Study on the Performance of a New Ultra-Low Temperature Air Source Heat Pump (ASHP) Unit in Cold Regions

Abstract

1. Introduction

2. Methods

2.1. Description of the Ultra-Low Temperature ASHP Unit

2.2. Field Measurement Protocols

2.3. Data Analysis

3. Results and Discussions

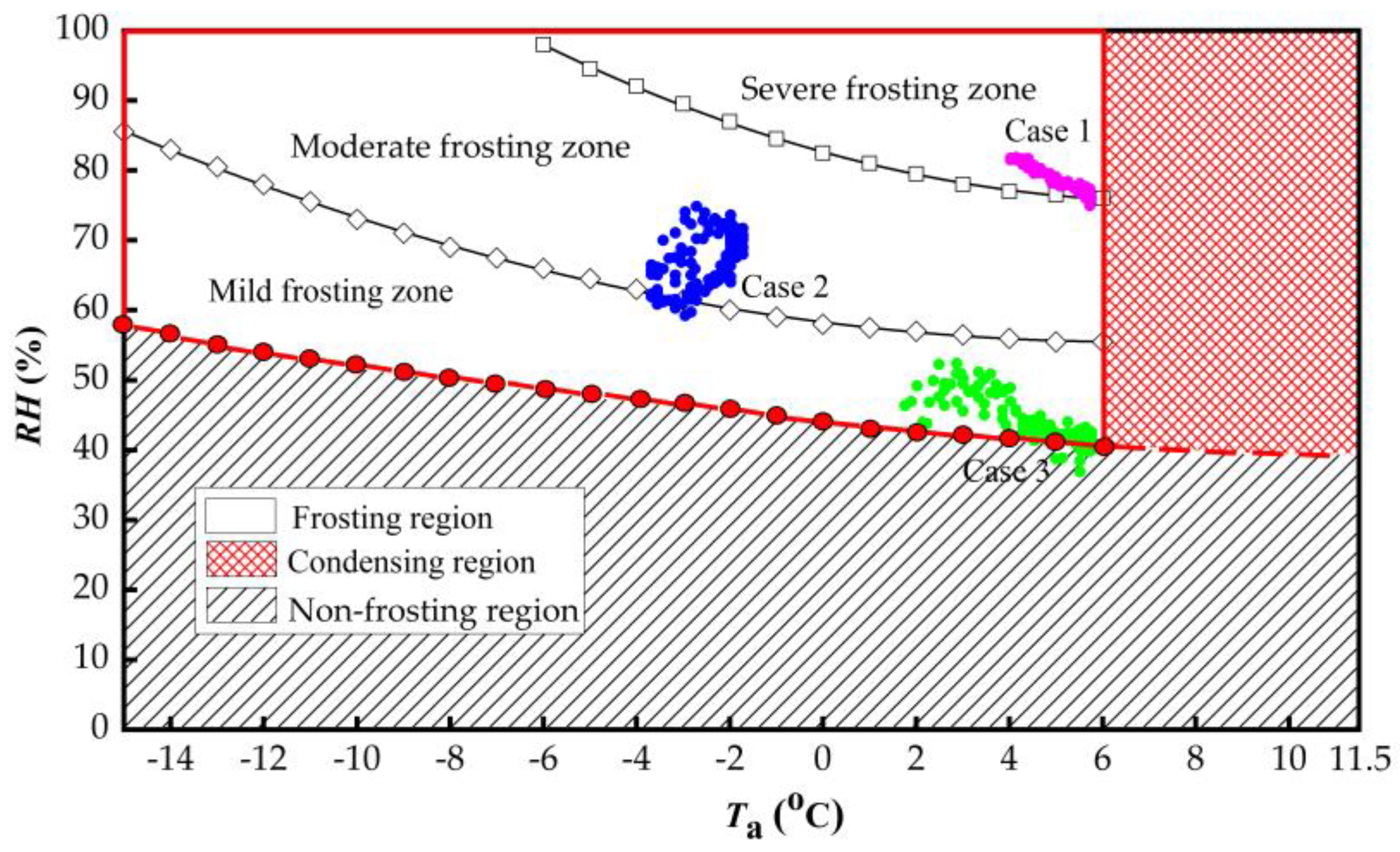

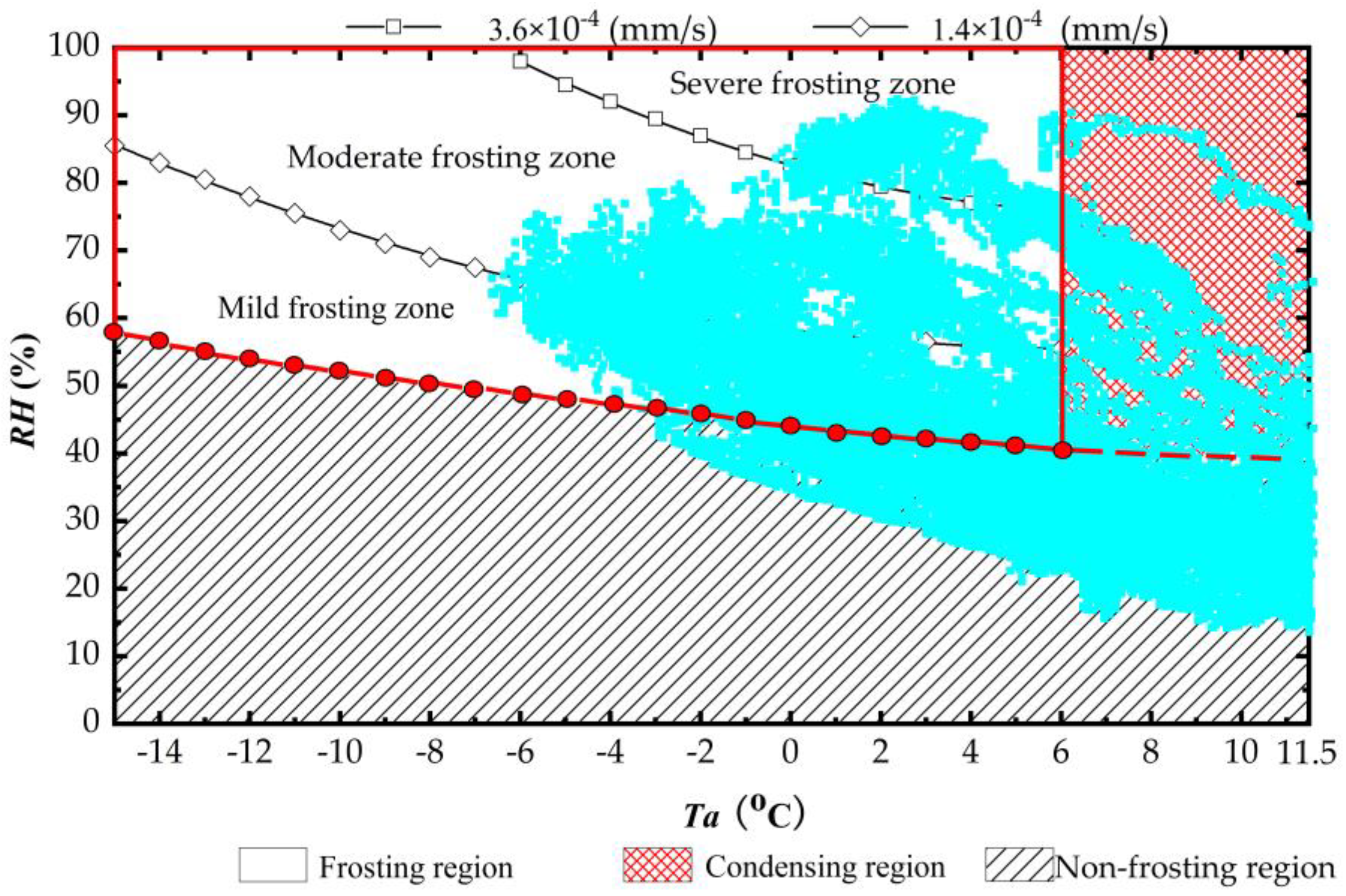

3.1. Environmental Data during the Measurement and the Predicted Frosting Levels

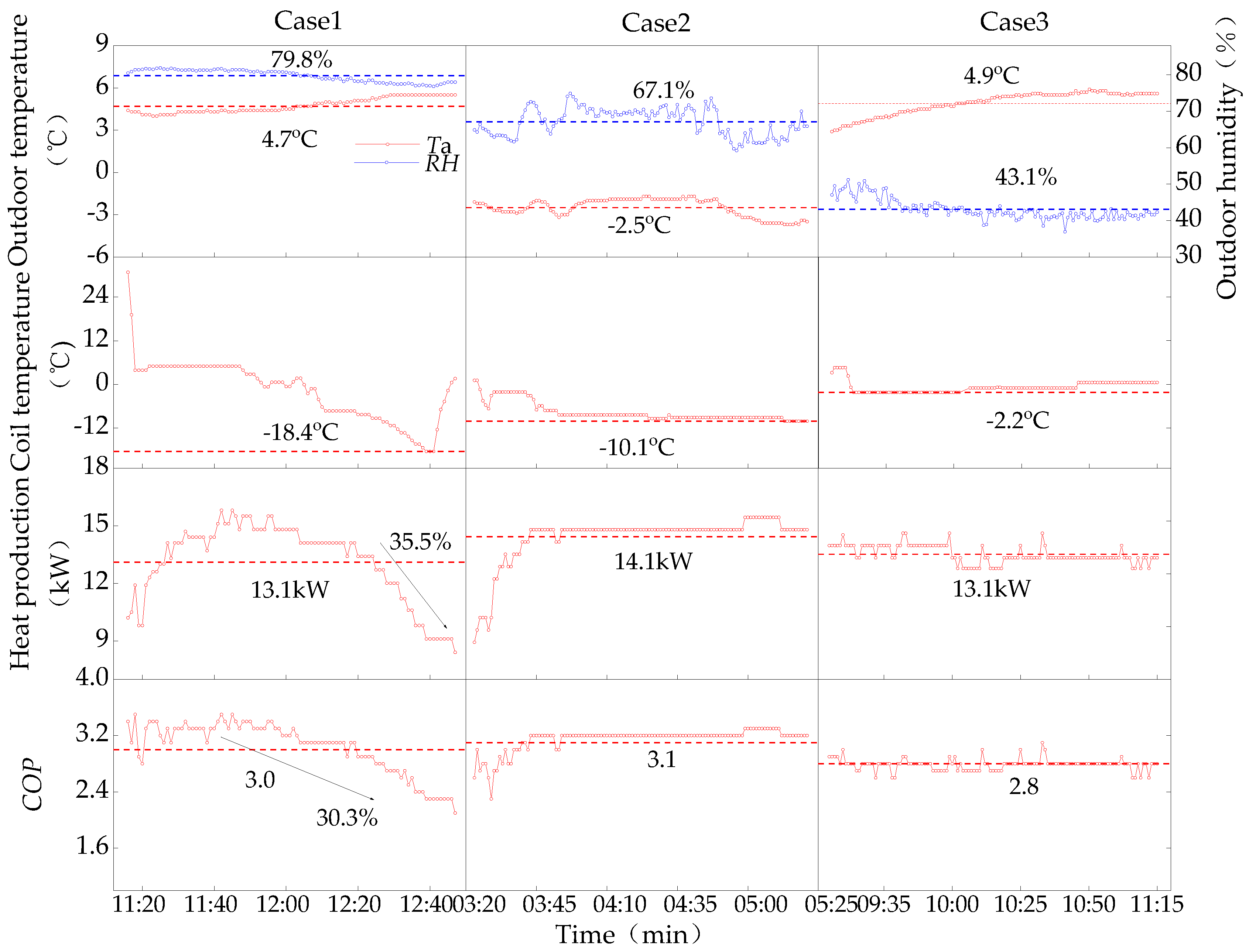

3.2. Actual Performance of the New ASHP Units under Three Typical Frosting Conditions

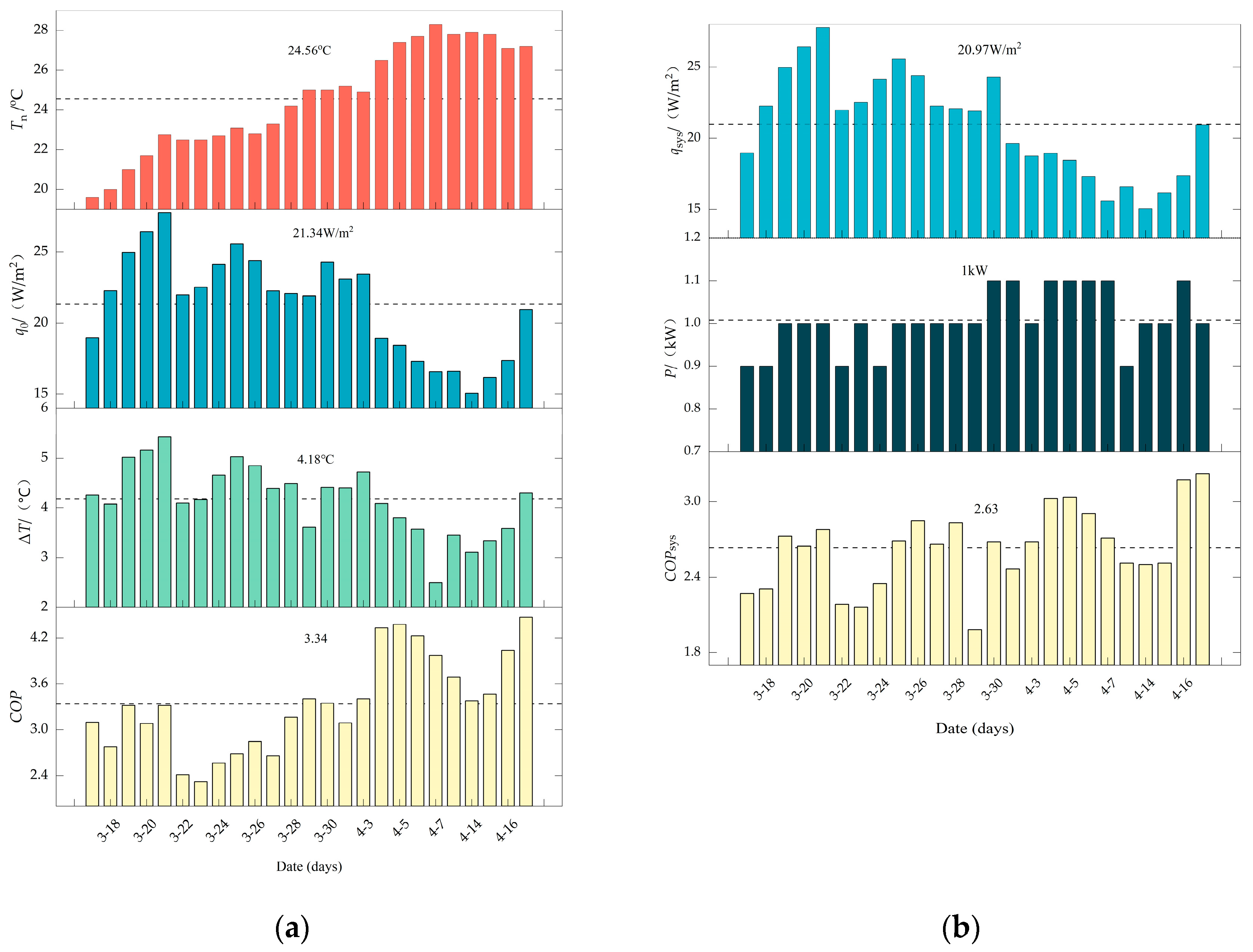

3.3. Long-Term Performance of the New ASHP in Regular Heating Season

3.4. Environmental and Economic Benefits of the ASHP

3.4.1. Environmental Benefits Analysis

