Numerical Simulation for Risk Assessment of Tunnel Construction through Fault Fracture Zones

Abstract

1. Introduction

2. Model Construction

2.1. Selection of Constitutive Model

2.1.1. Mohr–Coulomb Model

2.1.2. Concrete Damaged Plasticity (CDP) Model

2.2. Model Setup and Assumptions

- Isotropic, homogeneous rock and soil: The surrounding rock and soil bodies were assumed to be isotropic and homogeneous. This assumption simplifies the complex geological conditions but still allows for an accurate representation of the general behavior of fractured rocks in fault zones.

- Simplified shield–soil interaction: The interaction between the shield shell and the surrounding rock was modeled using a face-to-face frictional contact approach. The friction coefficient was calibrated to replicate the realistic friction between the shield and fault zone materials.

- Grouting process assumptions: The grouting process, which fills the gap between the lining segments and the surrounding rock, was simplified as an elastic, isostatic layer. It was assumed that after the grouting material hardens; it forms a cohesive bond with the surrounding rock, providing adequate support to resist further deformation.

- Support and grouting pressures: The support pressure at the tunnel’s palm face was assumed to be in equilibrium with the surrounding soil pressure, following established geotechnical principles. Grouting pressures were applied to the shield tail in phases and adjusted to reflect the decreasing pressure as the grout hardened.

