Abstract

Based on the composition design of warm-mixed rubber asphalt mixture and the analysis of the influence of warm mixing on the road performance of warm-mixed rubber asphalt mixture, the fatigue performance of warm-mixed rubber asphalt mixture is studied in this paper. The effects of gradation, asphalt dosage, and strain level on the fatigue life of the mixture are analyzed. Based on a comparative analysis of the fatigue life of warm-mixed and hot-mixed rubber asphalt mixture before aging, it is concluded that the fatigue performance of hot-mixed rubber asphalt mixture is slightly better than that of warm-mixed rubber asphalt mixture. The effect of aging on the fatigue performance of warm-mixed and hot-mixed rubber asphalt mixture is analyzed, and it is concluded that the fatigue durability of aging hot-mixed rubber asphalt mixture decreases much faster than that of warm-mixed rubber asphalt mixture. Based on a comparative analysis of the fatigue performance of three kinds of asphalt mixture used as a stress absorption layer, it is concluded that the fatigue performance of warm-mixed rubber asphalt mixture is basically the same as that of hot-mixed rubber asphalt mixture, but much higher than that of SBS-modified asphalt mixture. A warm-mixed agent can slow down the decreasing rate of fatigue performance of rubber asphalt mixture and improve the aging resistance of rubber asphalt mixture.

1. Introduction

Reflection cracks are the main problem existing in semi-rigid-base asphalt pavements and asphalt overlays on old roads. In technical systems that use a stress absorption layer to mitigate reflection cracks, rubber asphalt mixtures have increasingly been used as a new form of pavement structure. An effective way to prevent the issue of reflection cracks is to set up a stress absorption layer comprising a warm-mixed rubber asphalt mixture [1]. Due to the addition of rubber powder with high elastic properties, the flexibility of the pavement laid with rubber asphalt mixture is enhanced, and high-temperature performance and low-temperature crack resistance are improved [2]. Asphalt pavement is in a state of stress–strain overlap for a long time due to the repeated action of wheel load, which leads to a continuous decrease in pavement structural strength. When the number of repeated loads exceeds a certain value, the fatigue fracture failure of asphalt pavement will occur due to cracks [3]. The stress absorption layer plays an important role in road construction and maintenance, and can effectively extend the service life of roads [4]. Although traditional rubber asphalt mixtures have good performance, they need high temperature during construction, resulting in high energy consumption and serious environmental pollution. As a new kind of material, warm-mixed rubber asphalt mixture can be constructed at a lower temperature, which reduces energy consumption and environmental pollution. Moreover, the material has excellent fatigue performance [5].

This discovery provides a new, environmentally friendly material option in the field of road engineering. The research on the fatigue performance of warm-mixed rubber asphalt mixture is a complex and challenging subject, but it is of great significance to the safety and durability of road engineering.

At present, the research on stress absorption layers of rubber asphalt mixture at home and abroad mainly focuses on the basic properties and applications of the material, such as rutting resistance and durability. However, there is relatively little research on its fatigue performance, especially under the condition of warm mixing. This is mainly because the research on fatigue performance needs complex experimental equipment and technology, such as dynamic fatigue testing machines and advanced data analysis methods, which makes it difficult for many research institutions to conduct in-depth research. Fatigue property refers to the ability of a material to resist damage under repeated loads [6]. For rubber asphalt mixtures, research on fatigue performance is particularly important, because this is directly related to the service life and safety of the road. Through a systematic review of the relevant literature at home and abroad and an experimental study, we find that although rubber asphalt mixtures have broad application prospects in terms of the stress absorption layer, there are still many shortcomings in the research on fatigue performance [7].

At present, the research on the fatigue performance of rubber asphalt mixture used as a stress absorption layer at home and abroad is still in the initial stage, and the related research is not only limited in quantity, but also needs to be expanded in depth and breadth. In particular, the research on fatigue performance of warm-mixed rubber asphalt mixtures is facing many difficulties. On the one hand, due to the complexity and particularity of warm-mixed technology, it is very difficult to control and simulate the relevant experimental conditions. On the other hand, it is difficult for researchers to carry out large-scale and long-term experiments and observations due to the lack of sufficient funds and technical support. The shortcomings in this research area not only restrict the wider application of rubber asphalt mixture in engineering practice, but also make it difficult to give full play to its potential advantages in road construction. In the future, it will be necessary to increase investment in this field and deeply discuss the fatigue performance of rubber asphalt mixture, especially the related characteristics of warm-mixed rubber asphalt mixture, so as to provide strong technical support for the high-quality development of road engineering.

As the mixture is used in stress absorption layers, it should strike a balance between fatigue performance, high-temperature stability, and interlaminar shear strength. The high-temperature stability and shear strength of rubber asphalt mixture have been widely recognized in engineering practice [8]. Therefore, the fatigue performance of warm-mixed rubber asphalt mixture used for stress absorption layers is studied here, and the key factors affecting its fatigue life are analyzed and determined, which can provide reference for improving the fatigue life of warm-mixed rubber asphalt mixture and make it widely used.

In the field of materials science, fatigue damage theory and fracture mechanics theory are often used to study the fatigue performance of rubber asphalt mixture. Among them, fatigue damage theory explains the changes in the internal microstructure and the damage accumulation process under repeated loads, which is the basis of studying the fatigue performance of a mixture. Fracture mechanics theory is often used to analyze the initiation and propagation of cracks, which provides an important basis for understanding the fatigue failure mechanism of rubber asphalt mixture [9].

For the fatigue testing of asphalt mixture, the research methods and directions studied at home and abroad can be roughly divided into four categories: fatigue test failure under real pavement and vehicle load, full-scale pavement structure fatigue test under simulated vehicle load, test plate test research, and small-scale laboratory fatigue test research. Among them, the first three kinds of test methods have the characteristics of high cost and a long cycle, and have not been widely carried out. However, the indoor small fatigue test method is often used, which has the advantages of short period and low cost [10]. In the previous study, the researchers concluded that the factors that affect the fatigue performance of rubber asphalt mixture mainly include the content of rubber powder, the type and content of asphalt, the gradation of the mixture, the test temperature and the loading frequency. In addition, in order to better predict the fatigue life of rubber asphalt mixture, the researchers put forward a variety of fatigue life prediction models, such as the prediction model based on mechanical properties and the prediction model based on empirical formula. In this study, a four-point beam bending fatigue test is used to analyze the fatigue performance of warm mix rubber asphalt mixture, and the influence and difference of aging on the fatigue performance of warm-mixed rubber asphalt mixture and hot-mixed rubber asphalt mixture are analyzed.

The bending fatigue test of small beam under four-point loading shows that the fatigue life of the rubber asphalt mixture before aging is slightly higher than that of warm-mixed rubber asphalt mixture before aging. However, after aging, the fatigue life of the two kinds of rubber asphalt mixtures is reduced, but the fatigue life of warm-mixed rubber asphalt mixture after aging was obviously longer than that of hot-mixed rubber asphalt mixture. This shows that the addition of warm-mixed agent can attenuate the fatigue life decay rate of rubber asphalt mixture after aging, and also has a certain impact on improving the fatigue performance decay rate of rubber asphalt mixture. At the same time, it also shows that aging will have a negative impact on the fatigue performance of rubber asphalt mixture, especially on hot-mixed rubber asphalt mixture. As for the warm-mixed rubber asphalt mixture, because it may show stronger stability and anti-aging ability during the aging process, its fatigue performance is relatively less affected by aging.

2. Materials and Methods

The subsequent section mainly discusses the composition design and method of SAK-Ⅱ warm-mixed rubber asphalt mixture.

2.1. Materials

The material composition design of warm-mixed rubber asphalt mixture used as the stress absorption layer is summarized as follows.

2.1.1. Production of Rubber Asphalt

Rubber asphalt is fabricated through a wet process. Asphalt is procured from Panjin No. 90 road petroleum asphalt, while the rubber powder is sourced from the crushing and grinding of waste tires at room temperature. The performance of rubber asphalt varies with different parameter combinations. Through orthogonal experiment and result analysis, it is determined that the optimal combination of rubber asphalt is rubber powder content of 22%, rubber powder mesh of 40 mesh, stirring temperature of 200 °C and stirring time of 75 min. Rubber asphalt is made by adding 22% rubber powder of 40 mesh to No. 90 matrix asphalt, using blade mixing equipment, heating temperature of 200 °C and maintaining the rate of 1000 r/min and stirring for 75 min at a high speed. The performance test results of rubber asphalt are shown in Table 1.

Table 1.

Test results of rubber asphalt properties.

At present, the widely used warm-mixed agents in China are emulsifiers for emulsified asphalt and organic additives suitable for reducing asphalt viscosity [11]. Two typical products of organic additives are Sasobit warm-mixed agent and SAK series warm-mixed agent [12]. Sasobit is a polyolefin asphalt modifier, which is produced in South Africa. SAK-Ⅱ warm-mixed agent is a new type of domestic universal and high efficiency warm-mixed asphalt modifier developed on the basis of Sasobit. Its form is white powder. SAK-Ⅱ warm-mixed agent is suitable for petroleum asphalt, with less dosage, good effect and remarkable viscosity reducing effect [13]. The experimental results show that SAK-Ⅱ warm-mixed agent can reduce the high temperature viscosity of rubber asphalt, and the asphalt mixture still has good adhesion when the temperature is low, so that the mixing and compaction temperature of asphalt mixture can be effectively reduced. The mixture can bond well when the temperature is low in winter. Through the comprehensive analysis of various indexes and properties of rubber asphalt with different amounts of warm-mixed agent, and through repeated tests, it is determined that Sak-Ⅱwarm-mixed agent is most suitable, and the best amount is 3%.

After determining the content of rubber powder, in order to better improve the performance of rubber asphalt mixture as a stress absorption layer to resist reflection cracks, SAK-Ⅱ warm-mixed agent and Sasobit warm-mixed agent are added to the rubber asphalt. The dosage of warm-mixed agent is 2%, 3%, 4%, 5% in order. The indexes and properties of the two kinds of warm-mixed rubber asphalt were tested. On this basis, the most suitable kind of warm-mixed agent and its best dosage are selected to meet the requirements of stress absorption layer technology of rubber asphalt mixture. On the basis of referring to the actual engineering practice and the conventional technical requirements of stress absorption layer modified asphalt, combined with the research results at home and abroad, the general technical requirements of warm-mixed rubber binder for stress-absorbing layer are put forward, as shown in Table 2, as a basis for the research, index detection and quality control of warm-mixed rubber asphalt binder [14].

Table 2.

Technical requirements for stress absorption layer warm-mixed rubber asphalt binder.

