An Integrated Model for Multi-Mode Resource-Constrained Multi-Project Scheduling Problems Considering Supply Management with Sustainable Approach in the Construction Industry under Uncertainty Using Evidence Theory and Optimization Algorithms

Abstract

:1. Introduction

2. Literature Review

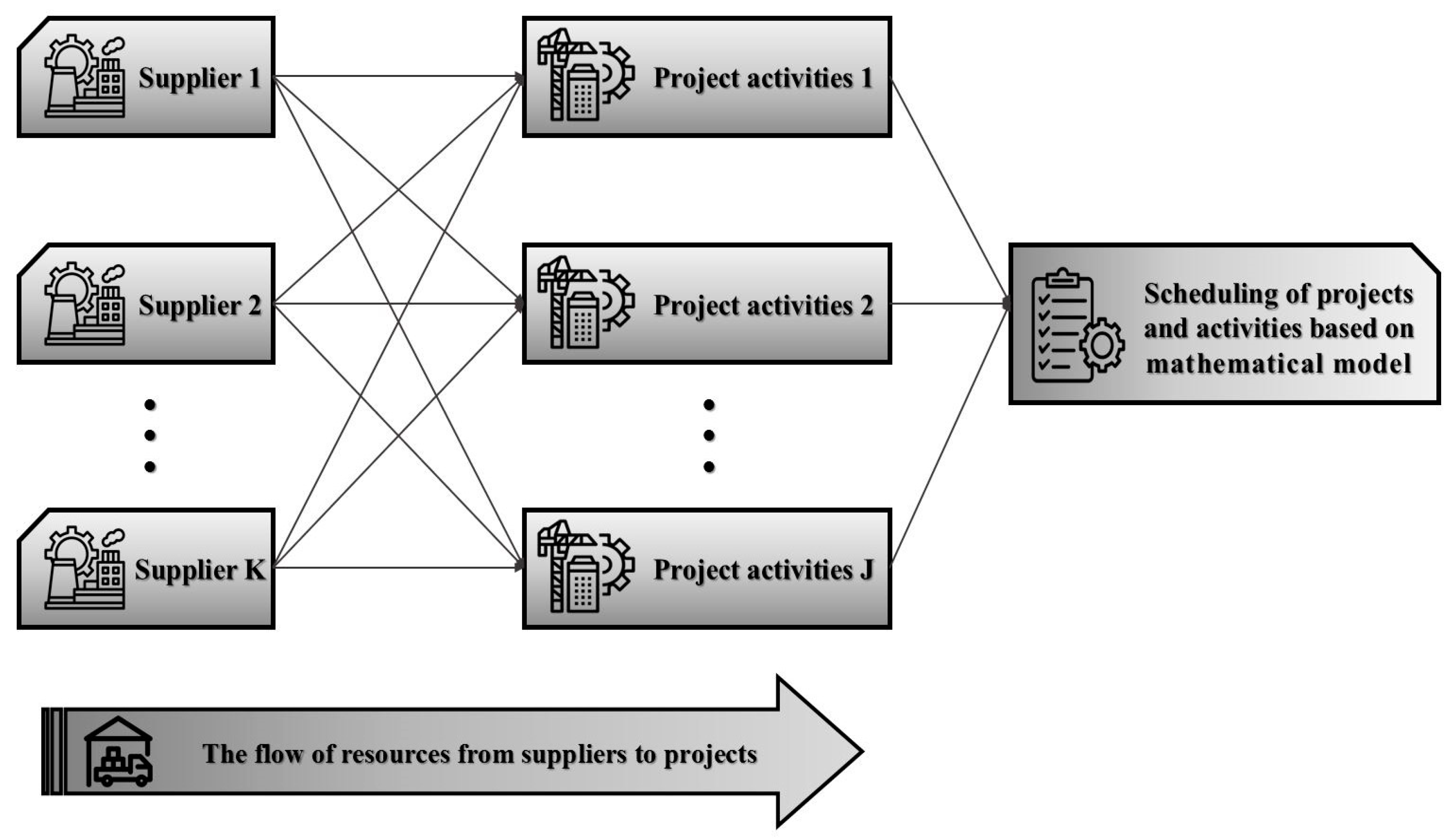

3. Mathematical Modeling

3.1. Assumptions of Modeling

- The research issue is a multi-project problem mainly focused on construction projects.

- Each project has its own activities, and projects do not share activities.

- Among the available projects, one or more projects can be selected.

- The beneficiaries of this issue are the employer, contractor, and suppliers.

- From the employer’s point of view, the projects have priority, which is determined in the form of project points according to economic, environmental, social, technical, organizational, and competitive factors and announced to the contractor.

- According to the experts’ opinions, there is a possibility of some risks occurring, such as the risk of financial and liquidity for suppliers, the risk of natural disasters for the supplier, the risk of defective and low-quality materials and equipment provided by the supplier, and the risk of delayed delivery of resources by the supplier.

- The processing time of activities is uncertain, and evidence theory is used to consider this uncertainty and related conditions.

- Renewable resources (such as labor and machinery) or non-renewable resources (such as construction materials, such as cement, plaster, steel rebar, brick, and tile) are required to complete project activities.

- Non-renewable resources are purchased from multiple suppliers, and each supplier can only deliver one type of non-renewable resource. For example, cement can be purchased from one supplier, and steel rebar can be bought from another.

- The mathematical model of the current research is multi-objective and aims to maximize the weight of selected projects based on the implementation priorities of the employer, which include economic, environmental, social, technical, organizational, and competitive factors; furthermore, it has the intention of maximizing the profits and minimizing the risks in projects.

