Application of Steel-Fiber-Reinforced Self-Stressing Concrete in Prefabricated Pavement Joints

Abstract

:1. Introduction

2. Experiment

2.1. Experimental Materials and Ratio

2.2. Experiment Method

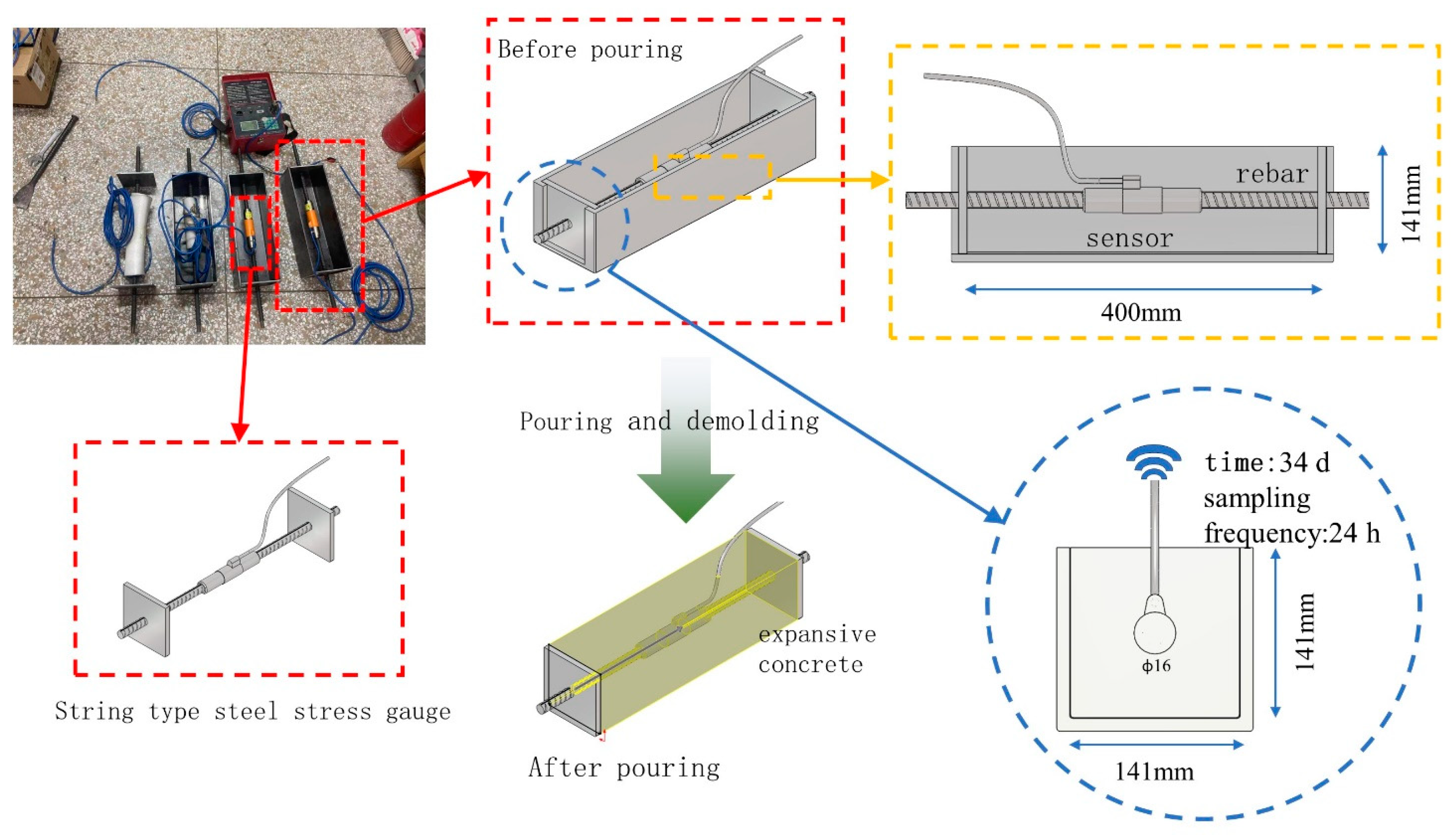

2.2.1. Stress and Mechanical Response Measurement of Steel-Fiber-Reinforced Self-Stressing Concrete

