Use of Waste Slag and Rubber Particles to Make Mortar for Filling the Joints of Snow-Melting Concrete Pavement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Curing of Specimens

2.3. Tests

2.3.1. Compressive Strength

2.3.2. Tensile Strength

2.3.3. Thermal Conductivity Test

2.3.4. Impermeability Pressure Value Test

2.3.5. Freezing and Thawing Resistance

3. Results and Discussion

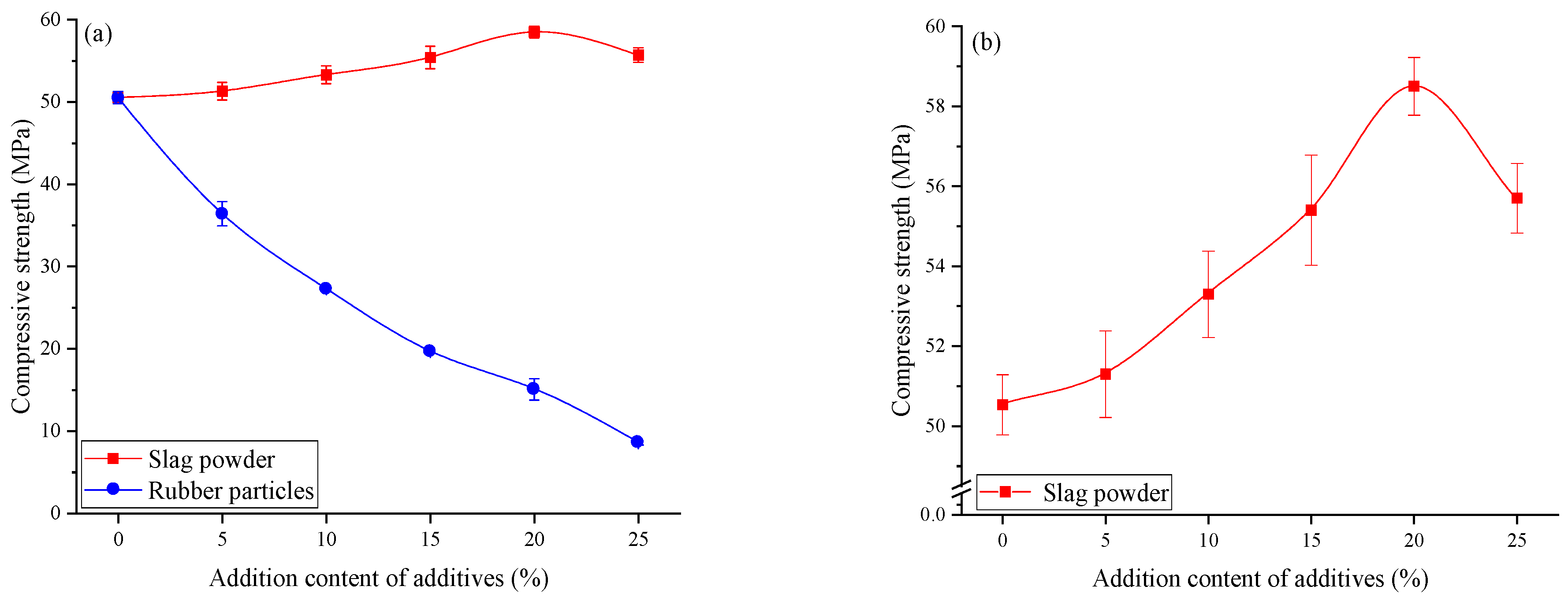

3.1. Mechanical Property

3.2. Thermal Conductivity

3.3. Impermeability Pressure Value

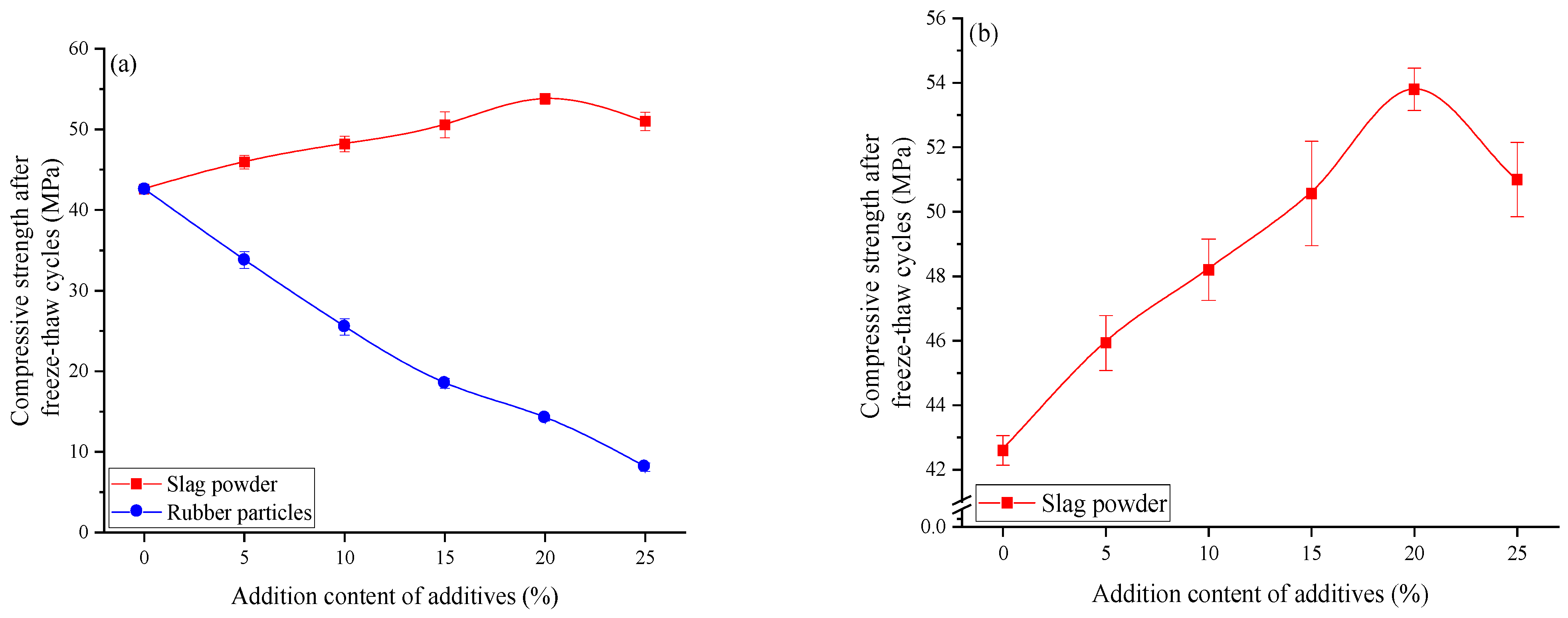

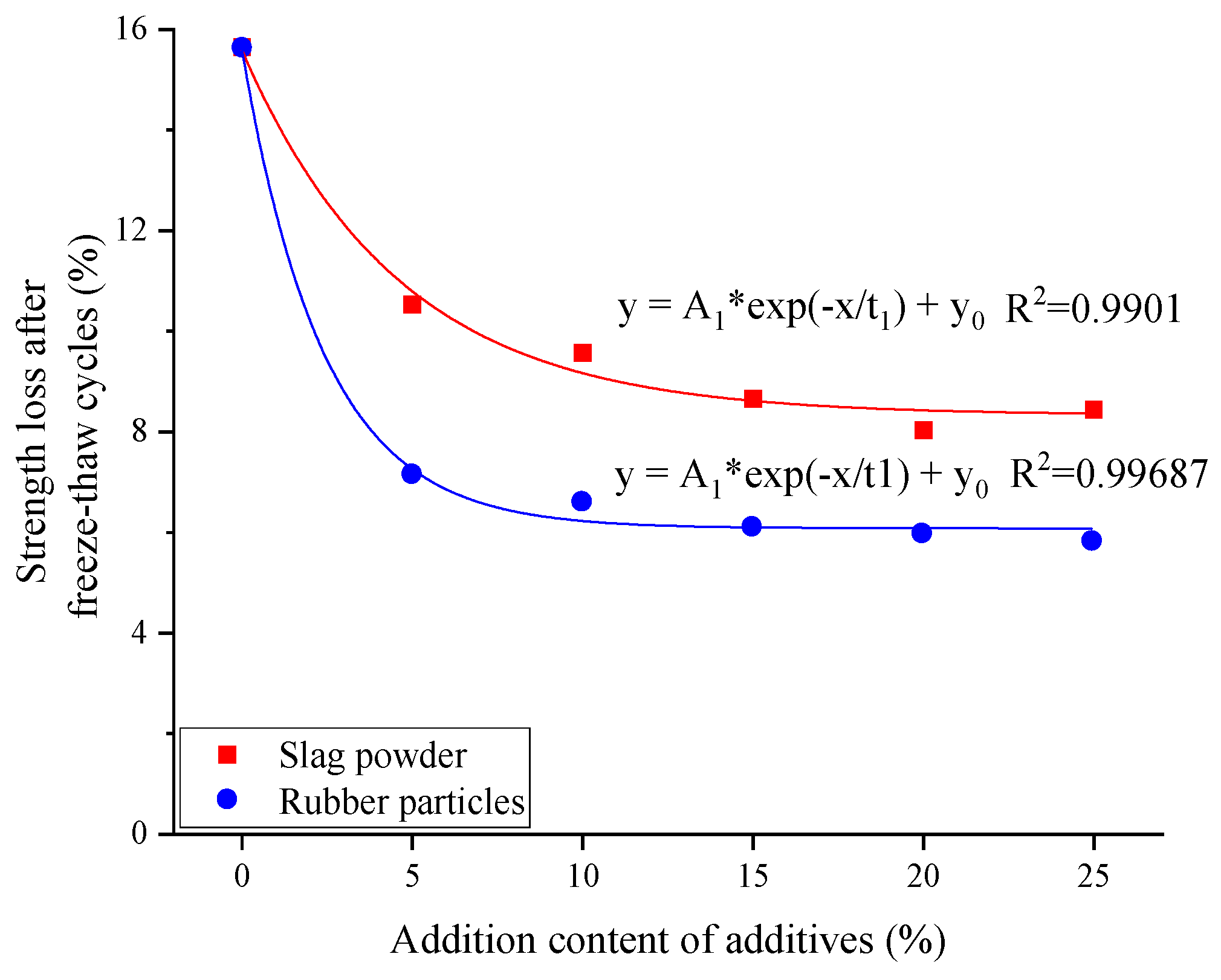

3.4. Cycles of Freezing and Thawing

4. Conclusions

- The use of micro-slag powder in appropriate amounts can enhance the mechanical properties of silicate cement mortar. At 20% slag powder content, the compressive strength