1. Introduction

The three predominant sectors contributing to society’s overall energy consumption are industrial energy, transportation energy, and building energy [

1]. As economic and societal progress marches forward, the expansion of built environments becomes more prominent, leading to a steady rise in the share of energy attributed to buildings [

2]. Of this, the energy required for heating, ventilation, and air conditioning (HVAC) commonly stands out as the most significant component, often constituting between 40% and 50% of a building’s total energy footprint [

3].

Given the magnitude of HVAC energy utilization, it is paramount to prioritize strategies that enhance building energy efficiency, specifically focusing on HVAC systems [

4]. In the area of curbing HVAC energy consumption, there are typically two primary strategies. The first entails enhancing the efficiency of HVAC systems, making them more proficient in delivering the desired output with reduced energy consumption. The second strategy is centered on reducing the energy demands imposed on these systems by optimizing building design and utilizing appropriate materials [

5,

6].

One crucial aspect that significantly dictates a building’s heating and cooling needs is the thermal performance of its envelope, which includes elements like windows, walls, floors, and notably, roofs [

7]. The heating and cooling requirements of buildings are significantly impacted by solar radiation. Roofs, in particular, are exposed to prolonged periods of sunlight, resulting in the absorption of a substantial amount of heat, which subsequently affects the indoor temperature of buildings [

8].

Recognizing the pivotal role that roofs play, numerous innovative techniques are being integrated into building design. These techniques aim to mitigate the amount of heat that roofs retain and include strategies such as enhanced insulation, improved ventilation cooling, innovative water storage cooling, planting vegetation, and applying high-reflectance coatings [

9,

10,

11,

12,

13]. Each of these methods offers its unique advantages, paving the way for more energy-efficient buildings in the future.

The pioneering concept of cool roofs was first unveiled by Parker [

14]. In contrast to conventional reflective roofs, the uniqueness of cool roofs lies in their dual-pronged approach. These roofs not only aim to reduce the absorption of solar radiation by enhancing solar reflectance but also endeavor to increase the emissivity of roofing materials for long-wave atmospheric radiation. This dual strategy primarily focuses on minimizing absorption while maximizing emission, ultimately resulting in a significant reduction in the roof’s surface temperature. Consequently, it diminishes the direct heat transfer from the roof into the indoor spaces of the building.

Through meticulous testing carried out on nine representative buildings located in Florida, USA, Parker was able to substantiate the effectiveness of employing cool roofing materials. The findings revealed a notable energy-saving trend, registering an impressive 19% reduction in energy consumption for residential buildings, and an even higher reduction of 25% for commercial structures.

The success showcased in Parker’s investigation underscores the substantial energy-saving potential inherent in the adoption of cool roof technologies. By tackling both solar absorption and material emissivity, cool roofs present a robust solution to one of the primary challenges in building energy efficiency. Furthermore, the empirical evidence obtained from real-world application in both residential and commercial settings in Florida provides a compelling case for the broader adoption of cool roof methodologies. Through continued exploration and implementation of such innovative roofing solutions, it is conceivable that significant strides can be made toward achieving enhanced energy efficiency in buildings, which is a critical step in navigating the broader challenges of societal energy consumption [

15].

Levinson et al. [

16,

17] conducted a robust and thorough exploration of cool roofs. This exploration was multidimensional, combining both theoretical analyses with hands-on empirical studies. Central to this examination was an in-depth evaluation of a plethora of materials and colors typically used in crafting cool roofs.

Levinson focused on their respective capabilities in terms of absorbing solar radiation and their radiation properties across the solar spectrum. This meticulous scrutiny gave rise to a comprehensive database that detailed the distinct material properties that define cool roofs.

To transition from the theoretical to the practical, Levinson’s research leveraged a broad array of engineering field tests to provide empirical substantiation. A salient revelation from these tests was the definitive energy-saving potential of cool roofs, particularly in the context of air conditioning. In the warm Californian summer months, buildings fitted with cool roofs were shown to achieve energy savings in air-conditioning cooling energy consumption, with savings rates ranging impressively from 7% to 21.5%.

Beyond the direct energy implications, Levinson’s study also delved into the broader environmental benefits of cool roofs. A noteworthy contribution was the assessment of cool roofs’ role in counteracting the urban heat island effect—a phenomenon where urban regions experience heightened temperatures due to human activities. Levinson’s findings highlighted the potency of cool roofs in substantially alleviating this effect.

Guo et al. [

18] conducted a comprehensive study that involved both experimental work during the summer and transition seasons and annual simulations. Their aim was to assess the thermal performance, energy savings, and enhancement of thermal comfort achieved by integrating a cool roof with night ventilation. Their research conclusively demonstrated that roof albedo is the most influential parameter affecting both building energy performance and indoor thermal comfort. Furthermore, they identified an optimal reduction of 28% in cooling energy consumption.

