3D-Printed Clay Enhanced with Graphene Nanoplatelets for Sustainable and Green Construction

Abstract

:1. Introduction

2. Research Methodology

2.1. Materials and Equipment

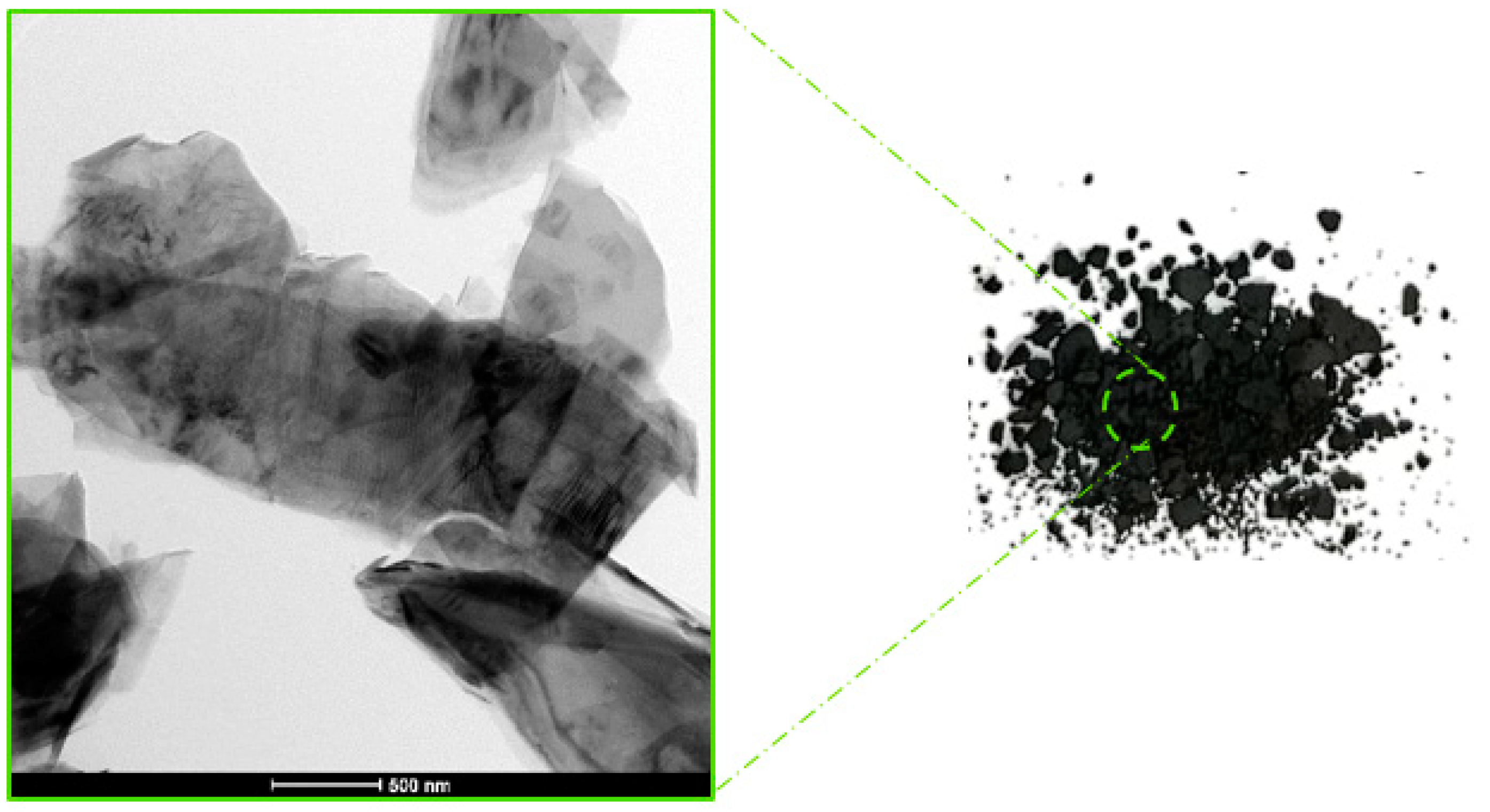

- Graphene nanoplatelets (GNPs): The GNPs were industrial-grade 4COOH graphene nanoplatelets obtained from “Cheap Tubes Ink”. According to the supplier, the GNPs consist of several sheets of graphene that were chemically segregated from natural graphene. Figure 2 shows a TEM image of GNPs. Table 3 presents the GNPs’ specifications.

- Equipment: A variety of equipment was used to perform the experiment, including: (i) Delta WASP 2040 clay 3D printer, supplied by WASP; (ii) an ultrasonic wave mixer, VCX 750 model, provided by Sonics and Materials Inc., Newton, CT, USA; (iii) steel molds with a size of 50 × 50 × 50 mm and 40 × 40 × 160 mm for compressive and flexural strengths testing, respectively; (iv) strength testing machine supplied by IBERTEST, Madrid, Spain; (v) an electric ceramic kiln; and (vi) a scanning electron microscope (SEM), Nova Nano SEM model, manufactured by FEI Inc., Hillsboro, OR, USA.

2.2. Experimental Procedure

- GNP dispersion: To achieve good GNP dispersion within the clay matrix, an ultrasonic wave mixer was used. The dispersion process involved the following tasks: (i) the water temperature was kept at 25 °C, then the GNPs were added and mixed according to the mix specified percentages; and (ii) using an ultrasonic wave mixer, the aqueous solution was then sonicated for 30 min at only 40% of the maximum power (400 W) to avoid nano-filaments particles damage.

