Thermodynamic Performance Analysis of High Thermal Conductivity Materials in Borehole Heat Exchangers in the European Climate

Abstract

:1. Introduction

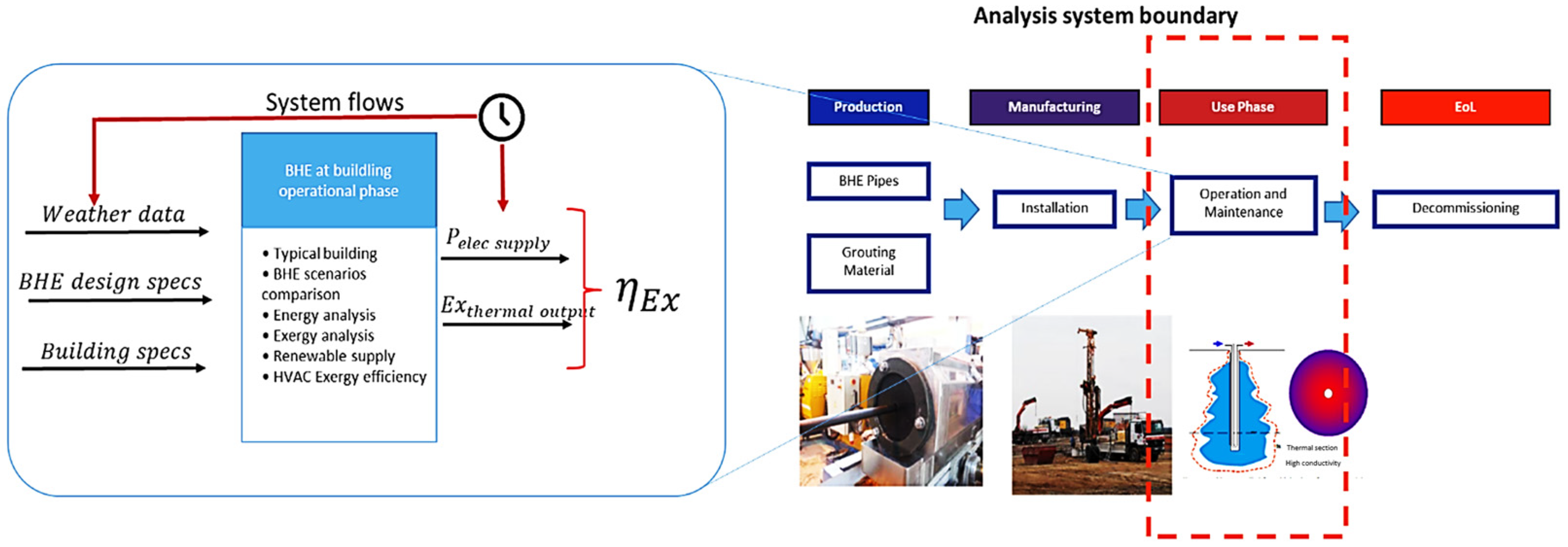

2. Exergy Analysis for Thermodynamic Performance Analysis of GSHPs

3. Methodology

3.1. Scope of Work and Simulation Approach

3.2. Scenarios Definition

- Baseline: This reference scenario is representative of the material and performance achievable using state of the art materials for BHE construction. Specifically, this includes the BHE pipe and grout. Badenes et al. [5] document the developments in pipe and grouting material achieved in the GEOCOND project. The baseline corresponds to the PE100 pipe (thermal conductivity of 0.42 W/mK) and a grout with thermal conductivity of 2 W/mK.

- Semi-GOECOND: The pipe used is the standard PE100 but with the improved GEOCOND grout (thermal conductivity of 3 W/mK).

- GEOCOND: In this scenario, both the pipe and grouting used GEOCOND materials, with thermal conductivity values of 1 W/mK and 3 W/mK, respectively.