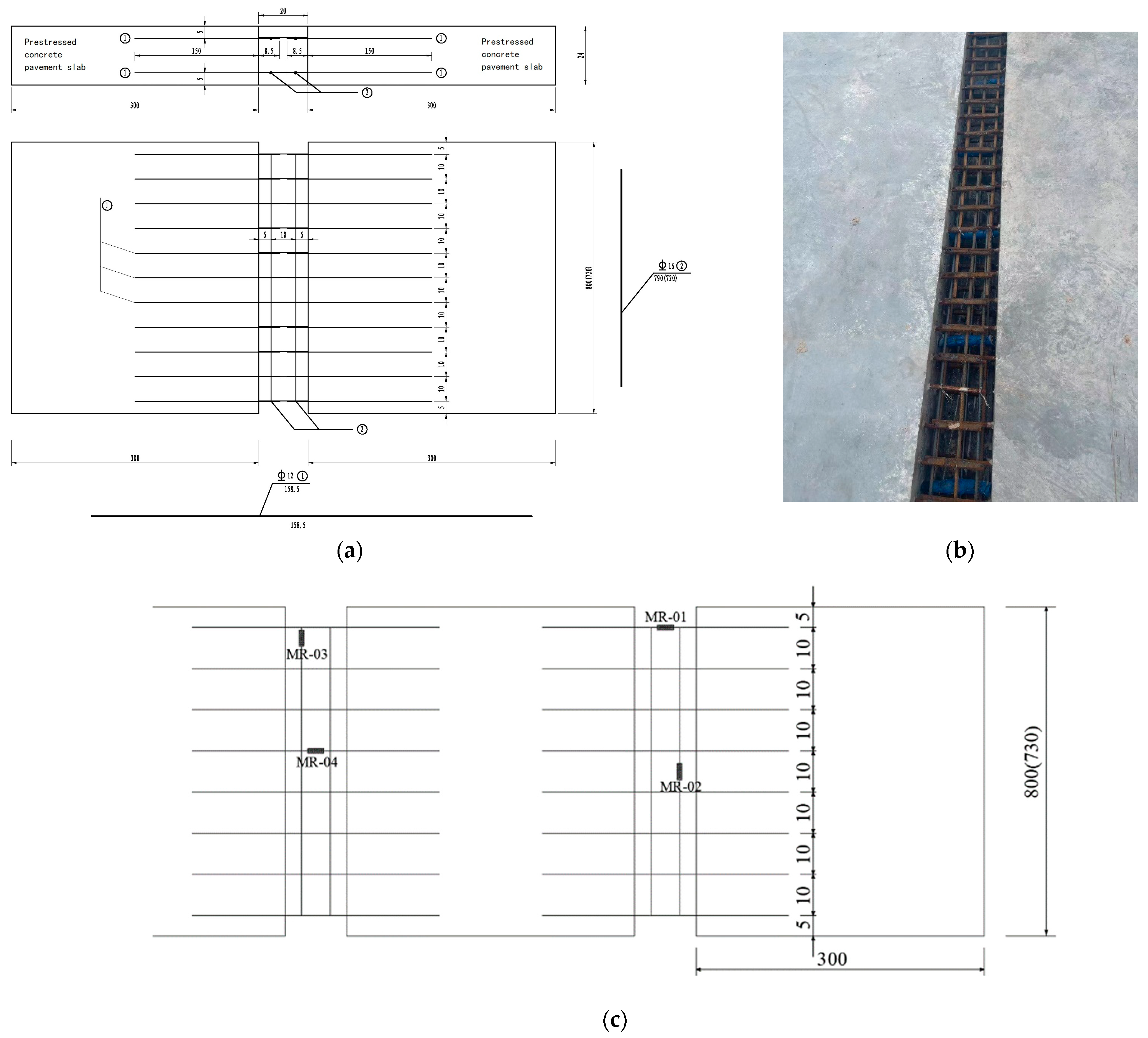

2.2.2. Field Test and Long-Term Observation of Steel-Fiber-Reinforced Self-Stressing Concrete

3. Results and Discussion

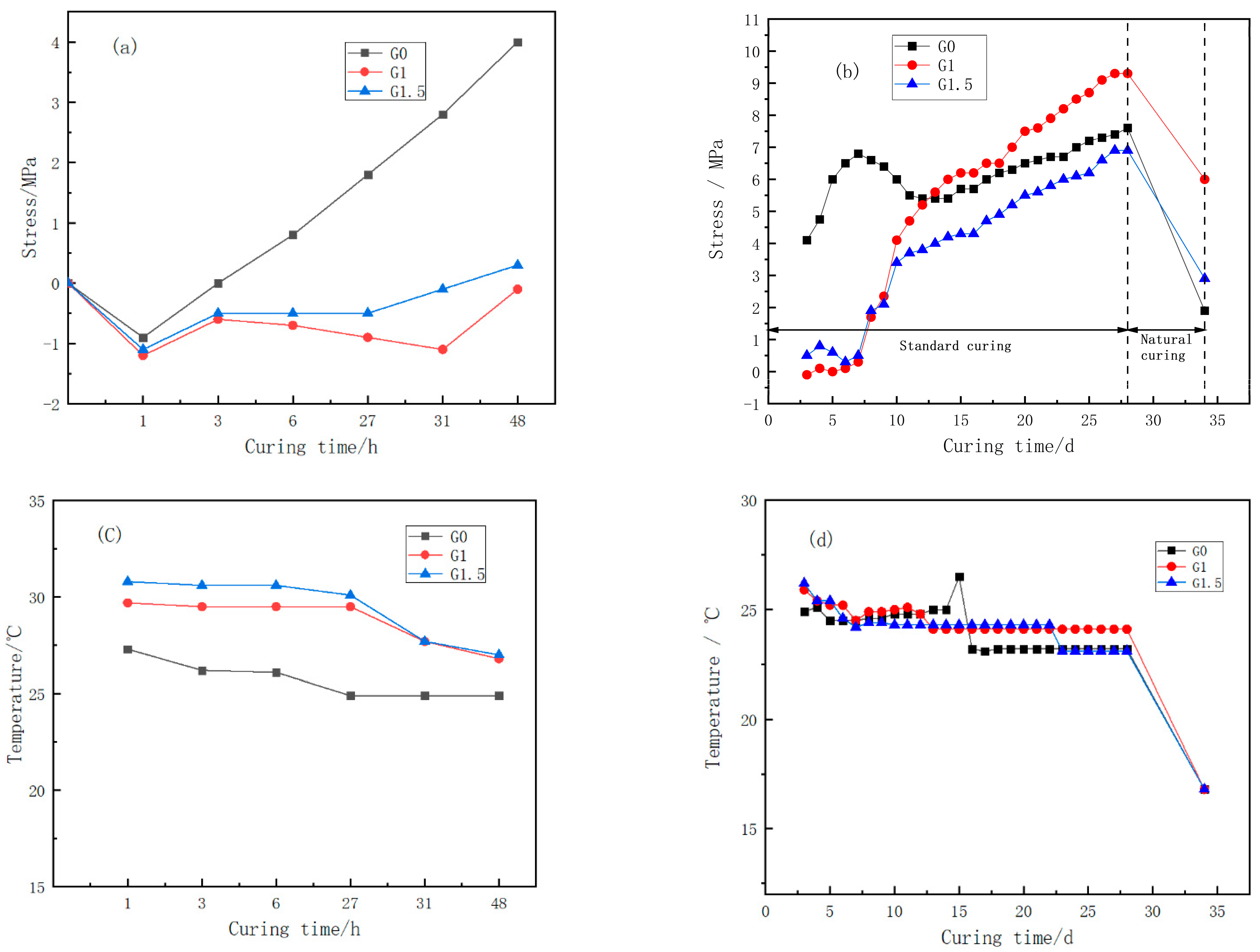

