nasr, M.; Abadel, A.; Özkılıç, Y.O.; Akeed, M.H. Application of ul-tra-high-performance concrete in bridge engineering: Current status, limitations, challenges, and future prospects. Buildings 2023, 13, 185. [Google Scholar] [CrossRef]

- Ilyas, M.; Ahmad, A.; Riaz, A.; Khan, F.A.; Sher, S.; Waseem, M.; Ali, S.Z.; Badrashi, Y.I.; Waqas, H.A.; Seitz, H.; et al. Review of Modeling Techniques for Analysis and Assessment of RC Beam–Column Joints Subjected to Seismic Loads. Materials 2022, 15, 7448. [Google Scholar] [CrossRef] [PubMed]

- Mina, A.L.; Petrou, M.F.; Trezos, K.G. Resistance of an Optimized Ultra-High Performance Fiber Reinforced Concrete to Projectile Impact. Buildings 2021, 11, 63. [Google Scholar] [CrossRef]

- Huang, H.; Guo, M.; Zhang, W.; Zeng, J.; Yang, K.; Bai, H. Numerical investigation on the bearing capacity of RC columns strengthened by HPFL-BSP under combined loadings. J. Build. Eng. 2021, 39, 102266. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Aksoylu, C.; Arslan, M.H. Numerical evaluation of effects of shear span, stirrup spacing and angle of stirrup on reinforced concrete beam behaviour. Struct. Eng. Mech. 2021, 79, 309–326. [Google Scholar]

- Li, J.; Chen, M.; Li, Z. Improved soil–structure interaction model considering time-lag effect. Comput. Geotech. 2022, 148, 104835. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Karalar, M.; Aksoylu, C.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban, E.M.; Qaidi, S.; Pereira, I.d.S.; Monteiro, S.N.; Azevedo, A.R. Shear performance of reinforced expansive concrete beams utilizing aluminium waste. J. Mater. Res. Technol. 2023, 24, 5433–5448. [Google Scholar] [CrossRef]

- Huang, H.; Huang, M.; Zhang, W.; Guo, M.; Liu, B. Progressive collapse of multistory 3D reinforced concrete frame structures after the loss of an edge column. Struct. Infrastruct. Eng. 2022, 18, 249–265. [Google Scholar] [CrossRef]

- Shafighfard, T.; Bagherzadeh, F.; Rizi, R.A.; Yoo, D.-Y. Data-driven compressive strength prediction of steel fiber reinforced concrete (SFRC) subjected to elevated temperatures using stacked machine learning algorithms. J. Mater. Res. Technol. 2022, 21, 3777–3794. [Google Scholar] [CrossRef]

- Kos, Z.; Klymenko, Y.; Crnoja, A.; Grynyova, I. Calculation Model for Estimation of Residual Bearing Capacity of Damaged Reinforced Concrete Slender Columns. Appl. Sci. 2022, 12, 7430. [Google Scholar] [CrossRef]

- Evtushenko, S.I.; Petrov, I.A.; Shutova, M.N.; Chernykhovsky, B.A. Bearing capacity of eccentrically compressed bisteel columns. Mag. Civ. Eng. 2021, 2, 10201. [Google Scholar] [CrossRef]

- Fang, B.; Hu, Z.; Shi, T.; Liu, Y.; Wang, X.; Yang, D.; Zhu, K.; Zhao, X.; Zhao, Z. Research progress on the properties and applications of magnesium phosphate cement. Ceram. Int. 2022, 49, 4001–4016. [Google Scholar] [CrossRef]

- Shi, T.; Liu, Y.; Zhao, X.; Wang, J.; Zhao, Z.; Corr, D.J.; Shah, S.P. Study on mechanical properties of the interfacial transition zone in carbon nanofiber-reinforced cement mortar based on the PeakForce tapping mode of atomic force microscope. J. Build. Eng. 2022, 61, 105248. [Google Scholar] [CrossRef]

- Shi, T.; Liu, Y.; Hu, Z.; Cen, M.; Zeng, C.; Xu, J.; Zhao, Z. Deformation Performance and Fracture Toughness of Carbon Nanofiber Modified Cement-Based Materials. ACI Mater. J. 2022, 119, 119–128. [Google Scholar] [CrossRef]

- Wang, M.; Yang, X.; Wang, W. Establishing a 3D aggregates database from X-ray CT scans of bulk concrete. Constr. Build. Mater. 2022, 315, 125740. [Google Scholar] [CrossRef]

