Abstract

A new type of laminated flooring decorated by resin impregnated paper (LWFWRIP) was designed, with the advantages of low formaldehyde emission, improved flame retardant, and high wear resistance. The structure of this new type of wood flooring is based on the ordinary laminated flooring, followed by a decorative layer of thin wood pieces, and then the transparent improved flame retardant, wear-resistant paper is added to the top. It is found that the hot-pressing temperature is the most significant factor affecting the adhesion of resin impregnated paper. The optimal hot-pressing parameters are selected as the hot-pressing pressure of 3.5 MPa, hot-pressing temperature of 180 °C, and hot-pressing time of 40 s. The new laminated flooring was improved with high flame retardant, high wear-resistant, combined with the conventional advantages of both solid wood composite flooring and reinforced wood flooring. The new laminated flooring decorated by resin impregnated paper has broad application prospects.

1. Introduction

With the continuous pursuit of living standards and the increasing demand for environmental protection and safety, ordinary artificial boards can no longer meet people’s needs [,]. Therefore, it is imperative for researchers and manufacturers to develop new building materials that meet the needs of architectural decoration. Depending on whether there is a coating with resin-impregnated paper, laminated wood flooring is currently divided into two main types. Both floorings have the advantages of little deformation and high dimensional stability. The laminated wood flooring without resin-impregnated paper coating (LWFNRIP) has poorer wear resistance than the laminated wood flooring with resin-impregnated paper coating (LWFWRIP) [,]. LWFWRIP has excellent wear resistance due to the surface being covered with a wear-resistant layer []. In recent years, due to its richer colors and textures, wear resistance, durability, ease of maintenance, and sustainable production, the LWFWRIP has become increasingly popular among consumers []. The decorative paper texture on the surface of LWFWRIP is artificially printed and lacks the naturalness of natural wood. The fiberboard in the core layer requires a large amount of adhesive during the production process, which can easily lead to excessive formaldehyde release and cause harm to the human body [,,]. At present, there is relatively little research on the volatile harmful gases released by LWFWRIP both domestically and internationally, and most of the research focuses on formaldehyde release. For example, Zhang et al. [] conducted a study on the formaldehyde release law of impregnated paper laminated wooden flooring for ground heating. Jae-Yoon An et al. [] explored the effects of the structure and heating conditions of LWFWRIP on its formaldehyde and TVOC release, and Li et al. [] used liquid chromatography to investigate the VOCs release law of LWFWRIP.

At present, flame-retardant flooring can be divided into the following categories based on different flame retardant mechanisms and addition methods: inorganic flame retardants, organic flame retardants, resin flame retardants, and reactive flame retardants. The methods of adding flame retardants can be divided into the following categories: impregnation method, spraying method, laminating method, and blending method. The impregnation method involves adding flame retardants by impregnating the floor substrate []. However, this method increases production cycles and costs. In addition, the introduction of a large amount of flame retardants can also have a negative impact on the physical and mechanical properties of the floor []. Using colored paint or fire-resistant paint on the decorative layer of the veneer on the floor can make the natural veneer color on the entire floor more uniform, and fire-resistant paint gives the floor fire-resistant performance. Kalali et al. [] used a synergistic effect of ammonium polyphosphate (APP) and phytic acid groups to prepare a class of multifunctional nanocomposites with high strength, stability, and flame retardancy to improve the flame retardant efficiency of wood plastic composites (WPCs). Rejesh et al. [] used coconut shell as raw material and different ratios of borax and boric acid as flame retardants. The addition of flame retardants endowed the fiberboard with certain flame retardancy. Battegazzzore et al. [] used hemp fiber and rice husk as raw materials, starch as adhesive, and ammonium dihydrogen phosphate as flame retardant. Ammonium dihydrogen phosphate formed a carbonaceous layer on the surface of fiberboard and particleboard, which could suppress the transfer of heat and oxygen, thus achieving flame retardant effect. Wang Jianheng et al. [] used sodium silicate as an inorganic binder, combined it with corn stover, and added additives such as ultrafine talc powder and ultrafine silica to produce corn stover boards with high fire resistance and mechanical strength. The ultimate oxygen index (LOI) was measured to be 41%, and the combustion performance reached A2 level. Shi Jiangjing et al. [] used two different methods, Ca2+ and NaOH, to vacuum impregnate poplar veneer and generate CaOH in situ inside it, significantly improving its fire resistance. Chen et al. [] modified MF resin with polyvinyl alcohol (PVA) and phenylguanidine amine (BG). Research has shown that the tensile strength and flame retardancy of modified MF impregnated paper have been improved, which can be used to develop high-performance flame retardant laminates. Erik et al. [] applied zinc oxide (ZnO) nanoparticles to MF impregnated resin and found that the presence of ZnO can improve the fungal resistance of the decorative panel. Tang Chaofa et al. [] stirred and uniformly dispersed nano TiO2 solution and silver loaded nano TiO2 solution in MF resin at room temperature as antibacterial agents. The experiment showed that it could improve the antibacterial performance of impregnated paper decorative panels without causing agglomeration or precipitation.