| Stockholm 2 × 107 m | |

|---|---|

| Ground | |

| Thermal conductivity | 3.5 W/(m·K) |

| Heat capacity | 2.16 MJ/(m3·K) |

| Surface temperature | 7.6 °C |

| Geothermal heat flux | 0.05 W/m2 |

| Borehole | |

| Configuration | 1 × 2 line |

| Depth | 107 m |

| Borehole Spacing | 10 |

| Borehole Installation | Single U |

| Borehole Diameter | 120 mm |

| U-pipe diameter | 32 mm |

| U-pipe thickness | 3 mm |

| U-pipe thermal conductivity | 0.42 W/(m·K) |

| U-pipe shank spacing | 60 mm |

| Filling thermal conductivity | 2 W/(m·K) |

| Contact resistance pipe/filling | 0 m·K/W |

| Thermal Resistances | |

| Number of multipoles | 10 |

| Heat Carrier Fluid | |

| Thermal conductivity | 0.48 W/(m·K) |

| Specific heat capacity | 3795 J/(Kg·K) |

| Density | 1052 Kg/m3 |

| Viscosity | 0.0052 Kg/(m·s) |

| Freezing point | −14 °C |

| Flow rate per borehole | 2 L/s |

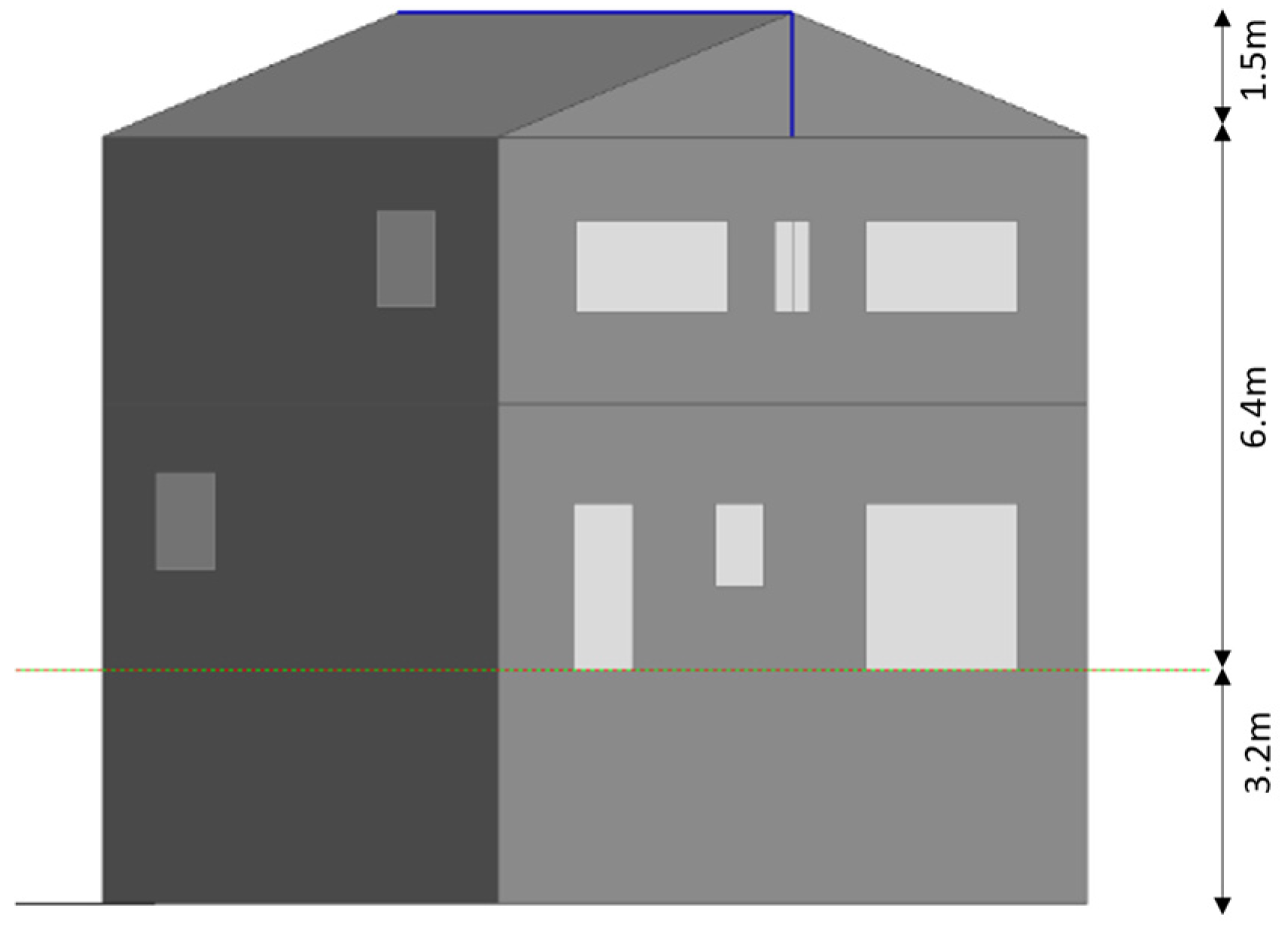

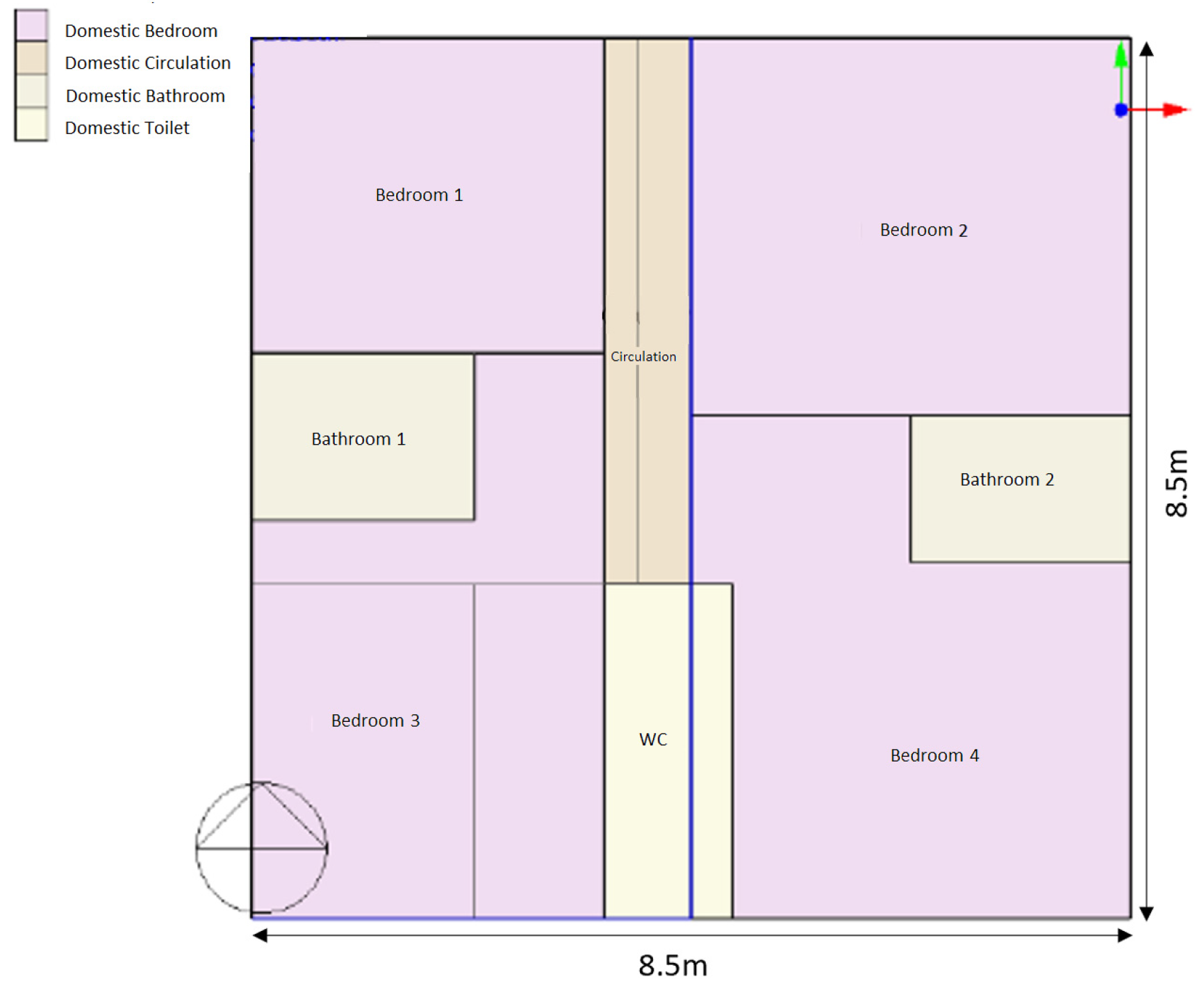

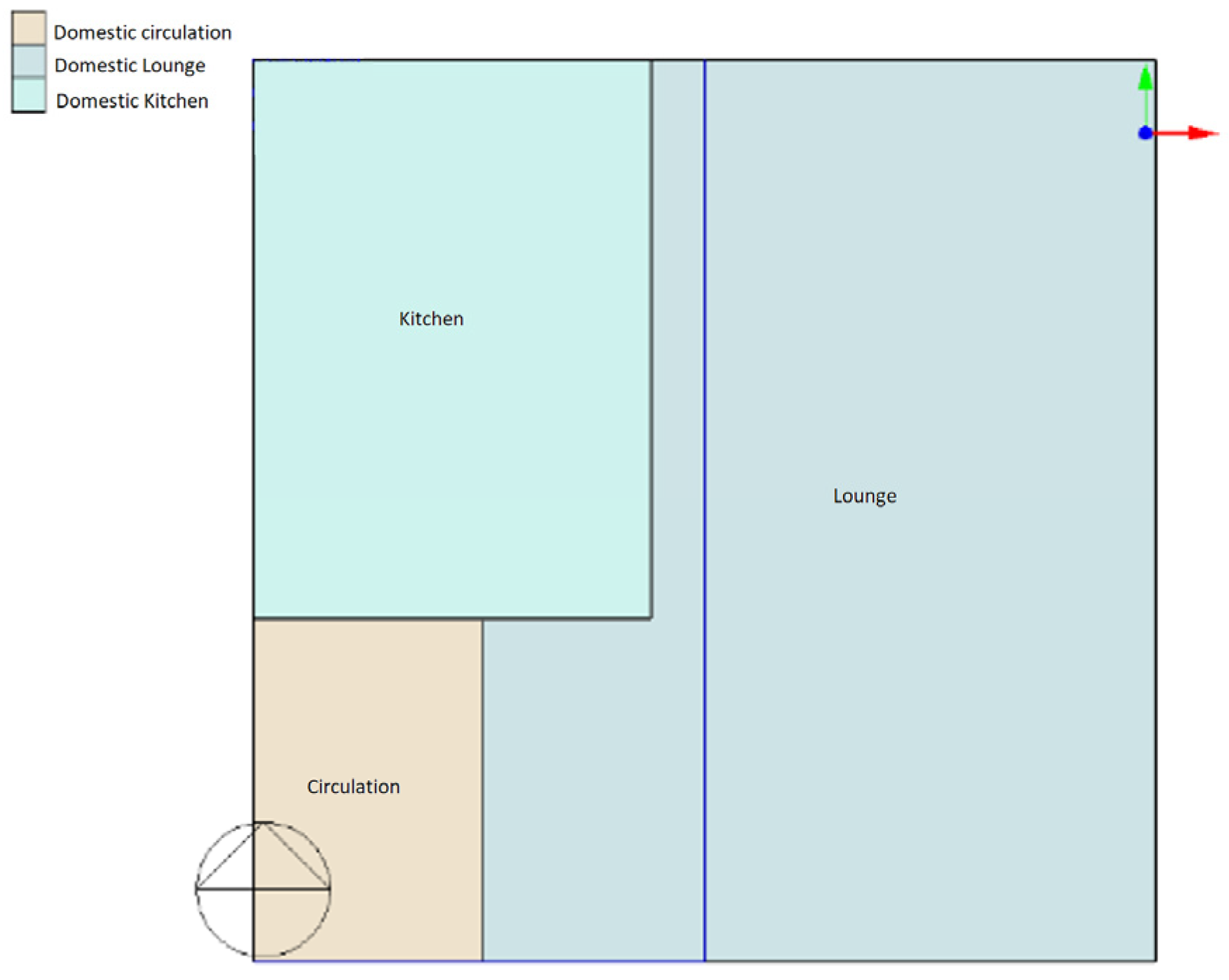

3.3. The Modelled Building

Exergetic Indicators for Performance Analysis

4. Results and Discussion

| Energy Demand | Exergy Demand | BHE Exergy Extracted | BHE Exergy Extracted Improvement | BHE Exergy Proportion | Electricity Demand | GSHP Exergy Efficiency | |

|---|---|---|---|---|---|---|---|

| kWh | kWh | kWh | % | % of total | kWh | % | |

| Stockholm 2 × 107 m | |||||||

| Baseline | 17,833 | 1166 | 235 | 0 | 20.15 | 4596 | 25.37 |

| Semi-GEOCOND | 17,833 | 1166 | 247 | 5.11 | 21.18 | 4554 | 25.6 |

| GOCOND | 17,833 | 1166 | 265 | 12.77 | 22.73 | 4497 | 25.93 |

| Stockholm 1 × 190 m | |||||||

| Baseline | 17,833 | 1166 | 333 | 0 | 28.56 | 4786 | 24.36 |

| Semi-GEOCOND | 17,833 | 1166 | 349 | 4.8 | 29.93 | 4763 | 24.48 |

| GOCOND | 17,833 | 1166 | 376 | 12.91 | 32.25 | 4727 | 24.67 |

| Valencia 2 × 80 m | |||||||

| Baseline | 14,366 | 378.22 | 229 | 0 | 60.55 | 3655 | 10.35 |

| Semi-GEOCOND | 14,382 | 384.9 | 219 | −4.37 | 56.9 | 3591 | 10.72 |

| GOCOND | 14,398 | 407.7 | 209.8 | −8.38 | 51.46 | 3513 | 11.61 |

5. Conclusions and Recommendations

- Enhanced BHE Exergy Extraction: The adoption of pipe and grout materials boasting thermal conductivities of 1 W/mK and 3 W/mK, respectively, can usher in notable improvements in the exergy extraction capabilities of the borehole heat exchanger (BHE). This assertion is substantiated by the observed 13% enhancement for the Stockholm scenario. This uptick subsequently curtails the GSHP’s electricity requisites by approximately 99 kWh/year, a factor with direct economic ramifications spanning the entire use phase of the life cycle.

