Study on Thermodynamic Properties of Spiral Tube-Encapsulated Phase-Change Material Energy Pile

Abstract

1. Introduction

2. Experimental Investigation

2.1. Preparation of Test Materials

2.1.1. Concrete Material

2.1.2. Selection of Experimental Equipment

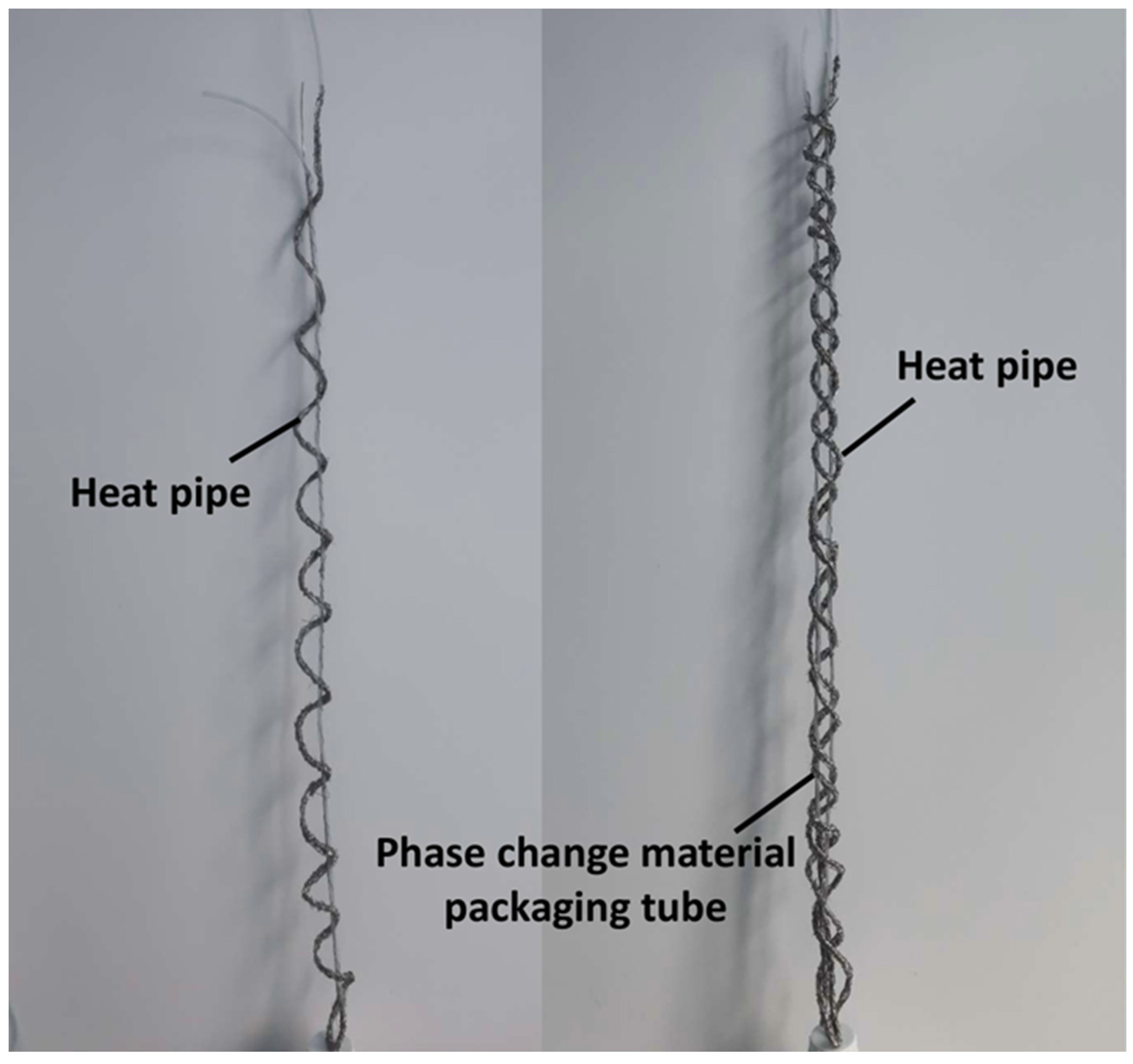

2.1.3. Preparation of Heat Conduction Tube and Phase-Change Material Packaging Tube

2.1.4. Phase-Change Material

2.2. Experiment Development

2.2.1. Design of Phase Change Material Energy Pile Model

2.2.2. Design of Indoor Physical Model Experimental System for Energy Pile

2.2.3. Experimental Measuring Point Arrangement

2.2.4. Implementation of Experimental Scheme

- Connect the pump, the water pipe, and the heat conduction pipe in the pile and check the water in advance to ensure that the pump can operate normally and the water pipe and the heat conduction pipe in the pile are not blocked.

- Connect each temperature sensor and strain gauge to the corresponding data acquisition equipment, and check whether the data can be collected normally; check whether the dial gauge can be used normally and place it at the top of the pile while reading to zero.

- Add an appropriate amount of water to the constant-temperature water bath and start the constant-temperature water bath to heat the water to 40 °C and keep the water temperature unchanged.

- Start the pump to start the water circulation and start to collect the experimental data. The main data acquisition is as follows: strain gauge to collect pile strain data; the temperature sensor collects the pile temperature data; the pile top dial gauge collects the pile top displacement data; the pT1000 temperature sensor collects the water temperature at the outlet.

- The experimental process lasts for 300 min. During the experimental process, it is necessary to continuously check whether the test equipment and data acquisition equipment are operating normally and problems are solved in time to avoid experimental results caused by experimental operation problems.

