Nondestructive Testing (NDT) for Damage Detection in Concrete Elements with Externally Bonded Fiber-Reinforced Polymer

Abstract

1. Introduction

1.1. FRP Composites

1.2. Application of EB-FRP Systems

1.3. Inspection of EB-FRP Concrete Elements

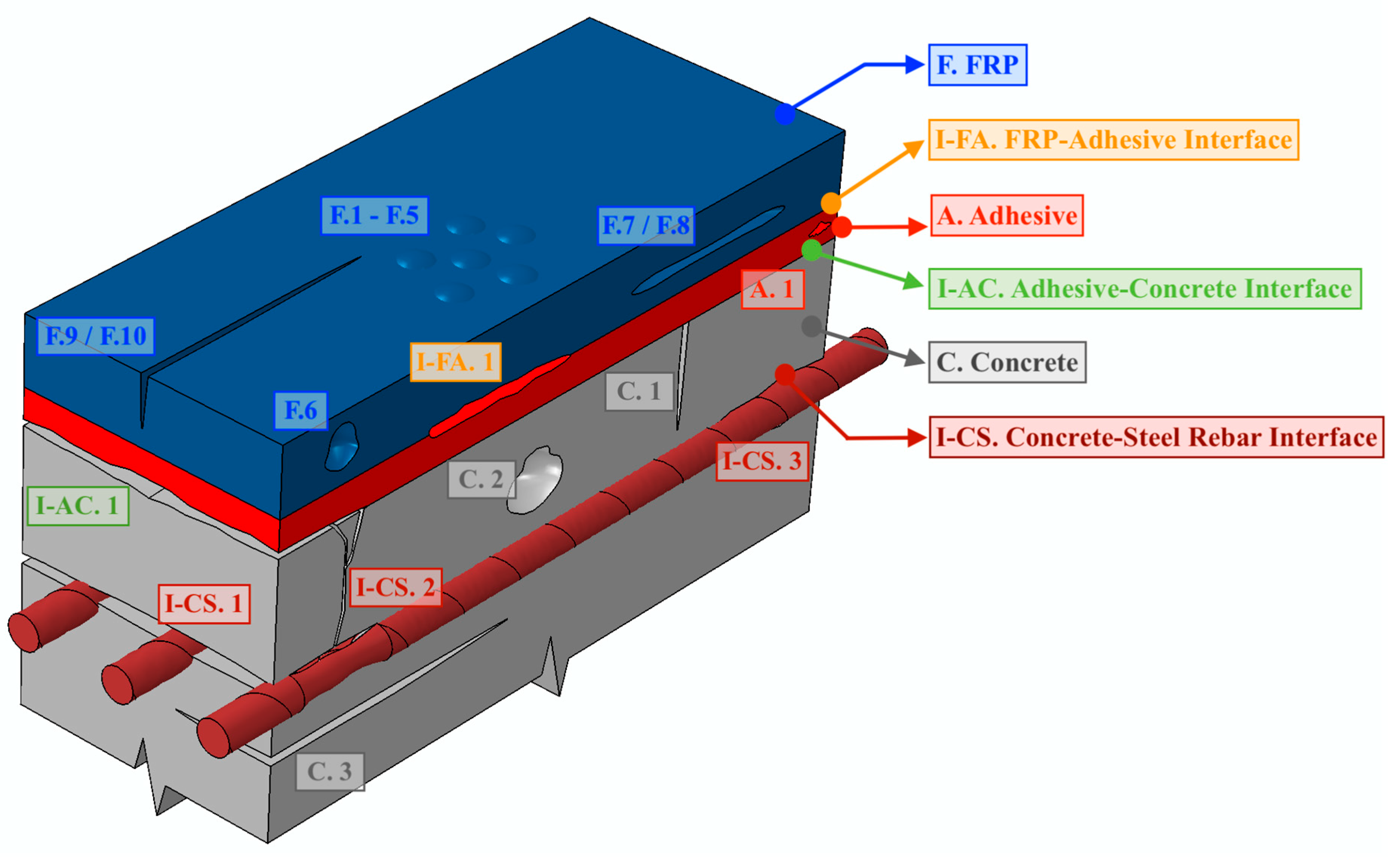

2. Location of Potential Defects or Damage

3. Damage and Defects in EB-FRP Concrete Elements

4. Source of Damage

5. NDT Methods Applicable to EB-FRP Concrete Elements

- Visual Inspection (VT): A common, versatile, and straightforward NDT method, is used to identify surface defects in EB-FRP concrete elements. Although some researchers do not consider VT as an NDT method, it completely fits the definition of NDT method as described earlier in this paper. In any case, it is a fast and cost-effective method, and provides real-time results, serving as a baseline for other NDT techniques. Based on its findings, decisions can be made about further inspection. However, it can only detect surface defects and may be subjective, depending on individual perception.

- Tap Testing (TT): This method detects defects by analyzing changes in stiffness and sound frequency upon impact. It is a quick, cost-effective, and user-friendly approach for inspecting large areas in real-time, but its results are subjective and can vary due to differences in applied force, angle, and equipment. Misinterpretations may occur due to ambient noise and geometric changes.

- Impact Echo Testing (IE): This method relies on stress waves from an impact to identify subsurface defects in materials, particularly in concrete. It is effective for evaluating issues like cracks and delamination. By using lower frequencies, it can penetrate deeper and requires access to only one surface for testing. However, its applicability is limited to materials up to 40 inches thick. Skilled operators are needed, and it may have difficulty detecting smaller cracks and discontinuities.

- Ground-Penetrating Radar (GPR): This method uses radio waves to pass through a material and detects reflections from any interfaces between materials or subsurface defects like voids, cracks, debonding, and delamination. It can go beyond concrete–air interfaces, inspecting features below, and identifying defects at greater depths than some other NDT methods. It is not effective for detecting air-filled defects.

- Ultrasonic Testing (UT) and Phased Array Ultrasonic Testing (PAU): This method uses the reflection of ultrasonic waves at material interfaces with differing acoustic impedances to locate defects. It excels in identifying defects in concrete and composites due to the strong reflection caused by these flaws. It offers fast and field-friendly testing with good resolution, capable of penetrating materials and detecting various defects. It necessitates highly trained personnel for conducting and interpreting tests and is primarily suitable for materials of limited thickness. PAU uses multiple transducer elements in a phased array probe to enable precise control.

- Infrared Thermography Testing (IR): This method relies on differences in thermal properties between anomalies and sound areas within the material. By measuring surface temperature, it can detect subsurface defects to some extent. It is particularly suitable for inspecting larger surface areas quickly and cost-effectively, with real-time data interpretation. However, it is not reliable for detecting water-filled defects, has limitations in identifying deep-seated defects in concrete, and necessitates specific environmental conditions for optimal results.