Due to its advantages of wear resistance, flame retardancy, non-fading, no need for coating technology, and affordable price, this wear-resistant reinforced wood floor inherits the beautiful natural texture of precious tree species, meets market demand, and is suitable for office and civilian use, construction, shipbuilding, interior decoration, and other fields. Based on the above analysis, this study aims to develop and evaluate a building material of laminated flooring with enhanced flame retardancy, wear resistance, and low formaldehyde emissions.

2. Materials and Methods

2.1. Materials and Instruments

The substrate of the wood laminate floorboard was from Zhejiang Yuhua Wood Industry Co., Ltd. (Jiaxing, China). The intrinsic quality, symmetrical structure, uniform thickness, and moisture content of the substrate directly affect the effect of hot-pressed veneers and the physical and mechanical properties of the product. Therefore, we selected materials with similar properties from the same batch wood flooring. (NH4PO3)n (n > 1500) (APP) and Pentaerythritol (C5H12O4) (PER) was purchased from Shanghai McLean Biochemical Technology Co., Ltd. (Shanghai, China). Urea-melamine formaldehyde resin (MUF) was purchased from Zhejiang Yuhua Wood Industry Co., Ltd. Veneer decorative layer was an oak veneer of 2.0 mm thickness, with no cracks, holes, and other defects on the surface. Impregnated base paper (80 g/m2) was from Zhejiang Dilong New Materials Co., Ltd. (Hangzhou, China). The size of wood flooring was set as 910 mm (length) × 127 mm (width) × 15 mm (thickness). The main experiment equipment included a universal mechanical testing machine (Jinan Xinguang Corp., Jinan, China), a hot-pressing laminator (Qingdao Guosen Corp., Qingdao, China), a ground test furnace, a material combustion test device (Nanjing Jiangning Corp., Nanjing, China), a building material flammability (Nanjing Jiangning Corp.), an abrasion tester (Shanghai Modern Environmental Engineering Technology Corp., Shanghai, China), a rotational viscometer (Brookfield Corp., Brookfield, MA, USA), a formaldehyde detection climate chamber (Shanghai Fuxian Environmental Protection Technology Co., Ltd., Shanghai, China), etc.

2.2. Laminating of Decorative Veneer and Balance Layer on the Substrate

The moisture content of the decorative layer (8.3%) and balance layer veneers (8.2%) was nearly uniform, and the moisture content of the surface layer was lower than that of the substrate (10.1%). The structure of the LWFNRIP without resin impregnated paper is shown in Figure 1a.

Figure 1.

Structure of LWFNRIP (a) and LWFWRIP (b).

The pre-laminating pressure was about 0.5–1.0 MPa, and the time was 30–60 min. The hot-pressing process parameters, when the hot-pressing temperature is set at 110 °C, the hot-pressing pressure is set at 0.7 MPa, and the hot-pressing time is set at 90 s, can ensure the quality and efficiency of the pressing of the decorative layer on the substrate. The LWFNRIP samples without resin impregnated paper were prepared through the above pre-laminating press and hot-pressing process.

2.3. Preparation and Performance Test of Improved Flame Retardant and Wear-Resistant Paper

The wear-resistant and flame-retardant resin was made with flame retardant ingredients including ammonium polyphosphate (NH4PO3)n (n > 1500) (APP) and Pentaerythritol (C5H12O4) (PER), mixed into urea methylene formaldehyde resin (MUF). The resin was prepared by weighing appropriate amounts of MUF, APP, and PER with the ratio of 15% (APP&PER: MUF). The ratio of APP/PER was set as 2/1 and 1/1. After blending the mixture thoroughly for 5 min, it was set aside for later use. Measure resin viscosity and curing time according to the method specified in GB/T 14732-2017 “Wood adhesives:urea-formaldehyde, phenol-formaldehyde and melamine- formaldehyde resins” []. Measure the viscosity of the wear resistant and flame-resistant resin prepared under each condition every hour within 1–7 h. Each test experimental condition is replicated three times and take the average as the measurement value.

Adjusting the ratio of formaldehyde, urea, and melamine F/(M + U) can control the curing time of impregnated flame retardant resin. In this experiment, a total of 9 conditions were conducted, and the F/(M + U) mass ratios were set as: 1.20, 1.21, 1.22, 1.23, 1.24, 1.25, 1.26, 1.27, 1.28. Under each condition, the impregnated flame-retardant resin was prepared and its curing time was tested. Each test experimental condition is replicated eight times and take the average as the measurement value. The result is displayed as the mean and standard deviation.

