Blast-Resistance and Damage Behavior of Underwater Explosion for Concrete Gravity Dam Considering Concrete Strength Partition

Abstract

:1. Introduction

2. Material Model

2.1. Concrete Material Model

2.2. Rock Foundation HJC Model

2.3. JWL Equation of State

2.4. Equation of State for Water

2.5. Equation of State for Air

3. Validation of the Fully Coupled Aerial Explosion Model

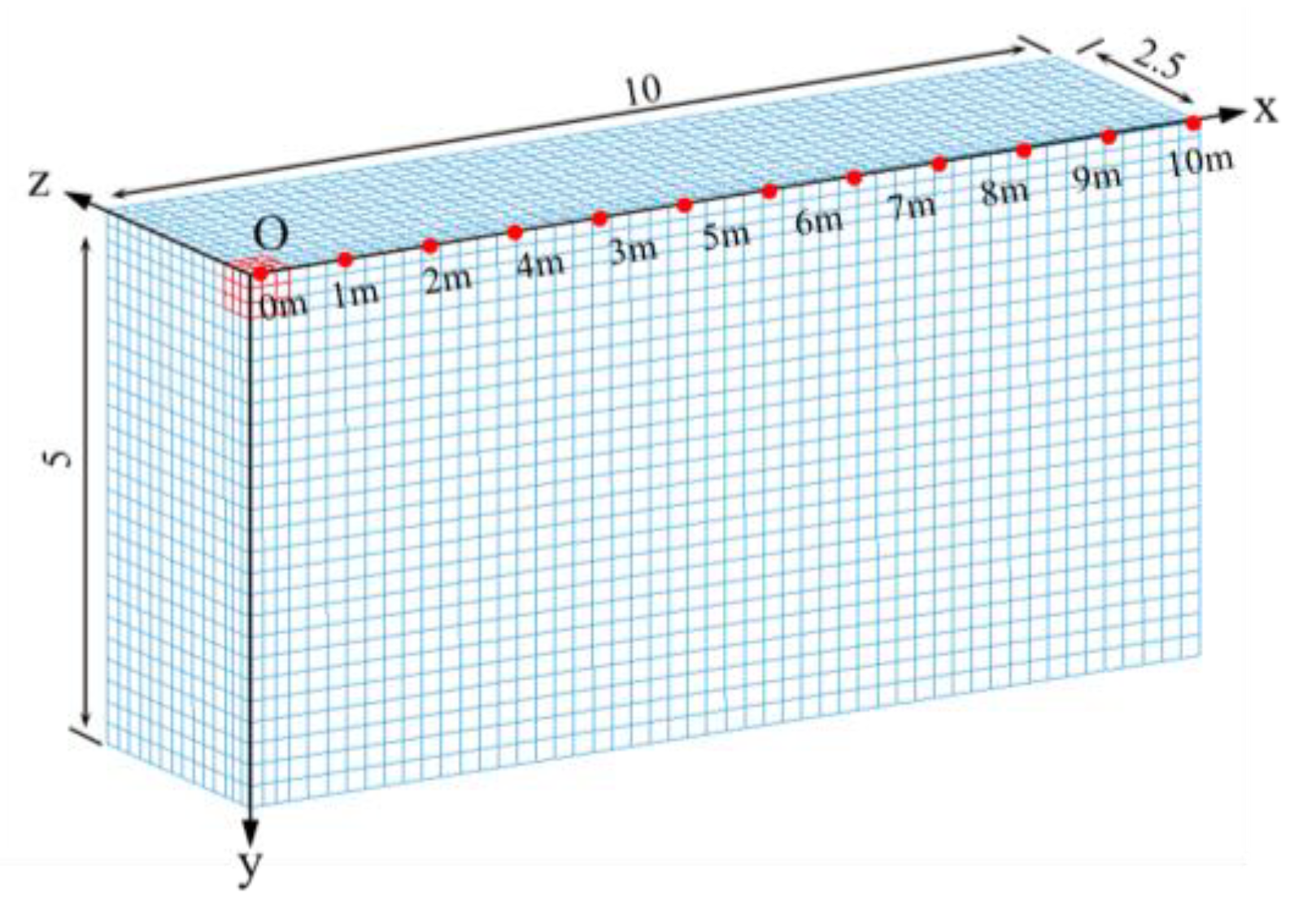

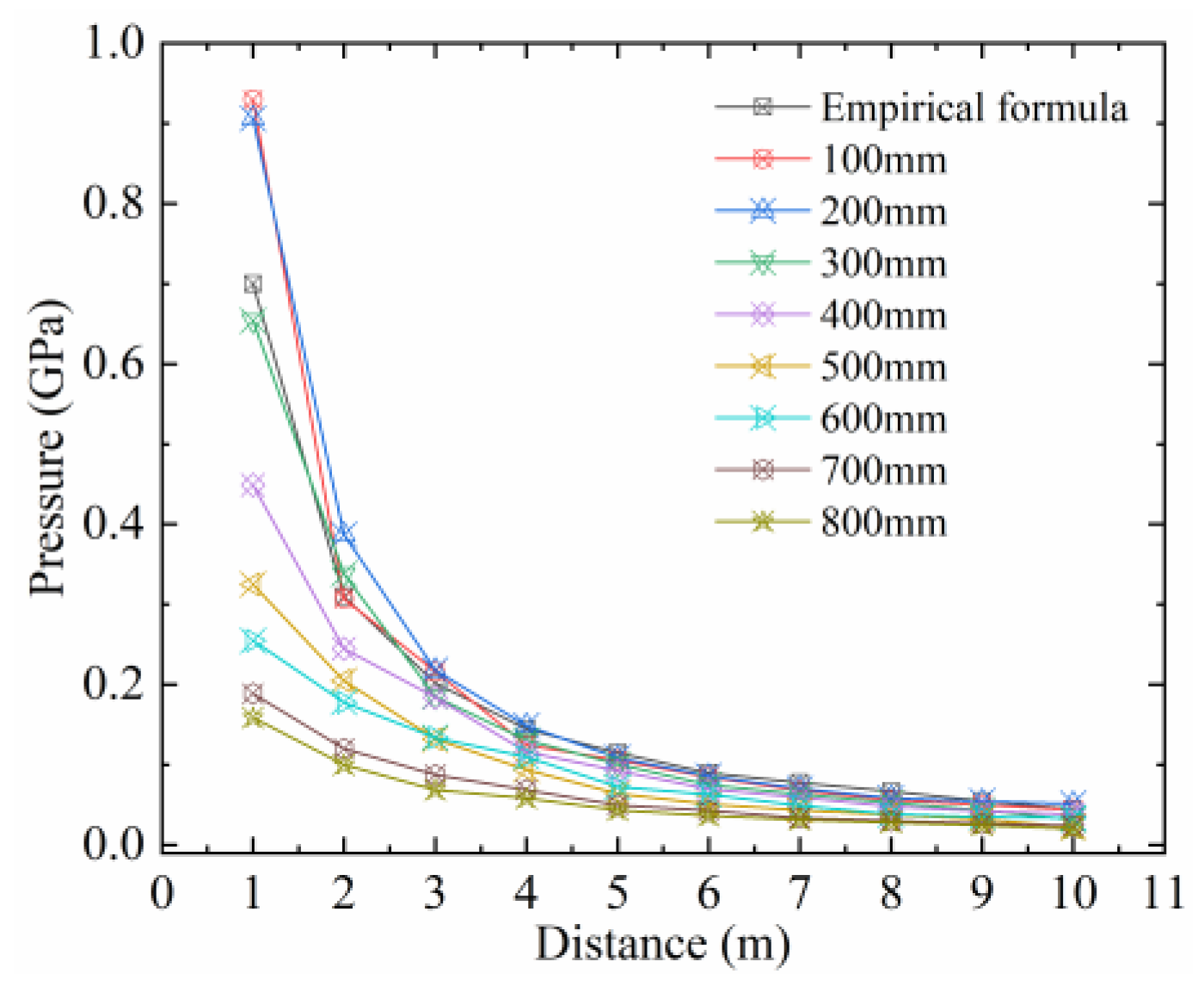

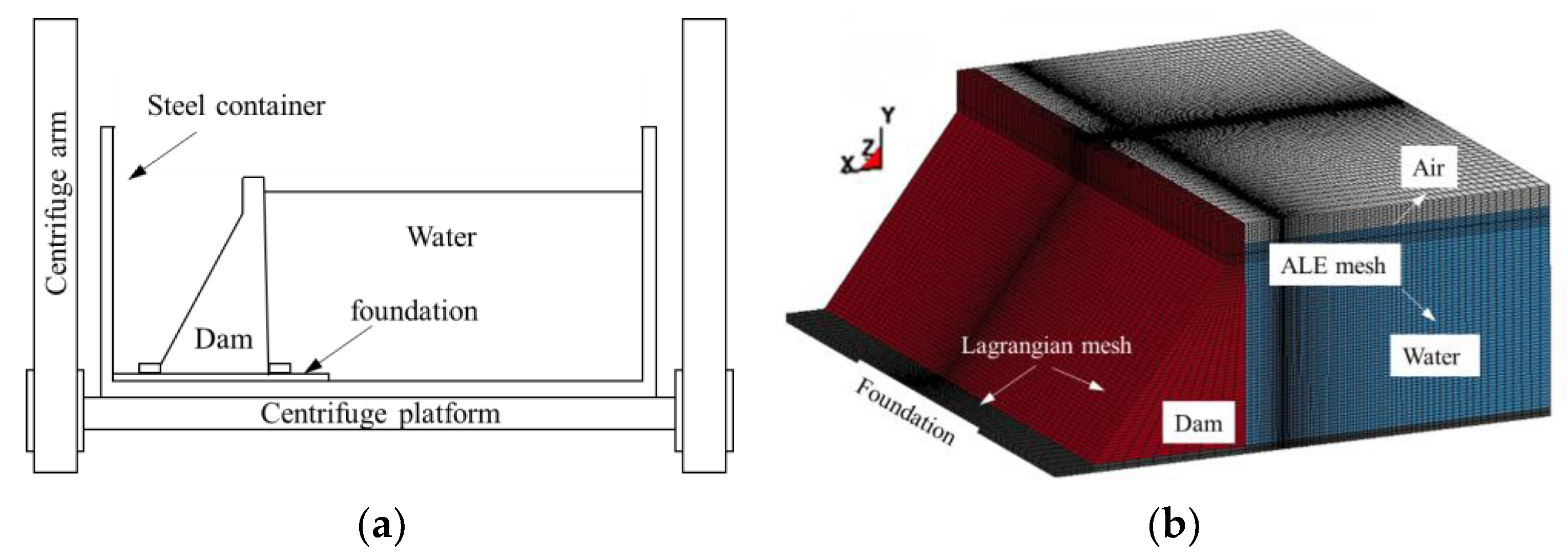

3.1. Numerical Model Validation