Rawat and Singh [

19] provided a comprehensive summary of cool roof thermal performance involving various surface coatings in distinct climate zones. Their work not only presents the advantages of cool roofs but also acknowledges their limitations while offering valuable recommendations for future research in this area. As per Rawat and Singh’s findings, the potential energy-saving impact of cool roofs ranges from 15% to 35.7% across diverse climate zones. Moreover, their research suggests that implementing cool roof technology can lead to an average reduction in roof surface temperatures ranging from 1.4 °C to as much as 4.7 °C.

In the contemporary academic landscape, there has been a marked surge in interest toward the study of radiative cooling mechanisms [

20,

21,

22]. This area of study seeks to harness the vast and unobstructed expanse of the sky as a reservoir for heat dissipation. Scholars from around the world, as well as those conducting region-specific research, have plunged into rigorous theoretical and empirical analyses. Their studies are aimed at gaining a deeper understanding of the foundational concepts, functional approaches, and intricate material engineering details inherent to radiative cooling.

In terms of the preparation of cool roofing materials, TiO

2 has conventionally served as the primary component for reflective “white” pigments or coatings due to its effective light-scattering characteristics [

23]. Consequently, TiO

2 was most commonly employed in the early stages for fabricating heat-reflective materials. However, recent studies in the literature have emphasized the exploration and advancement of alternative near-infrared (NIR) pigments to titanium dioxide, such as zinc oxide [

24], bismuth vanadate [

25], and inorganic salts [

26]. Rosati performed a comprehensive review of the state of the art of synthesis methods for pigments employed for cool roofs. However, the impact of reflectance and emittance on roof energy efficiency is intricate and conflicting between the cooling and heating seasons. The overall effect across the entire year is contingent on local climate factors, geographical considerations, the proportion of cooling to heating loads, and the prevailing energy usage patterns.

The impact of cool roofs extends beyond direct effects on building energy consumption, holding significant importance in ameliorating urban climate, particularly the urban heat island (UHI) effect [

27]. Prior research on urban climate models like ENVI-met, PALM, SOLWEIG, PALM-4U, RayMan, and TEB has underscored the significance of thermal performance parameters—such as absorptance, reflectance, emissivity, and heat capacity of urban structural elements, including rooftops—in influencing urban climate [

28]. Roof areas comprise over 25% of the urban surface and directly receive intense solar radiation, making their performance pivotal in the context of the urban heat island effect. Santamouris’ comprehensive research on the UHI effect, spanning its causes, energy and environmental impacts, modeling, and mitigation measures, particularly emphasizes rooftop performance, thereby providing a robust theoretical foundation for UHI studies [

29]. Zhao proposed a coupling effect of cool roofs under the UHI effect on building energy consumption, establishing a triple-model for assessing energy-saving effects. This study confirmed the significant role of cool roofs in enhancing urban climate conditions under UHI effects [

30]. The combined findings from these studies corroborate the direct and indirect effects of diverse cool roof parameters on building energy usage, underscoring reflectance and emissivity as the paramount factors in this regard [

31].

The aforementioned research has largely investigated the inherent characteristics of roofing materials and their energy-saving properties during cooling. However, there is a lack of research concerning the distinct performance of materials during both cooling and heating processes, particularly within the specific climatic regions of China. The specific details of material behavior in the unique climate zones of China have not yet been extensively studied.

Together, these dual axes of research—coating reflectivity and infrared emission—represent the cutting edge in the field of radiative cooling. The advancements in this domain not only hold promise for enhancing building efficiency but also offer potential solutions for a range of heat management challenges in various sectors.

A review of the existing literature highlights a predominant focus in domestic research on cool roofs in two key areas. Firstly, researchers have focused on roofing materials, with a particular emphasis on thermal reflective materials. Secondly, there has been a substantial body of work analyzing the impact of specific cool roof applications on building energy consumption, primarily through simulations or experimental methods. However, there exists a significant research gap concerning the intrinsic thermal characteristics of cool roofs, especially with regard to a detailed investigation of the individual parameters’ influence on building energy consumption.

This study aims to address this research gap by deconstructing a heat transfer model of cool roofs and conducting an exhaustive analysis of the diverse factors that influence their performance. To facilitate this exploration, we delved into the operational mechanisms of cool roofing materials. In this context, we prepared five distinct types of high-reflectance roof coatings based on their underlying principles. These coatings were subjected to rigorous testing, including a measurement of their near-infrared thermal reflectance.