Warm-mixed rubber asphalt is prepared by adding warm-mixed agent to rubber asphalt and stirring for 15 min at 150 °C.

2.1.2. Selection of Aggregates

The correct selection and inspection of aggregate can ensure the performance of warm-mixed rubber asphalt mixture. Due to the need for the stress absorption layer to prevent reflection cracks and block rain water infiltration, with reference to aggregates commonly used at home and abroad, aggregates with smaller sizes of 0~3 mm and 3~5 mm are adopted, and mineral powder is added for mixing, and each kind of aggregate is tested according to the Highway Engineering Aggregate Test Rules. Basalt with high strength and less needle flake content is selected for coarse aggregate and machine-made sand of 0~3 mm is selected for fine aggregate.

2.1.3. Determination of Aggregate Gradation

The aggregate gradation used in the warm-mixed rubber asphalt mixture of stress absorption layer belongs to the suspended dense structure, of which more than 75% is fine aggregates with a nominal maximum particle size of 4.75 mm. In this structure, the ore proportion of each key screen is uniform, and the ore particles are arranged in order from large to small. There are many small particles, and its space is embedded with large particles. The large particles are suspended together, but cannot contact each other, forming a bituminous dense structure of asphalt, with better compaction effect and higher strength.

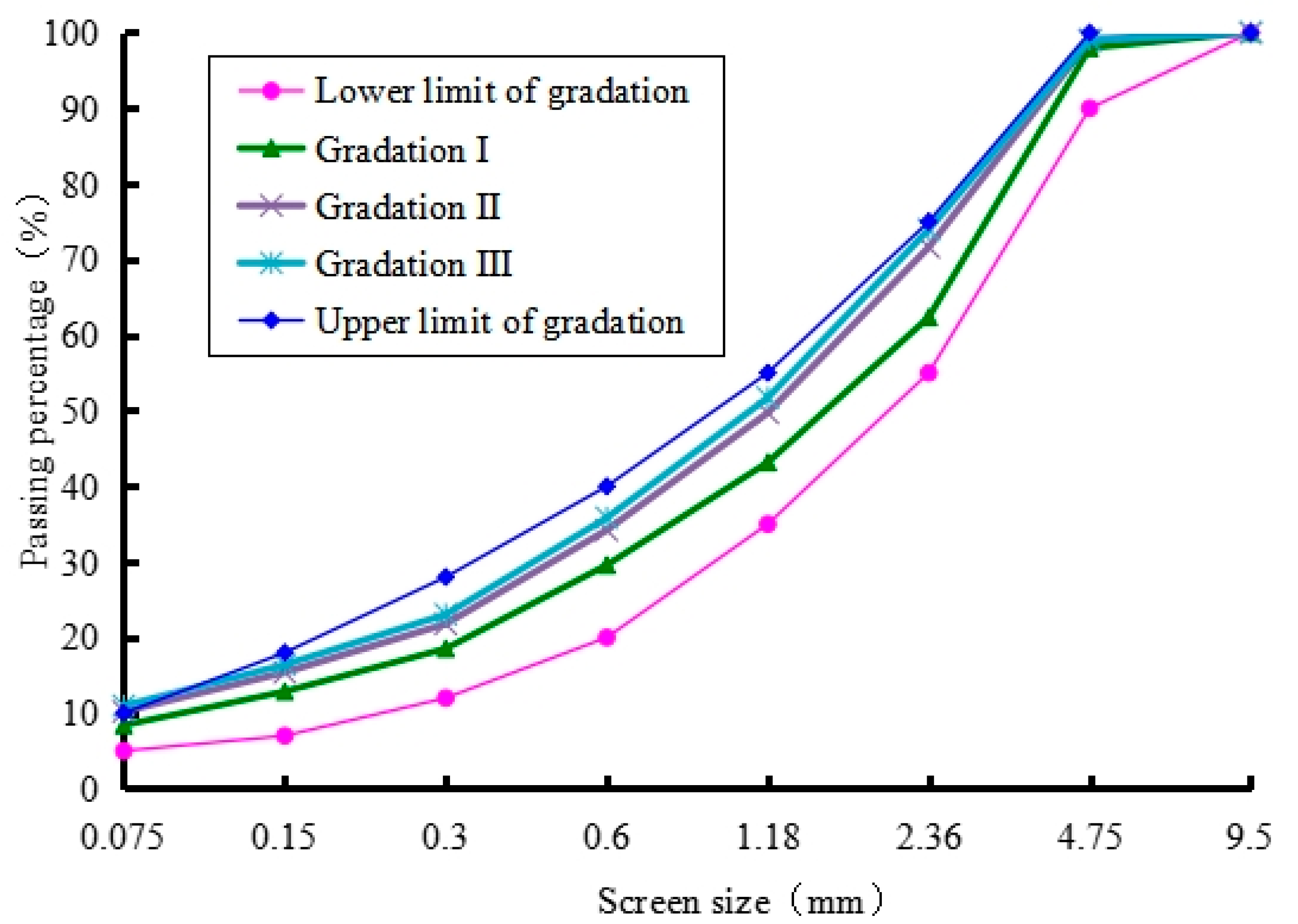

The aggregate gradation used in warm-mixed rubber asphalt mixture with stress absorption layer belongs to suspension and compaction structure. On the basis of AC-5 gradation range, combined with the stress absorption layer system gradation range recommended by Koch Materials Company of the United States [14], combined with the current engineering situation in cold areas of our country, according to the characteristics of aggregate gradation, and referring to the relevant regulations of aggregate gradation requirements at home and abroad, the aggregate composition and engineering control aggregate gradation of stress absorption layer warm-mixed rubber asphalt mixture are summarized, and the mineral aggregate mixing ratio is obtained by comprehensive graphic method. The synthetic gradation curve is drawn, and the different gradation ranges are given. Table 3 shows the synthetic gradation of warm-mixed rubber asphalt mixture. The gradation curve of warm-mixed rubber asphalt mixture is shown in Figure 1.

Table 3.

Synthetic gradation of warm-mixed rubber asphalt mixture suitable for stress absorption layer in cold area.

Figure 1.

Aggregate composition grading curve.

2.1.4. Determination of the Optimum Amount of Asphalt

Referring to the Superpave asphalt mixture volume design method, using SGC rotary compaction molding mixture, setting the design rotary compaction times Ndes = 50, setting the rotary compaction times Nlift = 25 to control the compaction level [15], and referring to the American SHRP asphalt mixture design steps, it is determined that the optimal asphalt dosage of SAK-Ⅱ warm-mixed rubber asphalt mixture is 8.9%, which is basically unchanged compared with the optimal asphalt dosage of hot-mixed rubber asphalt mixture.

2.1.5. Determination of Optimum Mixing and Compaction Temperature

According to the viscosity–temperature criterion and the viscosity–temperature semi-logarithmic curve regression equation, the mixing temperature range of warm-mixed rubber asphalt mixture is 165 °C~175 °C, and the mixing temperature is 170 °C. It is determined that the rotary compaction temperature of warm-mixed rubber mixture is 150 °C, which can be reduced by about 30 °C compared with hot-mixed rubber asphalt mixture, by the gross volumetric density curve at different molding temperatures [16].

2.2. Methods

2.2.1. Effect of Warm-Mixed Material on Road Performance of Rubber Asphalt Mixture

Before the fatigue test, the pavement performance of SAK-Ⅱ warm-mixed rubber asphalt mixture is tested. Referring to the temperature of hot summer weather in cold areas, the temperature of the rutting test is adjusted from 60 °C to 45 °C.The mixture forming method and experimental parameter setting are the same as the 60 °C rutting test [17]. Referring to the actual meteorological data, the lowest design temperature of pavement in cold areas is −23 °C [18]. The temperature of trabecular bending failure test of warm-mixed rubber asphalt mixture is adjusted to −23 °C, and other performance evaluation indexes remain unchanged.

2.2.2. Test Scheme and Parameters of Four-Point Loading Trabecular Bending Fatigue Test

Test Scheme

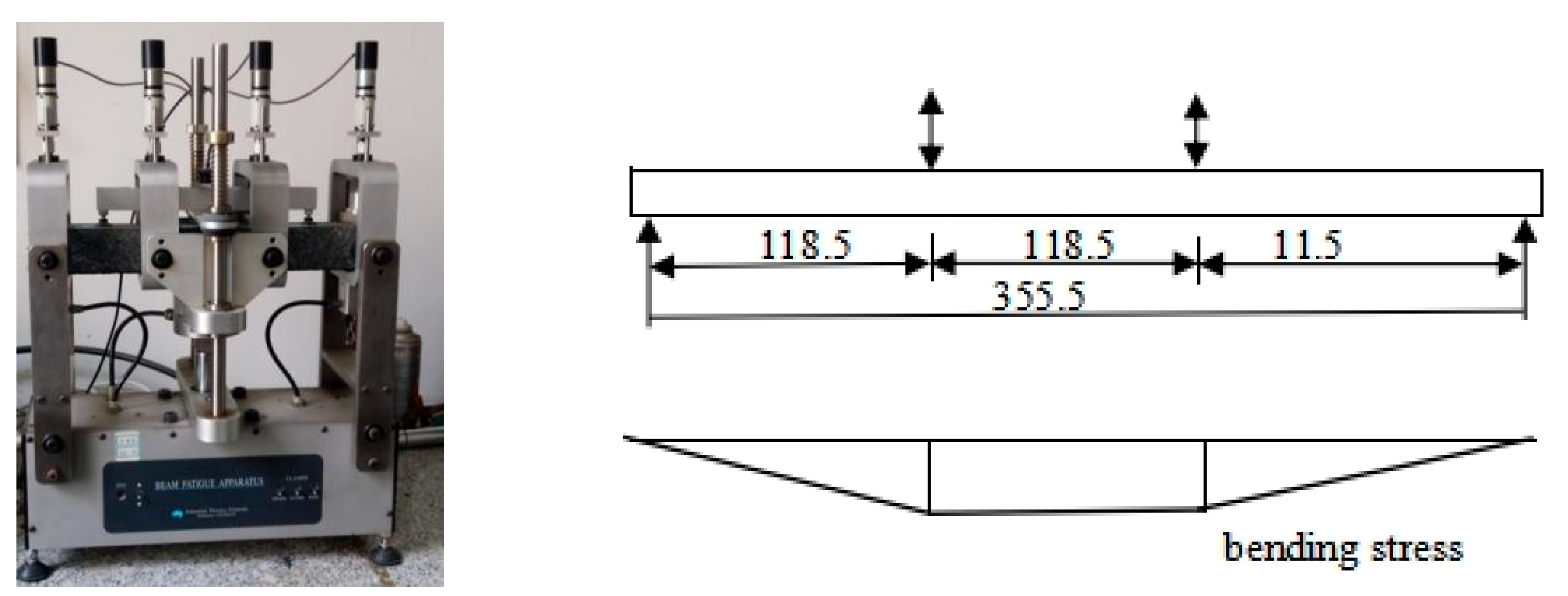

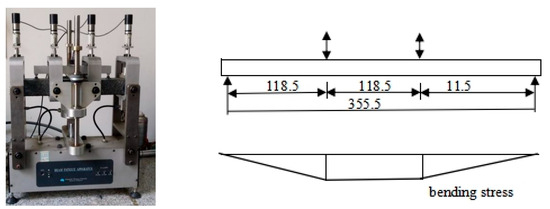

The four-point loading trabecular bending fatigue test is selected to evaluate the fatigue performance of the material. The selection of test parameters and the test process referred to “Chinese Test Rules for Asphalt and Asphalt Mixture of Highway Engineering”. The four-point loading bending fatigue test device is mainly composed of an environmental box, a data acquisition and control device and a loading device. The fatigue test process and the four-point loading diagram are shown in Figure 2.

