An Experimental Approach to Assess the Sensitivity of a Smart Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Mix Design

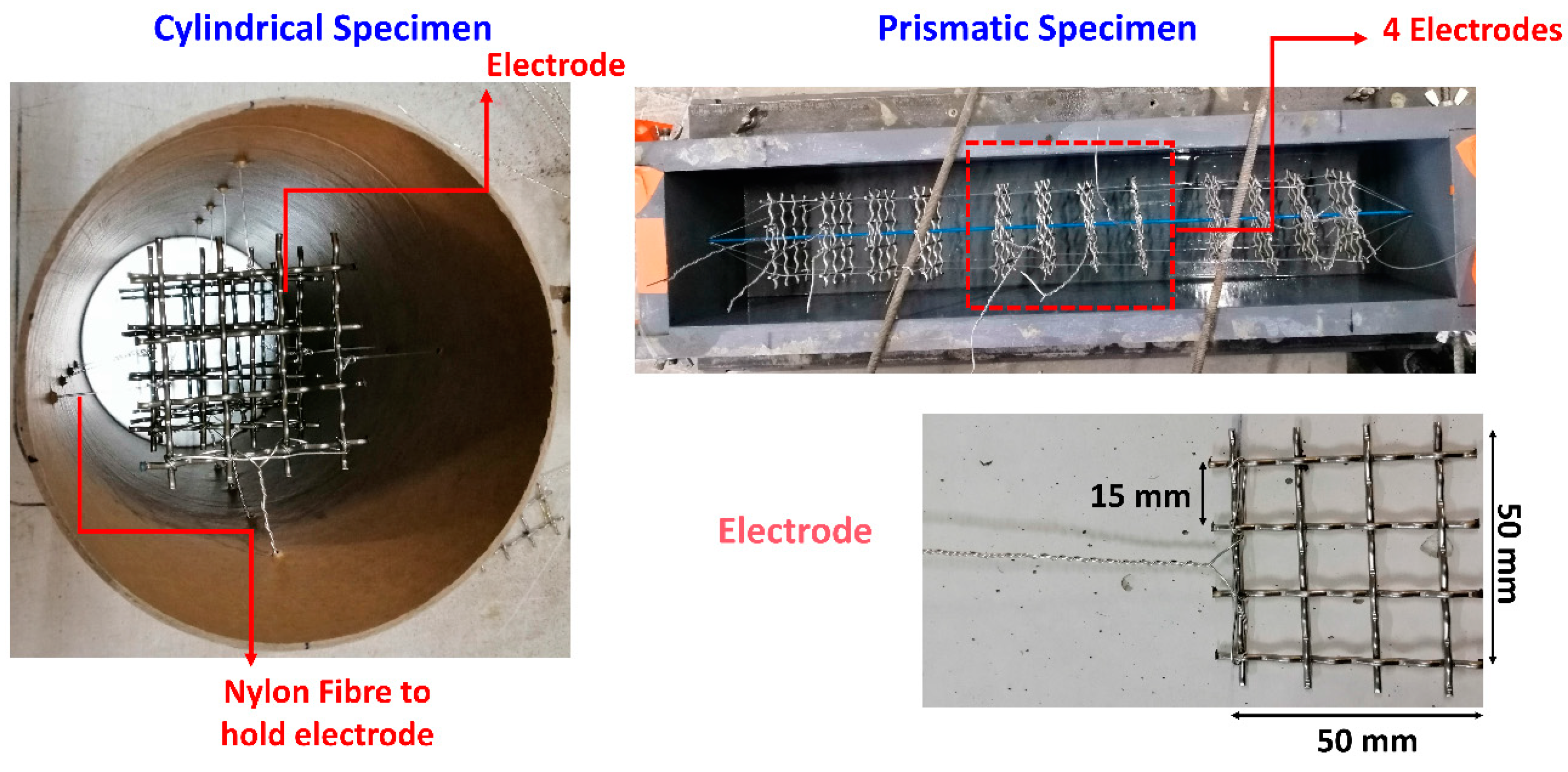

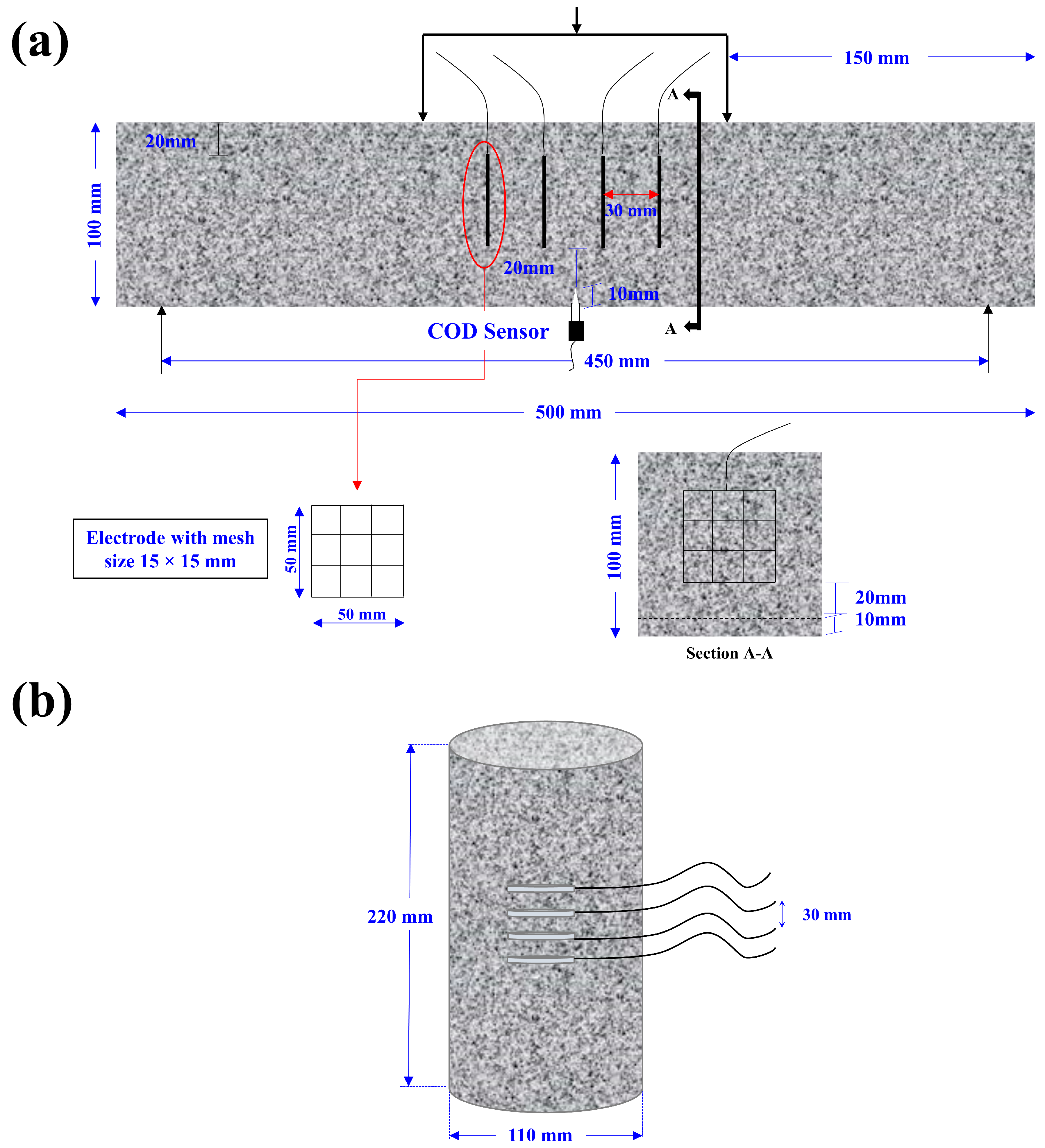

2.2. Preparation of Specimens

2.3. Testing Procedures

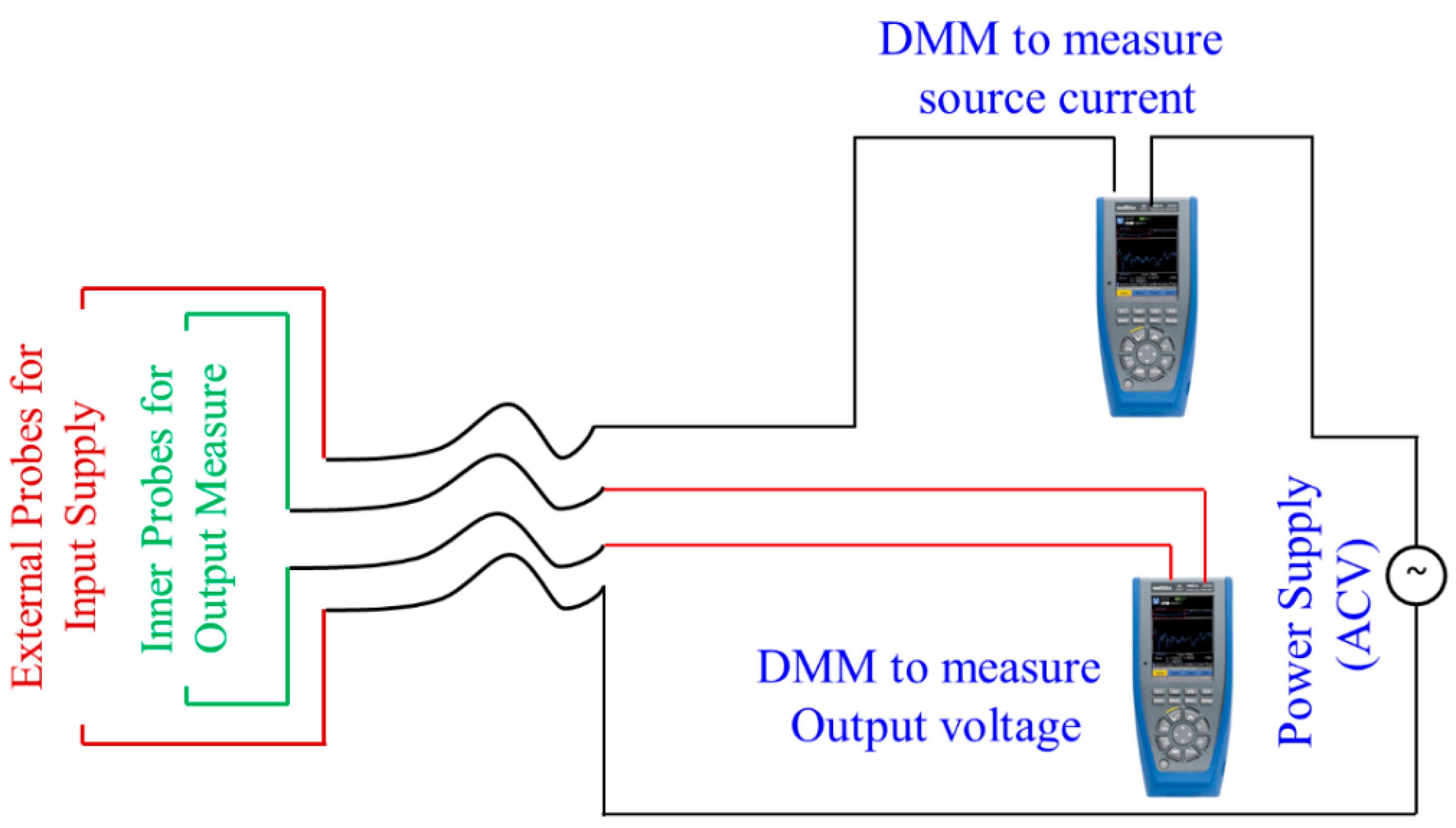

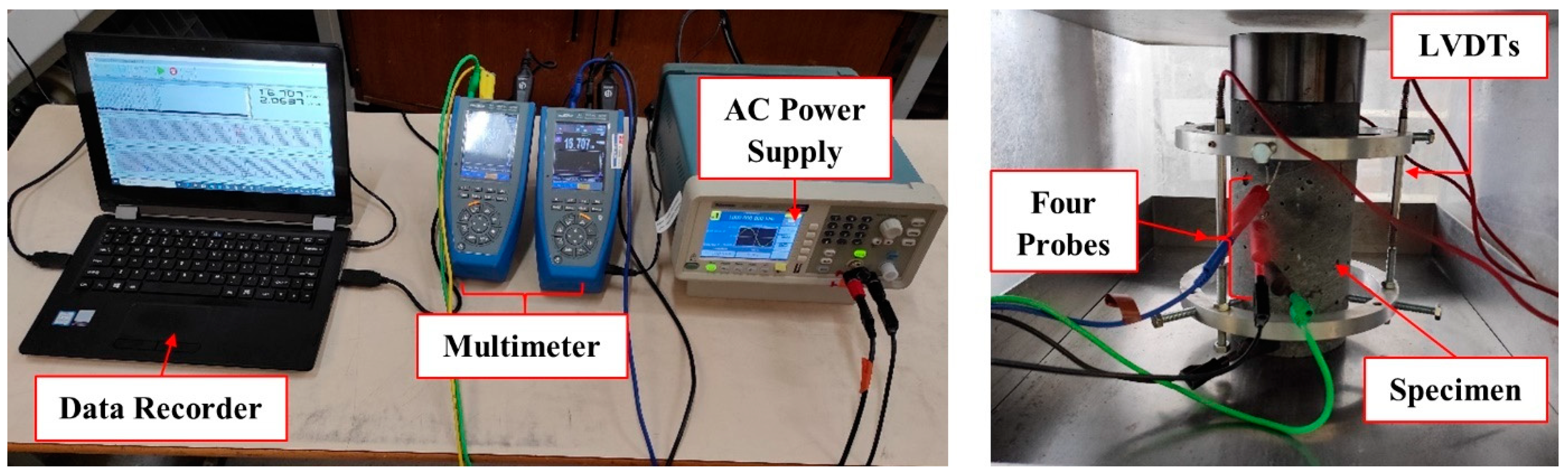

2.3.1. Four-Probe Method

2.3.2. Four-Point Bending Test

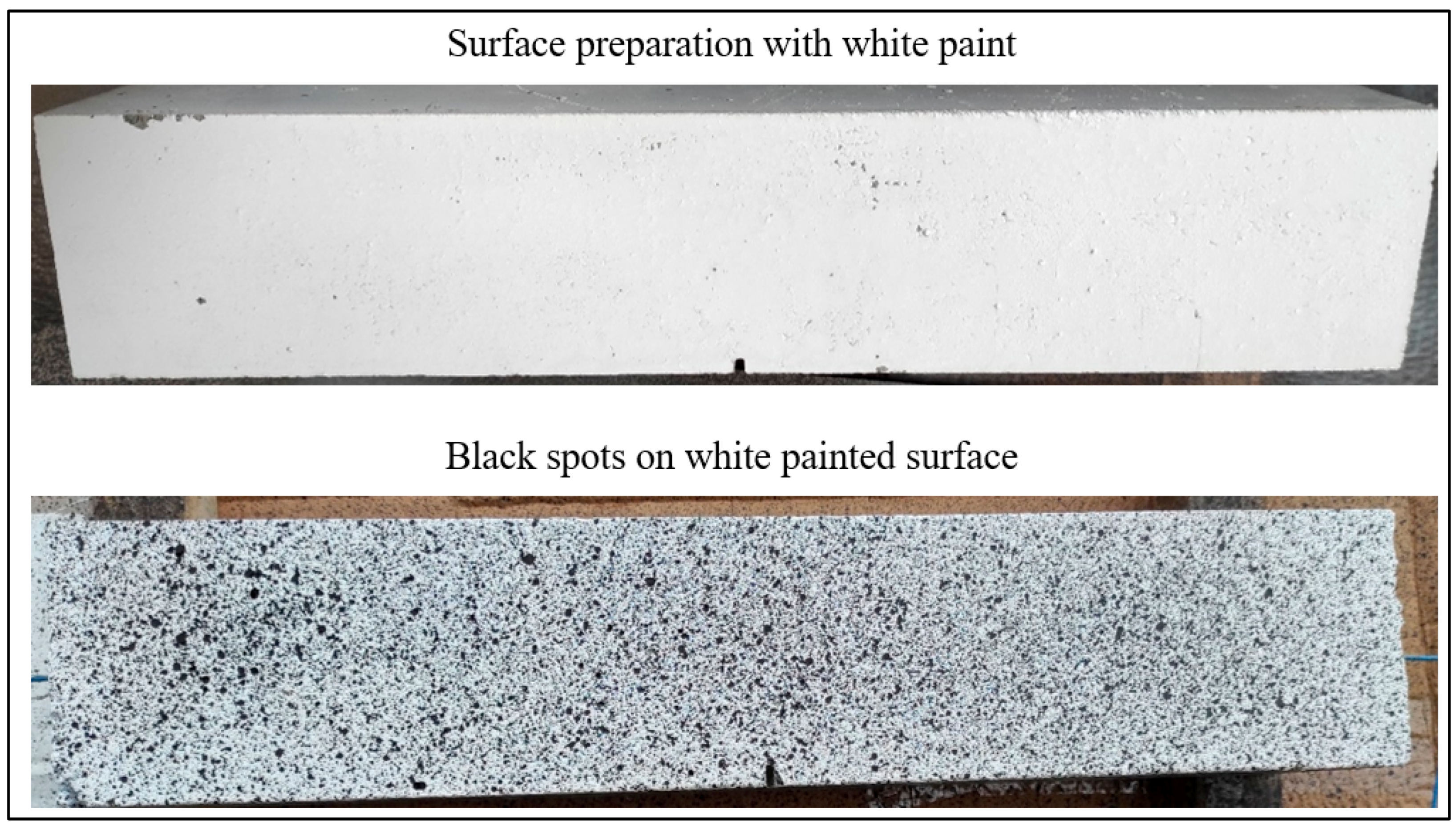