Furthermore, to ascertain their real-world energy-saving potential, a comprehensive comparative analysis against conventional colored coatings was conducted. Subsequently, the energy-saving rates achieved following the application of these high-reflectance coatings to roofing surfaces were simulated and quantified in different climate zones in China. In conclusion, this study undertook a meticulous comparative analysis, juxtaposing its findings with the existing literature. This comparative assessment was detailed, focusing on two pivotal aspects: rooftop surface temperature and the effectiveness of energy-saving measures. Additionally, a thorough and insightful elucidation was presented to expound upon the underlying reasons for any divergences noted between the outcomes of this research and the insights documented in the literature. This in-depth investigation not only broadens current understanding of cool roof performance but also offers practical insights into the implementation of these materials in building energy efficiency strategies.

2. Methodology

The critical thermal parameters impacting the indoor cooling load of buildings during the summer include solar reflectance, thermal emittance, heat transfer coefficient, and heat storage coefficient. To assess the relative influence of each parameter on building energy consumption, we employed an orthogonal design approach. The findings indicate that, across the majority of climate regions in China, solar reflectance exerts the most significant impact on building energy consumption. Therefore, enhancing rooftop reflectance emerges as a pivotal strategy for achieving energy efficiency.

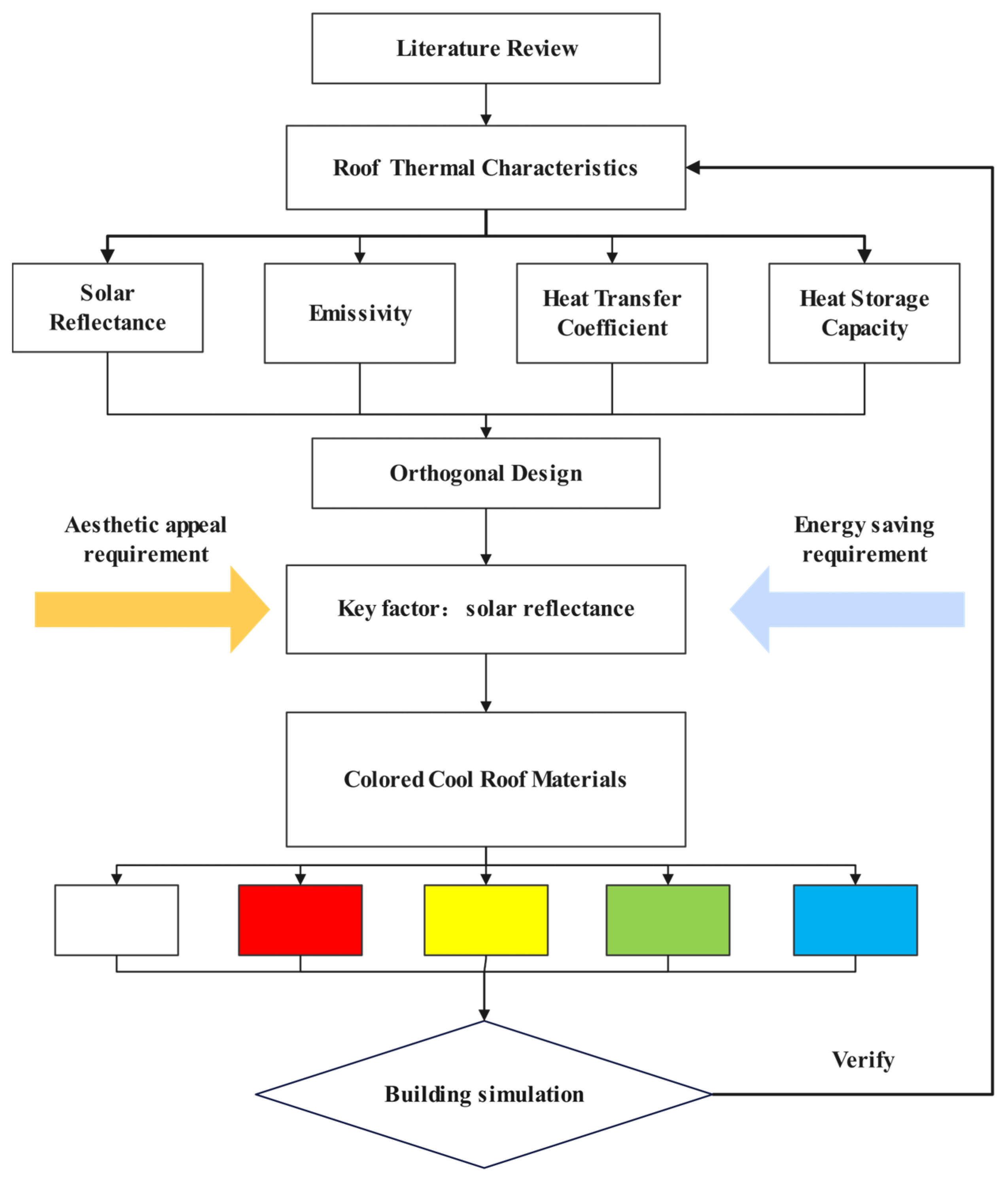

In an effort to balance esthetic appeal with energy efficiency requirements, our study introduced a novel, colored cool roofing material developed based on the gradient refractive index theory. We measured its near-infrared reflectance and assessed its energy-saving performance on typical meteorological days using an energy simulation software, as illustrated in

Figure 1. This innovative approach aims to contribute to both visually appealing building designs and energy-efficient building practices.