The wear-resistant and flame-retardant resin was prepared according to different flame retardant components (0%, 2%, 4%, 6%, 8%, 10%, 12%, 14%, 16%, 18%, 20%), and the ratio of APP/PER was preferred as 2:1. Prepare flame-retardant wear resistant paper by immersing the impregnated base paper in the prepared flame-retardant resin for 3 min. Use a dry spray machine to evenly spray Al2O3 (Shanghai McLean Biochemical Technology Co., Ltd.) on the surface of the impregnated paper at a rate of 38 g/m2 to improve the wear resistance. Place it in a blast drying oven at 103 °C for 2 min, then apply the flame-retardant resin on both sides of the impregnated paper to achieve a total weight gain of about 5 times that of the base paper. Place it in a blast drying oven at 103 °C for another 2 min. The flame-retardant resistant paper should be sealed and stored for future use within 3 months, and the storage conditions include relative humidity between 50% and 60%, and storage temperature between 20 °C and 25 °C. Under the condition of hot-pressing pressure 3.5 MPa, temperature 180 °C, time 50 s, the LWFWRIP samples (0–20%, total 11 levels) were manufactured by using the as-prepared flame-retardant resistant paper. Critical heat flux (CHF) is tested according to the national standard GB/T 11785-2005 “Reaction to fire tests for floorings—Determination of the burning behaviour using a radiant heat source” []. The height of the flame tip (FTH) is measured within 60 s according to the national standard GB/T 8626-2007 “Test method of flammability for building materials” []. The CHF and FTH of LWFWRIP were tested. The dimension of CHF samples was 1050 mm (length) × 280 mm (width), and the thickness is the same as the flooring. The dimension of FTH samples was 250 mm (length) × 90 mm (width), and the thickness is the same as the flooring. Each test was replicated six times and take the average as the measurement value.

2.4. Hot-Pressing of LWFNRIP Coated with Improved Flame Retardant and Wear-Resistant Paper

The process parameters for hot pressing including pressure, temperature, and time are shown in Table 1. The flame-retardant and wear-resistant papers were laminated onto the LWFNRIP surface to wood flooring coated with resin impregnated paper. The structure of the LWFWRIP with resin impregnated paper is shown in Figure 1b. The decorative layer was an oak veneer with 2.0 mm thickness. The substrate was a multi-layer plywood with 11 mm thickness. The balance layer was poplar veneer with 2.0 mm thickness. The hot-pressing pressure, temperature, and time are the three essential elements of hot pressing, and three groups of the hot-pressing process parameters were selected for this study based on relevant literature references and enterprise production experience [,]. In accordance with the requirements of the orthogonal experimental design, the designed three levels are selected for hot-pressing pressure: 3.0 MPa, 3.5 MPa, and 4.0 MPa; temperature: 160 °C, 180 °C, and 200 °C; and time: 30 s, 40 s, and 50 s. Experiments are conducted based on various set combinations, each experimental condition is replicated three times. The LWFWRIP samples with resin impregnated paper was prepared through the hot-pressing process. The LWFWRIPx represents the LWFWRIP sample prepared under test number x among 1–9.

Table 1.

Orthogonal Experiment Schedule.

2.5. Performance Test of the LWFNRIP and LWFWRIP Samples

The experimental testing items of the LWFNRIP and LWFWRIP1–9 include wear-resistant speed, surface bonding strength, static bending strength, and formaldehyde emission. The wear-resistant speed and static bending strength are tested according to the experimental method specified in the national standard GB/T 24507-2020 “Laminate engineered wood flooring” []. The size of the surface wear resistance test specimen is 100 mm (length) × 100 mm (width), with 6 replicates for each test. The size of the static bending strength test specimen is 250 mm (length) × 50 mm (width), with 6 replicates for each test. The surface bonding strength and formaldehyde emission is tested according to the test method specified in the Part 4.15 and Part 4.60 of national standard GB/T 17657-2022 “Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels” []. The size of the surface bonding strength test specimen is 50 mm (length) × 50 mm (width), with 6 replicates for each test. The size of the formaldehyde emission test specimen is 50 mm (length) × 50 mm (width), with 2 specimens and a total surface area of 1 square meter as one sample, with 6 replicates for each test. All test specimens with required specifications, dimensions, and quantities were prepared in accordance with the above-mentioned standards. The thickness of the sample is the same as the flooring. The performance of the LWFNRIP and LWFWRIP samples is analyzed by orthogonal experiments to obtain the average values of various factors at different levels. Take the average of the measured values.

3. Results and Discussion

3.1. Influence of Flame Retardant Content in Impregnated Resin on Viscosity and Curing Time

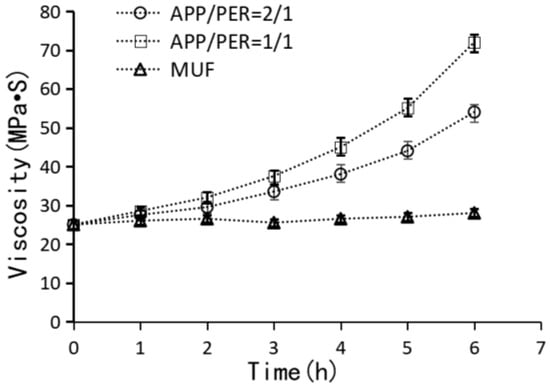

It is important to study the effects of flame-retardant components APP and PER on resin viscosity, as their addition can affect resin viscosity. Add different proportions of APP and PER flame retardant components to MUF, with the total amount of flame-retardant components accounting for 15% of the MUF resin content. The viscosity changes over time are shown in Figure 2.