3.1. Analysis of Self-Stress Influence of Micro-Expansion Fiber Concrete

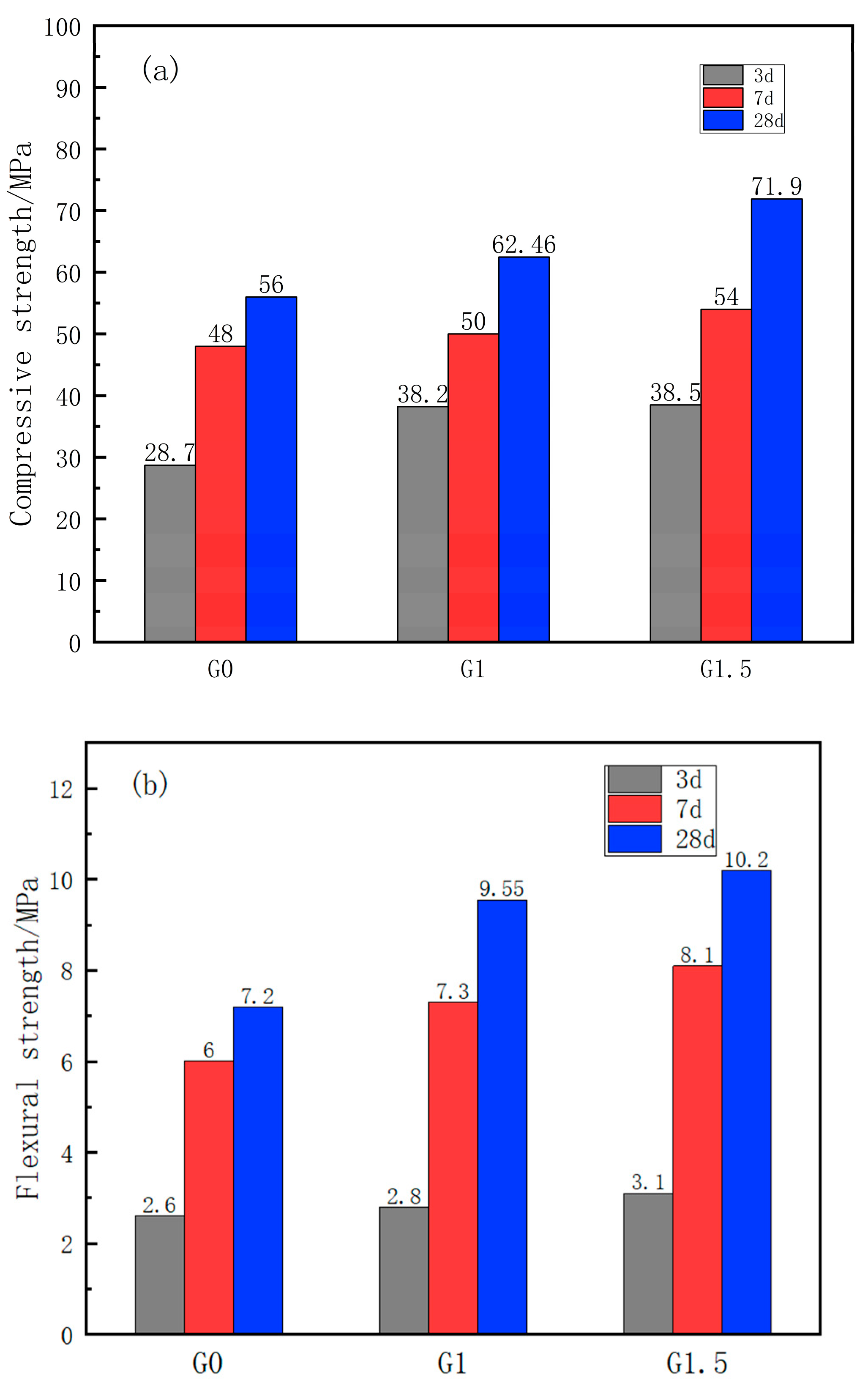

3.2. Mechanical Response Analysis of Micro-Expansion Fiber Concrete