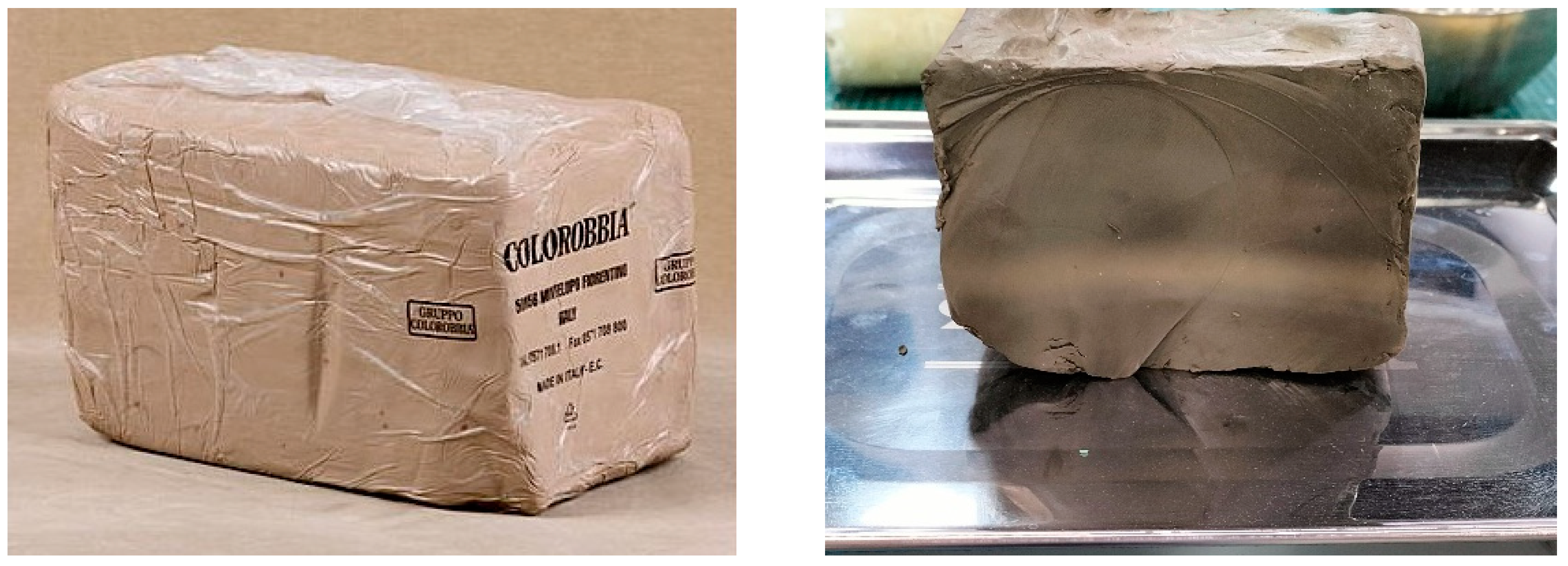

- Preparation of clay mixtures for 3D printing and molding: The mix design for the clay mixtures was evolved based on a trial-and-error method. The clay preparation was performed manually by mixing the clay paste with the appropriate amount of water for control mixtures, and by using the sonicated solution for nano-modified ones, as indicated above. The same type of clay was used for all batches with a constant water-to-clay ratio of 0.05. Only the GNP content was varied, which had no effect on the final consistency of the mixture. The hard clay was cut first into small pieces, as shown in Figure 3a. Then, the aqueous solution was added gradually to the clay, as shown in Figure 3b. The optimal water-to-clay ratio was determined after several trials. The clay was kneaded manually until it became homogeneous, and then its printability was checked through two manual tests. In the first test, the clay was shaped by hand and pressed lightly. If it contained many cracks, the clay was hard, and more water would need to be added to it. However, if it tended to stick on hand, the clay was soft and needed to be mixed with the hard clay. Several attempts were made until a clay mixture that was free of cracks and not sticking on hand was obtained. After that, the second test, which was the manual extrusion test, was carried out using a medical syringe with a removed tip. The syringe tank was filled with clay, which was slowly extruded onto a flat surface. The ideal clay was the one that was not completely standing or tilting too much, as illustrated in Figure 3c; hence the clay was ready for use. Thereafter, the air bubbles were removed by spreading the clay paste on a flat surface using a trowel. The paste was then formed in a cylindrical shape, filled once in the printer’s tank, and compacted well to remove air bubbles. Finally, the piston was plugged tightly. Mixes of the same proportions for each printed batch were prepared to make the same size molded specimens.

