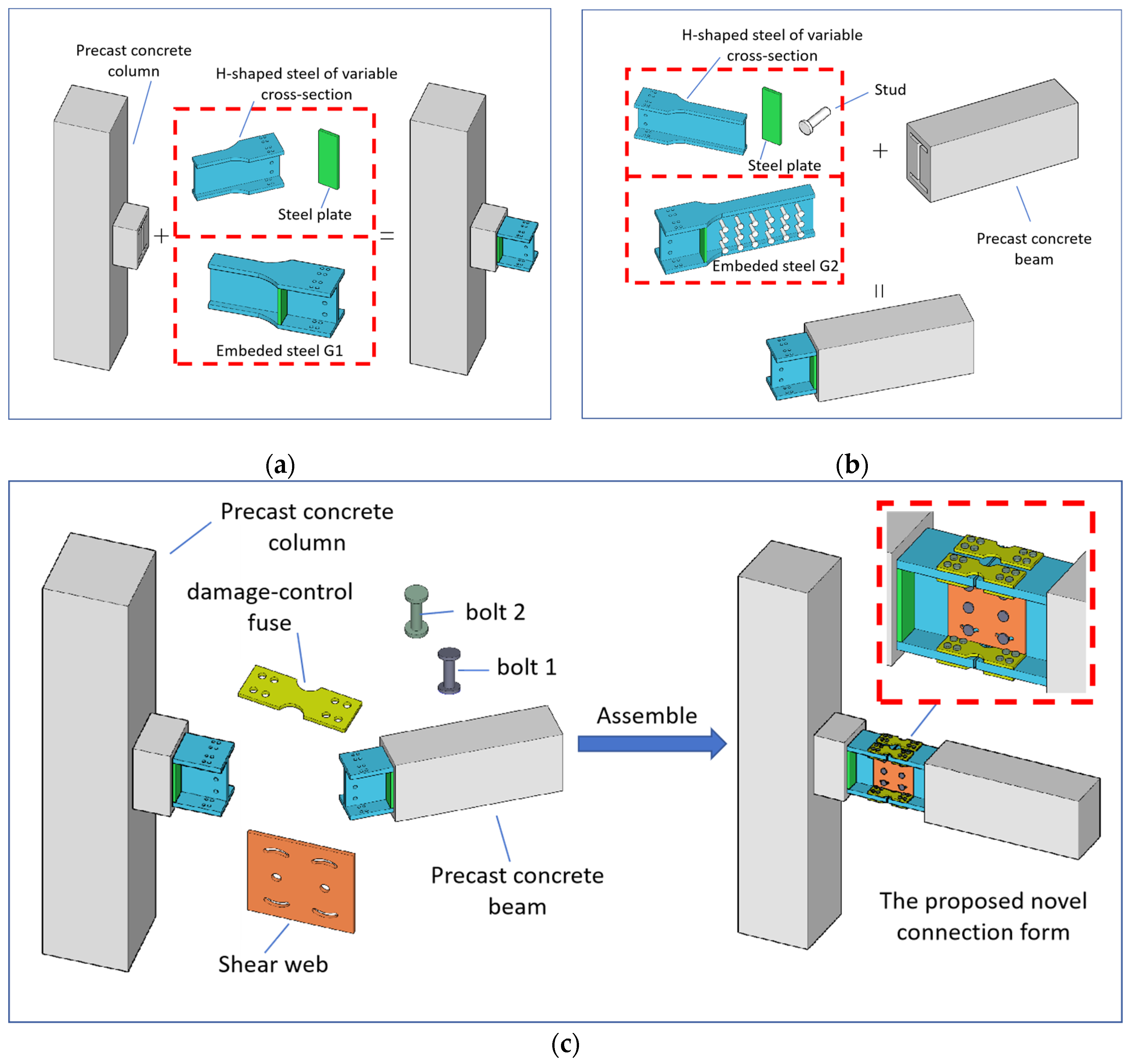

Figure 1.

New demountable RC beam–column joints: (a) precast concrete column; (b) precast concrete beam; and (c) demountable beam–column joints with seismic resilience.

Figure 1.

New demountable RC beam–column joints: (a) precast concrete column; (b) precast concrete beam; and (c) demountable beam–column joints with seismic resilience.

Figure 2.

Geometric dimensions and construction of joints (in mm): (

a) details of BCJ-C [

17], and (

b) details of J1.

