Mechanical Properties and Stress–Strain Constitutive Relations of Coal-Fired Slag Concrete

Abstract

1. Introduction

2. Overview of the Experiment

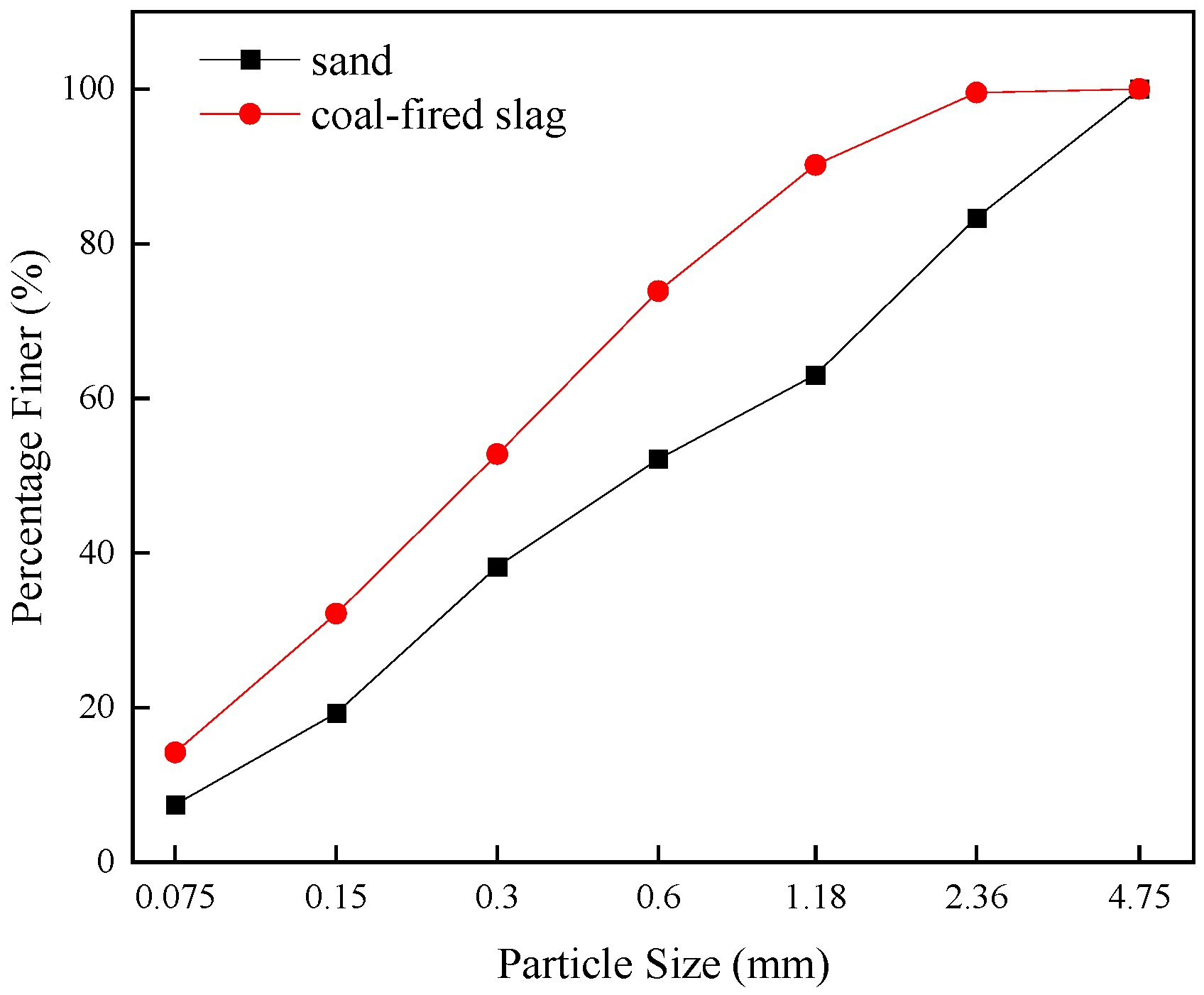

2.1. Raw Materials

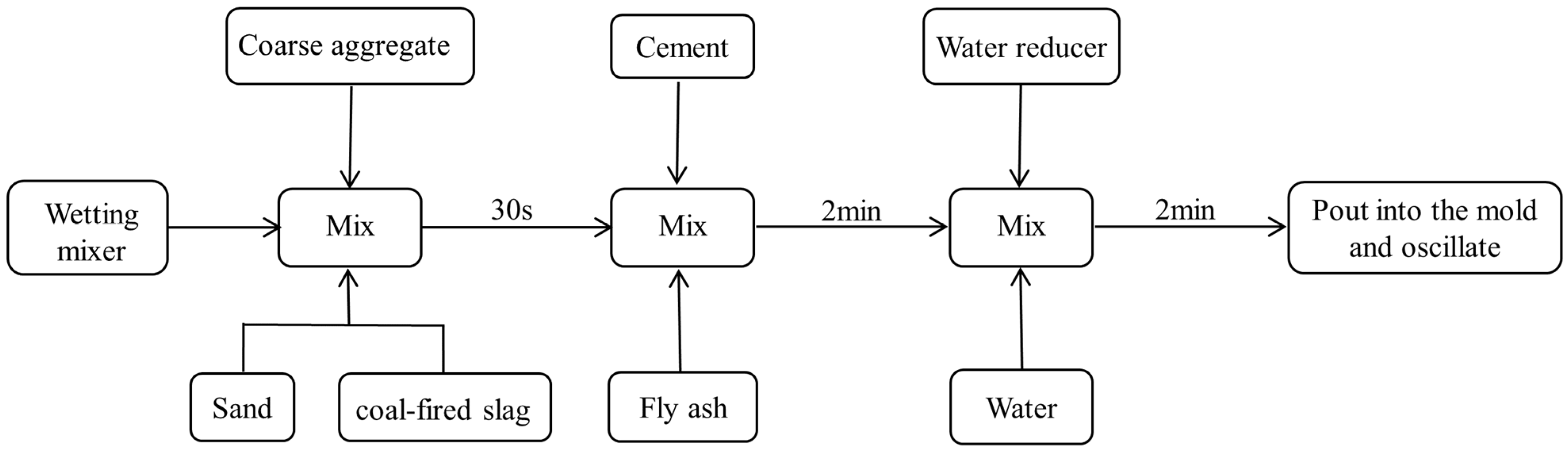

2.2. Design of the Experiment

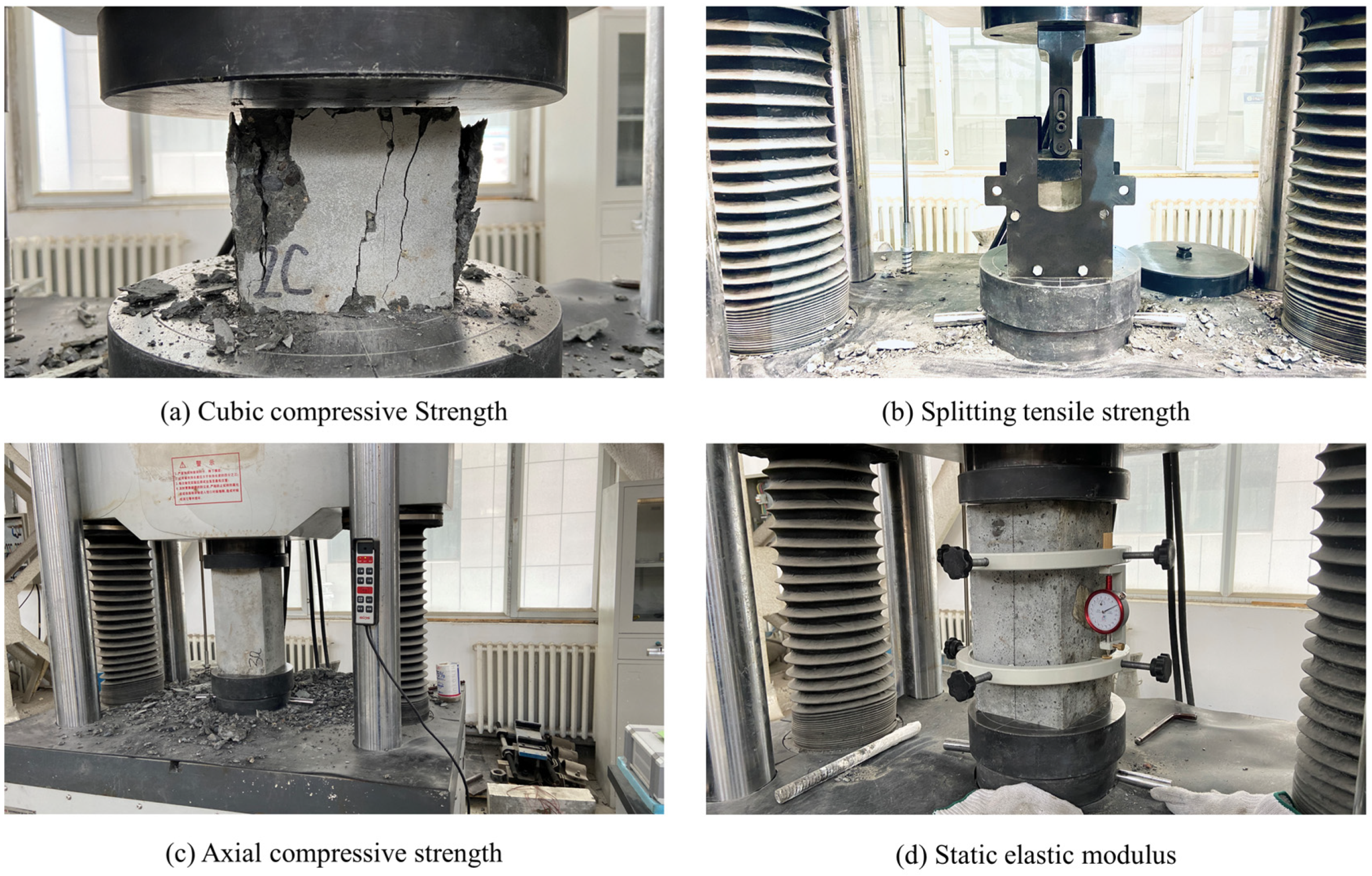

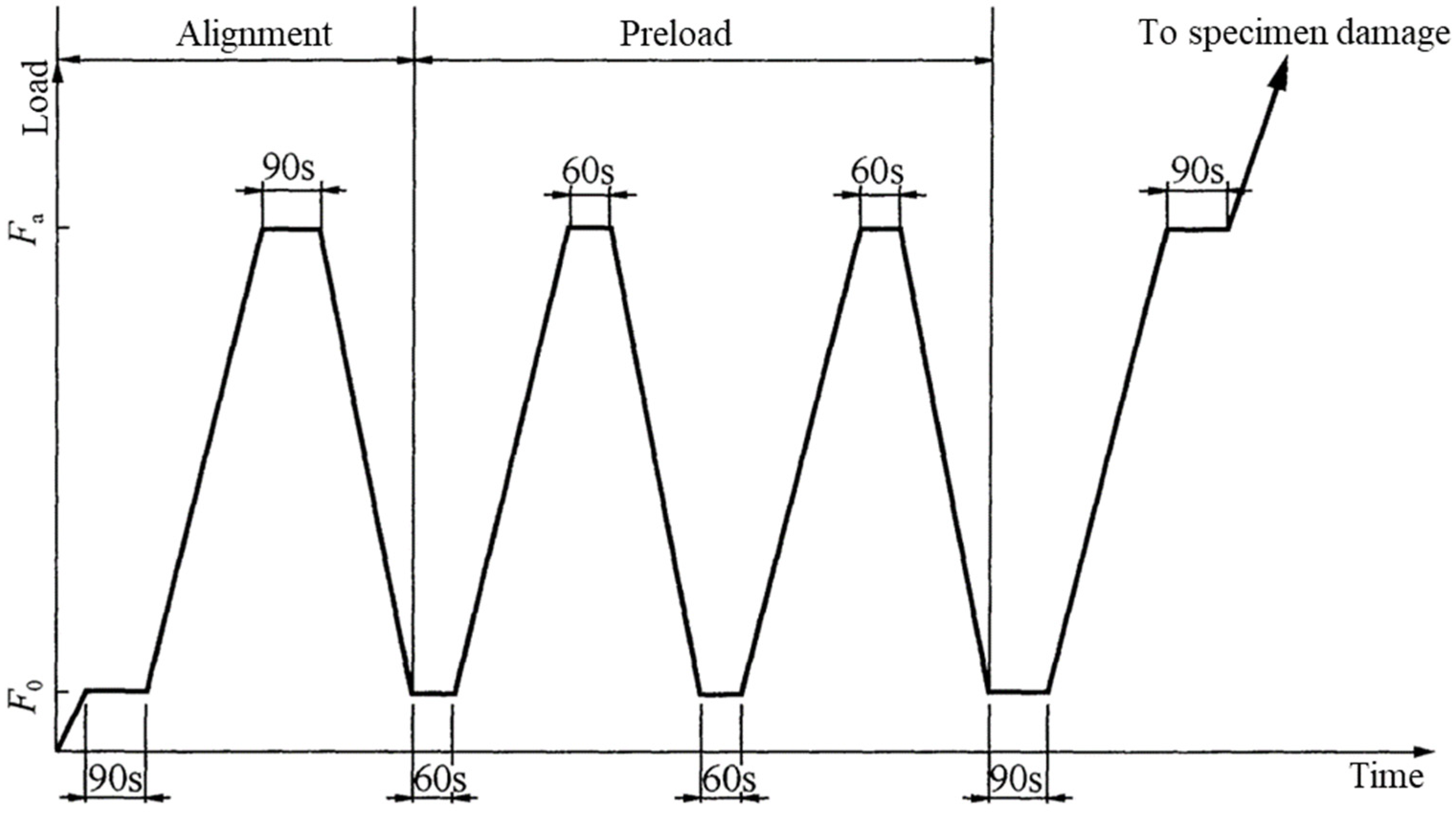

2.3. Test Methods and Loading Devices

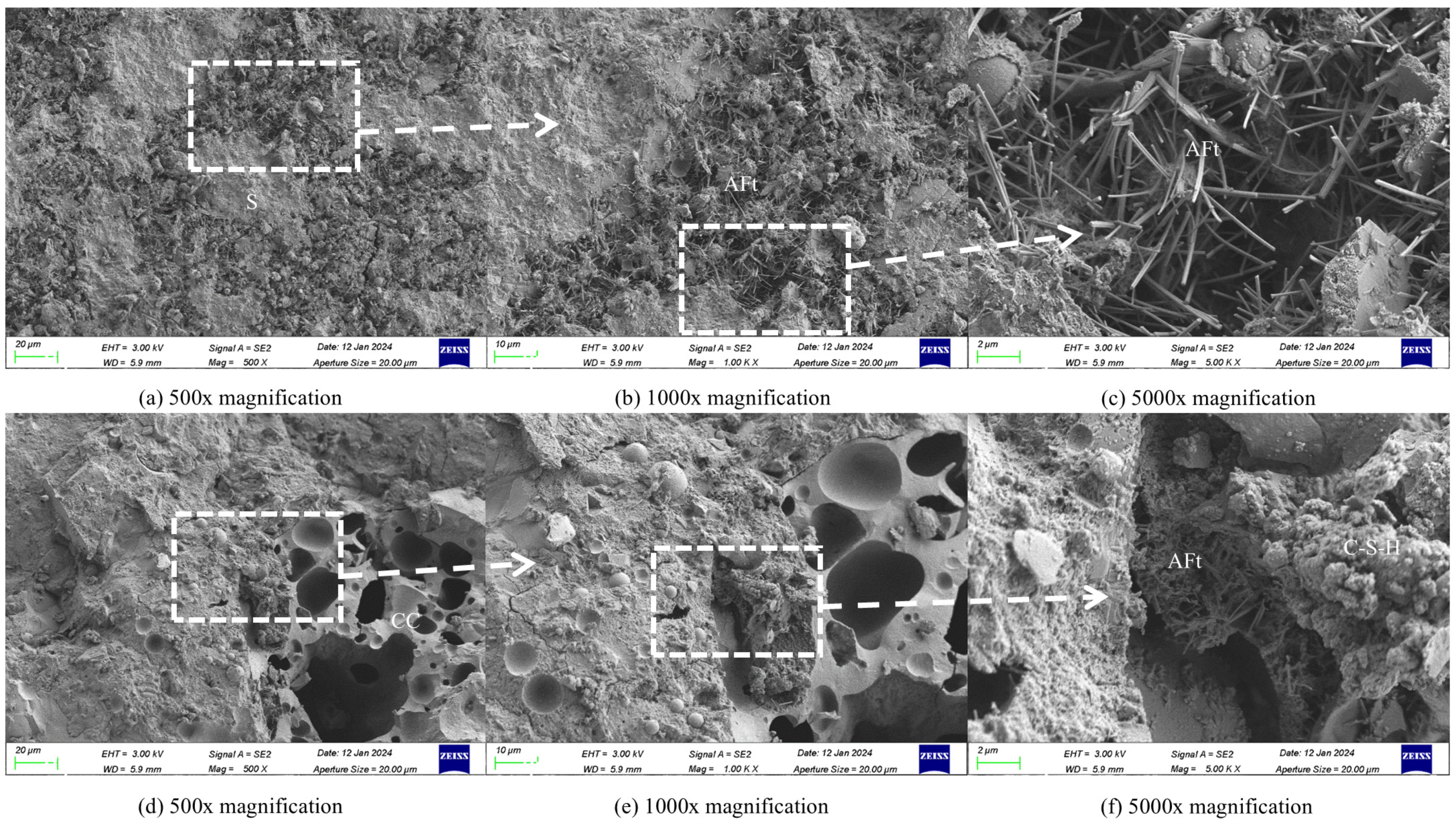

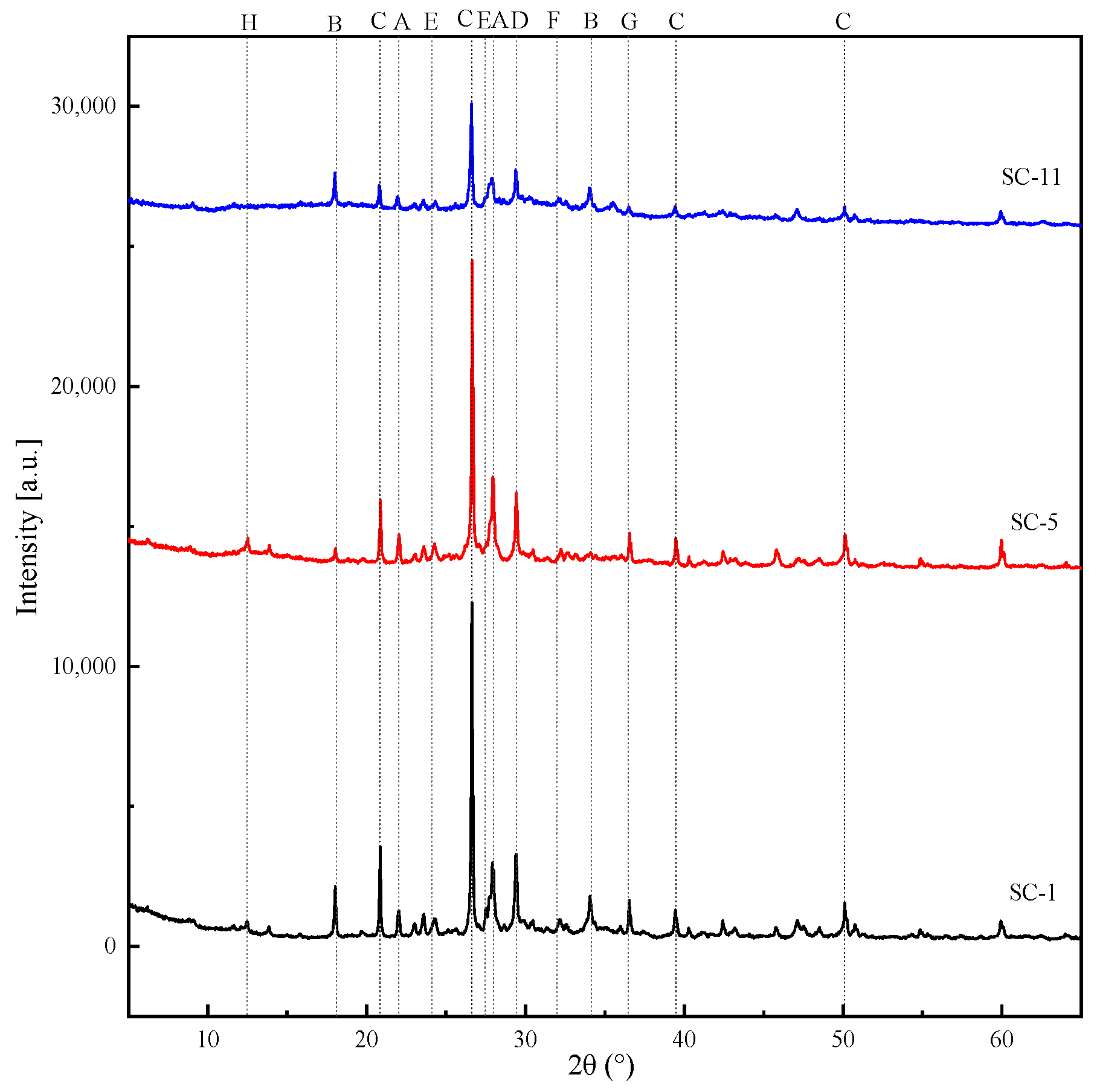

3. Test Results and Analyses

3.1. Test Results

3.2. Work Performance of the SC

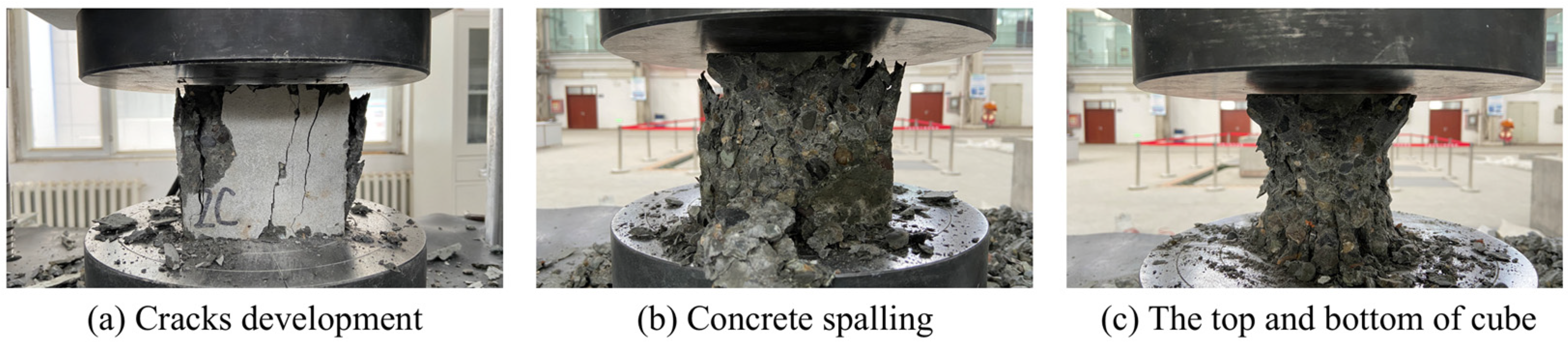

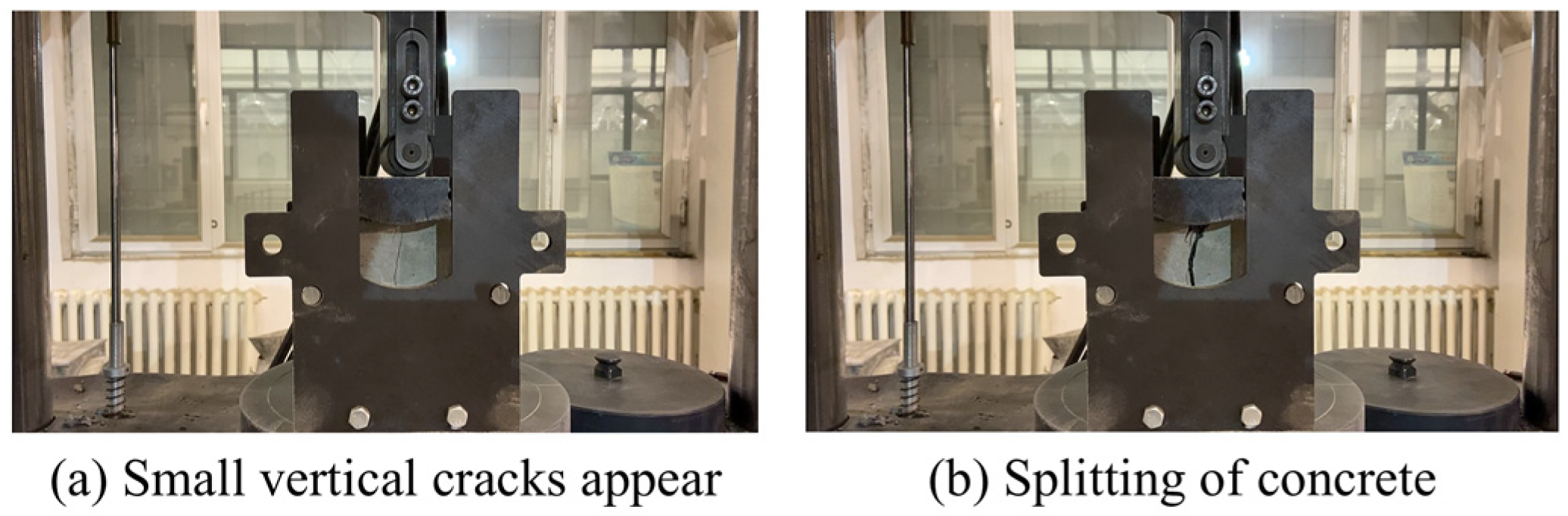

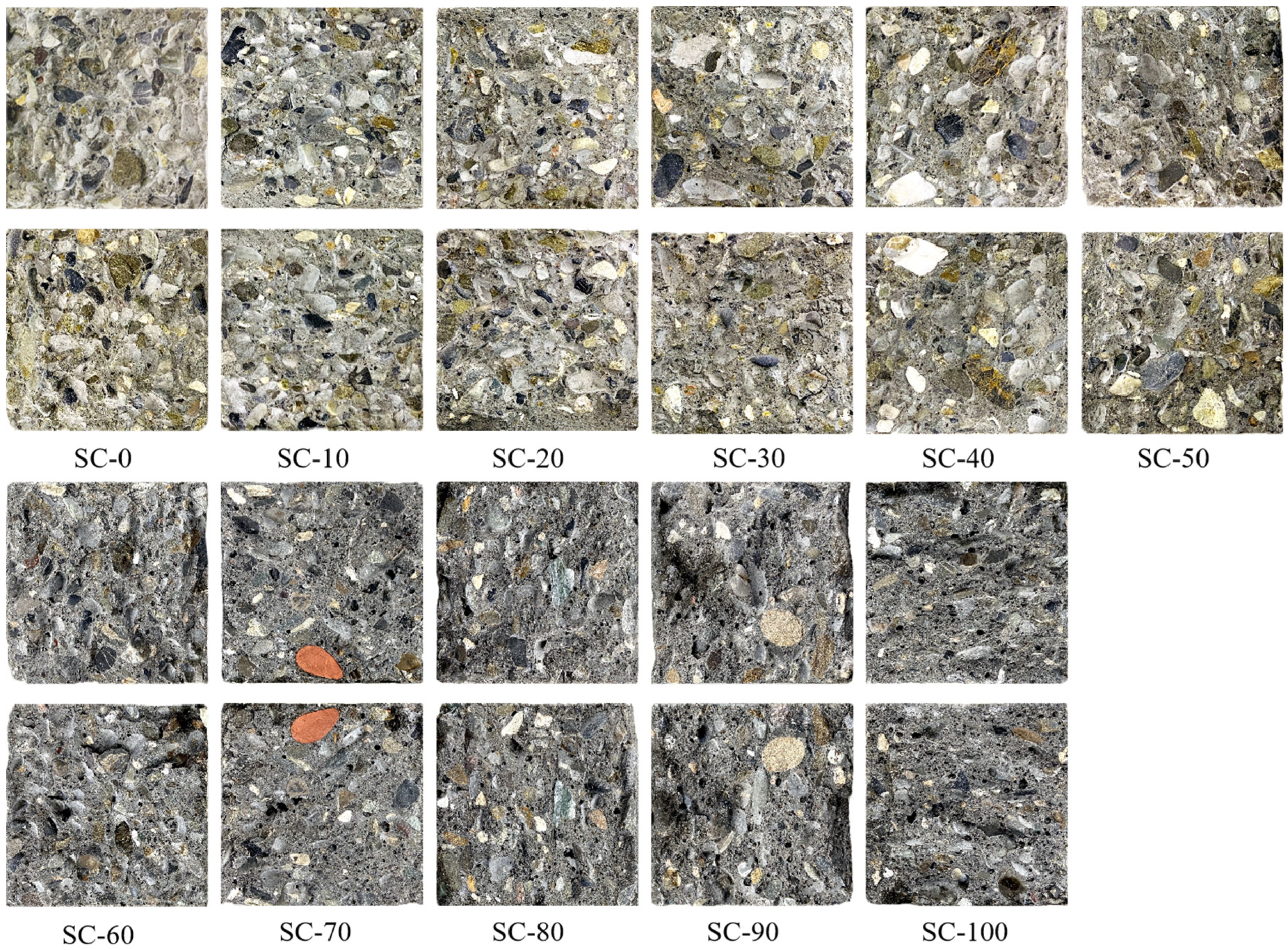

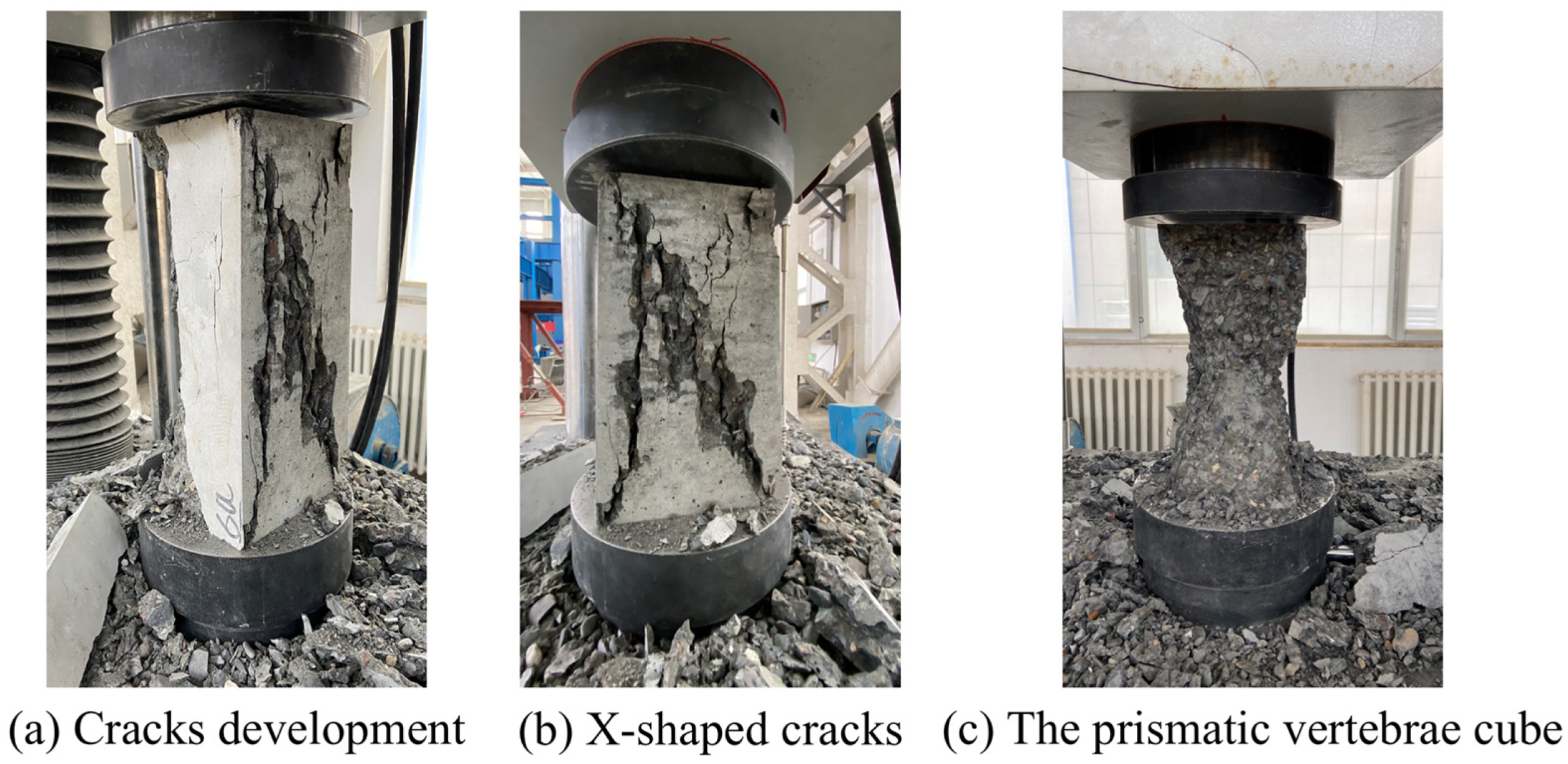

3.3. Destructive State of the SC

3.4. Analysis of Mechanical Properties of the SC

3.4.1. Cubic Compressive Strength of the SC

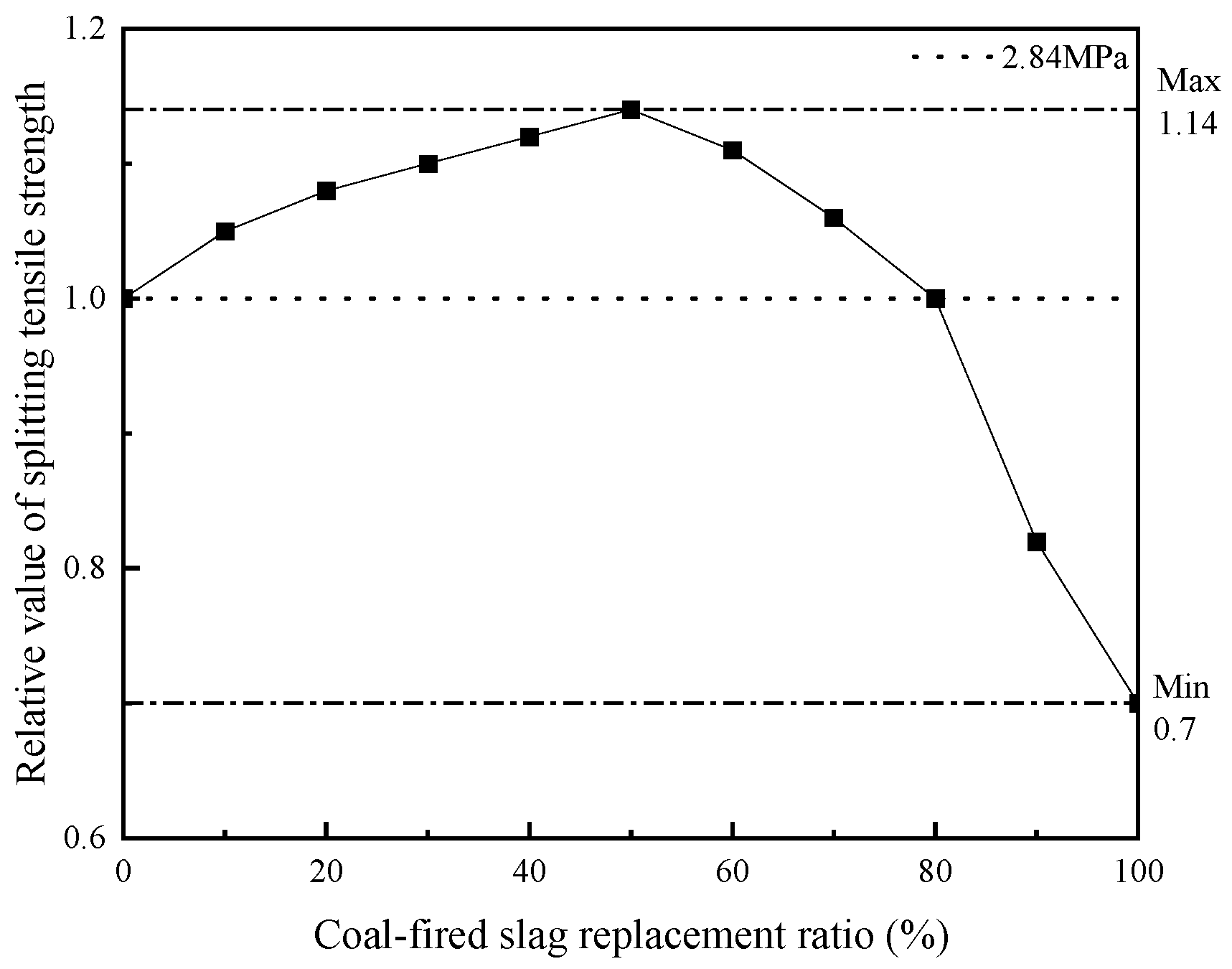

3.4.2. Splitting Tensile Strength of the SC

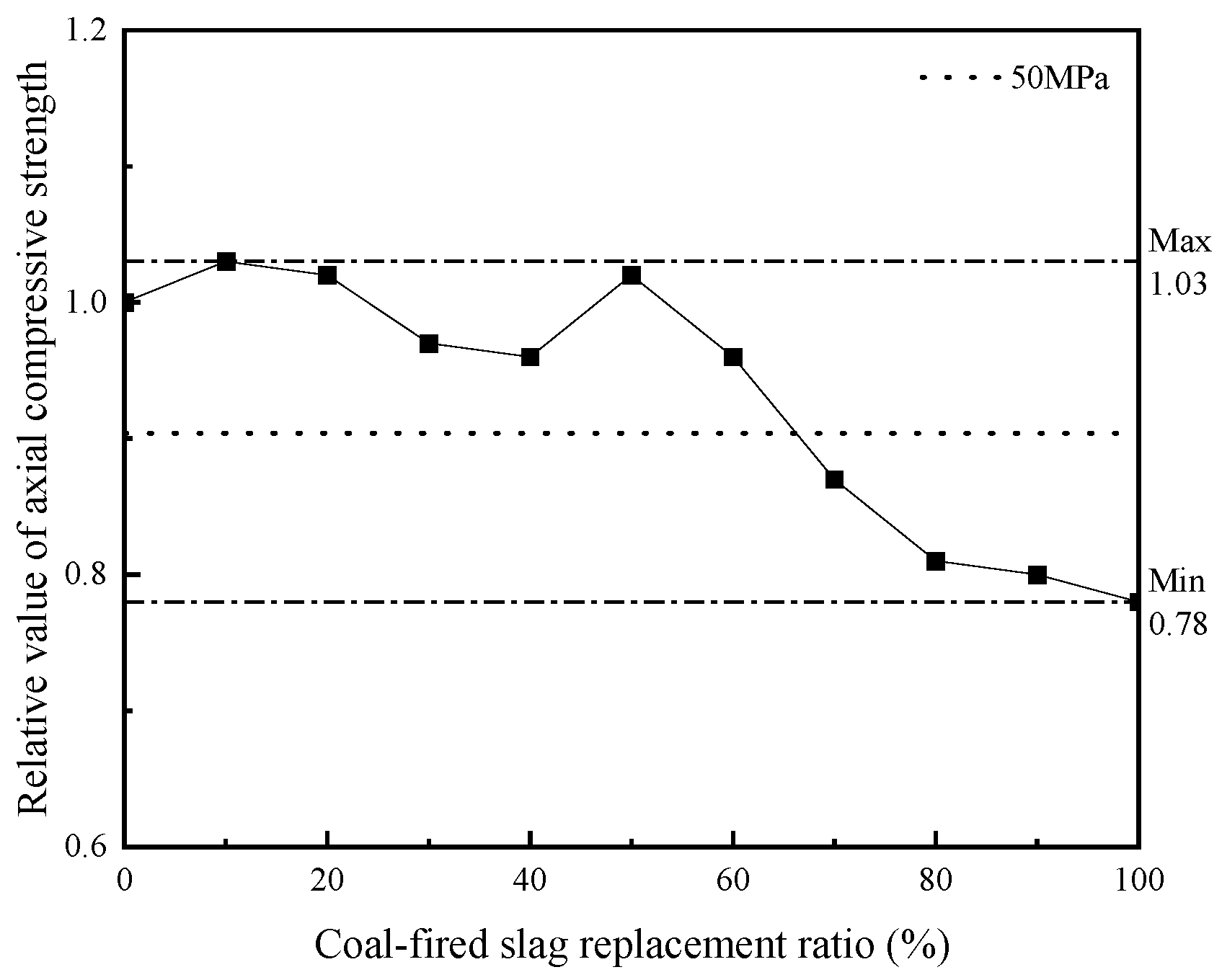

3.4.3. Axial Compressive Strength of the SC

3.4.4. Static Elastic Modulus of the SC