3.2. Components and Descriptions in the Mathematical Model

3.3. Relations of Objective Functions and Constraints in the Mathematical Model

3.4. Uncertainty and Evidence Theory

3.5. Project Scheduling Model Based on the Evidence

4. Solution Methods and Algorithms

| Algorithm 1. The main process and the general structure of the DE algorithm. |

| { G = 0 Create a random initial population Evaluate For G = 1 to MAX GEN Do For i = 1 to NP Do Select randomly r1 ≠ r2 ≠ r3: jrand = randint(1,D) For j = 1 to D Do If (randj [0, 1) < cr or j = jrand) Then Else End If End For If () Then Else End If End For G = G + 1 End For } |

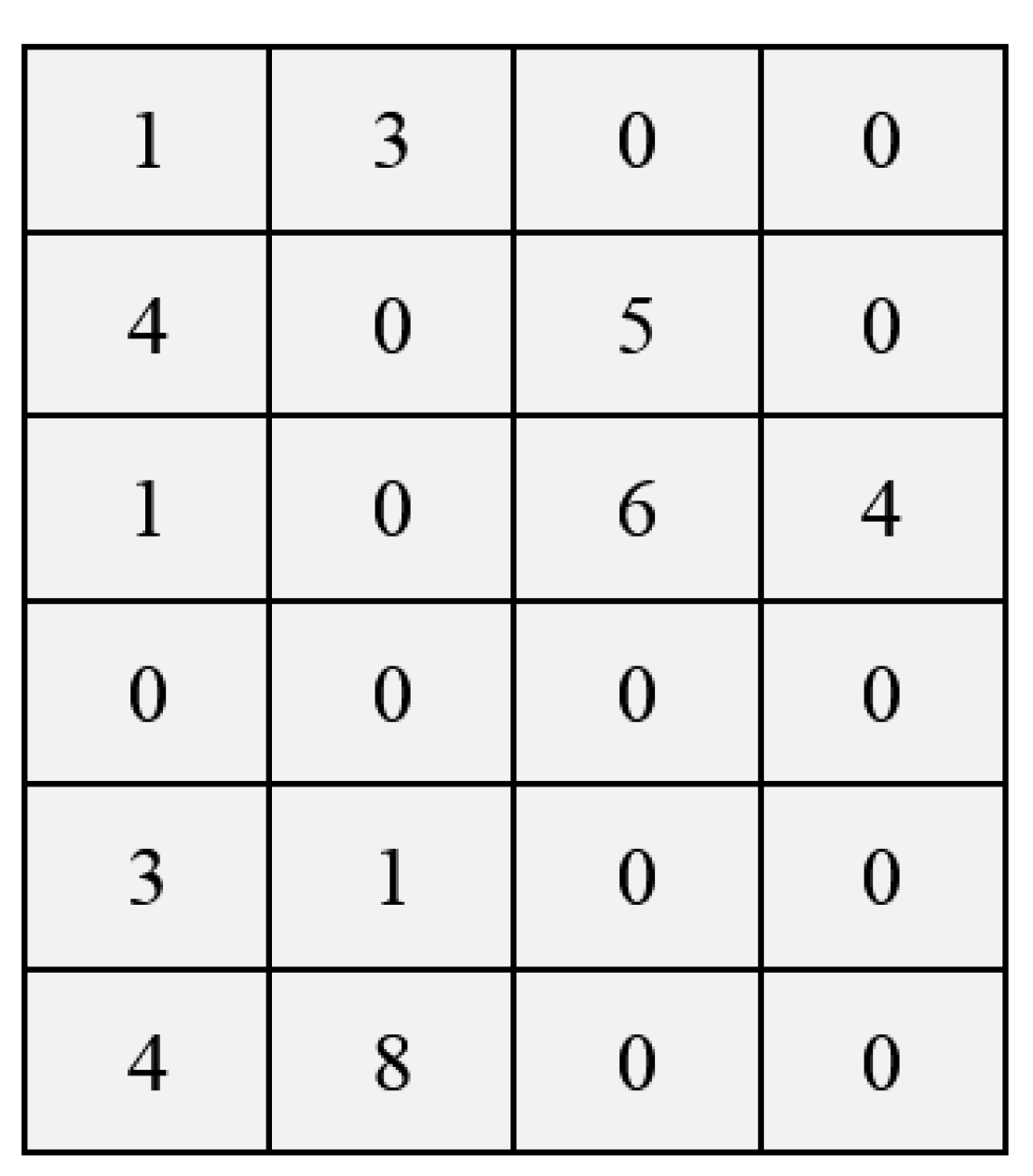

4.1. Representation and Structure of the Answers

4.1.1. Matrix of the First Type

4.1.2. Matrix of the Second Type

4.2. Mutation Operator

4.3. Crossover Operator

4.4. Selection Operator

4.5. Updating the Pareto Archive and Selecting the Next-Generation Answers

5. Results and Discussion

5.1. Setting of Parameters

- In the DE optimization algorithm, the cr value is set equal to 0.2.

- A rate of 0.8 for crossover and 0.1 for mutation is considered in the NSGA-II algorithm.

- For running the algorithms, the number of algorithm repetitions and the population size are set to 300 and 200, respectively.

- The maximum number of implementation modes is considered equal to three, and the number of resources required to complete the activities of each project and in each implementation mode is considered in a uniform interval [2..4].

- The completion time of each project is considered in the uniform interval [m1..m2], where m2 is equal to 1.5 times, and m1 is 1.2 times the total processing time of all projects.

- The cost of purchasing resources in a uniform interval [10..20] and the cost of performing activities in a uniform interval [5..15] are included.

- The rate related to the value of money is considered equal to 0.18.

- Transportation time in the uniform interval [1..5], supplier preparation time in the uniform interval [1..3], the capacity of suppliers in the uniform interval [150..300], and resource maintenance cost in the uniform interval [20..30] are considered.

- The total budget has been calculated based on the cost of providing resources, the cost of performing activities, and other related costs of the projects.

- The processing time of each project’s activities and implementation mode is considered in the uniform interval [10..40].