Figure 2.

Fatigue test specimen, four-point loading bending fatigue test process and four-point loading diagram.

In the experiment, the rutting specimen forming mechanism is used to make the trabecular specimen, and the size of the trabecular specimen is 400 mm × 63.5 mm × 50 mm. The standard double-knife saw is used to cut the trabecular beam, and the direction of rolling forming is selected for the length direction of the specimen. Before the fatigue test, the trabecular specimens should be kept in a temperature control box with a temperature accuracy of 15 °C ± 0.5 °C for more than 3 h. The specimens should be placed in parallel, and the distance between the specimens should be kept above 10 mm.

The fatigue test scheme of warm-mixed rubber asphalt mixture is as follows. The fatigue performance of warm-mixed rubber asphalt mixture under three gradation conditions is analyzed under four strain levels of 750 με, 1000 με, 1250 με and 1500 με. Under the condition of controlling strain level of 1000 με, the fatigue life of warm-mixed rubber asphalt mixture under different gradations and corresponding different rubber asphalt content is analyzed. Analyze the fatigue life of three graded samples of warm-mixed rubber asphalt mixture at different strain levels. Analyze the fatigue performance of two kinds of rubber asphalt mixture specimens with warm-mixed and hot-mixed material corresponding to grade Ⅱ. Analyze the fatigue performance before and after aging of warm-mixed rubber asphalt mixture corresponding to gradation Ⅱ. Compare and analyze the fatigue performance of hot-mixed rubber asphalt mixture, warm-mixed rubber asphalt mixture and SBS-modified asphalt mixture. Modified asphalt mixture is relative to ordinary asphalt mixture. The asphalt in this mixture is chemically or physically modified by matrix asphalt (asphalt No. 50, No. 70, No. 90, etc.). The purpose is to optimize the performance of asphalt, so that the performance of the asphalt mixture produced will become better. SBS-modified asphalt is the most commonly used modified asphalt in China, and the mixture prepared from this asphalt is SBS-modified asphalt mixture.

Test Parameters

When warm-mixed rubber asphalt mixture is used in the stress absorption layer, its structure thickness is thin, and strain-controlled loading mode should be adopted in fatigue performance test. The stress state in this mode is close to the real stress condition of the mixture. It is beneficial to determine the fatigue characteristics of the mixture [19]. The air temperature changes greatly in the cold area, and the fatigue failure of asphalt mixture mainly occurs in the northern spring melting period, which is the most unfavorable period for the anti-fatigue performance of pavement structure, and the strength of pavement structure is obviously weakened. A temperature of 15 °C is the reference value of allowable tensile stress index in the Chinese highway asphalt pavement design code. Therefore, the fatigue test temperature is selected as 15 °C and the fatigue test loading frequency is selected as 10 Hz. The sine waveform is close to the load waveform of the actual pavement, and the sine waveform is selected in the fatigue test [20]. In order to obtain effective test data, each group of tests has no less than three effective test specimens.

Aging Treatment Method of Asphalt Mixture

The aging treatment of asphalt mixture is mainly carried out by simulating various climatic conditions in the actual use environment to evaluate and verify the durability of the mixture. The performance of asphalt mixture under different aging conditions is evaluated through aging treatment, which provides a scientific basis for the design, construction and maintenance of asphalt mixture. At the same time, these aging tests also provide important test data for the long-term performance prediction of asphalt mixture. Short-term and long-term aging of asphalt mixture are two different processes. The short-term aging test method of asphalt mixture should be able to reflect the effect of volatilization and oxidation of loose asphalt mixture during mixing, storage and transportation, so as to simulate the aging effect of asphalt mixture in the construction stage. At present, the most commonly used oven heating method is developed from the experiment of Von Quintas in 1988 [1]. Its simulated construction conditions are good, the method is simple, and the equipment investment cost is not high, so it is widely evaluated as the most effective method for simulating short-term aging in the laboratory. The long-term aging method of asphalt mixture should emphasize the continuous oxidation of compacted specimens of asphalt mixture to simulate the aging effect of asphalt pavement during its service life. The SHRP plan to evaluate the long-term aging of asphalt mixtures recommended the delayed oven heating method, which was put forward by Harrigaii in 1994 and was evaluated as the most effective method for the long-term aging of mixing laboratory [21]. In the aging process of warm-mixed rubber asphalt mixture, the aging factors at different levels usually include the following aspects.

- The influence of temperature

Warm-mixed technology mainly reduces energy consumption and emissions by lowering the service temperature of asphalt, but the lowering of temperature may affect the aging process of asphalt. Usually, the decrease in temperature will slow down the chemical reaction rate and prolong the aging process, but the specific influence needs to be determined through experimental research.

- 2.

- The comprehensive role of environmental factors

The aging of asphalt is not only a chemical reaction process, but also affected by environmental factors, such as sunlight and rain. These factors may accelerate or slow down the aging process of asphalt in different ways. All-weather aging tests can simulate these environmental conditions to assess the aging process.

- 3.

- Effect of aging on microstructure

The aging process may change the microstructure of asphalt, such as the changes of surface morphology, adhesion and modulus observed by AFM. Through these changes, we can further analyze the influence of aging on asphalt properties.

- 4.

- The role of warm-mixed agent

The warm-mixed agent used in warm-mixed asphalt mixture may affect the aging process of asphalt. Warm-mixed material may slow down the aging process by providing extra protection or changing the chemical structure of asphalt.

- 5.

- Physical and chemical changes in the aging process

Aging asphalt may change its physical properties, such as hardening and embrittlement, and may also change chemically, such as oxidation and crosslinking.

These changes will affect the rheological properties, high-temperature stability and low-temperature cracking resistance of asphalt.

- 6.

- Effect of aging on fatigue properties

The fatigue performance of aged asphalt mixture under repeated loading is also an important consideration. The aging process may reduce the fatigue life of asphalt mixture and affect the safety performance of road.

By analyzing these aging factors to different degrees, we can fully understand the aging behavior of warm-mixed rubber asphalt mixture, thus providing a scientific basis for road design, construction and maintenance.

In this study, two kinds of aging specimens, warm-mixed rubber asphalt mixture and hot-mixed rubber asphalt mixture, were prepared by oven heating method, which is an indoor test method to simulate the aging of rubber asphalt mixture. Then, on this basis, through the four-point loading trabecular bending fatigue test, the fatigue performance and its changing law of warm-mixed rubber asphalt mixture and hot-mixed rubber asphalt mixture used for stress absorption layer before and after aging are studied.

The four-point loading trabecular bending fatigue test of rubber asphalt mixture after long-term aging is carried out, and the test parameters and various indexes of warm-mixed rubber asphalt mixture are the same as above. The long-term aging time is set at 5 days. Before long-term aging, the specimens are subjected to short-term aging treatment [22]. In this test, the long-term aging time of rubber asphalt mixture is set as 0 d, 3 d, 5 d, 7d, and the specimens should be subjected to short-term aging treatment before long-term aging. The short-term aging steps are as follows. Firstly, prepare the mixed rubber asphalt mixture, heat the mixture in an oven at 135 °C ± 3 °C for 4 h ± 5 min, and pay attention to forced ventilation. Long-term aging is to put the molded rubber asphalt mixture specimen into the oven at the temperature of 85 °C ± 3 °C, continuously heat the mixture under the condition of forced ventilation, and control the heating in three periods: 20 h ± 0.5 h, 72 h ± 0.5 h and 168 h ± 0.5 h, and then close the oven after the aging is completed. The specimen should be naturally cooled to room temperature before use, and the cooling time should not be less than 16 h [23]. The control strain levels of the four-point loading trabecular bending fatigue test are 750 με, 1000 με, 1250 με and 1500 με, respectively.

3. Results and Discussion

3.1. Optimum Content Determination and Performance of Warm-Mixed Agent

The technical requirements of warm-mixed rubber asphalt binder for stress absorption layer given in Table 2 are the standard and basis for determining the optimal dosage of warm-mixed agent. The process of determining the optimal dosage of warm-mixed agent is described in detail as follows.