peaks at 58.5 MPa, which is 15.8% higher than the control sample without slag powder. As the slag powder content increases from 0% to 20%, the flexural strength of the modified mortar test blocks rises from 7.2 MPa to 8.1 MPa. While rubber particles (1–3 mm in size) reduce the compressive and tensile strengths of the mortar, they increase the tensile-to-compressive strength ratio. At a rubber content of 25%, the strength drops to just 8.6 MPa. The tensile strength decreases from 7.2 MPa to 2.6 MPa as the rubber particle content increases from 0% to 25%.

- Adding slag powder also enhances the thermal conductivity of the mortar, with the thermal conductivity being closely related to the volume fraction of fine slag powder (optimal at 15–25%). Increasing the slag powder content from 0% to 20% raises the thermal conductivity of the mortar from 2.07 to 2.29, a 10.4% increase. In contrast, rubber particles (1–3 mm in diameter) reduce the thermal conductivity of the mortar, with greater amounts leading to lower conductivity. The thermal conductivity of mortars containing rubber particles steadily declines from 2.0734 to 1.0313.

- Adding more than 10% slag powder improves the impermeability of the mortar. When the slag powder content ranges from 0% to 20%, the mortar test blocks exhibit a steady increase in seepage pressure, rising from 0.35 MPa to 0.5 MPa, a 42.9% increase. A small amount of rubber particles can also enhance impermeability, but excessive rubber content reduces it. The impermeability pressure increases from 0.3 MPa to 0.5 MPa, but it then decreases from 0.5 MPa to 0.2 MPa as the rubber content increases from 5% to 25%.