2.1. Orthogonal Design

During the architectural design phase, it is imperative to tailor the building envelope designs to accommodate the distinct load characteristics present in various climate zones. This approach ensures a harmonious balance between energy efficiency and cost-effectiveness. The roof, being a pivotal component of the building enclosure, plays a particularly critical role in the overall energy-efficient design of low-rise buildings. To align with China’s climatic zoning criteria for building thermal design, this study chose Harbin, Beijing, Nanjing, Guangzhou, and Kunming as representative cities, each representing a specific climate zone, for detailed design analysis.

To analyze the impact of reflectance, emissivity, thermal conductivity, and heat storage coefficient on a building’s annual energy consumption, simulations of the building’s yearly heating and cooling energy consumption were conducted using EnergyPlus. The annual average energy consumption per unit area serves as the evaluation criterion. An orthogonal design experiment was employed to analyze the weight of each influencing parameter.

The China Academy of Building Research’s generic building energy consumption simulation model was chosen for this study [

32]. The building, measuring 50 m × 30 m, serves as a two-story office, as shown in

Figure 2. Parameters like air conditioning system type, set temperatures for cooling and heating, operational strategy, personnel distribution, building lighting indicators, air tightness, efficiency in heating and cooling, and roof thermal settings were all based on the stipulations in GB50189-2015 [

33]. Some indicators are detailed in

Table 1. For the walls, floor, and roof, a 50-mm-thick XPS insulation board structure was used, consisting of the following layers from the innermost to the outermost layers: the inner protective coating, the XPS insulation layer (thermal conductivity of 0.028 W/m·K), the fiberglass reinforcement layer, and the outer protective layer. The window-to-wall ratio was set to be 0.3.

If a particular result has multiple influencing parameters, due to practical limitations that prevent conducting numerous experiments to discern the primary and secondary factors, orthogonal design can be employed to analyze the influence weight.

Orthogonal design is an experimental methodology utilized to discern factors impacting experimental outcomes and their interactions. By systematically altering and combining various factor levels, it minimizes noise and errors, thereby facilitating a clearer understanding and analysis of the results. Within orthogonal design, factors are distributed across different experimental combinations, ensuring each factor level interacts evenly and equitably with every other factor level. This process effectively identifies the primary influencing factors while reducing the number of experiments required. Through orthogonal design, researchers can efficiently pinpoint key factors influencing the outcomes and comprehend their interactions, minimizing the need for extensive experimentation. This approach has found widespread application in engineering, scientific research, and experimentation, enabling the optimization of product design, process improvements, and efficiency enhancements.

A typical layout of roof construction can be seen in

Figure 3. Taking the roof’s solar emissivity, thermal emissivity, thermal conductivity, and heat storage capability as the four variables, we adopted the L9(34)-type orthogonal table (

Table 2) to conduct a comprehensive comparative analysis of the aforementioned influencing factors. This helps identify the primary and secondary relationships of these major factors on building air-conditioning energy consumption. Specific values are shown in the table. Here, the roof’s overall thermal conductivity coefficient K is chosen to express the thermal conductivity capability, and the specific heat of the roofing material is selected to represent the heat storage capability. The heat transfer coefficient of the roof represents the insulation capacity of the walls, indicating the rate of heat transfer from the temperature difference between the interior and exterior surfaces. In the simulation process, the thermal conductivity was altered by varying the thickness of the XPS material layer.

Regarding the heat storage capacity, the heat storage capacity index (

) is utilized as the metric. Its definition and calculation are presented in the following equation:

where

represents the

-th layer of the roof,

is the density of the material layer in kg/m

3,

is the volume of the material layer in m

3,

is the specific heat capacity of the material layer in J/(kg·K),

is the thickness of the layer in m,

is the roof area in m

2, and

is the heat storage capacity index in J/(m

2·K).

In this simulation, roof thicknesses of 0.06 m, 0.08 m, and 0.1 m were chosen, and their respective values were calculated.

