Modified Use of the Component Method to Get More Realistic Force Distribution in Joints of Steel Structures

Abstract

1. Introduction

2. Comparing the Results of the Manual Calculation and the Mechanical Model

2.1. Manual Calculation with the Use of the Component Method

- The calculated resistance of the currently checked bolt row, together with the bolt rows above it, exceeds the resistance of the compression components, or the resistance of the shear component. In this case, the assumed force in the actual bolt row must be defined by considering the smallest resistance of the compression components and the shear component, so that the pair-of-force can develop. (This is based on the seventh point of the referred chapter).

- The calculated resistance of the currently checked bolt row, together with those bolt rows above it, which are also included in the same group failure, exceeds the resistance of the group. In this case, the assumed force in the actual bolt row should be defined considering the previously defined forces in the other bolt rows involved in the group and the group resistance. (This is based on the eighth point of the referred chapter).

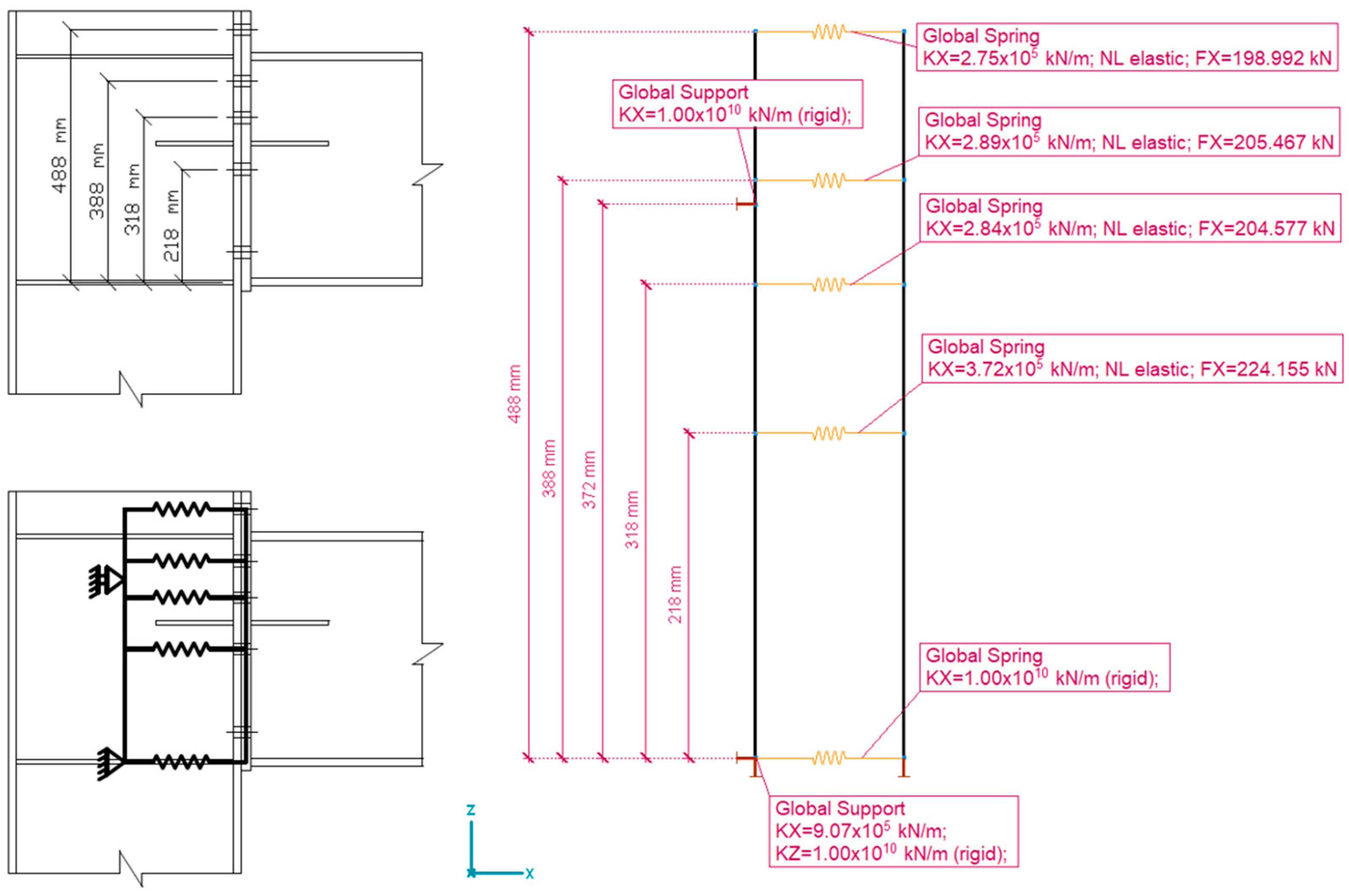

2.2. Checking the Results with the Mechanical Model

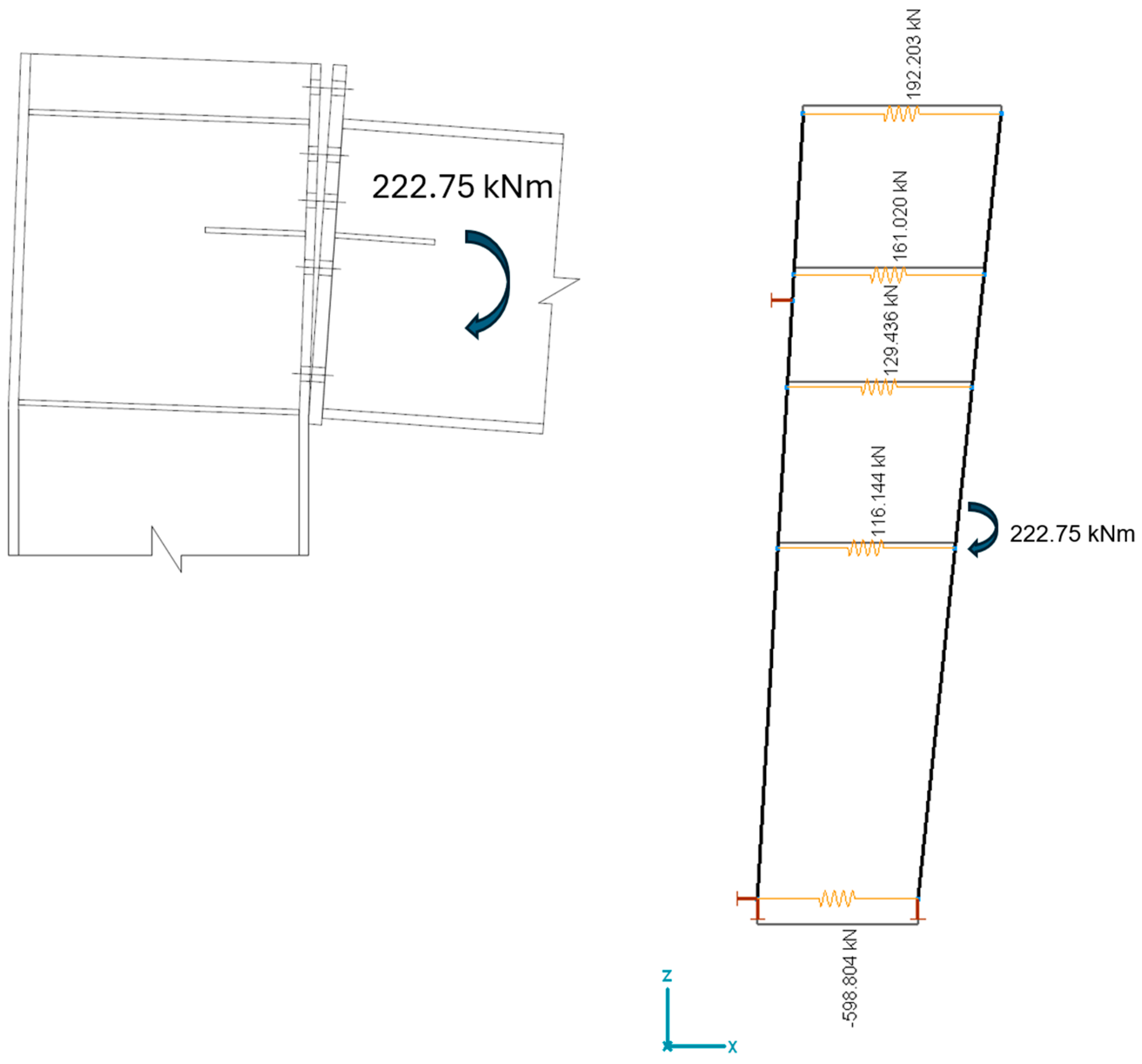

2.3. Comparison of the Results

- There are lower forces in the first and second bolt rows (far from the rotation point) in the case of the mechanical model;