3. Experimental Results and Discussion

3.1. Heat Transfer Performance Analysis

3.1.1. Unit Pile Heat Exchange

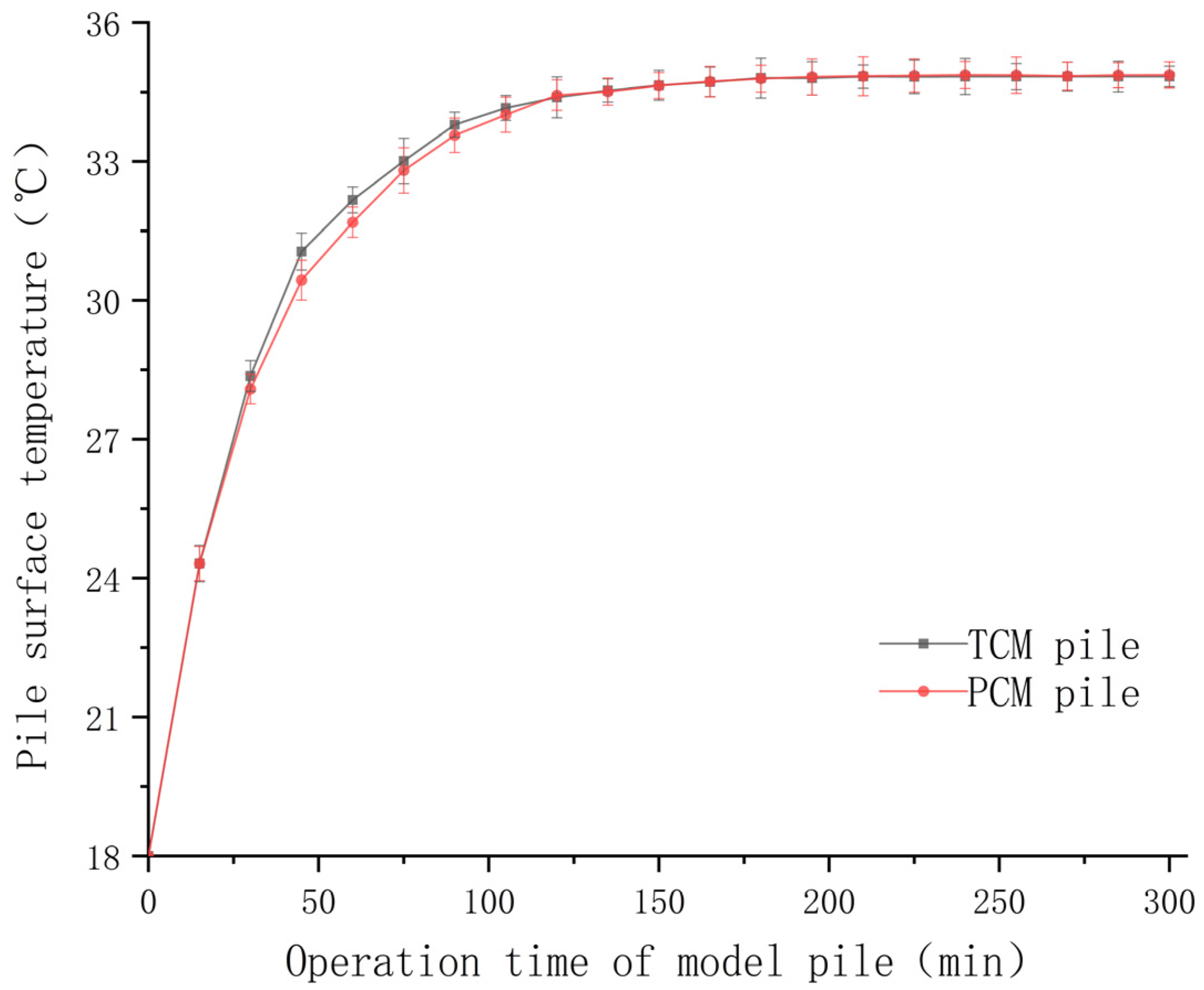

3.1.2. Pile Surface Temperature Analysis

3.2. Thermodynamic Effect Analysis

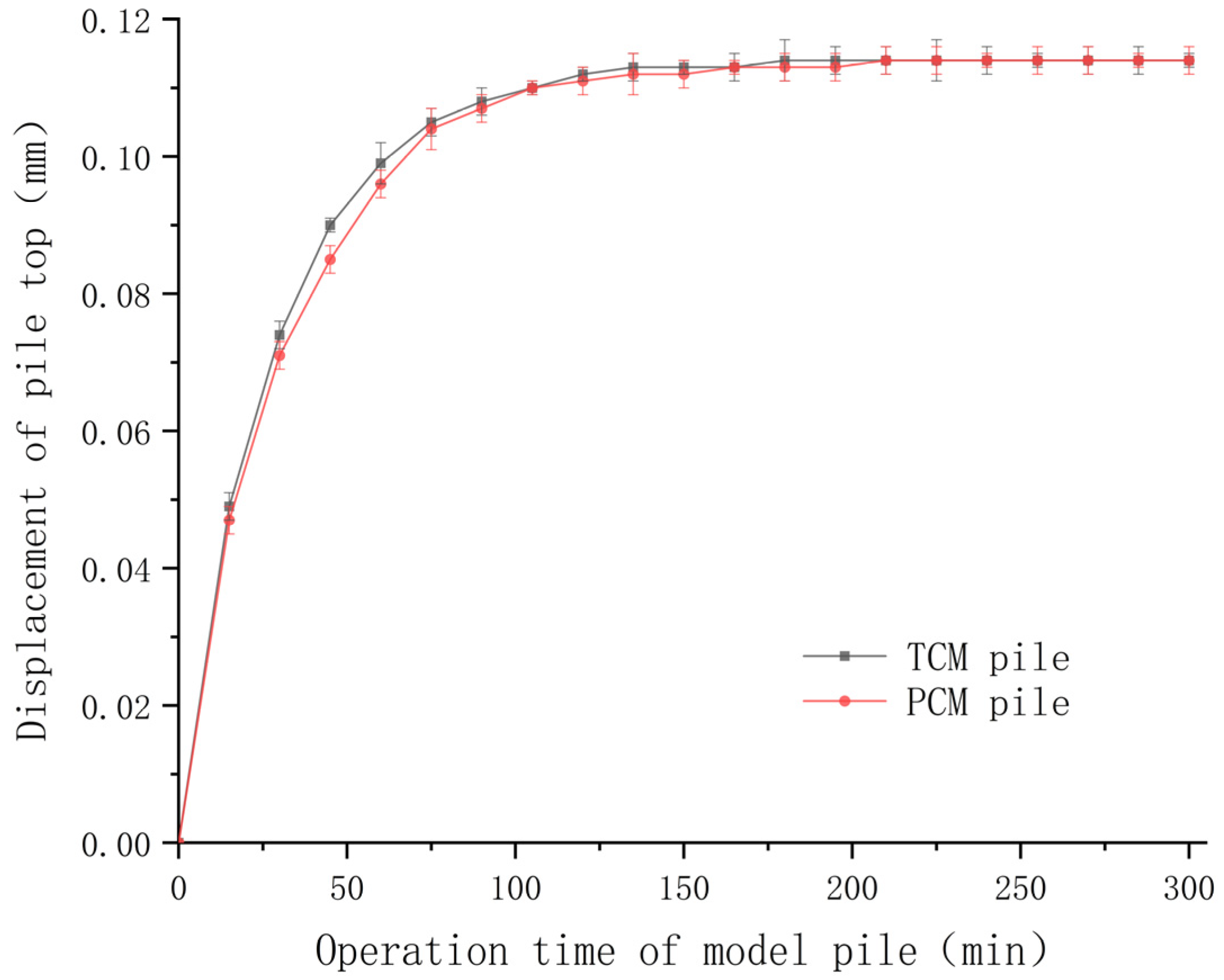

3.2.1. Pile Top Displacement Analysis

3.2.2. Pile Surface Stress Analysis

4. Conclusions

- The PCM pile increases the heat transfer per unit pile body in the early and middle stages of the whole operation and the total heat transfer during the whole operation. The heat transfer per unit pile depth increased by 6.52 W/m, and the overall heat transfer increased by 3.38%.

- The PCM pile reduces the surface temperature of the pile body and the heating rate of the surface temperature of the pile body in the early and middle stages of operation, and the maximum temperature difference is 0.62 °C.

