Investigating the Mechanical Deterioration Effect of Hard Sandstone Induced by Layer Structure under Uniaxial Compression

Abstract

:1. Introduction

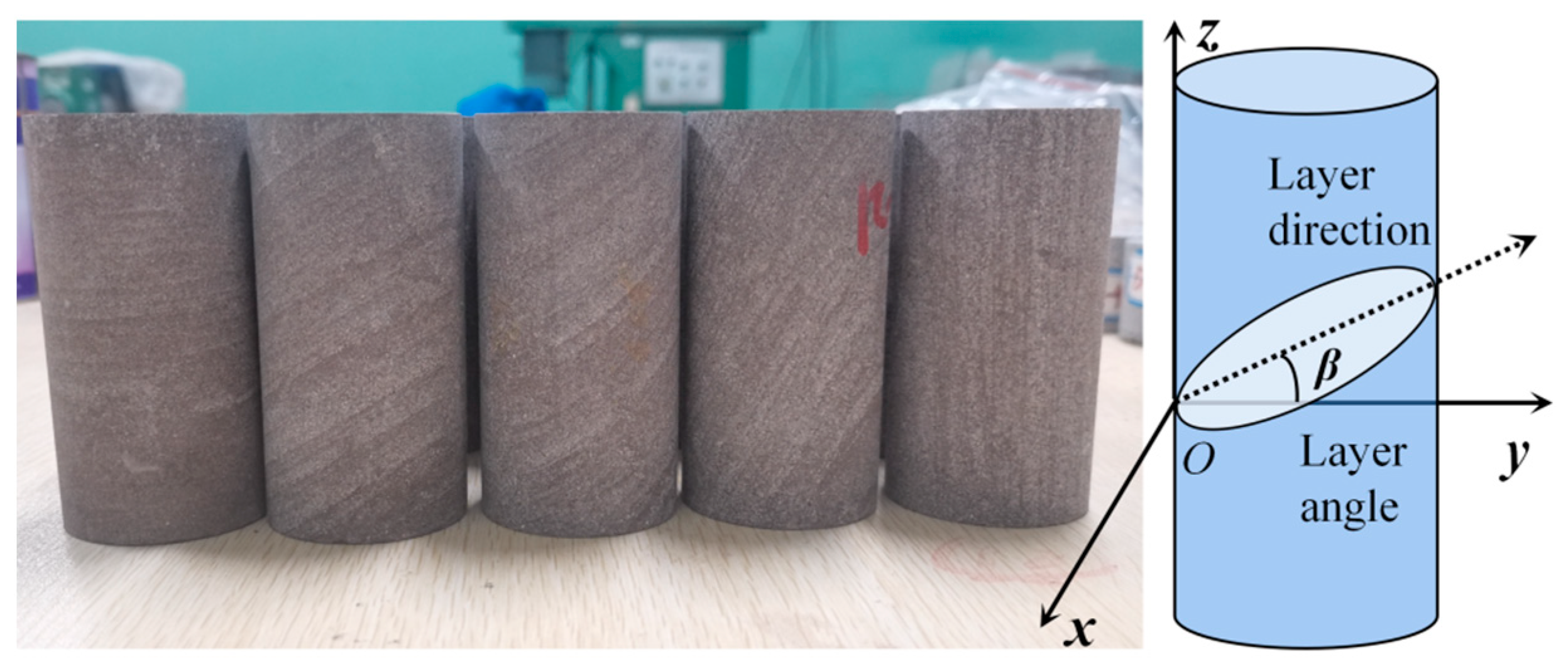

2. Materials and Methods

2.1. Sample Preparation

2.2. Experimental Equipment

2.3. Experimental Procedure

3. Results and Discussion

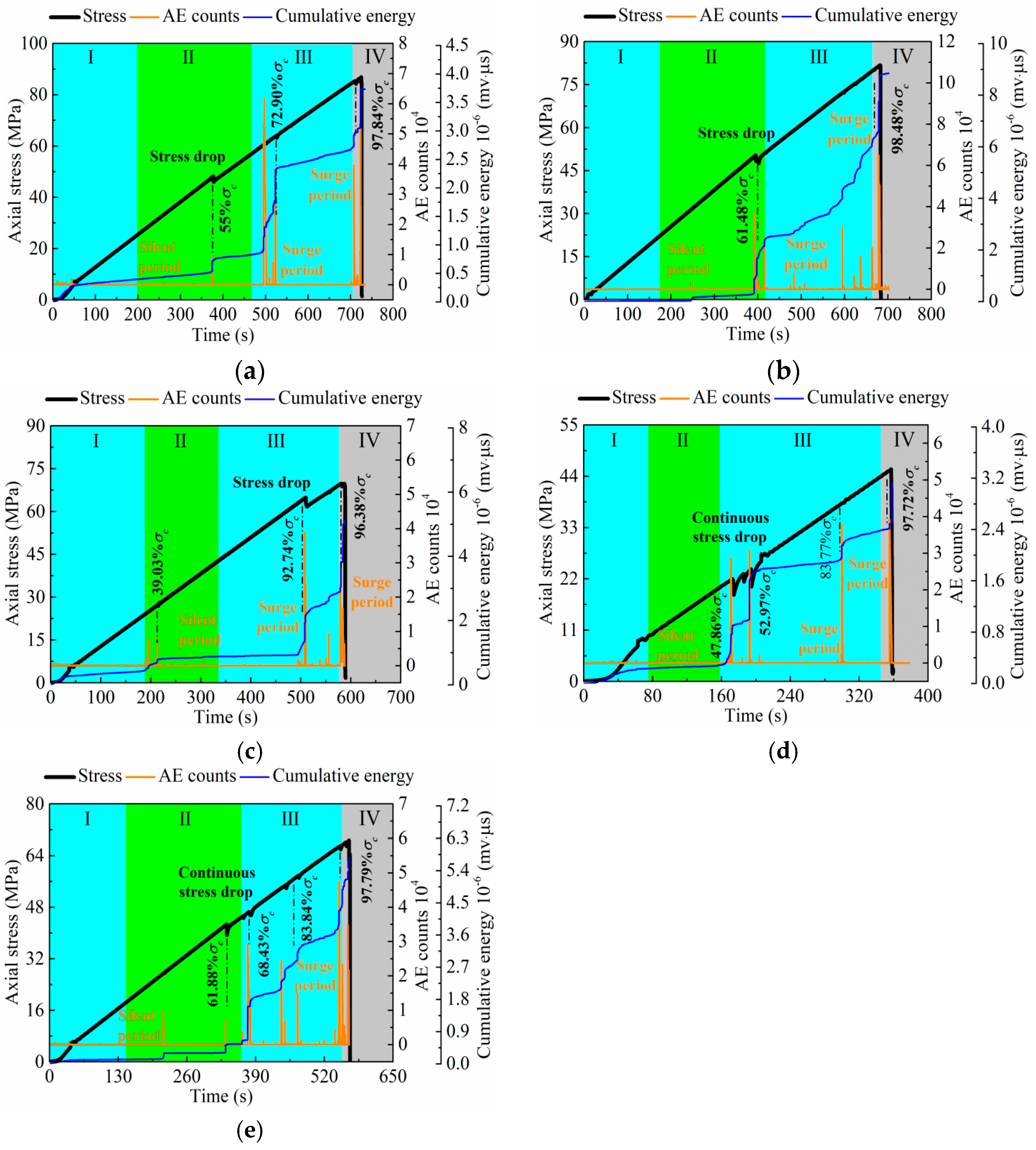

3.1. Effects of Acoustic Characteristics

3.2. Stress–Strain Response Characteristic

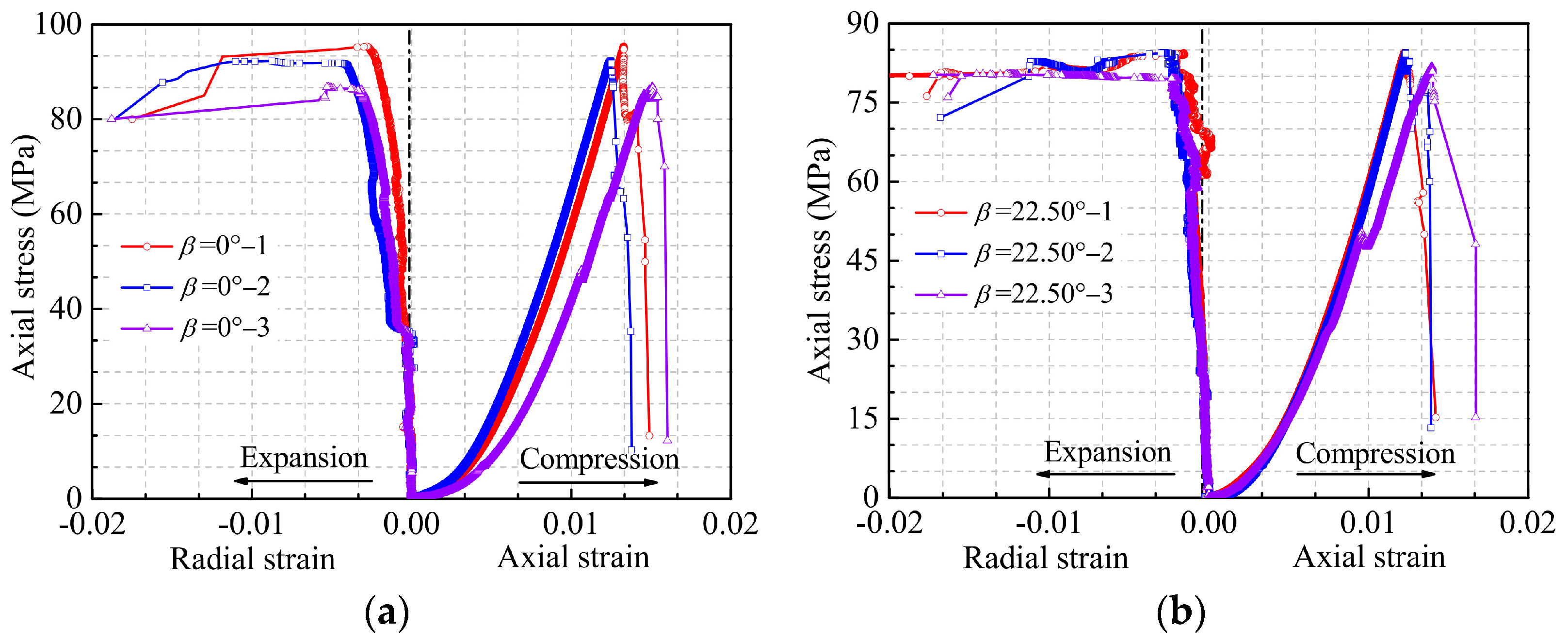

3.2.1. Stress–Strain Curves

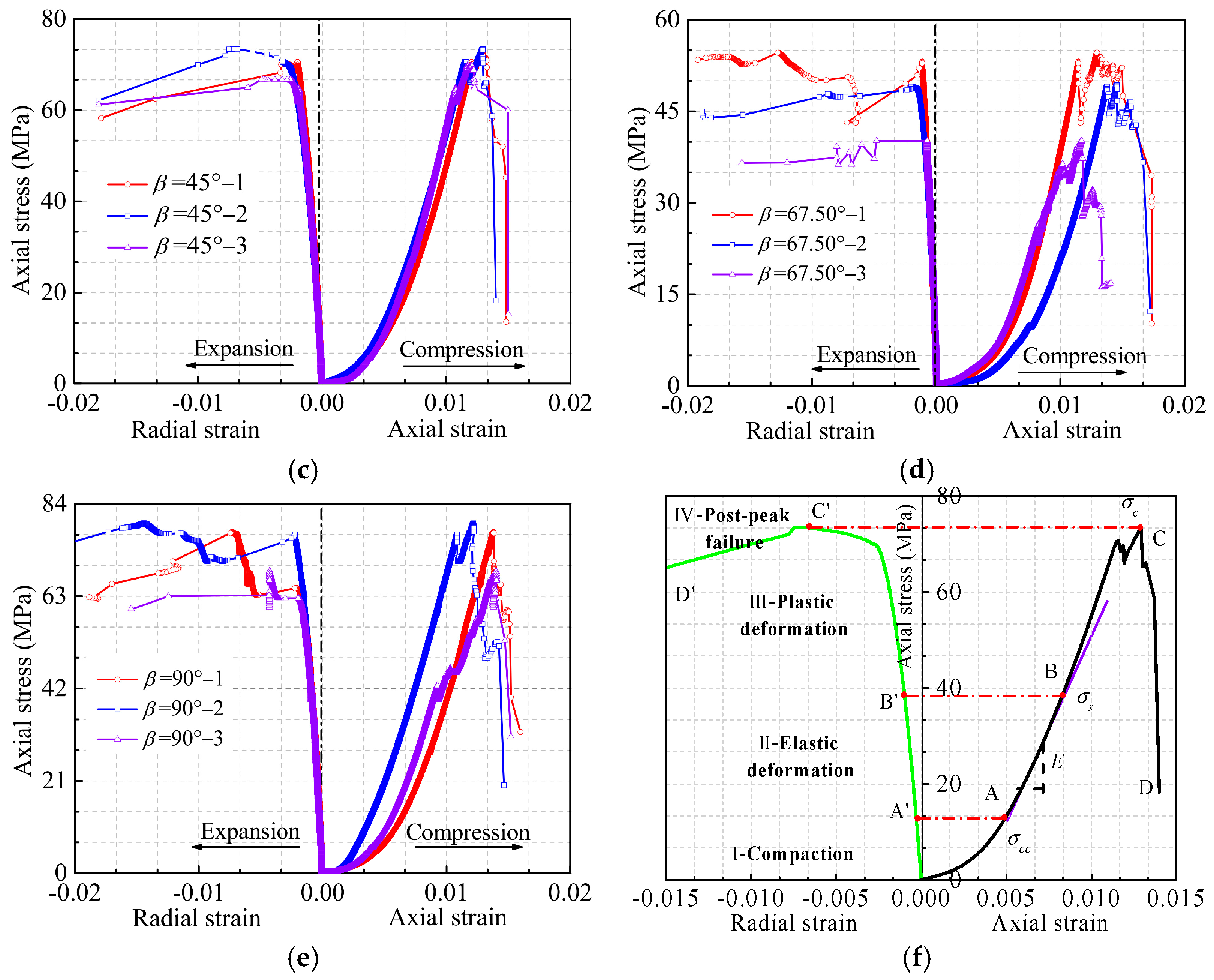

3.2.2. Local Strain–Time Curves

3.3. Mechanical Parameter Characteristics

3.4. Macroscopic Failure Mechanism

3.4.1. Evolution Mechanism of Macroscopic Cracks

3.4.2. Macroscopic Fractal Features