- Zhou, S.; Lu, C.; Zhu, X.; Li, F. Preparation and Characterization of High-Strength Geopolymer Based on BH-1 Lunar Soil Simulant with Low Alkali Content. Engineering 2021, 7, 1631–1645. [Google Scholar] [CrossRef]

- Huang, H.; Li, M.; Zhang, W.; Yuan, Y. Seismic behavior of a friction-type artificial plastic hinge for the precast beam–column connection. Arch. Civ. Mech. Eng. 2022, 22, 201. [Google Scholar] [CrossRef]

- Zhai, S.-Y.; Lyu, Y.-F.; Cao, K.; Li, G.-Q.; Wang, W.-Y.; Chen, C. Seismic behavior of an innovative bolted connection with dual-slot hole for modular steel buildings. Eng. Struct. 2023, 279, 115619. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, W.; Liu, X. Assessment of Diagonal Macrocrack-Induced Debonding Mechanisms in FRP-Strengthened RC Beams. J. Compos. Constr. 2022, 26, 4022056. [Google Scholar] [CrossRef]

- Ghasemi, M.; Zhang, C.; Khorshidi, H.; Zhu, L.; Hsiao, P.-C. Seismic upgrading of existing RC frames with displacement-restraint cable bracing. Eng. Struct. 2023, 282, 115764. [Google Scholar] [CrossRef]

- Huang, H.; Yao, Y.; Liang, C.; Ye, Y. Experimental study on cyclic performance of steel-hollow core partially encased composite spliced frame beam. Soil Dyn. Earthq. Eng. 2022, 163, 107499. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Meskhi, B.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Veremeenko, A.; Akopyan, V.; Shilov, A.V.; Chernil’nik, A.; Beskopylny, N. Numerical Simulation of the Bearing Capacity of Variotropic Short Concrete Beams Reinforced with Polymer Composite Reinforcing Bars. Polymers 2022, 14, 3051. [Google Scholar] [CrossRef]

- Beskopylny, A.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B. Nano modifying additive micro silica influence on integral and differential characteristics of vibrocentrifuged concrete. J. Build. Eng. 2022, 51, 104235. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Evtushenko, A.; Varavka, V.; Beskopylny, N. Nano-Modified Vibrocentrifuged Concrete with Granulated Blast Slag: The Relationship between Mechanical Properties and Micro-Structural Analysis. Materials 2022, 15, 4254. [Google Scholar] [CrossRef] [PubMed]

- Šapalas, A.; Mudrov, A. Analysing the Confinement Effect in Hollow Core Steel-Concrete Composite Columns under Axial Compression. Materials 2021, 14, 6046. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Duan, Y.; Wang, Y.; Wang, X.; Liu, Q. Analysis and Modification of Methods for Calculating Axial Load Capacity of High-Strength Steel-Reinforced Concrete Composite Columns. Materials 2021, 14, 6860. [Google Scholar] [CrossRef]

- Won, D.; Kim, S.; Seo, J.; Kang, Y.-J. Experimental Study of Composite Hollow RC Column under Uniaxial Compressive Load. Appl. Sci. 2019, 9, 373. [Google Scholar] [CrossRef] [Green Version]

- Cai, H.; Yan, Y. UHPC-Filled Rectangular Steel Tubular Beam–Column: Numerical Study and Design. Buildings 2022, 12, 1882. [Google Scholar] [CrossRef]

- Cao, B.; Xie, M.; Huang, B.; Hu, G.; Wang, J. Axial Compression Performance of Precast Circular Semi-Continuous Concrete-Filled Steel Tube Columns: Finite Element Analysis and Theoretical Modeling. Buildings 2023, 13, 284. [Google Scholar] [CrossRef]

- Sarir, P.; Jiang, H.; Asteris, P.G.; Formisano, A.; Armaghani, D.J. Iterative Finite Element Analysis of Concrete-Filled Steel Tube Columns Subjected to Axial Compression. Buildings 2022, 12, 2071. [Google Scholar] [CrossRef]

- Bai, W.; Li, Y.; Ji, J.; Liu, Y.; Zhang, L.; Wang, R.; Jiang, L.; He, L. Axial Compression Behavior of Symmetrical Full-Scale Concrete Filled Double Skin Steel Tube Stub Columns. Symmetry 2022, 14, 223. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Duan, Y.; Su, Y.; Yi, X. The Investigation on Mechanical Performances of High-Strength Steel Reinforced Concrete Composite Short Columns under Axial Load. Materials 2022, 15, 329. [Google Scholar] [CrossRef]