- The PCM pile can effectively reduce the upward displacement of the pile top in the early and middle stages of operation. The maximum difference between the two is 0.005 mm, which is reduced by 5.56%.

- The surface stress value of the PCM pile is higher than that of the TCM pile during the whole operation process. The maximum difference between the two is 9.84 kPa, and the maximum difference is 10.8%. Subsequently, the difference between the two gradually decreases with time, and finally stabilizes at 1.4 kPa, with a final difference of only 8.8%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sutman, M.; Speranza, G.; Ferrari, A.; Larrey-Lassalle, P.; Laloui, L. Long-term performance and life cycle assessment of energy piles in three different climatic conditions. Renew. Energy 2020, 146, 1177–1191. [Google Scholar] [CrossRef]

- Zakharov, A.V.; Ovchinnikov, N.M. Influence of soil thermophysical properties on the flow of thermal energy taken by the energy pile. J. Phys. Conf. Ser. 2021, 1928, 012036. [Google Scholar] [CrossRef]

- Elzeiny, R.; Suleiman, M.T. Pull-Out Response of a Laboratory-Scale Energy Pile Subjected to Cooling Cycles. J. Geotech. Geoenviron. Eng. 2021, 147, 04021044. [Google Scholar] [CrossRef]

- Chen, Z.; Sun, Y.; Xiao, H.; Ma, Q.; Zhang, L. In-Situ Thermomechanical Response Test of an Energy Pile Under Temperature Loading. Arab. J. Sci. Eng. 2021, 46, 10355–10364. [Google Scholar] [CrossRef]

- Qi, H.; Zhou, Y.; Zhang, Z.; Wang, B.; Zhang, Y.; Cui, H.; Wang, X. Heat Transfer Performance in Energy Piles in Urban Areas: Case Studies for Lambeth College and Shell Centre UK. Appl. Sci. 2020, 10, 5974. [Google Scholar] [CrossRef]

- Da Silva Oliveira Morais, T.; de Hollanda Cavalcanti Tsuha, C.; Bandeira Neto, L.A.; Singh, R.M. Effects of seasonal variations on the thermal response of energy piles in an unsaturated Brazilian tropical soil. Energy Build. 2020, 216, 109971. [Google Scholar]