3.2. Validation of the Fully Coupled Aerial Explosion Model

4. Analysis of Anti-Knock Performance of CSPGD

4.1. Description of Analysis Model

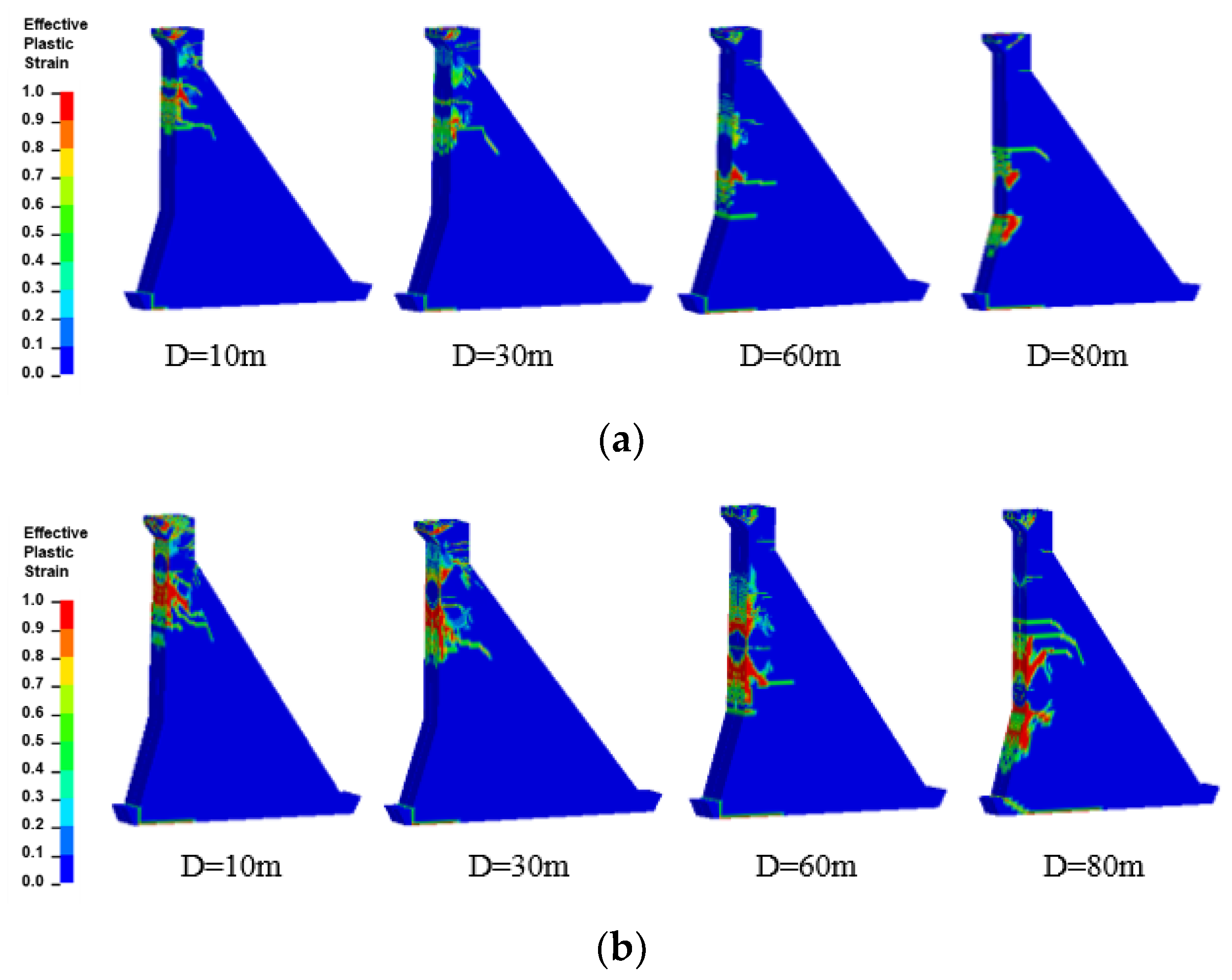

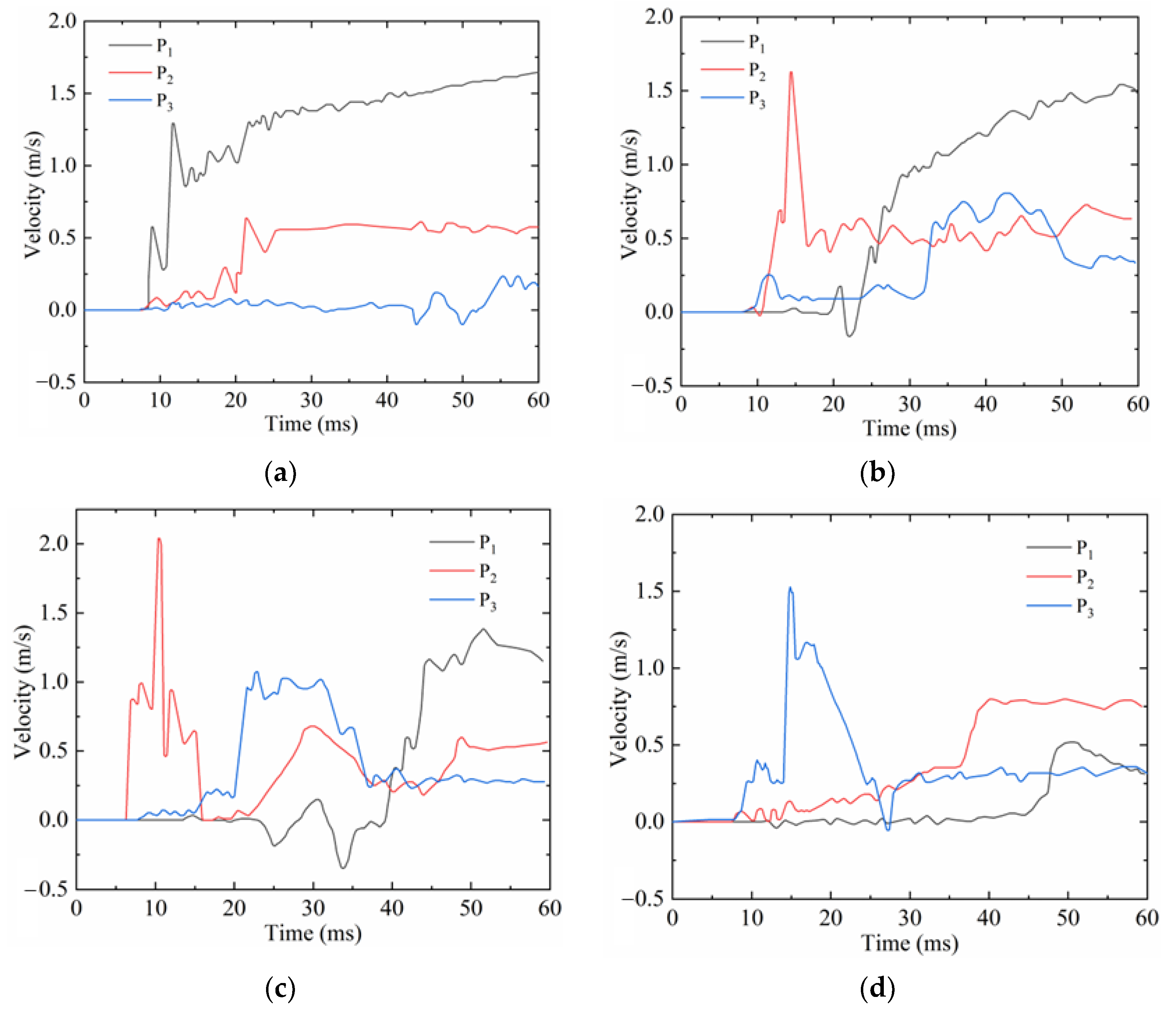

4.2. Effect of Detonation Depth on Destruction Mode

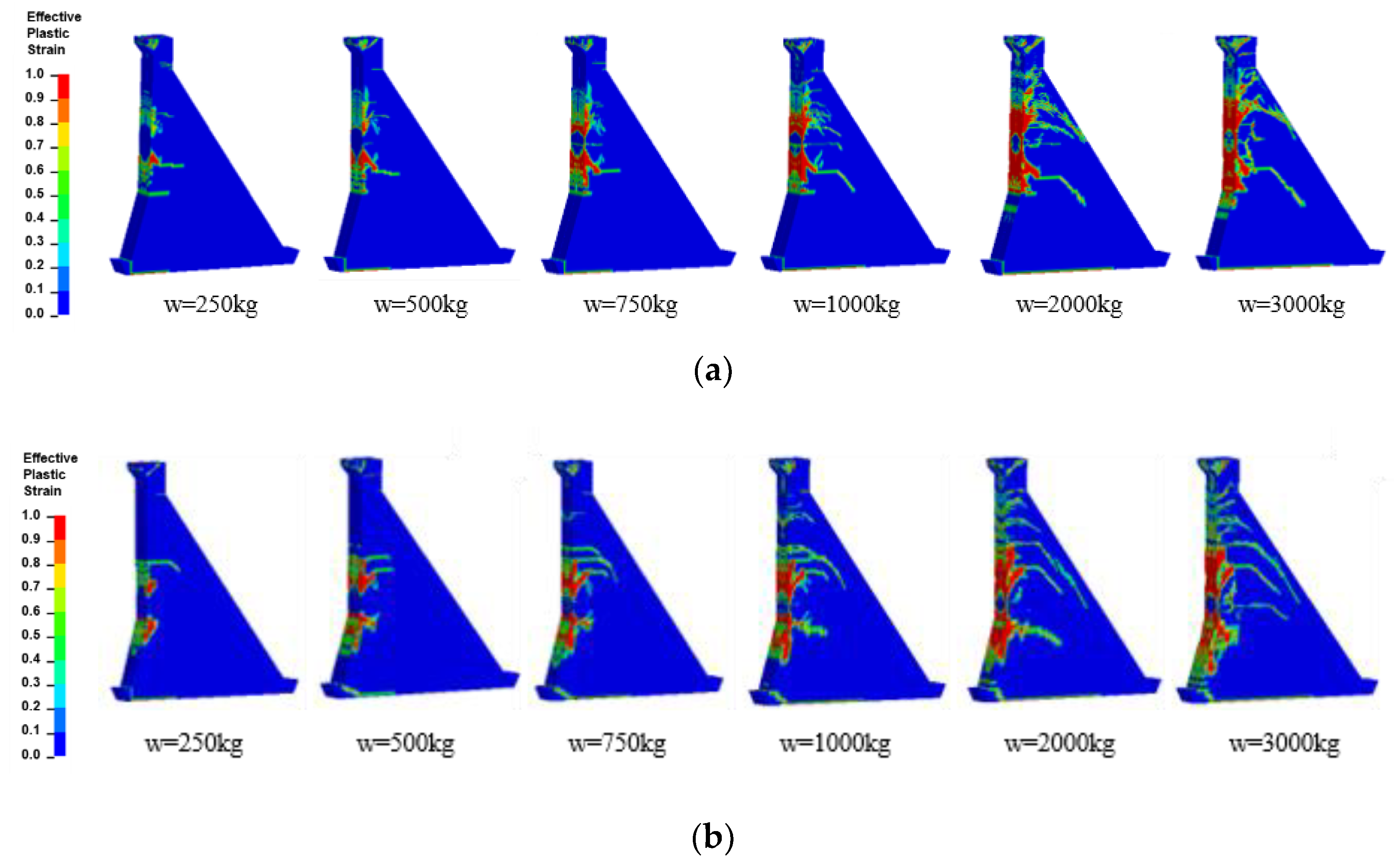

4.3. Effect of TNT Weight on Destruction Mode

4.4. Effect of Standoff Distance on Destruction Mode

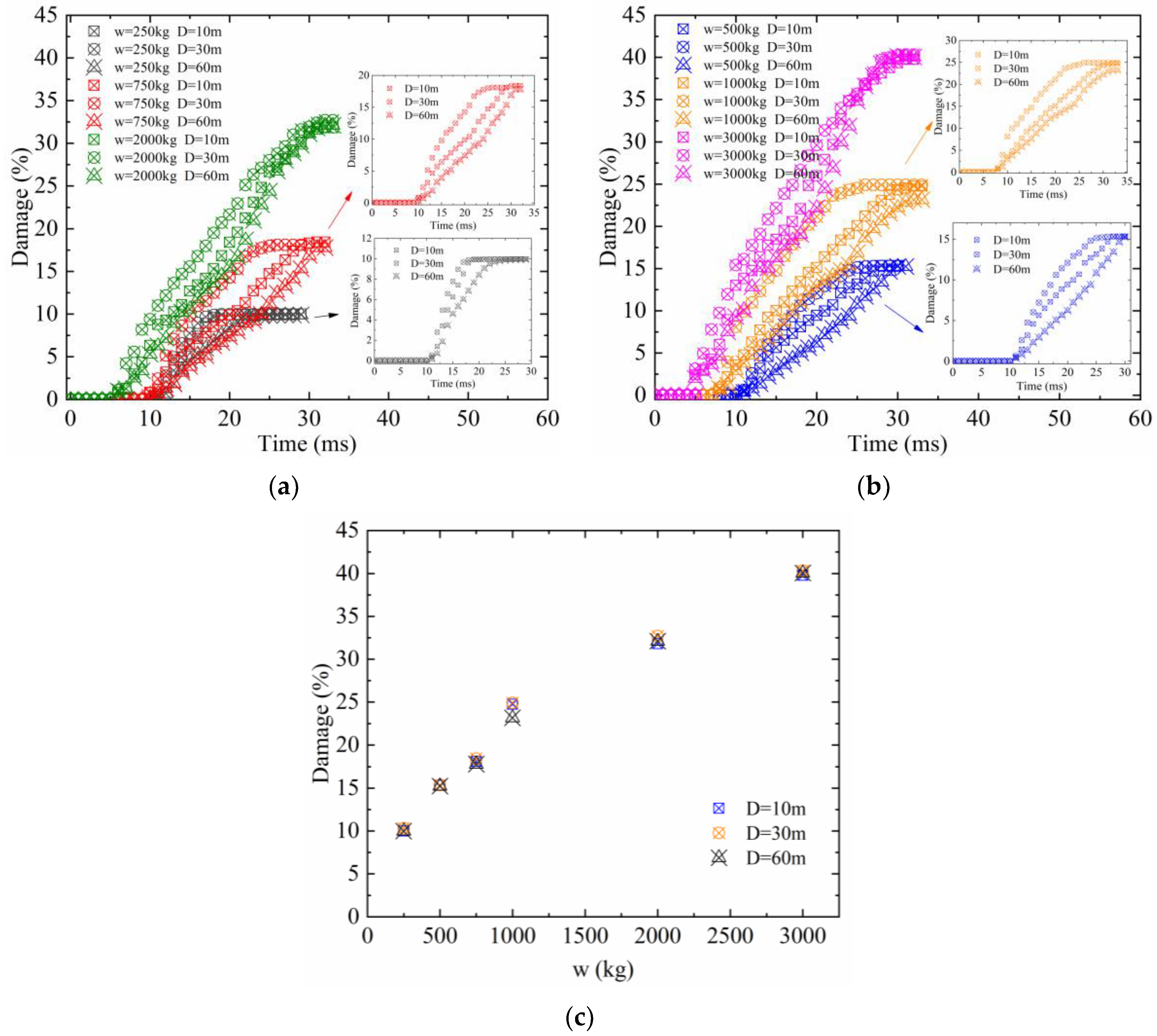

4.5. Effects of Detonation Depth and TNT Weight on Cumulative Damage

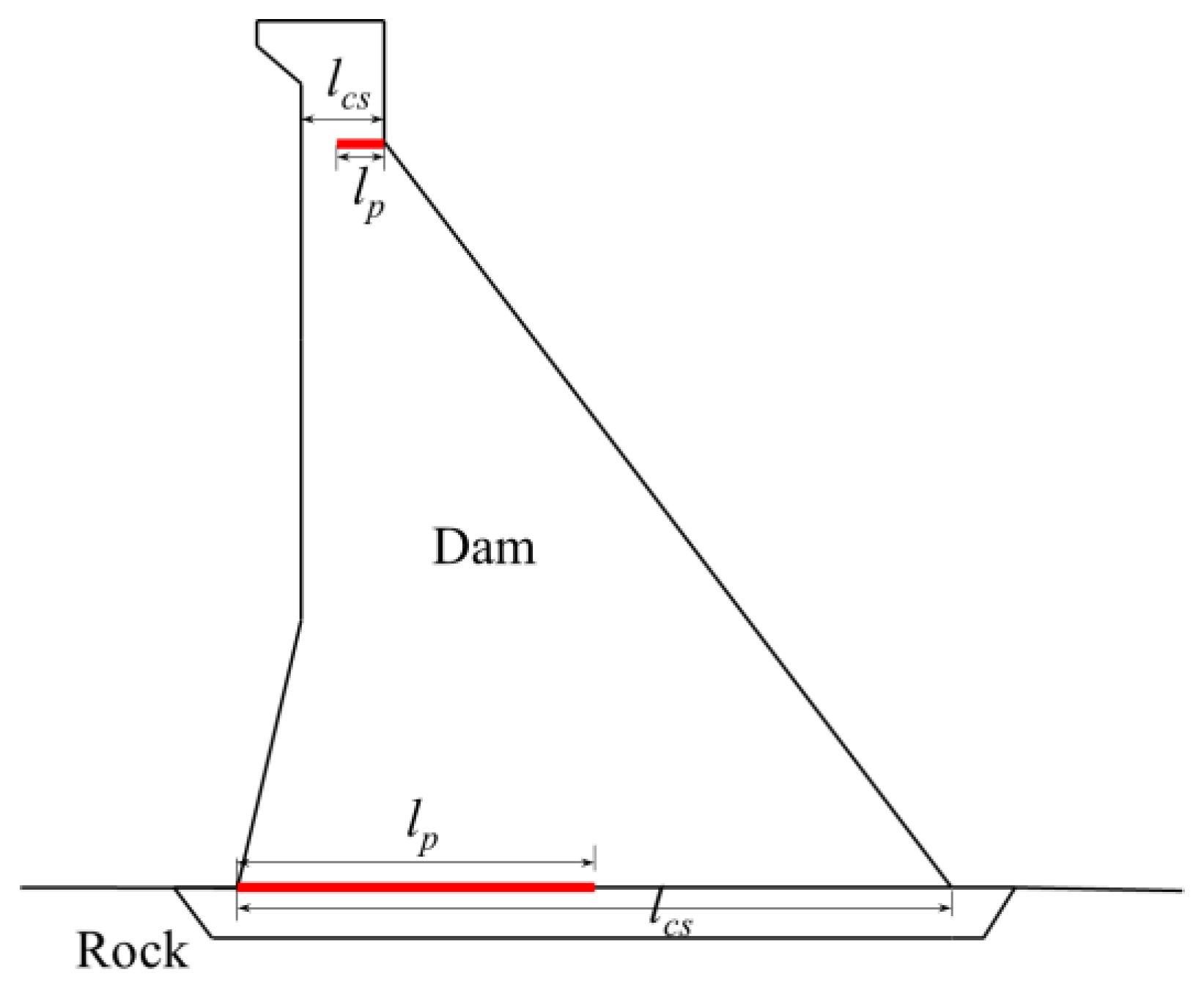