6. Experimental Verification—Inspection of EB-FRP Concrete Elements

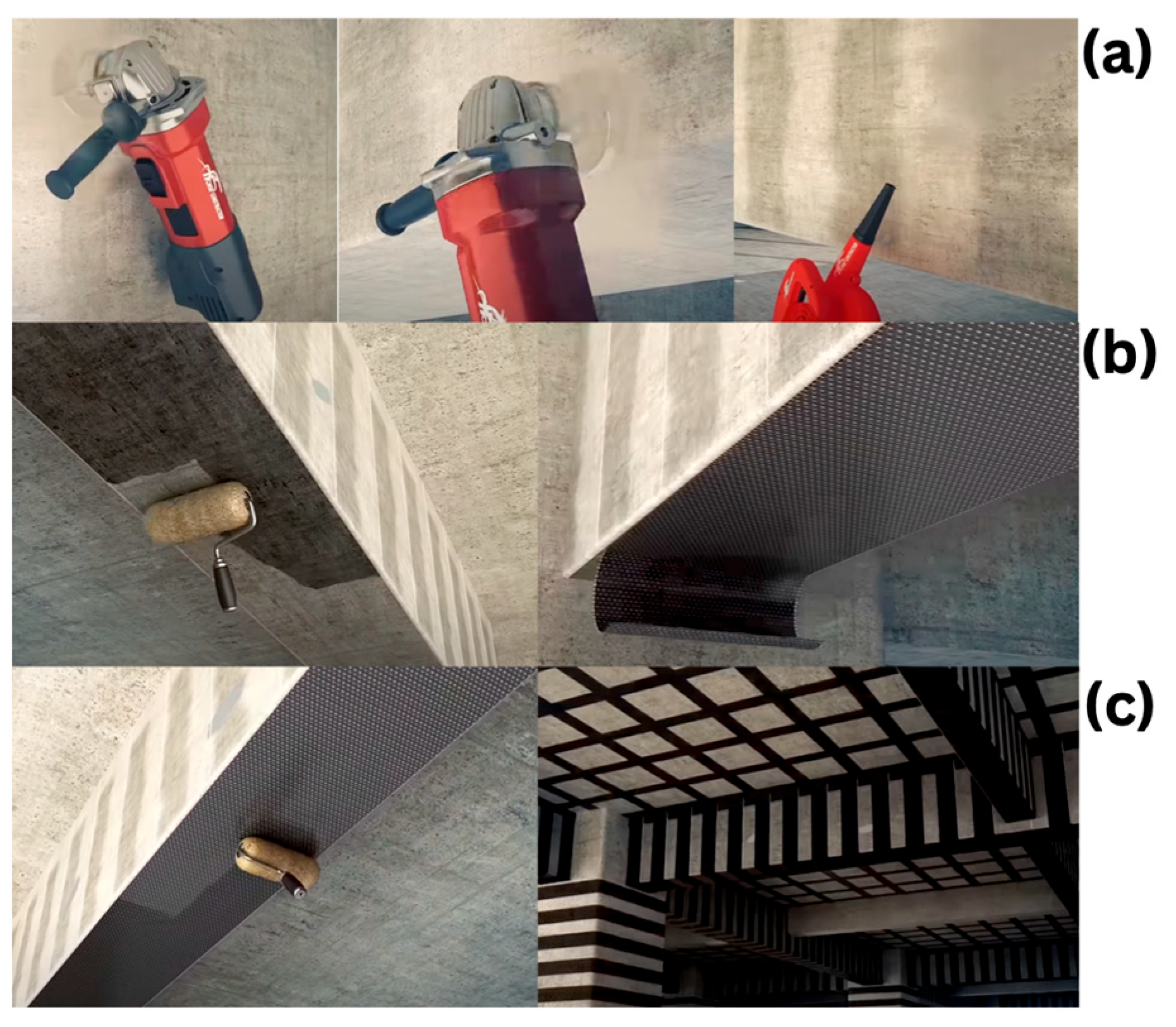

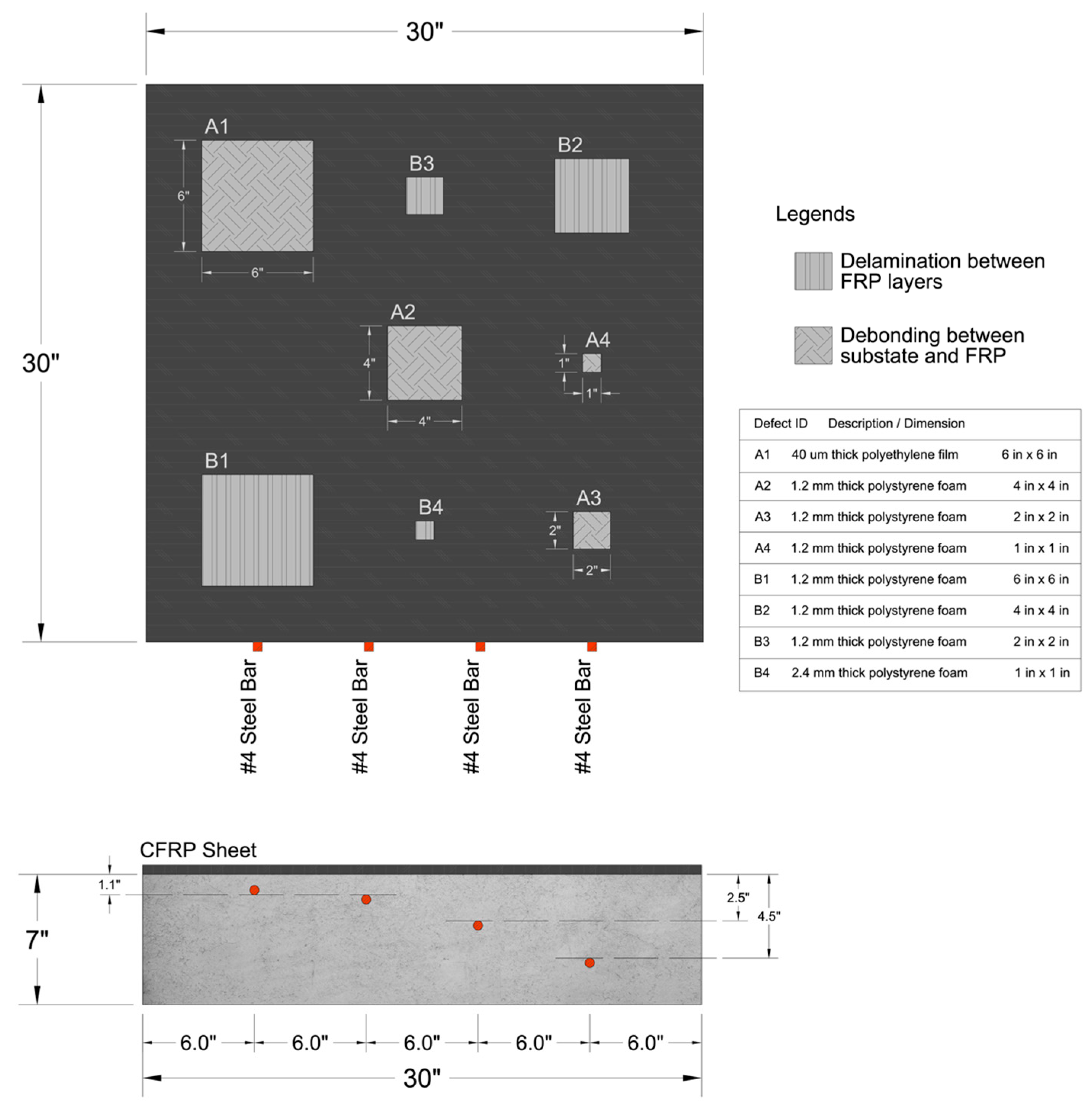

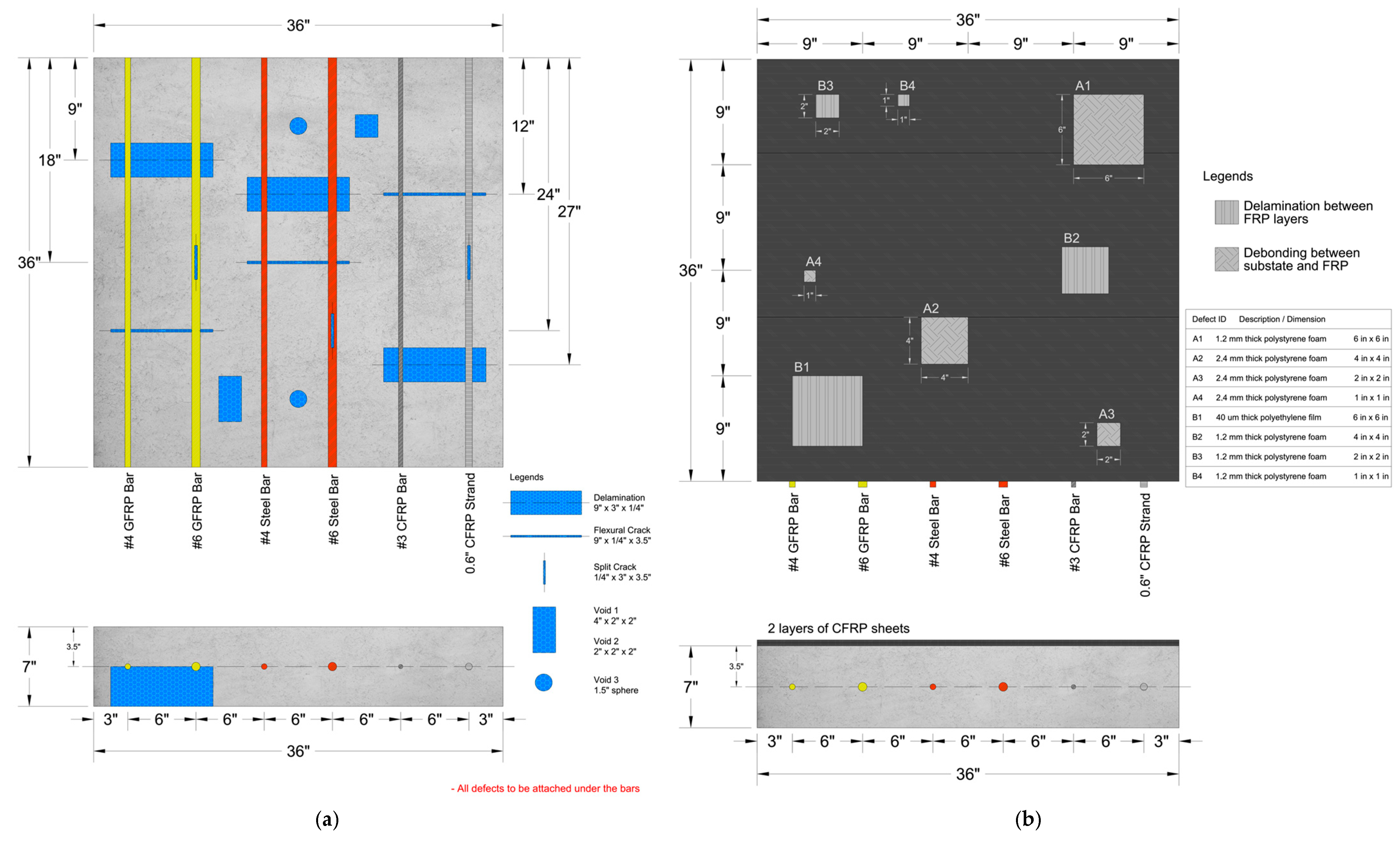

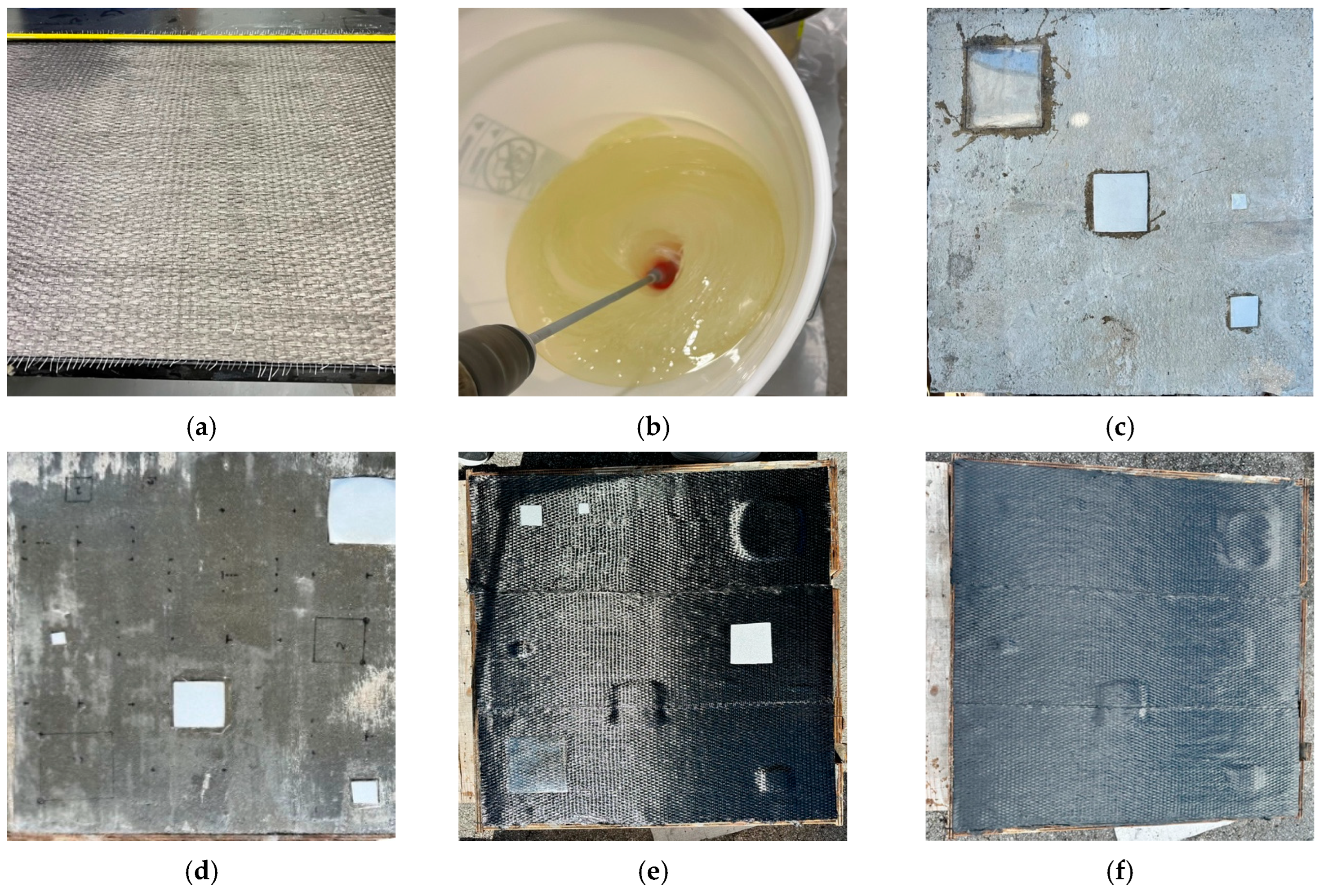

6.1. Materials and Constrcution

6.2. Defects Generation for EB-FRP Concrete Elements

7. Results and Discussion

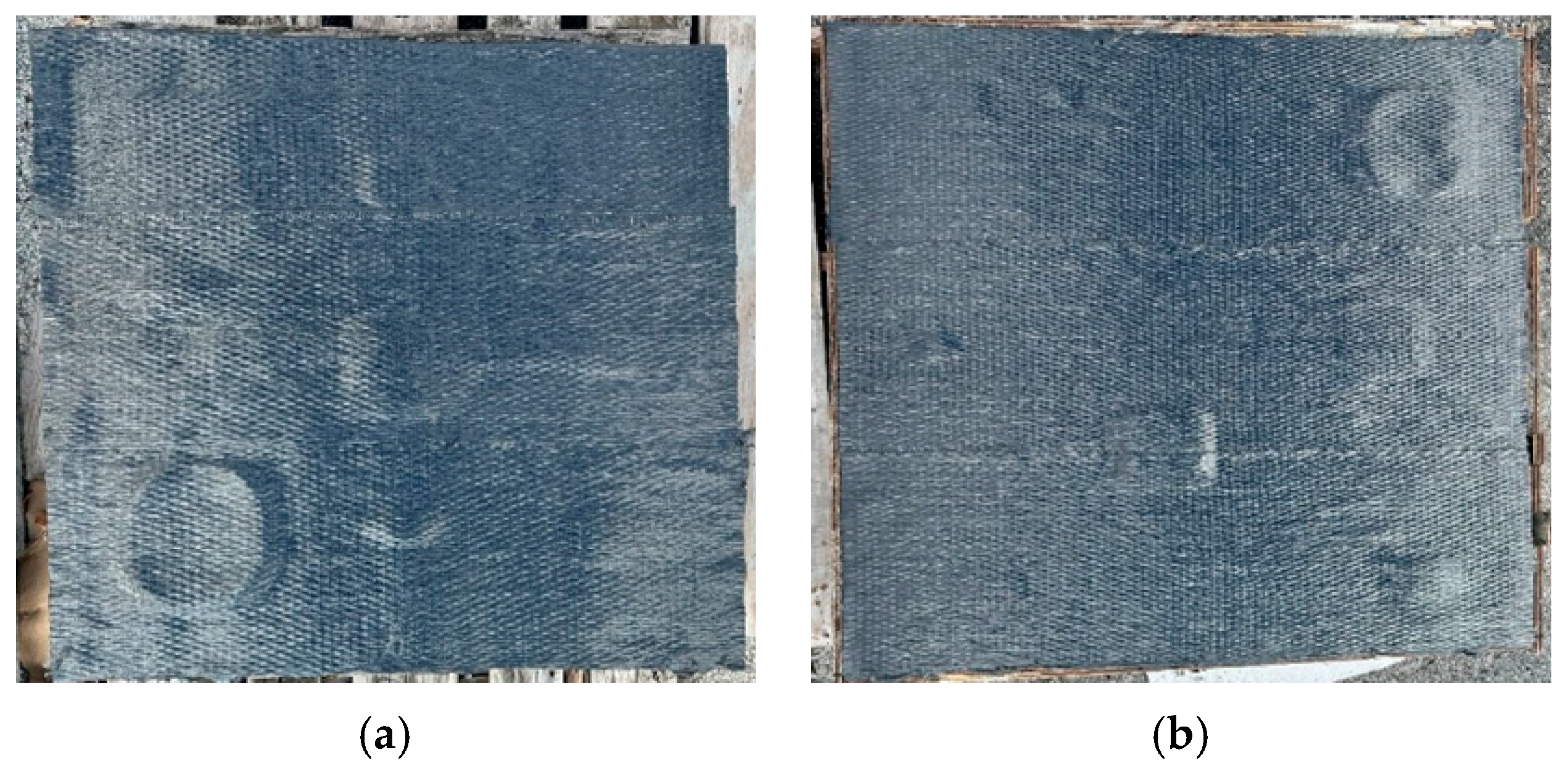

7.1. Visual Inspection (VT)

7.2. Tap Testing (TT)

7.3. Infrarred Thermography (IR)

7.4. Ground-Penetrating Radar (GPR)