3.4.5. Optimal Slag Substitution Rate

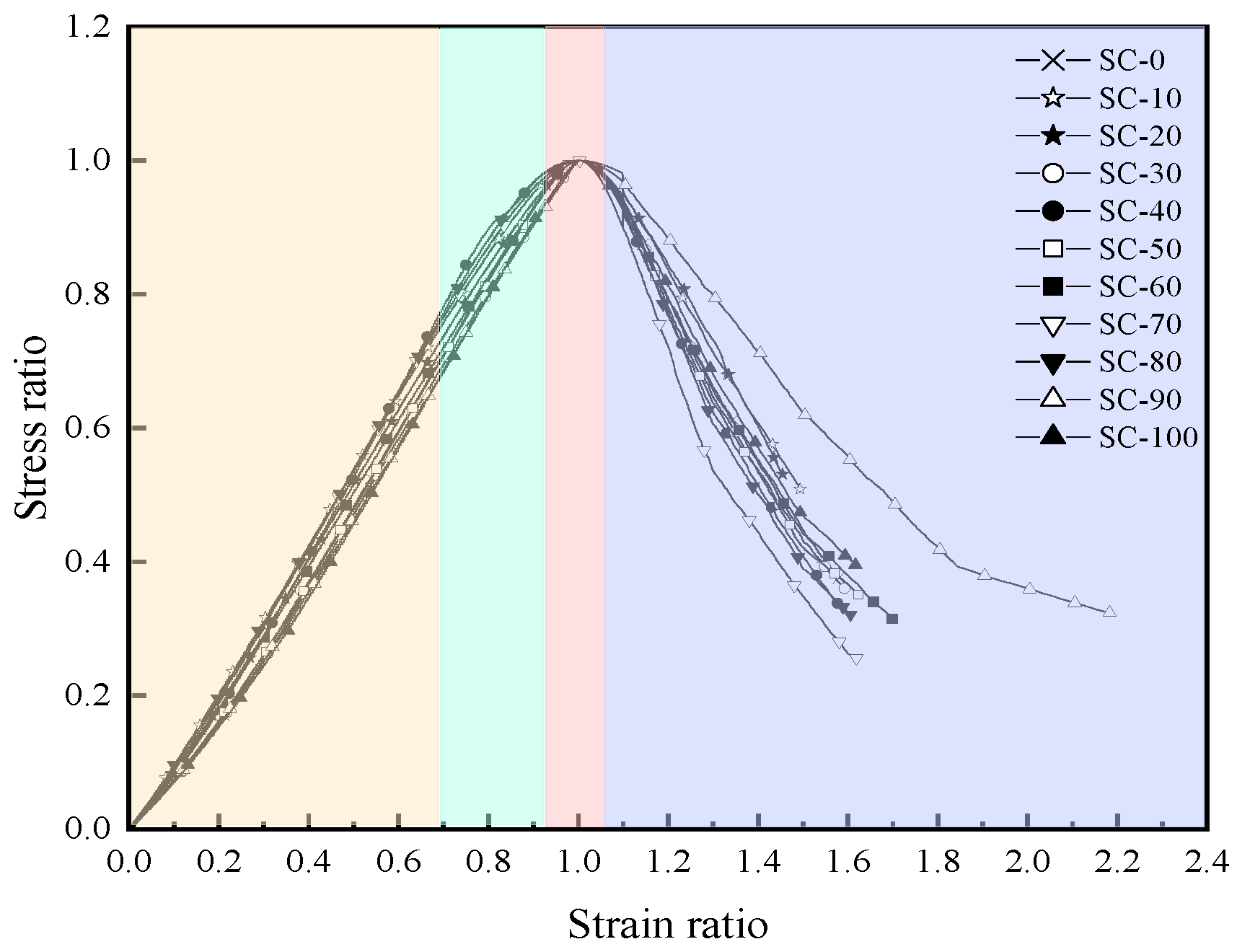

3.4.6. Stress–Strain Curve

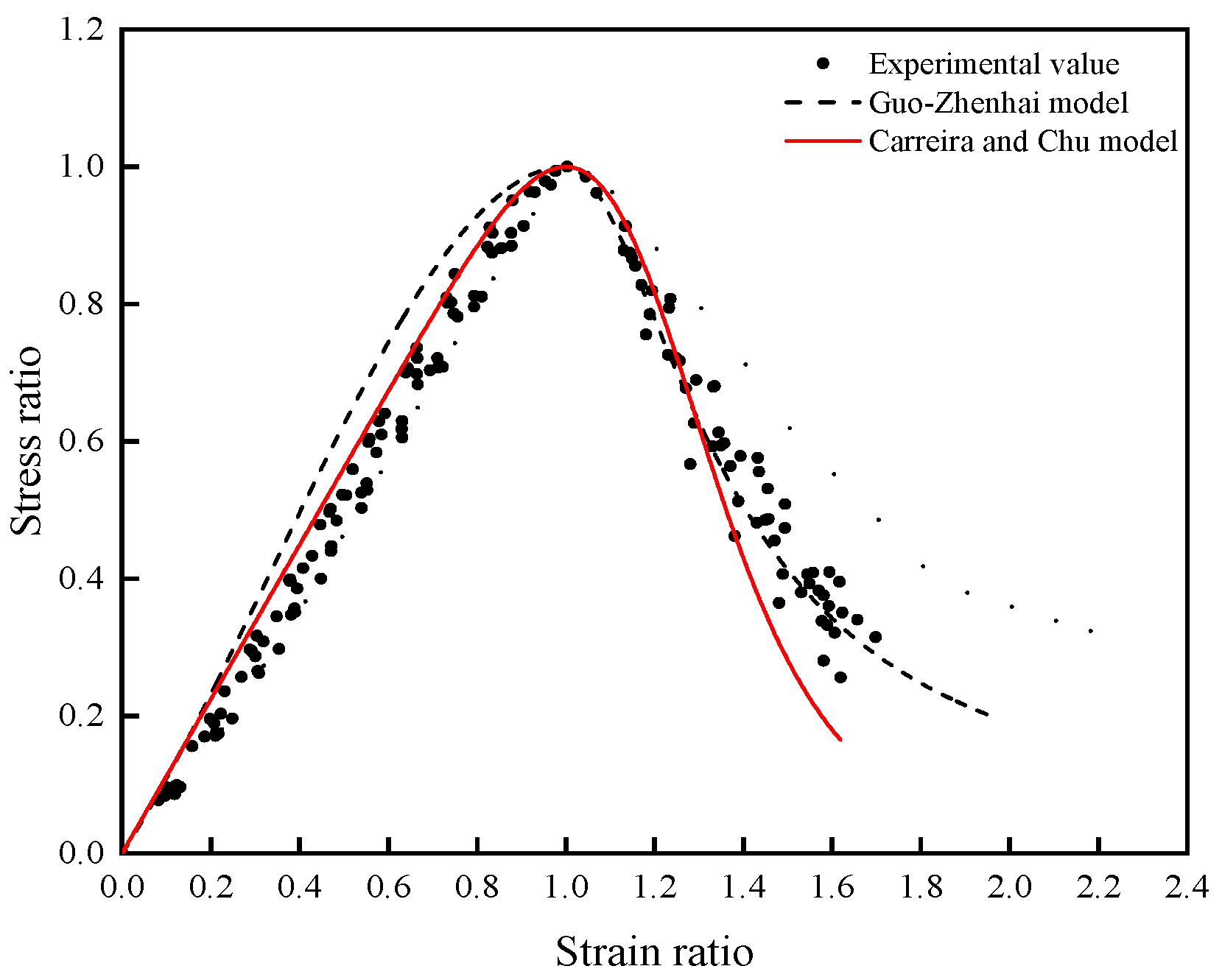

4. Constitutive Equation of the SC

4.1. Constitutive Equation

4.2. Damage Eigen Structure Equation

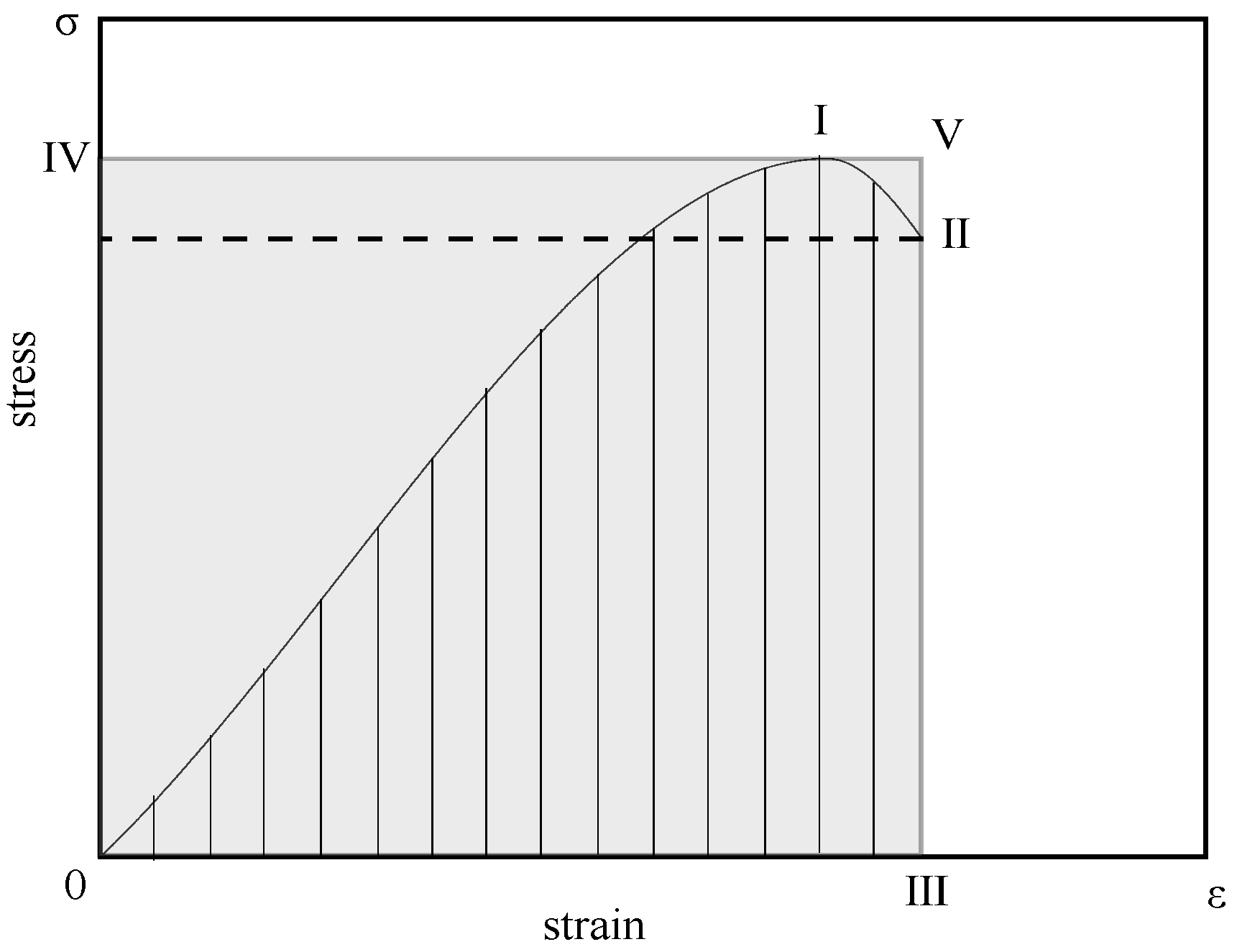

5. Energy Consumption Analysis of the SC

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- China Electric Power Planning & Engineering Institute. China Energy Development Report 2023; People’s Daily Press: Beijing, China, 2024; p. 306. [Google Scholar]

- Zhang, M.; Lv, T.; Deng, X.; Dai, Y.; Sajid, M. Diffusion of China’s coal-fired power generation technologies: Historical evolution and development trends. Nat. Hazards 2018, 95, 7–23. [Google Scholar] [CrossRef]

- Jayaranjan, M.L.D.; van Hullebusch, E.D.; Annachhatre, A.P. Reuse options for coal fired power plant bottom ash and fly ash. Rev. Environ. Sci. Bio/Technol. 2014, 13, 467–486. [Google Scholar] [CrossRef]