3.5. Response Mechanism of Acoustic Emission

4. Conclusions

- (1)

- The layer structure of sandstone causes remarkable anisotropic characteristics of wave velocities. The increased layer angle reduces the transmission and reflection times between the layer’s weak surfaces, reducing the dissipation degree of the wave energy. This results in a roughly positive correlation between wave velocity and layer angle.

- (2)

- The strain characteristics and mechanical parameters of sandstone have an obvious layer deterioration effect. The local strain and overall strain have a synergistic feature, and the local strain path is more complex with an extremely sensitive deformation response. The mechanical properties gradually deteriorate. The peak stress and elastic modulus have a nonlinear exponential correlation with layer angle, and the sandstone belongs to the intermediate anisotropy level.

- (3)

- The layer structure has a significant fracture effect on the sandstone, and the rupture pattern shows significant anisotropic characteristics. The failure modes include tension failure types tension failure type I and tension failure type Ⅱ, shear failure type, and tension–shear composite failure type. The fractal dimension is negatively correlated with the layer deterioration effect.

- (4)

- The AE activity has a phased response characteristic to the aging deformation of layer structure. The more obvious the layer deterioration effect is, the longer the AE delay is. The layer structure induces strain energy to release early, resulting in a negative correlation between AE accumulative events and AE accumulative energy and layer deterioration effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Du, D.C.; Lei, D.; Liu, K.Q.; Dias, D. Design of quasi-rectangular tunnel built in the rock masses following Hoek-Brown failure criterion. Buildings 2022, 12, 1578. [Google Scholar] [CrossRef]

- Lawongkerd, J.; Shiau, J.; Keawsawasvong, S.; Seehavong, S.; Jamsawang, P. Design equations for predicting stability of unlined horseshoe tunnels in rock masses. Buildings 2022, 12, 1800. [Google Scholar] [CrossRef]

- Si, X.F.; Luo, Y.; Luo, S. Influence of lithology and bedding orientation on failure behavior of “D” shaped tunnel. Theor. Appl. Fract. Mec. 2024, 129, 104219. [Google Scholar] [CrossRef]