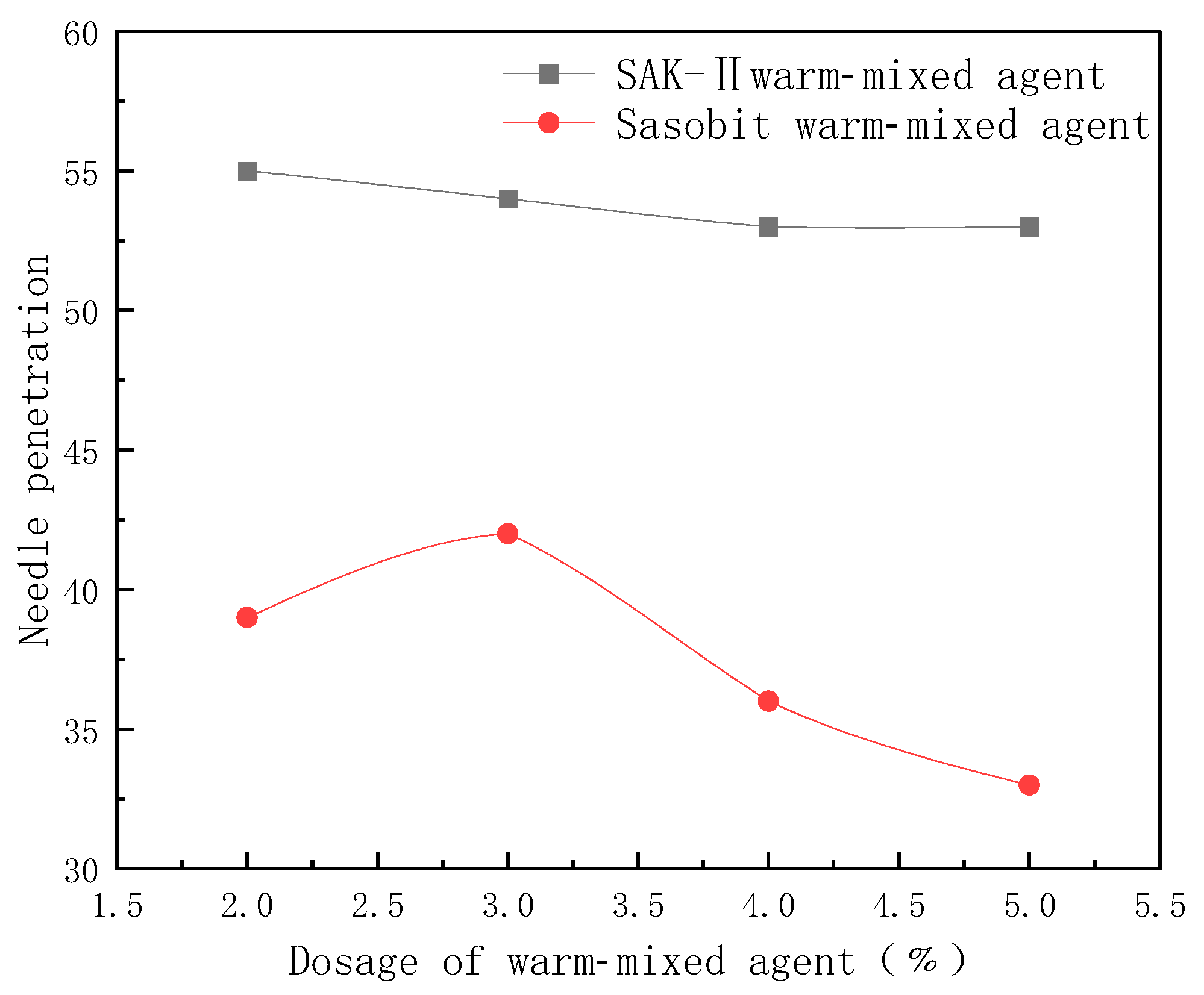

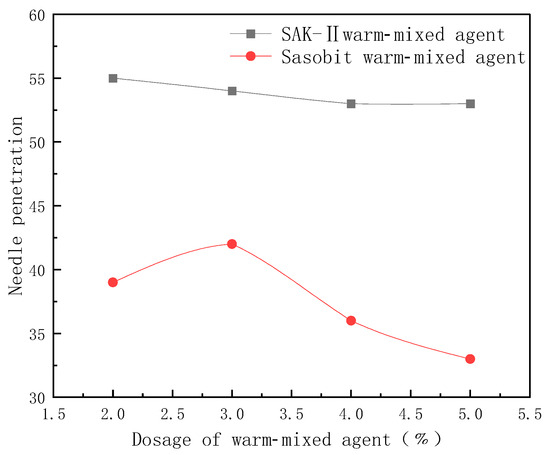

3.1.1. Needle Penetration Test

Needle penetration is an important index to evaluate the physical properties of asphalt, which indicates the depth of inserting a standard needle into asphalt under specific conditions and time. This index reflects the fluidity or thickening degree of asphalt. Specifically, the greater the needle penetration value, the softer the asphalt is and the more easily it flows. On the contrary, the smaller the needle penetration value, the harder the asphalt is, and the less easily it flows. For warm-mixed rubber asphalt, its performance is not only affected by the properties of asphalt itself, but also by additives such as warm-mixed agent and rubber powder. By controlling its influencing factors, the best performance of warm-mixed rubber asphalt can be obtained. The penetration curves of two kinds of rubber asphalt formed by different warm-mixed agents are shown in Figure 3.

Figure 3.

Needle penetration curves of rubber asphalt with two different warm-mixed agents.

Through the penetration test, it can be seen that within the selected dosage range of warm-mixed agent, the influence of two warm-mixed agents on penetration is very small. At the same time, the needle penetration of SAK-Ⅱ warm-mixed rubber asphalt is higher than that of Sasobit warm-mixed rubber asphalt.

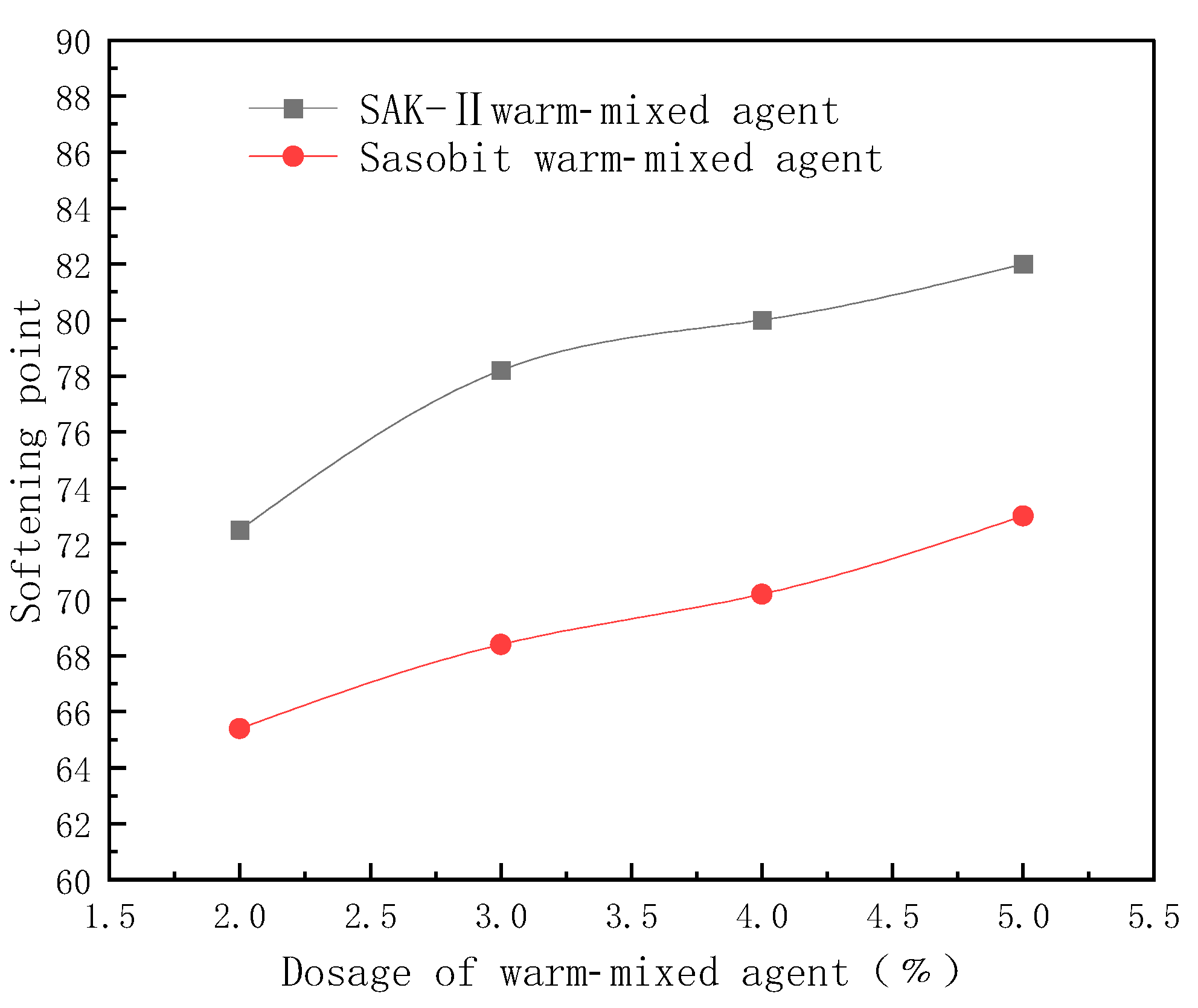

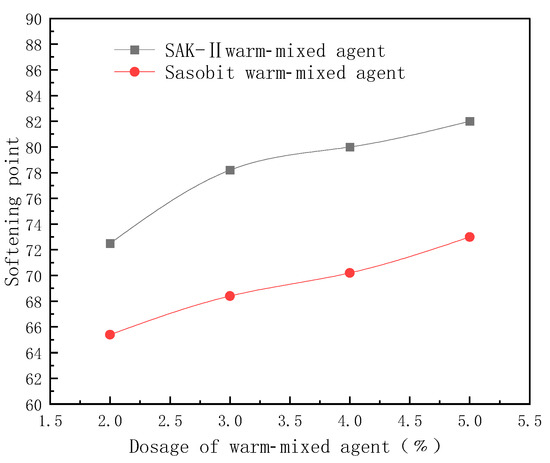

3.1.2. Softening Point Test

Softening point refers to the temperature point at which asphalt material becomes soft and can flow after being heated at a certain temperature.

Softening point is an important index to evaluate the high-temperature stability of asphalt. It effectively reflects the heat resistance of asphalt, which is the key to evaluating the performance of asphalt at high temperature.

A high softening point usually means that asphalt has better heat resistance and thermal stability, because asphalt with a high softening point is less likely to soften or flow at high temperature, thus maintaining its stability.

Therefore, when selecting and adjusting the formula of warm-mixed rubber asphalt, it is necessary to optimize the softening point of asphalt according to the type and dosage of warm-mixed agent used to ensure its performance requirements in practical applications.

The softening point curves of two kinds of rubber asphalt formed by different warm-mixing agents are shown in Figure 4.

Figure 4.

Softening point curve of rubber asphalt with two different warm-mixed agents.

From the softening point test, it can be seen that the softening point value of the warm-mixed asphalt formed by the two kinds of warm-mixed agent has the same change trend within the content range of the selected warm-mixed agent, and the softening point of SAK-Ⅱ warm-mixed rubber asphalt is obviously larger than that of Sasobit warm-mixed rubber asphalt. SAK-Ⅱ warm-mixed rubber asphalt has a high softening point, which shows that SAK-Ⅱ warm-mixed rubber asphalt has excellent high-temperature stability, and the softening point of SAK-Ⅱ warm-mixed rubber asphalt is much higher than the highest temperature of pavement in summer in cold areas. Therefore, using SAK-Ⅱ warm-mixed rubber asphalt mixture as a stress absorption layer for paving pavement in cold areas can effectively prevent pavement issues such as flooding and rutting.