In accordance with a 4-factor, 3-level orthogonal design table, the parameters of solar reflectivity, thermal emissivity, thermal conductivity coefficient, and specific heat were systematically assigned to their respective levels, thereby generating a total of 9 unique test scenarios, as shown in

Table 3. These scenarios were subsequently employed in EnergyPlus, a comprehensive building energy simulation software, to yield annual energy consumption data. This dataset encompassed various components, including energy utilization for the air-conditioning and heating systems, indoor lighting, electrical equipment, and the ventilation system.

An investigation was carried out across five principal thermal zones for building engineering analysis. The temperate zone, characterized by its absence of air-conditioning load, was excluded from this study. Instead, simulations were conducted for Harbin, Beijing, Nanjing, and Guangzhou to assess the influence of various thermal parameters on cool roof performance under different climatic conditions and load scenarios.

Of particular significance was the inclusion of the hot-summer-and-cold-winter zone as a representative climate region. This zone experiences sweltering summers with elevated temperatures and humidity levels, as well as frigid winters marked by low temperatures and increased humidity. Both seasons necessitate significant energy consumption for air conditioning and heating, thus resulting in a noteworthy annual energy demand. Consequently, the orthogonal design also employed the hot-summer-and-cold-winter zone as a key focal point for the computational analysis.

2.2. Material Preparation

Based on existing research findings, a water-based epoxy resin with good wear resistance, high hardness, strong adhesion, and stable performance was chosen as the film-forming base for the coating. Among known coating fillers, the rutile form of TiO

2 has one of the highest refractive indices, making it effective at increasing a coating’s reflectance. It also enhances the physical and chemical properties of coatings, improves their strength, and extends their lifespan, and its pure white color makes it an ideal choice as a base color filler that can be blended with other fillers without affecting their color. Therefore, it is the best choice for high-reflectance coating fillers. In addition to white fillers, other colored fillers include high-temperature-resistant inorganic pigments, as listed in

Table 4.

Taking into account the atmospheric window characteristics for electromagnetic radiation absorption by the sky, particularly in the wavelength range of 8–13 μm where emitted electromagnetic waves from objects can escape into space, radiative cooling of the material surface can be achieved by reducing absorption or reflection by the atmosphere. In this context, hollow SiO2 glass beads with a diameter of 5 μm, which are relatively easy to obtain, were chosen as the radiative cooling medium. During the film-forming mixture phase, these beads were added to the coating base liquid and thoroughly mixed. Through the inherent interactions between the medium and the coating base liquid, a stable and uniform coating was formed. Additionally, the presence of hollow glass beads helps improve the coating’s insulating properties, thereby reducing the transfer of heat through thermal conduction from the roof into the interior of the building.

The preparation of the coating involved two main steps [

34]: pigment preparation and pigment dispersion in the base liquid. In this experiment, a grinding and mixing method was employed to obtain the required pigments with specific colors. The grinding and mixing process utilized vibrational stirring equipment to modify the crystal structure on the particle surfaces, thus reducing reaction activation energy, increasing surface activity, and facilitating the adhesion of particles to form well-bound mixtures through intermolecular forces and electrostatic attraction.

To achieve the desired colors, the process involved mixing an appropriate quantity of pigments with titanium dioxide and subjecting the mixture to thorough grinding and fine pulverization using a planetary ball mill. Following this step, water, a film-forming material, and a dispersant were added and homogenously blended using a stirring machine. Subsequently, hollow glass beads, a curing agent, talcum powder (primarily added to enhance the coating’s mechanical properties, including wear resistance, heat resistance, durability, as well as impact and compression strength), and water were introduced into the mixture. A stirring machine was then employed to ensure the thorough mixing of all constituents. This was followed by a period of static rest, during which the desired cool roof coating in the corresponding color was obtained.

Pigment ratio: In this experiment, a 1:1 ratio of pigments was chosen, meaning that the mass of titanium dioxide (TiO2) was equal to the mass of the corresponding color pigment. In this specific experiment, both TiO2 and the corresponding color pigment were taken in quantities of 50 g each.

Base liquid ratio: For this experiment, the mass ratio of base liquid, water, pigments, and hollow glass beads was set at 2:1.5:1:0.5. This means that for every 100 g of pigment mixture, 200 milliliters of water-based epoxy resin, 150 milliliters of water, and 50 g of hollow glass beads were added. It is important to note that water should be added in two separate portions: 100 milliliters at first, and then 50 milliliters. The hollow glass beads were mixed in during the second addition of water.

Additive ratio: Since this was an experimental test, talcum powder was not used. Instead, 2 g of the curing agent and 2 g of the dispersant were added to the mixture.

3. Results and Discussion

3.1. Orthogonal Design Results

For the simulated results calculated based on the orthogonal design table, the range analysis method was used to determine the influence magnitude of each parameter.