- Zhao, D.P.; Fan, H.B.; Jia, L.L. Characteristics and mitigation measures of floor heave in operational high-speed railway tunnels. KSCE J. Civ. Eng. 2021, 25, 1479–1490. [Google Scholar] [CrossRef]

- Liu, N.F.; Li, N.; Wang, S.J.; Li, G.F.; Song, Z.P. A fully coupled thermo-hydro-mechanical model for fractured rock masses in cold regions. Cold. Reg. Sci. Technol. 2023, 205, 103707. [Google Scholar] [CrossRef]

- Liu, N.F.; Li, N.; Li, G.F.; Song, Z.P.; Wang, S.J. Method for evaluating the equivalent thermal conductivity of a freezing rock mass containing systematic fractures. Rock Mech. Rock Eng. 2022, 55, 7333–7355. [Google Scholar] [CrossRef]

- Tian, X.X.; Song, Z.P.; Zhang, Y.W. Monitoring and reinforcement of landslide induced by tunnel excavation: A case study from Xiamaixi tunnel. Tunn. Undergr. Space Technol. 2020, 110, 103796. [Google Scholar] [CrossRef]

- Tian, X.X.; Song, Z.P.; Wang, H.Z.; Zhang, Y.W.; Wang, J.B. Evolution characteristics of the surrounding rock pressure and construction techniques: A case study from Taoshuping tunnel. Tunn. Undergr. Space Technol. 2022, 125, 104522. [Google Scholar] [CrossRef]

- Zhu, C.; He, M.C.; Jiang, B.; Qin, X.Z.; Yin, Q.; Zhou, Y. Numerical investigation on the fatigue failure characteristics of water-bearing sandstone under cyclic loading. J. Mt. Sci. 2021, 18, 3348–3365. [Google Scholar] [CrossRef]

- Zhao, J.S.; Jiang, Q.; Pei, S.F. Microseismicity and focal mechanism of blasting-induced block falling of intersecting chamber of large underground cavern under high geostress. J. Cent. South Univ. 2023, 30, 542–554. [Google Scholar] [CrossRef]

- Zhang, J.; Liang, Y.; Feng, T.G. Investigation of the cause of shield-driven tunnel instability in soil with a soft upper layer and hard lower layer. Eng. Fail. Anal. 2020, 118, 104832. [Google Scholar] [CrossRef]

- Zhao, J.S.; Jiang, Q.; Lu, J.F.; Chen, B.R.; Pei, S.F.; Wang, Z.L. Rock fracturing observation based on microseismic monitoring and borehole imaging: In situ investigation in a large underground cavern under high geostress. Tunn. Undergr. Space Technol. 2022, 126, 104549. [Google Scholar] [CrossRef]

- Cho, J.W.; Hanna, K.; Seokwon, J.; Min, K.B. Deformation and strength anisotropy of Asangneiss, Boryeong shale, and Yeoncheon schist. Int. J. Rock Mech. Min. 2012, 50, 158–169. [Google Scholar] [CrossRef]

- Cheng, Y.; Song, Z.P.; Yang, T.T.; Han, J.J.; Wang, B.W.; Zhang, Z.K. Investigating the aging damage evolution characteristics of layered hard sandstone using digital image correlation. Constr. Build. Mater. 2022, 353, 128838–128856. [Google Scholar] [CrossRef]

- Song, Z.P.; Cheng, Y.; Zhang, Z.K.; Yang, T.T. Tunnelling performance prediction of cantilever boring machine in sedimentary hard-rock tunnel using deep belief network. J. Mt. Sci. 2023, 20, 2029–2040. [Google Scholar] [CrossRef]

- Wu, K.; Song, J.A.; Zhao, N.N.; Shao, Z. Study on the time—Dependent interaction between surrounding rock and yielding supports in deep soft rock tunnels. Int. J. Numer. Anal. Met. 2023, 47, 1–20. [Google Scholar] [CrossRef]

- Wu, K.; Zheng, X.M.; Zhao, N.N.; Shao, Z. Effect of compressible layer on time-dependent behaviour of soft-rock large deformation tunnels revealed by mathematical analytical method. Appl. Math. Model. 2024, 126, 457–481. [Google Scholar] [CrossRef]