- Miao, K.; Wei, Y.; Zhang, X.; Zheng, K.; Dong, F. Performance of Circular Concrete-Filled FRP-Grooved Steel Composite Tube Columns under Axial Compression. Polymers 2021, 13, 3638. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Sun, Q.; Tian, P.; Wang, J.; Wu, Y.; Li, Y. Experimental and Numerical Study of the Behavior of Concrete-Filled High-Strength Steel Tube Columns with Large D/t Ratio under Axial Compression. Buildings 2022, 12, 1953. [Google Scholar] [CrossRef]

- Veerapandian, V.; Pandulu, G.; Jayaseelan, R.; Sathish Kumar, V.; Murali, G.; Vatin, N.I. Numerical Modelling of Geopolymer Concrete In-Filled Fibre-Reinforced Polymer Composite Columns Subjected to Axial Compression Loading. Materials 2022, 15, 3390. [Google Scholar] [CrossRef]

- Wang, W.-D.; Ji, S.-H.; Shi, Y.-L. Experimental and numerical investigations on concrete-filled double-tubular slender columns under axial and eccentric loading. J. Constr. Steel Res. 2023, 201, 107714. [Google Scholar] [CrossRef]

- Abadel, A.A.; Khan, M.I.; Masmoudi, R. Experimental and numerical study of compressive behavior of axially loaded circular ultra-high-performance concrete-filled tube columns. Case Stud. Constr. Mater. 2022, 17, e01376. [Google Scholar] [CrossRef]

- Havlásek, P. Numerical modeling of axially compressed circular concrete columns. Eng. Struct. 2021, 227, 111445. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, Y.; Wang, X.; Sun, L. Study on Eccentric Compressive Behavior of Concrete Columns Reinforced with NPR735 High-Strength Steel Bars. Buildings 2023, 13, 188. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Zhao, Y.; Wei, Y.; Fan, J. Compressive Performance of RC Columns Strengthened with High-Strength Stainless Steel Wire Mesh-ECC under Small Eccentric Compression Load. Buildings 2022, 12, 1628. [Google Scholar] [CrossRef]

- Chepurnenko, A.; Lipovich, A.; Beskopylny, A.N.; Meskhi, B. Reinforced Concrete Columns with Local Prestressing Rebars: A Calculation Theory and an Experimental Study. Buildings 2022, 12, 1152. [Google Scholar] [CrossRef]

- Cassese, P.; Menna, C.; Occhiuzzi, A.; Asprone, D. Experimental Behavior of Existing RC Columns Strengthened with HPFRC Jacket under Concentric and Eccentric Compressive Load. Buildings 2021, 11, 521. [Google Scholar] [CrossRef]

- Li, Q.; Kuang, Y.; Guo, W.; Zhang, Y. Experimental Research on Mechanical Performance of SSRC Columns under Eccentric Compression. Appl. Sci. 2020, 10, 5629. [Google Scholar] [CrossRef]

- Hou, Y.; Cao, S.; Ni, X.; Li, Y. Research on Concrete Columns Reinforced with New Developed High-Strength Steel under Eccentric Loading. Materials 2019, 12, 2139. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, C.; Geng, H.; Deng, C.; Li, B.; Zhao, S. Experimental Investigation on Columns of Steel Fiber Reinforced Concrete with Recycled Aggregates under Large Eccentric Compression Load. Materials 2019, 12, 445. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Berardi, V.P.; Mancusi, G. Time-Dependent Behavior of Reinforced Polymer Concrete Columns under Eccentric Axial Loading. Materials 2012, 5, 2342–2352. [Google Scholar] [CrossRef] [Green Version]

- Polskoy, P.P.; Mailyan, D.; Beskopylny, A.N.; Meskhi, B.; Shilov, A.V.; Umarov, A. Strength of Compressed Reinforced Concrete Elements Reinforced with CFRP at Different Load Application Eccentricity. Polymers 2023, 15, 26. [Google Scholar] [CrossRef]

- Wysmulski, P. Load Eccentricity of Compressed Composite Z-Columns in Non-Linear State. Materials 2022, 15, 7631. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Xie, H.; Yan, M.; Gou, H.; Zhao, G.; Bao, Y. Eccentric Compressive Behavior of Reinforced Concrete Columns Strengthened Using Steel Mesh Reinforced Resin Concrete. Appl. Sci. 2018, 8, 1827. [Google Scholar] [CrossRef] [Green Version]

- Hu, B.; Wang, J.-G.; Li, G.-Q. Numerical simulation and strength models of FRP-wrapped reinforced concrete columns under eccentric loading. Constr. Build. Mater. 2011, 25, 2751–2763. [Google Scholar] [CrossRef]