5.2. Evaluating the Results of Solving the Model by Algorithms

5.2.1. Solving the Problem of Multi-Project Construction

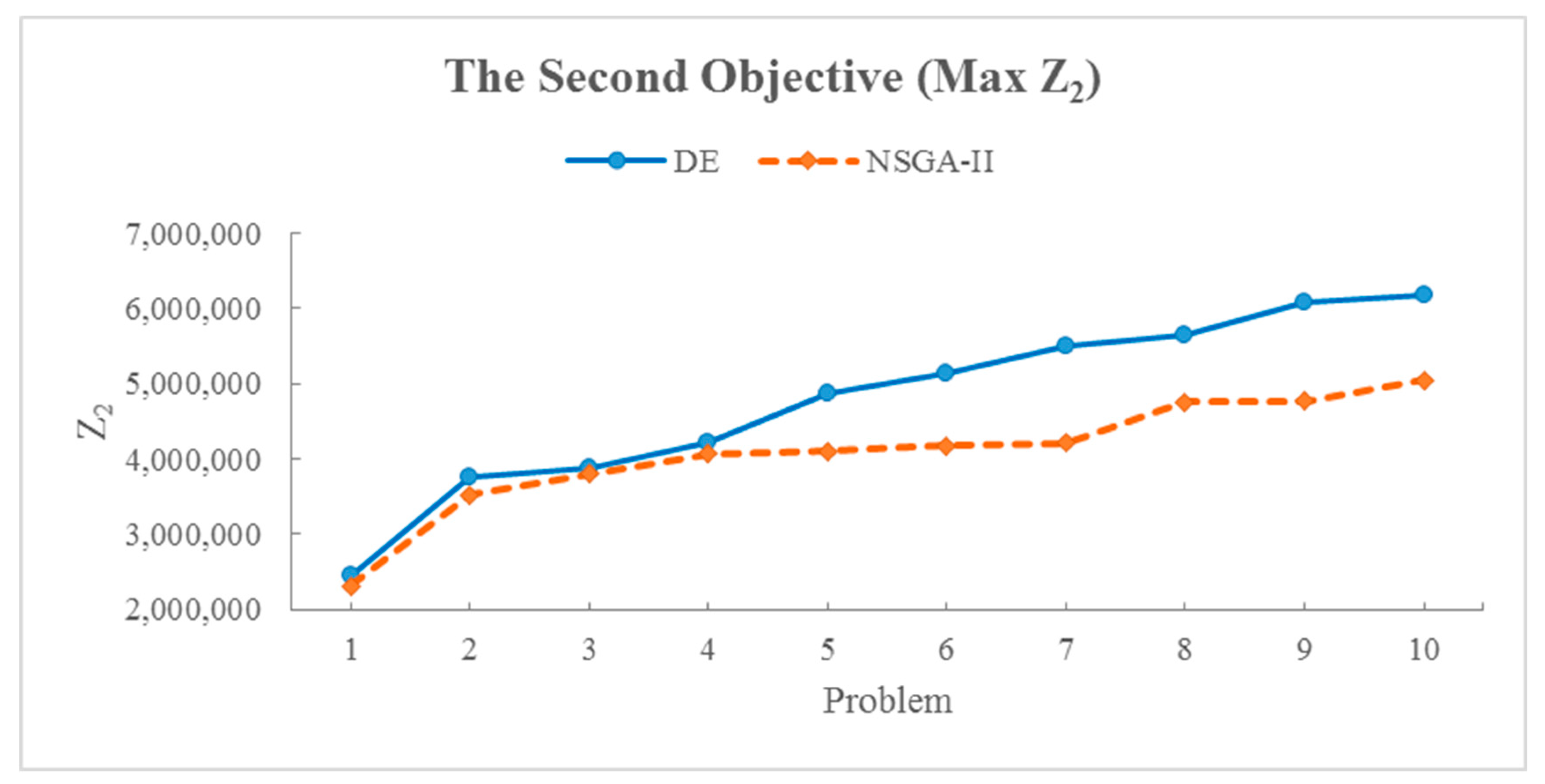

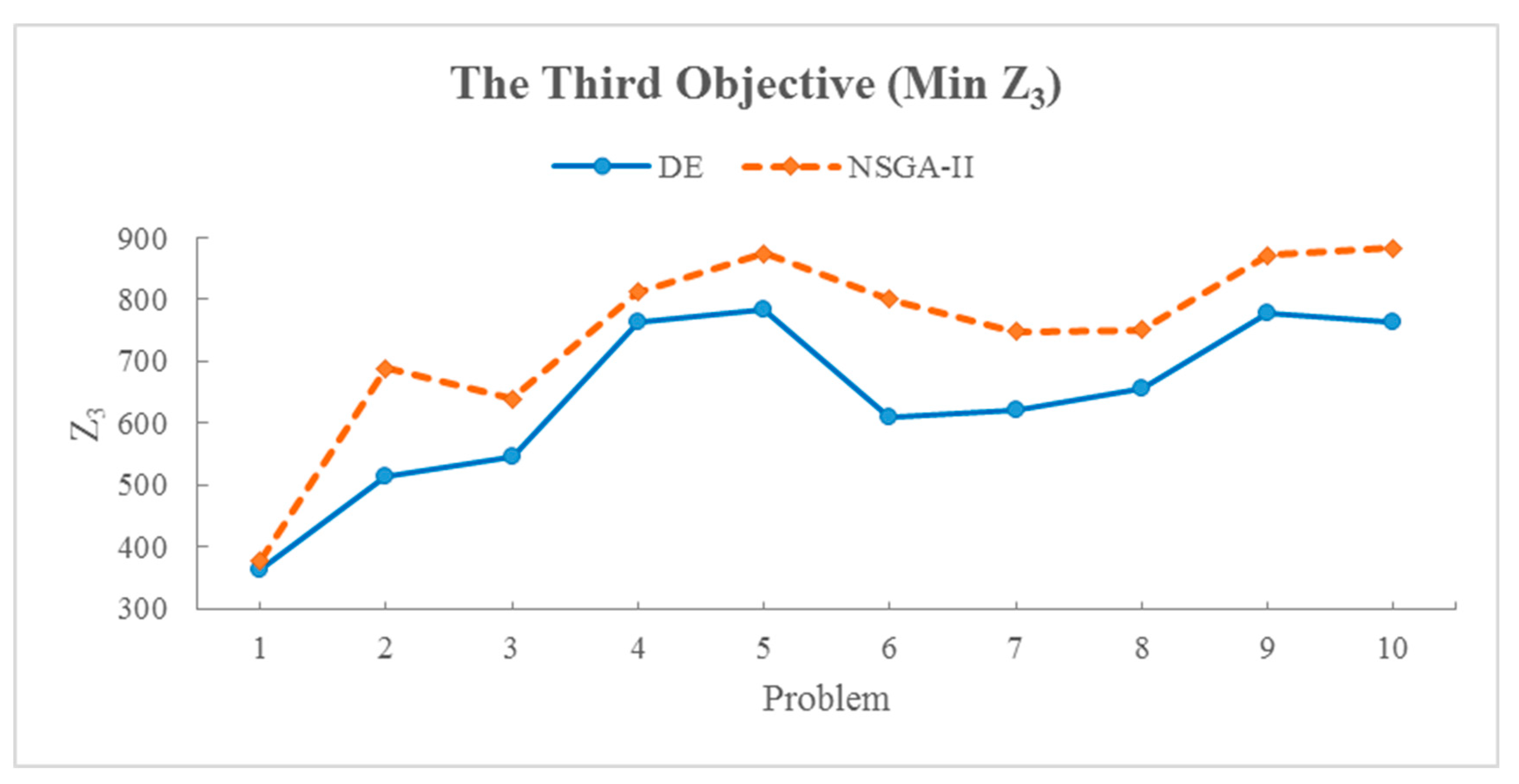

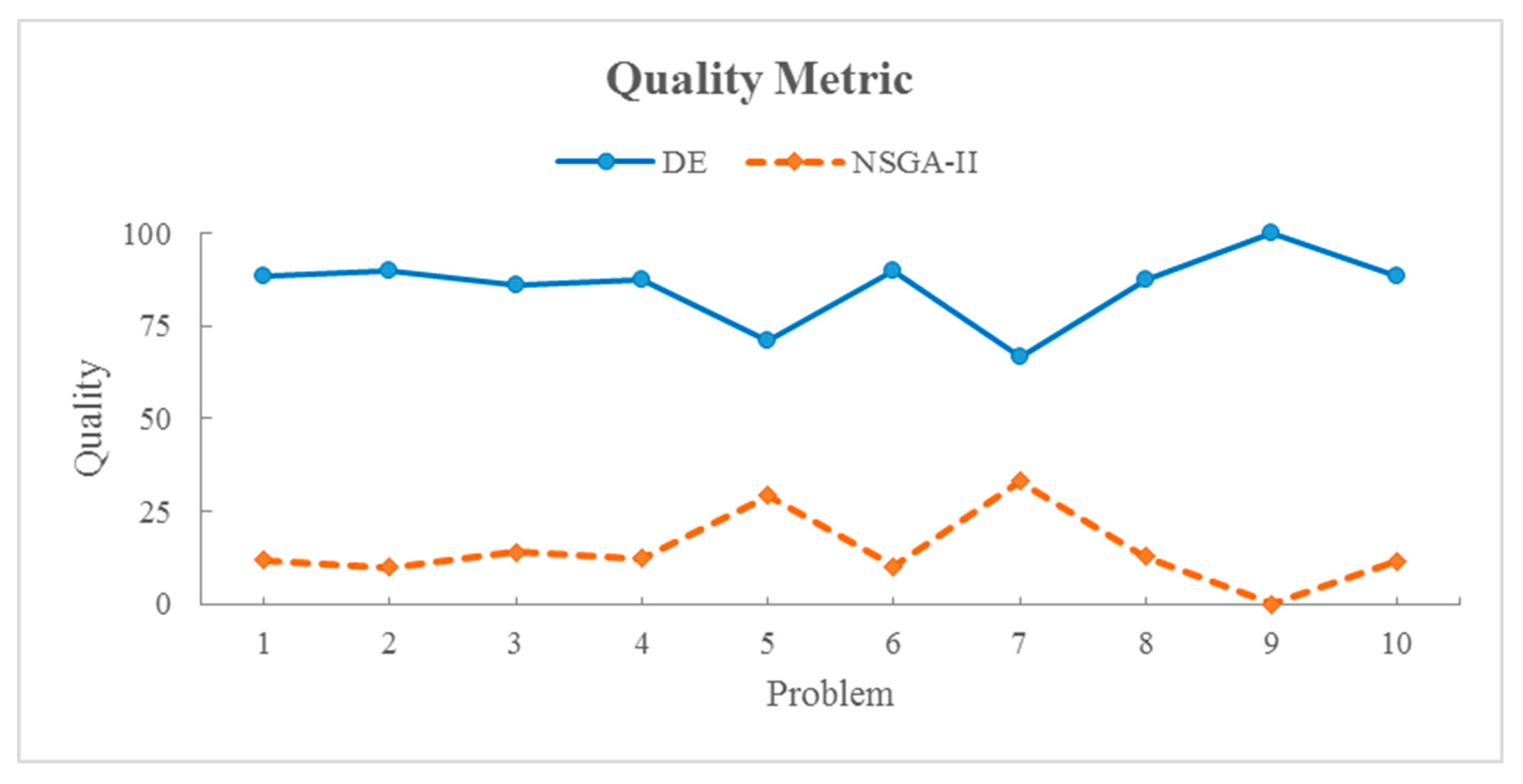

5.2.2. Solving Random Sample Problems

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Afruzi, E.N.; Aghaie, A.; Najafi, A.A. Robust Optimization for the Resource Constrained Multi-Project Scheduling Problem with Uncertain Activity Durations. Sci. Iran. 2020, 27, 361–376. [Google Scholar] [CrossRef]

- Lova, A.; Tormos, P. Analysis of Scheduling Schemes and Heuristic Rules Performance in Resource-Constrained Multiproject Scheduling. Ann. Oper. Res. 2001, 102, 263–286. [Google Scholar] [CrossRef]

- Pritsker, A.A.B.; Waiters, L.J.; Wolfe, P.M. Multiproject scheduling with limited resources: A zero-one programming approach. Manag. Sci. 1969, 16, 93–108. [Google Scholar] [CrossRef] [Green Version]