2.3. Boundary Conditions and Load Application

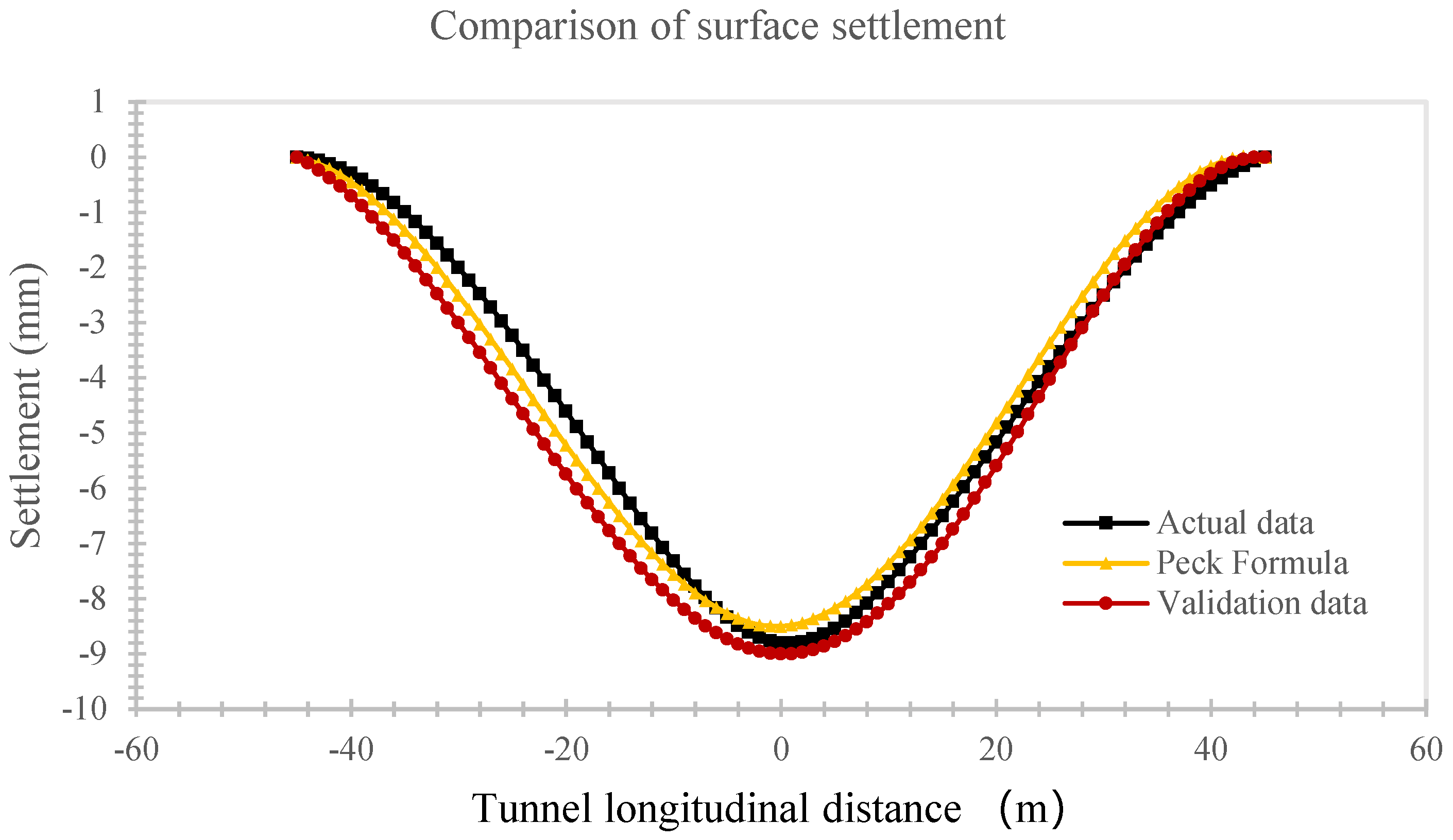

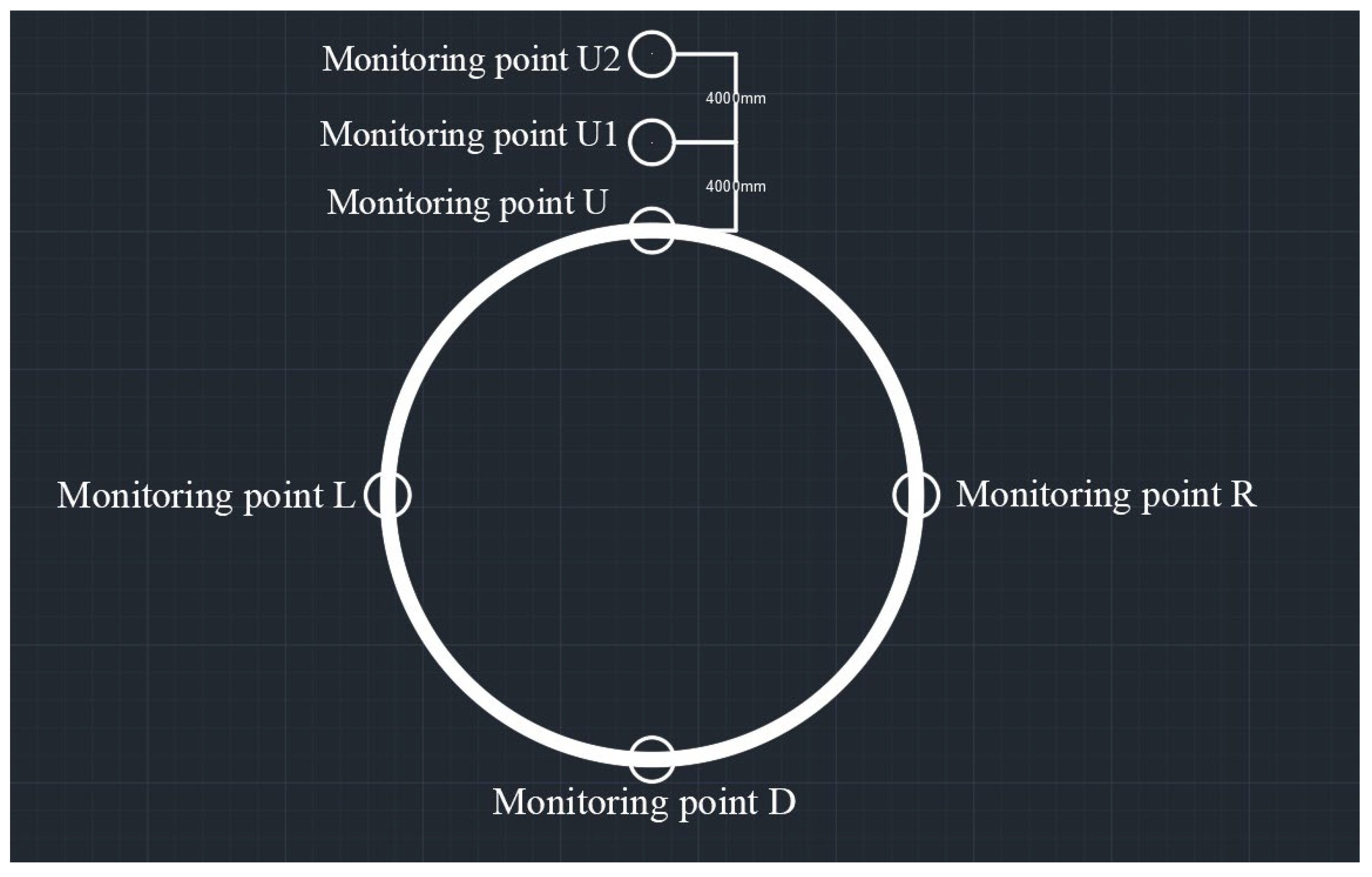

3. Validation of the Constructed Model

4. Modelling Program in This Study

5. Results and Discussion

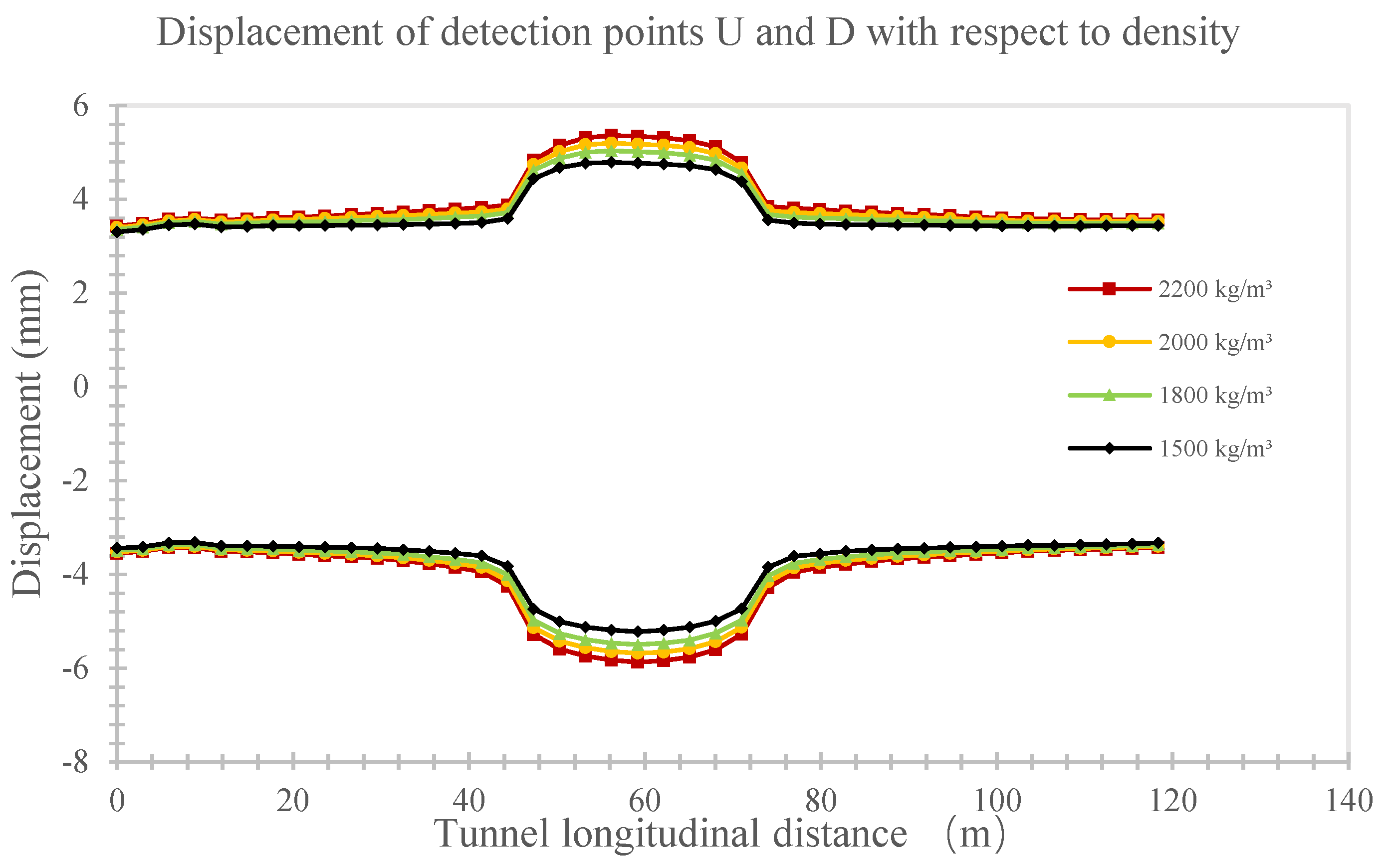

5.1. Effect of Density

5.2. Effect of Poisson’s Ratio

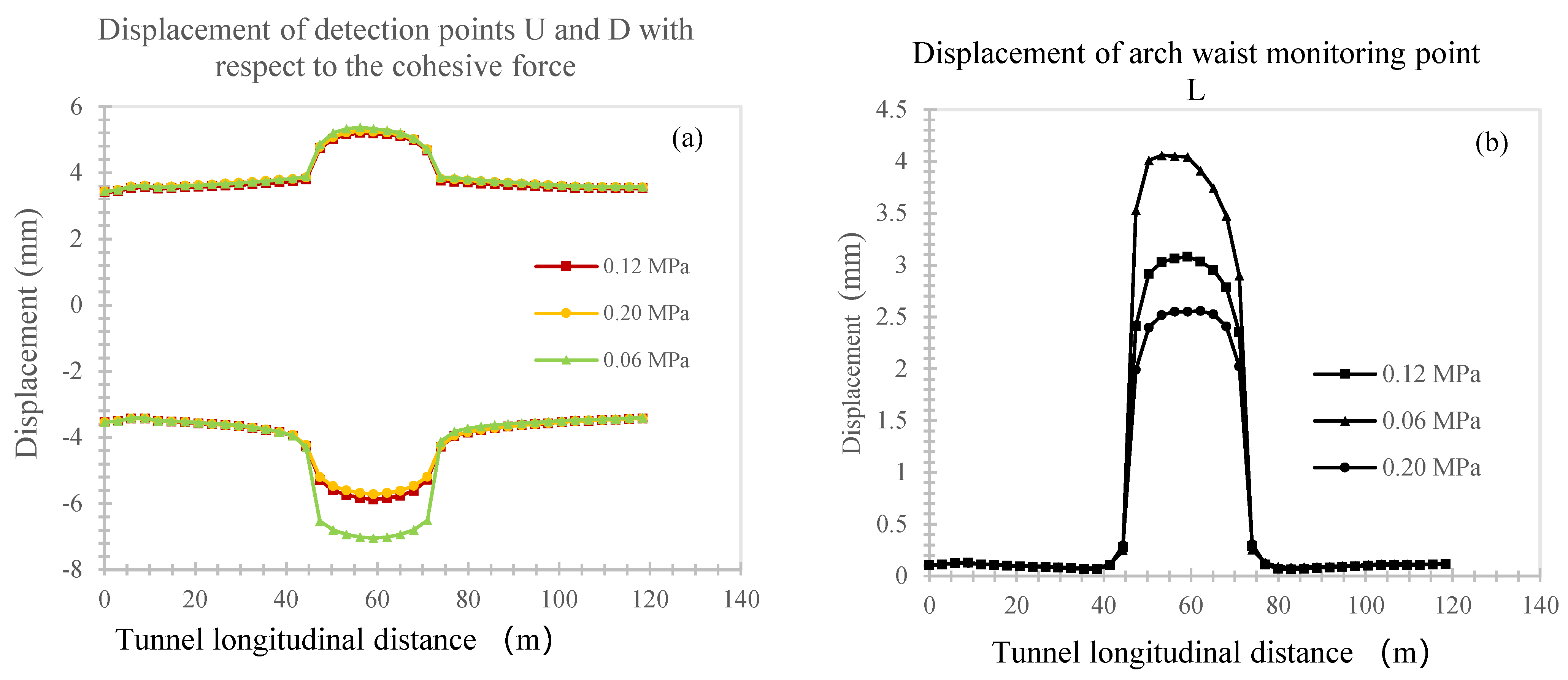

5.3. Effect of Crushing Belt Cohesion

5.4. Effect of Grouting Pressure

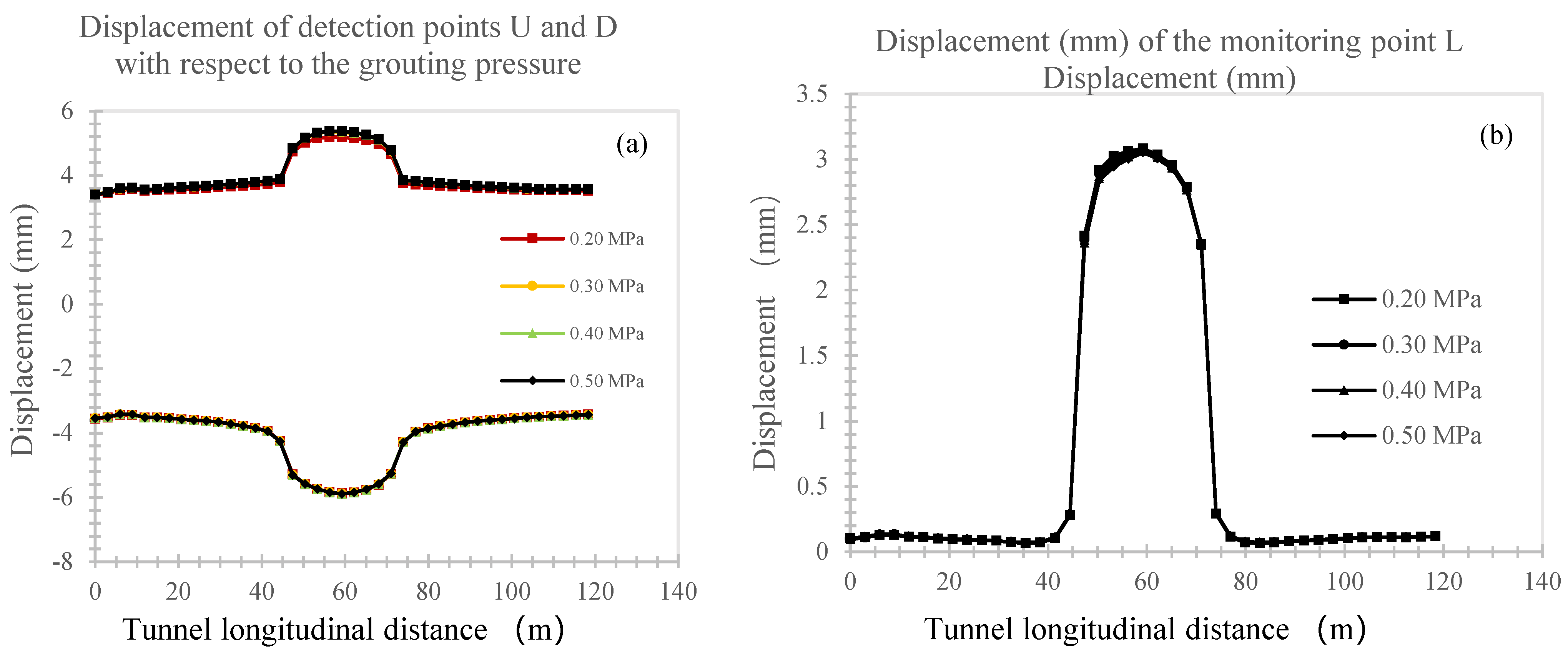

5.5. Effect of Slurry Strength

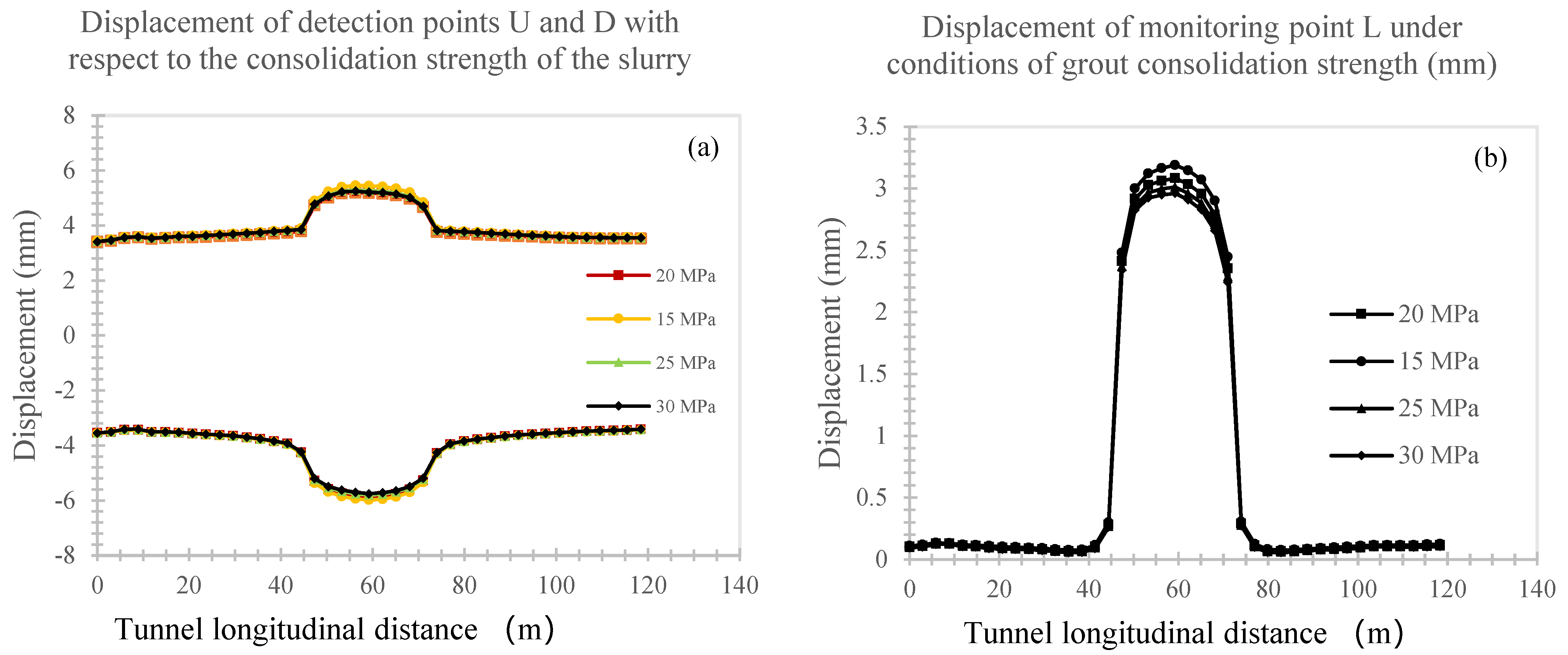

6. Conclusions

