A Novel Approach to Detecting Blockages in Sewers and Drains: The Reflected Wave Technique

Abstract

1. Introduction

1.1. Methods of Blockage Detection

1.2. The Reflected Wave Technique

2. Materials and Methods

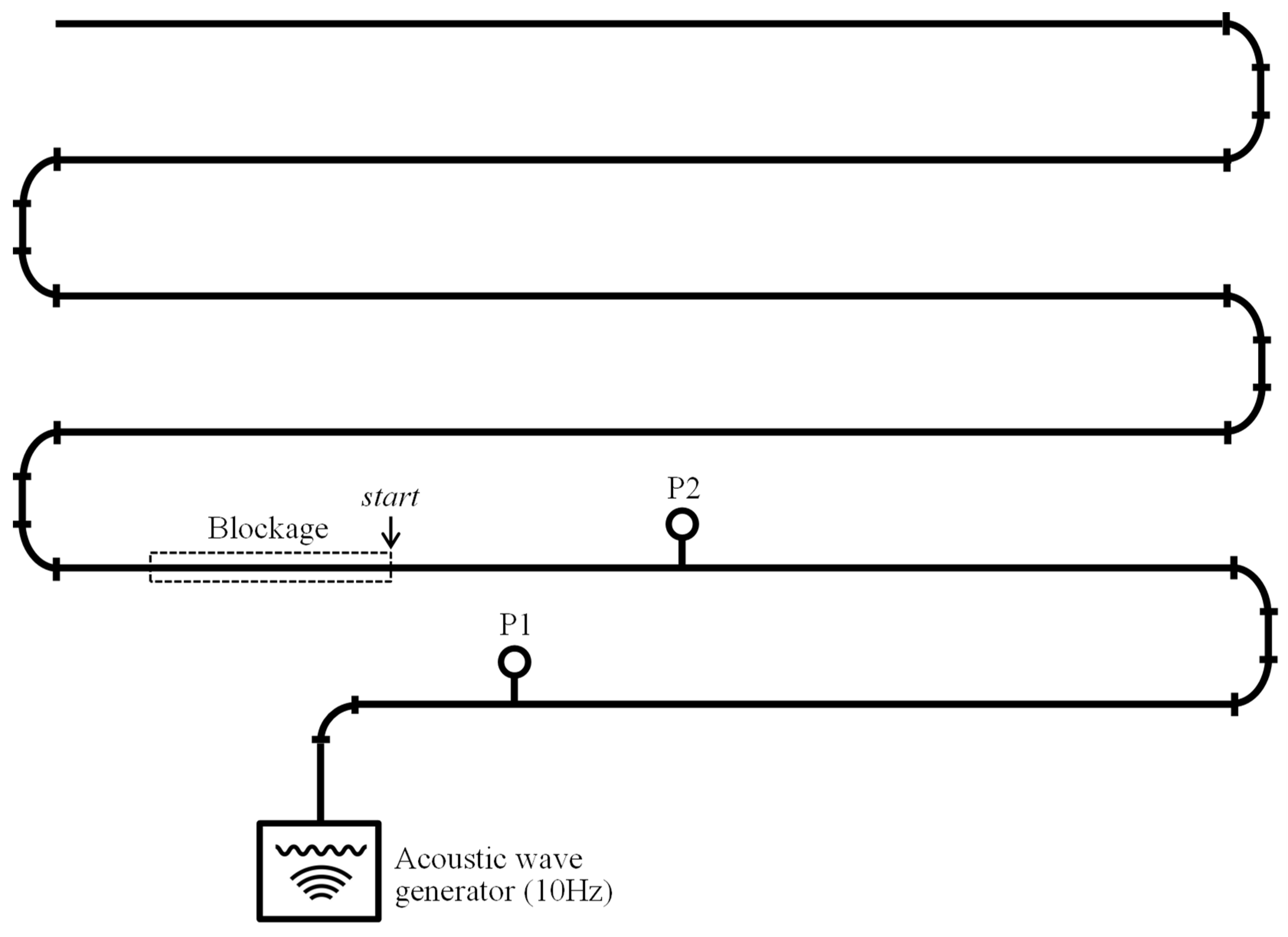

2.1. Apparatus

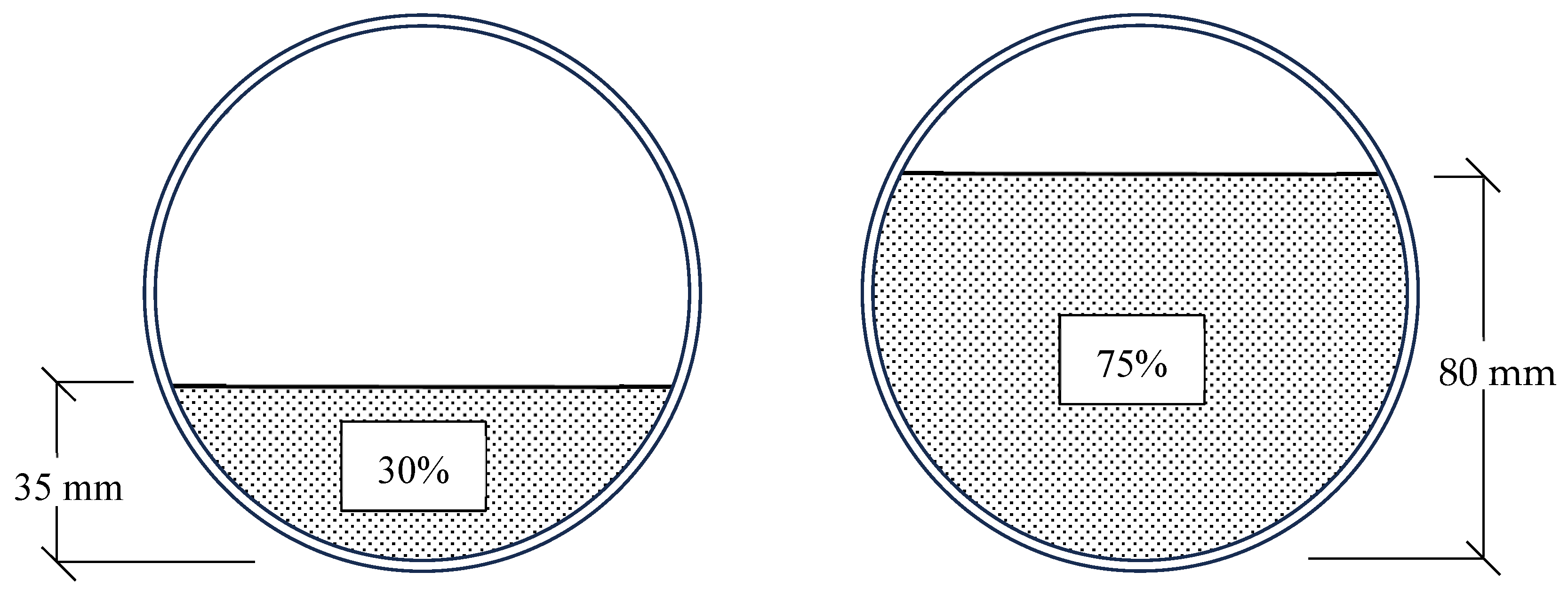

2.2. Simulating a Blockage

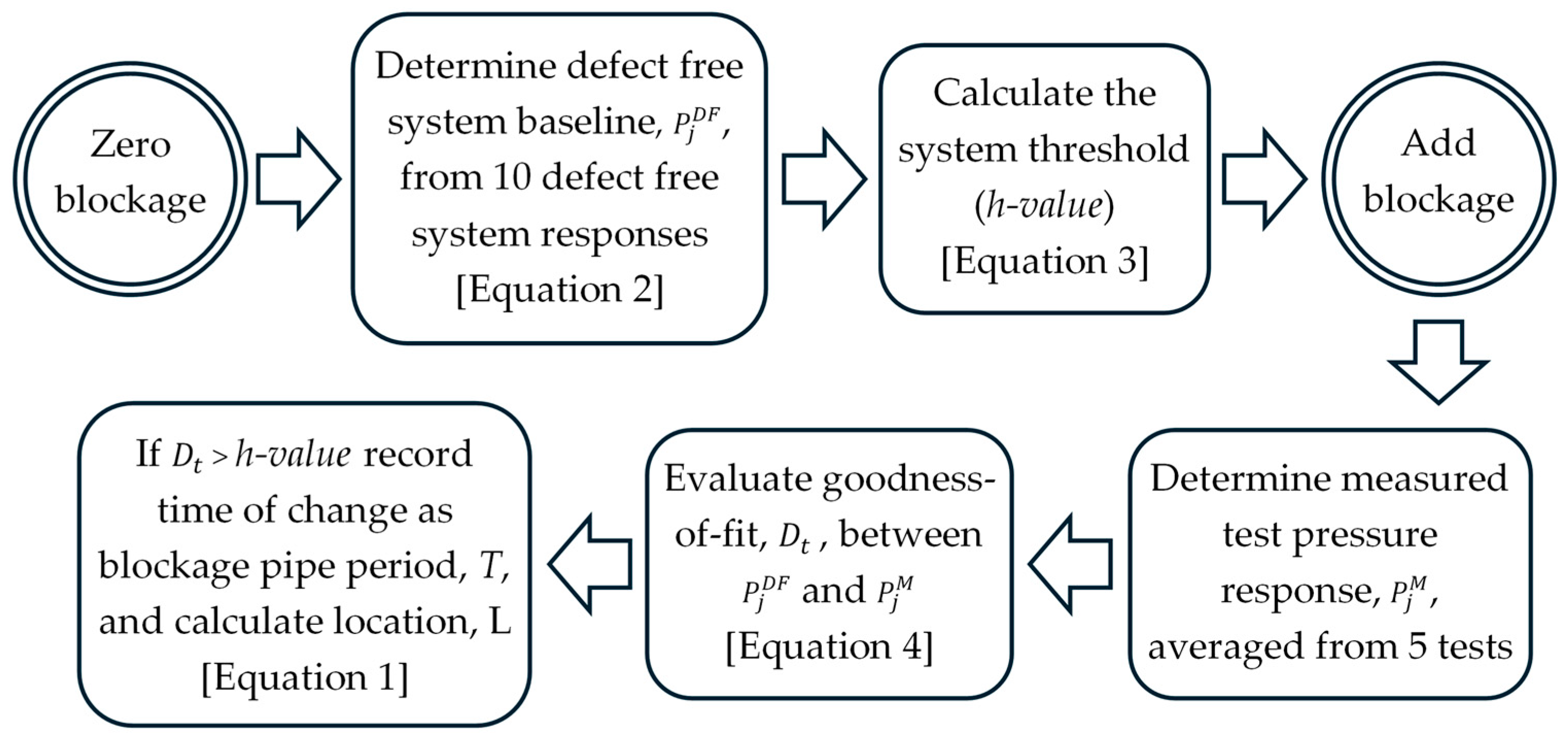

2.3. Test Procedure

2.4. Adding a Blockage

3. Results and Discussion

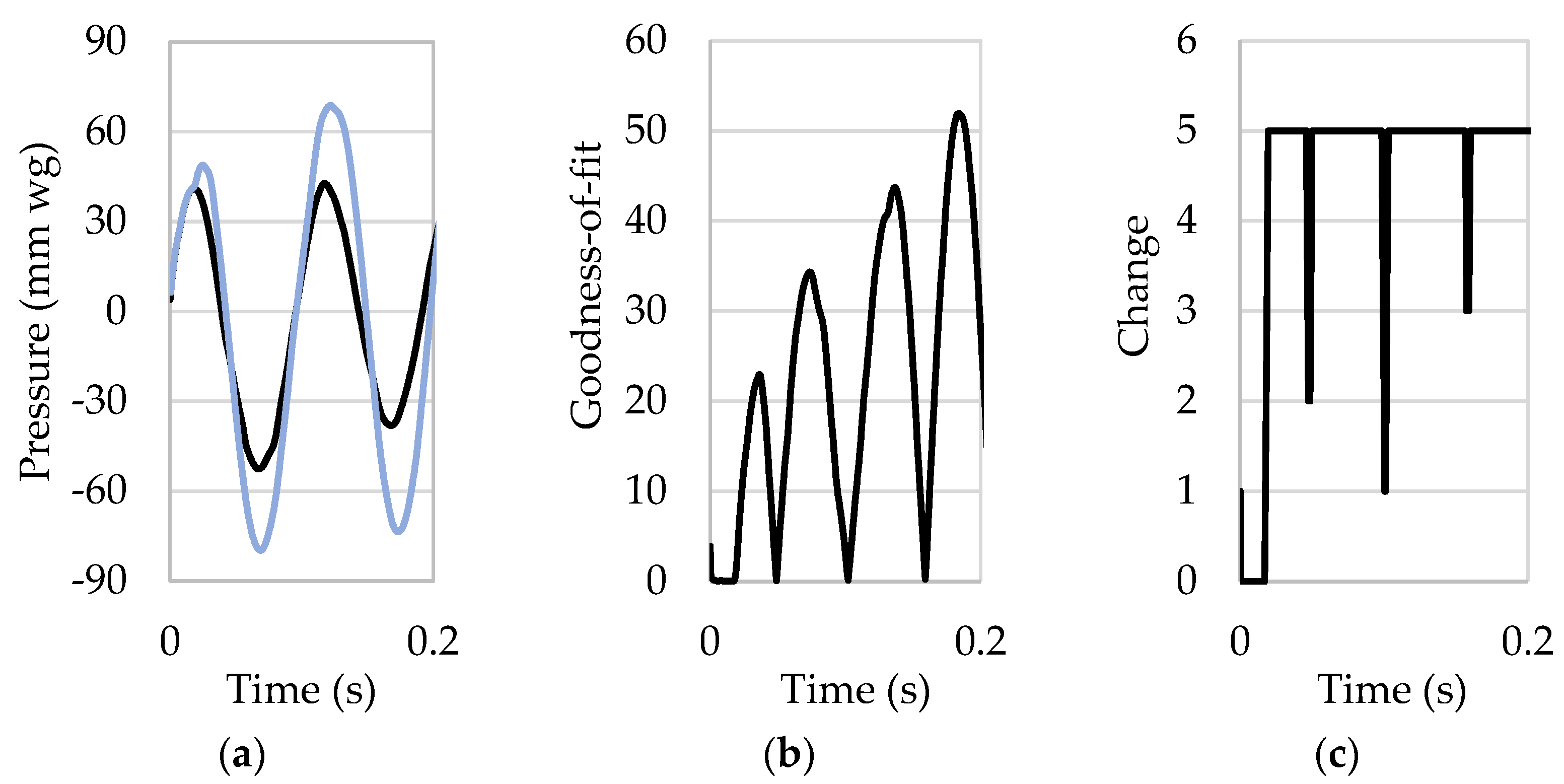

3.1. Determination of the System Threshold (h-Value)

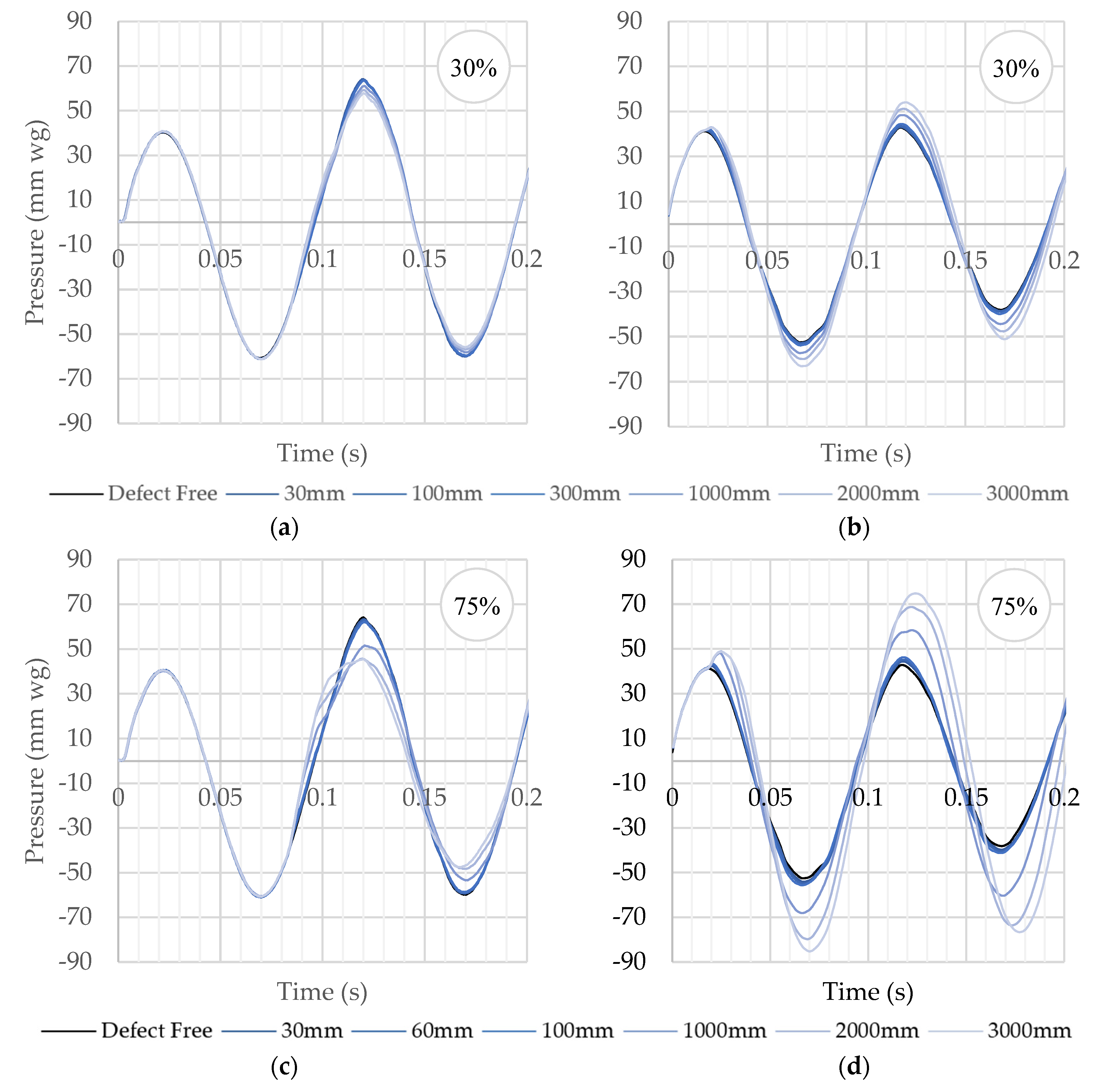

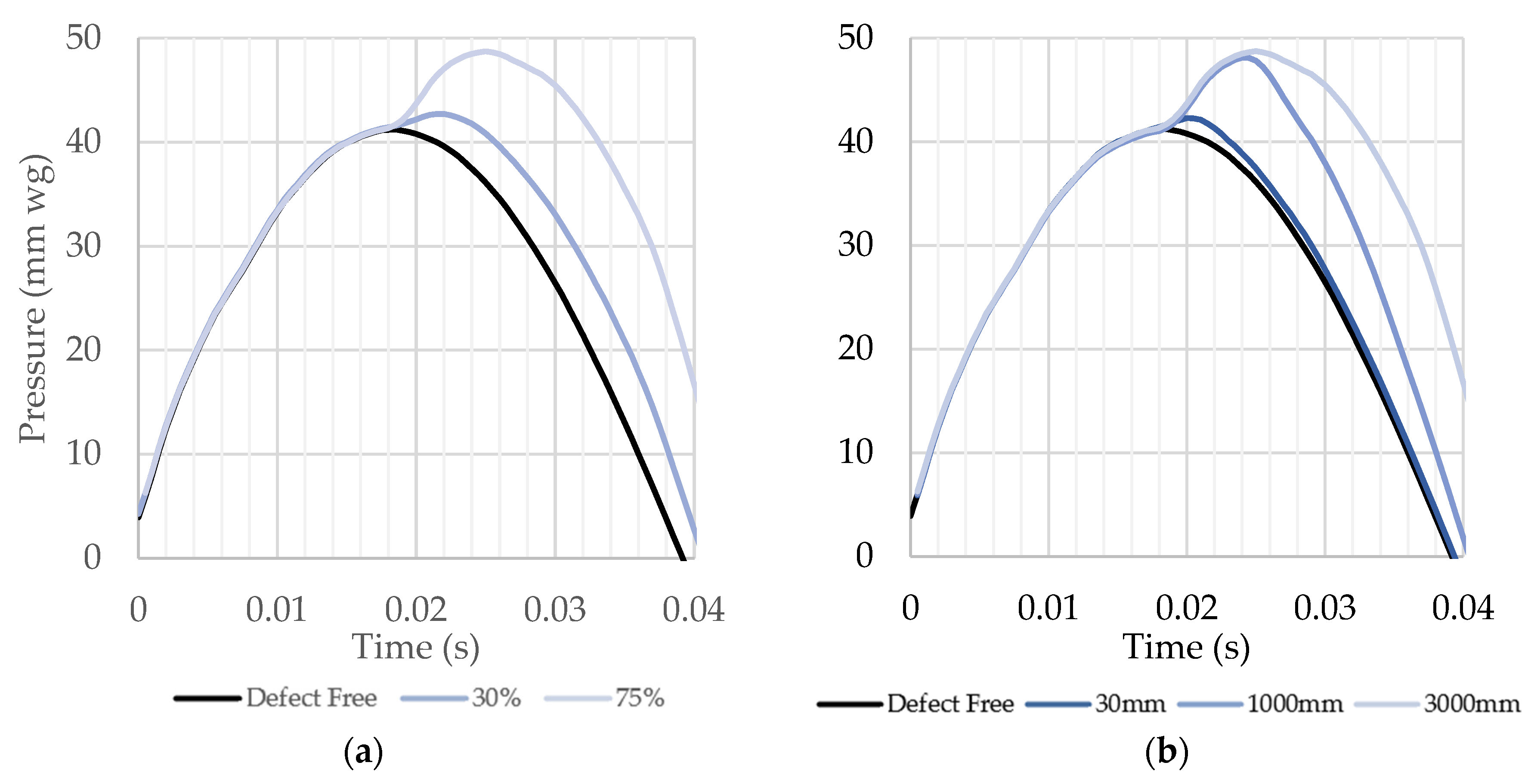

3.2. Measured Test Pressure Responses: Blockage Reflections

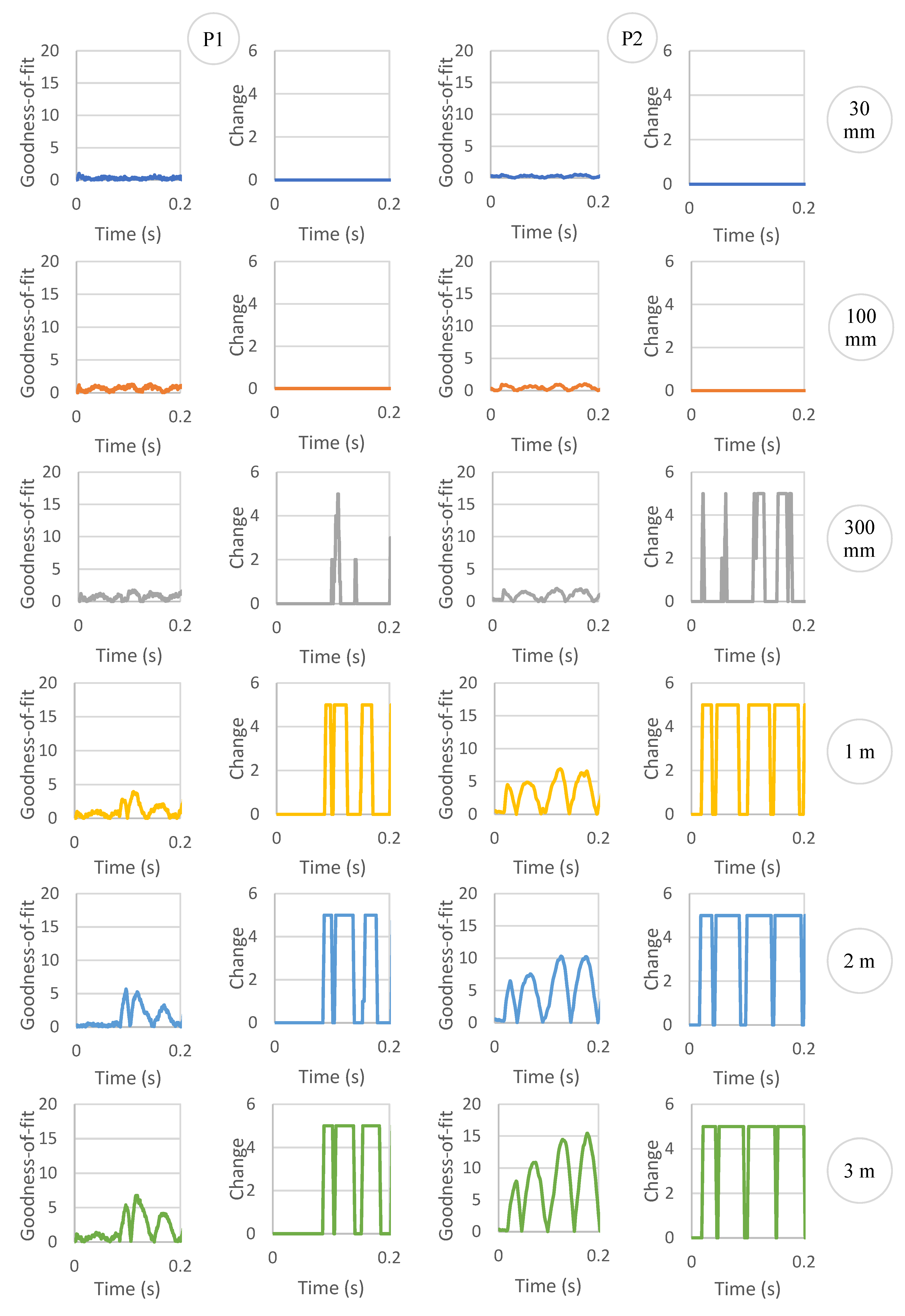