- Asadujjaman; Rahman, H.F.; Chakrabortty, R.K.; Ryan, M.J. Resource constrained project scheduling and material ordering problem with discounted cash flows. Comput. Ind. Eng. 2021, 158, 107427. [Google Scholar] [CrossRef]

- Qazi, A.; Shamayleh, A.; El-Sayegh, S.; Formaneck, S. Prioritizing risks in sustainable construction projects using a risk matrix-based Monte Carlo Simulation approach. Sustain. Cities Soc. 2020, 65, 102576. [Google Scholar] [CrossRef]

- Armenia, S.; Dangelico, R.M.; Nonino, F.; Pompei, A. Sustainable project management: A conceptualization-oriented review and a framework proposal for future studies. Sustainability 2019, 11, 2664. [Google Scholar] [CrossRef] [Green Version]

- Habibi, F.; Barzinpour, F.; Sadjadi, S.J. A mathematical model for project scheduling and material ordering problem with sustainability considerations: A case study in Iran. Comput. Ind. Eng. 2019, 128, 690–710. [Google Scholar] [CrossRef]

- RezaHoseini, A.; Noori, S.; Ghannadpour, S.F. Integrated scheduling of suppliers and multi-project activities for green construction supply chains under uncertainty. Autom. Constr. 2021, 122, 103485. [Google Scholar] [CrossRef]

- Fan, W.; Xiao, F. A New Conflict Management in Evidence Theory Based on DEMATEL Method. J. Sens. 2019, 2019, 7145373. [Google Scholar] [CrossRef] [Green Version]

- Le, H.Q. Resource-Constrained Multi-Project Scheduling with Resource Moving Time for Construction Projects in Vietnam. In Proceedings of the First International Conference on Construction in Developing Countries (ICCIDC–I), Karachi, Pakistan, 4–5 August 2008. [Google Scholar]

- Tseng, C.C. Two heuristic algorithms for a multi-mode resource-constrained multi-project scheduling problem. J. Sci. Eng. Technol. 2008, 4, 63–74. [Google Scholar]

- Browning, T.R.; Yassine, A.A. Resource-constrained multi-project scheduling: Priority rule performance revisited. Int. J. Prod. Econ. 2010, 126, 212–228. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, R. An improvement of resource-constrained multi-project scheduling model based on priority-rule based heuristics. In Proceedings of the ICSSSM11, Tianjin, China, 25–27 June 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 1–5. [Google Scholar]

- Liu, S.S.; Chen, W.T. Construction multi-project scheduling model considering different resource allocation behavior. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2012; Volume 174, pp. 2815–2819. [Google Scholar]

- Singh, A. Resource Constrained Multi-project Scheduling with Priority Rules & Analytic Hierarchy Process. Procedia Eng. 2014, 69, 725–734. [Google Scholar] [CrossRef]

- Suresh, M.; Dutta, P.; Jain, K. Resource constrained multi-project scheduling problem with resource transfer times. Asia-Pac. J. Oper. Res. 2015, 32, 1550048. [Google Scholar] [CrossRef]

- El-Abbasy, M.S.; Elazouni, A.; Zayed, T. MOSCOPEA: Multi-objective construction scheduling optimization using elitist non-dominated sorting genetic algorithm. Autom. Constr. 2016, 71, 153–170. [Google Scholar] [CrossRef]

- Pinha, D.; Ahluwalia, R.; Senna, P. The Combinatorial Multi-Mode Resource Constrained Multi-Project Scheduling Problem. Int. J. Supply Oper. Manag. 2016, 3, 1391–1412. [Google Scholar] [CrossRef]

- Joo, B.J.; Chua, P.C. Multimode resource-constrained multi-project scheduling with ad hoc activity splitting. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 2261–2265. [Google Scholar]

- Rostami, M.; Bagherpour, M.; Mazdeh, M.M.; Makui, A. Resource pool location for periodic services in decentralized multi-project scheduling problems. J. Comput. Civ. Eng. 2017, 31, 04017022. [Google Scholar] [CrossRef]

- Li, F.; Xu, Z. A multi-agent system for distributed multi-project scheduling with two-stage decomposition. PLoS ONE 2018, 13, e0205445. [Google Scholar] [CrossRef]

- Shafahi, A.; Haghani, A. Project selection and scheduling for phase-able projects with interdependencies among phases. Autom. Constr. 2018, 93, 47–62. [Google Scholar] [CrossRef]

- Birjandi, A.; Mousavi, S.M. Fuzzy resource-constrained project scheduling with multiple routes: A heuristic solution. Autom. Constr. 2019, 100, 84–102. [Google Scholar] [CrossRef]

- García-Nieves, J.D.; Ponz-Tienda, J.L.; Ospina-Alvarado, A.; Bonilla-Palacios, M. Multipurpose linear programming optimization model for repetitive activities scheduling in construction projects. Autom. Constr. 2019, 105, 102799. [Google Scholar] [CrossRef]

- Zou, X.; Zhang, L. A constraint programming approach for scheduling repetitive projects with atypical activities considering soft logic. Autom. Constr. 2020, 109, 102990. [Google Scholar] [CrossRef]

- Rahman, H.F.; Chakrabortty, R.K.; Ryan, M.J. Memetic algorithm for solving resource constrained project scheduling problems. Autom. Constr. 2019, 111, 103052. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, N. Project scheduling and material ordering problem with storage space constraints. Autom. Constr. 2021, 129, 103796. [Google Scholar] [CrossRef]

- El-Alfy, A.E.D. Design of sustainable buildings through Value Engineering. J. Build. Apprais. 2010, 6, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Hwang, B.-G.; Leong, L.P.; Huh, Y.-K. Sustainable green construction management: Schedule performance and improvement. Technol. Econ. Dev. Econ. 2014, 19, S43–S57. [Google Scholar] [CrossRef] [Green Version]

- Ali, F.; Boks, C.; Bey, N. Design for Sustainability and Project Management Literature—A Review. Procedia CIRP 2016, 48, 28–33. [Google Scholar] [CrossRef] [Green Version]