- Higher rock densities and Poisson’s ratios lead to increased vertical and horizontal displacements, indicating the necessity for stronger support systems in denser rock areas.

- The cohesion of the fault zone significantly influences stability; lower cohesion results in greater settlement and lateral displacement, underscoring the importance of stabilizing weak zones.

- While grouting pressure has a minimal direct impact on deformation, it is essential for stabilizing the tunnel lining, thereby enhancing overall structural integrity.

- Increased slurry strength markedly reduces vertical and horizontal deformation, facilitating better load transfer and ensuring the structural integrity of the tunnel.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, S.Y.; Jiang, C.; Huang, L. Public health impacts from subway noise: Case study Hong Kong. J. Acoust. Soc. Am. 2019, 145, 1867. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, W.; Wu, Z.; Dai, Y.; Li, Y.; Dai, H. Effect of periodic pile row in subway vibration Isolation. Procedia Eng. 2017, 199, 302–309. [Google Scholar] [CrossRef]

- Wang, L.; Liu, P.; Jing, Q.; Liu, Y.; Wang, W.; Zhang, Y.; Li, Z. Strength properties and thermal conductivity of concrete with the addition of expanded perlite filled with aerogel. Constr. Build. Mater. 2018, 188, 747–757. [Google Scholar] [CrossRef]

- Vogiatzis, K. Protection of the Cultural Heritage from Underground Metro Vibration and Ground-Borne Noise in Athens Centre: The Case of the Kerameikos Archaeological Museum and Gazi Cultural Centre. Int. J. Acoust. Vib. 2012, 17, 59. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Işıkdağ, B. Effect of expanded perlite aggregate on the properties of lightweight concrete. J. Mater. Process. Technol. 2008, 204, 34–38. [Google Scholar] [CrossRef]

- Song, J.; Xu, M.; Tan, C.; You, F.; Wang, X.; Zhou, S. Study on an epoxy resin system used to improve the elasticity of oil-well cement-based composites. Materials 2022, 15, 5258. [Google Scholar] [CrossRef] [PubMed]

- Sheng, T.; Bian, X.; Liu, G.; Xiao, C.; Chen, Y.; Li, Y. Experimental study on the sandbag isolator of buildings for subway-induced vertical vibration and secondary air-borne noise. Geotext. Geomembr. 2020, 48, 504–515. [Google Scholar] [CrossRef]