- As the slag powder content increases from 0% to 25%, the strength loss decreases from 15.64% to 8.44%, while the strength loss of rubber particle mortar decreases from 15.64% to 5.81%. Both slag powder and rubber particles contribute positively to the freeze–thaw resistance of mortar.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, H.M.; Wang, S.G.; Wu, Z.M.; Che, G.J. Concrete slab installed with carbon fiber heating wire for bridge deck deicing. J. Transp. Eng. 2010, 136, 500–509. [Google Scholar] [CrossRef]

- Wang, K.J.; Nelsen, D.E.; Nixon, W.A. Damaging effects of deicing chemicals on concrete materials. Cem. Concr. Compos. 2006, 28, 173–188. [Google Scholar] [CrossRef]

- Zhao, H.M.; Wu, Z.M.; Wang, S.; Zheng, J.; Che, G. Concrete pavement deicing with carbon fiber heating wires. Cold Reg. Sci. Technol. 2011, 65, 413–420. [Google Scholar] [CrossRef]

- Zhang, Q.W.; Zhao, Y.H.; Wu, Z.M. Deicing performance of carbon fiber heating wires embedded in concrete pavement. J. Highw. Transp. Res. Dev. 2015, 2, 41–48. [Google Scholar] [CrossRef]

- Xiao, W. Research on the Performances of Ultra-Fine Cement Crack Repair Material Modified by Silica Fume. Master’s Thesis, Chang’an University, Xian, China, 2009. (In Chinese). [Google Scholar]

- Alex, A.G.; Kedir, A.; Tewele, T.G. Review on effects of graphene oxide on mechanical and microstructure of cement-based materials. Constr. Build. Mater. 2022, 360, 129609. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Y.; Cao, J. Prediction and evaluation of thermal conductivity in nanomaterial-reinforced cementitious composites. Cem. Concr. Res. 2023, 172, 107240. [Google Scholar] [CrossRef]

- Shamsaei, E.; de Souza, F.B.; Yao, X.; Benhelal, E.; Akbari, A.; Duan, W. Graphene-based nanosheets for stronger and more durable concrete: A review. Constr. Build. Mater. 2018, 183, 642–660. [Google Scholar] [CrossRef]

- Win, T.T.; Raengthon, N.; Prasittisopin, L. Advanced cement composites: Investigating the role of graphene quantum dots in improving thermal and mechanical performance. J. Build. Eng. 2024, 96, 110556. [Google Scholar] [CrossRef]

- Exarchos, D.A.; Dalla, P.T.; Tragazikis, I.K.; Alafogianni, P.; Barkoula, N.M.; Paipetis, A.S.; Dassios, K.G.; Matikas, T.E. Thermal and electrical behavior of nano-modified cement mortar. Smart Sens. Phenom. Technol. Netw. Syst. Integr. 2014, 9062, 303–312. [Google Scholar] [CrossRef]

- Shi, Y. Study on the Crack Mending Materials of Cement Concrete Pavement. Master’s Thesis, Chang’an University, Xian, China, 2014. [Google Scholar]

- Ortega, J.M.; Letelier, V.; Solas, C.; Moriconi, G.; Climent, M.Á.; Sánchez, I. Long-term effects of waste brick powder addition in the microstructure and service properties of mortars. Constr. Build. Mater. 2018, 182, 691–702. [Google Scholar] [CrossRef]

- Lee, T.C. Recycling of municipal incinerator fly-ash slag and semiconductor waste sludge as admixtures in cement mortar. Constr. Build. Mater. 2009, 23, 3305–3311. [Google Scholar] [CrossRef]

- Zhao, S.J.; Fan, J.J.; Sun, W. Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Constr. Build. Mater. 2014, 50, 540–548. [Google Scholar] [CrossRef]

- Lawrence, P.; Cyr, M.; Ringot, E. Mineral admixtures in mortars: Effect of inert materials on short-term hydration. Cem. Concr. Res. 2003, 33, 1939–1947. [Google Scholar] [CrossRef]

- Kadri, E.H.; Aggoun, S.; Schutter, G.D.; Ezziane, K. Combined effect of chemical nature and fineness of mineral powders on Portland cement hydration. Mater. Struct. 2010, 43, 665–673. [Google Scholar] [CrossRef]