- Ma, Y.-X.; Zhao, O.; Tan, K.H. Experimental and numerical studies of concrete-encased concrete-filled steel tube stub columns under uniaxial and biaxial eccentric compression. Eng. Struct. 2021, 232, 111796. [Google Scholar] [CrossRef]

- Li, G.-C.; Chen, B.-W.; Yang, Z.-J.; Liu, Y.-P.; Feng, Y.-H. Experimental and numerical behavior of eccentrically loaded square concrete-filled steel tubular long columns made of high-strength steel and concrete. Thin-Walled Struct. 2021, 159, 107289. [Google Scholar] [CrossRef]

- Ahmed, M.; Liang, Q.Q.; Patel, V.I.; Hadi, M.N.S. Experimental and numerical studies of square concrete-filled double steel tubular short columns under eccentric loading. Eng. Struct. 2019, 197, 109419. [Google Scholar] [CrossRef]

- Nie, G.J.; Batra, R.C. Material tailoring and analysis of functionally graded isotropic and incompressible linear elastic hollow cylinders. Compos. Struct. 2010, 92, 265–274. [Google Scholar] [CrossRef]

- Abdelkarim, O.I.; ElGawady, M.A. Dynamic and Static Behavior of Hollow-Core FRP-Concrete-Steel and Reinforced Concrete Bridge Columns under Vehicle Collision. Polymers 2016, 8, 432. [Google Scholar] [CrossRef] [Green Version]

- Chepurnenko, A.; Litvinov, S.; Meskhi, B.; Beskopylny, A. Optimization of Thick-Walled Viscoelastic Hollow Polymer Cylinders by Artificial Heterogeneity Creation: Theoretical Aspects. Polymers 2021, 13, 2408. [Google Scholar] [CrossRef]

- Wei, Y.; Xu, Y.; Wang, G.; Cheng, X.; Li, G. Influence of the Cross-Sectional Shape and Corner Radius on the Compressive Behaviour of Concrete Columns Confined by FRP and Stirrups. Polymers 2022, 14, 341. [Google Scholar] [CrossRef]

- Li, D.-C.; Xu, C.; Cui, Z.-D.; Chen, J.-M.; Xu, X.-Q.; Zhang, T.-T.; Zhang, Z.-W.; Song, G. Mechanical Properties of Functionally Graded Concrete Lining for Deep Underground Structures. Adv. Civ. Eng. 2022, 2022, 2363989. [Google Scholar] [CrossRef]

- Skrivanek, J.; Holec, P.; Batka, O.; Bilek, M.; Pokorny, P. Optimization of the Spinneret Rotation Speed and Airflow Parameters for the Nozzleless Forcespinning of a Polymer Solution. Polymers 2022, 14, 1042. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.-H.; Huang, S.-Y.; Huang, S.-Y.; Lin, J.-D.; Huang, B.-Y.; Kuo, C.-T. Improvement of the Centrifugal Force in Gravity Driven Method for the Fabrication of Highly Ordered and Submillimeter-Thick Colloidal Crystal. Polymers 2021, 13, 692. [Google Scholar] [CrossRef] [PubMed]

- Feng, Z.; Hu, H.; Dong, Y.; Wang, F.; Jia, M.; Zhao, Y.; He, J. Effect of Steel Casing on Vertical Bearing Characteristics of Steel Tube-Reinforced Concrete Piles in Loess Area. Appl. Sci. 2019, 9, 2874. [Google Scholar] [CrossRef] [Green Version]

- Kliukas, R.; Lukoševičienė, O.; Jaras, A.; Jonaitis, B. The Mechanical Properties of Centrifuged Concrete in Reinforced Concrete Structures. Appl. Sci. 2020, 10, 3570. [Google Scholar] [CrossRef]

- Feng, B.; Zhu, Y.-H.; Xie, F.; Chen, J.; Liu, C.-B. Experimental Investigation and Design of Hollow Section, Centrifugal Concrete-Filled GFRP Tube Columns. Buildings 2021, 11, 598. [Google Scholar] [CrossRef]

- Mailyan, L.R.; Stel’makh, S.A.; Shcherban, E.M. Differential characteristics of concrete in centrifugally spun and vibrospun building structures. Mag. Civ. Eng. 2021, 108, 10812. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; El’shaeva, D.; Kotenko, M. The Investigation of Compacting Cement Systems for Studying the Fundamental Process of Cement Gel Formation. Gels 2022, 8, 530. [Google Scholar] [CrossRef]