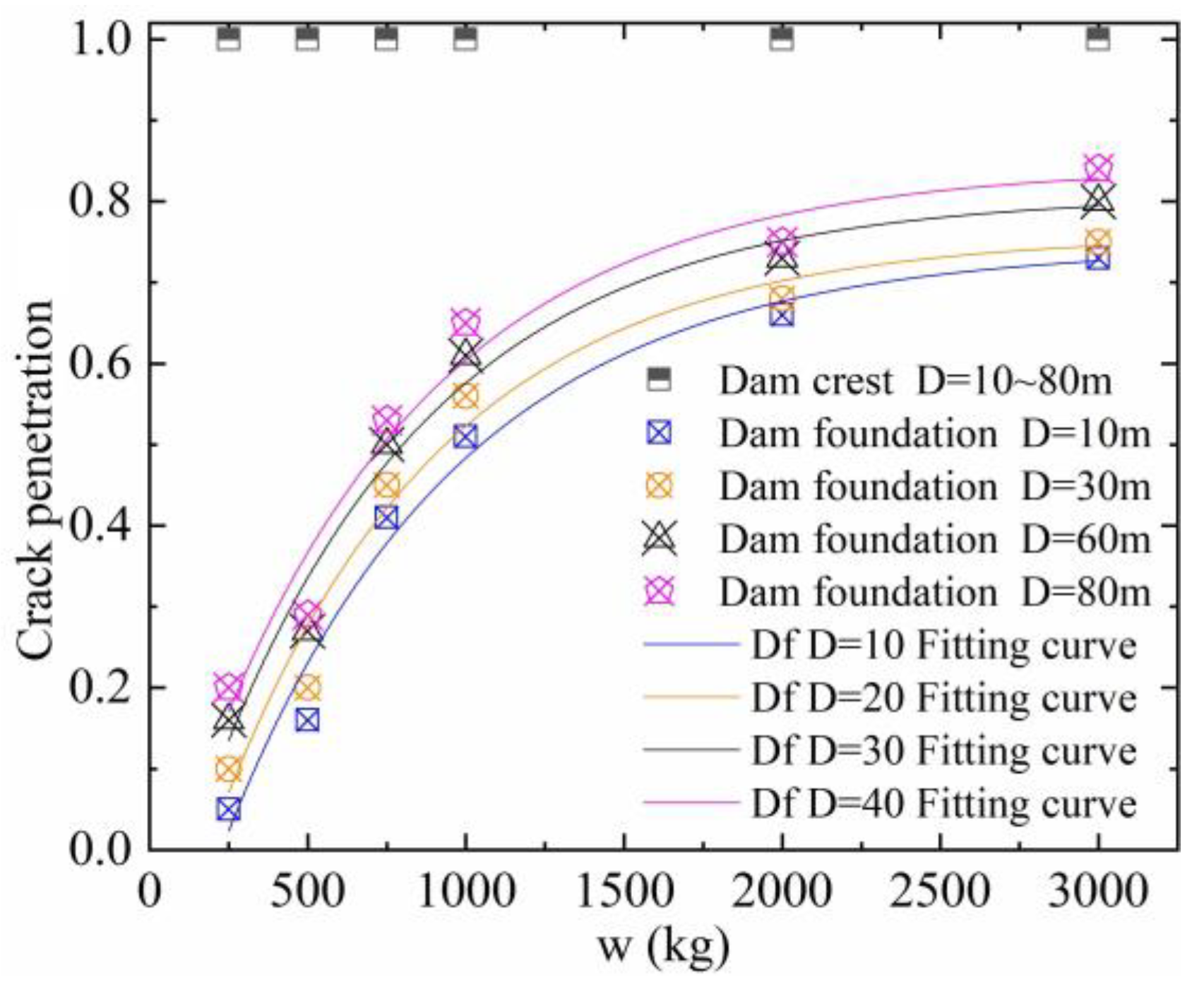

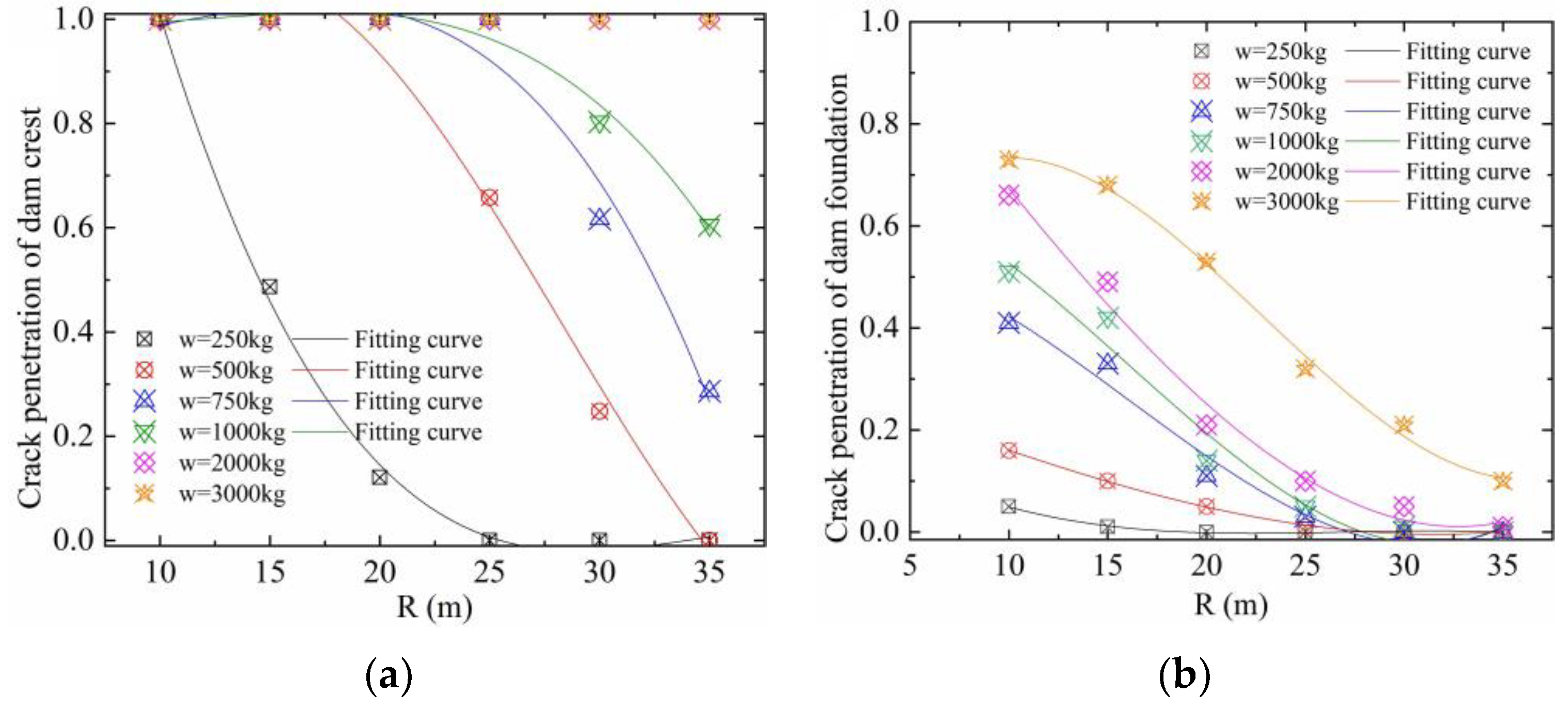

4.6. Relationship between the TNT Weight, Horizontal Initiation Distance, and the Crack Penetration Ratio

4.7. CSPGD Damage Statistics

5. Conclusions

- The detonation depth had a significant impact on the dam anti-knock performance. When TNT weight and standoff distance remained unchanged, the damage position and horizontal velocity response on upstream surface showed a downward trend with the increase in detonation depth. The dam foundation cracks at the interface between the RI and rock