- Orozco, C.; Babel, S.; Tangtermsirikul, S.; Sugiyama, T. Comparison of environmental impacts of fly ash and slag as cement replacement materials for mass concrete and the impact of transportation. Sustain. Mater. Technol. 2024, 39, e00796. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Gong, X.; Nie, Z.; Cui, S.; Wang, Z.; Chen, W. Environmental impact analysis of blast furnace slag applied to ordinary Portland cement production. J. Clean. Prod. 2016, 120, 221–230. [Google Scholar] [CrossRef]

- Orna Carmona, M.; González Paules, J.; Sánchez Catalán, J.C.; Fernández Pousa, L.; Ade Beltrán, R.; Quero Sanz, F. Recycling power plant slag for use as aggregate in precast concrete components. Mater. Construcción 2010, 60, 99–113. [Google Scholar] [CrossRef]

- Mohammed, S.A.; Koting, S.; Katman, H.Y.B.; Babalghaith, A.M.; Abdul Patah, M.F.; Ibrahim, M.R.; Karim, M.R. A Review of the Utilization of Coal Bottom Ash (CBA) in the Construction Industry. Sustainability 2021, 13, 8031. [Google Scholar] [CrossRef]

- Andreev, V.; Bryukhan, F. Some prospects for the use of ash and slag wastes of coal power plants for production of building materials. MATEC Web Conf. 2016, 86, 04004. [Google Scholar] [CrossRef]