- Mailyan, L.R.; Stel’makh, S.A.; Shcherban’, E.M.; Khalyushev, A.K.; Smolyanichenko, A.S.; Sysoev, A.K.; Parinov, I.A.; Cherpakov, A.V. Investigation of Integral and Differential Characteristics of Variatropic Structure Heavy Concretes by Ultrasonic Methods. Appl. Sci. 2021, 11, 3591. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B. Influence of Mechanochemical Activation of Concrete Components on the Properties of Vibro-Centrifugated Heavy Concrete. Appl. Sci. 2021, 11, 10647. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhao, O. Behaviour of eccentrically loaded circular recycled aggregate concrete-filled stainless steel tube stub columns. J. Constr. Steel Res. 2022, 198, 107568. [Google Scholar] [CrossRef]

- Jin, H.; Wei, Y.; Zhang, Y.; Huang, Z.; Liu, L. Compressive performance of underwater concrete columns strengthened by nondispersive mortar and stainless steel tubes. Case Stud. Constr. Mater. 2023, 19, e02220. [Google Scholar] [CrossRef]

- Zhang, S.; Miao, K.; Wei, Y.; Xu, X.; Bin Luo, B.; Shi, W. Experimental and Theoretical Study of Concrete-Filled Steel Tube Columns Strengthened by FRP/Steel Strips Under Axial Compression. Int. J. Concr. Struct. Mater. 2023, 17, 1. [Google Scholar] [CrossRef]

- More, F.M.D.S.; Subramanian, S.S. Experimental Investigation on the Axial Compressive Behaviour of Cold-Formed Steel-Concrete Composite Columns Infilled with Various Types of Fibre-Reinforced Concrete. Buildings 2023, 13, 151. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Z.; Zhou, X.; Wang, Z. Experimental Study and Finite Element Calculation of the Behavior of Special T-Shaped Composite Columns with Concrete-Filled Square Steel Tubulars under Eccentric Loads. Buildings 2022, 12, 1756. [Google Scholar] [CrossRef]

| Number | Title | Characteristics |

|---|---|---|

| 1 | Outer layer | Modulus of elasticity: 4.351 × 1010 Pa Poisson’s Ratio: 0.2 Tensile strength: 3.87 MPa Compressive Elasticity: 30 MPa Compressive strength: 38.7 MPa Compressive hardening modulus: 8.610 × 109 Pa |

| 2 | Middle layer | Modulus of elasticity: 4.041 × 1010 Pa Poisson’s Ratio: 0.2 Tensile strength: 3.32 MPa Compressive Elasticity: 25 MPa Compressive strength: 33.2 MPa Compressive hardening modulus: 6.941 × 109 Pa |

| 3 | Inner layer | Modulus of elasticity: 3.721 × 1010 Pa Poisson’s Ratio: 0.2 Tensile strength: 2.92 MPa Compressive Elasticity: 20 MPa Compressive strength: 29.2 MPa Compressive hardening modulus: 6.752 × 109 Pa |

| 4 | Steel reinforcement | Modulus of elasticity: 2.1 × 1011 Pa Poisson’s Ratio: 0.3 Yield strength: 500 MPa Hardening modulus: 870 MPa |

| 5 | Plate for eccentrical loading | Modulus of elasticity: 2.0 × 1015 Pa Poisson’s Ratio: 0.3. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Veremeenko, A.; Shilov, A.V.; Ananova, O.; Karalar, M.; Aksoylu, C.; Onuralp Özkılıç, Y. Modeling and Calculation of Improved Centrifuged Reinforced Concrete Columns with Variotropic Structure. Buildings 2023, 13, 2005. https://doi.org/10.3390/buildings13082005

Stel’makh SA, Shcherban’ EM, Beskopylny AN, Mailyan LR, Veremeenko A, Shilov AV, Ananova O, Karalar M, Aksoylu C, Onuralp Özkılıç Y. Modeling and Calculation of Improved Centrifuged Reinforced Concrete Columns with Variotropic Structure. Buildings. 2023; 13(8):2005. https://doi.org/10.3390/buildings13082005

Chicago/Turabian StyleStel’makh, Sergey A., Evgenii M. Shcherban’, Alexey N. Beskopylny, Levon R. Mailyan, Andrey Veremeenko, Aleksandr V. Shilov, Oxana Ananova, Memduh Karalar, Ceyhun Aksoylu, and Yasin Onuralp Özkılıç. 2023. "Modeling and Calculation of Improved Centrifuged Reinforced Concrete Columns with Variotropic Structure" Buildings 13, no. 8: 2005. https://doi.org/10.3390/buildings13082005