foundation continued to increase, which adversely affected the anti-sliding stability of the dam foundation. The interface between RIII and RII had a strain rate effect and the RIII and RII were prone to tensile cracks under low strain. The detonation depth had no significant effect on the penetration degree of the dam crest crack and the dam crest was always a penetrating crack. At the same time, the detonation depth affected the response time of the dam damage but did not affect the final damage range value.

- The standoff distance affected the dam anti-knock performance. The dam damage caused by a short-range underwater explosion was more serious, and the dynamic response of the dam crest was also more severe than that of a long-distance explosion. In special periods, isolation measures should be taken to avoid underwater explosions near the dams.

- The dam damage degree was evaluated by the crack penetration ratio. According to the calculation results, different detonation depths, standoff distances, and the dam crest and dam foundation crack penetration ratio were fitted. The study found that the crack penetration ratio conformed a logarithmic relationship with TNT weights and conformed a cubic polynomial relationship with standoff distance, which provided a reference for the dam damage prediction under the action of explosion impact.

- By introducing the concept of crack penetration, the dam crest (TNT = 250 kg) and dam foundation (TNT > 250 kg) were used as damage indicators to evaluate the anti-knock performance of the dams with different TNT weights. The dam failure curves were obtained based on the statistical method to count the damage results in all scenarios.