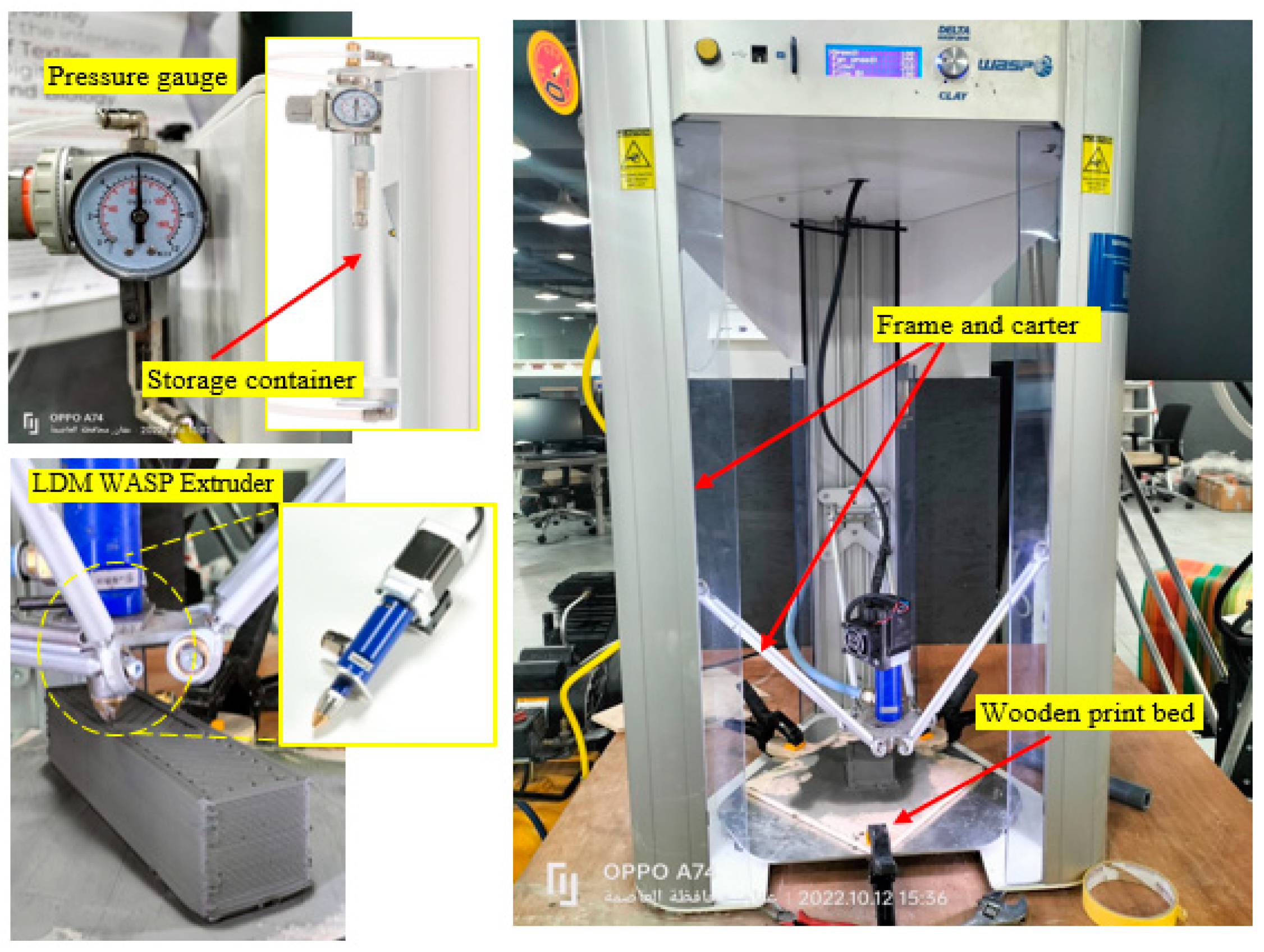

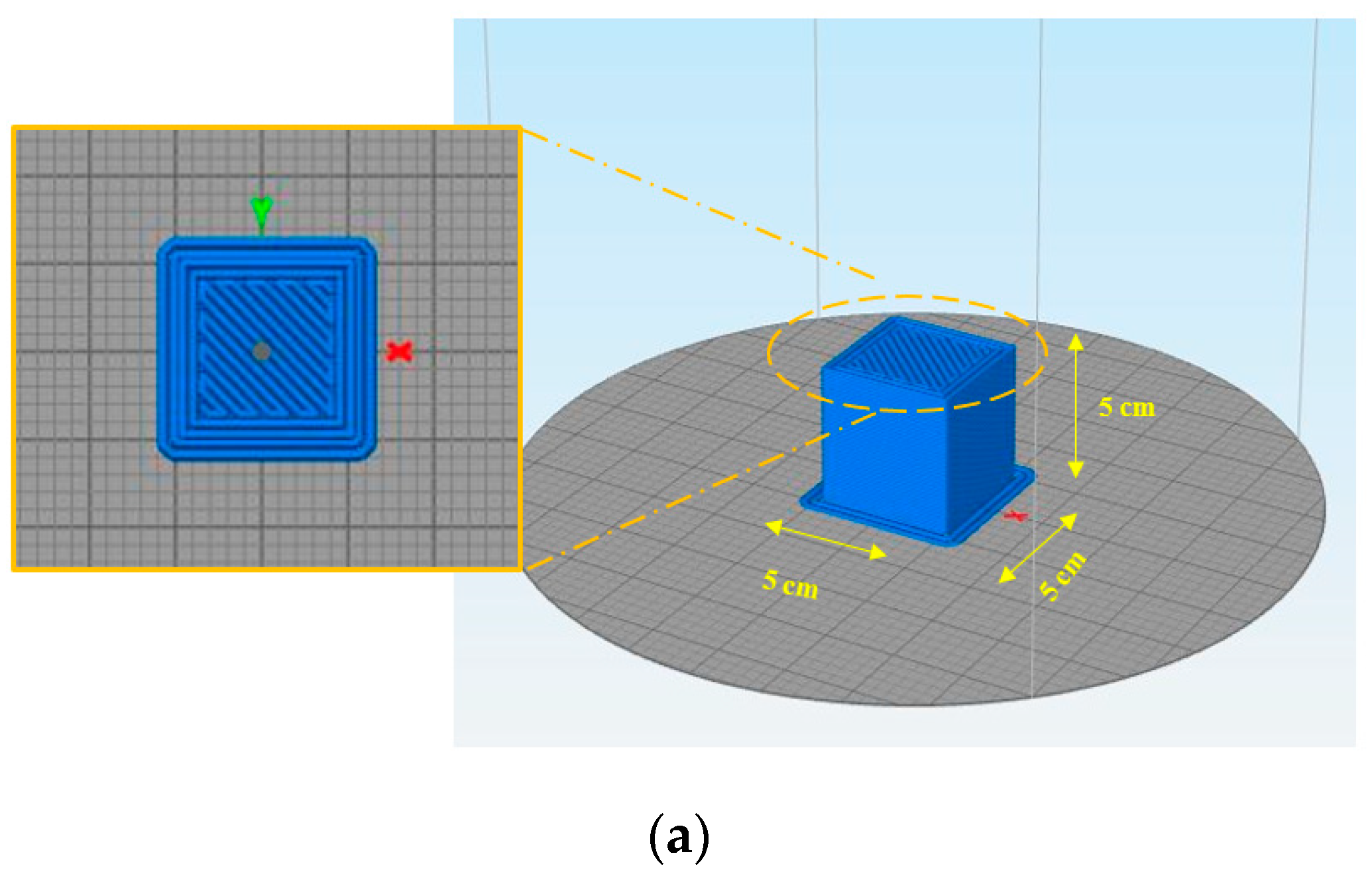

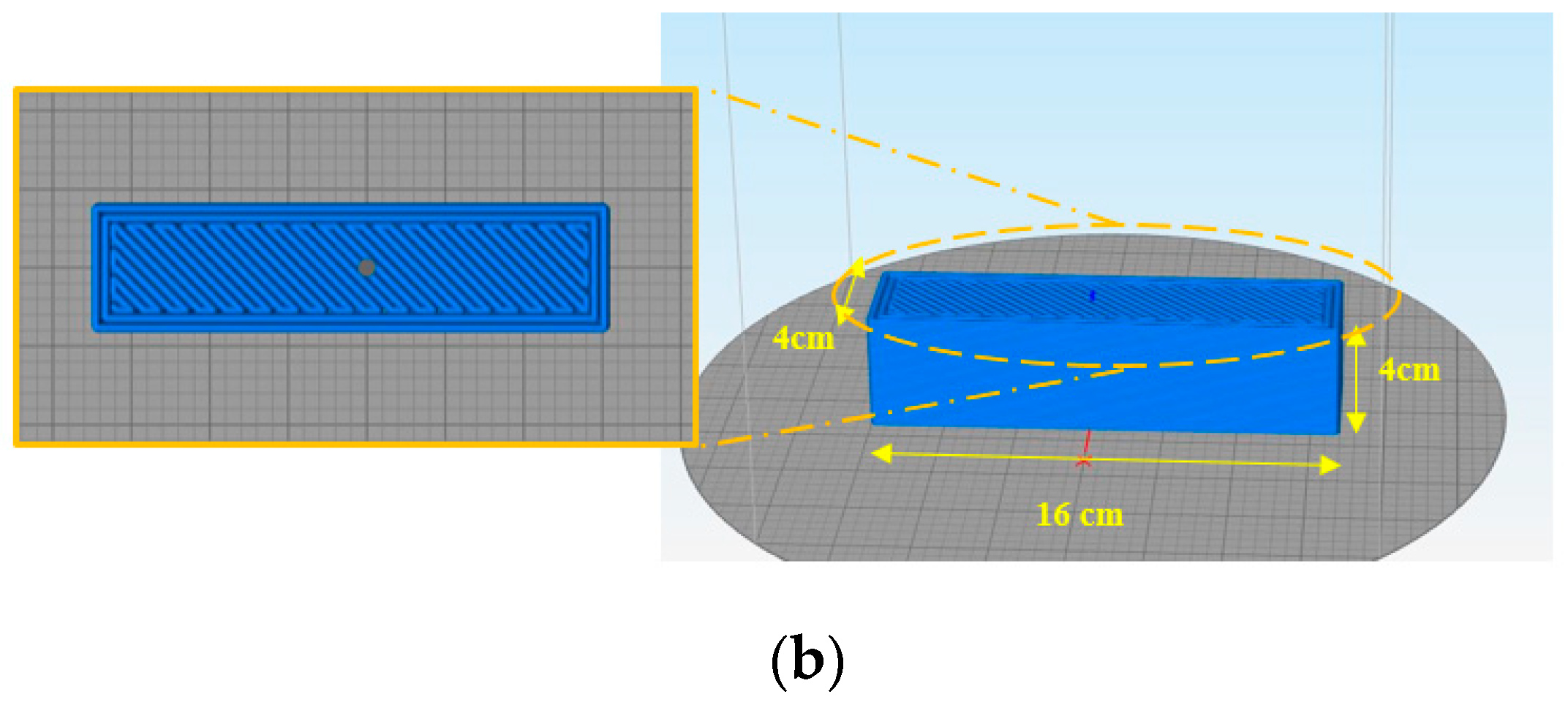

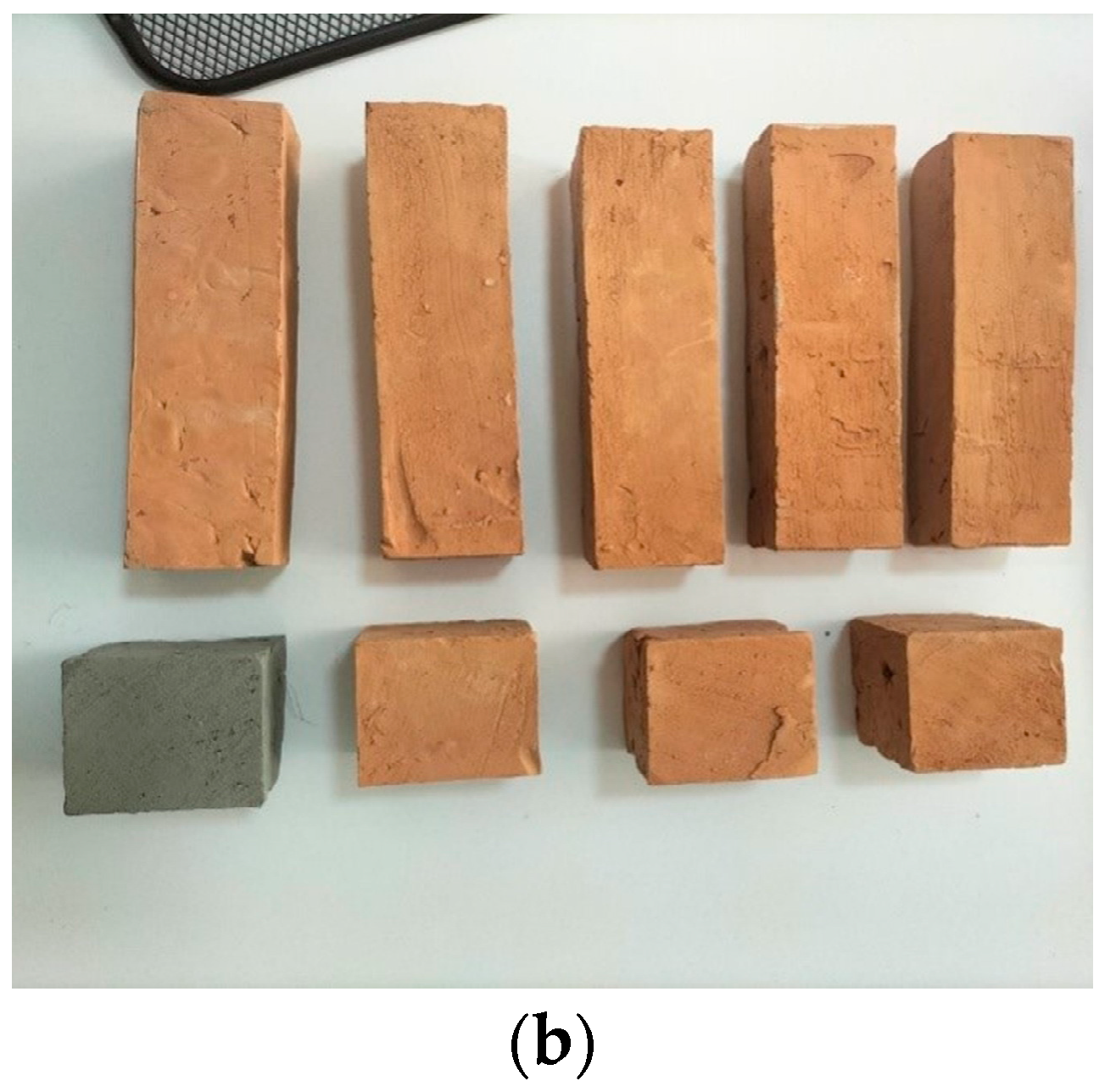

- Printing system and sample preparation: The printing of clay samples was performed using a DeltaWASP 2040 3D Printer, along with an LDM WASP Extruder with a 3-mm diameter nozzle supplied by WASP, Lombarda, Italy. The printer was equipped with a screw system capable of regulating the clay output flow, allowing a rapid flow interjection, and a good retraction control. An external compressor was used with the printer to deliver the material under pressure. The details of the 3D printer used in this research are shown in Figure 4. The printed specimens were sketched using the computer-aided design software, Onshape 1.157 version. Additionally, a 3D printing slicing software, simplifying 3D, was used to create g-code print paths. The configurations of the compression and flexure samples, and the layered printing plan made with the Simplifying 3D software are presented in Figure 5. After preparing the clay mixtures, they were directly loaded into the 3D-printing system storage container. Then, a pressure of six bars was applied on the storage container piston and kept constant at this value during specimen printing, which was accomplished within an average of 20 min and 40 min for the cube and prism, respectively. Table 4 presents the printing and modeling parameters that yielded the best results. The printed cubes and prisms, along with their molded counterparts, are displayed in Figure 6.