Figure 2.

Effect of flame-retardant ingredient addition on viscosity.

It can be seen that the addition of flame-retardant components accelerates the growth rate of resin viscosity, and the higher the PER ratio, the faster the growth rate. Therefore, increasing the APP/PER ratio can reduce the growth rate of resin viscosity. In this study, the flooring was prepared at the ratio 2:1 of APP to PER, and finally, the viscosity of the resin was adjusted and reduced by adding urea to weaken the hydrogen bonding in the system, resulting in an overall viscosity of the resin below 50 MPa·S (20 °C) after 6 h.

The addition of APP will promote the curing of resin. Under the current process, the curing time of impregnated flame-retardant resin is suitable between 350 s–500 s. We can further adjust the ratio of formaldehyde, urea, and melamine F/(M + U) to achieve the desired curing time. The effect of adjusting the F/(M + U) ratio on curing time is shown in Table 2. According to the process conditions, the curing time of the floor trial production in this experiment is controlled at around 420 s. The curing time of the impregnated flame retardant resin paint varies at different F/(M + U) ratios. Based on the actual production needs, the most suitable ratio is selected as 1.23. The F/(M + U) ratio of 1.23 is the most suitable for flame retardant components, and the curing time of the impregnated paper adhesive is around 420 s.

Table 2.

Effect of F/(M + U) ratio on curing time.

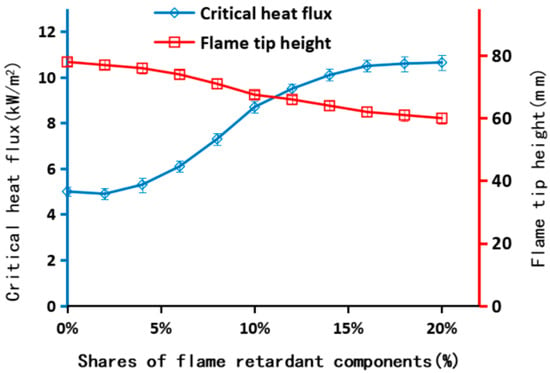

3.2. Influence of Flame-Retardant Components on the Flame Retardant Performance

Comparing the total flame-retardant content with the resin content ranging from 0% to 20%, the flame-retardant performance is shown in Figure 3. It can be seen that the addition of flame-retardant components enhances the flame retardant performance of the flooring. As the proportion of flame-retardant components increases, its CHF value gradually increases and its FTP value continuously decreases. An increase in the content of flame-retardant components can enhance the flame-retardant performance of floor samples. As the proportion of flame-retardant ingredients continues to increase, the rate of change in CHF and FTP values slows down, indicating that after the flame-retardant ingredient content reaches a certain value, the effect of continuing to add it significantly decreases. Taking into account the cost factors of flame retardants and production experience, we have selected a flame-retardant ingredient addition ratio of 15%. The content of flame-retardant components have a significant impact on its flame-retardant performance.

Figure 3.

Influence of the proportion of flame-retardant components on flame retardant performance.

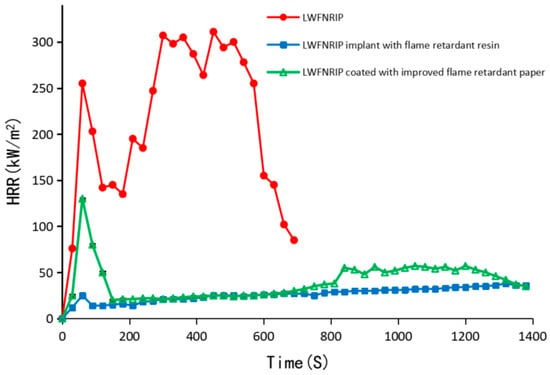

3.3. Analysis of Heat Release Rates

The magnitude of heat release rate can effectively measure the fire hazard of different materials, and the higher the heat release rate, the higher the surface hazard. Flame-retardant materials play an important role in the initial 600 s of a fire, but as the fire rapidly develops, fire-resistant materials no longer play a significant role. From Figure 4, the heat release rate of the board changes rapidly. The first peak that appears rapidly is in the early stage of ignition, followed by the formation of a carbonized protective layer on the flame-retardant impregnated film paper, effectively reducing the thermal decomposition of the wood material and thus reducing the heat release rate in the early stage of the fire, which can effectively suppress the expansion speed of the fire. The surface coated with flame-retardant impregnated paper has a significant improvement in the flame resistance of solid wood composite flooring. Within the first 600 s, the flame-retardant performance is comparable to that of flame-retardant solid wood composite flooring produced by immersion method, but the amount of flame retardant used is only 1/4, which can save a lot of costs. The heat release rate of LWFNRIP is the highest, while the heat release rate is lower after covering and impregnating flame-retardant paper. This indicates that impregnated flame-retardant paper has an improved flame-retardant performance, which can further prevent the combustion of internal wooden floors and release heat energy. The heat release rate of LWFNRIP implant with flame-retardant resin and LWFNRIP coated with improved flame-retardant paper are relatively close within the first 600 s. The coating of resin-impregnated paper on laminated flooring can achieve high flame-retardant effect on wood flooring.