- Wu, K.; Sharifzadeh, M.; Shao, Z.S.; Zheng, X.; Zhao, N.; Yang, Y. Analytical model for soft rock tunnel with large deformation using stiff and yielding lining solutions. Int. J. Geomech. 2023, 23, 04023207. [Google Scholar] [CrossRef]

- Tien, Y.M.; Kuo, M.C.; Juang, C.H. An experimental investigation of the failure mechanism of simulated transversely isotropic rocks. Int. J. Rock Mech. Min. 2006, 43, 1163–1181. [Google Scholar] [CrossRef]

- Li, D.X.; Wang, E.Y.; Feng, X.J.; Wang, D.; Zhang, X.; Ju, Y. Weak current induced by coal deformation and fracture and its response to mine seismicity in a deep underground coal mine. Eng. Geol. 2023, 315, 107018. [Google Scholar] [CrossRef]

- Li, D.X.; Wang, E.Y.; Yue, J.H.; Li, M.; Li, L.; Wang, D.; Liang, W. Characteristics of pressure stimulated current and damage evolution of granite under progressive uniaxial loading. Sustainability 2023, 15, 14526. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.S.; Jiang, Y.L.; Zhao, N.N.; Qin, S.; Chu, Z.F. Determination of stiffness of circumferential yielding lining considering the shotcrete hardening property. Rock Mech. Rock Eng. 2023, 56, 3023–3036. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.S. Visco-elastic analysis on the effect of flexible layer on mechanical behavior of tunnels. Int. J. Appl. Mech. 2019, 11, 1950027. [Google Scholar] [CrossRef]

- Wu, K.; Shao, Z.S.; Sharifzadeh, M.; Hong, S.Y.; Qin, S. Analytical computation of support characteristic curve for circumferential yielding lining in tunnel design. J. Rock Mech. Geotech. Eng. 2022, 14, 144–152. [Google Scholar] [CrossRef]

- Liu, J.; Wang, E.Y.; Song, D.Z.; Yang, S.L.; Niu, Y. Effects of rock strength on mechanical behavior and acoustic emission characteristics of samples composed of coal and rock. J. China Coal Soc. 2014, 39, 685–691. [Google Scholar]

- Zuo, J.P.; Xie, H.P.; Meng, B.B.; Liu, J.F. Experimental research on loading-unloading behavior of coal-rock combination bodies at different stress levels. Rock Soil Mech. 2011, 32, 1287–1296. [Google Scholar]

- Li, C.J.; Xu, Y.; Feng, M.M.; Pan, B. Deformation law and failure mechanism of coal-rock-like combined body under uniaxial loading. J. China Coal Soc. 2020, 45, 1773–1782. [Google Scholar]

- Wang, B.W.; Li, Y.P.; Yang, C.H.; Liu, W.; Zhang, G.M. Influences of interface inclination on mechanical properties of composite bedded physical model material. Rock Soil Mech. 2015, 36, 139–147. [Google Scholar]

- Zeng, J.Q.; Yang, Z.C. Dip effect of structural plane on shearing strength parameters of rock mass. China J. Rock Mech. Eng. 2004, 23, 3418–3425. [Google Scholar]

- Zhang, Z.K.; Song, Z.P.; Cheng, Y.; Huo, R.K.; Song, W.X.; Wang, K.S.; Wang, T.; Yang, T.T.; Liu, W. Acoustic emission characteristics and fracture response behavior of hard rock-like material under influence of loading rate. Coal Geol. Explor. 2022, 50, 115–124. [Google Scholar]

- Zhang, Z.X.; Cheng, Y.; Song, Z.P.; Ye, X.W. Anisotropy and directivity effects on uniaxial compression of carbonaceous slate form Jinman mine. Appl. Sci. 2022, 12, 9811. [Google Scholar] [CrossRef]

- Attewell, P.B. Sandford MR (1974) Intrinsic shear strength of a brittle, anisotropic rock-III. Int. J. Rock Mech. Min. Sci. 1974, 11, 439–451. [Google Scholar] [CrossRef]

- Wasantha, P.L.P.; Ranjith, P.G.; Shao, S.S. Energy monitoring and analysis during deformation of bedded-sandstone: Use of acoustic emission. Ultrasonics 2014, 54, 217–226. [Google Scholar] [CrossRef]

- Amann, F.E.; Button, A.; Evans, K.F. Experimental study of the brittle behavior of clay shale in rapid unconfined compression. Rock Mech. Rock Eng. 2011, 44, 415–430. [Google Scholar] [CrossRef]