Orthogonal design commonly employs range analysis to assess the extent to which variations in different factor levels impact the experimental outcomes. The method of calculating ranges can vary based on the design type and specific context, but generally follows these steps [

35]:

- (1)

Determining factor levels: Identify the levels for each factor. For instance, if factors A, B, and C are involved, each factor might have two or more levels (e.g., low and high levels).

- (2)

Conducting experiments and recording results: Conduct experiments using the orthogonal design, following the design matrix, and record the results or response values for each experimental condition.

- (3)

Calculating the mean for each factor level: Compute the average of all relevant experimental results for each level of every factor ().

- (4)

Computing range for each factor level: For each level of every factor, calculate the difference between the maximum and minimum values of all relevant experimental results and define the range for that level.

- (5)

Analyzing range values: Compare the ranges across different factors and levels to determine which factors or levels have a greater impact on the experimental outcomes.

Range analysis in orthogonal design facilitates the identification of factors or levels that significantly influence the experimental results, aiding in the prioritization of influencing factors for further investigation.

When the range value of a certain factor is larger, it indicates that this factor has the most significant impact on the test results and takes a more dominant role in influencing the test index. The relationship between the mean value

of a factor and its range R can be represented as follows:

In the formula , , and represent the average building energy consumption values corresponding to each level of the following factors: solar emissivity, thermal radiation rate, heat transfer capacity, and heat storage capacity. The magnitude of the value indicates the level of influence of a factor on building energy consumption.

Taking the hot-summer-and-cold-winter region as an example, the orthogonal design table and the results from the range analysis are shown in

Table 5 (cooling energy) and

Table 6 (annual total energy).

It can be observed that, concerning cooling energy consumption, solar reflectance has the most significant impact, followed by thermal emittance. The influence of the heat transfer coefficient is minimal, primarily because during the summer cooling season, the primary source of heat inside the building is the direct absorption of solar radiation by the roof. Hence, the impacts of solar reflectance and thermal emittance are the most significant. During this time period, the temperature difference between the indoor and outdoor environments is not substantial (usually within 10 °C), resulting in minimal heat transfer due to temperature difference and, consequently, a minimal effect of the heat transfer coefficient.

A comparison of the results shown in

Table 5 and

Table 6 highlights a noteworthy shift in annual energy consumption, specifically a diminished influence of reflectance and a heightened impact of the heat transfer coefficient, unlike the trends observed in cooling energy consumption. This divergence is primarily attributed to the contrasting effects of reflectance during the summer cooling and winter heating seasons. In the summer, elevated reflectance effectively hinders heat from penetrating the interior, resulting in reduced indoor cooling loads and lower air-conditioning energy consumption. Conversely, during the winter, high reflectance diminishes the positive impact of solar radiation as a heat source, thus obstructing interior heating and leading to increased indoor heating loads, consequently raising the air-conditioning energy consumption. As a result, the pronounced influence of reflectance on energy consumption in the summer is partially counterbalanced in the winter, contributing to a reduced significance of reflectance in the overall impact. On the other hand, the heat transfer coefficient, especially notable in winter, exhibits a heightened impact due to substantial temperature differences, often exceeding 20 °C and reaching up to 30 °C between the indoor and outdoor environments. This significant temperature difference amplifies the heat transfer between the interior and exterior surfaces of the roof, thereby strengthening the impact of the roof’s heat transfer coefficient. From an annual perspective, emphasizing the role of thermal reflectance in energy saving becomes crucial in the design of buildings, considering both energy conservation and economic efficiency.

Using the orthogonal design method described above, an energy consumption analysis was performed for four of the five major climate zones in China, excluding the temperate zone. The primary and secondary relationships between the effects of solar reflectance (A), long-wave radiation rate (B), heat transfer capacity (C), and heat storage capacity (D) on building energy consumption are displayed in

Figure 4a–d. The magnitude of the range value for each factor represents its impact on building energy consumption.

From an analysis of

Figure 4, it is evident that apart from the extremely cold zone, solar reflectance demonstrates the highest variance in the other three climate zones. This suggests that within cold regions, regions with hot summers and cold winters, and regions with hot summers and warm winters, solar reflectance has the most significant influence on building energy consumption among the four thermal parameters of cool roofs. This is followed by the heat radiation rate, while the heat conductivity coefficient and heat storage capacity exert the least impact on energy consumption.