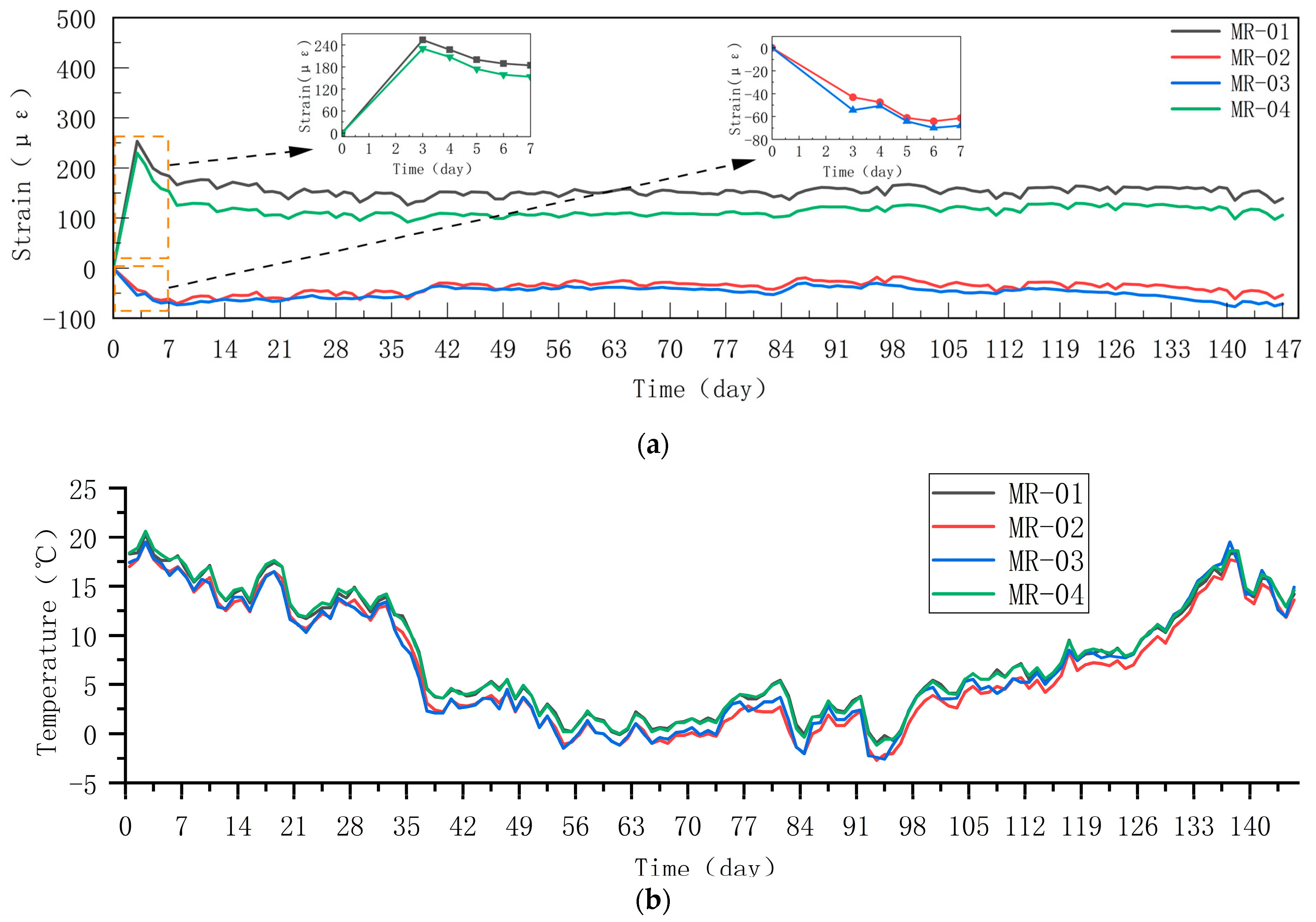

3.3. Influence Analysis of Long-Term Changes in the Use of Micro-Expansion Fiber Concrete

4. Conclusions

- (1)