- Shahrour, I.; Khoshnoudian, F.; Sadek, M.; Mroueh, H. Elastoplastic analysis of the seismic response of tunnels in soft soils. Tunn. Undergr. Space Technol. 2010, 25, 478–482. [Google Scholar] [CrossRef]

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011, 43, 671–676. [Google Scholar] [CrossRef]

- Reda Taha, M.M.; El-Dieb, A.S.; Abd El-Wahab, M.A.; Abdel-Hameed, M.E. Mechanical, Fracture, and Microstructural Investigations of Rubber Concrete. J. Mater. Civ. Eng. 2008, 20, 640–649. [Google Scholar] [CrossRef]

- Rashad, A.M. A synopsis about perlite as building material—A best practice guide for Civil Engineer. Constr. Build. Mater. 2016, 121, 338–353. [Google Scholar] [CrossRef]

- Raj, B.; Ganesan, N.; Shashikala, A. Engineering properties of self-compacting rubberized concrete. J. Reinf. Plast. Compos. 2011, 30, 1923–1930. [Google Scholar] [CrossRef]

- Pierce, C.; Williams, R. Sustainable Waste Management and Recycling: Challenges and Opportunities. Volume 3-Used/Post-Consumer Tyres. In Proceedings of the International Conference Organised by the Concrete and Masonry Research Group and held at Kingston University, London, UK, 14–15 September 2004; Volume 14, p. 15. [Google Scholar]

- Ohama, Y.; Demura, K. Relation between curing conditions and compressive strength of polyester resin concrete. Int. J. Cem. Compos. Lightweight Concr. 1982, 4, 241–244. [Google Scholar] [CrossRef]

- Yao, C.; Zhong, H.; Zhu, Z. Development of a Large Shaking Table Test for Sand Liquefaction Analysis. Lithosphere 2024, 2024. [Google Scholar] [CrossRef]

- Li, Q.; Zhu, Z. Calibration of an elastoplastic model of sand liquefaction using the swarm intelligence with a multi-objective function. J. Rock Mech. Geotech. Eng. 2023, 15, 789–802. [Google Scholar] [CrossRef]

- Zhao, J.; Zhu, Z.; Zhang, D.; Wang, H.; Li, X. Assessment of fabric characteristics with the development of sand liquefaction in cyclic triaxial tests: A DEM study. Soil Dyn. Earthq. Eng. 2024, 176, 108343. [Google Scholar] [CrossRef]

- Niaki, M.H.; Ahangari, M.G.; Fereidoon, A. Mechanical properties of reinforced polymer concrete with three types of resin systems. Proc. Inst. Civ. Eng.-Constr. Mater. 2022, 176, 233–241. [Google Scholar] [CrossRef]

- Neitzel, R.; Gershon, R.R.; Zeltser, M.; Canton, A.; Akram, M. Noise levels associated with New York City’s mass transit systems. Am. J. Public Health 2009, 99, 1393–1399. [Google Scholar] [CrossRef]

- Mahdi, F.; Abbas, H.; Khan, A.A. Flexural, shear and bond strength of polymer concrete utilizing recycled resin obtained from post consumer PET bottles. Constr. Build. Mater. 2013, 44, 798–811. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, C.; Baghbani, A. Initial state of excavated soil and rock (ESR) to influence the stabilisation with cement. Constr. Build. Mater. 2023, 400, 132879. [Google Scholar] [CrossRef]

- Lu, Y.; Leong, E.-C.; Zeng, L.; Xu, C.; Li, B. Suitability charts to select stabilizer for excavated soils and rocks (ESR). Int. J. Geotech. Eng. 2023, 17, 108–123. [Google Scholar] [CrossRef]

- Baghbani, A.; Faradonbeh, R.S.; Lu, Y.; Soltani, A.; Kiany, K.; Baghbani, H.; Abuel-Naga, H.; Samui, P. Enhancing earth dam slope stability prediction with integrated AI and statistical models. Appl. Soft Comput. 2024, 164, 111999. [Google Scholar] [CrossRef]

- El-Hawary, M.M.; Abdel-Fattah, H. Temperature effect on the mechanical behavior of resin concrete. Constr. Build. Mater. 2000, 14, 317–323. [Google Scholar] [CrossRef]

- Fiala, P.; Degrande, G.; Augusztinovicz, F. Numerical modelling of ground-borne noise and vibration in buildings due to surface rail traffic. J. Sound Vib. 2007, 301, 718–738. [Google Scholar] [CrossRef]

- TB 10003-2016; Rail Road Tunnel Design Specification. China Railway Second Academy Engineering Group Limited Liability Company: Beijing, China, 2016.