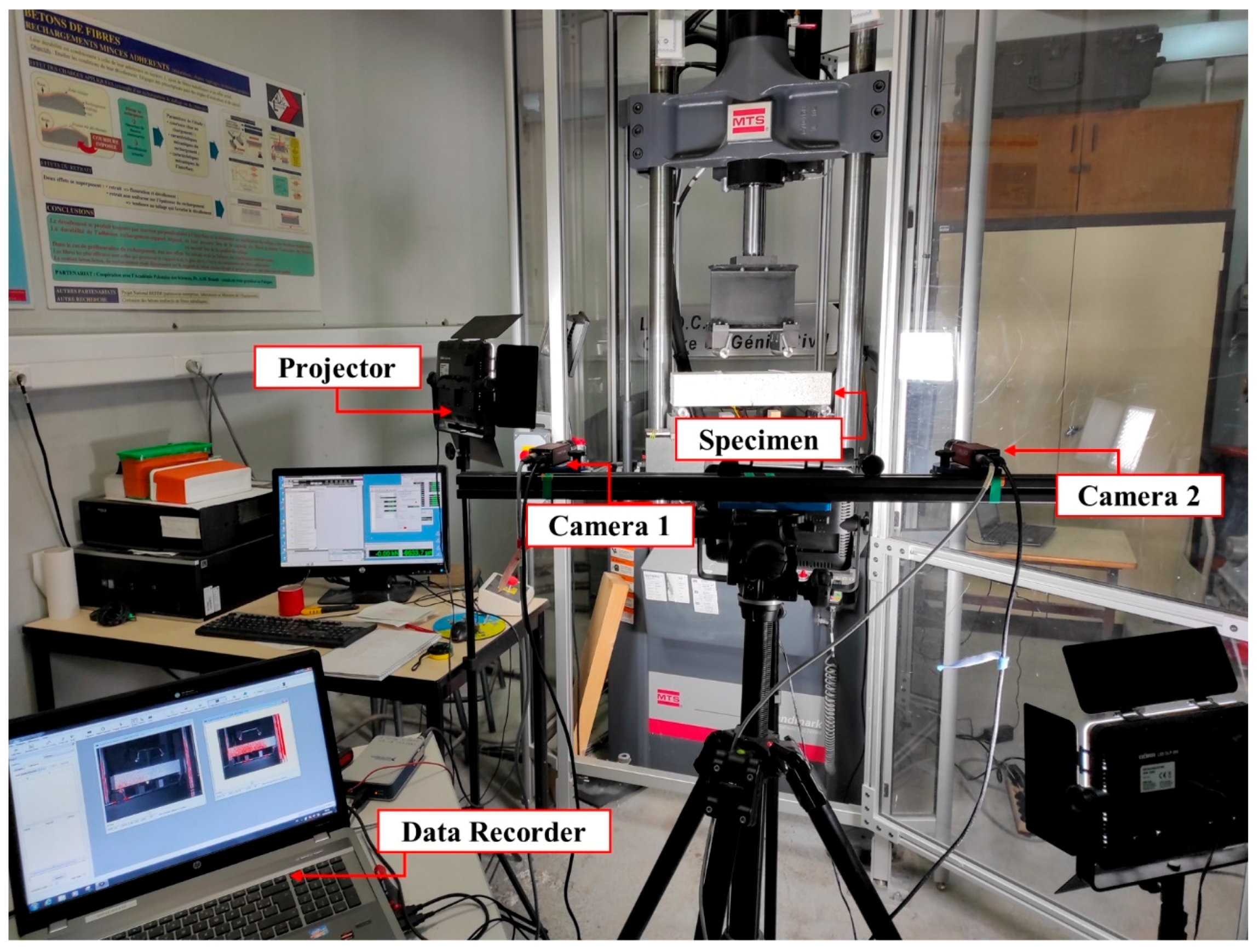

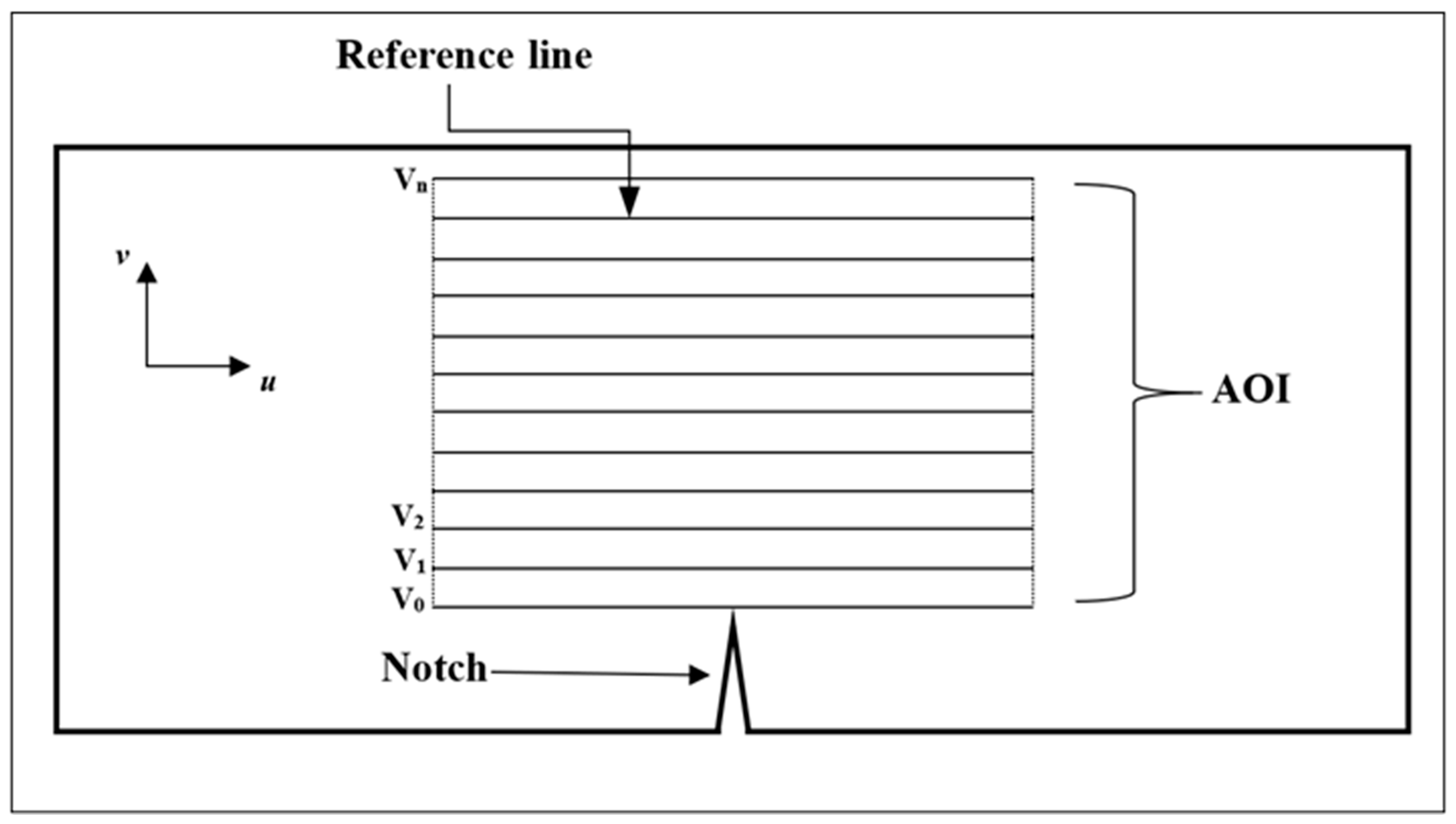

2.3.3. Digital Image Correlation (DIC)

2.3.4. Compressive Test

3. Results & Discussions

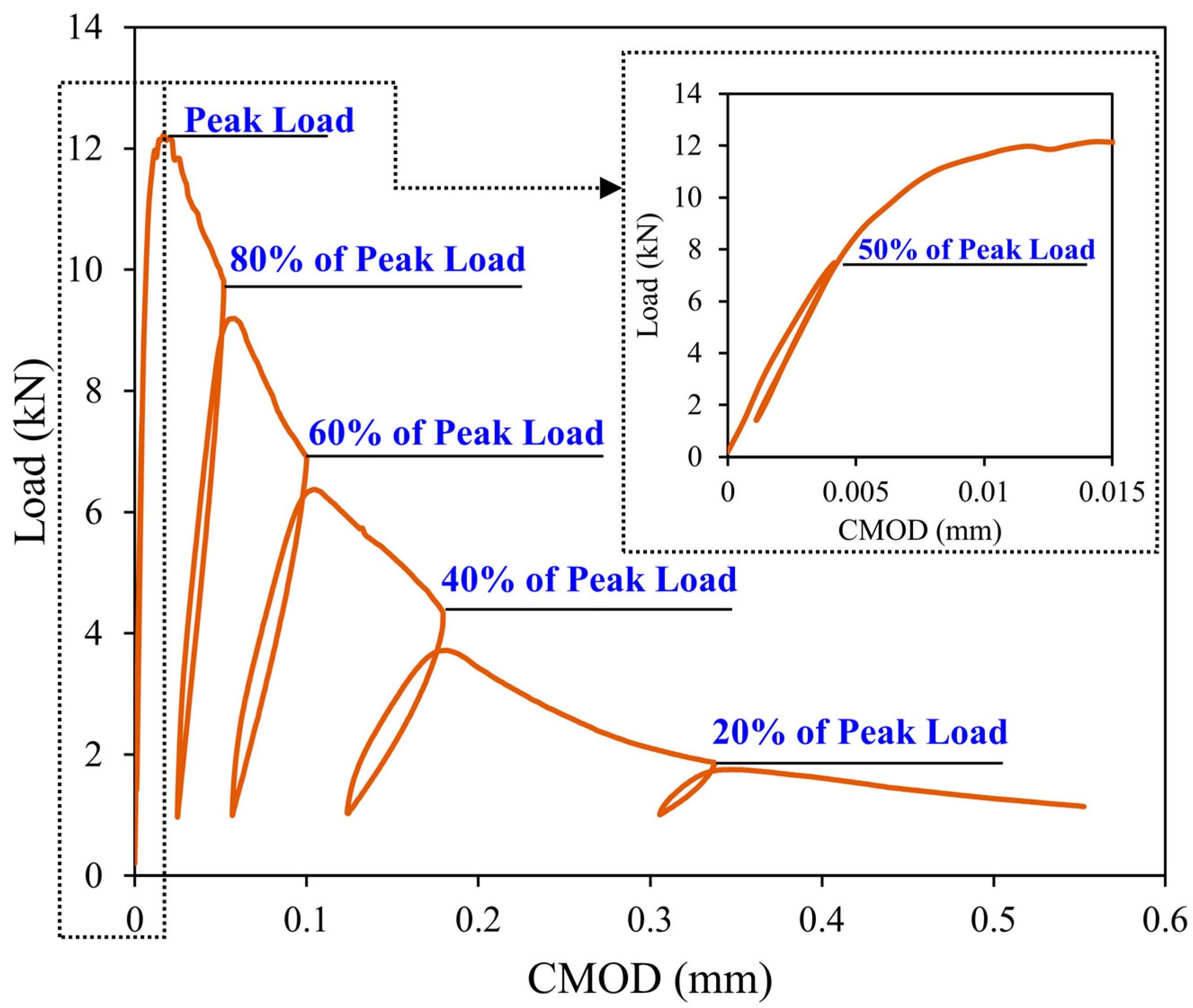

3.1. Four-Point Bending Test

3.1.1. Load versus CMOD

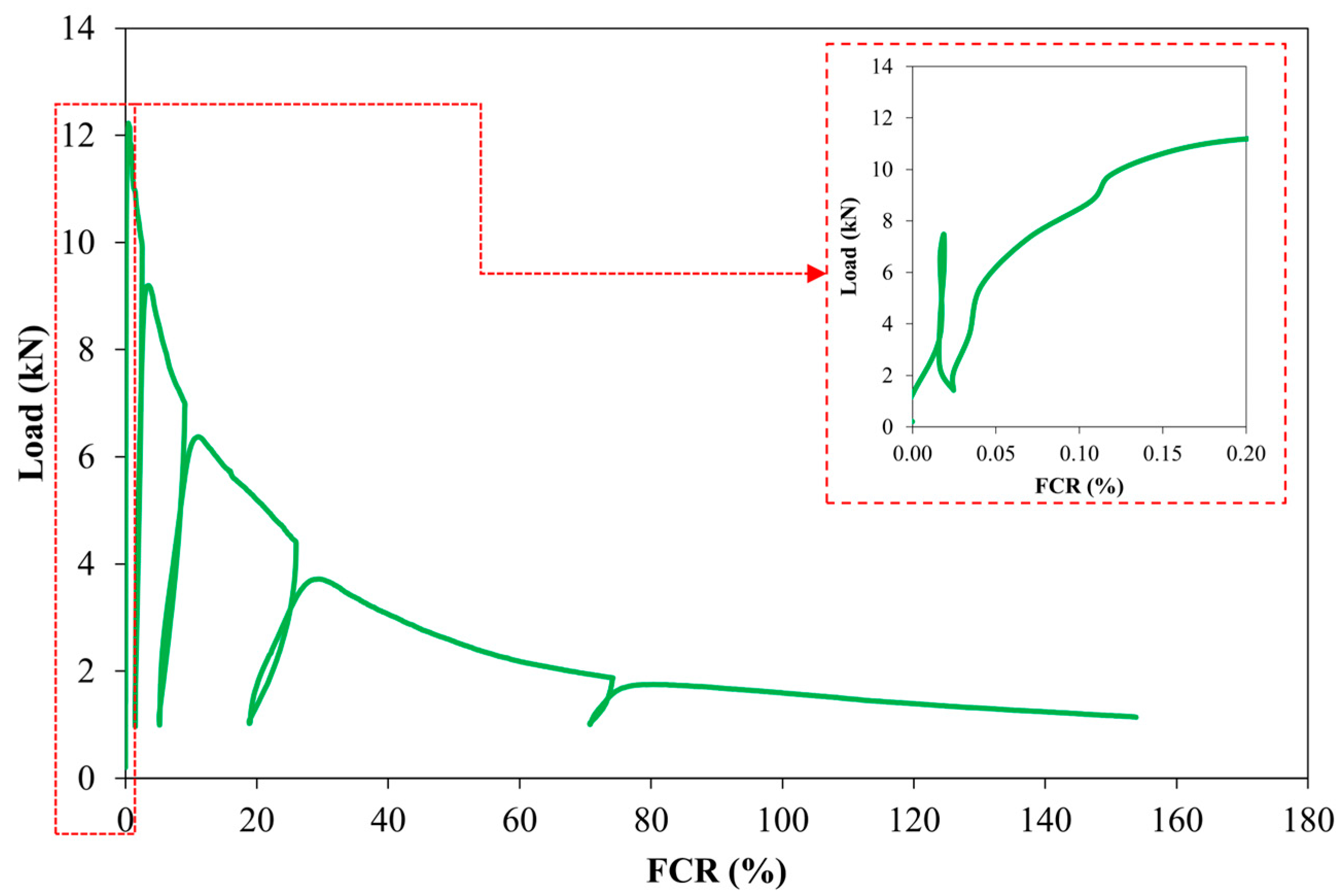

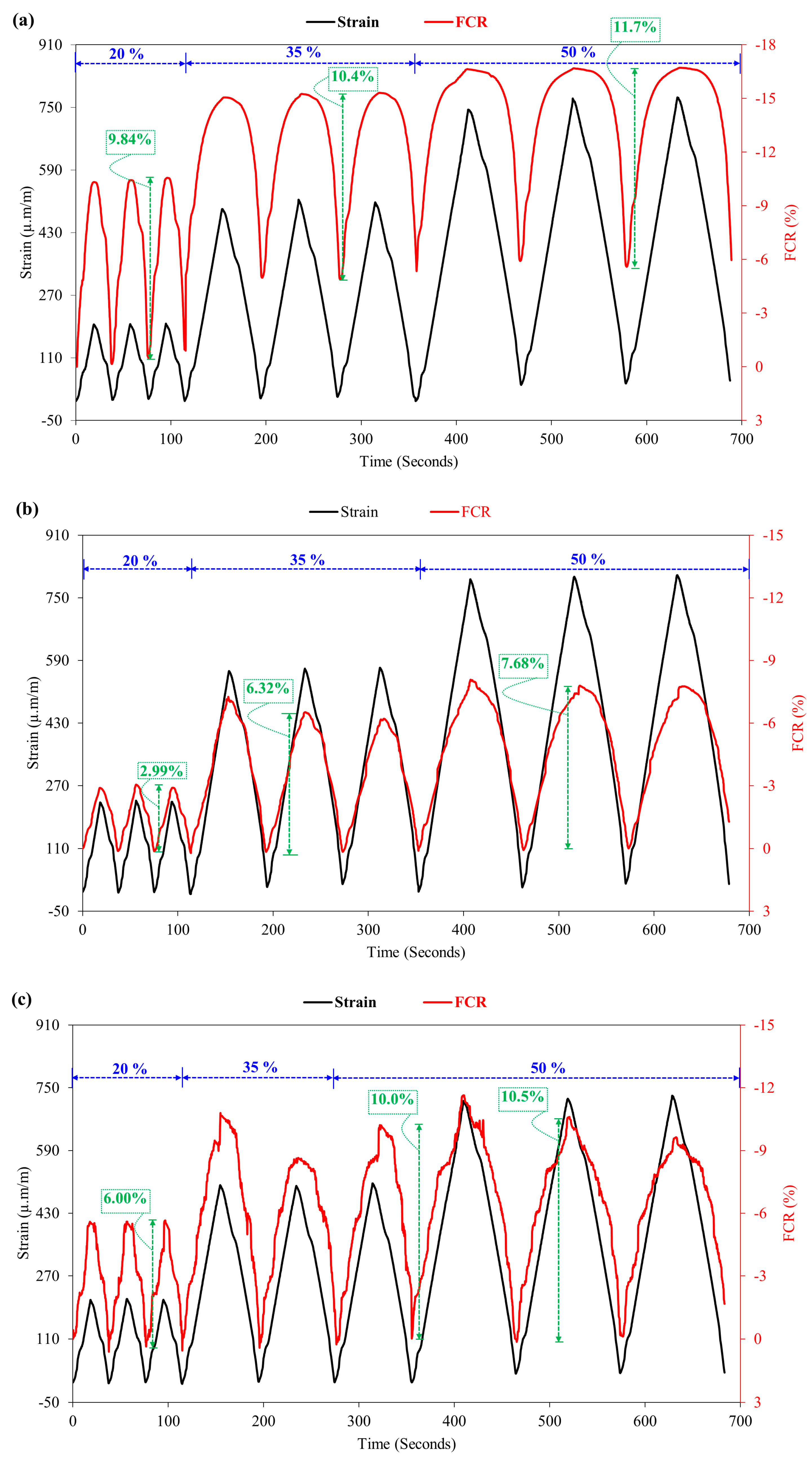

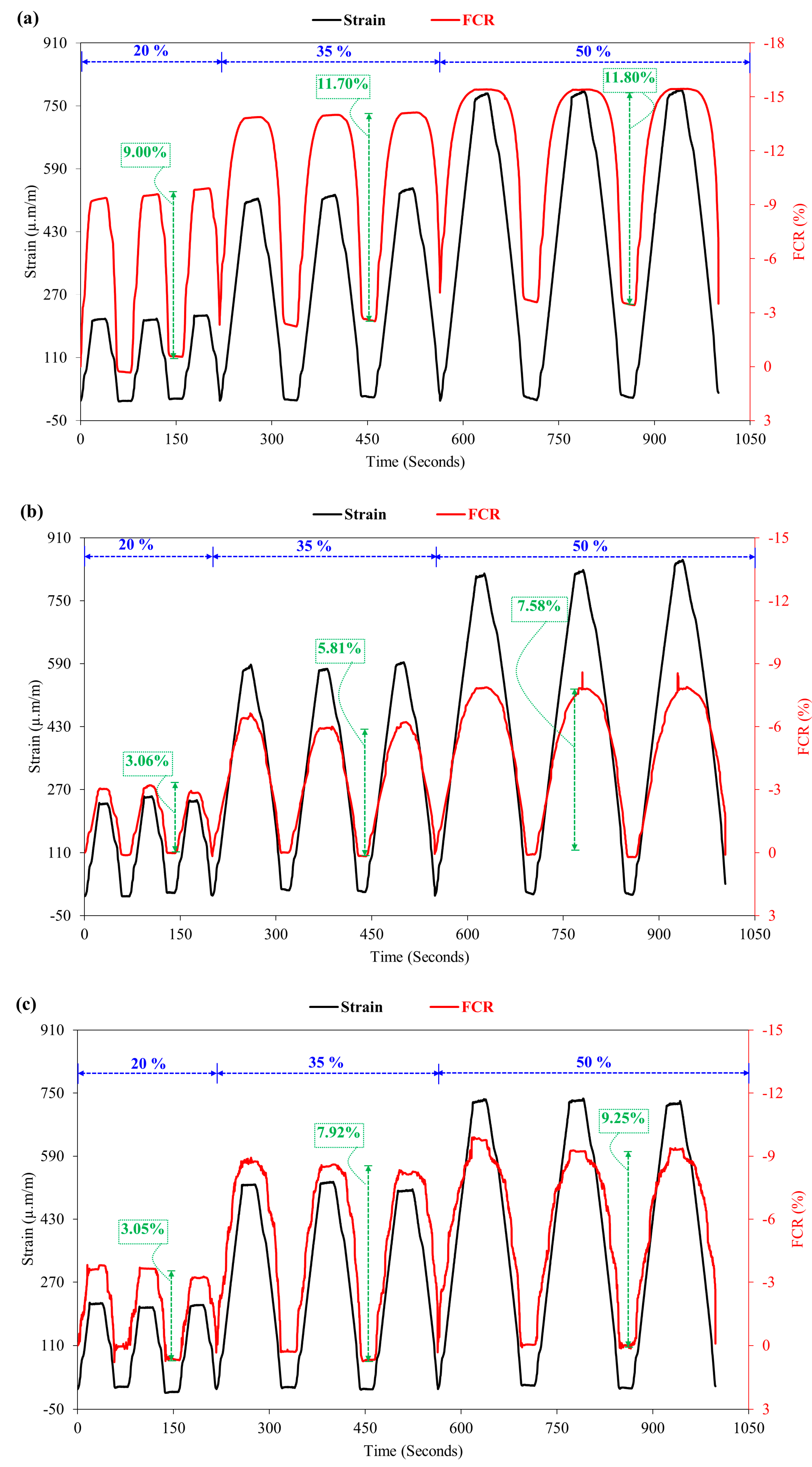

3.1.2. Load versus FCR