- You, M.Q. Instable failure of rock specimen in uniaxial compression and the loading behavior of testing machine. Rock Soil Mech. 1998, 19, 43–49. [Google Scholar]

- Damjanac, B.; Fairhurst, C. Evidence for a long-term strength threshold in crystalline rock. Rock Mech. Rock Eng. 2010, 43, 513–531. [Google Scholar] [CrossRef]

- Du, M.Q.; Su, J.; Wang, X.C.; Zhang, S.L.; Zhang, Y.J. Dynamic response and crack propagation law of tunnel invert with initial damage. Eng. Fail. Anal. 2021, 119, 104939. [Google Scholar]

- Lee, C.H.; Wang, T.T. Invert anomalies in operational rock tunnels: Appearance, causes, and countermeasures. J. Perform Constr. Fac. 2016, 30, 04015048. [Google Scholar] [CrossRef]

- Chen, Y.L.; Wei, Z.A.; Zhang, Q.G. Experimental study on Felicity effect of acoustic emission in rock under cyclic loading and tiered cyclic loading. J. China Coal Soc. 2012, 37, 226–230. [Google Scholar]

- Chu, C.Q.; Wu, S.C.; Zhang, S.H.; Guo, P.; Zhang, M. Mechanical behavior anisotropy and fracture characteristics of bedded sandstone. J. Cent. South Univ. 2020, 51, 2232–2246. [Google Scholar]

- Chen, Q.N.; Zeng, A.; Luo, P.; An, Y.L.; Hu, W.; Luo, X.G. Study on mechanical characteristics of initial supporting structure of large deformation section of carbonaceous slate in Yuanbaoshan tunnel. China, J. Appl. Mech. 2020, 30, 810–817. [Google Scholar]

- Cheng, Y.; Song, Z.P.; Song, W.X.; Li, S.; Yang, T.; Zhang, Z.; Wang, T.; Wang, K. Strain performance and fracture response characteristics of hard rock under cyclic loading. Geomech. Eng. 2021, 26, 551–563. [Google Scholar]

- Xu, P.; Yang, S.Q. Numerical analysis of creep mechanical property for bedded composite rock. J. Min. Saf. Eng. 2018, 35, 179–187. [Google Scholar]

- Pan, Y.S.; Tang, Z.; Li, Z.H. Study on charge induced rule of uniaxial compression of coal and rock under different loading rates. Acta. Phys. Sin. 2013, 56, 1043–1048. [Google Scholar]

- Zhao, P.X.; Li, S.G.; Ho, C.H.; Lin, H.F.; Zhuo, R.S. Crack propagation and material characteristics of rocklike specimens subject to different loading rates. J. Mater. Civ. Eng. 2016, 31, 04019113. [Google Scholar] [CrossRef]

- Deng, H.F.; Li, T.; Li, J.L.; Xiong, Y.; Qi, Y.; Wan, L.P. Study on calculation method of anisotropic acoustic and mechanical parameters of layered rock. J. Rock Mech. Eng. 2020, 39, 2725–2732. [Google Scholar]

- Saeidi, O.; Rasouli, V.; Vaneghi, R.G.; Gholami, R.; Seyed, R.T. A modified failure criterion for transversely isotropicrocks. Geosci. Front. 2014, 5, 215–225. [Google Scholar] [CrossRef]

- Hou, Z.K.; Yang, C.H.; Guo, Y.T.; Zhang, B.P.; Wei, Y.L.; Heng, S.; Wang, L. Experimental study on anisotropic properties of Longmaxi formation shale under uniaxial compression. Rock Soil Mech. 2015, 36, 2541–2550. [Google Scholar]

- Yin, P.F.; Yang, S.Q.; Gao, F.; Tian, W.L. Application of different joint models in stratified composite rock DEM simulation. J. Min. Saf. Eng. 2023, 40, 164–173+183. [Google Scholar]

- Novikov, E.A.; Shkuratnik, V.L.; Zaitsev, M.G.; Klementyev, E.A.; Blokhin, D.I. Acoustic emission of frozen soils under quasi-static mechanical and cyclic thermal loading. Soil Mech. Found Eng. 2020, 57, 97–104. [Google Scholar] [CrossRef]