- Burning process: A high-temperature kiln was used to produce ceramic from raw clay. The printed and mold-cast samples were heated progressively during a 12 h time period from a low to a high temperature of 1000 °C (1830 °F) inside the electric ceramic kiln, as shown in Figure 7a. A red-colored cube after burning is shown in Figure 7b.

2.3. Mechanical Testing

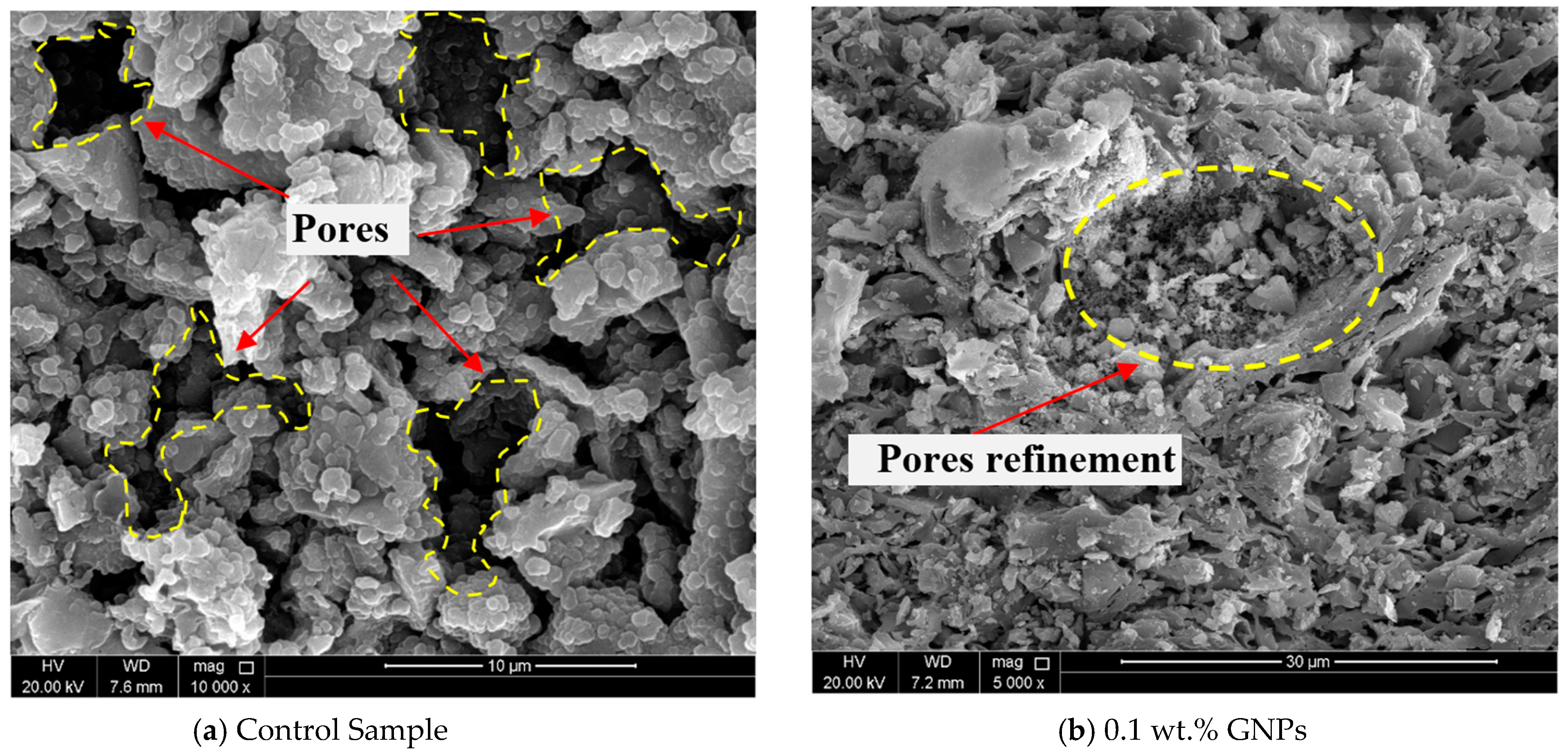

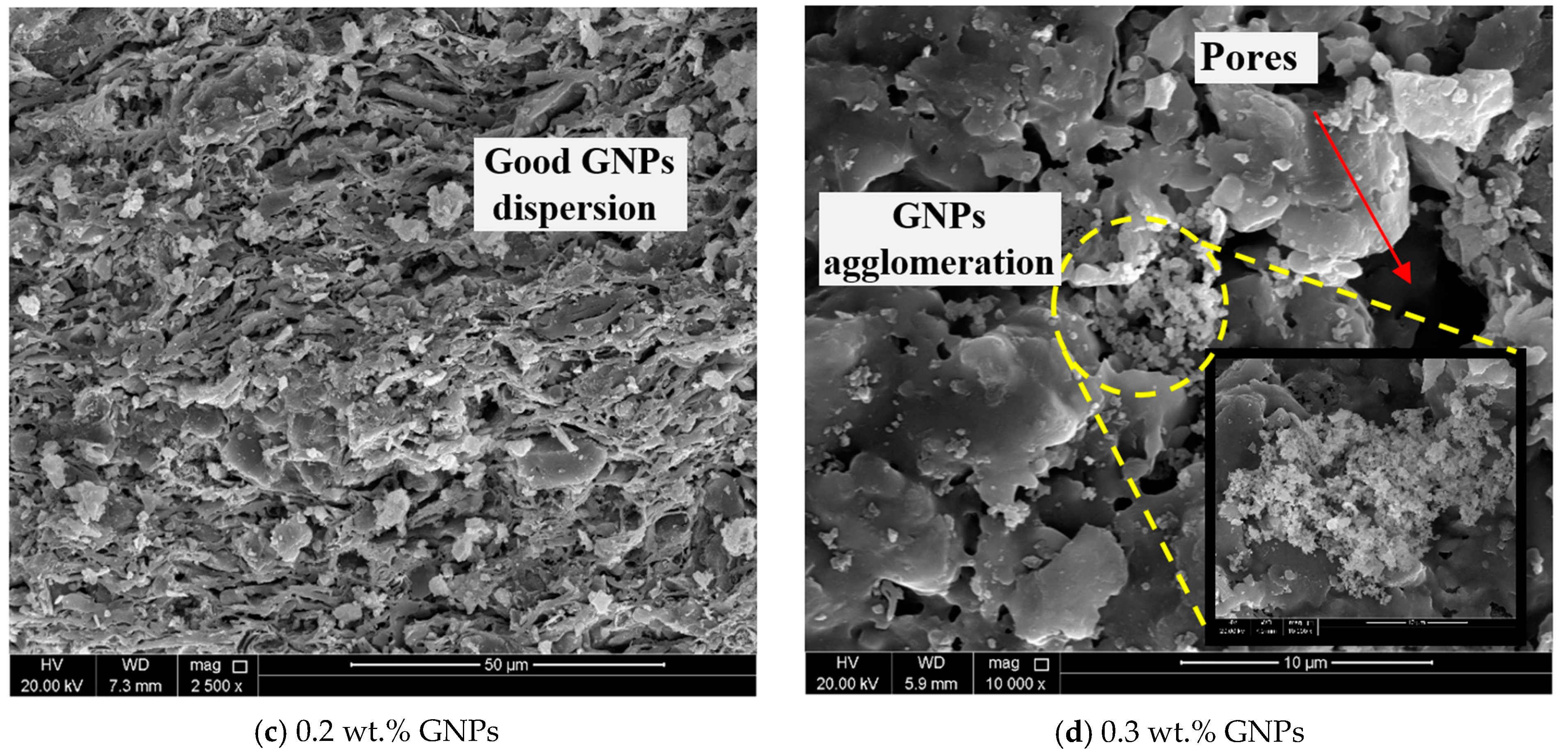

- Microstructural and Elemental Analysis: The dispersion of GNPs within the clay matrix and their effect on strength factor were qualitatively examined by microscopic analysis. The analysis was carried out on the fractured surfaces of the samples using SEM secondary imaging techniques. The samples were cut into 1.5 mm thick pieces, and then they were dried in a vacuum chamber. After that, the surfaces were sprayed with a 10 nm thick gold-palladium coating every 40 min in order to dissipate any overcharges and to increase surface conductivity. The scanning process was then commenced, and varied images were captured for each mix sample at different scales. Simultaneously, the elemental compositions of the fractured sample surfaces were determined using an Energy Dispersive X-ray (EDX).

2.4. T-Statistical Test

- -

- A two-tailed significance level of 0.05 was considered.

- -

- The null hypothesis is correct when the average strength values of the control and GNPs mixes are equal.

- -

- The null hypothesis is rejected if the t-statistic () is equal to or larger than the critical t-test value ().

- -

- When the null hypothesis is rejected, the strength values of the GNPs and control mixes are considered not equivalent, indicating that the use of GNPs in the mixes improved the strength significantly.

- -

- The degree of freedom () was determined as:

- -

- The standard error () was computed using the following equation:

- -

- The t-statistics value (ꞇst) was determined by:

3. Results and Discussion

3.1. Mechanical Strength

3.1.1. Effect of GNPs’ Content on the Flexural Strength of Clay Samples

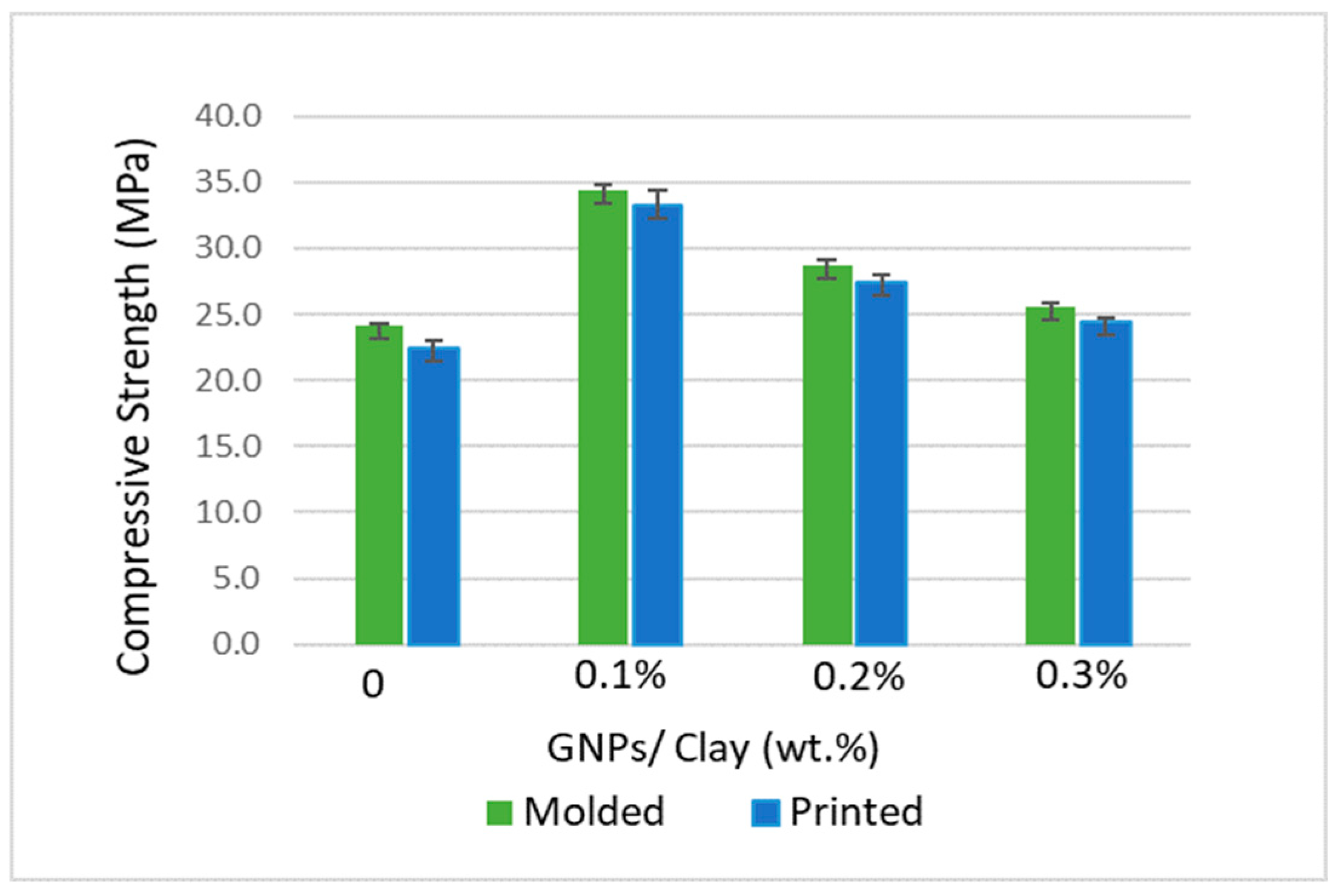

3.1.2. Effect of GNPs’ Content on the Compressive Strength of Clay Samples

3.2. SEM Microstructural Analysis and EDX

3.3. T-Statistical Analysis

4. Conclusions

- Printed and molded nano-modified clay exhibited distinct results in terms of flexural strengths; however, the fabrication method used was the key parameter in impacting GNP dispersion.

- Among all molded batches, the one prepared with 0.1 wt.% GNPs achieved the highest flexural strength, while the printed batch prepared using 0.2 wt.% GNPs resulted in the highest flexural strength, with an increment of 7.5% and 21.1%, respectively.

- The compressive strength results showed a similar trend for the clay samples fabricated by both methods, using different GNP dosages.

- Clay that incorporated 0.1 wt.% GNPs attained the highest improvement in compressive strength of 47.8% and 42.7%, for both printed and molded samples, respectively, when compared to control samples for each group. This enhancement could be attributed to pore filling and the uniform dispersion of GNPs at low content.

- The high-resolution SEM images revealed a clear vision of the reinforcing mechanism provided by different GNP ratios to the clay, either positively with a good nano-sheet dispersion, or negatively due to the existence of a porous structure along with the aggregation, which supports the mechanical strength results.

- EDX analysis indicated a similarity between the results of the clay/GNP composites and those of pure clay, showing that the interaction with the GNPs’ carbonaceous components did not significantly alter the silicate bands.

- The t-statistical analysis results revealed the efficiency of using different weight fractions of GNPs to significantly improve the flexural and compressive strengths of 3D printed clay, as all measured t-statistical values were higher than the critical t-values.

- The t-statistical analysis confirmed the significance of using a low GNP content of 0.1 wt.% in increasing the compressive strength of molded and printed clay.

- In summary, 3D-printed clay enhanced with GNPs shows promise for sustainable and green construction by potentially improving material properties, reducing waste, and enhancing energy efficiency. However, further research and development are necessary to fully understand its long-term viability and address associated challenges such as cost-effectiveness, scalability, and the environmental impact of graphene production. Additionally, the long-term durability and the behavior of these materials under various environmental conditions needs to be further studied.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Romdhane, L.; El-Sayegh, S.M. 3D Printing in Construction: Benefits and Challenges. Int. J. Struct. Civ. Eng. Res 2020, 9, 314–317. [Google Scholar] [CrossRef]