3.1.3. Ductility Test

Ductility describes the extent to which asphalt materials can be extended under tensile force, and it is an important index to reflect the elastic characteristics of asphalt materials. In the properties of warm-mixed rubber asphalt, the ductility has a certain influence on its low-temperature performance. Specifically, a decrease in ductility correlates with a decrease in plasticity and flexibility of asphalt, which will lead to the decrease in low-temperature crack resistance and low-temperature fluidity of asphalt, thus affecting its construction workability and pavement performance at low temperature. In the low-temperature beam test, the ductility will affect the ability of asphalt mixture to resist low-temperature cracking. Asphalt mixture with high ductility is less prone to cracking when it is affected by low temperature, and it has better crack resistance. The addition of warm-mixed agent may affect the ductility. For example, some warm-mixed agents can reduce the viscosity of asphalt and increase its softening temperature, which may improve the ductility of asphalt to some extent, thus improving its low-temperature performance. However, the types and application conditions (dosage, adding method, etc.) of warm-mixed agent will also have an impact on the final ductility and asphalt performance. In practical engineering application, it is necessary to choose the appropriate ductility level according to the specific use environment and performance requirements to ensure that the comprehensive performance of warm-mixed rubber asphalt meets the engineering requirements. Low-temperature ductility is an index to evaluate the low-temperature performance of asphalt. Usually, most countries stipulate that 5 °C ductility is used as the control index of binder.

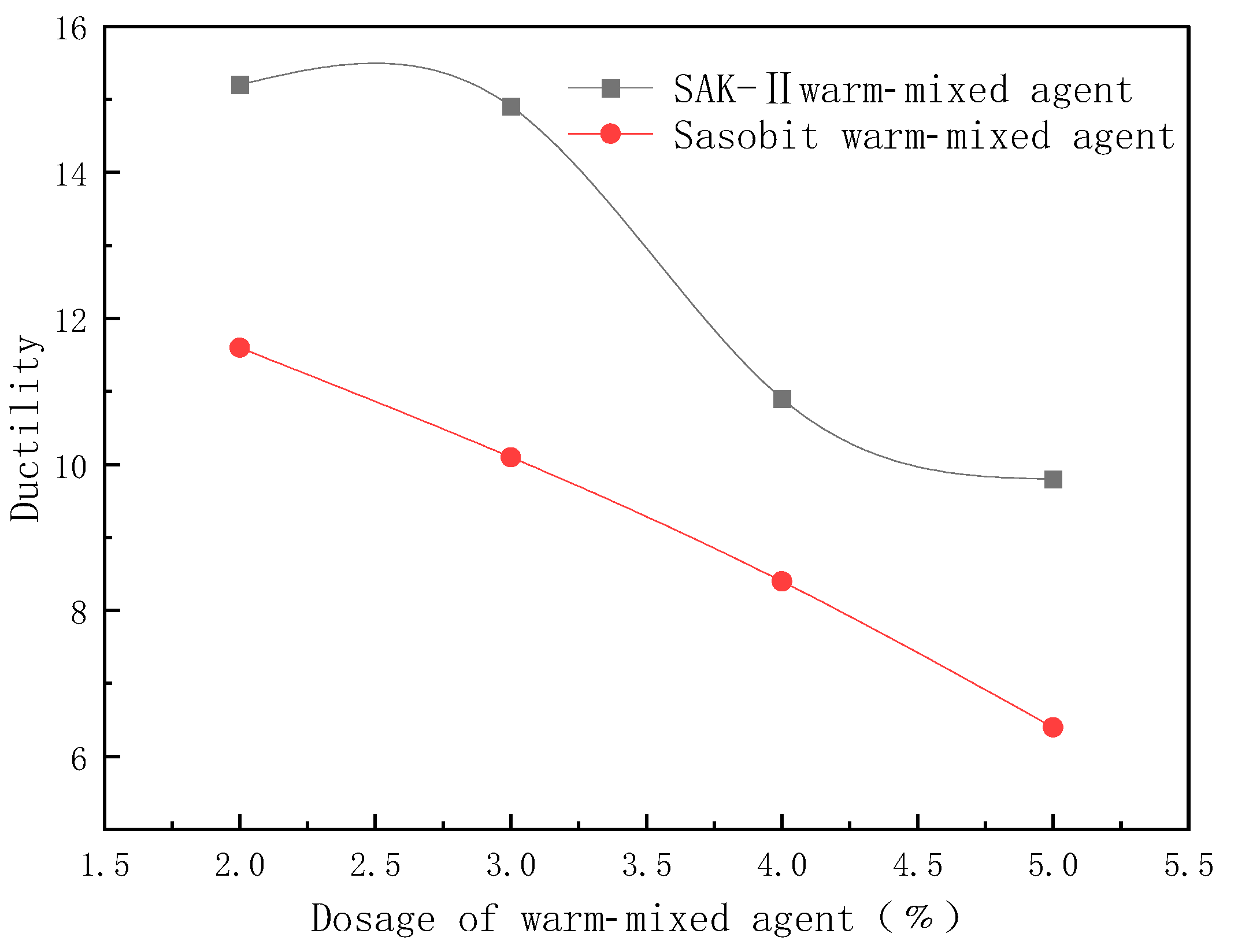

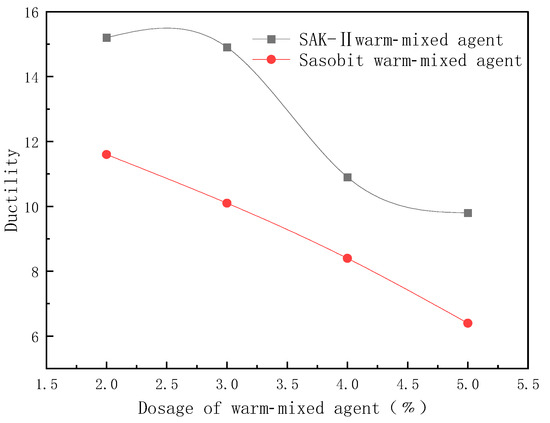

The ductility curves of two kinds of rubber asphalt formed by different warm-mixed agents are shown in Figure 5.

Figure 5.

Ductility curve of rubber asphalt with two different warm-mixed agents.

According to the ductility test, there is a big difference between the elongation values of the two kinds of warm-mixed rubber asphalt. The ductility value of SAK-Ⅱ warm-mixed rubber asphalt is obviously greater than that of Sasobit warm-mixed rubber asphalt. After adding Sasobit warm-mixed agent, the ductility of rubber asphalt decreases linearly, and its low-temperature performance is greatly affected. After adding SAK-Ⅱ warm-mixed agent, the ductility value of rubber asphalt decreased slowly at first, and then decreased rapidly when the content exceeded 3%. It shows that the addition of warm-mixed agent has little influence on the low-temperature performance of rubber asphalt before the content is less than 3%, and the influence on the low-temperature performance of rubber asphalt becomes slightly faster when the content of warm-mix agent exceeds 3%.

3.1.4. Elastic Recovery Test

Elastic recovery refers to the ability of a material to recover its original shape and size after being stretched or compressed. In the performance research of warm-mixed rubber asphalt, elastic recovery is an important index which reflects the elasticity and ductility of asphalt and is an important parameter to characterize the reversible deformation ability of asphalt under external force. Elastic recovery is an important parameter that comprehensively reflects the performance of warm-mixed rubber asphalt, which is closely related to warm-mixed agent, rubber powder type and content, mixing process parameters and aging state. By optimizing the above factors, the elastic recovery of warm-mixed rubber asphalt can be improved, and then its road performance can be improved. The elastic recovery is related to the type and dosage of warm-mixed agent, and different warm-mixed agents have different effects on the elastic recovery of asphalt rubber. The increase in the content of warm mix agent may improve the elastic recovery performance of warm mix rubber asphalt, but when the content of warm mix agent exceeds a certain proportion, the improvement range of elastic recovery performance may become smaller. The measurement of elastic recovery can evaluate the elasticity and resilience of asphalt, which is an important index to evaluate the resilience and crack resistance of asphalt.