3.3. Applying the Time Series Change Detection Algorithm

4. Conclusions

- Detection and location accuracy: The reflected wave technique demonstrated good accuracy in detecting and locating blockages within sewers and drains. The technique was able to detect blockages with cross-sectional coverage of 30% and 75%, and lengths ranging from 30 mm to 3000 mm.

- Sensor positioning: The accuracy of blockage detection and location improved by having multiple pressure sensors distributed along the drainpipe, with those positioned closer to the blockage showing better accuracy in estimating blockage location (−2% to 3% error) compared to those further from the blockage (4% to 33% error).

- Blockage characteristics: The accuracy of detection and location improved with increased blockage cross-sectional area and length. Whilst small blockages were detected, the technique becomes more reliable as blockages grow in size.

- Non-invasive and rapid monitoring: The reflected wave technique offers a non-invasive and rapid approach to blockage detection and overall system monitoring of sewers and drains. This is a significant advantage over traditional inspection methods that require direct access or camera systems.

- Potential for proactive maintenance: By enabling early detection of blockages through continuous system monitoring, this technique could allow for proactive maintenance of sewer and drain systems, potentially reducing the risk of flooding and associated environmental health hazards.

- Versatility: The technique could potentially be applied to various pipe configurations, geometries, and materials, making it adaptable to different sewer and drain systems.

5. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Drinkwater, A.; Moy, F. Wipes in Sewer Blockage Study: Final Report. Report Ref. No. 21CDP; WS; Water UK: London UK, 2017. [Google Scholar]

- Arthur, S.; Crow, H.; Pedezert, L. Understanding blockage formation in combined sewer networks. Proc. Inst. Civ. Eng. -Water Manag. 2008, 161, 215–221. [Google Scholar] [CrossRef]

- Ofwat. Customer Experiences of Sewer Flooding: A Joint REPORT by CCW and Ofwat; Ofwat: Birmingham, UK, 2022. Available online: https://www.ofwat.gov.uk/wp-content/uploads/2022/05/customer-experiences-of-sewer-flooding-a-joint-report-by-ccw-and-ofwat.pdf (accessed on 30 August 2024).

- Blockages. Available online: https://www.thameswater.co.uk/help/water-and-waste-help/blockages (accessed on 20 May 2024).

- New Proof That Flushing Wipes Is a Major Cause of Sewer Blockages. Available online: https://www.stwater.co.uk/news/news-releases/new-proof-that-flushing-wipes-is-a-major-cause-of-sewer-blockage/ (accessed on 20 May 2024).

- Ashley, R.M.; Bertrand-Krajewski, J.-L.; Hvitved-Jacobsen, T.; Verbanck, M. Solids in Sewers: Characteristics, Effects and Control of Sewer Solids and Associated Pollutants; IWA Publishing: London, UK, 2004. [Google Scholar]

- BS EN 12056-2:2000; Gravity Drainage Systems Inside Buildings—Part 2: Sanitary Pipework, Layout and Calculation. British Standards Institution: London, UK, 2000.

- BS EN 12056-3:2000; Gravity Drainage Systems Inside Buildings—Part 3: Roof Drainage, Layout and Calculation. British Standards Institution: London, UK, 2000.

- Water UK. Design and Construction Guidance for Foul and Surface Water Sewers Offered for Adoption under the Code for Adoption Agreements for Water and Sewerage Companies Operating Wholly or Mainly in England (“the Code”), Approved Version 2.1. 25 May 2021. Water UK: London, UK, 2021. Available online: https://www.water.org.uk/wp-content/uploads/2021/07/SSG-App-C-Des-Con-Guide.pdf (accessed on 29 August 2024).