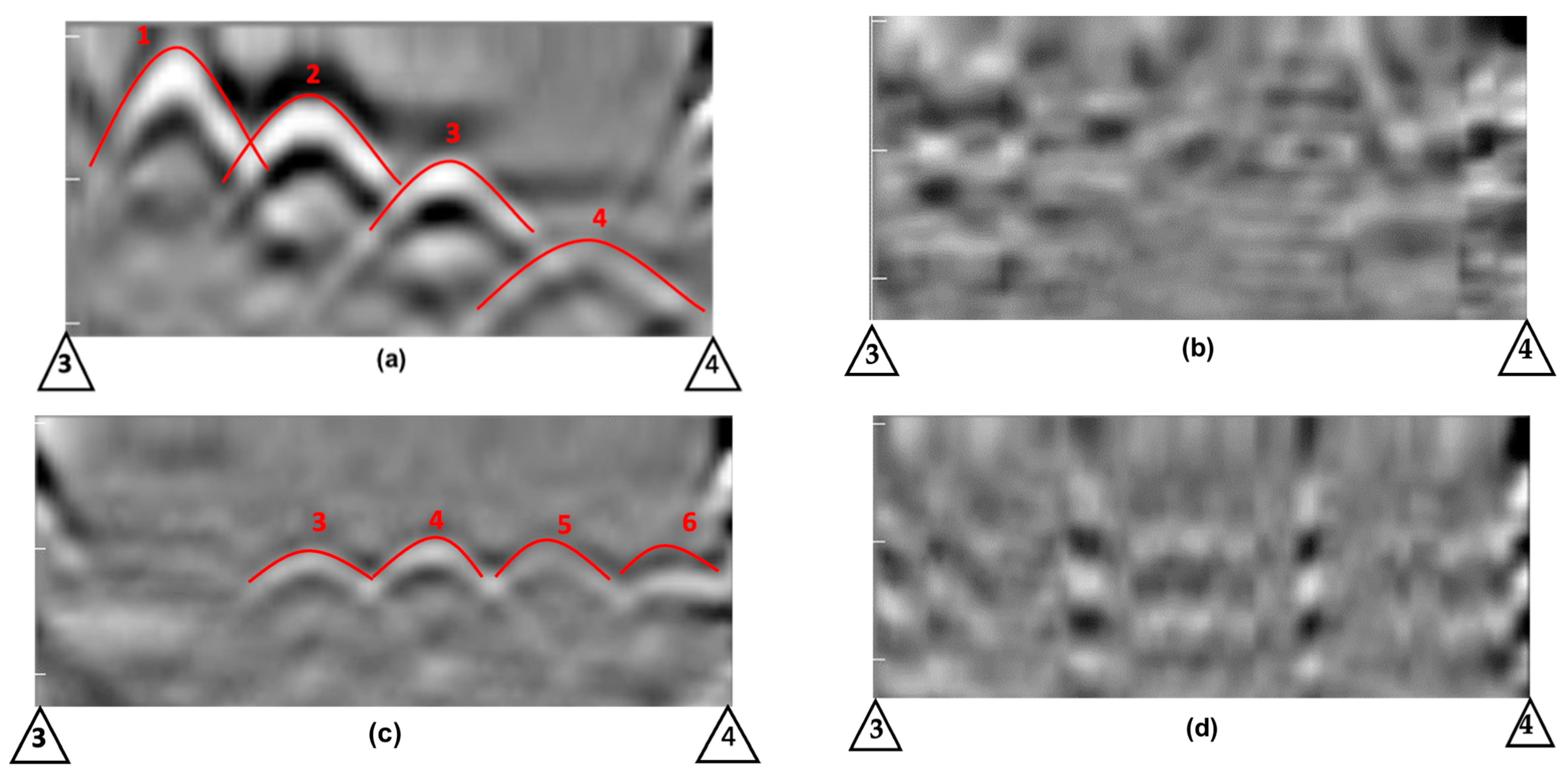

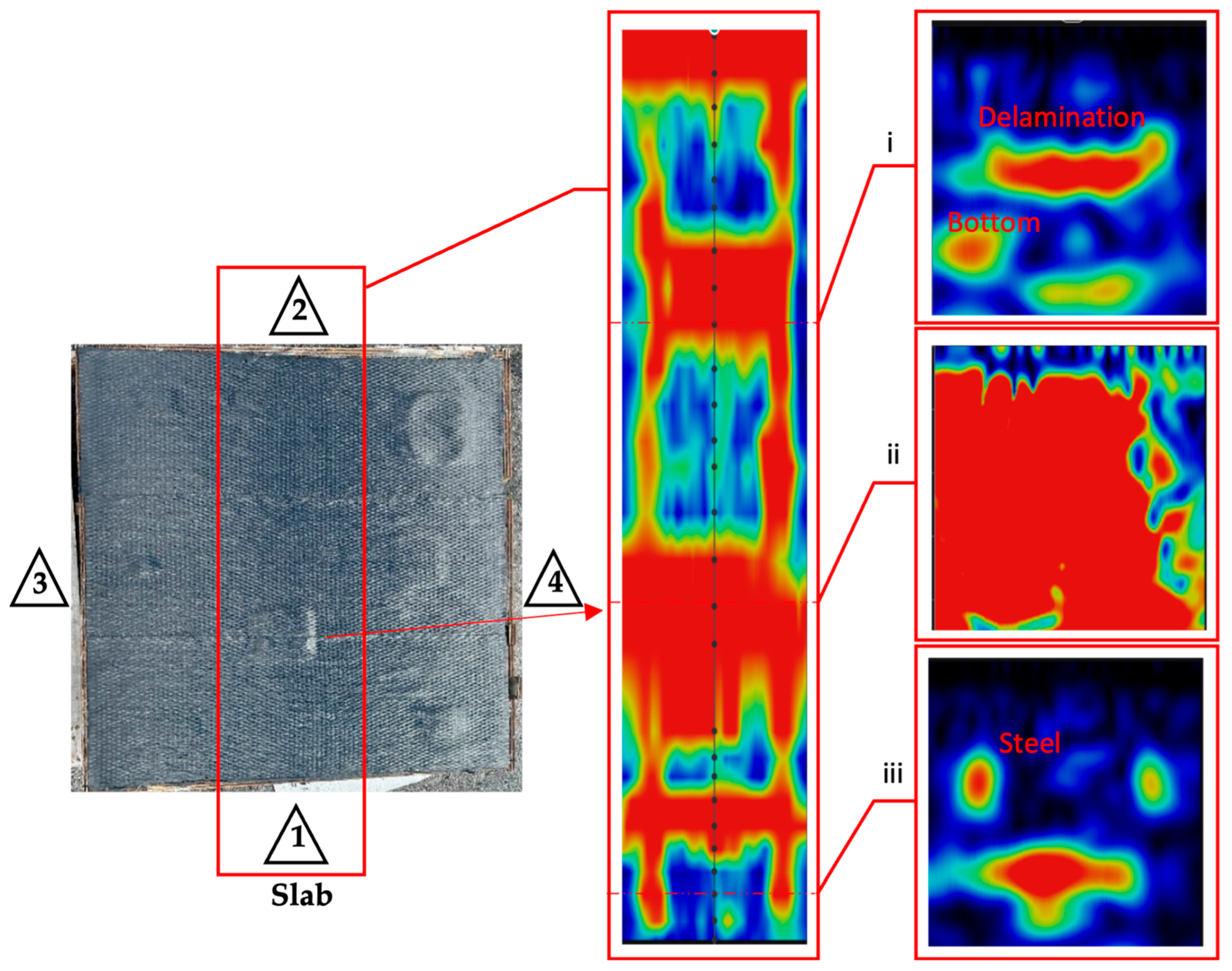

7.5. Phased Array Ultrasonic Testing (PAU)

8. Conclusions

- The externally applied FRP system should be visually examined thoroughly to identify surface anomalies, including blister-like formations, exposed fibers, surface scratches, and cracks. Signs of moisture and water stains near joints or lower areas underneath the structure. Surface anomalies observed in the externally applied FRP may indicate defects within the FRP composite or bonding issues between the FRP and concrete.

- Inspecting FRP composite defects and bond issues may necessitate NDT methods beyond visual inspection (VT). Tap testing (TT) is suitable for detecting bond defects to prevent the separation of externally applied FRP system from the concrete substrate. Additionally, IR can be employed for quantitative defect assessment within the FRP composite or between the FRP and concrete, capable of detecting areas as small as 625 mm2. PAU can be employed for qualitative assessment of the EB-FRP.