- Ashish, D.K.; Verma, S.K.; Singh, J.; Sharma, N. Strength and durability characteristics of bricks made using coal bottom and coal fly ash. Adv. Concr. Constr. 2018, 6, 407422. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of coal combustion by-products in sustainable construction materials. Resour. Conserv. Recycl. 2010, 54, 1060–1066. [Google Scholar] [CrossRef]

- Argiz, C.; Menéndez, E.; Moragues, A.; Sanjuán, M.Á. Recent Advances in Coal Bottom Ash Use as a New Common Portland Cement Constituent. Struct. Eng. Int. 2018, 24, 503–508. [Google Scholar] [CrossRef]

- Skoko, B.; Babić, D.; Marović, G.; Papić, S. Environmental radiological risk assessment of a coal ash and slag disposal site with the use of the ERICA Tool. J. Environ. Radioact. 2019, 208–209, 106018. [Google Scholar] [CrossRef] [PubMed]

- Saha, D.; Chatterjee, D.; Chakravarty, S.; Roychowdhury, T. Investigation of Environmental-Concern Trace Elements in Coal and Their Combustion Residues from Thermal Power Plants in Eastern India. Nat. Resour. Res. 2019, 28, 1505–1520. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Compressive strength, drying shrinkage and chemical resistance of concrete incorporating coal bottom ash as partial or total replacement of sand. Constr. Build. Mater. 2014, 68, 39–48. [Google Scholar] [CrossRef]

- Huang, Y.; Zhou, A.; Gong, B. Study on Mechanical Properties of PET Fiber-Reinforced Coal Gangue Fine Aggregate Concrete. Geofluids 2021, 2021, 6627447. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, S.; Jin, B.; Li, S.; Zheng, C.; Wang, J. Study on the mechanical properties of self-compacting recycled aggregate concrete using CFB slag as fine aggregate. Phys. Chem. Earth Parts A/B/C 2023, 132, 103476. [Google Scholar] [CrossRef]

- Horiguchi, I.; Shirai, A.; Watanabe, M.; Sugihara, S. Fundamental study on concrete with coal gasification slag. Cem. Sci. Concr. Technol. 2012, 66, 615–621. [Google Scholar] [CrossRef][Green Version]

- Jianpeng, Z.; Gang, L.; Yuwei, M.; Hua, T.; Haifeng, X.; Fangfang, Y.; Pengfei, S.; Yangmei, Z. Experimental study on the performance of the self-compacting slag concrete. New Build. Mater. 2017, 44, 43–45+76. [Google Scholar]