For extremely cold regions, the heat transfer coefficient shows the most significant variance, indicating its predominant influence on building energy consumption in these areas, and relegating solar reflectance to the second place. This observation can be primarily attributed to two reasons:

- (1)

In extremely cold regions, where lower temperatures prevail, a building’s heating load significantly outweighs the cooling load in its annual energy consumption. While high solar reflectance offers advantages during the summer months by reducing the roof’s surface temperature and minimizing indoor heat gain through the reflectance of solar radiation, it poses challenges during the winter heating periods. Solar reflectance inhibits the building’s ability to absorb heat from solar radiation at these times. In these regions, which are characterized by substantial heating demands, the adverse impact of solar reflectance is amplified, thereby diminishing its overall annual effectiveness.

- (2)

In extremely cold regions, particularly during the winter heating season when there is a substantial temperature difference between the indoor and outdoor environments, heat dissipation from the building interior to the exterior through the roof becomes more pronounced. This heat transfer is primarily driven by roof conduction, emphasizing the crucial role of the heat transfer coefficient in influencing annual energy consumption.

On a nationwide scale, as latitude increases, the influence of solar reflectance and heat radiation rate gradually diminishes, while the impact of the heat transfer capability steadily intensifies. This trend is primarily due to the variations in environmental temperatures and the proportional shift in winter/summer heating and cooling loads as latitude rises. The influence of specific heat capacity (i.e., heat storage capability) on the annual building energy consumption remains relatively stable. This is because conventional roofing materials typically have a lower specific heat, and their capacity to store or absorb heat/cold is comparatively minimal against the overall heating and cooling loads, making their effect less pronounced. However, this dynamic might significantly shift if phase-change materials are integrated into roofing systems, potentially enhancing their thermal performance.

3.2. Material Indicator Testing

We methodically applied the coatings, each differing in color, onto white panels to ensure uniform coverage. These coatings were allowed to completely dry before progressing to the subsequent phase, which involved the rigorous process of reflectance testing. During this stage, the solar reflectance (SR) values were meticulously measured using a highly specialized spectrophotometer, specifically the Japanese Shimadzu UV3600 model. The use of this sophisticated instrumentation, illustrated in

Figure 5, ensured the precision and accuracy of our measurements.

The SR values, acquired through rigorous testing and measurement, serve as crucial indicators of the materials’ solar reflectance capabilities. The results obtained from this comprehensive procedure are presented graphically in

Figure 6, offering a clear visual representation of how different coating materials, with their distinct color variations, perform in terms of solar reflectance. Emittance measurements for the coatings were also conducted. However, the results reveal that the emittance values for the coatings of different colors are quite consistent, hovering around 0.85.

For pure white pigment, i.e., 100% titanium dioxide + 5 μm hollow SiO2 glass beads + water-based epoxy resin coating, the calculated reflectance is 0.85. For yellow pigment, i.e., 50% titanium dioxide + 50% Nickel Titanium Yellow + 5 μm hollow SiO2 glass beads + water-based epoxy resin coating, the calculated reflectance is 0.75. For red pigment, i.e., 50% titanium dioxide + 50% Silicon Iron Red + 5 μm hollow SiO2 glass beads + water-based epoxy resin coating, the calculated reflectance is 0.68. For blue pigment, i.e., 50% titanium dioxide + 50% Cobalt Blue + 5 μm hollow SiO2 glass beads + water-based epoxy resin coating, the calculated reflectance is 0.62. For green pigment, i.e., 50% titanium dioxide + 50% Cobalt Green + 5 μm hollow SiO2 glass beads + water-based epoxy resin coating, the calculated reflectance is 0.56.

The results are summarized below and compared with the conventional pigments in

Table 7.

3.3. Energy Saving Analysis

For the energy saving analysis of the colored high-reflectance coatings that were prepared as mentioned earlier and to study their energy-saving characteristics compared to conventional pigments, this study employed EnergyPlus to compare the roof surface temperatures and energy consumption between cool roofs (CRs), conventional paint roofs (CPRs), and standard asphalt roofs (SARs) in a typical summer for a two-story office building, measuring 50 m × 30 m, located in a region with hot summers and cold winters.

Based on the GB50189-2015 various parameters were set for the building’s thermal performance based on the enclosure structure, airtightness, and efficiency of the heating and cooling systems [

33]. This included considerations of the cooling and heating loads, personnel distribution, lighting, and electrical use.

Figure 7 displays the external surface temperatures and hourly heat loads for the yellow-pigmented roofs during the summer. From the graph, it is evident that, compared to conventional yellow pigments, the titanium nickel yellow cool material exhibits an increase of 0.24 in reflectance. Consequently, the maximum external roof surface temperature during the summer decreases by 9.4 °C, resulting in a maximum instantaneous energy savings of 4.1%. Compared to a black roof, this translates to energy savings of 9.5%.

Other colored materials were simulated using the same methodology to derive their roof surface temperatures and energy consumption, as illustrated in

Table 8.