Figure 2.

Geometric dimensions and construction of joints (in mm): (

a) details of BCJ-C [

17], and (

b) details of J1.

Figure 4.

Loading protocol.

Figure 4.

Loading protocol.

Figure 5.

Developed FE models of joints: (a) demountable joint and (b) monolithic joint.

Figure 5.

Developed FE models of joints: (a) demountable joint and (b) monolithic joint.

Figure 6.

Uniaxial stress–strain curve of concrete.

Figure 6.

Uniaxial stress–strain curve of concrete.

Figure 7.

Stress–strain relationship of steel.

Figure 7.

Stress–strain relationship of steel.

Figure 8.

Boundary conditions of the model.

Figure 8.

Boundary conditions of the model.

Figure 9.

Overall meshing of the joint specimens.

Figure 9.

Overall meshing of the joint specimens.

Figure 10.

Verification of the finite element model: (

a) the failure mode of the overall joint BCJ-C [

17] and (

b) comparison of the hysteresis curves between the experimental test and finite element simulation.

Figure 10.

Verification of the finite element model: (

a) the failure mode of the overall joint BCJ-C [

17] and (

b) comparison of the hysteresis curves between the experimental test and finite element simulation.

Figure 11.

Stress cloud diagram of different structural forms of damage-control fuses: (a) arc-notch damage-control fuse J1; (b) noncutting damage-control fuse J2; (c) triangular-notch damage-control fuse J3; (d) circular-notch damage-control fuse J4; and (e) inner-circular-notch damage-control fuse J5.

Figure 11.

Stress cloud diagram of different structural forms of damage-control fuses: (a) arc-notch damage-control fuse J1; (b) noncutting damage-control fuse J2; (c) triangular-notch damage-control fuse J3; (d) circular-notch damage-control fuse J4; and (e) inner-circular-notch damage-control fuse J5.

Figure 12.

Influence of different structural forms of damage-control fuses on the load–displacement performance of demountable beam–column joints.

Figure 12.

Influence of different structural forms of damage-control fuses on the load–displacement performance of demountable beam–column joints.

Figure 13.

Load displacement and yield displacement of specimens: (a) definition of load displacement and (b) definition of yield displacement.

Figure 13.

Load displacement and yield displacement of specimens: (a) definition of load displacement and (b) definition of yield displacement.

Figure 14.

Effect of damage-control fuses with different structural forms on ductility.

Figure 14.

Effect of damage-control fuses with different structural forms on ductility.

Figure 15.

Stiffness-degradation curve.

Figure 15.

Stiffness-degradation curve.

Figure 16.

Energy-dissipation curves of joints.

Figure 16.

Energy-dissipation curves of joints.

Figure 17.

Critical sections of a joint.

Figure 17.

Critical sections of a joint.

Figure 18.

The middle-weakened part of arc-notch damage-control fuse J1: (a) effective cross-sectional slope map; (b) top view of the joint; and (c) perspective of the joint.

Figure 18.

The middle-weakened part of arc-notch damage-control fuse J1: (a) effective cross-sectional slope map; (b) top view of the joint; and (c) perspective of the joint.

Figure 19.

The middle-weakened part of noncutting damage-control fuse J2: (a) effective cross-sectional slope map and (b) top view of the joint.

Figure 19.

The middle-weakened part of noncutting damage-control fuse J2: (a) effective cross-sectional slope map and (b) top view of the joint.

Figure 20.

The middle-weakened part of circular-notch damage-control fuse J4: (a) effective cross-sectional slope map and (b) top view of the joint.

Figure 20.

The middle-weakened part of circular-notch damage-control fuse J4: (a) effective cross-sectional slope map and (b) top view of the joint.

Figure 21.

Bending moment at the b-b section of the middle-weakened part of three different damage-control fuses: (a) intermediate bending moment of J1; (b) intermediate bending moment of J2; and (c) intermediate bending moment of J4.

Figure 21.

Bending moment at the b-b section of the middle-weakened part of three different damage-control fuses: (a) intermediate bending moment of J1; (b) intermediate bending moment of J2; and (c) intermediate bending moment of J4.

Figure 22.

Effect of concrete strength on load–displacement performance of demountable beam–column joints.

Figure 22.

Effect of concrete strength on load–displacement performance of demountable beam–column joints.