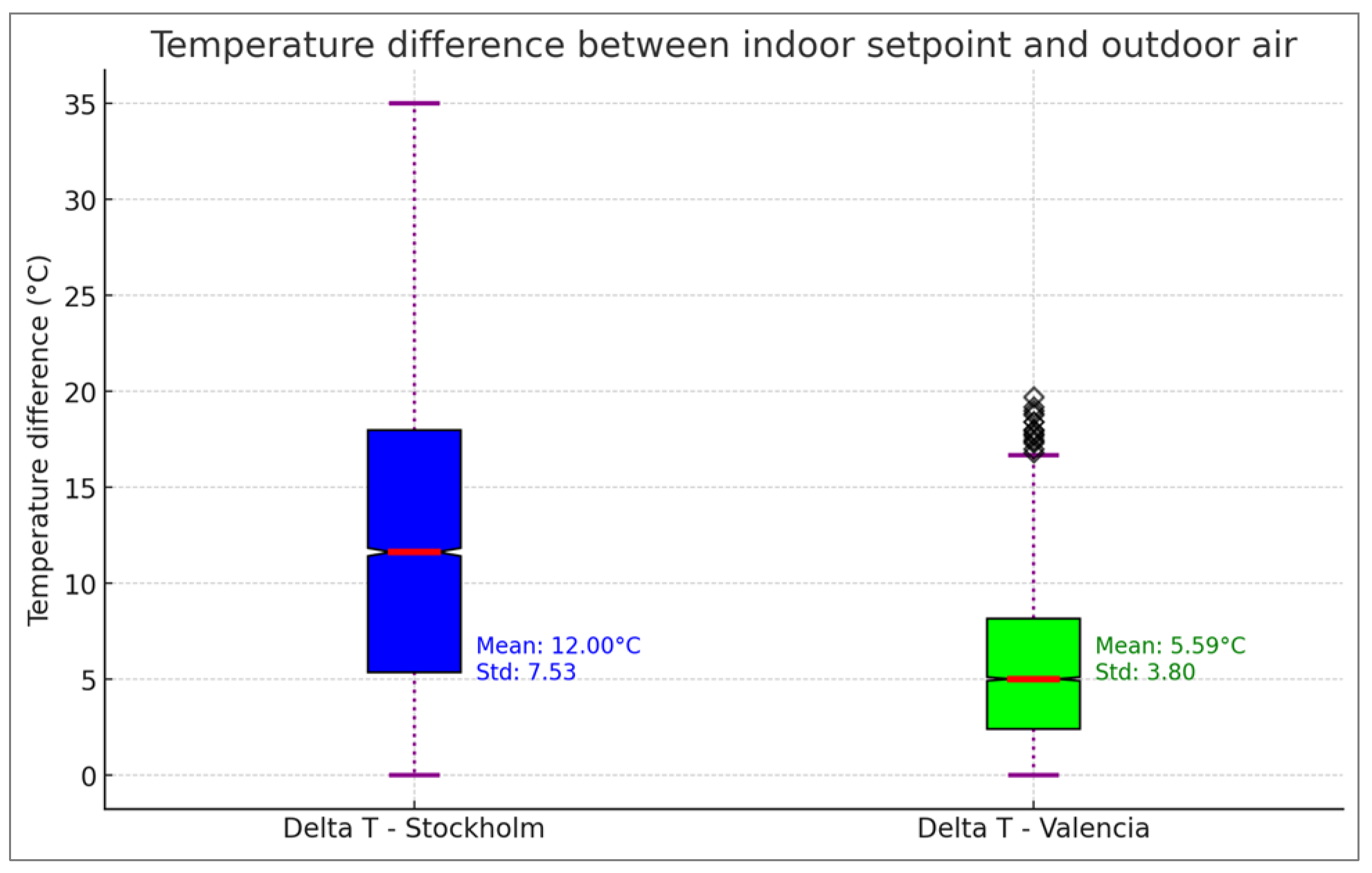

- Regional Variations in Exergetic Performance: For Valencia, the exergetic gains were found to be rather marginal. Additionally, the average exergy efficiency in Valencia trailed at roughly 11%, as opposed to Stockholm’s more robust 25%. A pivotal takeaway from our analysis underscores the dependency of exergy efficiency—and the scope for thermodynamic augmentation via high-conductivity materials—on external factors like the outdoor dry bulb temperature and its deviation from the indoor setpoint.

- Advantages of Increased BHE Depth: A deeper BHE (1 × 190 m in contrast to 2 × 107 m) results in more potent exergy extraction. This depth increment not only results in exergy efficiency that rivals the shallower BHE but also achieves this with a 24 m reduction in total BHE length. It is imperative to note, however, that this study didn’t encompass potential variations in electricity demands due to pumping, which could be influenced by the increased depth.