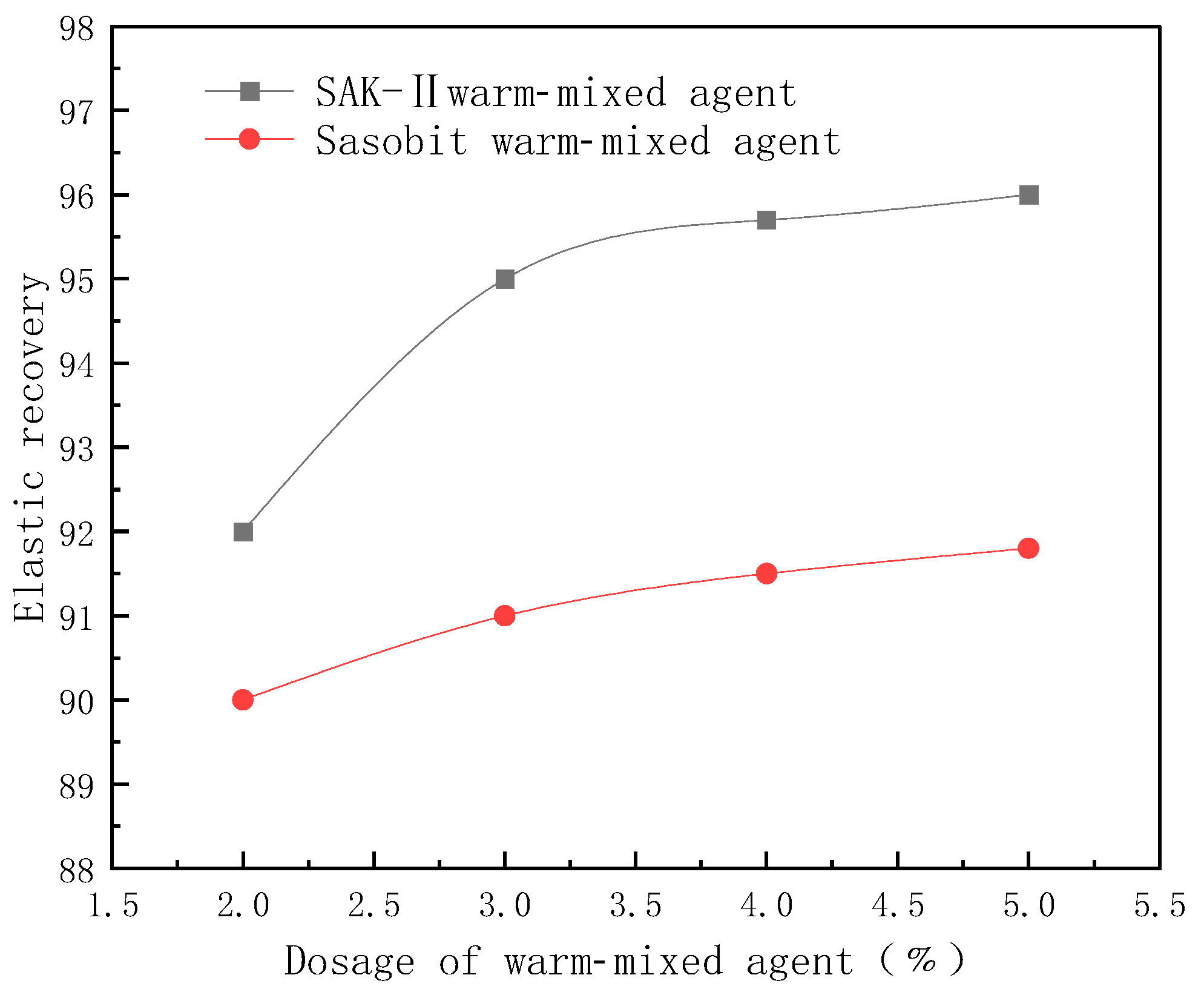

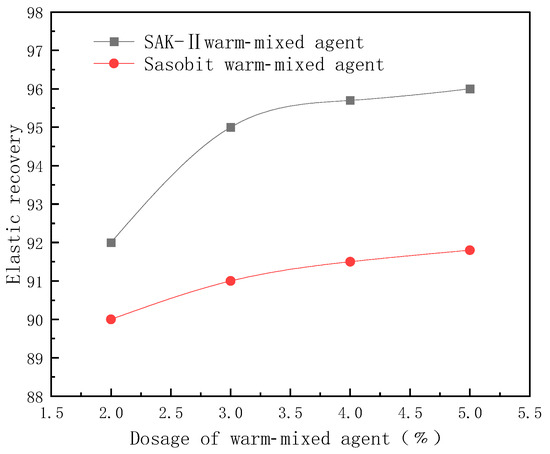

The elastic recovery test curves of two kinds of rubber asphalt formed by two different warm-mixed agents are shown in Figure 6.

Figure 6.

Elastic recovery curve of rubber asphalt added with two different warm-mixed agents.

After adding two kinds of warm-mixed agents, the elastic recovery test shows that the elastic recovery ability of the two kinds of rubber asphalt is improved within the dosage range of the selected warm-mixed agent, but the elastic recovery ability of SAK-Ⅱ warm-mixed rubber asphalt is obviously better than that of Sasobit warm-mixed rubber asphalt.

3.1.5. Low-Temperature Trabecular Bending Test

Low-temperature trabecular bending test is a test method for evaluating the mechanical properties and properties of asphalt and its mixture at low temperature. During the test, the two ends of a small beam with a specific size and shape are loaded to simulate the action of traffic load, and the mechanical properties of the material are evaluated by measuring the strain (i.e., deformation) of the beam. The test can reflect the crack resistance and bearing capacity of asphalt mixture at low temperature.

Low-temperature trabecular bending test is an effective method to evaluate the performance of warm-mixed rubber asphalt and its mixture at low temperature, which can provide scientific basis for its application and performance optimization in cold areas. For warm-mixed rubber asphalt and its mixture, the results of low-temperature trabecular bending test are analyzed, and the stiffness modulus (that is, the bending stiffness modulus in the test) and the maximum bending strain under different conditions are compared to evaluate the low-temperature performance of warm-mixed rubber asphalt and its mixture. The lower the values of stiffness modulus and maximum bending strain, the better the low-temperature performance of the material.

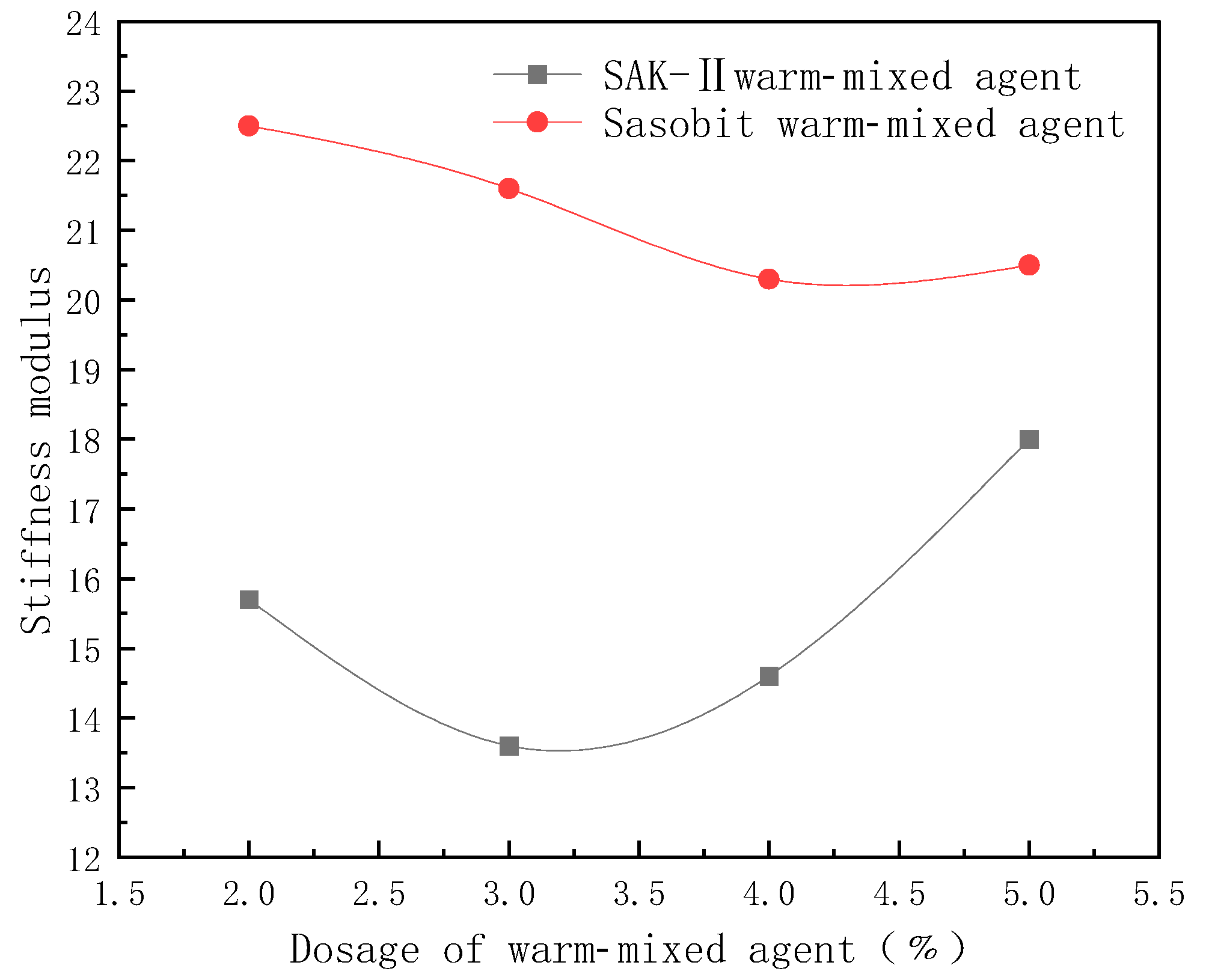

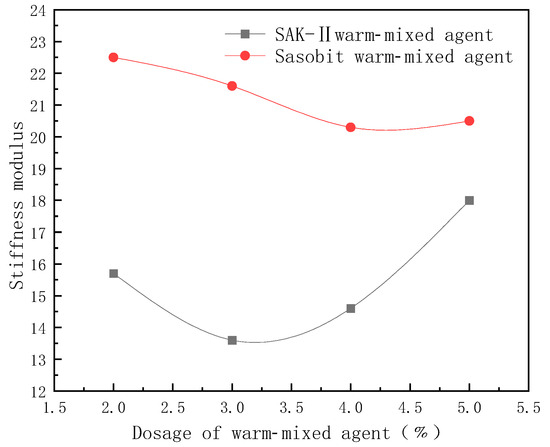

The stiffness modulus curves of two kinds of rubber asphalt with two different temperature mixtures are shown in Figure 7.

Figure 7.

Stiffness modulus curve of rubber asphalt mixture with two different dosages of warm-mixed agents.

According to the low-temperature beam bending test of rubber asphalt mixture, the stiffness modulus of SAK-Ⅱ warm-mixed rubber asphalt is obviously lower than that of Sasobit warm-mixed rubber asphalt within the selected range of warm-mixed agent content, and the stiffness modulus is the lowest when the content of SAK-Ⅱ warm-mixed agent is 3%.

According to the above analysis, it can be seen that SAK-Ⅱ warm-mixed agent can significantly improve the properties of rubber asphalt. Considering its technical performance, construction convenience, economic benefits, environmental protection value and other factors, it is recommended that the content of warm-mixed agent be 3%.

The above results shows that the viscosity of rubber asphalt decreases, the softening point increases significantly, the penetration decreases and the ductility decreases slowly with SAK-Ⅱ warm-mixed agent, and the temperature sensitivity, aging resistance and low-temperature deformation properties of SAK-Ⅱ warm-mixed rubber asphalt are better than those of rubber asphalt.

3.2. Analysis of Influence of Warm-Mixed on Road Performance of Rubber Asphalt Mixture

Through the experiment, it is concluded that the SAK-Ⅱ warm-mixed rubber asphalt mixture has the best performance of high temperature, low temperature and water temperature under the condition of gradation Ⅱ, the optimum amount of asphalt is 8.9%, the content of rubber powder is 22%, and the compaction temperature is reduced by 150 °C. At the same time, compared with the road performance of hot-mixed rubber asphalt mixture, the test results of two different rubber asphalt mixtures are shown in Table 4.

Table 4.

Comparison of road performance results of two different rubber asphalt mixtures.

The results show that the high-temperature stability and water stability of SAK-Ⅱ warm-mixed rubber asphalt mixture are better than that of hot-mixed rubber asphalt mixture, and the crack resistance at low temperature is not different from that of hot-mixed rubber asphalt mixture. The above results show that SAK-Ⅱ warm-mixed agent can play a good modifier role, so that the warm-mixed rubber asphalt mixture can still obtain good road performance when the mixing temperature and compaction temperature are reduced by 30 °C.