- SFRSSC exhibits higher self-stress compared to ordinary concrete, and this self-stress is mainly influenced by the moisture content and the amount of added steel fibers. A higher moisture content allows the expansive agent in SFRSSC to fully hydrate, leading to significant early expansion. However, a significant portion of this expansion is ineffective and decreases noticeably as the concrete leaves the moisture curing stage. The addition of steel fibers primarily limits the development of self-stress in the early stage, and this restriction reduces with increasing steel fiber content. However, in the later stages of concrete development, this limitation on self-stress also partially restricts the shrinkage of the concrete, enabling higher self-stress to be retained in the concrete over the long term, thereby improving the pavement’s crack resistance. It should be noted that excessive steel fiber content is not ideal during usage, as a high content of steel fibers (1.5%) limits early self-stress development without retaining high self-stress in the later stages.

- (2)

- SFRSSC overcomes the brittle fracture characteristics of ordinary concrete and exhibits high resistance to deformation under compressive and flexural loads. At the age of 28 days of curing, the compressive strength and flexural strength of SFRSSC can reach 62.46 MPa and 9.55 MPa, respectively, meeting the design strength requirements for assembly-type prestressed pavement materials.

- (3)

- Through long-term monitoring of the experimental road section, SFRSSC demonstrates high stability in the joints. After 28 days, SFRSSC deformation remains in a relatively stable state, and its strain values do not vary significantly with changes in temperature. Even after 120 days, the longitudinal strain of the road remains in an expanded state. Although the transverse strain of the road is in a shrinking state, the shrinkage value slowly decreases, with only a −25.2 με variation observed at 120 days.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Editorial Department of China Journal of Highway and Transport. Review on China’s Pavement Engineering Research·2020. China J. Highw. Transp. 2020, 33, 1–66. [Google Scholar] [CrossRef]

- Liu, M.; Zhan, H.; Zeng, P.; Gong, J.; Li, X.; Sun, Z.; Zhang, W. Design Optimization and Experimental Study of Assembled Prestressed Concrete Pavement. Build. Sci. 2020, 36 (Suppl. 1), 245–252. [Google Scholar]

- Rangkang, J.; Samang, L.; Adisasmita, S.; Hustim, M. The Infiltration Capacity of Eco-concrete Paving on Different Block Shapes. IOP Conf. Ser. Earth Environ. Sci. 2020, 419, 012086. [Google Scholar] [CrossRef]

- Jamshidi, A.; Kurumisawa, K.; White, G.; Nishizawa, T.; Igarashi, T.; Nawa, T.; Mao, J. State-of-the-art of Interlocking Concrete Block Pavement Technology in Japan as a Post-modern Pavement. Constr. Build. Mater. 2019, 200, 713–755. [Google Scholar] [CrossRef]

- Zhang, J.; Weng, X.; Yang, B.; Li, Y.; Liu, J.; Jiang, L. Bonding characteristics of grouting layer in Prefabricated Cement Concrete Pavement. Constr. Build. Mater. 2017, 145, 528–537. [Google Scholar] [CrossRef]

- Qu, B.; Weng, X.-Z.; Zhang, J.; Mei, J.-J.; Guo, T.-X.; Li, R.-F.; An, S.-H. Analysis on the deflection and load transfer capacity of a prefabricated airport prestressed concrete pavement. Constr. Build. Mater. 2017, 157, 449–458. [Google Scholar] [CrossRef]