- Cyr, M.; Lawrence, P.; Ringot, E. Efficiency of mineral admixtures in mortars: Quantification of the physical and chemical effects of fine admixtures in relation with compressive strength. Cem. Concr. Res. 2006, 36, 264–277. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Meshgin, P.; Xi, Y.; Li, Y. Utilization of phase change materials and rubber particles to improve thermal and mechanical properties of mortar. Constr. Build. Mater. 2012, 28, 713–721. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Wang, R.; Lei, Y. Performance enhancement of rubberised concrete via surface modification of rubber: A review. Constr. Build. Mater. 2019, 227, 116691.1–116691.20. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Byzyka, J.; Ghaffar, S.H. Sustainable valorisation of silane-treated waste glass powder in concrete pavement. Sustainability 2021, 13, 4949. [Google Scholar] [CrossRef]

- Placino, P.; Rugkhapan, N.T. Making visible concrete’s shadow places: Mixing environmental concerns and social inequalities into building materials. Environ. Urban. 2024, 36, 195–213. [Google Scholar] [CrossRef]

- Shao, J.; Gao, J.; Zhao, Y.; Chen, X. Study on the pozzolanic reaction of clay brick powder in blended cement pastes. Constr. Build. Mater. 2019, 213, 209–215. [Google Scholar] [CrossRef]

- Lee, T.C.; Wang, W.J.; Shih, P.Y.; Lin, K.L. Enhancement in early strengths of slag-cement mortars by adjusting basicity of the slag prepared from fly-ash of MSWI. Cem. Concr. Res. 2009, 39, 651–658. [Google Scholar] [CrossRef]

- Dang, J.T.; Zhao, J.; Hu, W.Y.; Du, Z.H.; Gao, D.Y. Properties of mortar with waste clay bricks as fine aggregate. Constr. Build. Mater. 2018, 166, 898–907. [Google Scholar] [CrossRef]

- Huang, X.Y.; Ranade, R.; Ni, W.; Li, V.C. Development of green engineered cementitious composites using iron ore tailings aggregates. Constr. Build. Mater. 2013, 44, 757–764. [Google Scholar] [CrossRef]

- Itim, A.; Ezziane, K.; Kadri, E.H. Compressive strength and shrinkage of mortar containing various amounts of mineral additions. Constr. Build. Mater. 2011, 25, 3603–3609. [Google Scholar] [CrossRef]

- Shi, X.; Yang, Z.; Liu, Y.; Cross, D. Strength and corrosion properties of Portland cement mortar and concrete with mineral admixtures. Constr. Build. Mater. 2011, 25, 3245–3256. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Liu, C.S.; Zhu, H.; Li, Z.G.; Zhang, J.; Yuan, L. Research in the fundamental characteristics of crumb rubber mortar. Concrete 2005, 139, 38–42. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Mazzoli, A.; Moriconi, G. Mechanical behaviour and thermal conductivity of mortars containing waste rubber particles. Mater. Des. 2011, 32, 1646–1650. [Google Scholar] [CrossRef]

- Turatsinze, A.; Garros, M. On the modulus of elasticity and strain capacity of self-compacting concrete incorporating rubber aggregates. Resour. Conserv. Recycl. 2008, 52, 1209–1215. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Zhao, Z.Y.; Chen, S.X.; Sun, W. Impact of rubber powder on frost resistance of concrete in water and NaCl solution. J. Southeast Univ. (Nat. Sci. Ed.) 2006, 36, 248–252. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber—An overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef] [PubMed]

- GB/T 17671-1999; Method of Testing Cements-Determination of Strength. The State Bureau of Quality and Technical Supervision: Beijing, China, 1999.

- JGJ/T 70-2009; Standard for Test Method of Basic Properties of Construction Mortar. China Architecture & Building Press: Beijing, China, 2009.

- JTJ/T98-2010; Specification for Mix Proportion Design of Masonry Mortar. China Architecture & Building Press: Beijing, China, 2010.