- Rollakanti, C.R.; Prasad CV, S.R. Applications, performance, challenges and current progress of 3D concrete printing technologies as the future of sustainable construction—A state of the art review. Mater. Today Proc. 2022, 65, 995–1000. [Google Scholar] [CrossRef]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A critical review of 3D printing in construction: Benefits, challenges, and risks. Arch. Civ. Mech. Eng. 2020, 20, 34. [Google Scholar] [CrossRef]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Camacho, D.D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of additive manufacturing in the construction industry–A forward-looking review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Anagnostopoulou, S. Composite materials in ancient structures. Cement and concrete composites 2005, 27, 295–300. [Google Scholar] [CrossRef]

- Weaver, C.E.; Pollard, L.D. The Chemistry of Clay Minerals; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar] [CrossRef]

- Rael, R.; San Fratello, V. Clay bodies: Crafting the future with 3D printing. Architectural Design 2017, 87, 92–97. [Google Scholar] [CrossRef]

- Palumbo, J. Is this 3D-printed home made of clay the future of housing. CNN. Retrieved Oct. 2021, 10, 2021. Available online: https://edition.cnn.com/style/article/tecla-3d-printed-house-clay/index.html (accessed on 22 September 2022).

- Manikandan, K.; Jiang, X.; Singh, A.A.; Li, B.; Qin, H. Effects of nozzle geometries on 3D printing of clay constructs: Quantifying contour deviation and mechanical properties. Procedia Manuf. 2020, 48, 678–683. [Google Scholar] [CrossRef]

- Sangiorgio, V.; Parisi, F.; Fieni, F.; Parisi, N. The New Boundaries of 3D-Printed Clay Bricks Design: Printability of Complex Internal Geometries. Sustainability 2022, 14, 598. [Google Scholar] [CrossRef]

- Wolf, A.; Rosendahl, P.L.; Knaack, U. Additive manufacturing of clay and ceramic building components. Autom. Constr. 2022, 133, 103956. [Google Scholar] [CrossRef]

- Balaguru, P.; Chong, K. Nanotechnology and concrete: Research opportunities. Proc. ACI Sess. Nanotechnol. Concr. Recent Dev. Future Perspect. 2006, 254, 15–28. [Google Scholar] [CrossRef]

- Shen, M.Y.; Chang, T.Y.; Hsieh, T.H.; Li, Y.L.; Chiang, C.L.; Yang, H.; Yip, M.C. Mechanical properties and tensile fatigue of graphene nanoplatelets reinforced polymer nanocomposites. J. Nanomater. 2013, 2013, 565401. [Google Scholar] [CrossRef]

- Wang, B.; Jiang, R.; Wu, Z. Investigation of the mechanical properties and microstructure of graphene nanoplatelet-cement composite. Nanomaterials 2016, 6, 200. [Google Scholar] [CrossRef] [PubMed]

- Mohsen, M.O.; Al-Diseet, M.M.; Aburumman, M.O.; Taha, R.; Al Ansari, M.S.; Taqa, A.A. Hybrid effect of GNPs, GOs, and CNTs on the flexural and compressive strengths of cement paste. J. Build. Eng. 2023, 73, 106679. [Google Scholar] [CrossRef]

- Baomin, W.; Shuang, D. Effect and mechanism of graphene nanoplatelets on hydration reaction, mechanical properties, and microstructure of cement composites. Constr. Build. Mater. 2019, 228, 116720. [Google Scholar] [CrossRef]

- Tao, J.; Wang, X.; Wang, Z.; Zeng, Q. Graphene nanoplatelets as an effective additive to tune the microstructures and piezoresistive properties of cement-based composites. Constr. Build. Mater. 2019, 209, 665–678. [Google Scholar] [CrossRef]

- ASTM C348; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM C109/C109M; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2016.