- Exergy Loss Due to Energy Quality Degradation: Within the GSHP energy paradigm, the most pronounced exergy drain stems from the inevitable quality degradation as electricity morphs into low-grade heat. This accounted for a significant 77% loss for Stockholm and an even steeper 89% for Valencia. These figures accentuate the importance of energy quality alignment between supply and demand mechanisms.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thomaßen, G.; Kavvadias, K.; Jiménez Navarro, J.P. The decarbonisation of the EU heating sector through electrification: A parametric analysis. Energy Policy 2021, 148, 111929. [Google Scholar] [CrossRef]

- Huang, B.; Mauerhofer, V. Life cycle sustainability assessment of ground source heat pump in Shanghai, China. J. Clean. Prod. 2016, 119, 207–214. [Google Scholar] [CrossRef]

- Bonamente, E.; Aquino, A. Environmental performance of innovative ground-source heat pumps with PCM energy storage. Energies 2019, 13, 117. [Google Scholar] [CrossRef]

- Dong, S.; Liu, G.; Zhan, T.; Yao, Y.; Ni, L. Performance Study of Cement-Based Grouts Based on Testing and Thermal Conductivity Modeling for Ground-Source Heat Pumps. Energy Build. 2022, 272, 112351. [Google Scholar] [CrossRef]

- Badenes, B.; Sanner, B.; Mateo Pla, M.Á.; Cuevas, J.M.; Bartoli, F.; Ciardelli, F.; González, R.M.; Ghafar, A.N.; Fontana, P.; Lemus Zuñiga, L.; et al. Development of advanced materials guided by numerical simulations to improve performance and cost-efficiency of borehole heat exchangers (BHEs). Energy 2020, 201, 117628. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Xu, Y. Influence of Grout Thermal Properties on Heat-Transfer Performance of Ground Source Heat Exchangers. Sci. Technol. Built Environ. 2018, 24, 461–469. [Google Scholar] [CrossRef]

- Frąc, M.; Szudek, W.; Szołdra, P.; Pichór, W. Grouts with Highly Thermally Conductive Binder for Low-Temperature Geothermal Applications. Constr. Build. Mater. 2021, 295, 123680. [Google Scholar] [CrossRef]

- Dong, S.; Liu, G.; Zhan, T.; Yao, Y.; Ni, L. A Thermal Conductivity Prediction Model of Cement-Based Grouts for Ground Source Heat Pump. Int. Commun. Heat Mass Transf. 2022, 135, 106079. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, Y.; Xie, Y.; Zhang, Y.; Gao, X. Thermal Performance Analysis on the Composition Attributes of Deep Coaxial Borehole Heat Exchanger for Building Heating. Energy Build. 2020, 221, 110019. [Google Scholar] [CrossRef]

- Mahon, H.; O’Connor, D.; Friedrich, D.; Hughes, B. A Review of Thermal Energy Storage Technologies for Seasonal Loops. Energy 2022, 239, 122207. [Google Scholar] [CrossRef]

- Deng, Y.; Feng, Z.; Fang, J.; Cao, S.J. Impact of Ventilation Rates on Indoor Thermal Comfort and Energy Efficiency of Ground-Source Heat Pump System. Sustain. Cities Soc. 2018, 37, 154–163. [Google Scholar] [CrossRef]

- Habibi, M.; Hakkaki-Fard, A. Long-Term Energy and Exergy Analysis of Heat Pumps with Different Types of Ground and Air Heat Exchangers. Int. J. Refrig. 2019, 100, 414–433. [Google Scholar] [CrossRef]

- Tang, F.; Nowamooz, H. Factors influencing the performance of shallow Borehole Heat Exchanger. Energy Convers. Manag. 2019, 181, 571–583. [Google Scholar] [CrossRef]

- Khattak, S.H.; Brown, N.; Greenough, R. Suitability of exergy analysis for industrial energy efficiency, manufacturing and energy management. In Proceedings of the ECEEE 2012 Summer Study on Energy Efficiency in Industry, Arnhem, The Netherlands, 11–14 September 2012; pp. 237–245. [Google Scholar]

- Yantovski, E. What Is Exergy? Ecos 2004, 2004, 7–9. [Google Scholar]

- Kizilkan, O.; Dincer, I. Borehole thermal energy storage system for heating applications: Thermodynamic performance assessment. Energy Convers. Manag. 2015, 90, 53–61. [Google Scholar] [CrossRef]

- Lucia, U.; Simonetti, M.; Chiesa, G.; Grisolia, G. Ground-source pump system for heating and cooling: Review and thermodynamic approach. Renew. Sustain. Energy Rev. 2017, 70, 867–874. [Google Scholar] [CrossRef]