- Hu, Y.; Diao, L.; Lai, Z.; He, Y.; Yan, T.; He, X.; Wu, J.; Lu, Z.; Lv, S. Effects of bentonite on pore structure and permeability of cement mortar. Constr. Build. Mater. 2019, 224, 276–283. [Google Scholar] [CrossRef]

- Li, L.; Ye, T.; Li, Y.; Wang, Z.; Feng, Z.; Liu, Z. Improvement of microporous structure and impermeability of cement mortars using fly ash and blast furnace slag under low curing pressures. Constr. Build. Mater. 2023, 401, 132890. [Google Scholar] [CrossRef]

- Raj, A.; Ngamkhanong, C.; Prasittisopin, L.; Kaewunruen, S. Nonlinear dynamic responses of ballasted railway tracks using concrete sleepers incorporated with reinforced fibres and pre-treated crumb rubber. Nonlinear Eng. 2023, 12, 20220320. [Google Scholar] [CrossRef]

| Chemical Composition, % | Loss on Ignition | CaO | MgO | Al2O3 | SiO2 |

|---|---|---|---|---|---|

| Slag powder | 4.09 | 35.58 | 11.32 | 16.32 | 36.10 |

| Hole size, mm | 2.0 | 1.6 | 1.0 | 0.5 | 0.16 | 0.08 |

| Rest, % | 0 | 7 ± 5 | 33 ± 5 | 67 ± 5 | 87 ± 5 | 99 ± 1 |

| Type | Loss on Ignition | Setting Time (min) | Stability | Specific Surface Area (m2/kg) | Compressive Strength 28 d (MPa) | Tensile Strength 28 d (MPa) | |

|---|---|---|---|---|---|---|---|

| Initial | Final | ||||||

| CEM 42.5R | 3.28% | 222 | 227 | Qualified | 348.7 | 55.1 | 8.5 |

| Mix ID | Cement | Slag Powder | Sand | Water | Rubber Particles |

|---|---|---|---|---|---|

| S | 585.9 | 0 | 1757.8 | 293.0 | 0 |

| SK1 | 556.6 | 29.3 | 1757.8 | 293.0 | 0 |

| SK2 | 527.3 | 58.6 | 1757.8 | 293.0 | 0 |

| SK3 | 498.0 | 87.9 | 1757.8 | 293.0 | 0 |

| SK4 | 468.7 | 117.2 | 1757.8 | 293.0 | 0 |

| SK5 | 439.4 | 146.5 | 1757.8 | 293.0 | 0 |

| SX1 | 585.9 | 0 | 1669.9 | 293.0 | 87.9 |

| SX2 | 585.9 | 0 | 1582.0 | 293.0 | 175.8 |

| SX3 | 585.9 | 0 | 1494.1 | 293.0 | 263.7 |

| SX4 | 585.9 | 0 | 1406.2 | 293.0 | 351.6 |

| SX5 | 585.9 | 0 | 1318.3 | 293.0 | 439.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, W.; Geng, Z.; Zhang, X.; Zeng, Q.; Wei, L.; Zhou, L.; Li, W. Use of Waste Slag and Rubber Particles to Make Mortar for Filling the Joints of Snow-Melting Concrete Pavement. Buildings 2024, 14, 3226. https://doi.org/10.3390/buildings14103226

Peng W, Geng Z, Zhang X, Zeng Q, Wei L, Zhou L, Li W. Use of Waste Slag and Rubber Particles to Make Mortar for Filling the Joints of Snow-Melting Concrete Pavement. Buildings. 2024; 14(10):3226. https://doi.org/10.3390/buildings14103226

Chicago/Turabian StylePeng, Wenbo, Zhiyuan Geng, Xueting Zhang, Qi Zeng, Longhai Wei, Li Zhou, and Wentao Li. 2024. "Use of Waste Slag and Rubber Particles to Make Mortar for Filling the Joints of Snow-Melting Concrete Pavement" Buildings 14, no. 10: 3226. https://doi.org/10.3390/buildings14103226

APA StylePeng, W., Geng, Z., Zhang, X., Zeng, Q., Wei, L., Zhou, L., & Li, W. (2024). Use of Waste Slag and Rubber Particles to Make Mortar for Filling the Joints of Snow-Melting Concrete Pavement. Buildings, 14(10), 3226. https://doi.org/10.3390/buildings14103226