3.4.2. Economic Benefits Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, X.; Hao, B.; Liu, S.; Zhou, W.; Yao, C.; Wang, S. Study on Demand-side Design Parameters of Solar Domestic Hot Water System in Residential Buildings. Energy Procedia 2015, 70, 340–346. [Google Scholar] [CrossRef][Green Version]

- Sun, X.; Yao, C.; Zhao, H.; Dai, Y. Research on roadmap of taking air thermal energy into the scope of renewable energy sources. Chin. J. Refrig. Technol. 2015, 35, 36–40. [Google Scholar]

- Hou, L.; Ding, H.; Liu, Y.; Wang, S. Evaluation and suggestion on the subsidy policies for rural clean heating in winter in the Bei-jing-Tianjin-Hebei region. Energy Build. 2022, 274, 112456. [Google Scholar] [CrossRef]

- Ma, L.; Liu, Z.; Zhang, X.; Zhang, C. Design and thermodynamic optimization of enhanced Vapor injection technology in double stage coupling heat pump. Build. Energy Environ. 2016, 35, 17–21. [Google Scholar]

- Chen, J.; Yang, C.; Cai, B. Experimental of low temperature heat flash type air source heat pump water heater. Fluid Mach. 2010, 38, 72–74. [Google Scholar]

- Wu, C.; Liu, F.; Li, X.; Wang, Z.; Xu, Z.; Zhao, W.; Yang, Y.; Wu, P.; Xu, C.; Wang, Y. Low-temperature air source heat pump system for heating in severely cold area: Long-term applicability evaluation. Build. Environ. 2022, 208, 108594. [Google Scholar] [CrossRef]

- Safa, A.A.; Fung, A.S.; Kumar, R. Comparative thermal performances of a ground source heat pump and a variable capacity air source heat pump systems for sustainable houses. Appl. Therm. Eng. 2015, 81, 279–287. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Q.; Li, B.; Fan, X.; Fu, Z. Application of an air source heat pump (ASHP) for heating in Harbin, the coldest provincial capital of China. Energ. Build. 2017, 138, 96–103. [Google Scholar] [CrossRef]

- Zhang, H.; Jiang, L.; Zheng, W.; You, S.; Jiang, T.; Shao, S.; Zhu, X. Experimental study on a novel thermal storage refrigerant-heated radiator coupled with air source heat pump heating system. Build. Environ. 2019, 164, 106341. [Google Scholar] [CrossRef]

- Standardization Administration of China. GB/T25127.1; Low Ambient Temperature Air Source Heat Pump (Water Chilling) Packages—Part 1: Heat Pump (Water Chilling) Packages for Industrial & Commercial and Similar Application. Standards Press of China: Beijing, China, 2020.

- Standardization Administration of China. GB/T25127.2; Low Ambient Temperature Air Source Heat Pump (Water Chilling) Packages—Part 2: Heat Pump (Water Chilling) Packages for House Hold and Similar Application. Standards Press of China: Beijing, China, 2020.

- Liang, S.; Wang, H.; Gao, X.; Tian, X.; Zhu, H.; Hu, S.; Lin, C. Experimental study on the operating performance of the air source heat pump (ASHP) with variable outdoor airflow rate under the standard frosting condition. Energy Built Environ. 2023. [Google Scholar] [CrossRef]

- Dong, J.; Deng, S.; Jiang, Y.; Xia, L.; Yao, Y. An experimental study on defrosting heat supplies and energy consumptions during a reverse cycle defrost operation for an air source heat pump. Appl. Therm. Eng. 2012, 37, 380–387. [Google Scholar] [CrossRef]