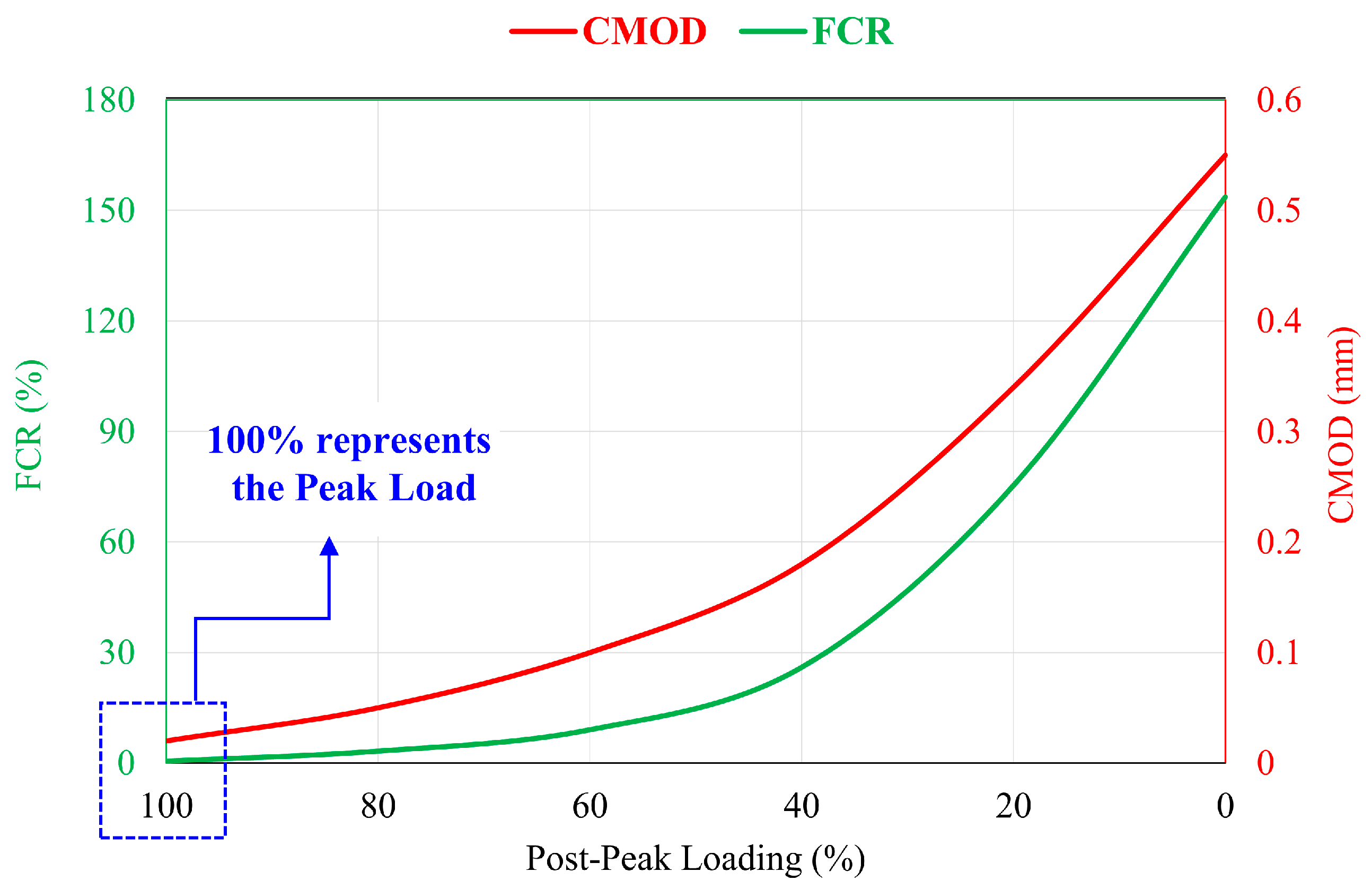

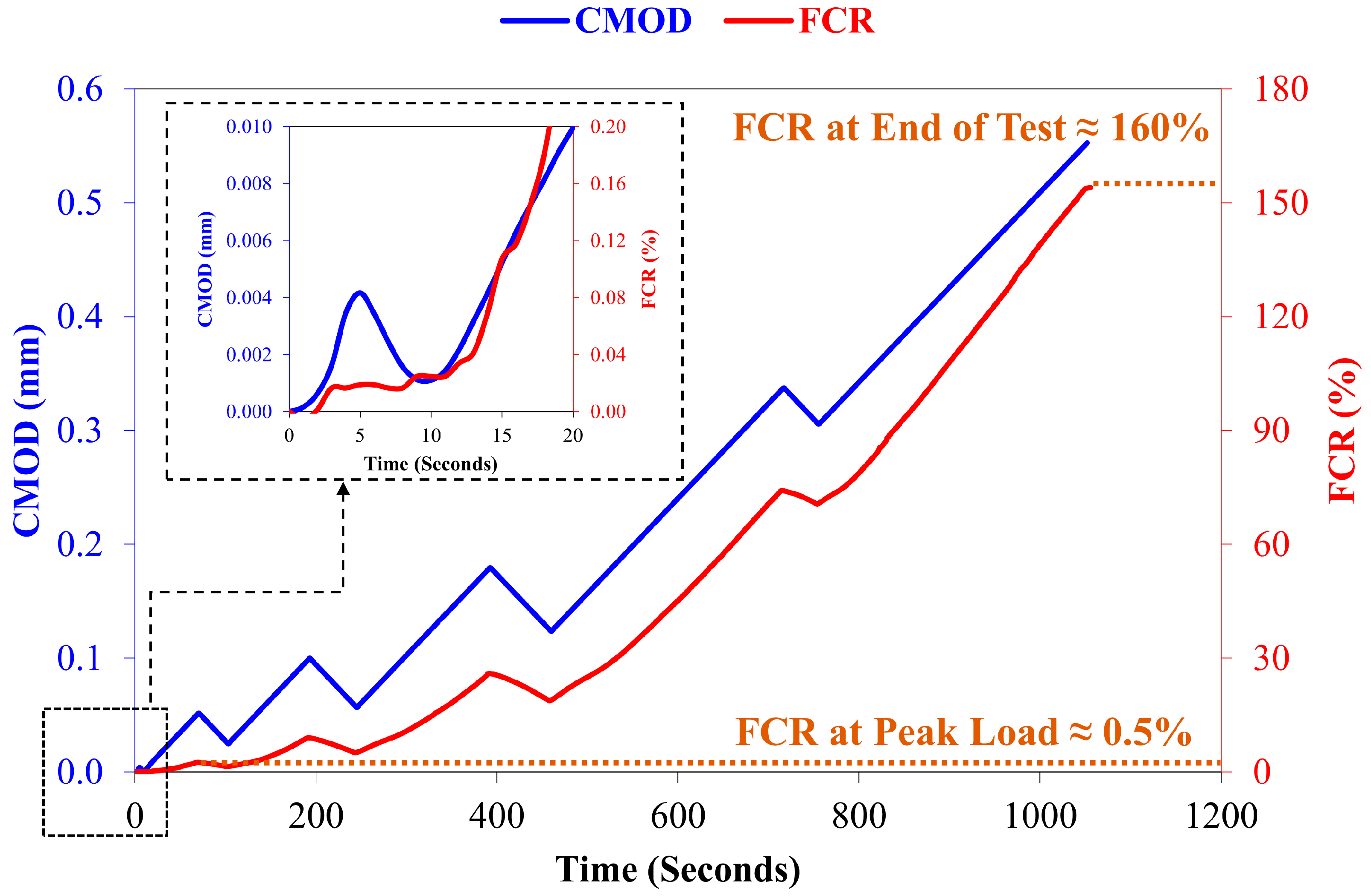

3.1.3. CMOD and FCR

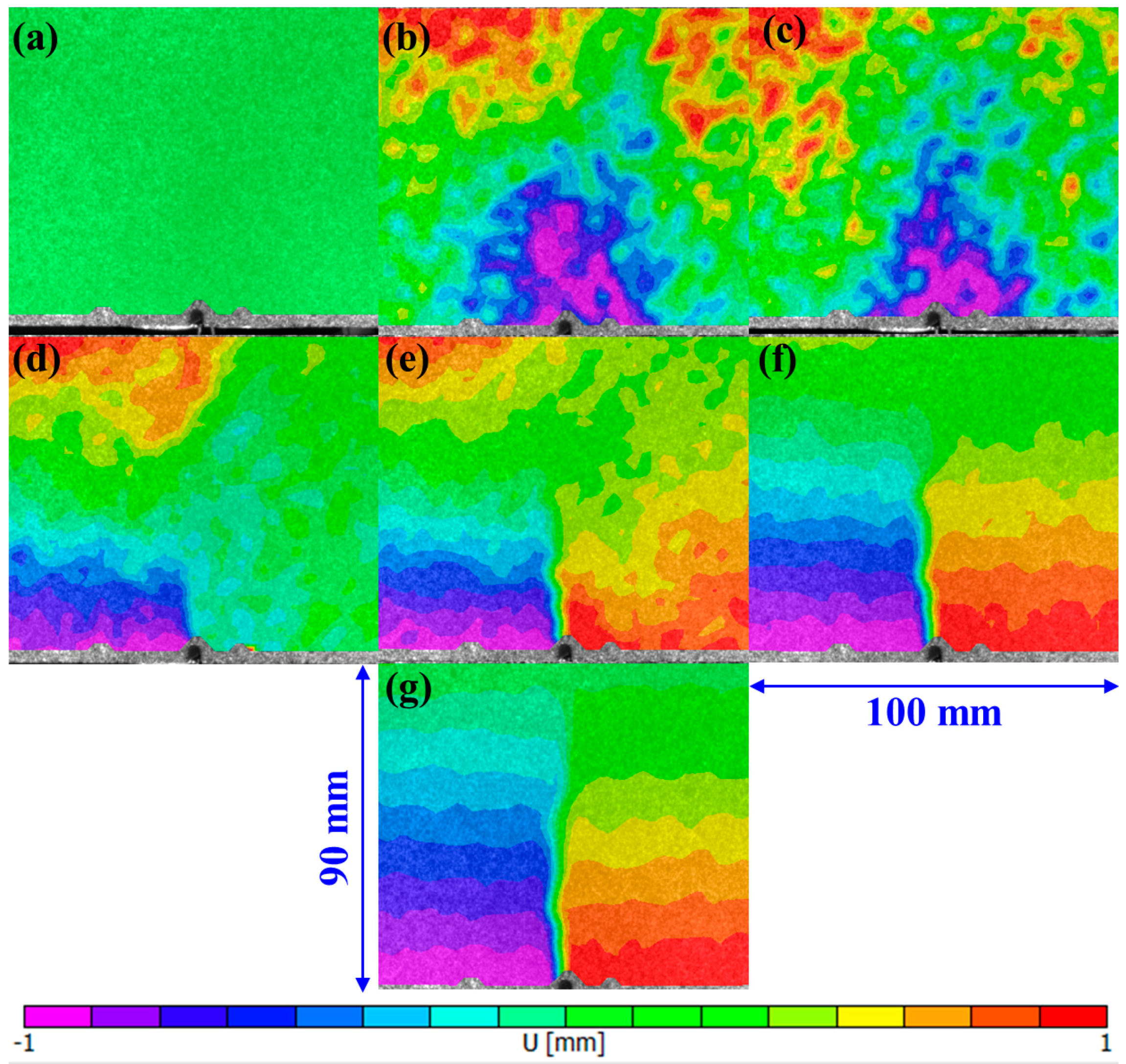

3.1.4. Crack Propagation by DIC

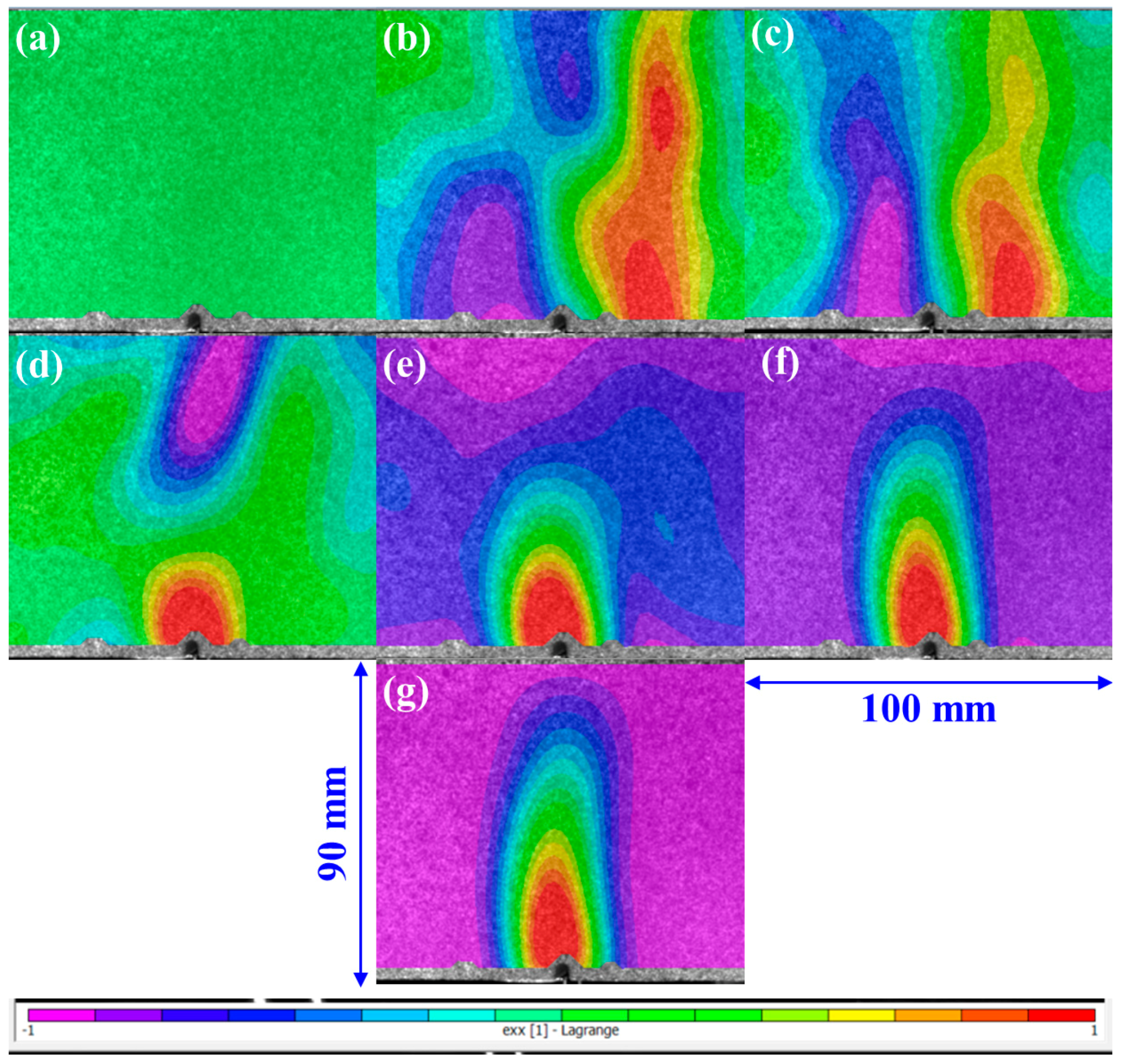

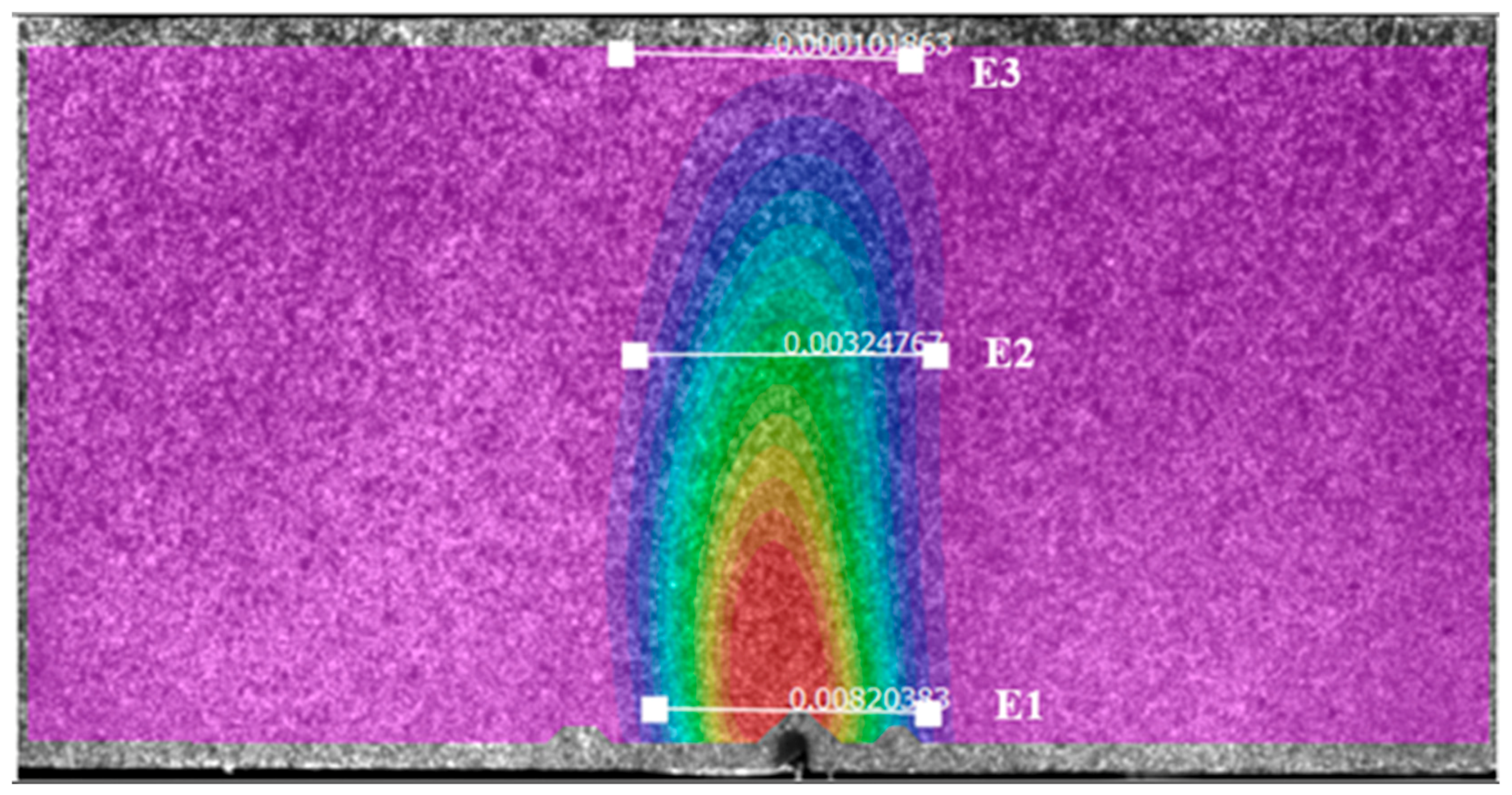

3.1.5. Evolution of Strain by DIC

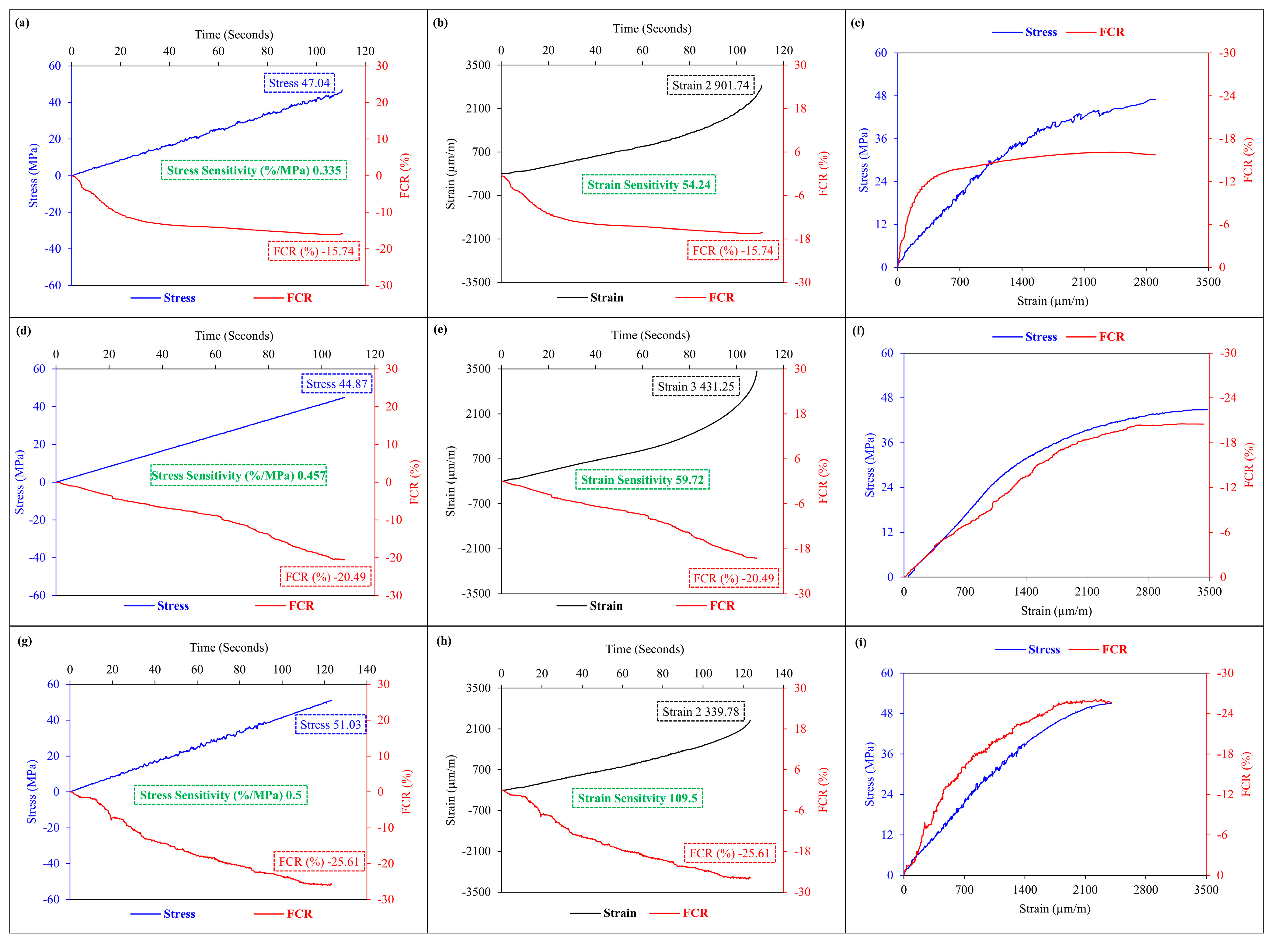

3.2. Compressive Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Preciado, A.; Peña, F.; Fonseca, F.C.; Silva, C. Damage