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, J.; Shi, Y.; Li, Z.X.; Chen, L. Failure analysis and damage assessment of RC columns under close-in explosions. J. Perform. Constr. Fac. 2015, 29, B4015003. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Y.; Zhao, H.; Qian, H.; Mou, J. An experimental study on the dynamic response of a hull girder subjected to near field underwater explosion. Mar. Struct. 2015, 44, 43–60. [Google Scholar] [CrossRef]

- Tang, E.K.C.; Hao, H. Numerical simulation of a cable-stayed bridge response to blast loads, Part I: Model development and response calculations. Eng. Struct. 2010, 32, 3180–3192. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, S. Damage prediction of concrete gravity dams subjected to underwater explosion shock loading. Eng. Fail. Anal. 2014, 39, 72–91. [Google Scholar] [CrossRef]

- Li, Q.; Wang, G.; Lu, W.; Niu, X.; Chen, M.; Yan, P. Failure modes and effect analysis of concrete gravity dams subjected to underwater contact explosion considering the hydrostatic pressure. Eng. Fail. Anal. 2018, 85, 62–76. [Google Scholar] [CrossRef]

- Williams, G.D.; Williamson, E.B. Response of reinforced concrete bridge columns subjected to blast loads. J. Struct. Eng. 2011, 137, 903–913. [Google Scholar] [CrossRef]

- Turgut, P.; Gurel, M.A.; Pekgokgoz, R.K. LPG explosion damage of a reinforced concrete building: A case study in Sanliurfa, Turkey. Eng. Fail. Anal. 2013, 32, 220–235. [Google Scholar] [CrossRef]

- Zong, Z.; Zhao, Y.; Li, H. A numerical study of whole ship structural damage resulting from close-in underwater explosion shock. Mar. Struct. 2013, 31, 24–43. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, G.; Wang, C.; Pang, B.; Du, C. Numerical simulation of failure modes of concrete gravity dams subjected to underwater explosion. Eng. Fail. Anal. 2014, 36, 49–64. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, S.; Wang, C.; Cui, W.; Cao, K.; Fang, X. Blast-induced damage and evaluation method of concrete gravity dam subjected to near-field underwater explosion. Eng. Struct. 2020, 209, 109996. [Google Scholar] [CrossRef]

- Falconer, J. The Dam Buster Story; Sutton Publishing Ltd.: Stroud, UK, 2007. [Google Scholar]

- Vanadit-Ellis, W.; Davis, L.K. Physical modeling of concrete gravity dam vulnerability to explosions. In Proceedings of the International WaterSide Security Conference, Carrara, Italy, 3–5 November 2010. [Google Scholar] [CrossRef]

- Huang, X.; Kong, X.; Hu, J.; Fang, Q. Failure modes of concrete gravity dam subjected to near-field underwater explosion: Centrifuge test and numerical simulation. Eng. Fail. Anal. 2022, 137, 106243. [Google Scholar] [CrossRef]

- Huang, X.; Kong, X.; Hu, J.; Fang, Q. Scaling the failure of concrete gravity dam subjected to underwater explosion—Part I: Suggestion of a dimensionless number. Ocean Eng. 2023, 277, 114316. [Google Scholar] [CrossRef]

- Huang, X.; Kong, X.; Hu, J.; Fang, Q. Scaling the failure of concrete gravity dam subjected to underwater explosion—Part II: Correction method to consider the strain-rate effect. Ocean Eng. 2023, 281, 114728. [Google Scholar] [CrossRef]

- Huang, X.; Hu, J.; Zhang, X.; Zhang, Z. Effect of bubble pulse on concrete gravity dam subjected to underwater explosion: Centrifuge test and numerical simulation. Ocean Eng. 2022, 243, 110291. [Google Scholar] [CrossRef]

- Zhou, X.Q.; Kuznetsov, V.A.; Hao, H.; Waschl, J. Numerical prediction of concrete slab response to blast loading. Int. J. Impact Eng. 2008, 35, 1186–1200. [Google Scholar] [CrossRef]

- Riedel, W.; Mayrhofer, C.; Thoma, K.; Stolz, A. Engineering and numerical tools for explosion protection of reinforced concrete. Int. J. Prot. Struct. 2010, 1, 85–101. [Google Scholar] [CrossRef]

- Yu, T. Dynamical response simulation of concrete dam subjected to underwater contact explosion load. In Proceedings of the 2009 WRI world Congress on Computer Science and Information Engineering, Los Angeles, CA, USA, 31 March–2 April 2009. [Google Scholar] [CrossRef]

- Linsbauer, H. Hazard potential of zones of weakness in gravity dams under impact loading conditions. Front. Archit. Civ. Eng. China 2011, 5, 90–97. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, S.; Kong, Y.; Li, H. Comparative study of the dynamic response of concrete gravity dams subjected to underwater and air explosions. J. Perform. Constr. Fac. 2015, 29, 04014092. [Google Scholar] [CrossRef]

- Shu, Y.; Wang, G.; Lu, W.; Chen, M.; Lv, L.; Chen, Y. Damage characteristics and failure modes of concrete gravity dams subjected to penetration and explosion. Eng. Fail. Anal. 2022, 134, 106030. [Google Scholar] [CrossRef]

- Wang, G.; Shu, Y.; Lu, W.; Chen, M.; Pan, X.; Lu, A. Damage prediction of concrete gravity dams subjected to penetration explosion. Eng. Fail. Anal. 2023, 143, 106855. [Google Scholar] [CrossRef]

- Ma, S.; Chen, Y.; Wang, Z.; Li, S.; Zhu, Q.; Chen, L. The damage to model concrete gravity dams subjected to water explosions. Def. Technol. 2022, in press. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, Y.; Lyu, L. Failure analysis for concrete gravity dam subjected to underwater explosion: A comparative study. Eng. Fail. Anal. 2022, 134, 106052. [Google Scholar] [CrossRef]

- Zhang, L.M.; Xu, Y.; Jia, J.S. Analysis of earth dam failures: A database approach. Georisk. 2009, 3, 184–189. [Google Scholar] [CrossRef]

- Schwer, L.E.; Murray, Y.D. A three-invariant smooth cap model with mixed hardening. Int. J. Numer. Anal. Met. 1994, 18, 657–688. [Google Scholar] [CrossRef]

- Sandler, I.S.; Baladi, G.Y.; DiMaggio, F.L. Generalized cap model for geological materials. J. Geotech. Eng. Div. 1976, 102, 683–699. [Google Scholar] [CrossRef]

- Rubin, M.B. Simple; convenient isotropic failure surface. J. Eng. Mech. 1991, 117, 348–369. [Google Scholar] [CrossRef]