Figure 4.

Heat release rate curves of flooring samples.

3.4. Effects of Different Hot-Pressing Technologies on the Performance of LWFWRIP

This experiment manufactured a new type of wood flooring according to the orthogonal experiment. The relevant performance test results of the LWFWRIP1–9 samples are shown in Table 3.

Table 3.

Performance of LWFWRIP and LWFNRIP.

The analysis of wear resistance results of different hot-pressing technologies was shown in Table 4. K1, K2, and K3 represent the average values under the conditions of level 1, level 2, and level 3. R is the extremum value, representing the difference between the maximum and minimum values. Its meaning is the same in the following Table 5, Table 6 and Table 7.

Table 4.

Wear resistance results of LWFWRIP.

Table 5.

Surface bonding strength results of LWFWRIP.

Table 6.

Static bending strength results of LWFWRIP.

Table 7.

Formaldehyde emission results of LWFWRIP.

When the hot-pressing pressure increases from 3.0 MPa to 3.5 MPa, the wear resistance value increases, and as the pressure increases to 4.0 MPa, the wear resistance value decreases significantly. When the hot-pressing temperature reaches 160–180 °C, the resin adhesive can be fully cured, and the wear resistance value can reach 4000 rpm. If the temperature is further increased, the increase in wear resistance value is not significant, but instead defects such as water stains and bubbles may occur. At the same time, if the temperature is too low, it is easy to stick to the board. Even within a short cycle of 30 s, the hot-pressing time can still maintain a wear-resistant speed of 4000 revolutions per minute, while extending the cycle to 50 s does not significantly increase the wear-resistant speed. This is because under the condition that the temperature and time of hot pressing can ensure that the resin adhesive is fully cured, the Al2O3 wear-resistant particles have been firmly adhered to the cured adhesive layer []. At this time, increasing the hot-pressing temperature and extending the time cannot increase its wear-resistant speed. Therefore, when designing the hot-pressing process for reinforced wood flooring, the main consideration should be that the adhesive can be fully cured to ensure the physical and chemical properties of the board surface. But if we blindly pursue production and shorten the hot-pressing cycle, it may affect the hardness and other properties such as water vapor resistance of the board surface. In this study, the hot-pressing process did not show a significant impact on the wear resistance of the product. When designing the hot-pressing process, the main consideration should be to ensure that the adhesive can fully cure and guarantee the physical and chemical properties of the board surface.

The analysis of surface bonding strength results of different hot-pressing technologies was shown in Table 5. The effects of hot-pressing parameters on surface bonding strength were shown in Table 5. When the hot-pressing pressure increased from 3.0 MPa to 3.5 MPa, the surface bonding strength did not change largely; when it rose from 3.5 MPa to 4.0 MPa, the surface bonding strength did not change much when the hot-pressing temperature was low, and decreased when the hot-pressing temperature was high. The higher the hot-pressing pressure, the faster the heat transfer. As a result, the surface of the slab quickly reached a higher temperature. The time spent at higher temperatures was increased compared to that at lower pressure. The continuous high temperature causes embrittlement of the adhesive, which reduces the surface bond strength [].

When the hot-pressing temperature rose from 160 °C to 180 °C, the surface bonding strength increased. This is because as the temperature rises, the adhesive flows faster due to the effect of heat, the contact between the slab and the improved flame retardant and wear-resistant paper is better, and the adhesive can be cured better. However, when the temperature rose to 200 °C, the surface bonding strength decreased, which may be ascribed to the embitterment of the adhesive layer at a higher temperature, which affects the bonding between materials and reduces the surface bonding strength []. When the hot-pressing time was extended from 30 s to 40 s, the surface bonding strength increased slightly. It is because as the temperature increases, the adhesive can be cured better. When it was extended from 40 s to 50 s, the surface bonding strength decreased instead. The hot-pressing temperature had the greatest effect on the bonding strength of the product surface, followed by hot-pressing time and then hot-pressing pressure.

The analysis of static bending strength results for different hot-pressing technologies was shown in Table 6. The hot-pressing pressure had little effect on the static bending strength within the designed pressure range [,].When the hot-pressing temperature rose from 160 °C to 180 °C, the static bending strength decreased slightly, and when it rose from 180 °C to 200 °C, the static bending strength still decreased. This is because the increase in the hot-pressing temperature improves the internal temperature of the slab. A high temperature of the core layer will affect the original cured adhesive layer inside the substrate, making the adhesive layer brittle and affecting the strength, so the hot-pressing temperature should not be too high.