- Mcdougall, J.A.; Swaffield, J.A. Transport of deformable solids within building drainage networks. Build. Res. Inf. 2007, 35, 220–232. [Google Scholar] [CrossRef]

- Gormley, M.; Campbell, D.P. Modelling water reduction effects: Method and implications for horizontal drainage. Build. Res. Inf. 2006, 34, 131–144. [Google Scholar] [CrossRef]

- Gormley, M.; Campbell, D.P. The transport of discrete solids in above ground near horizontal drainage pipes: A wave speed dependent model. Build. Environ. 2006, 41, 534–547. [Google Scholar] [CrossRef]

- Owolabi, T.A.; Mohandes, S.A.; Zayed, T. Investigating the impact of sewer overflow on the environment: A comprehensive literature review paper. J. Environ. Manag. 2022, 301, 113810. [Google Scholar] [CrossRef] [PubMed]

- Alshami, A.; Elsayed, M.; Ali, E.; Eltoukhy, A.E.E.; Zayed, T. Monitoring Blockage and Overflow Events in Small-Sized Sewer Network Using Contactless Flow Sensors in Hong Kong: Problems, Causes, and Proposed Solution. IEEE Access 2023, 11, 87131–87149. [Google Scholar] [CrossRef]

- Kumar, J.S.J.; Tiwari, J.; Khasnavis, S.; Joseph, A.A. Design of a sewer robot to detect blockages in sewer. Middle-East J. Sci. Res. 2016, 24, 236–239. [Google Scholar] [CrossRef]

- Yu, Y.; Safari, A.; Niu, X.; Drinkwater, B.; Horoshenkov, K.V. Acoustic and ultrasonic techniques for defect detection and condition monitoring in water and sewerage pipes: A review. Appl. Acoust. 2021, 183, 108282. [Google Scholar] [CrossRef]

- Bin Ali, M.T.; Horoshenkov, K.V.; Tait, S.J. Rapid detection of sewer defects and blockages using acoustic-based instrumentation. Water Sci. Technol. 2011, 64, 1700–1707. [Google Scholar] [CrossRef] [PubMed]

- Mabpa, P.; Na Ayudhya, P.N.; Kunthong, J. Clogged Pipe Detection and Monitoring by Using Acoustic Analysis Methodology. In Proceedings of the 17th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Phuket, Thailand, 24–27 June 2020; pp. 177–180. [Google Scholar] [CrossRef]

- Abdullahi, M.; Oyadiji, S.O. Simulation and detection of blockage in a pipe under mean fluid flow using acoustic wave propagation technique. Struct. Control Health Monit. 2020, 27, e2449. [Google Scholar] [CrossRef]

- Nasraoui, S.; Louati, M.; Ghidaoui, M.S. Blockage detection in pressurized water-filled pipe using high frequency acoustic waves. Mech. Syst. Signal Process. 2023, 185, 109817. [Google Scholar] [CrossRef]

- Papadopoulou, K.A.; Shamout, M.N.; Lennox, B.; Mackay, D.; Taylo, A.R. An evaluation of acoustic reflectometry for leakage and blockage detection. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2008, 222, 959–966. [Google Scholar] [CrossRef]

- Monteiro, P.C.C., Jr.; da Silva Monteiro, L.L.; Netto, T.A.; Vidal, J.L.A. Assessment of the Acoustic Reflectometry Technique to Detect Pipe Blockages. ASME. J. Offshore Mech. Arct. Eng. 2021, 143, 051801. [Google Scholar] [CrossRef]

- Kelly, D.A.; Swaffield, J.A.; Jack, L.B.; Campbell, D.P.; Gormley, M. Pressure transient identification of depleted appliance trap seals: A pressure pulse technique. Build. Serv. Eng. Res. Technol. 2008, 29, 165–181. [Google Scholar] [CrossRef]

- Kelly, D.A.; Swaffield, J.A.; Jack, L.B.; Campbell, D.P.; Gormley, M. Pressure transient identification of depleted appliance trap seals: A sinusoidal wave technique. Build. Serv. Eng. Res. Technol. 2008, 29, 219–232. [Google Scholar] [CrossRef]

- Kelly, D.A.; Gormley, M. Automatic detection of depleted fixture trap seals using the reflected wave technique. Build. Serv. Eng. Res. Technol. 2013, 35, 254–267. [Google Scholar] [CrossRef]

- Furse, C.; Kafal, M.; Razzaghi, R.; Shin, Y.-J. Fault Diagnosis for Electrical Systems and Power Networks: A Review. IEEE Sens. J. 2021, 21, 888–906. [Google Scholar] [CrossRef]

- Kingston, S.; Benoit, E.; Edun, A.S.; Elyasichamazkoti, F.; Sweeney, D.E.; Harley, J.B.; Kuhn, P.K.; Furse, C.M. A SSTDR Methodology, Implementations, and Challenges. Sensors 2021, 21, 5268. [Google Scholar] [CrossRef] [PubMed]

- Sharp, D.B.; Campbell, D.M. Leak detection in pipes using acoustic pulse reflectometry. Acustica 1997, 83, 560–566. [Google Scholar]

- Swaffield, J.A.; Boldy, A.P. Pressure Surge in Pipe and Duct Systems; Avebury Technical Press: Wiltshire, UK, 1993. [Google Scholar]

- A Guide to Drains and Sewers. Scottish Water. Available online: https://www.scottishwater.co.uk/-/media/ScottishWater/Document-Hub/Your-Home/Pipework-in-your-home/181223SW_Drains_Sewers_Dec23.pdf (accessed on 29 August 2024).