- Liu, J.; Sun, Y.; Wang, W.; Zhu, J. Performance evaluation of air source heat pump under unnecessary defrosting phenomena for nine typical cities in China. Int. J. Refrig. 2016, 74, 385–398. [Google Scholar] [CrossRef]

- Qu, M.; Xia, L.; Deng, S.; Jiang, Y. An experimental investigation on reverse-cycle defrosting performance for an air source heat pump using an electronic expansion valve. Appl. Energy 2012, 97, 327–333. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, W.; Sun, Y.; Cui, Y.; Lin, Y. Development of evaluation indexes for assessing the regional operating performances of air source heat pump (ASHP) units operated in different climate regions based on the equivalent temperature drop method. Energy Build. 2021, 247, 111111. [Google Scholar] [CrossRef]

- Wang, W.; Guo, Q.C.; Feng, Y.C.; Lu, W.P.; Dong, X.G.; Zhu, J.H. Theoretical study on the critical heat and mass transfer characteristics of a frosting tube. Appl. Therm. Eng. 2013, 54, 160. [Google Scholar] [CrossRef]

- Wang, W.; Feng, Y.C.; Zhu, J.H.; Li, L.T.; Guo, Q.C.; Lu, W.P. Performances of air source heat pump system for a kind of mal-defrost phenomenon appearing in moderate climate conditions. Appl. Energy 2013, 112, 1138–1145. [Google Scholar] [CrossRef]

- Guo, X.M.; Chen, Y.G.; Wang, W.H.; Chen, C.Z. Experimental study on frost growth and dynamic performance of air source heat pump system. Appl. Therm. Eng. 2008, 28, 2267–2278. [Google Scholar] [CrossRef]

- Wang, W.; Xiao, J.; Guo, Q.C.; Lu, W.P.; Feng, Y.C. Field test investigation of the characteristics for the air source heat pump under two typical mal-defrost phenomena. Appl. Energy 2011, 88, 4470–4480. [Google Scholar] [CrossRef]

- Zhu, J.H.; Sun, Y.Y.; Wang, W.; Deng, S.M.; Ge, Y.J.; Li, L.T. Developing a new frosting map to guide defrosting control for air-source heat pump units. Appl. Therm. Eng. 2015, 90, 782–791. [Google Scholar] [CrossRef]

- Wu, C.; Wang, Z.; Li, X.; Xu, Z.; Xu, C.; Yang, Y.; Zhao, W.; Wang, Y. Field experimental research on retarding frosting and improving defrosting performance of air source heat pumps through variable frequency technology. J. Build. Eng. 2023, 64, 105628. [Google Scholar] [CrossRef]

- China Association for Engineering Construction Standardization. T/CECS 564-2018; Technical Specification for Air Source Heat Pump Heating System. Architecture & Building Press: Beijing, China, 2018.

- Yang, H. Annual-cost Analysis and Application of Ground-Water Heat Pump System. Bachelor’s Thesis, Tianjin University, Tianjin, China, 2005. [Google Scholar]

- Steiner, H.M. Engineering Economic Principles; Economic Science Press: Beijing, China, 2000. [Google Scholar]

- Bai, X.; Wang, W.; Sun, Y.; Liu, J.; Ge, Y.; Deng, S. Operating performances of an ASHP unit operated in a mild and humid region using tube-encircled photoelectric sensor based defrosting initiation strategy. Energy Build. 2018, 177, 140–153. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, W.; Shao, S.; Wang, Z.; Xu, W.; Li, H.; Wang, Y.; Wang, W.; Yang, Q.; Xu, C. Analysis on key influence factors of air source heat pumps with field monitored data in Beijing. Sustain. Energy Technol. Assess. 2021, 48, 101642. [Google Scholar] [CrossRef]