When the hot-pressing time was extended from 30 s to 40 s, there was little effect on the static bending strength [,]. With the extension of the hot-pressing time, the static bending strength decreased slightly. It may also be attributed to the fact that the original cured adhesive layer inside the substrate is affected with the extension of time, causing the adhesive layer to become brittle and thus affecting its strength. According to Table 4, hot-pressing temperature displayed the greatest effect on the static bending strength of the product surface, followed by hot-pressing time and then hot-pressing pressure.

The analysis of formaldehyde emission results for different hot-pressing technologies was shown in Table 7. Both hot-pressing time and temperature have a significant effect on reducing formaldehyde emission. When the hot-pressing time exceeds 40 s, low formaldehyde emission can be obtained.

In summary, the hot-pressing temperature is the most important factor affecting the laminating of the improved flame retardant, wear-resistant paper. The hot-pressing pressure of 3.5 MPa, the temperature of 180 °C, and the time of 40 s should be selected as the optimal hot-pressing technology parameters.

3.5. Performance of the Improved Flame Retardant and Wear-Resistant LWFWRIP

It is stipulated in the GB/T 18102-2020 [] that the surface bonding strength of the LWFWRIP shall be ≥1.0 MPa, and the measured value of the surface bonding strength of all the LWFWRIP sample pieces shall be not less than 80% of the standard value; the surface wear-resistant rotate speed shall be ≥4000 rpm (Level II). GB/T 24507-2020 [] also stipulates that the static bending strength of the wood laminate floorboard shall be ≥30 MPa. The arithmetic mean of the surface bonding strength, surface wear-resistant rotate speed and static bending strength of the improved flame retardant, wear-resistant paper veneer solid wood composite flooring was 1.60 MPa, 4072 rpm, and 39.6 MPa, respectively, indicating that it is feasible to paste the improved flame retardant, wear-resistant paper on the plywood for solid wood composite flooring with thin wood veneer. The products fully combine the advantages of the solid wood composite flooring and the laminate wood flooring, which maximize their strengths and are highly cost-effective. By re-pressing and sealing the surface with impregnated film paper veneer, the formaldehyde emission of the floor can be reduced again. The floor trial produced in this experiment meets the optimal level specified in GB/T 39600-2021 “Formaldehyde emission grading for wood-based panel and finishing products” [], namely ENF level.

For general household floorboards, a wear-resistant rotate speed of 4000 rpm or above is far enough [,]. In this study, therefore, the improved flame retardant and wear-resistant paper with Al2O3 content of 38 g/m2 was used for laminating to reduce production costs. If a floorboard with special requirements for wear resistance, such as for public places, is to be developed, products with a higher grade of wear resistance can be produced by simply laminating an improved flame-retardant, wear-resistant paper with Al2O3 content of 46–62 g/m2.

4. Conclusions

When the ratio of APP to PER in the flame-retardant component is 2:1, the viscosity of the impregnated paper adhesive is more suitable, reaching 50 MPa·S (20 °C). The F/(M + U) ratio of 1.23 is the most suitable for flame retardant components, and the curing time of the impregnated paper adhesive is about 420 s. When the addition amount of flame-retardant components accounts for about 15% of the total mass of the adhesive, its flame-retardant performance is improved. At this time, its CHF reaches 10.5 Kw/m2 and its FTP reaches 63 mm. According to the analysis of heat release rate, the LWFNRIP samples showed a significant decrease in heat release rate after being coated with impregnated flame-retardant paper, indicating that the flame-retardant impregnated paper had a more pronounced flame-retardant effect on the LWFWRIP sample. Hot-pressing temperature is crucial for laminating improved flame retardant, wear-resistant paper. Optimal hot-pressing parameters: 3.5 MPa pressure, 180 °C temperature, and 40 s time were selected to obtain cost-effective and high-quality floorboard products. For extra wear resistance, using improved flame-retardant paper with high Al2O3 content is recommended. The aim of this research was fulfilled: a product with improved flame retardant, wear-resistant paper veneer solid wood composite flooring that combines the benefits of solid wood composite flooring and laminate wood flooring was developed. It is suggested that the wear resistance of the flooring can be customized by using different types of improved flame-retardant paper. This flexibility allows manufacturers to offer products that meet specific customer requirements, such as those in high-traffic areas or environments with stringent safety standards. This research findings contribute to a better understanding of the factors influencing the quality of composite flooring and provide valuable insights for manufacturers and consumers.

Author Contributions

Conceptualization, M.F. and K.Z.; methodology, M.F. and K.Z.; software, K.Z.; validation, M.F., J.C. and K.Z.; investigation, M.F. and K.Z.; resources, M.F. and J.C.; writing—original draft preparation, K.Z.; writing—review and editing, M.F.; supervision, M.F.; project administration, M.F. and K.Z.; funding acquisition, M.F. and K.Z. All authors have read and agreed to the published version of the manuscript.