- Kerdan, I.G.; Raslan, R.; Ruyssevelt, P. Dynamic exergy simulation coupled with thermoeconomic analysis to support retrofit decisions in non-domestic buildings. Future 2014, 52, 1. [Google Scholar]

- Khattak, S.H.; Greenough, R.; Korolija, I.; Brown, N. An exergy based method to resource accounting for factories. J. Clean. Prod. 2015, 121, 99–108. [Google Scholar] [CrossRef]

- Khattak, S.H.; Oates, M.; Greenough, R. Towards Improved Energy and Resource Management in Manufacturing. Energies 2018, 11, 1006. [Google Scholar] [CrossRef]

- Hepbasli, A.; Kalinci, Y. A review of heat pump water heating systems. Renew. Sustain. Energy Rev. 2009, 13, 1211–1229. [Google Scholar] [CrossRef]

- Tsatsaronis, G. Definitions and nomenclature in exergy analysis and exergoeconomics. Energy 2007, 32, 249–253. [Google Scholar] [CrossRef]

- Bakshi, B.R.; Gutowski, T.G.P.; Sekulić, D.P. Thermodynamics and the Destruction of Resources; Cambridge University Press: New York, NY, USA, 2011; ISBN 0521884551. [Google Scholar]

- Gundersen, T. An Introduction to the Concept of Exergy and Energy Quality; Department of Energy and Process Engineering Norwegian University of Science and Technology: Trondheim, Norway, 2010; Version 4. [Google Scholar]

- Schmidt, D.; Ala-Juusela, M. Low Exergy Systems for Heating and Cooling of Buildings. Available online: https://alexandria.tue.nl/openaccess/635611/p0595final.pdf (accessed on 27 August 2023).

- Shukuya, M.; Hammache, A. Introduction to the concept of exergy. In Low Exergy Systems for Heating and Cooling of Buildings; IEA Annex Finl.; 2002; pp. 41–44. ISBN 951-38-6075-2. Available online: http://www.inf.vtt.fi/pdf/ (accessed on 30 April 2023).

- Hepbasli, A. Low exergy (LowEx) heating and cooling systems for sustainable buildings and societies. Renew. Sustain. Energy Rev. 2012, 16, 73–104. [Google Scholar] [CrossRef]

- Helena, T.; Schmidt, D. ECBCS Annex 49—Low Exergy Systems for High-Performance Buildings and Communities. In Exergy Assessment Guidebook for the Built Environment; Summary Report; Fraunhofer IBP: Kassel, Germany, 2011; ISBN 9783839602393. [Google Scholar]

- Lohani, S.P.; Schmidt, D. Comparison of energy and exergy analysis of fossil plant, ground and air source heat pump building heating system. Renew. Energy 2010, 35, 1275–1282. [Google Scholar] [CrossRef]

- Hu, P.; Hu, Q.; Lin, Y.; Yang, W.; Xing, L. Energy and exergy analysis of a ground source heat pump system for a public building in Wuhan, China under different control strategies. Energy Build. 2017, 152, 301–312. [Google Scholar] [CrossRef]

- Verda, V.; Cosentino, S.; Russo, S.L.; Sciacovelli, A. Second law analysis of horizontal geothermal heat pump systems. Energy Build. 2016, 124, 236–240. [Google Scholar] [CrossRef]

- Erbay, Z.; Hepbasli, A. Application of conventional and advanced exergy analyses to evaluate the performance of a ground-source heat pump (GSHP) dryer used in food drying. Energy Convers. Manag. 2014, 78, 499–507. [Google Scholar] [CrossRef]

- Ally, M.R.; Munk, J.D.; Baxter, V.D.; Gehl, A.C. Exergy analysis of a two-stage ground source heat pump with a vertical bore for residential space conditioning under simulated occupancy. Appl. Energy 2015, 155, 502–514. [Google Scholar] [CrossRef]

- Menberg, K.; Heo, Y.; Choi, W.; Ooka, R.; Choudhary, R.; Shukuya, M. Exergy analysis of a hybrid ground-source heat pump system. Appl. Energy 2017, 204, 31–46. [Google Scholar] [CrossRef]

- Kayaci, N. Energy and exergy analysis and thermo-economic optimization of the ground source heat pump integrated with radiant wall panel and fan-coil unit with floor heating or radiator. Renew. Energy 2020, 160, 333–349. [Google Scholar] [CrossRef]

- EnergyPlus Weather Data. Available online: https://energyplus.net/weather-region/europe_wmo_region_6 (accessed on 7 September 2020).

- Nordman, R.; Zottl, A.; Miara, M.; Huber, H. System boundaries for SPF-calculation. In Proceedings of the 10th IEA Heat Pump Conference, Tokyo, Japan, 16–19 May 2011; pp. 16–19. [Google Scholar]

- Designbuilder Software Limited Design Builder. Available online: http://www.designbuilder.co.uk/ (accessed on 10 January 2023).