3.3. Fatigue Test Results and Analysis of Warm-Mixed Rubber Asphalt Mixture Used as Stress Absorption Layer

3.3.1. Fatigue Life of Specimens with Different Gradations

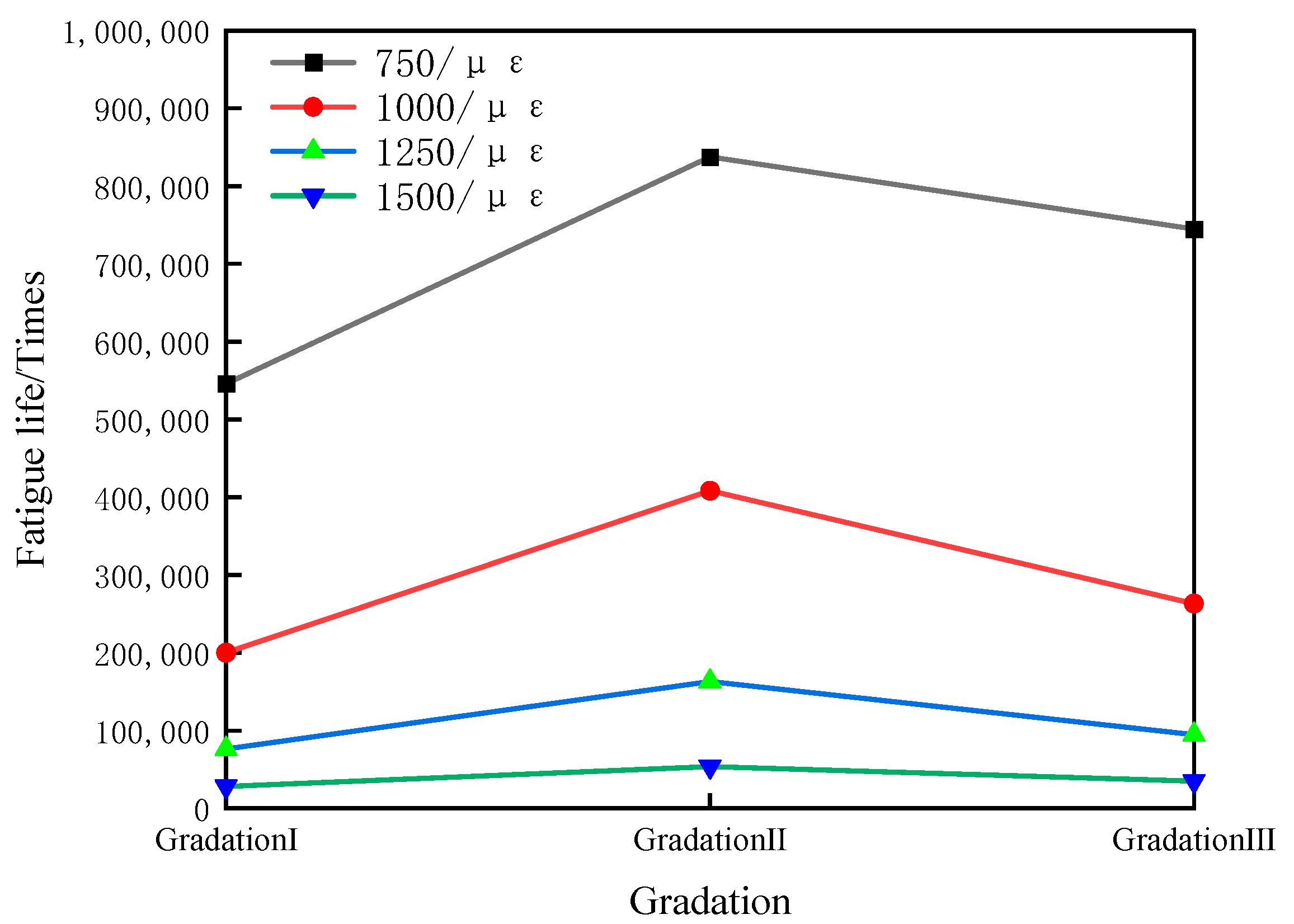

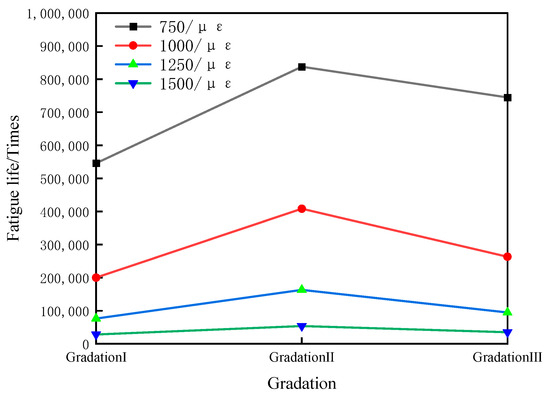

Experimental setup of strain control conditions is 750 με, 1000 με, 1250 με and 1500 με, respectively. The gradation is used as abscissa and fatigue life as ordinate, and the gradation fatigue life curve is drawn, as shown in Figure 8 [24].

Figure 8.

Fatigue life curve of warm-mixed rubber asphalt mixture with different gradation.

According to the analysis of Figure 8, under the conditions of the respective optimal asphalt content corresponding to the three gradations, no matter which strain level, the fatigue life of warm-mixed rubber asphalt mixture increases at first and then decreases with the change in gradation. The fatigue life increases rapidly with the change in gradation under the condition of low strain level of 750 με and 1000 με, and decreases slowly with the change in gradation under the condition of high strain level of 1250 με and 1500 με. On the whole, under the condition of the optimum amount of asphalt of each gradation, the fatigue life of each gradation is gradation Ⅱ, gradation Ⅲ and gradation Ⅰ from large to small.

From gradation Ⅰ to gradation Ⅲ, the fine aggregate in the mixture increases gradually, while the coarse aggregate decreases slowly. Gradation Ⅱ has more fine aggregate and larger specific surface area, so it adheres well to rubber asphalt and produces greater adhesion between particles. In addition, the gaps between coarse aggregates can be filled with more fine aggregates, and the gaps inside the asphalt mixture specimens are smaller and the fatigue life is larger. In terms of the maximum nominal particle size, gradation Ⅰ, gradation Ⅲ and gradation Ⅱ are the same, but because gradation Ⅲ has more internal fine aggregate and more rubber asphalt, the asphalt film becomes thicker and slips. The lubrication of free asphalt leads to the decrease in bending tensile stress and aggregate cohesion of warm-mixed rubber asphalt mixture, and the fatigue life of gradation Ⅲ is smaller than that of gradation Ⅱ [25]. The coarse aggregate of gradation Ⅰ is more, and the amount of rubber asphalt is less, which leads to the decrease in the bonding force between aggregate and rubber asphalt, so the fatigue life of gradation Ⅰ becomes smaller. It can be seen that a certain proportion of fine aggregate can improve the fatigue performance of warm-mixed rubber asphalt mixture, but too much fine aggregate will reduce the fatigue performance of trabecular specimens. Of course, the method of controlling the degree of compaction is adopted when the specimen is made, without considering the difference of particle size, it will also have an impact on the fatigue life of the trabecular specimen and reduce the fatigue life of the trabecular specimen. In addition, the existence of segregation phenomenon will also make the porosity of asphalt mixture different, and the degree of segregation will increase with the coarsening of gradation, so that the contact area and cohesion between warm-mixed rubber asphalt and aggregate will be reduced, resulting in a decrease in fatigue life. The effect of gradation on the fatigue life of warm-mixed rubber asphalt mixture is also related to the amount of rubber asphalt. Compared with the gradation with large particle size, the content of gradation rubber asphalt with small particle size is more, and the fatigue life of the corresponding mixture is larger.

As can be seen above, gradation is a major factor affecting the fatigue life of asphalt mixture, and it cannot be ignored in the design of rubber–asphalt mixture as stress absorption layer. Fatigue failure is the main issue in the process of road use. In order to improve the fatigue life of asphalt mixture pavement, dense gradation, as a type of gradation with more fine aggregate, should be the primary consideration in the design. So the warm-mixed rubber asphalt mixture with gradation Ⅱ configuration is selected.