description and schematic crack propagation in Colonial Churches and old masonry buildings by the 2017 Puebla-Morelos earthquakes (Mw = 8.2 and 7.1). Eng. Fail. Anal. 2022, 141, 106706. [Google Scholar] [CrossRef]

- Qin, D.; Gao, P.; Aslam, F.; Sufian, M.; Abdul-Jabbar, H. A comprehensive review on fire damage assessment of reinforced concrete structures. Case Stud. Constr. Mater. 2022, 16, e00843. [Google Scholar] [CrossRef]

- Golewski, G.L. The Phenomenon of Cracking in Cement Concretes and Reinforced Concrete Structures: The Mechanism of Cracks Formation, Causes of Their Initiation, Types and Places of Occurrence, and Methods of Detection—A Review. Buildings 2023, 13, 765. [Google Scholar] [CrossRef]

- Kovler, K.; Chernov, V. Types of damage in concrete structures. In Failure, Distress and Repair of Concrete Structures; Woodhead Publishing: Sawston, UK, 2009; pp. 32–56. [Google Scholar]

- Portland Cement Association. Types, Causes of Concrete Deterioration; IS536 Portland Cement Association: Skokie, IL, USA, 2002. [Google Scholar]

- Nguyen-Tat, T.; Ranaivomanana, N.; Balayssac, J.P. Characterization of damage in concrete beams under bending with Acoustic Emission Technique (AET). Constr. Build. Mater. 2018, 187, 487–500. [Google Scholar] [CrossRef]

- Zhao, J.; Bao, T.; Chen, R. Crack monitoring capability of plastic optical fibers for concrete structures. Opt. Fiber Technol. 2015, 24, 70–76. [Google Scholar] [CrossRef]

- Howiacki, T.; Sieńko, R.; Bednarski, Ł.; Zuziak, K. Structural monitoring of concrete, steel, and composite bridges in Poland with distributed fibre optic sensors. Struct. Infrastruct. Eng. 2023, 2023, 2230558. [Google Scholar] [CrossRef]