- There are higher forces in the third and fourth bolt rows (closer to the rotation point) in the case of the mechanical model;

- The force is higher in the compression zone in the case of the mechanical model. This exceeds the calculated limit value for the component “column web in shear”, which means that, according to this model, the moment resistance of the joint is lower than it was calculated with the common assumptions of the manual calculation.

3. The Methodology of the Modified Calculation

3.1. Defining the Effective Length for Each Bolt Row

3.2. Defining the Stiffness and Resistance Parameters of the Components

3.3. The Redistribution of the Forces in the Bolts

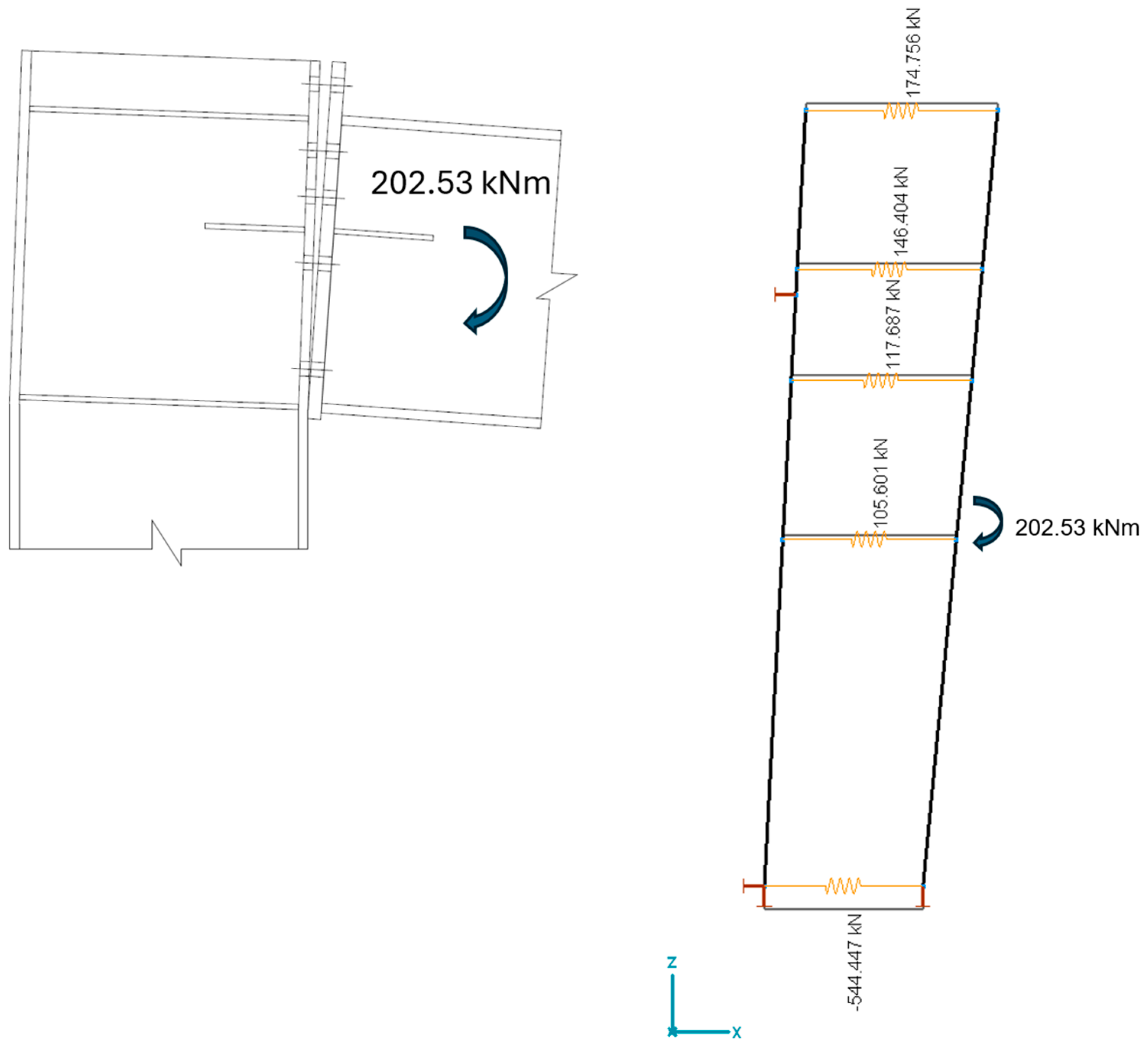

3.4. Compring the Results of the Modified Component Method and the Mechanical Model

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| α | Angle between the two rigid bodies in Figure 3 |

| E | Modulus of elasticity |

| FcfbRd | The design resistance of the “beam flange in compression” component |

| FcwcRd | The design resistance of the “column web in compression” component |

| FTbolt_mod∑ | The summarized value of the actual tension forces in the bolt rows |

| FTRd_i | Combined tension resistance of the bolt row number “i” |

| FTRd∑ | The summarized value of the tension resistance of the bolt rows |

| hi | Distance between the rotation point and the bolt row number “i” |

| keff_i | Combined stiffness coefficient of the bolt row number “i” |

| VwpRd | The design resistance of the “column web in shear” component |

References

- EN 1993-1-8; Eurocode 3: Design of Steel Structures, Part 1-8: Design of Joints. European Committee for Standardization: Brussels, Belgium, 2024.

- InterCad Ltd. Axis VM 17, Commercial version; SC1 steel connection design module; InterCad Ltd.: Budapest, Hungary, 2023. [Google Scholar]