- Chang, H.; Shen, F.Q.; Wang, Y.; Wang, H.; Zhao, S.Y. Test on bearing capacity of new energy pile under thermal-mechanical coupling. Sci. Technol. Eng. 2022, 22, 11609–11615. [Google Scholar]

- Faizal, M.; Moradshahi, A.; Bouazza, A.; McCartney, J.S. Soil thermal responses around a field-scale energy pile. E3S Web Conf. 2020, 205, 05027. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, L.; Cui, P.; Gao, Y.; Liu, J.; Yu, M. The influence of groundwater seepage on the performance of ground source heat pump system with energy pile. Appl. Therm. Eng. 2019, 162, 114217. [Google Scholar] [CrossRef]

- Wu, D.; Liu, H.; Kong, G.; Li, C. Thermo-mechanical behavior of energy pile under different climatic conditions. Acta Geotech. 2019, 14, 1495–1508. [Google Scholar] [CrossRef]

- Faizal, M.; Bouazza, A.; McCartney, J.S.; Haberfield, C. Effects of Cyclic Temperature Variations on Thermal Response of an Energy Pile under a Residential Building. J. Geotech. Geoenviron. Eng. 2019, 145, 04019066. [Google Scholar] [CrossRef]

- Weibo, Y.; Lei, J.; Laijun, Z.; Feng, W. Experimental investigations of the thermo-mechanical behaviour of an energy pile with groundwater seepage. Sustain. Cities Soc. 2022, 77, 103588. [Google Scholar]

- Lou, J.; Fang, P.-F.; Xie, X.-Y.; Chong, C.S.A.; Li, F.-Y.; Liu, C.-Y.; Wang, Z.-J.; Zhu, D.-J. Numerical research on thermal response for geothermal energy pile groups under groundwater flow. Geomech. Energy Environ. 2021, 28, 100257. [Google Scholar] [CrossRef]

- You, T.; Yang, H. Influences of different factors on the three-dimensional heat transfer of spiral-coil energy pile group with seepage. Int. J. Low-Carbon Technol. 2020, 15, 458–470. [Google Scholar] [CrossRef]

- Zhong, Y.; Narsilio, G.A.; Makasis, N.; Scott, C. Experimental and numerical studies on an energy piled wall: The effect of thermally activated pile spacing. Geomech. Energy Environ. 2022, 29, 100276. [Google Scholar] [CrossRef]

- Cecinato, F.; Salciarini, D. Energy performance assessment of thermo-active micro-piles via numerical modeling and statistical analysis. Geomech. Energy Environ. 2021, 29, 100268. [Google Scholar] [CrossRef]

- Zhang, G.; Cao, Z.; Liu, Y.; Chen, J. Field Test and Numerical Simulation on the Long-Term Thermal Response of PHC Energy Pile in Layered Foundation. Sensors 2021, 21, 3873. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wang, B.; Zheng, L.; Xiao, H.; Wang, J. Research on Heat Exchange Law and Structural Design Optimization of Deep Buried Pipe Energy Piles. Energies 2021, 14, 6449. [Google Scholar] [CrossRef]

- Yin, Y.; Li, Q.; Qiao, L. Response of energy pile-soil structure and pile group effect: An indoor similarity simulation study. J. Build. Eng. 2022, 51, 104247. [Google Scholar] [CrossRef]

- Wu, D.; Kong, G.; Liu, H.; Jiang, Q.; Yang, Q.; Kong, L. Performance of a full-scale energy pile for underground solar energy storage. Case Stud. Therm. Eng. 2021, 27, 101313. [Google Scholar] [CrossRef]

- Sani, A.K.; Singh, R.M. Response of unsaturated soils to heating of geothermal energy pile. Renew. Energy 2020, 147 Pt 2, 2618–2632. [Google Scholar] [CrossRef]

- Bao, X.; Qi, X.; Cui, H.; Tang, W.; Chen, X. Experimental study on thermal response of a PCM energy pile in unsaturated clay. Renew. Energy 2022, 185, 790–803. [Google Scholar] [CrossRef]

- Sutman, M.; Brettmann, T.; Olgun, C.G. Full-scale in-situ tests on energy piles: Head and base-restraining effects on the structural behaviour of three energy piles. Geomech. Energy Environ. 2018, 18, 56–68. [Google Scholar] [CrossRef]