- Inspecting hidden concrete under external FRP is challenging but achievable by noting evidence of internal defects (e.g., detecting FRP tearing due to concrete spalling), observing anomalies deviating from sound FRP (e.g., CFRP bulging indicating underlying cracks), and checking for rust stains (e.g., a sign of embedded steel corrosion). Employment of NDT devices capable of penetrating FRP (e.g., PAU) is desirable for an in-depth investigation. The coupling of these defects potentially adds complexity to accurate defect identification. However, the effectiveness of the device and the technician’s expertise play a crucial role in detecting and distinguishing such complex defects. Nevertheless, the presence of damage regardless of the type and complexity should trigger further examination and potentially corrective action.

- In a contrast to the results of a previous literature review, it was determined that GPR could not detect defects or damage introduced into the externally applied CFRP and the internal targets beneath the CFRP layer due to its conductive nature. PAU exhibited relatively better performance in inspecting the external application of FRP, being able to qualitatively detect introduced debonding/delamination in the external FRP and delamination within the concrete. Other NDT techniques, including visual inspection (VT), tap testing (TT), and infrared thermography (IR), were also found to be quite effective in detecting primarily surface anomalies and some bond defects, such as voids.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rodrigues, R.; Gaboreau, S.; Gance, J.; Ignatiadis, I.; Betelu, S. Reinforced Concrete Structures: A Review of Corrosion Mechanisms and Advances in Electrical Methods for Corrosion Monitoring. Constr. Build. Mater. 2021, 269, 121240. [Google Scholar] [CrossRef]

- Angst, U.M.; Isgor, O.B.; Hansson, C.M.; Sagüés, A.; Geiker, M.R. Beyond the Chloride Threshold Concept for Predicting Corrosion of Steel in Concrete. Appl. Phys. Rev. 2022, 9, 011321. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.C. Properties and Applications of FRP in Strengthening RC Structures: A Review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Liu, T.Q.; Liu, X.; Feng, P. A Comprehensive Review on Mechanical Properties of Pultruded FRP Composites Subjected to Long-Term Environmental Effects. Compos. B Eng. 2020, 191, 107958. [Google Scholar] [CrossRef]

- Benmokrane, B.; Hassan, M.; Robert, M.; Vijay, P.V.; Manalo, A. Effect of Different Constituent Fiber, Resin, and Sizing Combinations on Alkaline Resistance of Basalt, Carbon, and Glass FRP Bars. J. Compos. Constr. 2020, 24, 04020010. [Google Scholar] [CrossRef]

- Zaman, A.; Gutub, S.A.; Wafa, M.A. A Review on FRP Composites Applications and Durability Concerns in the Construction Sector. J. Reinf. Plast. Compos. 2013, 32, 1966–1988. [Google Scholar] [CrossRef]

- Moy, S. Advanced Fiber-Reinforced Polymer (FRP) Composites for Civil Engineering Applications. In Developments in Fiber-reinforced Polymer (FRP) Composites for Civil Engineering; Elsevier: Amsterdam, The Netherlands, 2013; pp. 177–204. [Google Scholar]

- Hollaway, L.C. A Review of the Present and Future Utilisation of FRP Composites in the Civil Infrastructure with Reference to Their Important In-Service Properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Teng, J.G.; Chen, J.-F.; Smith, S.T.; Lam, L. FRP: Strengthened RC Structures; John Wiley & Sons: Hoboken, NJ, USA, 2002; ISBN 0471487066. [Google Scholar]

- Benzecry, V.; Brown, J.; Al-Khafaji, A.; Haluza, R.; Koch, R.; Nagarajan, M.; Bakis, C.; Myers, J.; Nanni, A. Durability of GFRP Bars Extracted from Bridges with 15 to 20 Years of Service Life; ACI Foundation: Farmington Hills, MI, USA, 2019. [Google Scholar]

- Benmokrane, B.; Wang, P.; Ton-That, T.M.; Rahman, H.; Robert, J.-F. Durability of Glass Fiber-Reinforced Polymer Reinforcing Bars in Concrete Environment. J. Compos. Constr. 2002, 6, 143–153. [Google Scholar] [CrossRef]

- Micelli, F.; Nanni, A. Durability of FRP Rods for Concrete Structures. Constr. Build. Mater. 2004, 18, 491–503. [Google Scholar] [CrossRef]

- Ceroni, F.; Cosenza, E.; Gaetano, M.; Pecce, M. Durability Issues of FRP Rebars in Reinforced Concrete Members. Cem. Concr. Compos. 2006, 28, 857–868. [Google Scholar] [CrossRef]

- Chen, Y.; Davalos, J.F.; Ray, I.; Kim, H.Y. Accelerated Aging Tests for Evaluations of Durability Performance of FRP Reinforcing Bars for Concrete Structures. Compos. Struct. 2007, 78, 101–111. [Google Scholar] [CrossRef]

- Malla, P.; Khedmatgozar Dolati, S.S.; Ortiz, J.D.; Mehrabi, A.; Nanni, A. Damage and Defects in Fiber-Reinforced Polymer Reinforced and Strengthened Concrete Elements. J. Compos. Constr. 2023, 27. [Google Scholar] [CrossRef]

- Das, S.C.; Nizam, M. Applications of Fiber Reinforced Polymer Composites (FRP) in Civil Engineering. Int. J. Adv. Struct. Geotech. Eng. 2014, 3, 299–309. [Google Scholar]

- Wu, Z.; Wu, Y.; Fahmy, M.F.M. Structures Strengthened with Bonded Composites; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2020; Volume 1, ISBN 9780128210888. [Google Scholar]

- Frigione, M.; Lettieri, M. Durability Issues and Challenges for Material Advancements in FRP Employed in the Construction Industry. Polymers 2018, 10, 247. [Google Scholar] [CrossRef]

- Motavalli, M.; Czaderski, C. FRP Composites for Retrofitting of Existing Civil Structures in Europe: State-of-the-Art Review. In Proceedings of the International Conference of Composites & Polycon, Tampa, FL, USA, 17–19 October 2007; American Composites Manufacturers Association: Tampa, FL, USA, 2007; pp. 17–19. [Google Scholar]

- Ritchie, P.A.; Thomas, D.A.; Lu, L.-W.; Connelly, G.M. External Reinforcement of Concrete Beams Using Fiber Reinforced Plastic. Master’s Thesis, Lehigh University, Bethlehem, PA, USA, 1988. [Google Scholar]

- Arduini, M.; Nanni, A. Parametric Study of Beams with Externally Bonded FRP Reinforcement. ACI Struct. J. 1997, 94, 493–501. [Google Scholar]

- Toutanji, H.; Zhao, L.; Zhang, Y. Flexural Behavior of Reinforced Concrete Beams Externally Strengthened with CFRP Sheets Bonded with an Inorganic Matrix. Eng. Struct. 2006, 28, 557–566. [Google Scholar] [CrossRef]

- Hutchinson, A.R. Surface Preparation of Component Materials; Woodhead Publishing Limited: Sawston, UK, 2008; ISBN 9781845694487. [Google Scholar]

- Hutchinson, A. Adhesives for Externally Bonded FRP Reinforcement. ICE Man. Constr. Mater. 2009, 2, 667–674. [Google Scholar]

- Hollaway, L.C. Applications of Advanced Fibre-Reinforced Polymer (FRP) Composites in Bridge Engineering: Rehabilitation of Metallic Bridge Structures, All-FRP Composite Bridges, and Bridges Built with Hybrid Systems; Woodhead Publishing Limited: Sawston, UK, 2013; ISBN 9780857094186. [Google Scholar]

- Alkhrdaji, T.; Nanni, A.; Chen, G.; Barker, M.G. Destructive and Non-Destructive Testing of Bridge J857, Phelps County, Missouri. Volume I-Strengthening and Testing to Failure of Bridge Decks; 2001; Vol. No. RDT01-. Available online: https://spexternal.modot.mo.gov/sites/cm/CORDT/RDT01002A.pdf (accessed on 14 December 2023).

- Ortiz, J.D.; Khedmatgozar Dolati, S.S.; Malla, P.; Nanni, A.; Mehrabi, A. FRP-Reinforced/Strengthened Concrete: State-of-the-Art Review on Durability and Mechanical Effects. Materials 2023, 16, 1990. [Google Scholar] [CrossRef]

- Horse Construction-Structural Strengthening System Structural Strengthening with Carbon Fiber CFRP Composite System. Available online: www.horseen.com (accessed on 21 October 2023).