- Murray, Y.D. Users Manual for LS-DYNA Concrete Material Model 159; Federal Highway Administration: Washington, DC, USA, 2007. [Google Scholar]

- Holomquist, T.J.; Johnson, G.R.; Cook, W.H. A computational constitutive model for concrete subjective to large strains, high strain rates, and high pressures. In The 14th International Symposium on Ballistics; Jackson, N., Dickert, S., Eds.; American Defense Prepareness Association: Arlington, VA, USA, 1993; pp. 591–600. [Google Scholar] [CrossRef]

- Johnson, G.R.; Beissel, S.R.; Holmquist, T.J.; Frew, D.J. Computed Radial Stresses in a Concrete Target Penetrated by a Steel Projectile; WIT Press: Southampton, UK, 1970; Volume 35. [Google Scholar] [CrossRef]

- Corporation LST. LS-DYNA Keyword User’s Manual; Livermore Software Technology Corporation: Livermore, CA, USA, 2006. [Google Scholar]

- Cole, R.H. Underwater Explosions; Dover Publications: New York, NY, USA, 1948. [Google Scholar]

- Mair, H.U. Hydrocode methodologies for underwater explosion structure medium/interaction. Shock Vib. 1995, 2, 227–248. [Google Scholar]

- Shin, Y.S.; Chisum, J.E. Modeling and simulation of underwater shock problems using a coupled Lagrangian-Eulerian analysis approach. Shock Vib. 1997, 4, 123617. [Google Scholar] [CrossRef]

- Mair, H.U. Hydrocodes for structural response to underwater explosions. Shock Vib. 1999, 6, 81–96. [Google Scholar] [CrossRef]

- Van der Veen, W.A. Simulation of a Compartmented Airbag Deployment Using an Explicit, Coupled Euler/Lagrange Method with Adaptive Euler Domains; NAFEMS: Tampa, FL, USA, 2003. [Google Scholar]

- Zhang, Q.L.; Li, D.Y.; Hu, L.; Hu, C. Viscous damping and contraction joint friction in underwater explosion resistant design of arch dams. J. Perform. Constr. Fac. 2019, 33, 04019020. [Google Scholar] [CrossRef]

- Chung, Y.S.; Meyer, C.; Shinozuka, M. Modeling of concrete damage. ACI Struct. J. 1989, 86, 259–271. [Google Scholar]

- Hu, J.; Zhang, Z.T.; Wen, Y.F.; Zhang, X.D.; Liang, J.H.; Huang, X.P. Physical modeling on dynamic responses of gravity dams by underwater explosion in a centrifuge. J. Perform. Constr. Fac. 2021, 35, 04021023. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Y.; Lu, W.; Zhou, W.; Chen, M.; Yan, P. On the determination of the mesh size for numerical simulations of shock wave propagation in near field underwater explosion. Appl. Ocean Res. 2016, 59, 1–9. [Google Scholar] [CrossRef]

- Hao, Y.; Hao, H.; Li, Z.X. Influence of end friction confinement on impact tests of concrete material at high strain rate. Int. J. Impact Eng. 2013, 60, 82–106. [Google Scholar] [CrossRef]

- Park, Y.J.; Ang, A.H.S. Mechanistic seismic damage model for reinforced concrete. J. Struct. Eng. 1985, 111, 722–739. [Google Scholar] [CrossRef]

| Fundamental Parameters | Value | Strength Surface | Value | Damage Parameters | Value | EOS Parameters | Value |

|---|---|---|---|---|---|---|---|

| Density (kg/m3) | 2800 | 0.79 | 0.04 | Crushing pressure (MPa) | 16 | ||

| Shear modulus (Gpa) | 16.7 | 1.60 | 1.0 | Crushing volumetric strain | 0.001 | ||

| Compressive strength (Mpa) | 150 | 0.61 | 0.01 | Locking pressure (Mpa) | 800 | ||

| 0.004 | 0.007 | (Mpa) | 7.00 | Locking volumetric strain | 0.10 | ||

| 0.01 | (Mpa) | 85 | |||||

| 7.00 | (Mpa) | −171 | |||||

| (Mpa) | 208 |

| D/m | m | n | R*2 |

|---|---|---|---|

| 10 | 0.2922 | 1.5702 | 0.9592 |

| 30 | 0.2796 | 1.4482 | 0.9477 |

| 60 | 0.2736 | 1.3521 | 0.9551 |

| 80 | 0.2731 | 1.3172 | 0.9470 |

| w/kg | t | s | k | l | R*2 |

|---|---|---|---|---|---|

| 250 | −1 × 10−5 | 0.0011 | −0.0279 | 0.2343 | 0.9929 |

| 500 | 4 × 10−6 | 3 × 10−5 | −0.0151 | 0.3043 | 0.9986 |

| 750 | 4 × 10−5 | −0.0021 | 0.0047 | 0.5395 | 0.9753 |

| 1000 | 5 × 10−5 | −0.0024 | 0.0043 | 0.6762 | 0.9701 |

| 2000 | 2 × 10−5 | −0.0002 | −0.0494 | 1.1700 | 0.9865 |

| 3000 | 7 × 10−5 | −0.005 | 0.0783 | 0.3776 | 0.9962 |

| w/kg | t | s | k | l | R*2 |

|---|---|---|---|---|---|

| 250 | −8 × 10−5 | 0.0084 | −0.2815 | 3.0638 | 0.9977 |

| 500 | 0.0001 | −0.0102 | 0.2177 | −0.2982 | 0.9859 |

| 750 | −7 × 10−5 | 0.0021 | −0.0158 | 0.9983 | 0.9725 |

| 1000 | −4 × 10−5 | 0.0017 | −0.0187 | 1.0565 | 0.9796 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, W. Blast-Resistance and Damage Behavior of Underwater Explosion for Concrete Gravity Dam Considering Concrete Strength Partition. Buildings 2023, 13, 2237. https://doi.org/10.3390/buildings13092237

Huo W. Blast-Resistance and Damage Behavior of Underwater Explosion for Concrete Gravity Dam Considering Concrete Strength Partition. Buildings. 2023; 13(9):2237. https://doi.org/10.3390/buildings13092237

Chicago/Turabian StyleHuo, Wenlong. 2023. "Blast-Resistance and Damage Behavior of Underwater Explosion for Concrete Gravity Dam Considering Concrete Strength Partition" Buildings 13, no. 9: 2237. https://doi.org/10.3390/buildings13092237

APA StyleHuo, W. (2023). Blast-Resistance and Damage Behavior of Underwater Explosion for Concrete Gravity Dam Considering Concrete Strength Partition. Buildings, 13(9), 2237. https://doi.org/10.3390/buildings13092237