- Blocon, A.B. Earth Energy Designer 4.20 (EED 4.20). Available online: https://buildingphysics.com/eed-2/ (accessed on 27 August 2023).

- Bohne, D.; Wohlfahrt, M.; Harhausen, G.; Sanner, B.; Mands, E.; Sauer, M.; Grundmann, E. Geothermal Monitoring of eight non-residential buildings with heat and cold production–experiences, results and optimization. In Proceedings of the 12th International Conference on Energy Storage, Lleida, Spain, 16–18 May 2012. [Google Scholar]

- Sanner, B.; Bockelmann, F.; Kühl, L.; Mands, E. System optimisation of ground-coupled heat and-cold supply of office buildings. In Proceedings of the European Geothermal Congress, Strasbourg, France, 19–24 September 2016. [Google Scholar]

- Ochsner Heat Pumps GMSW 28 HK Monovalent Heating System with Brine as a Heat Source. 2021. Available online: https://www.ochsnerengineering.com/gmsw-28-hk/ (accessed on 20 July 2021).

- Curtis, R.; Lund, J.; Sanner, B.; Rybach, L.; Hellström, G. Ground source heat pumps–geothermal energy for anyone, anywhere: Current worldwide activity. In Proceedings of the World Geothermal Congress, Antalya, Turkey, 24–29 April 2005; pp. 24–29. [Google Scholar]

- Zangheri, P.; Armani, R.; Pietrobon, M.; Pagliano, L.; Fernandez Boneta, M.; Müller, A. Heating and Cooling Energy Demand and Loads for Building Types in Different Countries of the EU; The ENTRANZE Project; Intelligent Energy Europe Programme of the European Union; 2014; p. 86. Available online: https://www.entranze.eu/files/downloads/D2_3/Heating_and_cooling_energy_demand_and_loads_for_building_types_in_different_countries_of_the_EU.pdf (accessed on 27 August 2023).

- Khattak, S.H.; Natarajan, S.; Chung, W.J. Out with the power outages: Peak load reduction in the developing world. In Proceedings of the Windsor 2020 Resilient Comfort, Windsor, UK, 16–19 April 2020; pp. 904–922. [Google Scholar]

- Hoyt, T.; Arens, E.; Zhang, H. Extending air temperature setpoints: Simulated energy savings and design considerations for new and retrofit buildings. Build. Environ. 2015, 88, 89–96. [Google Scholar] [CrossRef]

- Traylor, C.; Zhao, W.; Tao, Y.X. Utilizing modulating-temperature setpoints to save energy and maintain alliesthesia-based comfort. Build. Res. Inf. 2019, 47, 190–201. [Google Scholar] [CrossRef]

- Chung, W.J.; Park, S.H.; Yeo, M.S.; Kim, K.W. Control of thermally activated building system considering zone load characteristics. Sustainability 2017, 9, 586. [Google Scholar] [CrossRef]

- Kim, D.; Oh, S. Relationship between the thermal properties and degree of saturation of cementitious grouts used in vertical borehole heat exchangers. Energy Build. 2019, 201, 1–9. [Google Scholar] [CrossRef]

- Liu, L.; Cai, G.; Liu, X.; Liu, S.; Puppala, A.J. Evaluation of thermal-mechanical properties of quartz sand–bentonite–carbon fiber mixtures as the borehole backfilling material in ground source heat pump. Energy Build. 2019, 202, 109407. [Google Scholar] [CrossRef]

- Mascarin, L.; Garbin, E.; Di Sipio, E.; Dalla Santa, G.; Bertermann, D.; Artioli, G.; Bernardi, A.; Galgaro, A. Selection of backfill grout for shallow geothermal systems: Materials investigation and thermo-physical analysis. Constr. Build. Mater. 2022, 318, 125832. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khattak, S.; Badenes, B.; Urchueguia, J.; Sanner, B. Thermodynamic Performance Analysis of High Thermal Conductivity Materials in Borehole Heat Exchangers in the European Climate. Buildings 2023, 13, 2276. https://doi.org/10.3390/buildings13092276

Khattak S, Badenes B, Urchueguia J, Sanner B. Thermodynamic Performance Analysis of High Thermal Conductivity Materials in Borehole Heat Exchangers in the European Climate. Buildings. 2023; 13(9):2276. https://doi.org/10.3390/buildings13092276

Chicago/Turabian StyleKhattak, Sanober, Borja Badenes, Javier Urchueguia, and Burkhard Sanner. 2023. "Thermodynamic Performance Analysis of High Thermal Conductivity Materials in Borehole Heat Exchangers in the European Climate" Buildings 13, no. 9: 2276. https://doi.org/10.3390/buildings13092276