- AASHTO. Guide Specifications for Design of Bonded FRP Systems for Repair and Strengthening of Concrete Bridge Elements, 2nd ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2023; ISBN 978-1-56051-807-5. [Google Scholar]

- American Concrete Institute (ACI) Committee 440. ACI 440.2R-17. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2017. [Google Scholar]

- JPCI. Recommendation for Design and Construction of Concrete Structures Using Fiber Reinforced Polymer; Japan Prestressed Concrete Institute: Tokyo, Japan, 2021. [Google Scholar]

- Riccitelli, F.; Mehrabi, A.; Abedin, M.; Farhangdoust, S.; Khedmatgozar Dolati, S.S. Performance of Existing Abc Projects: Inspection Case Studies; Accelerated Bridge Construction University Transportation Center (ABC-UTC): Miami, FL, USA, 2020. [Google Scholar]

- Khedmatgozar Dolati, S.S.; Malla, P.; Mehrabi, A.; Ortiz Polanco, J.; Nanni, A. Non-Destructive Testing Applications for in-Service FRP Reinforced/Strengthened Concrete Bridge Elements. In Proceedings of the Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure, and Transportation XVI, Long Beach, CA, USA, 6 March–11 April 2022; Wu, H.F., Gyekenyesi, A.L., Shull, P.J., Yu, T., Eds.; SPIE: Long Beach, CA, USA, 2022; Volume 12047, p. 1204708. [Google Scholar]

- Malla, P.; Khedmatgozar Dolati, S.S.; Ortiz, J.D.; Mehrabi, A.B.; Nanni, A.; Dinh, K. Feasibility of Conventional Non-Destructive Testing Methods in Detecting Embedded FRP Reinforcements. Appl. Sci. 2023, 13, 4399. [Google Scholar] [CrossRef]

- Khedmatgozar Dolati, S.S.; Caluk, N.; Mehrabi, A.; Khedmatgozar Dolati, S.S. Non-Destructive Testing Applications for Steel Bridges. Appl. Sci. 2021, 11, 9757. [Google Scholar] [CrossRef]

- Yazdani, N.; Garcia, E.C.; Riad, M. Field Assessment of Concrete Structures Rehabilitated with FRP; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780081021811. [Google Scholar]

- Ettouney, S.; Alampalli, M. Infrastructure Health in Civil Engineering; CRC Press: Boca Raton, FL, USA, 2011; ISBN 9781439866542. [Google Scholar]

- Khanal, S. Review of Modern Nondestructive Testing Techniques for Civil Infrastructure; West Virginia University: Morgantown, WV, USA, 2020. [Google Scholar]

- Wheeler, A.S. Nondestructive Evaluation of Concrete Bridge Columns Rehabilitiated with Fiber Reinforced Polymers Using Digital Tap Hammer and Infrared Thermography Nondestructive Evaluation of Concrete Bridge Columns; West Virginia University: Morgantown, WV, USA, 2018. [Google Scholar]

- Halabe, U.B.; Joshi, R.M.; Gangarao, H.V.S. Nondestructive Testing of FRP Composite Structural Components and FRP Rehabilitated Bridge Using Digital Tap Testing. J. Multidiscip. Eng. Sci. Technol. 2020, 7, 11477–11482. [Google Scholar]

- Taillade, F.; Quiertant, M.; Benzarti, K.; Aubagnac, C.; Moser, E. Non-Destructive Evaluation (NDE) of Composites: Using Shearography to Detect Bond Defects. In Non-Destructive Evaluation (NDE) of Polymer Matrix Composites Techniques and Applications; Woodhead Publishing: Sawston, UK, 2013; pp. 542–556. [Google Scholar] [CrossRef]

- Ekenel, M.; Myers, J.J. Nondestructive Evaluation of RC Structures Strengthened with FRP Laminates Containing Near-Surface Defects in the Form of Delaminations. Sci. Eng. Compos. Mater. 2007, 14, 299–315. [Google Scholar] [CrossRef]

- Hsieh, C.T.; Lin, Y. Detecting Debonding Flaws at the Epoxy-Concrete Interfaces in near-Surface Mounted CFRP Strengthening Beams Using the Impact-Echo Method. NDT E Int. 2016, 83, 1–13. [Google Scholar] [CrossRef]

- Crawford, K.C. Non-Destructive Testing of FRP-Structural Systems Applied to Concrete Bridges. In Nondestructive Testing of Materials and Structures; Springer: Dordrecht, The Netherlands, 2013; pp. 835–840. [Google Scholar]

- Crawford, K.C. NDT Evaluation of Long-Term Bond Durability of CFRP-Structural Systems Applied to RC Highway Bridges. Int. J. Adv. Struct. Eng. 2016, 8, 161–168. [Google Scholar] [CrossRef]

- ACI. ACI 228.2R-13: Report on Nondestructive Test Methods for Evaluation of Concrete in Structures; American Concrete Institute: Farmington Hills, MI, USA, 2013. [Google Scholar]

- Dong, Y.; Ansari, F. Non-Destructive Testing and Evaluation (NDT/NDE) of Civil Structures Rehabilitated Using Fiber Reinforced Polymer (FRP) Composites. In Service Life Estimation and Extension of Civil Engineering Structures; Elsevier: Amsterdam, The Netherlands, 2011; pp. 193–222. [Google Scholar]

- Gower, M.; Lodeiro, M.; Aktas, A.; Shaw, R.; Maierhofer, C.; Krankenhagen, R.; Augustin, S.; Rollig, M.; Knazovicka, L.; Blahut, A.; et al. Design and Manufacture of Reference and Natural Defect Artefacts for the Evaluation of NDE Techniques for Fibre Reinforced Plastic (FRP) Composites in Energy Applications. In Proceedings of the 19th World Conference on Non-Destructive Testing (WCNDT 2016), Munich, Germany, 13–17 June 2016; Volume 21. [Google Scholar]

- Aboukhousa, M.; Qaddoumi, N. Near-Field Microwave Imaging of Subsurface Inclusions in Laminated Composite Structures. In Proceedings of the 16th World Conference on Nondestructive Testing, Montreal, QC, Canada, 30 August–3 September 2004. [Google Scholar]

- Kharkovsky, S.; Ryley, A.C.; Stephen, V.; Zoughi, R. Dual-Polarized near-Field Microwave Reflectometer for Noninvasive Inspection of Carbon Fiber Reinforced Polymer-Strengthened Structures. IEEE Trans. Instrum. Meas. 2008, 57, 168–175. [Google Scholar] [CrossRef]

- Navagato, M.D.; Narayanan, R.M. Microwave Imaging of Multilayered Structures Using Ultrawideband Noise Signals. NDT E Int. 2019, 104, 19–33. [Google Scholar] [CrossRef]

- Ekenel, M.; Stephen, V.; Myers, J.J.; Zoughi, R. Microwave Nde of Rc Beams Strengthened With Cfrp Laminates Containing Surface Defects and Tested Under Cyclic Loading; Electrical and Computer Engineering, University of Missouri-Rolla: Rolla, MO, USA, 2004. [Google Scholar]

- Akuthota, B.; Hughes, D.; Zoughi, R.; Myers, J.; Nanni, A. Near-Field Microwave Detection of Disbond in Carbon Fiber Reinforced Polymer Composites Used for Strengthening Cement-Based Structures and Disbond Repair Verification. J. Mater. Civ. Eng. 2004, 16, 540–546. [Google Scholar] [CrossRef]

- Drobiec, Ł.; Jasiński, R.; Mazur, W. The Use of Non-Destructive Methods to Detect Non-Metallic Reinforcement in Concrete and Masonry. Preprints 2019. [Google Scholar] [CrossRef]

- Jackson, D.; Islam, M.; Alampalli, S. Feasibility of Evaluating the Performance of Fiber Reinforced Plastic (FRP) Wrapped Reinforced Concrete Columns Using Ground Penetrating RADAR (GPR) and Infrared (IR) Thermography Techniques. In Proceedings of the Structural Materials Technology IV—An NDT Conference, Atlantic City, NJ, USA, 28 February–3 March 2000. [Google Scholar]

- Yazdani, N.; Beneberu, E.; Riad, M. Nondestructive Evaluation of FRP-Concrete Interface Bond Due to Surface Defects. Adv. Civ. Eng. 2019, 2019, 2563079. [Google Scholar] [CrossRef]

- La Malfa Ribolla, E.; Rezaee Hajidehi, M.; Rizzo, P.; Fileccia Scimemi, G.; Spada, A.; Giambanco, G. Ultrasonic Inspection for the Detection of Debonding in CFRP-Reinforced Concrete. Struct. Infrastruct. Eng. 2018, 14, 807–816. [Google Scholar] [CrossRef]

- Hing, C.L.C.; Halabe, U.B. Nondestructive Testing of GFRP Bridge Decks Using Ground Penetrating Radar and Infrared Thermography. J. Bridge Eng. 2010, 15, 391–398. [Google Scholar] [CrossRef]