- Mingkai, Z.; Yuqiang, W.; Xiao, C. Influence Mechanism of Circulating Fluidized Bed Slag Replacing Machine-Made Sand on Concrete Strength. J. Build. Mater. 2022, 25, 1241–1247. [Google Scholar]

- Guo, Z.; Liu, W.; Wang, C.; He, C.; Zhang, F. Fractal characteristics of mesostructure and optimization of axial compression constitutive model of coal-fired slag concrete. Mater. Today Commun. 2021, 28, 102686. [Google Scholar] [CrossRef]

- Tyulenev, M.; Murko, V.; Khyamyalyainen, V.; Baranova, M.; Zhironkin, S.; Khoreshok, A.; Vöth, S.; Cehlár, M.; Nuray, D.; Janocko, J.; et al. Use of Ash-and-Slag Wastes after Burning of Fine-Dispersed Coal-Washing Wastes. E3S Web Conf. 2018, 41, 01042. [Google Scholar] [CrossRef]

- Poudel, S.; Menda, S.; Useldinger-Hoefs, J.; Guteta, L.E.; Dockter, B.; Gedafa, D.S. The Use of Ground Coal Bottom Ash/Slag as a Cement Replacement for Sustainable Concrete Infrastructure. Materials 2024, 17, 01042. [Google Scholar] [CrossRef] [PubMed]

- Reshma, T.V.; Kumar, P.C. Effect of slag sand as river sand and its influence on compressive strength of the cement mortar. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Korkut, F.; Karalar, M.; Motameni, A.; Althaqafi, E.; Özdöner, N.; Özkılıç, Y.O. Experimental and Numerical Investigation of the Flexural Behavior of Reinforced-Concrete Beams Utilizing Waste Andesite Dust. Materials 2024, 17, 4413. [Google Scholar] [CrossRef] [PubMed]

- Ecemiş, A.S.; Madenci, E.; Karalar, M.; Fayed, S.; Althaqafi, E.; Özkılıç, Y.O. Shear performance of reinforced concrete beams with rubberas form of fiber from waste tire. Steel Compos. Struct. 2024, 51, 337–349. [Google Scholar] [CrossRef]

- Alharthai, M.; Özkılıç, Y.O.; Karalar, M.; Mydin, M.A.O.; Özdöner, N.; Çelik, A.İ. Performance of aerated lightweighted concrete usingaluminum lathe and pumice under elevated temperature. Steel Compos. Struct. 2024, 51, 271–288. [Google Scholar] [CrossRef]

- GB175-2007; Common Portland Cement. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China & China National Standardization Administration: Beijing, China, 2007.