Funding

The work was financially supported by the Zhejiang Province Forest Product Quality and Safety Inspection Project (Grant No. 01202301 & Grant No. 01202404).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Wu, Y.; Sun, M.; Wu, X.; Shi, T.; Chen, H.; Wang, H. Preparation of nanocellulose aerogel from the poplar (Populus Tomentosa) catkin fiber. Forests 2019, 10, 749. [Google Scholar] [CrossRef]

- Jimenez, M.; Duquesne, S.; Bourbigot, S. Intumescent fire protective coating: Toward a better understanding of their mechanism of action. Thermochim. Acta 2006, 449, 16–26. [Google Scholar] [CrossRef]

- Huang, L.L.; Xiao, F.; Ji, J.; Guo, X.L.; Cao, P.X. Research on the properties of liquid wear-resisting paper for laminate flooring. China For. Prod. Ind. 2012, 39, 34–36. [Google Scholar] [CrossRef]

- Silva, D.A.P.L.; Varanda, L.D.; Christoforo, A.L.; Lahr, F.A.R. Addition of impregnated paper residue to produce MDP wood panel: Example of solid waste recycling. Int. J. Mater. Eng. 2012, 2, 75–79. [Google Scholar] [CrossRef]

- Zou, H.J. Analysis of influencing factors of laminate wood floor. Build. Mater. Decor. 2019, 3, 64. [Google Scholar]

- Deng, Y.; Wang, S.; Gong, H.; Tang, Z. Research and prospect of surface wear resistance technology of laminate flooring. China Wood-Based Panels 2022, 29, 10–14. [Google Scholar]

- Pavlič, M.; Petrič, M.; Žigon, J. Interactions of coating and wood flooring surface system properties. Coatings 2021, 11, 91. [Google Scholar] [CrossRef]

- Song, Y.H.; Seo, J.H.; Choi, Y.S.; Kim, D.H.; Choi, B.H.; Cha, H.J. Mussel adhesive protein as an environmentally-friendly harmless wood furniture adhesive. Int. J. Adhes. Adhes. 2016, 70, 260–264. [Google Scholar] [CrossRef]

- Dilik, T.; Hiziroglu, S. Some properties of linoleum and wood laminated flooring panels with magnesium substrate. BioResources 2015, 10, 1667–1674. [Google Scholar] [CrossRef][Green Version]

- Zhang, Y.F.; Liu, Z.J.; Zhang, H.Y. Formaldehyde release law of solid wood composite flooring and impregnated paper laminated wooden flooring for underfloor heating. Constr. Mater. Decor. 2020, 47–48. [Google Scholar]

- An, J.Y.; Kim, S.; Kim, H.J. Formaldehyde and TVOC emission behavior of Impregnated paper laminated wood flooring by structure of Impregnated paper laminated wood flooring and heating condition. J. Hazard. Mater. 2011, 187, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Liu, S.; Jing, Y.T. Study on the release of VOC in four kinds of impregnated paper laminated wood floor. J. Jilin Jianzhu Univ. 2019, 36, 43–47+58. [Google Scholar]

- Zhang, Y.C.; Yin, T.Y.; Guo, X.G.; Du, H.; Gao, Y.P. The effect of adding fire retardants on manufacturing technique of three layers solid wood reuniting floor. J. Jilin For. Sci. Technol. 2015, 44, 33–37+53. [Google Scholar] [CrossRef]

- Thébault, M.; Kandelbauer, A.; Müller, U.; Zikulnig-Rusch, E.; Lammer, H. Factors influencing the processing and technological properties of laminates based on phenolic resin impregnated papers. Eur. J. Wood Prod. 2017, 75, 785–806. [Google Scholar] [CrossRef]

- Luo, J. Ignition properties of panels coated with finishing fire-retardant paints under external radiation. Procedia Eng. 2016, 135, 123–127. [Google Scholar] [CrossRef]

- Rejeesh, C.R.; Saju, K.K. Relative improvements in flame resistance of coir fiberboards treated with fire-retardant solution. J. Wood Sci. 2018, 64, 697–705. [Google Scholar] [CrossRef]

- Battegazzore, D.; Alongi, J.; Duraccio, D.; Frache, A. Reuse and valorisation of hemp fibres and rice husk particles for fire resistant fibreboards and particleboards. J. Polym. Environ. 2018, 26, 3731–3744. [Google Scholar] [CrossRef]

- Wang, J.H.; Xu, Y.F.; Zhang, P.Y.; Liu, T.; Zhang, J.Z.; Mao, Z.Y.; Teng, T. An effective way to improve the flame retardancy of corn straw board. New Build. Mater. 2019, 46, 142–144. [Google Scholar] [CrossRef]

- Shi, J.; Chen, H.; Ye, J.; Zhang, Y.; Wu, Z.; Zhan, X. Properties of poplar veneer and plywood modified by in-situ synthesis of CaCO3. J. For. Eng. 2022, 7, 43–51. [Google Scholar] [CrossRef]

- Chen, X.; Afreen, S.; Yu, X.; Dong, C.; Kong, Q. Modified melamine-formaldehyde resins improve tensile strength along with antifouling and flame retardancy in impregnation of cellulose paper. RSC Adv. 2019, 63, 36492–37126. [Google Scholar] [CrossRef]