- Taheri, H.; Hassen, A.A. Nondestructive Ultrasonic Inspection of Composite Materials: A Comparative Advantage of Phased Array Ultrasonic. Appl. Sci. 2019, 9, 1628. [Google Scholar] [CrossRef]

- Taheri, H.; Delfanian, F.; Du, J. Acoustic emission and ultrasound phased array technique for composite material evaluation. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), San Diego, CA, USA, 15–21 November 2013; American Society of Mechanical Engineers (ASME): New York, NY, USA, 2013; Volume 1. [Google Scholar]

- Meola, C.; Boccardi, S.; Carlomagno, G.M.; Boffa, N.D.; Monaco, E.; Ricci, F. Nondestructive Evaluation of Carbon Fibre Reinforced Composites with Infrared Thermography and Ultrasonics. Compos. Struct. 2015, 134, 845–853. [Google Scholar] [CrossRef]

- Boychuk, A.S.; Generalov, A.S.; Stepanov, A.V. CFRP Structural Health Monitoring by Ultrasonic Phased Array Technique. In Proceedings of the 7th European Workshop on Structural Health Monitoring, EWSHM 2014—2nd European Conference of the Prognostics and Health Management (PHM) Society, Nantes, France, 8–11 July 2014; pp. 2206–2211. [Google Scholar]

- Ryan, T.W.; EricMann, J.; Chill, Z.M.; Ott, B.T. Bridge Inspector’s Reference Manual. FHWA 2012, BIRM 1, 1020. [Google Scholar]

- Galietti, U.; Luprano, V.; Nenna, S.; Spagnolo, L.; Tundo, A. Non-Destructive Defect Characterization of Concrete Structures Reinforced by Means of FRP. Infrared Phys. Technol. 2007, 49, 218–223. [Google Scholar] [CrossRef]

- Taillade, F.; Quiertant, M.; Benzarti, K.; Aubagnac, C.; Moser, E. Shearography Applied to the Non Destructive Evaluation of Bonded Interfaces between Concrete and CFRP Overlays: From the Laboratory to the Field. Eur. J. Environ. Civ. Eng. 2010, 15, 545–556. [Google Scholar] [CrossRef]

- Yang, L. Recent Developments in Digital Shearography for Nondestructive Testing. Mater. Eval. 2006, 64, 704–709. [Google Scholar]

- Qiu, Q.; Lau, D. A Novel Approach for Near-Surface Defect Detection in FRP-Bonded Concrete Systems Using Laser Reflection and Acoustic-Laser Techniques. Constr. Build. Mater. 2017, 141, 553–564. [Google Scholar] [CrossRef]

- Qiu, Q.; Lau, D. Experimental Evaluation on the Effectiveness of Acoustic-Laser Technique towards the FRP-Bonded Concrete System. Struct. Health Monit. Insp. Adv. Mater. Aerosp. Civ. Infrastruct. 2015, 9437, 943705. [Google Scholar] [CrossRef]

- Büyüköztürk, O.; Haupt, R.; Tuakta, C.; Chen, J. Remote Detection of Debonding in FRP-Strengthened Concrete Structures Using Acoustic-Laser Technique. In Nondestructive Testing of Materials and Structures; Springer: Dordrecht, The Netherlands, 2013; Volume 6, pp. 19–24. [Google Scholar]

- Chen, J.G.; Haupt, R.W.; Büyüköztürk, O. Remote Characterization of Defects in FRP Strengthened Concrete Using the Acoustic-Laser Vibrometry Method. In Proceedings of the ASNT Fall Conference, Las Vegas, NV, USA, 4–7 November 2013. [Google Scholar]

- Zhu, Y.K.; Tian, G.Y.; Lu, R.S.; Zhang, H. A Review of Optical NDT Technologies. Sensors 2011, 11, 7773–7798. [Google Scholar] [CrossRef]

- Chen, J.G.; Buyukozturk, O.; Haupt, R.W. Operational and Defect Parameters Concerning the Acoustic-Laser Vibrometry Method for FRP-Reinforced Concrete. NDT Int. 2015, 71, 43–53. [Google Scholar] [CrossRef]

- Malhotra, V.M.; Carino, N.J. Handbook on Nondestructive Testing of Concrete; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Garney, G. Defects Found through Non-Destructive Testing Methods of Fiber Reinforced Polymeric Composites. Master’s Thesis, California State University, Fullerton, CA, USA, 2006. [Google Scholar]

- Wan, B. Using Fiber-Reinforced Polymer (FRP) Composites in Bridge Construction and Monitoring Their Performance: An Overview; Woodhead Publishing Limited: Sawston, UK, 2014; ISBN 9780857097019. [Google Scholar]

- American Society for Nondestructive Testing. Nondestructive Testing Handbook, 3rd ed.; Moore, D.G., Moore, P.O., Eds.; American Society for Nondestructive Testing: Columbus, OH, USA, 2008; Volume 8, ISBN 9781571171849. [Google Scholar]

- Farrar, C.R.; Worden, K. An Introduction to Structural Health Monitoring. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 303–315. [Google Scholar] [CrossRef]

- Böer, P.; Holliday, L.; Kang, T.H.K. Interaction of Environmental Factors on Fiber-Reinforced Polymer Composites and Their Inspection and Maintenance: A Review. Constr. Build. Mater. 2014, 50, 209–218. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Chin, J.W.; Hunston, D.; Benmokrane, B.; Juska, T.; Morgan, R.; Lesko, J.J.; Sorathia, U.; Reynaud, D. Durability Gap Analysis for Fiber-Reinforced Polymer Composites in Civil Infrastructure. J. Compos. Constr. 2003, 7, 238–247. [Google Scholar] [CrossRef]

- Miracle, D.B.; Donaldson, S.L. ASM Handbook (Volume 21): Composites; ASM International: Novelty, OH, USA, 2001. [Google Scholar]

- Telang, N.; Dumalo, C.; Mehrabi, A.B.; Ciolko, A.T.; Jim, G. Field Inspection of In-Service FRP Bridge Decks; National Academies Press: Washington, DC, USA, 2006. [Google Scholar]

- Kang, T.H.K.; Howell, J.; Kim, S.; Lee, D.J. A State-of-the-Art Review on Debonding Failures of FRP Laminates Externally Adhered to Concrete. Int. J. Concr. Struct. Mater. 2012, 6, 123–134. [Google Scholar] [CrossRef]

- Yumnam, M.; Gupta, H.; Ghosh, D.; Jaganathan, J. Inspection of Concrete Structures Externally Reinforced with FRP Composites Using Active Infrared Thermography: A Review. Constr. Build. Mater. 2021, 310, 125265. [Google Scholar] [CrossRef]

- Barry, K.F.; Silva, M.; Biagini, G.; Santamarina, J.C.; Wall, J.J.; Marcel, Y.; Le, R.; Lindberg, J.T.; Cha, M.; Dai, S.; et al. Void Detection System. US patent 2013/0192375 A1, 1 August 2013. [Google Scholar]

- Karbhar, V.M.; Kaiser, H.; Navada, R.; Ghosh, K.; Lee, L. Methods for Detecting Defects in Composite Rehabilitated Concrete Structures; Federal Highway Administration: Washington, DC, USA, 2005. [Google Scholar]

- Da Fonseca, B.S.; Castela, A.S.; Silva, M.A.G.; Duarte, R.G.; Ferreira, M.G.S.; Montemor, M.F. Influence of GFRP Confinement of Reinforced Concrete Columns on the Corrosion of Reinforcing Steel in a Salt Water Environment. J. Mater. Civ. Eng. 2015, 27, 04014107. [Google Scholar] [CrossRef]

- Masoud, S.; Soudki, K. Evaluation of Corrosion Activity in FRP Repaired RC Beams. Cem. Concr. Compos. 2006, 28, 969–977. [Google Scholar] [CrossRef]

- Mehrabi, A.; Farhangdoust, S. NDT Methods Applicable to Health Monitoring of ABC Closure Joints; Accelerated Bridge Construction University Transportation Center: Miami, FL, USA, 2019. [Google Scholar]

- Khedmatgozar Dolati, S.S.; Malla, P.; Ortiz, J.D.; Mehrabi, A.; Nanni, A. Identifying NDT Methods for Damage Detection in Concrete Elements Reinforced or Strengthened with FRP. Eng. Struct. 2023, 287, 116155. [Google Scholar] [CrossRef]

- Sen, R. Developments in the Durability of FRP-Concrete Bond. Constr. Build. Mater. 2015, 78, 112–125. [Google Scholar] [CrossRef]