- André, P.S.; Varum, H.; Antunes, P.; Ferreira, L.; Sousa, M.G. Monitoring of the concrete curing process using plastic optical fibers. Measurement 2012, 45, 556–560. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D. Damage monitoring of cement paste by electrical resistance measurement. Cem. Concr. Res. 2000, 30, 1979–1982. [Google Scholar] [CrossRef]

- Chung, D.D. Damage in cement-based materials, studied by electrical resistance measurement. Mater. Sci. Eng. R Rep. 2003, 42, 1–40. [Google Scholar] [CrossRef]

- Cholker, A.K.; Tantray, M.A. Electrical resistance-based health monitoring of structural smart concrete. Mater. Today Proc. 2021, 43, 3774–3779. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Damage in carbon fiber-reinforced concrete, monitored by both electrical resistance measurement and acoustic emission analysis. Constr. Build. Mater. 2008, 22, 2196–2201. [Google Scholar] [CrossRef]

- Bontea, D.M.; Chung, D.D.; Lee, G.C. Damage in carbon fiber-reinforced concrete, monitored by electrical resistance measurement. Cem. Concr. Res. 2000, 30, 651–659. [Google Scholar] [CrossRef]

- Chen, P.W.; Chung, D.D. Concrete as a new strain/stress sensor. Compos. Part B Eng. 1996, 27, 11–23. [Google Scholar] [CrossRef]

- Sun, M.; Li, Z.; Song, X. Piezoelectric effect of hardened cement paste. Cem. Concr. Compos. 2004, 26, 717–720. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Lu, J.P. Elastic properties of carbon nanotubes and nanoropes. Phys. Rev. Lett. 1997, 79, 1297. [Google Scholar] [CrossRef] [Green Version]

- Dresselhaus, M.S.; Dresselhaus, G.; Charlier, J.C.; Hernandez, E. Electronic, thermal and mechanical properties of carbon nanotubes. Philosophical Transactions of the Royal Society of London. Ser. A Math. Phys. Eng. Sci. 2004, 362, 2065–2098. [Google Scholar] [CrossRef]

- Salvetat, J.P.; Bonard, J.M.; Thomson, N.H.; Kulik, A.J.; Forro, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Yakobson, B.I.; Avouris, P. Mechanical properties of carbon nanotubes. In Carbon Nanotubes: Synthesis, Structure, Properties, and Applications; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Dresselhaus, G.; Dresselhaus, M.S.; Saito, R. Physical Properties of Carbon Nanotubes; World Scientific: Singapore, 1998. [Google Scholar]

- Shahzad, S.; Toumi, A.; Balayssac, J.P.; Turatsinze, A.; Mazars, V. Cementitious composites incorporating Multi-Walled Carbon Nanotubes (MWCNTs): Effects of annealing and other dispersion methods on the electrical and mechanical properties. Matériaux Tech. 2022, 110, 104. [Google Scholar] [CrossRef]

- Ferdiansyah, T.; Balayssac, J.P.; Turatsinze, A. An experimental approach for characterisation of concrete damage using the wheatstone bridge circuit. Int. J. Civ. Eng. 2022, 20, 75–89. [Google Scholar] [CrossRef]

- Wang, L.; Aslani, F. Development of self-sensing cementitious composites incorporating CNF and hybrid CNF/CF. Constr. Build. Mater. 2021, 273, 121659. [Google Scholar] [CrossRef]

- Bu, J.; Chen, X.; Hu, L.; Yang, H.; Liu, S. Experimental study on crack propagation of concrete under various loading rates with digital image correlation method. Int. J. Concr. Struct. Mater. 2020, 14, 25. [Google Scholar] [CrossRef]

- Li, J.; Chen, L.; Hu, G.; Guo, J.; Wang, Z.; Lu, W.; Luo, J.; Fan, X.; Zhu, Y.; Wang, X.; et al. Research on performance of smart concrete materials and self-monitoring of cracks in beam members. Mater. Today Commun. 2023, 35, 105775. [Google Scholar] [CrossRef]

- Birgin, H.B.; D’Alessandro, A.; Ubertini, F. Dynamic behavior of structural beams made of innovative smart concrete. Procedia Struct. Integr. 2023, 44, 1624–1631. [Google Scholar] [CrossRef]

- BS EN 197-1:2011; Cement. Composition, Specifications and Conformity Criteria for Common Cements. British Standards Institution: London, UK, 2011.

- Shahzad, S.; Toumi, A.; Balayssac, J.P.; Turatsinze, A. Design of smart cementitious composites based on multi-walled carbon nanotubes (MWCNTs) using probe ultrasonicator for dispersion. In Proceedings of the 6th International Conference on Concrete Repair, Rehabilitation and Retrofitting (ICCRRR 2022), Cape Town, South Africa, 3 October 2022; Volume 364. No. 05012. [Google Scholar]

- Singh, Y. Electrical resistivity measurements: A review. In International Journal of Modern Physics: Conference Series 2013; World Scientific Publishing Company: Singapore, 2013; Volume 22, pp. 745–756. [Google Scholar]

- Gencturk, B.; Hossain, K.; Kapadia, A.; Labib, E.; Mo, Y.L. Use of digital image correlation technique in full-scale testing of prestressed concrete structures. Measurement 2014, 47, 505–515. [Google Scholar] [CrossRef]

- Pickerd, V. Optimisation and Validation of the ARAMIS Digital Image Correlation System for Use in Large-Scale High-Strain-Rate Events; Defense Science and Technology Organization Victoria: Maritime, Australia, 2013. [Google Scholar]

- Dong, W.; Li, W.; Tao, Z.; Wang, K. Piezoresistive properties of cement-based sensors: Review and perspective. Constr. Build. Mater. 2019, 203, 146–163. [Google Scholar] [CrossRef]

- Ho, A.C.; Turatsinze, A.; Hameed, R.; Vu, D.C. Effects of rubber aggregates from grinded used tyres on the concrete resistance to cracking. J. Clean. Prod. 2012, 23, 209–215. [Google Scholar] [CrossRef]

- Bhowmik, S.; Ray, S. An experimental approach for characterization of fracture process zone in concrete. Eng. Fract. Mech. 2019, 211, 401–419. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, X.; Zhao, Y. Piezoresistivity of cement matrix composites incorporating multiwalled carbon nanotubes due to moisture variation. Adv. Civ. Eng. 2020, 2020, 1. [Google Scholar] [CrossRef] [Green Version]

- Le, H.V.; Kim, M.K.; Kim, S.U.; Chung, S.Y.; Kim, D.J. Enhancing self-stress sensing ability of smart ultra-high performance concretes under compression by using nano functional fillers. J. Build. Eng. 2021, 44, 102717. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Sun, S.; Yu, X.; Dong, X.; Wu, T.; Ou, J. Electrostatic self-assembled carbon nanotube/nano carbon black composite fillers reinforced cement-based materials with multifunctionality. Compos. Part A Appl. Sci. Manuf. 2015, 79, 103–115. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Wang, J.; Ou, J.; Han, B.; Ding, S.; Wang, J.; Ou, J. Electrostatic Self-Assembled Carbon Nanotube/Nano-Carbon Black Fillers-Engineered Cementitious Composites. In Nano-Engineered Cementitious Composites: Principles and Practices; Springer: Singapore, 2019; pp. 665–707. [Google Scholar]

- Demircilioglu, E.; Teomete, E.; Ozbulut, O.E. Strain sensitivity of steel-fiber-reinforced industrial smart concrete. J. Intell. Mater. Syst. Struct. 2020, 31, 127–136. [Google Scholar] [CrossRef]

- Wang, L.; Aslani, F. Structural performance of reinforced concrete beams with 3D printed cement-based sensor embedded and self-sensing cementitious composites. Eng. Struct. 2023, 275, 115266. [Google Scholar] [CrossRef]

| Material | Quantity |

|---|---|

| OPC (CEM I 52.5R) | 350 kg |

| Fine Aggregates | 875 kg |

| Coarse Aggregates | 980 kg |

| Water | 175 kg |

| Superplasticizer 1 | 4% |

| MWCNTs 1 | 0.75% |

| Designation | C1 | C2 | C3 |

|---|---|---|---|

| Condition | 20 °C RH ≈ 100% | 23 °C 50% < RH < 100% | 40 °C RH < 50% |

| Mass Loss (Water) % | 0 | 2.2 | 5.1 |

| Properties | Condition of Specimens | ||

|---|---|---|---|

| C1 | C2 | C3 | |

| FCR at Failure (%) | 15.74 | 20.49 | 25.61 |

| Stress Sensitivity (%/MPa) | 0.335 | 0.457 | 0.5 |

| Strain Sensitivity | 54.24 | 59.72 | 109.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahzad, S.; Toumi, A.; Balayssac, J.-P.; Turatsinze, A. An Experimental Approach to Assess the Sensitivity of a Smart Concrete. Buildings 2023, 13, 2034. https://doi.org/10.3390/buildings13082034

Shahzad S, Toumi A, Balayssac J-P, Turatsinze A. An Experimental Approach to Assess the Sensitivity of a Smart Concrete. Buildings. 2023; 13(8):2034. https://doi.org/10.3390/buildings13082034

Chicago/Turabian StyleShahzad, Shaban, Ahmed Toumi, Jean-Paul Balayssac, and Anaclet Turatsinze. 2023. "An Experimental Approach to Assess the Sensitivity of a Smart Concrete" Buildings 13, no. 8: 2034. https://doi.org/10.3390/buildings13082034