- Tao, L.; Ma, X.; Peng, X.; Huang, S. Comparison of Pouring Schemes for PC Stiffening Beams Wet Joints of Yunnan Moon Bay Bridge. Bridge Constr. 2019, 49 (Suppl. 1), 121–126. [Google Scholar]

- Li, G.; Hu, H.; Ren, C.; Zhou, S.; Li, J. Durability Performance of Bridge Concrete Structural Joints. J. Civ. Eng. 2018, 51, 98–103. [Google Scholar] [CrossRef]

- Verger-Leboeuf, S.; Charron, J.-P.; Massicotte, B. Design and Behavior of UHPFRC Field-Cast Transverse Connections between Precast Bridge Deck Elements. J. Bridge Eng. 2017, 22, 7. [Google Scholar] [CrossRef]

- Fang, M.; Zhou, R.; Ke, W.; Tian, B.; Zhang, Y.; Liu, J. Precast System and Assembly Connection of Cement Concrete Slabs for Road Pavement: A Review. J. Traffic Transp. Eng. 2022, 9, 208–222. [Google Scholar] [CrossRef]

- Murugan, R.B.; Natarajan, C.; Chen, S.-E. Material Development for a Sustainable Precast Concrete Block Pavement. J. Traffic Transp. Eng. 2016, 3, 483–491. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Q. Test Research on Load Transfer of Tie Bar of Concrete Pavement. J. Zhengzhou Univ. Eng. Sci. 2015. [Google Scholar]

- Peng, P.; Tian, B.; Niu, K. A Study on the Working Performance of Dowel Bars with Horizontal Installation Errors. J. Highw. Transp. Res. Dev. 2012, 6, 33–38. [Google Scholar] [CrossRef]

- Tan, Y.Q.; Li, L.K.; Cao, P.; Mi, F.Y.; Gong, X.B. Analysis of Corrosion Mechanism and Deterioration Process for Dowel under Deicing Salt Environment. Eng. Mech. 2013, 30, 199–205. [Google Scholar]

- Suta, M.; Lukasenoks, A.; Cepuritis, R. Determination of Material Design Values for Steel Fibre Reinforced Self-Stressing Concrete (SFRSSC) Structures. In Proceedings of the 19th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 26–28 May 2020; pp. 631–637. [Google Scholar]

- Suta, M.; Cepuritis, R.; Zegelis, A. Determination of Material Design Values for Steel Fibre Reinforced Self-Stressing Concrete (SFRSSC) and Regular Steel Fibre Reinforced Concrete (SFRC) in Statically Indeterminate Round Panel Tests. Mater. Sci. Forum 2022, 1053, 297–302. [Google Scholar] [CrossRef]

- Xi, Y.F.; Lee, J.; Chen, B.L.; Yang, B.; Yu, M.Z.; Yan, X.Z.; Zhu, L. Impact of High-Performance Expansion and Shrinkage-Reducing Agents on the Mechanical Properties and Shrinkage Compensation of High-Strength Concrete. Buildings 2023, 13, 717. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Huang, Z.; Wu, Y. Solving Shrinkage Problem of Ultra-High-Performance Concrete by a Combined Use of Expansive Agent, Super Absorbent Polymer, and Shrinkage-Reducing Agent. Compos. Part B Eng. 2021, 230, 109503. [Google Scholar] [CrossRef]

- Wang, T.; Gong, J.; Chen, B.; Gong, X.; Luo, H.; Zhang, Y.; Qu, Z. Effects of Shrinkage Reducing Agent and Expanded Cement on UHPC Fluidity, Mechanical Properties, and Shrinkage Performance. Adv. Mater. Sci. Eng. 2021, 2021, 9045754. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Wang, Y.; Liu, J.; Tian, Q. Effect of CaO and MgO Based Expansive Agent on Deformation and Mechanical Properties of Concrete-Filled Steel Tubes—ScienceDirect. Constr. Build. Mater. 2020, 250, 118723. [Google Scholar] [CrossRef]

- GB/T 50081-2009; China National Standard for Test Methods for Mechanical Properties of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2009. (In Chinese)

- JTG D40-2011; China Communications Highway Planning and Design Institute Co., Ltd. Design Specification for Highway Cement Concrete Pavement: JTG D40-2011. People’s Communications Press: Beijing, China, 2011.