- ASTM Committee C09 C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

| Defects | Description |

|---|---|

| F.1 Surface Defects—Blisters | Blisters are observed as bubble-like formations on the surfaces of the EB-FRP system because of the combined action of freeze–thaw cycles and entrapped moisture. However, since their effects are primarily limited to the surface, this imperfection have minimal impact on the structural performance of the structure. |

| F.2 Surface Defects—Wrinkling | Wrinkling appears as creases or folds on the surface of the FRP composites, often occurring at corners and curves of the structure. It is caused by improper installation practices. The safety of the structure is compromised only if they result in insufficient surface contact of the FRP composites with the substrate. |

| F.3 Surface Defects—Scratches | Scratches represent marks or wounds on the surface of the FRPs and can occur at any point during the installation and service life of the structure. They become detrimental when they evolve into full-depth cracks. |

| F.4 Surface Defects—Discoloration | Discoloration manifests as stains on the FRP composites and is primarily induced by exposure to UV rays, heat, chemicals, fire, excessive strain, subsurface defects, voids, and moisture penetration. These stains serve as indicators of composite degradation, frequently preceding the occurrence of cracks and embrittlement. |

| F.5 Surface Defects—Fiber Exposure | Improper handling and installation of FRP composites results in exposed fibers of FRP composites. These exposed fibers serve as entry points for moisture and contamination into the composite, leading to the deterioration of its properties. |

| F.6 Voids in FRP | Voids are cavities that exist at the fiber–matrix interface, formed as a result of entrapped air within the layers of the composites. They can also occur due to the overlapping of fabrics during fabrication or installation. They cand lead to a reduction in their laminar shear strength. |

| F.7 Debonding | Debonding within FRP composites refers to the separation at the interface between the two components of the composite: the fiber and the matrix. This separation is primarily triggered by the presence of surface moisture on the fibers. The consequences of debonding encompass a loss of composite action. |

| F.8 Delamination in FRP Layers | Delamination in FRP involves the separation at the interface between the layers. It is frequently induced by factors such as moisture, foreign object contamination, and trapped air between the FRP layers. The repercussions are significant and can result in a substantial reduction in the material’s shear transfer capacity. |

| F.9 Cracks | Cracks in FRP composites primarily occur parallel to fiber layers due to factors like trapped air, uneven resin distribution, and exposure to impact and service loads. Failure risk increases as cracks deepen and widen under sustained or dynamic loading. |

| F.10 Impact Damage in FRP | Impact damage can happen from both slow-moving and fast-moving objects. Slow-moving objects may harm the internal structure, while fast-moving ones cause severe surface damage. Regardless, impact damage harms the system’s structural integrity. |

| Defects | Description |

|---|---|

| I-FA.1 FRP–Adhesive Debonding | FRP–adhesive debonding between laminates can occur due to factors such as the use of an inappropriate adhesive, improper mixing, poor adhesive application, or insufficient curing of the adhesive. These factors can lead to a weakened bond between the FRP layers, reducing the effectiveness of the composite material. |

| A.1 Voids in Adhesive | Voids are areas where FRP composites lack contact with the concrete substrate. They result from trapped air, contaminants in the resin, or substrate irregularities, and can sometimes resemble “bubbles.” Voids create stress concentrations, weakening the bond strength of the FRP application. |

| I-AC.1 Adhesive–Concrete Debonding | Debonding is the separation of externally applied FRP from the concrete substrate, often due to factors like high loads, improper installation, inadequate resin curing, or surface moisture. Excessive debonding can lead to brittle concrete fracture, as the composite loses its ability to transfer stresses to the substrate. |

| Defects | Description |

|---|---|

| C.1 Cracks in Concrete | Obscured cracks in the concrete substrate, hidden beneath the externally applied FRP, result from various factors such as shrinkage, thermal stresses, chemical exposure, and more. They can lead to structural failure by allowing corrosive chemicals to attack steel reinforcement and weaken the bond between FRP and concrete. |

| C.2 Voids in Concrete | Concrete voids, unrelated to external FRP application, stem from inadequate design and construction practices during casting. Causes include improper vibration, concrete quality issues, rebar congestion, consolidation problems, and irregular aggregates. These voids lead to gradual structural deterioration. |

| C.3 Delamination/Spalling in Concrete | Delamination is caused by the relatively weaker nature of concrete compared to the adhesive and FRP materials. It occurs when high stresses in the FRP material pull the concrete apart, typically near cracks or the ends of the FRP system where stress buildup is significant. Delamination failures are sudden and brittle, posing a serious structural risk. |

| I-CS.1 Cover Separation | Cover separation differs from delamination and occurs deeper within the concrete, extending to the cover distance of internal reinforcement. This separation happens as cracks near the internal reinforcement propagate horizontally due to high stresses from external FRP. Like delamination, it is a sudden, brittle failure. |

| I-CS.2 Corrosion in Steel Reinforcement | External FRP strengthening is typically applied to steel-reinforced concrete elements. Although it can reduce the corrosion rate of steel reinforcement, it does not completely stop it. As a result, corrosion continues over time, and it is essential to monitor corrosion activity in concrete elements even after applying strengthening measures. |

| I-CS.3 Concrete Reinforcement Debonding | Due to environmental and load factors, the bond may gradually weaken over time, resulting in bond failure of the steel-reinforced concrete element. Debonding might compromise the structure integrity and tensile resistance, making it susceptible to more damage. |

| Fabrication and Workmanship | Design Factors | Environmental Factors | Mechanical Factors |

|---|---|---|---|

|

|

|

|

| NDT Method | i. Surface Anomalies * | ii. FRP Composite | iii. Bond Defects | iv. Cracks in Concrete | v. Voids in Concrete | vi. Concrete Delamination | vii. Rebar Defects |

|---|---|---|---|---|---|---|---|

| Tap testing (TT) | - | 12% | 6% | 0% | 0% | 0% | 0% |

| Impact echo testing (IE) | - | 5% | 5% | 15% | 20% | 20% | 10% |

| Ground-penetrating radar (GPR) and microwave testing (MW) | - | 7% | 17% | 12% | 30% | 42% | 70% |

| Ultrasonic testing (UT) and phased array ultrasonic testing (PAU) | - | 27% | 16% | 37% | 15% | 9% | 10% |

| Infrared thermography testing (IR) | - | 26% | 38% | 8% | 9% | 5% | 0% |

| Acoustic emission testing (AE) | - | 4% | 5% | 0% | 0% | 0% | 0% |

| Laser testing method (LT) | - | 7% | 11% | 0% | 0% | 0% | 0% |

| Radiography testing (RT) | - | 12% | 2% | 5% | 9% | 1% | 0% |

| Impulse response testing (IRT) | - | 0% | 0% | 20% | 17% | 23% | 5% |

| Magnetic flux leakage (MFL) | - | 0% | 0% | 3% | 0% | 0% | 5% |

| * Visual inspection (VT) can be used for qualitative and quantitative detection of almost all surface anomalies. | |||||||

| Slab | Parameters 1 | Selected NDTs | |||||

|---|---|---|---|---|---|---|---|

| GPR | PAU | VT | TT | IR | |||

| M’ | Internal Targets | ND | D 2 | - | - | - | |

| External defects/damage | Debonding or Delamination | ND | LD 3 | LD 1 | D | D | |

| Q’ | Internal Targets | ND | D 2 | - | - | - | |

| External defects/damage | Debonding or Delamination | ND | LD 3 | LD 1 | D | D | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortiz, J.D.; Dolati, S.S.K.; Malla, P.; Mehrabi, A.; Nanni, A. Nondestructive Testing (NDT) for Damage Detection in Concrete Elements with Externally Bonded Fiber-Reinforced Polymer. Buildings 2024, 14, 246. https://doi.org/10.3390/buildings14010246

Ortiz JD, Dolati SSK, Malla P, Mehrabi A, Nanni A. Nondestructive Testing (NDT) for Damage Detection in Concrete Elements with Externally Bonded Fiber-Reinforced Polymer. Buildings. 2024; 14(1):246. https://doi.org/10.3390/buildings14010246

Chicago/Turabian StyleOrtiz, Jesús D., Seyed Saman Khedmatgozar Dolati, Pranit Malla, Armin Mehrabi, and Antonio Nanni. 2024. "Nondestructive Testing (NDT) for Damage Detection in Concrete Elements with Externally Bonded Fiber-Reinforced Polymer" Buildings 14, no. 1: 246. https://doi.org/10.3390/buildings14010246

APA StyleOrtiz, J. D., Dolati, S. S. K., Malla, P., Mehrabi, A., & Nanni, A. (2024). Nondestructive Testing (NDT) for Damage Detection in Concrete Elements with Externally Bonded Fiber-Reinforced Polymer. Buildings, 14(1), 246. https://doi.org/10.3390/buildings14010246