- GB/T 50218-2014; Rock Classification. People’s Republic of China Industry Standard: Beijing, China, 2014.

- JTG/T D71-2004; Design Specification for Highway Tunnels. Industry standard of the People’s Republic of China: Beijing, China, 2004.

| Density (kg/m3) | Poisson’s Ratio | Modulus of Elasticity (GPa) | Angle of Internal Friction (°) | Cohesive Force (MPa) | |

|---|---|---|---|---|---|

| Condition O | 2200 | 0.4 | 0.445 | 25 | 0.12 |

| Condition A1 | 2000 | 0.4 | 0.445 | 25 | 0.12 |

| Condition A2 | 1800 | 0.4 | 0.445 | 25 | 0.12 |

| Condition A3 | 1500 | 0.4 | 0.445 | 25 | 0.12 |

| Condition B1 | 2200 | 0.35 | 0.445 | 25 | 0.12 |

| Condition B2 | 2200 | 0.45 | 0.445 | 25 | 0.12 |

| Condition B3 | 2200 | 0.5 | 0.445 | 25 | 0.12 |

| Condition C1 | 2200 | 0.4 | 0.8 | 25 | 0.12 |

| Condition C2 | 2200 | 0.4 | 0.6 | 25 | 0.12 |

| Condition C3 | 2200 | 0.4 | 0.3 | 25 | 0.12 |

| Condition D1 | 2200 | 0.4 | 0.445 | 20 | 0.12 |

| Condition D2 | 2200 | 0.4 | 0.445 | 15 | 0.12 |

| Condition E1 | 2200 | 0.4 | 0.445 | 25 | 0.2 |

| Condition E2 | 2200 | 0.4 | 0.445 | 25 | 0.06 |

| Density (kg/m3) | Poisson’s Ratio | Modulus of Elasticity (GPa) | Angle of Internal Friction (°) | Cohesive Force (MPa) | Slurry Strength (MPa) | |

|---|---|---|---|---|---|---|

| Condition O | 2200 | 0.4 | 0.445 | 25 | 0.12 | 0.2 |

| Condition P1 | 2200 | 0.4 | 0.445 | 25 | 0.12 | 0.3 |

| Condition P2 | 2200 | 0.4 | 0.445 | 25 | 0.12 | 0.4 |

| Condition P3 | 2200 | 0.4 | 0.445 | 25 | 0.12 | 0.5 |

| Density (kg/m3) | Poisson’s Ratio | Modulus of Elasticity (GPa) | Angle of Internal Friction (°) | Cohesive Force (MPa) | Slurry Strength (MPa) | |

|---|---|---|---|---|---|---|

| Condition O | 2200 | 0.4 | 0.445 | 25 | 0.12 | 20 |

| Condition S1 | 2200 | 0.4 | 0.445 | 25 | 0.12 | 15 |

| Condition S2 | 2200 | 0.4 | 0.445 | 25 | 0.12 | 25 |

| Condition S3 | 2200 | 0.4 | 0.445 | 25 | 0.12 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nong, X.; Bai, W.; Yi, S.; Lu, Z.; Lu, Y. Numerical Simulation for Risk Assessment of Tunnel Construction through Fault Fracture Zones. Buildings 2024, 14, 3161. https://doi.org/10.3390/buildings14103161

Nong X, Bai W, Yi S, Lu Z, Lu Y. Numerical Simulation for Risk Assessment of Tunnel Construction through Fault Fracture Zones. Buildings. 2024; 14(10):3161. https://doi.org/10.3390/buildings14103161

Chicago/Turabian StyleNong, Xingzhong, Wenfeng Bai, Shixuan Yi, Zizhao Lu, and Yi Lu. 2024. "Numerical Simulation for Risk Assessment of Tunnel Construction through Fault Fracture Zones" Buildings 14, no. 10: 3161. https://doi.org/10.3390/buildings14103161

APA StyleNong, X., Bai, W., Yi, S., Lu, Z., & Lu, Y. (2024). Numerical Simulation for Risk Assessment of Tunnel Construction through Fault Fracture Zones. Buildings, 14(10), 3161. https://doi.org/10.3390/buildings14103161