The results depicted in

Table 8 indicate temperature reductions ranging from 9.4 °C to 13.9 °C on the roof surface for materials of different colors under typical meteorological conditions. Additionally, they showcase total energy savings ranging between 3.9% and 5.5%.

3.4. Discussion

The outcomes of energy saving performance, as detailed in

Table 9, illuminate a significant and consistent trend across all cool roof coatings—they consistently manifest higher reflectance values in comparison to their conventional counterparts. This pattern underscores their inherent capacity to efficiently redirect a more substantial portion of incident solar radiation. Consequently, this redirection leads to a noteworthy reduction in heat absorption and, consequently, a substantial decrease in rooftop temperatures. A positive correlation becomes evident, indicating that an escalation in reflectance levels corresponds proportionally to a reduction in roof temperatures. This temperature decline directly translates into immediate and greater energy savings. This observation underscores the pivotal role played by enhanced reflectance in bolstering building energy efficiency. Moreover, this correlation emphasizes the potential for substantial real-world benefits associated with the adoption of cool roof coatings. Beyond the immediate energy savings, the diminished rooftop temperatures can contribute to a more comfortable indoor environment, potentially reducing the reliance on air-conditioning systems and further enhancing the overall energy efficiency of buildings.

The results of

Table 9 were compared with findings from other studies. A review on cool roof performance showed that the energy-saving impact of cool roofs varies from 15% to 35.7% across different climatic regions, and the reduction in rooftop surface temperature ranges from 1.4 °C to 4.7 °C [

19]. In terms of energy efficiency, the energy savings achieved in this study are approximately 5%, notably lower than values reported in the literature. A comprehensive analysis reveals two key factors contributing to this difference.

Firstly, previous studies did not consider aspects of building energy consumption such as lighting and equipment use, resulting in a high proportion of solar radiative heat being included in the total cooling load. Cool roofs primarily derive energy savings from the reduction in solar radiative heat. Therefore, the energy-saving effect of cool roofs is particularly pronounced when these heat loads are considered.

Secondly, the simulations conducted in this study employed a double-layer structure. It is important to note that the energy-saving benefits of cool roofs are significantly higher for the second layer compared to the first layer, to the extent that cool roofs may have negligible energy-saving benefits for the first layer. As a result, the more floors a building has, the smaller the proportion of energy savings attributable to cool roofs in the total building cooling load, leading to less pronounced energy efficiency gains. Hence, the application of cool roofs is more impactful in single-story buildings compared to multi-story or multi-level structures.

Considering the reduction in rooftop temperatures, the materials utilized in this study have the capacity to lower rooftop surface temperatures by approximately 10 °C. This performance surpasses the data available in the literature. This outcome can be attributed to the fact that rooftop temperature has a weak correlation with building floors and indoor loads, but it has a direct positive correlation with solar radiation and rooftop materials. As such, the materials developed in this study exhibit more pronounced benefits in terms of reducing rooftop temperatures.

By delving into these factors, this study provides a more comprehensive understanding of the variations in energy-saving outcomes and the specific conditions under which cool roofs can offer substantial energy efficiency improvements.

Considering the varied effects of cool roofs during the summer and winter, simulation was conducted to determine the applicability of different colored materials across diverse climatic regions in China, assessing their year-round energy saving performance. The outcomes of this simulation are presented in

Table 9.

Table 9 reveals that, concerning the annual energy consumption, in cold regions, hot-summer/cold-winter regions, and hot-summer/warm-winter regions, increasing heat reflectance significantly enhances energy savings. As the dimension of a building decreases and the cooling load increases, the energy-saving effect becomes more pronounced. However, for cold regions, due to the higher proportion of heating load, cool roofing materials could paradoxically increase building energy consumption. This phenomenon is influenced by the distinct operational characteristics of cool roofs in the summer and winter, aligning with the results obtained from the orthogonal analysis discussed earlier.

The limitations of this study are mainly demonstrated in the following aspects: (1) as observed from the analysis, the energy-saving effectiveness of cool roofs is more pronounced in low-rise buildings, while in high-rise constructions, the energy-saving efficiency diminishes due to a reduced proportion of heat absorption through the roof; (2) the actual effectiveness of cool roofs varies significantly across different climatic regions, necessitating a consideration of regional factors when deploying cool roofs; and (3) the annual energy consumption in this study is primarily derived from the simulation data. Given the challenge of finding buildings with identical thermal parameters that can sustain consistent loads over extended periods, it is difficult to calibrate these findings through experiments. Future research will focus on verifying the simulated outcomes through methods like small-sample analysis or small-scale models. Additionally, a multidimensional study on energy efficiency and economics will be conducted, comparing cool roofs with other roof types such as green roofs, ventilated roofs, and photovoltaic roofs.