- Li, Y.; Ruan, X.; Huo, N. Experimental and Numerical Analysis on Early Shrinkage of Microporous Concrete. J. Tongji Univ. Nat. Sci. 2023, 51, 696–705. [Google Scholar]

- Sun, H.; Ye, L.; Ding, J.; Guo, Y. Shrinkage and Creep Test of High-Strength Lightweight Aggregate Concrete. Tsinghua Univ. J. Nat. Sci. Ed. 2007, 765–767+780. [Google Scholar] [CrossRef]

- Zhang, J.; Yi, J.; Zhang, M.; Wang, K.; Wang, L. Experimental Study on Shrinkage Performance of All-Coral Concrete. Concrete 2023, 399, 165–168+177. [Google Scholar]

| Composite | CaO | Al2O3 | MgO | SiO2 | Fe2O3 | SO3 | LOI |

|---|---|---|---|---|---|---|---|

| Cement | 65.1 | 3.1 | 2.8 | 23.2 | 2.6 | 1.6 | 1.6 |

| Fly ash | 6.2 | 32.6 | 0.7 | 48.5 | 8.7 | 1.2 | 2.1 |

| Material | Physical Properties |

|---|---|

| Cement | Ordinary Portland cement (OPC, density: 3.15 g/cm3, specific surface area: 3440 cm2/g) |

| Fly ash | (Density: 2.35 g/cm3, specific surface area: 4110 cm2/g) |

| Fine aggregate | (River sand, size: 0.35~0.45 mm, density: 2.58 g/cm3, absorption: 1%) |

| Coarse aggregate | (Basalt gravel, 5~20 mm, apparent density 2.933 g/cm3) |

| Superplasticizer | Polycarboxylic-based superplasticizer (specific gravity: 1.05 ± 0.05, pH: 5.0 ± 1.5) |

| Steel fiber | (Milling type, size: 32 mm ± 2, length–diameter ratio: 35–45, tensile strength ≥ 700 MPa) |

| Components | CaO | Al2O3 | MgO | SiO2 | Fe2O3 | SO3 | LOI |

|---|---|---|---|---|---|---|---|

| HCSA | 65.21 | 4.88 | 1.45 | 1.81 | 1.22 | 22.33 | 3.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, Y.-F.; Ren, S.-J.; Chen, B.-L.; Yang, B.; Lee, J.; Zhu, G.-H.; Zhou, T.-C.; Xu, H. Application of Steel-Fiber-Reinforced Self-Stressing Concrete in Prefabricated Pavement Joints. Buildings 2023, 13, 2129. https://doi.org/10.3390/buildings13092129

Xi Y-F, Ren S-J, Chen B-L, Yang B, Lee J, Zhu G-H, Zhou T-C, Xu H. Application of Steel-Fiber-Reinforced Self-Stressing Concrete in Prefabricated Pavement Joints. Buildings. 2023; 13(9):2129. https://doi.org/10.3390/buildings13092129

Chicago/Turabian StyleXi, Yun-Feng, Sheng-Jun Ren, Bao-Ling Chen, Bing Yang, Jin Lee, Guang-Hao Zhu, Tian-Cheng Zhou, and Hao Xu. 2023. "Application of Steel-Fiber-Reinforced Self-Stressing Concrete in Prefabricated Pavement Joints" Buildings 13, no. 9: 2129. https://doi.org/10.3390/buildings13092129

APA StyleXi, Y.-F., Ren, S.-J., Chen, B.-L., Yang, B., Lee, J., Zhu, G.-H., Zhou, T.-C., & Xu, H. (2023). Application of Steel-Fiber-Reinforced Self-Stressing Concrete in Prefabricated Pavement Joints. Buildings, 13(9), 2129. https://doi.org/10.3390/buildings13092129