Figure 23.

Effect of concrete strength: (a) effect of concrete strength on bearing capacity and (b) effect of concrete strength on ductility.

Figure 23.

Effect of concrete strength: (a) effect of concrete strength on bearing capacity and (b) effect of concrete strength on ductility.

Figure 24.

Effect of longitudinal reinforcement ratio on load–displacement performance of demountable beam–column joints.

Figure 24.

Effect of longitudinal reinforcement ratio on load–displacement performance of demountable beam–column joints.

Figure 25.

Effect of longitudinal reinforcement ratio: (a) effect of longitudinal reinforcement ratio on bearing capacity and (b) effect of longitudinal reinforcement ratio on ductility.

Figure 25.

Effect of longitudinal reinforcement ratio: (a) effect of longitudinal reinforcement ratio on bearing capacity and (b) effect of longitudinal reinforcement ratio on ductility.

Figure 26.

Effect of damage-control fuse thickness on load–displacement performance of demountable beam–column joints.

Figure 26.

Effect of damage-control fuse thickness on load–displacement performance of demountable beam–column joints.

Figure 27.

Effect of damage-control fuse thickness: (a) effect of damage-control fuse thickness on bearing capacity and (b) effect of damage-control fuse thickness on ductility.

Figure 27.

Effect of damage-control fuse thickness: (a) effect of damage-control fuse thickness on bearing capacity and (b) effect of damage-control fuse thickness on ductility.

Figure 28.

Effect of damage-control fuse strength on load–displacement performance of demountable beam–column joints.

Figure 28.

Effect of damage-control fuse strength on load–displacement performance of demountable beam–column joints.

Figure 29.

Effect of damage-control fuse strength: (a) effect of damage-control fuse strength on bearing capacity and (b) effect of damage-control fuse strength on ductility.

Figure 29.

Effect of damage-control fuse strength: (a) effect of damage-control fuse strength on bearing capacity and (b) effect of damage-control fuse strength on ductility.

Figure 30.

Effect of shear web strength on load–displacement performance of demountable beam–column joints.

Figure 30.

Effect of shear web strength on load–displacement performance of demountable beam–column joints.

Figure 31.

Effect of shear web strength: (a) effect of shear web strength on bearing capacity and (b) effect of shear web strength on ductility.

Figure 31.

Effect of shear web strength: (a) effect of shear web strength on bearing capacity and (b) effect of shear web strength on ductility.

Figure 32.

Effect of axial compression ratio on load–displacement performance of demountable beam–column joints.

Figure 32.

Effect of axial compression ratio on load–displacement performance of demountable beam–column joints.

Figure 33.

Effect of axial compression ratio: (a) effect of axial compression ratio on bearing capacity and (b) effect of axial compression ratio on ductility.

Figure 33.

Effect of axial compression ratio: (a) effect of axial compression ratio on bearing capacity and (b) effect of axial compression ratio on ductility.

Figure 34.

Stress state of concrete columns under different axial compression ratios.

Figure 34.

Stress state of concrete columns under different axial compression ratios.

Figure 35.

Compression damage of concrete columns under different axial compression ratios.

Figure 35.

Compression damage of concrete columns under different axial compression ratios.

Table 1.

Parameter values of uniaxial tensile stress–strain curve of concrete.

Table 1.

Parameter values of uniaxial tensile stress–strain curve of concrete.

| 1.0 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 |

| 65 | 81 | 95 | 107 | 118 | 128 | 137 |

| 0.31 | 0.70 | 1.25 | 1.95 | 2.81 | 3.82 | 5.00 |

Table 2.

Parameter values of stress–strain curve of concrete under uniaxial compression.

Table 2.

Parameter values of stress–strain curve of concrete under uniaxial compression.

| Parameter | |

|---|

| 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 |

| 1470 | 1560 | 1640 | 1720 | 1790 | 1850 | 1920 | 1980 | 2030 | 2080 | 2130 | 2190 | 2240 |

| 0.74 | 1.06 | 1.36 | 1.65 | 1.94 | 2.21 | 2.48 | 2.74 | 3.00 | 3.25 | 3.50 | 3.75 | 3.99 |

| 3.0 | 2.6 | 2.3 | 2.1 | 2.0 | 1.9 | 1.9 | 1.8 | 1.8 | 1.7 | 1.7 | 1.7 | 1.6 |

Table 3.