- Nosal, E.; Reinprecht, L. Anti-bacterial and anti-mold efficiency of ZnO nanoparticles present in melamine- laminated surfaces of particleboards. BioResources 2017, 12, 7255–7267. [Google Scholar] [CrossRef]

- Tang, C.F.; Li, Y.; Li, C.F.; Liu, M.L.; Liu, Y.L. Effect of different anti-bacterial agencies on properties of veneer impregnated melamine formaldehyde resin. China For. Prod. Ind. 2015, 42, 29–31. [Google Scholar] [CrossRef]

- GB/T 14732-2017Wood Adhesives: Urea-Formaldehyde, Phenol-Formaldehyde and Melamine-Formaldehyde Resins; National Standards of the People’s Republic of China: Beijing, China, 2017.

- GB/T 11785-2005Reaction to Fire Tests for Floorings-Determination of the Burning Behaviour Using a Radiant Heat Source; National Standards of the People’s Republic of China: Beijing, China, 2005.

- GB/T 8626-2007Test Method of Flammability for Building Materials; National Standards of the People’s Republic of China: Beijing, China, 2017.

- Zhu, S.M.; Zhu, Z.H.; Luo, Q.Y.; Li, J.B.; Lu, Y.T. Common problems and solutions of surface decorated wood-based panels with impregnated thermosetting resins. China Wood-Based Panels 2024, 31, 28–32. [Google Scholar]

- Ye, Z.Y.; Li, X.B.; Li, Y.W.; Zhang, Z.C. Effect of pressing process on surface performance of particleboard decorated with melamine resin impregnated paper. China Wood-Based Panels 2023, 30, 23–27. [Google Scholar]

- GB/T 24507-2020Laminate Engineered Wood Flooring; National Standards of the People’s Republic of China: Beijing, China, 2020.

- GB/T 17657-2022Test Methods of Evaluating the Properties of Wood-Based Panels and Surface Decorated Wood-Based Panels; National Standards of the People’s Republic of China: Beijing, China, 2022.

- Voß, M.; Vallée, T. Effects of Curie particle induced accelerated curing on thermo mechanical performance of 2K structural adhesives—Part I: Bulk properties. J. Adhes. 2021, 98, 1298–1339. [Google Scholar] [CrossRef]

- Park, S.J.; Park, Y.R.; Park, S.J.; Kim, Y.H. High-temperature adhesive properties of CF/PEKK composites applied fusion bonding and adhesive bonding. Mod. Phys. Lett. B 2022, 36, 6. [Google Scholar] [CrossRef]

- Özer, H.; Erbayrak, E. The effects of curing temperature on fracture energy and cohesive parameters for the adhesive Araldite 2015. J. Adhes. Sci. Technol. 2017, 32, 1287–1312. [Google Scholar] [CrossRef]

- De Souza, F.; Del Menezzi, C.H.S.; Bortoletto, G. Material properties and nondestructive evaluation of laminated veneer lumber (LVL) made from Pinus oocarpa and P. kesiya. Eur. J. Wood Wood Prod. 2011, 69, 183–192. [Google Scholar] [CrossRef]

- Spulle, U.; Meija, A.; Kūliņš, L.; Kopeika, E.; Liepa, K.H.; Šillers, H.; Zudrags, K. Influence of hot pressing technological parameters on plywood bending properties. BioResources 2021, 16, 7549–7560. [Google Scholar] [CrossRef]

- Li, Q.; Liu, R.Y.; Chen, X.Q.; Lin, H. Box-bexnken design for process parameters optimization of bamboo-based composite panel manufacturing. Wood Res. 2020, 65, 989–1000. [Google Scholar] [CrossRef]

- Sözbir, G.D.; Bektas, I.; Ak, A.K. Influence of combined heat treatment and densification on mechanical properties of poplar wood. Maderas. Cienc. Tecnol. 2019, 21, 481–492. [Google Scholar] [CrossRef]

- GB/T 18102-2020Laminate Floor Coverings; National Standards of the People’s Republic of China: Beijing, China, 2020.

- GB/T 39600-2021Formaldehyde Emission Grading for Wood-Based Panel and Finishing Products; National Standards of the People’s Republic of China: Beijing, China, 2021.

- Jiang, M.H.; Liu, Z.L.; Cheng, A.K.; Feng, S.H.; Fang, C.H.; Tu, D.Y. Enhancing wood functionality: A novel approach with Al2O3 impregnated paper on densified wood surface. J. Mater. Res. Technol. 2024, 29, 3456–3464. [Google Scholar] [CrossRef]

- Li, J.K.; Xu, L.Y.; Wang, Y.N.; Xiao, Z.R.; Yu, Y. Mechanical properties and photostability of fast-growing wood deposited with nano-Al2O3/ZnO composite films. Wood Mater. Sci. Eng. 2024, 19, 774–782. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).