- Ruiz-Hitzky, E.; Sobral MM, C.; Gómez-Avilés, A.; Nunes, C.; Ruiz-García, C.; Ferreira, P.; Aranda, P. Clay-graphene nanoplatelets functional conducting composites. Adv. Funct. Mater. 2016, 26, 7394–7405. [Google Scholar] [CrossRef]

| Test Group | Production Technique | Batch # | Batch Code | GNPs/Clay Weight Fraction (wt.%) |

|---|---|---|---|---|

| Molded Group | Molding | 1 | MC | 0.0 |

| 2 | M-0.1%GNPs | 0.1 | ||

| 3 | M-0.2%GNPs | 0.2 | ||

| 4 | M-0.3%GNPs | 0.3 | ||

| Printed Group | 3D printing | 5 | PC | 0.0 |

| 6 | P-0.1%GNPS | 0.1 | ||

| 7 | P-0.2%GNPS | 0.2 | ||

| 8 | P-0.3%GNPS | 0.3 |

| Identification | Content % |

|---|---|

| Quartz | 40–60 |

| Aluminum oxide | 9–25 |

| Yellow iron oxide | 5–9 |

| Property | Material Specification |

|---|---|

| Average thickness | Friable to <4 nm |

| # of layers | Friable to <4 layers |

| Surface Area | Friable to >700 m2/g |

| Primary functionality | COOH |

| Other Functionalities | COH, C=O, other oxygen |

| Purity | >99 wt.% |

| Source Material | Natural graphite |

| Printing Parameters | |

|---|---|

| Average speed | 90 mm/s |

| Flow | 250–300% |

| Pressure | 6 bar |

| Modelling Parameters | |

| Layer height | 1 mm |

| Infill percentage | 100% |

| Infill shape | Rectilinear |

| Group | Batch No. | Batch Name | Compressive Strength (MPa) | Flexural Strength (MPa) | ||||

|---|---|---|---|---|---|---|---|---|

| CS | % Change | 1sd% | FS | %Change | 1sd% | |||

| Mold-cast Group | 1 | MC | 24.1 | - | 0.81 | 17.1 | - | 1.7 |

| 2 | M-0.1%GNPs | 34.4 | 42.68 | 1.14 | 18.4 | 7.5 | 6.2 | |

| 3 | M-0.2%GNPs | 28.8 | 19.25 | 1.43 | 14.8 | −13.8 | 7.7 | |

| 4 | M-0.3%GNPs | 25.5 | 5.83 | 1.45 | 9.4 | −45.2 | 4.5 | |

| Printed Group | 5 | PC | 22.5 | - | 2.04 | 11.1 | - | 2.1 |

| 6 | P-0.1%GNPS | 33.3 | 47.81 | 3.46 | 11.8 | 6.3 | 2.7 | |

| 7 | P-0.2%GNPS | 27.4 | 21.82 | 2.05 | 14.3 | 21.1 | 2.5 | |

| 8 | P-0.3%GNPS | 24.5 | 8.77 | 0.82 | 13.7 | 15.9 | 2.4 | |

| Mix | Degree of Freedom (DF) | Standard Error (SD) | T-Statistic Value (Tst) | Critical t-Test Value | Remarks |

|---|---|---|---|---|---|

| M-0.1%GNPS | 2 | 0.676 | 1.91 | 4.303 | A |

| M-0.2%GNPS | 2 | 0.680 | 0.60 | 4.303 | A |

| M-0.3%GNPS | 2 | 0.594 | 1.7 | 4.303 | A |

| P-0.1%GNPS | 4 | 0.228 | 3.09 | 2.776 | R |

| P-0.2%GNPS | 3 | 0.244 | 13.09 | 3.182 | R |

| P-0.3%GNPS | 4 | 0.230 | 11.27 | 2.776 | R |

| Mix | Degree of Freedom (DF) | Standard Error (SD) | T-Statistic Value (Tst) | Critical t-Test Value | Remarks |

|---|---|---|---|---|---|

| M-0.1%GNPS | 3 | 0.254 | 40.60 | 3.182 | R |

| M-0.2%GNPS | 3 | 0.263 | 17.65 | 3.182 | R |

| M-0.3%GNPS | 3 | 0.242 | 5.82 | 3.182 | R |

| P-0.1%GNPS | 3 | 0.716 | 15.03 | 3.182 | R |

| P-0.2%GNPS | 4 | 0.419 | 11.72 | 2.776 | R |

| P-0.3%GNPS | 3 | 0.289 | 6.82 | 3.182 | R |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohsen, M.O.; Al-Diseet, M.M.; Aburumman, M.O.; Taha, R.; Taqa, A.A.; Senouci, A.; Naji, K. 3D-Printed Clay Enhanced with Graphene Nanoplatelets for Sustainable and Green Construction. Buildings 2023, 13, 2321. https://doi.org/10.3390/buildings13092321

Mohsen MO, Al-Diseet MM, Aburumman MO, Taha R, Taqa AA, Senouci A, Naji K. 3D-Printed Clay Enhanced with Graphene Nanoplatelets for Sustainable and Green Construction. Buildings. 2023; 13(9):2321. https://doi.org/10.3390/buildings13092321

Chicago/Turabian StyleMohsen, Mohamed O., Malak M. Al-Diseet, Mervat O. Aburumman, Ramzi Taha, Ala Abu Taqa, Ahmed Senouci, and Khalid Naji. 2023. "3D-Printed Clay Enhanced with Graphene Nanoplatelets for Sustainable and Green Construction" Buildings 13, no. 9: 2321. https://doi.org/10.3390/buildings13092321

APA StyleMohsen, M. O., Al-Diseet, M. M., Aburumman, M. O., Taha, R., Taqa, A. A., Senouci, A., & Naji, K. (2023). 3D-Printed Clay Enhanced with Graphene Nanoplatelets for Sustainable and Green Construction. Buildings, 13(9), 2321. https://doi.org/10.3390/buildings13092321