- Shkuratnik, V.L.; Filimonov, Y.L.; Kuchurin, S.V. Regularities of acoustic emission in coal samples under triaxial compression. J. Min. Sci. 2005, 41, 44–52. [Google Scholar] [CrossRef]

- Cyril, G.; Yveshenri, F.; Remi, B.; Rémi, B.; Chia-Chun, H. Contact erosion at the interface between granular coarse soil and various base soils under tangential flow condition. J. Geotech. Geoenviron. Eng. 2010, 136, 741–750. [Google Scholar] [CrossRef]

- Zhang, Z.K.; Song, Z.P.; Lai, J.X. Critical slowing down precursor information for the acoustic emission response characteristics of defective tuffs. Theor. Appl. Fract. Mech. in press. 2023. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Puzzi, S. From criticality to final collapse: Evolution of the “b-value” from 1.5 to 1.0. Chaos Solitons Fractals 2009, 41, 843–853. [Google Scholar] [CrossRef]

| Layer Angle (°) | Peak Stress (MPa) | Elastic Modulus (GPa) | Deformation Modulus (GPa) | Peak Strain (%) | Poisson’s Ratio | Failure Modes | |

|---|---|---|---|---|---|---|---|

| 0 | 0-1 | 95.35 | 10.11 | 7.17 | 1.328 | 0.1082 | Tension failure |

| 0-2 | 92.24 | 10.11 | 7.40 | 1.246 | 0.1876 | ||

| 0-3 | 86.85 | 8.95 | 5.76 | 1.509 | 0.1529 | ||

| Average | 91.48 | 9.72 | 6.78 | 1.361 | 0.1496 | ||

| 22.50 | 22.50-1 | 84.40 | 9.44 | 6.90 | 1.224 | 0.1597 | Tension failure |

| 22.50-2 | 84.46 | 9.94 | 6.84 | 1.234 | 0.1313 | ||

| 22.50-3 | 81.80 | 9.63 | 5.86 | 1.397 | 0.1673 | ||

| Average | 83.55 | 9.67 | 6.53 | 1.285 | 0.1528 | ||

| 45 | 45-1 | 72.89 | 8.71 | 5.68 | 1.284 | 0.2200 | Tension–shear composite failure |

| 45-2 | 73.43 | 9.28 | 5.68 | 1.292 | 0.1681 | ||

| 45-3 | 69.80 | 10.41 | 5.96 | 1.171 | 0.1542 | ||

| Average | 72.04 | 9.47 | 5.77 | 1.249 | 0.1808 | ||

| 67.50 | 67.50-1 | 54.62 | 8.30 | 4.22 | 1.295 | 0.2028 | Shear failure |

| 67.50-2 | 49.39 | 6.32 | 3.40 | 1.251 | 0.1441 | ||

| 67.50-3 | 40.17 | 6.55 | 3.43 | 1.170 | 0.3076 | ||

| Average | 48.06 | 7.06 | 3.68 | 1.238 | 0.2182 | ||

| 90 | 90-1 | 77.55 | 9.25 | 5.62 | 1.381 | 0.2370 | Tension failure |

| 90-2 | 79.59 | 9.48 | 6.54 | 1.217 | 0.2151 | ||

| 90-3 | 68.87 | 9.24 | 4.91 | 1.402 | 0.2136 | ||

| Average | 75.34 | 9.32 | 5.69 | 1.333 | 0.2219 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Y.; Song, Z.; Wu, F.; Zhu, X.; Yuan, W. Investigating the Mechanical Deterioration Effect of Hard Sandstone Induced by Layer Structure under Uniaxial Compression. Buildings 2024, 14, 51. https://doi.org/10.3390/buildings14010051

Cheng Y, Song Z, Wu F, Zhu X, Yuan W. Investigating the Mechanical Deterioration Effect of Hard Sandstone Induced by Layer Structure under Uniaxial Compression. Buildings. 2024; 14(1):51. https://doi.org/10.3390/buildings14010051

Chicago/Turabian StyleCheng, Yun, Zhanping Song, Fahong Wu, Xiaoping Zhu, and Wei Yuan. 2024. "Investigating the Mechanical Deterioration Effect of Hard Sandstone Induced by Layer Structure under Uniaxial Compression" Buildings 14, no. 1: 51. https://doi.org/10.3390/buildings14010051