- StruSoft Ltd. FEM-Design, Educational version; Steel connection design module; StruSoft Ltd.: Malmö, Sweden, 2023. [Google Scholar]

- ConSteel Solutions Ltd. ConSteel Joint, Educational version; ConSteel Solutions Ltd.: Budapest, Hungary, 2023. [Google Scholar]

- Golea, T.; Corman, A.; Mathieu, J.; Duchêne, Y.; Jaspart, J.P.; Demonceau, J.F. An innovative mechanical model for structural steel joints. Eng. Struct. 2023, 277, 115459 . [Google Scholar] [CrossRef]

- Gil-Martín, L.M.; Hernández-Montes, E. A compact and simpler formulation of the component method for steel connections. J. Constr. Steel Res. 2020, 164, 105782. [Google Scholar] [CrossRef]

- Da Silva, L.S.; Coelho, A.G. Ductility model for steel connections. J. Constr. Steel Res. 2001, 57, 45–70. [Google Scholar] [CrossRef]

- Coelho, A.G.; da Silva, L.S.; Bijlaard, F.S. Ductility analysis of bolted extended end plate beam-to-column connections in the framework of the component method. Steel Compos. Struct. 2006, 6, 33–53. [Google Scholar] [CrossRef]

- Golea, T.; Bodson, R.; De Ville De Goyet, V.; Jaspart, J.P.; Demonceau, J.F. A generalised mechanical model for the characterisation of steel joints. Ce/Paper 2023, 6, 1222–1227. [Google Scholar] [CrossRef]

- Bayo, E.; Cabrero, J.M.; Gil, B. An effective component-based method to model semi-rigid connections for the global analysis of steel and composite structures. Eng. Struct. 2006, 28, 97–108. [Google Scholar] [CrossRef]

- Rasmussen, K.J.R.; Zhao, X.; Yan, S.; Dai, L.; Zhu, C.; Jiang, L. Recent developments of the Component Method. Ce/Paper 2019, 3, 313–323. [Google Scholar] [CrossRef]

- EN 1993-1-8; Eurocode 3: Design of Steel Structures, Part 1-8: Design of Joints. European Committee for Standardization: Brussels, Belgium, 2010.