- Mahmoudi, R.; Alinaghian, M.; Mogouie, H. A mathematical model for sustainable probabilistic network design problem with construction scheduling considering social and environmental issues. J. Ind. Syst. Eng. 2017, 10, 17–37. [Google Scholar]

- Wang, W.; Chen, J.; Liu, Q.; Guo, Z. Green Project Planning with Realistic Multi-Objective Consideration in Developing Sustainable Port. Sustainability 2018, 10, 2385. [Google Scholar] [CrossRef] [Green Version]

- Mahmoudi, R.; Shetab-Boushehri, S.N.; Hejazi, S.R.; Emrouznejad, A.; Rajabi, P. A hybrid egalitarian bar-gaining game-DEA and sustainable network design approach for evaluating, selecting and scheduling urban road construction projects. Transp. Res. Part E: Logist. Transp. Rev. 2019, 130, 161–183. [Google Scholar] [CrossRef]

- Khayamim, R.; Shetab-Boushehrib, S.N.; Hosseininasab, S.M.; Karimi, H. A sustainable approach for selecting and timing the urban transportation infrastructure projects in large-scale networks: A case study of Isfahan, Iran. Sustain. Cities Soc. 2020, 53, 101981. [Google Scholar] [CrossRef]

- Askarifard, M.; Abbasianjahromi, H.; Sepehri, M.; Zeighami, E. A robust multi-objective optimization model for project scheduling considering risk and sustainable development criteria. Environ. Dev. Sustain. 2021, 23, 11494–11524. [Google Scholar] [CrossRef]

- Khandelwal, M.; Marto, A.; Fatemi, S.A.; Ghoroqi, M.; Armaghani, D.J.; Singh, T.N.; Tabrizi, O. Implementing an ANN model optimized by genetic algorithm for estimating cohesion of limestone samples. Eng. Comput. 2018, 34, 307–317. [Google Scholar] [CrossRef]

- Shahnazar, A.; Rad, H.N.; Hasanipanah, M.; Tahir, M.M.; Armaghani, D.J.; Ghoroqi, M. A new developed approach for the prediction of ground vibration using a hybrid PSO-optimized ANFIS-based model. Environ. Earth Sci. 2017, 76, 527. [Google Scholar] [CrossRef]

- Mojtahedi, S.F.F.; Tabatabaee, S.; Ghoroqi, M.; Soltani Tehrani, M.; Gordan, B.; Ghoroqi, M. A novel probabilistic simulation approach for forecasting the safety factor of slopes: A case study. Eng. Comput. 2019, 35, 637–646. [Google Scholar] [CrossRef]

- Aczél, J.; Forte, B.; Ng, C.T. Why the Shannon and Hartley entropies are ‘natural’. Adv. Appl. Probab. 1974, 6, 131–146. [Google Scholar] [CrossRef]

- Dubois, D.J. Fuzzy Sets and Systems: Theory and Applications; Academic Press: Cambridge, MA, USA, 1980; Volume 144. [Google Scholar]

- Zadeh, L.A. Probability measures of fuzzy events. J. Math. Anal. Appl. 1968, 23, 421–427. [Google Scholar] [CrossRef] [Green Version]

- Dubois, D.; Prade, H. Properties of measures of information in evidence and possibility theories. Fuzzy Sets Syst. 1987, 24, 161–182. [Google Scholar] [CrossRef]

- Shafer, G. A Mathematical Theory of Evidence; Princeton University Press: Princeton, NJ, USA, 1976; Volume 42. [Google Scholar]

- Nguyen, H.T. On entropy of random sets and possibility distributions. Anal. Fuzzy Inf. 1987, 1, 145–156. [Google Scholar]

- Klement, E.P. Fuzzy σ-algebras and fuzzy measurable functions. Fuzzy Sets Syst. 1980, 4, 83–93. [Google Scholar] [CrossRef]

- Huynh, V.N. Discounting and Combination Scheme in Evidence Theory for Dealing with Conflict in Information Fusion. In Proceedings of the MDAI, Perpignan, Japan, 30 November–2 December 2009; pp. 217–230. [Google Scholar]

- Choi, H.; Katake, A.; Choi, S.; Kang, Y.; Choe, Y. Probabilistic combination of multiple evidence. In Proceedings of the Neural Information Processing: 16th International Conference, ICONIP 2009, Bangkok, Thailand, 1–5 December 2009; Proceedings, Part I 16. Springer: Berlin/Heidelberg, Germany, 2009; pp. 302–311. [Google Scholar]

- Kay, R.U. Fundamentals of the Dempster-Shafer theory and its applications to system safety and reliability modelling. Reliab. Theory Appl. 2007, 2, 173–185. [Google Scholar]

- Challa, S.; Koks, D. Bayesian and Dempster-Shafer fusion. Sadhana 2004, 29, 145–174. [Google Scholar] [CrossRef]

- Zhang, D.; Guo, M.; Zhou, J.; Kang, D.; Cao, J. Context reasoning using extended evidence theory in pervasive computing environments. Future Gener. Comput. Syst. 2010, 26, 207–216. [Google Scholar] [CrossRef]

- Nassreddine, G.; Abdallah, F.; Denoux, T. State estimation using interval analysis and belief-function theory: Application to dynamic vehicle localization. IEEE Trans. Syst. Man Cybern. Part B (Cybern.) 2009, 40, 1205–1218. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yager, R.R. Arithmetic and other operations on Dempster-Shafer structures. Int. J. Man-Mach. Stud. 1986, 25, 357–366. [Google Scholar] [CrossRef]

- Masri, H.; Abdelaziz, F.B. Belief linear programming. Int. J. Approx. Reason. 2010, 51, 973–983. [Google Scholar] [CrossRef] [Green Version]

- Sungur, I.; Ordóñez, F.; Dessouky, M. A robust optimization approach for the capacitated vehicle routing problem with demand uncertainty. IIE Trans. 2008, 40, 509–523. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential evolution–A simple and efficient heuristic for global optimization over continuous spaces. J. Glob. Optim. 1997, 11, 341. [Google Scholar] [CrossRef]