- Kelly, D.A. Identification of depleted appliance trap seals within the building drainage and ventilation system—A transient based technique. In Proceedings of the CIB W062 33rd International Symposium on Water Supply and Drainage for Buildings, Brno, Czech Republic, 19–21 September 2007. [Google Scholar]

- Swaffield, J.A. Influence of unsteady friction on trap seal depletion. In Proceedings of the CIB W062 33rd International Symposium on Water Supply and Drainage for Buildings, Brno, Czech Republic, 19–21 September 2007. [Google Scholar]

- Sharp, D.B. Increasing the length of tubular objects that can be measured using acoustic pulse reflectometry. Meas. Sci. Technol. 1998, 9, 1469–1479. [Google Scholar] [CrossRef]

| Cross-Sectional Coverage | Cross-Sectional Area (cm2) | Length (mm) | Volume (m3) |

|---|---|---|---|

| 30% | 23.6 | 30 | 0.07 |

| 100 | 0.24 | ||

| 300 | 0.71 | ||

| 1000 | 2.36 | ||

| 2000 | 4.71 | ||

| 3000 | 7.07 | ||

| 75% | 58.9 | 30 | 0.18 |

| 60 | 0.35 | ||

| 100 | 0.59 | ||

| 1000 | 5.89 | ||

| 2000 | 11.78 | ||

| 3000 | 17.67 |

| Cross-Sectional Coverage | Pressure Sensor | Blockage Characteristics | Detected Blockage Information | Variance | |||

|---|---|---|---|---|---|---|---|

| Location (m) | Pipe Period (s) | Length (mm) | Pipe Period (s) | Location (m) | |||

| 30% | P1 | 14 | 0.0816 | 30 | #N/A | #N/A | #N/A |

| 100 | #N/A | #N/A | #N/A | ||||

| 300 | 0.1085 | 18.61 | 33% | ||||

| 1000 | 0.0875 | 15.01 | 7% | ||||

| 2000 | 0.0865 | 14.83 | 6% | ||||

| 3000 | 0.0880 | 15.09 | 8% | ||||

| P2 | 3.4 | 0.0198 | 30 | #N/A | #N/A | #N/A | |

| 100 | #N/A | #N/A | #N/A | ||||

| 300 | 0.0205 | 3.52 | 3% | ||||

| 1000 | 0.0200 | 3.43 | 1% | ||||

| 2000 | 0.0200 | 3.43 | 1% | ||||

| 3000 | 0.0205 | 3.52 | 3% | ||||

| 75% | P1 | 14 | 0.0816 | 30 | #N/A | #N/A | #N/A |

| 60 | 0.1070 | 18.35 | 31% | ||||

| 100 | 0.0850 | 14.58 | 4% | ||||

| 1000 | 0.0855 | 14.66 | 5% | ||||

| 2000 | 0.0845 | 14.49 | 4% | ||||

| 3000 | 0.0850 | 14.58 | 4% | ||||

| P2 | 3.4 | 0.0198 | 30 | 0.0200 | 3.43 | 1% | |

| 60 | 0.0195 | 3.34 | −2% | ||||

| 100 | 0.0195 | 3.34 | −2% | ||||

| 1000 | 0.0200 | 3.43 | 1% | ||||

| 2000 | 0.0195 | 3.34 | −2% | ||||

| 3000 | 0.0195 | 3.34 | −2% | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kelly, D.A.; Garden, M.; Sharif, K.; Campbell, D.; Gormley, M. A Novel Approach to Detecting Blockages in Sewers and Drains: The Reflected Wave Technique. Buildings 2024, 14, 3138. https://doi.org/10.3390/buildings14103138

Kelly DA, Garden M, Sharif K, Campbell D, Gormley M. A Novel Approach to Detecting Blockages in Sewers and Drains: The Reflected Wave Technique. Buildings. 2024; 14(10):3138. https://doi.org/10.3390/buildings14103138

Chicago/Turabian StyleKelly, David A., Mark Garden, Khanda Sharif, David Campbell, and Michael Gormley. 2024. "A Novel Approach to Detecting Blockages in Sewers and Drains: The Reflected Wave Technique" Buildings 14, no. 10: 3138. https://doi.org/10.3390/buildings14103138

APA StyleKelly, D. A., Garden, M., Sharif, K., Campbell, D., & Gormley, M. (2024). A Novel Approach to Detecting Blockages in Sewers and Drains: The Reflected Wave Technique. Buildings, 14(10), 3138. https://doi.org/10.3390/buildings14103138