- Son, M.P. Experimental determination of yield in beam-to-column flange connections. IOP Conf. Ser. Mater. Sci. Eng. 2019, 687, 033006. [Google Scholar] [CrossRef]

- Da Silva, L.S.; Simoes, R.D.; Cruz, P.J. Experimental behaviour of end-plate beam-to-column composite joints under monotonical loading. Eng. Struct. 2001, 23, 1383–1409. [Google Scholar] [CrossRef]

| Resistance | Approximated Force in Component | |||

|---|---|---|---|---|

| Single | 2–3 as a Group | |||

| [kN] | [kN] | [kN] | ||

| Tension side | Bolt row no. 1 | 198.992 | 198.992 | 198.992 |

| Bolt row no. 2 | 225.045 | 410.044 | 225.045 | |

| Bolt row no. 3 | 224.155 | 120.505 | ||

| Bolt row no. 4 | 224.155 | 224.155 | 0.000 | |

| Total (Sum) | 872.347 | 833.191 | 544.542 | |

| Compression side | Column web in compression | 733.977 | 544.542 | |

| Beam flange in compression | 918.513 | 544.542 | ||

| Column web in shear | 544.542 | 544.542 | ||

| Total (min) | 544.542 | 544.542 | ||

| Stiffness of the Replacing Spring Element [kN/m] | ||||||

|---|---|---|---|---|---|---|

| Column Web in Tension | Column Flange in Bending | Bolt in Tension | Endplate in Bending | Beam Web in Tension | Total | |

| Bolt row no. 1 | 4.40 × 105 | 3.06 × 106 | 1.46 × 106 | 2.82 × 106 | 1.00 × 1010 | 2.75 × 105 |

| Bolt row no. 2 | 4.55 × 105 | 3.17 × 106 | 1.46 × 106 | 3.92 × 106 | 1.00 × 1010 | 2.89 × 105 |

| Bolt row no. 3 | 4.46 × 105 | 3.11 × 106 | 1.46 × 106 | 3.63 × 106 | 1.00 × 1010 | 2.84 × 105 |

| Bolt row no. 4 | 6.29 × 105 | 4.38 × 106 | 1.46 × 106 | 5.29 × 106 | 1.00 × 1010 | 3.72 × 105 |

| C. web in comp. | 1.00 × 1010 | |||||

| B. flange in comp. | 1.00 × 1010 | |||||

| C. web in shear | 9.07 × 105 | |||||

| Resistance | Approximated Force in Component | |||

|---|---|---|---|---|

| Single | 2–3 as a Group | |||

| [kN] | [kN] | [kN] | ||

| Tension side | Bolt row no. 1 | 198.992 | 198.992 | 174.746 |

| Bolt row no. 2 | 225.045 | 205.467 | 146.399 | |

| Bolt row no. 3 | 224.155 | 204.577 | 117.686 | |

| Bolt row no. 4 | 224.155 | 224.155 | 105.608 | |

| Total (Sum) | 872.347 | 833.191 | 544.439 | |

| Compression side | Column web in compression | 733.977 | 544.439 | |

| Beam flange in compression | 918.513 | 544.439 | ||

| Column web in shear | 544.542 | 544.439 | ||

| Total (min) | 544.542 | 544.439 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radnay, L.; Kovács, I. Modified Use of the Component Method to Get More Realistic Force Distribution in Joints of Steel Structures. Buildings 2024, 14, 3553. https://doi.org/10.3390/buildings14113553

Radnay L, Kovács I. Modified Use of the Component Method to Get More Realistic Force Distribution in Joints of Steel Structures. Buildings. 2024; 14(11):3553. https://doi.org/10.3390/buildings14113553

Chicago/Turabian StyleRadnay, László, and Imre Kovács. 2024. "Modified Use of the Component Method to Get More Realistic Force Distribution in Joints of Steel Structures" Buildings 14, no. 11: 3553. https://doi.org/10.3390/buildings14113553

APA StyleRadnay, L., & Kovács, I. (2024). Modified Use of the Component Method to Get More Realistic Force Distribution in Joints of Steel Structures. Buildings, 14(11), 3553. https://doi.org/10.3390/buildings14113553