Steel parameters.

Table 3.

Steel parameters.

| Component Name | Name of Material | (MPa) | (MPa) | (GPa) |

|---|

| Longitudinal bar | HRB400 | 428 | 569 | 198 |

| Stirrup | HRB400 | 431 | 580 | 200 |

| Other steel members | Q390 | 390 | 490 | 200 |

Table 4.

The meshing of each component for the joint models.

Table 4.

The meshing of each component for the joint models.

| Part Name | Element Type | Delineation Technique | Element Number | Mesh Size |

|---|

| Column | C3D8R | Structured, sweep | 492 | 80 |

| Beam | C3D8R | Structured, sweep | 120 | 80 |

| H-shaped steel at the column end | C3D8R | Structured | 1805 | 20 |

| H-shaped steel at the beam end | C3D8R | Structured | 11,960 | 20 |

| Energy dissipation plate | C3D8R | Structured | 1092 | 10 |

| Bolt 1 | C3D8R | Structured | 176 | 5 |

| Bolt 2 | C3D8R | Structured | 584 | 5 |

| Shear web | C3D8R | Structured | 1144 | 10 |

Table 5.

Comparison of bending moment and required bending moment of three kinds of damage-control fuses (bending moment unit: kN·m).

Table 5.

Comparison of bending moment and required bending moment of three kinds of damage-control fuses (bending moment unit: kN·m).

| Name | MT-y | MT-P | MS-P | Difference | My | Mu | Yes or No |

|---|

| J1 | 305.9 | 367.1 | 500.4 | 26.6% | 549.6 | 612.2 | Yes |

| J2 | 336.9 | 404.3 | 543.3 | 25.6% | Yes |

| J4 | 287.1 | 344.5 | 499.6 | 31.0% | Yes |

Table 6.

The influence of different steel strengths on the bending moment in the middle of a damage-control fuse (bending moment unit: kN·m).

Table 6.

The influence of different steel strengths on the bending moment in the middle of a damage-control fuse (bending moment unit: kN·m).

| d-c-f-s (MPa) | MT-y | MT-P | MS-P | Difference | My | Mu | Yes or No |

|---|

| 345 | 270.6 | 324.7 | 486.9 | 33.3% | 374.6 | 449.5 | Yes |

| 390 | 305.9 | 367.1 | 500.4 | 26.6% | 423.5 | 508.2 | Yes |

| 460 | 360.8 | 433.0 | 538.3 | 19.6% | 499.7 | 599.6 | Yes |

Table 7.

The influence of different web steel strengths on the bending moment in the middle of a damage-control fuse (bending moment unit: kN·m).

Table 7.

The influence of different web steel strengths on the bending moment in the middle of a damage-control fuse (bending moment unit: kN·m).

| s-w-s (MPa) | MT-y | MT-P | MS-P | Difference | My | Mu | Yes or No |

|---|

| 345 | 305.9 | 367.1 | 500.4 | 26.6% | 549.6 | 612.2 | Yes |

| 390 | 500.4 | 26.6% | Yes |

| 460 | 500.4 | 26.6% | Yes |

Table 8.

Influence of different concrete strengths on the bending moment in the middle of a damage-control fuse (bending moment unit: kN·m).

Table 8.

Influence of different concrete strengths on the bending moment in the middle of a damage-control fuse (bending moment unit: kN·m).

| c-s (MPa) | MT-y | MT-P | MS-P | Difference | My | Mu | Yes or No |

|---|

| C25 | 305.9 | 367.1 | 507.2 | 27.6% | 549.6 | 612.2 | Yes |

| C40 | 500.4 | 26.6% | Yes |

| C55 | 564.0 | 34.9% | Yes |

Table 9.

Effect of different axial compression ratios on the bending moment in the middle of the damage-control fuse (bending moment unit: kN·m).

Table 9.

Effect of different axial compression ratios on the bending moment in the middle of the damage-control fuse (bending moment unit: kN·m).

| a-c-r | MT-y | MT-P | MS-P | Difference | My | Mu | Yes or No |

|---|

| 0.1 | 305.9 | 367.1 | 607.3 | 39.6% | 549.6 | 612.2 | Yes |

| 0.3 | 500.4 | 26.6% | Yes |

| 0.5 | 435.2 | 15.6% | Yes |