- Möhring, R.H.; Schäffter, M.W. Scheduling series-parallel orders subject to 0/1-communication delays. Parallel Comput. 1999, 25, 23–40. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef] [Green Version]

- Tavakkoli-Moghaddam, R.; Azarkish, M.; Sadeghnejad-Barkousaraie, A. A new hybrid multi-objective Pareto archive PSO algorithm for a bi-objective job shop scheduling problem. Expert Syst. Appl. 2011, 38, 10812–10821. [Google Scholar] [CrossRef]

| Works and References | Single Project | Multi-Project | Single Objective | Multi-Objective | Supplier and Ordering | Project Selection | Transportation Time | Risk Factor | Competition Factor | Organization Factor | Sustainability | Interest Rate | Discount Factor | Carbon Penalty | Evidence Theory |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nabipoor Afruzi et al. [1] | ✓ | ✓ | |||||||||||||

| Habibi et al. [7] | ✓ | ✓ | ✓ | ✓ | |||||||||||

| RezaHoseini et al. [8] | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||

| Le [10] | ✓ | ✓ | |||||||||||||

| Tseng [11] | ✓ | ✓ | |||||||||||||

| Browning and Yassine [12] | ✓ | ✓ | |||||||||||||

| Zhang and Sun [13] | ✓ | ✓ | |||||||||||||

| Liu and Chen [14] | ✓ | ✓ | |||||||||||||

| Singh [15] | ✓ | ✓ | |||||||||||||

| Suresh et al. [16] | ✓ | ✓ | ✓ | ||||||||||||

| El-Abbasy et al. [17] | ✓ | ✓ | |||||||||||||

| Pinha et al. [18] | ✓ | ✓ | |||||||||||||

| Joo and Chua [19] | ✓ | ✓ | |||||||||||||

| Rostami et al. [20] | ✓ | ✓ | |||||||||||||

| Li and Xu [21] | ✓ | ✓ | |||||||||||||

| Shafahi and Haghani [22] | ✓ | ✓ | ✓ | ||||||||||||

| Birjandi and Mousavi [23] | ✓ | ✓ | |||||||||||||

| Garcia-Nieves et al. [24] | ✓ | ✓ | |||||||||||||

| Zou and Zhang [25] | ✓ | ✓ | |||||||||||||

| Rahman et al. [26] | ✓ | ✓ | |||||||||||||

| Zhang and Cui [27] | ✓ | ✓ | ✓ | ||||||||||||

| El-Alfy [28] | ✓ | ||||||||||||||

| Hwang et al. [29] | ✓ | ||||||||||||||

| Ali et al. [30] | ✓ | ||||||||||||||

| Mahmoudi et al. [31] | ✓ | ✓ | ✓ | ||||||||||||

| Wang et al. [32] | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||

| Mahmoudi et al. [33] | ✓ | ✓ | ✓ | ✓ | |||||||||||

| Khayamim et al. [34] | ✓ | ✓ | ✓ | ✓ | |||||||||||

| Askarifard et al. [35] | ✓ | ✓ | ✓ | ✓ | |||||||||||

| Current Research | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Symbol | Description |

|---|---|

| Projects | |

| Project activities | |

| Number of activities for the project j | |

| Suppliers | |

| Non-renewable resource | |

| Renewable resource | |

| Number of available implementation modes (m) | |

| Time () |

| Symbol | Description |

|---|---|

| Set of activities for the project j | |

| Set of all the activities | |

| Set of non-renewable resources required by activity i of the project j | |

| Set of non-renewable resources required by the project j | |

| Set of all the non-renewable resources | |

| Set of suppliers for the non-renewable resource k | |

| Set of all suppliers for the non-renewable resources | |

| Set of renewable resources for the project j | |

| Set of activities in project j that require a renewable resource l | |

| Set of prerequisite constraints for activities in the project j (The activity must be completed before the activity .) | |

| The required number of the resource k to complete activity i of project j in the implementation mode m | |

| The processing time of activity i of project j in the implementation mode m | |

| The delivery date of project j to complete all activities and examinations | |

| The time of transportation from supplier s to project j(In the units of time, such as days) | |

| The time of release supplier s | |

| The amount requested from the non-renewable resource k to complete all activities in the project j | |

| The capacity of the supplier s | |

| The review duration of the project j | |

| The total budget for the purchase of non-renewable resources | |

| The weight and relative importance of the project j to reach its due date | |

| The earliest start time of activity i of the project j | |

| The latest start time of activity i of the project j | |

| The earliest finish time of activity i of the project j | |

| The latest finish time of activity i of the project j | |

| The incomes dependent on activity i of the project j in mode m | |

| The expenses dependent on activity i of the project j in mode m | |

| The interest rate | |

| The future value of money under discount factor based on interest rate in each period of times | |

| The cost of implementation for activity i of the project j in mode m | |

| The cost of holding and maintaining the resource k in the day | |

| The employment score of the project j | |

| The local development score of the project j | |

| The score of complying with the safety principles of the project j | |

| The score of complying with the environmental preservation of the project j | |

| The organization score of the project j | |

| The competitive score of the project j | |

| The amount of emission of polluting gases resulting from the production and transportation of materials by supplier s for the project j | |

| Maximum permissible pollution for suppliers(The government and rules determine it.) | |

| The amount of tax discount (ρ ≤ 0, which means if the required conditions be as , a tax discount will be received amount of monetary units.) | |

| The amount of risk of delay in the delivery of materials by the supplier s for the project j | |

| The amount of risk of defective, low quality, and non-green materials and equipment by the supplier s for the project j | |

| The amount of risk caused by natural disasters for the supplier s | |

| The amount of liquidity and financial risk for the supplier s |

| Symbol and Description |

|---|

| : The start time of activity i of the project j |

| : The completion time of activity i of the project j |

| : The completion time of the project j |

| : The amount of transportation from supplier s to project j |

| : The due time for examination of project j (DT0 indicates the earliest examination start time) |