- JGJ 55-2011; Specification for the Design of Ordinary Concrete Ratio. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China: Beijing, China, 2019.

- GB/T 50080-2016; Standard of Test Methods for Properties of Ordinary Concrete Mixes. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China & General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2016.

- GB/T 50081-2019; Standard of Test Methods for Physical and Mechanical Properties of Concrete. Ministry of Housing and Urban-Rural Construction of the People’s Republic of China & State Administration for Market Regulation of the People’s Republic of China: Beijing, China, 2019.

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on workability and strength properties of concrete. J. Clean. Prod. 2016, 112, 620–630. [Google Scholar] [CrossRef]

- Singh, M.; Siddique, R. Strength properties and micro-structural properties of concrete containing coal bottom ash as partial replacement of fine aggregate. Constr. Build. Mater. 2014, 50, 246–256. [Google Scholar] [CrossRef]

- Juntao, H.; Xiangdong, S. Experimental study on early mechanical properties of natural lightweight aggregate concrete with external mixing fly ash. Bull. Chin. Ceram. Soc. 2012, 31, 847–851. [Google Scholar] [CrossRef]

- Chanda, S.S.; Patel, S.K.; Nayak, A.N.; Mohanty, C.R. Performance evaluation on bond, durability, micro-structure, cost effectiveness and environmental impacts of fly ash cenosphere based structural lightweight concrete. Constr. Build. Mater. 2023, 397, 132429. [Google Scholar] [CrossRef]

- Ma, X.; He, T.; Xu, Y.; Yang, R.; Sun, Y. Hydration reaction and compressive strength of small amount of silica fume on cement-fly ash matrix. Case Stud. Constr. Mater. 2022, 16, e00989. [Google Scholar] [CrossRef]

- Carreira, D.J.; Kuanghan, C. Stress-strain relationship for plain concrete in compression. ACI J. Proc. 1985, 82, 797–804. [Google Scholar]

- Zhenhai, G. Principles and Applications of Strength and Constitutive Relationship of Concrete; China Architecture & Building Press: Beijing, China, 2004; p. 247. [Google Scholar]

- Weibull, W. A statistical distribution function of wide applicability. J. Appl. Mech. Trans. ASME 1951, 18, 293–297. [Google Scholar] [CrossRef]

- Lemaitre, J. Evalution of dissipation and damage in metals submitted to dynamic loading. In Proceedings of the International Conference of Mechanical Behavior of Materials, Kyoto, Japan, 15–20 August 1971. [Google Scholar]

- Zhiqiang, L.; Guoqing, W.; Sen, Y.; Guannan, J. Experimental study on mechanical properties and stress-strain constitutive relations of desert sand concrete. Chin. J. Appl. Mech. 2019, 36, 1131–1137. [Google Scholar]

| Properties | Cement | Limit as Per GB175-2007 |

|---|---|---|

| Fineness (m2·kg) | 356.4 | Minimum 300 |

| Soundness: pat test | Pass | No cracks or bends |

| Initial setting time (min) | 178 | Minimum 45 |

| Final setting time (min) | 228 | Maximum 600 |

| 3-day compressive strength [11] | 30.6 | Minimum 22.0 |

| 3-day flexural strength [11] | 6.4 | Minimum 4.0 |

| MgO (%) | 2.13 | Maximum 5.0 |

| SO3 (%) | 2.58 | Maximum 3.5 |

| LOI (%) | 1.10 | Maximum 5.0 |

| Grade | Fineness/% | Loss on Ignition/% | Water Demand Ratio/% | Moisture Content/% |

|---|---|---|---|---|

| Ⅰ | 7.7 | 2.1 | 94 | 0.3 |

| SiO2 | Al2O3 | CaO | Fe2O3 | TiO2 | SO3 | MgO | K2O | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|---|

| 42.16 | 16.85 | 12.64 | 10.12 | 0.86 | 9.96 | 3.78 | 1.15 | 1.92 | 0.56 |

| Test Number | Coal-Fired Slag Replacement Ratio/% | Water/kg·m−3 | Cement/kg·m−3 | Fly Ash/kg·m−3 | Slags/kg·m−3 | Sand/kg·m−3 | Rock/kg·m−3 | Water-Reducing Agent/kg·m−3 |

|---|---|---|---|---|---|---|---|---|

| SC-0 | 0 | 175 | 350 | 39 | 0 | 793 | 1073 | 3.89 |

| SC-10 | 10 | 175 | 350 | 39 | 79 | 714 | 1073 | 3.89 |

| SC-20 | 20 | 175 | 350 | 39 | 159 | 634 | 1073 | 3.89 |

| SC-30 | 30 | 175 | 350 | 39 | 238 | 555 | 1073 | 3.89 |

| SC-40 | 40 | 175 | 350 | 39 | 317 | 476 | 1073 | 3.89 |

| SC-50 | 50 | 175 | 350 | 39 | 397 | 397 | 1073 | 3.89 |

| SC-60 | 60 | 175 | 350 | 39 | 476 | 317 | 1073 | 3.89 |

| SC-70 | 70 | 175 | 350 | 39 | 555 | 238 | 1073 | 3.89 |

| SC-80 | 80 | 175 | 350 | 39 | 634 | 159 | 1073 | 3.89 |

| SC-90 | 90 | 175 | 350 | 39 | 714 | 79 | 1073 | 3.89 |

| SC-100 | 100 | 175 | 350 | 39 | 793 | 0 | 1073 | 3.89 |

| Test Number | Cubic Compressive Strength/MPa | Splitting Tensile Strength/MPa | Axial Compressive Strength/MPa | Axial Compressive Strain | Static Elastic Modulus/MPa | Slump/mm |

|---|---|---|---|---|---|---|

| SC-0 | 65.24 | 2.24 | 55.33 | 5.36 × 10−3 | 45,250 | 270 |

| SC-10 | 69.49 | 2.62 | 57.23 | 5.46 × 10−3 | 41,700 | 276 |

| SC-20 | 65.78 | 3.06 | 56.28 | 5.34 × 10−3 | 40,267 | 268 |

| SC-30 | 68.72 | 3.12 | 53.70 | 5.40 × 10−3 | 43,067 | 248 |

| SC-40 | 63.02 | 3.86 | 41.33 | 5.32 × 10−3 | 41,200 | 213 |

| SC-50 | 65.61 | 3.50 | 56.22 | 5.37 × 10−3 | 41,667 | 190 |

| SC-60 | 65.66 | 2.41 | 53.04 | 5.39 × 10−3 | 43,933 | 132 |

| SC-70 | 64.49 | 3.01 | 48.16 | 5.35 × 10−3 | 40,500 | 64 |

| SC-80 | 61.74 | 3.15 | 45.06 | 5.22 × 10−3 | 39,700 | 19 |

| SC-90 | 61.37 | 2.33 | 53.40 | 5.37 × 10−3 | 46,800 | 7 |

| SC-100 | 57.83 | 1.98 | 42.98 | 5.33 × 10−3 | 37,767 | 4 |

| Model Name | Curvilinear Equation |

|---|---|

| Guo-Zhenhai model | |

| Carreira and Chu model |

| Energy Dissipation Coefficient | SC-0 | SC-1 | SC-2 | SC-3 | SC-4 | SC-5 | SC-6 | SC-7 | SC-8 | SC-9 | SC-10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| δ | 0.652 | 0.645 | 0.642 | 0.644 | 0.636 | 0.633 | 0.621 | 0.618 | 0.609 | 0.578 | 0.562 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Li, G.; Yu, D.; Lei, Y.; Zhang, Y. Mechanical Properties and Stress–Strain Constitutive Relations of Coal-Fired Slag Concrete. Buildings 2024, 14, 3103. https://doi.org/10.3390/buildings14103103

Zhang J, Li G, Yu D, Lei Y, Zhang Y. Mechanical Properties and Stress–Strain Constitutive Relations of Coal-Fired Slag Concrete. Buildings. 2024; 14(10):3103. https://doi.org/10.3390/buildings14103103

Chicago/Turabian StyleZhang, Jianpeng, Gang Li, Daidong Yu, Yingdong Lei, and Yonghua Zhang. 2024. "Mechanical Properties and Stress–Strain Constitutive Relations of Coal-Fired Slag Concrete" Buildings 14, no. 10: 3103. https://doi.org/10.3390/buildings14103103

APA StyleZhang, J., Li, G., Yu, D., Lei, Y., & Zhang, Y. (2024). Mechanical Properties and Stress–Strain Constitutive Relations of Coal-Fired Slag Concrete. Buildings, 14(10), 3103. https://doi.org/10.3390/buildings14103103