- Najma, A.; Sharma, J. Incremental load transfer analysis of an energy pile under arbitrary mechanical and thermal loads. Geomech. Energy Environ. 2021, 28, 100243. [Google Scholar] [CrossRef]

- Wang, Z.-j. Analysis of an Energy Pile Enduring Cyclic Temperature Loads. Geotech. Res. 2019, 6, 227–233. [Google Scholar] [CrossRef]

- Shuang, Y.; Zhang, C.H.; Jiang, P. Heat transfer performance and structure response of energy piles. Therm. Sci. 2019, 23, 1647. [Google Scholar]

- Yang, B. Theoretical and Experimental Study on Heat Transfer Performance and Thermal-Mechanical Coupling Characteristics of Phase Change Concrete Energy Pile. Master’s Thesis, Yangzhou University, Yangzhou, China, 1 June 2020. [Google Scholar]

- Jin, L. Study on Thermo-Mechanical Properties of Phase Change Steel Ball Energy Pile in Saturated Sand Foundation. Master’s Thesis, Jilin Jianzhu University, Changchun, China, 1 June 2021. [Google Scholar]

- Cui, H.; Zou, J.; Gong, Z.; Zheng, D.; Bao, X.; Chen, X. Study on the thermal and mechanical properties of steel fibre reinforced PCM-HSB concrete for high performance in energy piles. Constr. Build. Mater. 2022, 350, 128822. [Google Scholar] [CrossRef]

- Mousa, M.M.; Bayomy, A.M.; Saghir, M.Z. Phase Change Materials Effect on The Thermal Radius and Energy Storage Capacity of Energy Piles: Experimental and Numerical study. Int. J. Thermofluids 2021, 10, 100094. [Google Scholar] [CrossRef]

- Han, C.; Shen, Y.; Chen, K.; Gong, C.; Liu, T.; Qu, B. Characteristics and energy performance of novel MicroPCM C50 energy pile in cooling mode. Energy Build. 2022, 274, 112442. [Google Scholar] [CrossRef]

- Cao, Z.; Zhang, G.; Liu, Y.; Zhao, X. Thermal performance analysis and assessment of PCM backfilled precast high-strength concrete energy pile under heating and cooling modes of building. Appl. Therm. Eng. 2022, 216, 119144. [Google Scholar] [CrossRef]

| Material Parameter | Solid Phase | Liquid Phase | |

|---|---|---|---|

| Density (g/cm3) | 0.88 | 0.77 | |

| Thermal conductivity (W·m−1·K−1) | 0.21 | 0.20 | |

| Heat capacity (kJ·kg−1·K−1) | 3.40 | 2.60 | |

| Transformation temperature * (°C) | 11.90 | 19.30 | 44.20 |

| Latent heat of phase change (kJ·kg−1) | 99.70 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Zhang, P.; Yang, Z.; Zhu, Z.; Liu, X.; Ma, C. Study on Thermodynamic Properties of Spiral Tube-Encapsulated Phase-Change Material Energy Pile. Buildings 2024, 14, 188. https://doi.org/10.3390/buildings14010188

Liu M, Zhang P, Yang Z, Zhu Z, Liu X, Ma C. Study on Thermodynamic Properties of Spiral Tube-Encapsulated Phase-Change Material Energy Pile. Buildings. 2024; 14(1):188. https://doi.org/10.3390/buildings14010188

Chicago/Turabian StyleLiu, Ming, Peng Zhang, Zhiyu Yang, Zhen Zhu, Xiaozheng Liu, and Chuntang Ma. 2024. "Study on Thermodynamic Properties of Spiral Tube-Encapsulated Phase-Change Material Energy Pile" Buildings 14, no. 1: 188. https://doi.org/10.3390/buildings14010188

APA StyleLiu, M., Zhang, P., Yang, Z., Zhu, Z., Liu, X., & Ma, C. (2024). Study on Thermodynamic Properties of Spiral Tube-Encapsulated Phase-Change Material Energy Pile. Buildings, 14(1), 188. https://doi.org/10.3390/buildings14010188