| : The delay of project j |

| : The inventory level of resource k in the period t |

| : The time value of income from the implementation of the activity |

| : The time value of cost from the implementation of the activity |

| : The time value for the implementation of activity in mode m |

| : The time value of cost for maintenance of resources |

| : The penalty for delay in projects |

| Objectives | Company | DE | NSGA-II | Improvement by DE | Improvement by NSGA-II |

|---|---|---|---|---|---|

| The first objective function | 2.87 | 3.67 | 3.13 | 27.8% | 9.0% |

| The second objective function | 461,507 | 532,191 | 506,489 | 15.3% | 9.7% |

| The third objective function | 409.5 | 354.8 | 389.7 | 13.3% | 4.8% |

| No. | Problem J/I/S/L/K | Multi-Objective Optimization Algorithms | |||||

|---|---|---|---|---|---|---|---|

| DE | NSGA-II | ||||||

| Z1 | Z2 | Z3 | Z1 | Z2 | Z3 | ||

| 1 | 10/10/3/3/3 | 6.6 | 2,461,507.1 | 361.8 | 5.0 | 2,311,212.9 | 378.2 |

| 2 | 10/10/5/3/3 | 6.7 | 3,751,235.1 | 515.1 | 5.6 | 3,526,973.8 | 687.9 |

| 3 | 15/10/3/3/3 | 8.1 | 3,866,516.7 | 547.1 | 7.5 | 3,796,087.3 | 638.5 |

| 4 | 15/10/5/3/3 | 9.7 | 4,210,047.2 | 763.4 | 8.9 | 4,059,576.1 | 811.6 |

| 5 | 20/10/5/3/3 | 16.9 | 4,865,074.1 | 782.2 | 15.3 | 4,107,462.6 | 874.3 |

| 6 | 20/10/10/3/3 | 15.2 | 5,135,227.1 | 610.4 | 14.6 | 4,179,287.8 | 800.3 |

| 7 | 25/10/5/3/3 | 15.4 | 5,500,734.3 | 622.3 | 13.5 | 4,216,197.8 | 748.2 |

| 8 | 25/10/10/3/3 | 16.8 | 5,642,828.7 | 654.7 | 14.9 | 4,757,346.1 | 751.3 |

| 9 | 30/10/5/3/3 | 17.7 | 6,082,742.3 | 777.5 | 16.2 | 4,764,090.6 | 870.7 |

| 10 | 30/10/10/3/3 | 16.9 | 6,175,004.6 | 762.7 | 15.1 | 5,038,724.2 | 882.3 |

| No. | Problem J/I/S/L/K | Multi-Objective Optimization Algorithms | |||||

|---|---|---|---|---|---|---|---|

| DE | NSGA-II | ||||||

| Quality Metric | Spacing Metric | Diversity Metric | Quality Metric | Spacing Metric | Diversity Metric | ||

| 1 | 10/10/3/3/3 | 88.1 | 1.01 | 1930.2 | 11.9 | 0.79 | 1218.4 |

| 2 | 10/10/5/3/3 | 90.0 | 0.75 | 2871.6 | 10.0 | 0.63 | 1901.6 |

| 3 | 15/10/3/3/3 | 85.9 | 1.02 | 2685.3 | 14.1 | 0.81 | 1954.2 |

| 4 | 15/10/5/3/3 | 87.6 | 1.10 | 3063.5 | 12.4 | 0.85 | 2112.5 |

| 5 | 20/10/5/3/3 | 70.9 | 0.93 | 2636.3 | 29.1 | 0.77 | 1901.9 |

| 6 | 20/10/10/3/3 | 89.9 | 0.89 | 2816.5 | 10.1 | 0.61 | 2265.1 |

| 7 | 25/10/5/3/3 | 66.8 | 1.21 | 3486.3 | 33.2 | 0.84 | 2793.6 |

| 8 | 25/10/10/3/3 | 87.2 | 1.02 | 4121.9 | 12.8 | 0.80 | 3278.6 |

| 9 | 30/10/5/3/3 | 100 | 1.11 | 4565.9 | 0 | 0.79 | 3397.7 |

| 10 | 30/10/10/3/3 | 88.4 | 1.20 | 5054.1 | 11.6 | 0.86 | 4758.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghoroqi, M.; Ghoddousi, P.; Makui, A.; Shirzadi Javid, A.A.; Talebi, S. An Integrated Model for Multi-Mode Resource-Constrained Multi-Project Scheduling Problems Considering Supply Management with Sustainable Approach in the Construction Industry under Uncertainty Using Evidence Theory and Optimization Algorithms. Buildings 2023, 13, 2023. https://doi.org/10.3390/buildings13082023

Ghoroqi M, Ghoddousi P, Makui A, Shirzadi Javid AA, Talebi S. An Integrated Model for Multi-Mode Resource-Constrained Multi-Project Scheduling Problems Considering Supply Management with Sustainable Approach in the Construction Industry under Uncertainty Using Evidence Theory and Optimization Algorithms. Buildings. 2023; 13(8):2023. https://doi.org/10.3390/buildings13082023

Chicago/Turabian StyleGhoroqi, Mahyar, Parviz Ghoddousi, Ahmad Makui, Ali Akbar Shirzadi Javid, and Saeed Talebi. 2023. "An Integrated Model for Multi-Mode Resource-Constrained Multi-Project Scheduling Problems Considering Supply Management with Sustainable Approach in the Construction Industry under Uncertainty Using Evidence Theory and Optimization Algorithms" Buildings 13, no. 8: 2023. https://doi.org/10.3390/buildings13082023

APA StyleGhoroqi, M., Ghoddousi, P., Makui, A., Shirzadi Javid, A. A., & Talebi, S. (2023). An Integrated Model for Multi-Mode Resource-Constrained Multi-Project Scheduling Problems Considering Supply Management with Sustainable Approach in the Construction Industry under Uncertainty Using Evidence Theory and Optimization Algorithms. Buildings, 13(8), 2023. https://doi.org/10.3390/buildings13082023