| Component | Project | Unit | Parameter |

|---|---|---|---|

| Compressor | Number | / | 1 |

| Type | / | Rotary | |

| Rated speed | rps | 70 | |

| Volume | m3/rev | 4.24 × 10−5 | |

| Refrigerant | / | R410A | |

| Outdoor heat exchanger (Evaporator) | Number | / | 1 |

| Type of the fins | / | Hydrophilic corrugated wavy fins | |

| Dimensions | mm | 1550 × 750 × 80 | |

| Thickness of the fin | mm | 0.1 | |

| Distance between adjacent fins | mm | 1.8 | |

| Diameter of the tube | mm | 7 | |

| Distance between adjacent tubes | mm | 25 | |

| Row of the tubes | / | 3 | |

| Heat exchange area | m2 | 65 | |

| Outdoor fan | Number | / | 2 |

| Type | / | Brushless DC Motor | |

| Range of the air flow rate | m3/s | 0~2.5 | |

| Rated air flow rate | m3/s | 2.5 |

| Critical Parameters | Designed Value | Measured Value |

|---|---|---|

| Dry bulb/Wet Bulb temperature (DB/WB) (°C) | −25/- | −25/- |

| Supply hot water temperature (°C) | 41 | 41 |

| Heating power(kW) | 7 | 7.5 |

| COP | >1.8 | 1.83 |

| Frosting Condition | Case 1 | Case 2 | Case 3 |

|---|---|---|---|

| The actual frosting levels |  Moderate frosting |  Mild frosting |  Zero frosting |

| The actual frosting time | 109 min | 114 min | / |

| Frosting predicted by Reference [21] | t ≤ 30 min Severe frosting | 30 min ≤ t ≤ 90 min Moderate frosting | 90 min ≤ t ≤ 150 Mild frosting |

| Parameter | Case 1 | Case 2 | Case 3 |

|---|---|---|---|

| Ur(COP) | 4.3 | 3.7 | 3.6 |

| Parameter | Ur(q0) | Ur(COP) | Ur(qsys) | Ur(COPsys) |

|---|---|---|---|---|

| Values | 3.7% | 4.3% | 3.8% | 4.6% |

| C (Initial Investment)/CNY | B (Net Salvage)/CNY | Co (Annual Cost on Operation)/CNY | Cm (Annual Cost on Maintenance)/CNY | AC (Annual Cost)/CNY | |

|---|---|---|---|---|---|

| Conventional ASHP | 6800 | 680 | 10,901 | 408 | 11,914 |

| Ultra-low temperature ASHP | 9000 | 900 | 8687 | 540 | 10,027 |

| Component | Conventional ASHP (CNY) | Ultra-Low Temperature ASHP (CNY) | Difference (CNY) |

|---|---|---|---|

| Compressor | 900 | 1200 | 300 |

| Outdoor heat exchanger | 850 | 1430 | 580 |

| Outdoor fan | 60 | 220 | 160 |

| Sheet metal processing | 550 | 1337 | 787 |

| Total | 2360 | 4187 | 1827 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di, Y.; Zhao, C.; Lian, X.; Li, X.; Bao, D.; Liu, J. Study on the Performance of a New Ultra-Low Temperature Air Source Heat Pump (ASHP) Unit in Cold Regions. Buildings 2023, 13, 2107. https://doi.org/10.3390/buildings13082107

Di Y, Zhao C, Lian X, Li X, Bao D, Liu J. Study on the Performance of a New Ultra-Low Temperature Air Source Heat Pump (ASHP) Unit in Cold Regions. Buildings. 2023; 13(8):2107. https://doi.org/10.3390/buildings13082107

Chicago/Turabian StyleDi, Yanqiang, Chen Zhao, Xueli Lian, Xiaolong Li, Daorina Bao, and Jinxing Liu. 2023. "Study on the Performance of a New Ultra-Low Temperature Air Source Heat Pump (ASHP) Unit in Cold Regions" Buildings 13, no. 8: 2107. https://doi.org/10.3390/buildings13082107

APA StyleDi, Y., Zhao, C., Lian, X., Li, X., Bao, D., & Liu, J. (2023). Study on the Performance of a New Ultra-Low Temperature Air Source Heat Pump (ASHP) Unit in Cold Regions. Buildings, 13(8), 2107. https://doi.org/10.3390/buildings13082107