3.3.2. Fatigue Life of Specimens with Different Asphalt Content

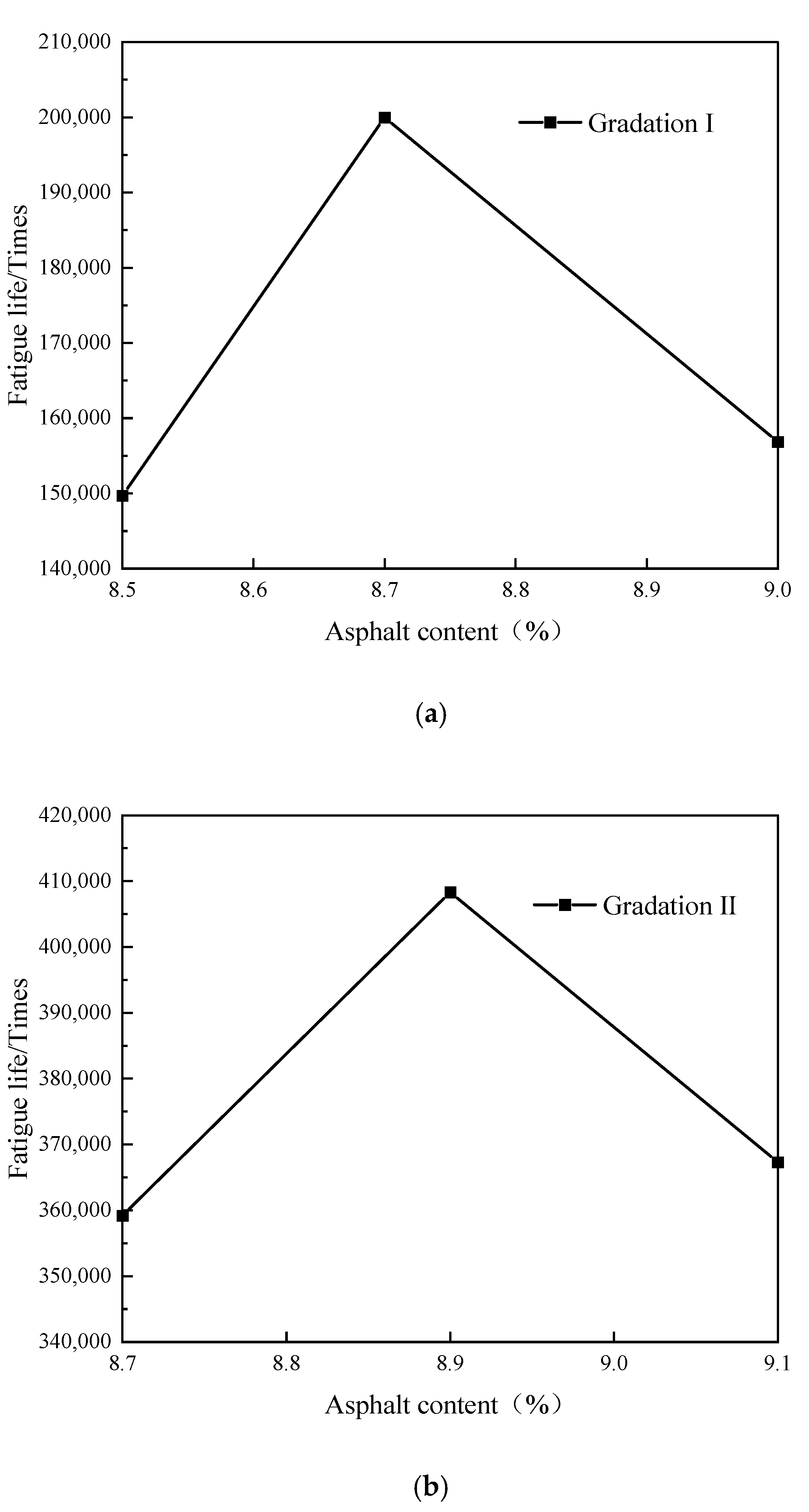

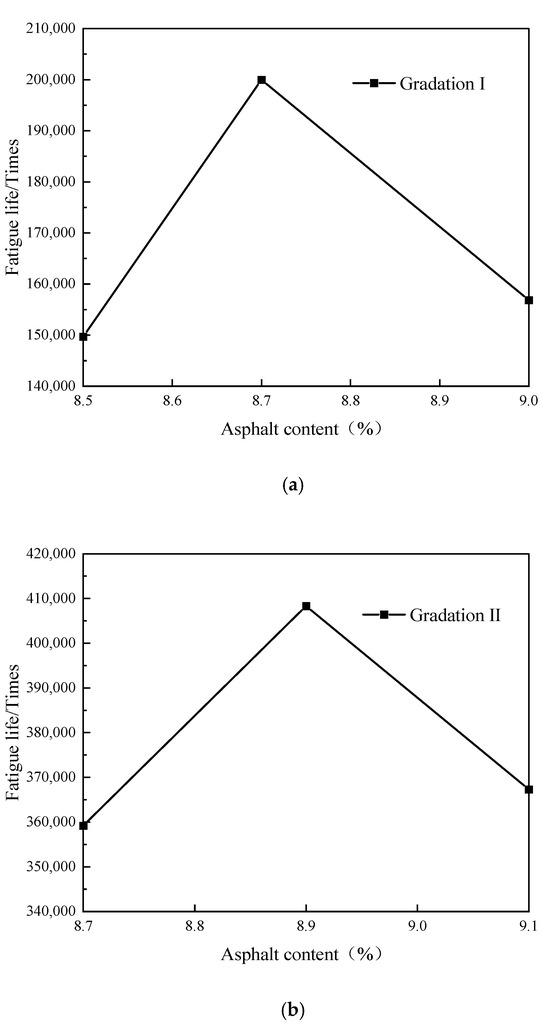

When the strain level is 1000 με, the fatigue life curve of warm-mixed rubber asphalt mixture with different rubber asphalt content is shown in Figure 9.

Figure 9.

Fatigue life curve of warm-mixed rubber asphalt mixture with different rubber asphalt content. (a) Warm-mixed rubber asphalt mixture corresponding to gradation Ⅰ. (b) Warm-mixed rubber asphalt mixture corresponding to gradation Ⅱ. (c) Warm-mixed rubber asphalt mixture corresponding to gradation Ⅲ.

As can be seen from Figure 9, at the beginning, the fatigue life of all graded warm-mixed rubber asphalt mixtures increases with the increase in the amount of rubber asphalt, and the fatigue life reaches the maximum when the amount of rubber asphalt increases to a certain extent; the fatigue life of the three gradations reaches the maximum at their respective optimal asphalt content. After that, when the amount of rubber asphalt continues to increase, the fatigue life decreases. It can be seen that the main effect of the amount of rubber asphalt on the fatigue life of the mixture is that there is an optimal amount of asphalt. When the amount of rubber asphalt is not in the optimal amount of asphalt, the fatigue life of warm-mixed rubber asphalt mixture will decrease. The reason is that rubber asphalt and aggregate have cohesive force. In the case of the same gradation, the appropriate increase in the amount of rubber asphalt increases the asphalt film on the surface of aggregate to form structural asphalt, which increases the cohesion and ductility, and increases the fatigue life of warm-mixed rubber asphalt mixture. However, when the amount of rubber asphalt is too much, more than the optimum amount of asphalt, the free asphalt will be formed and the asphalt film will be too thick, which can easily lead to the formation of slippage. The lubricating effect of free asphalt results in the decrease in flexural and tensile stress of warm-mixed rubber asphalt mixture and the cohesion between aggregates, which makes the fatigue life smaller. In the composition design of the stress absorption layer, the effect of the amount of rubber asphalt on the fatigue life of the stress absorption layer should be fully considered, and the amount of rubber asphalt should be appropriate, not only to meet the economy, but also to meet the fatigue durability of the stress absorption layer.

3.3.3. Fatigue Life of Specimens with Different Strain Levels

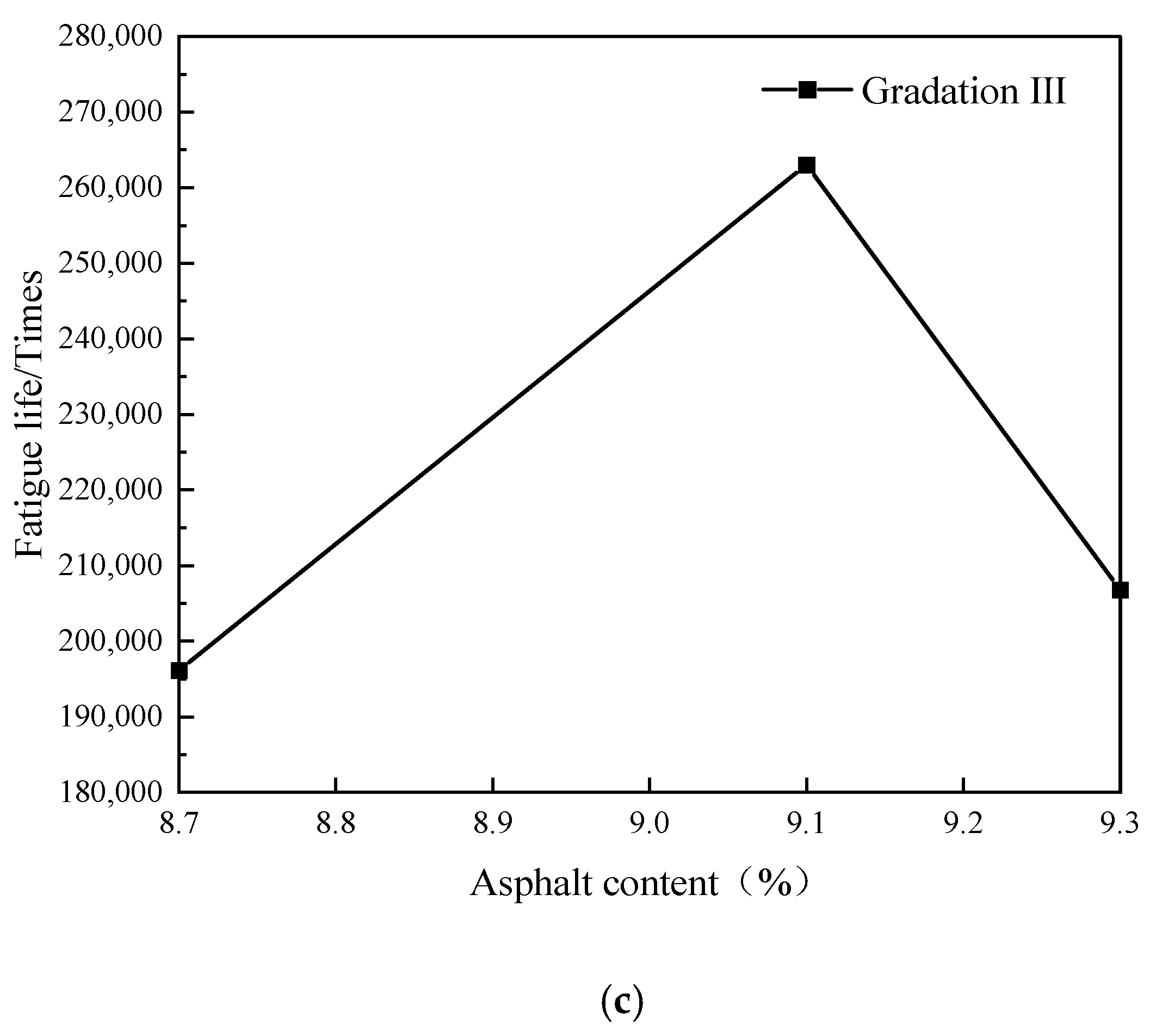

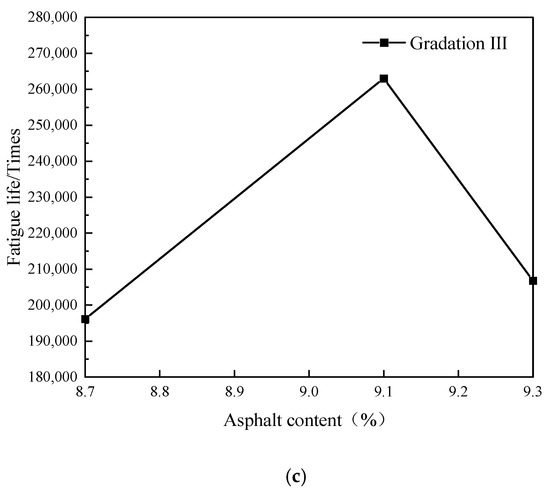

The strain level and fatigue life curve is shown in Figure 10. The abscissa and ordinate of the diagram are two indicators of strain level and fatigue life, respectively.

Figure 10.

Strain level and fatigue life curve.

By the analysis of Figure 10, it is found that the fatigue life of each gradation of warm-mixed rubber asphalt mixture decreases with the increase in strain level, which shows that the fatigue life of warm-mixed rubber asphalt mixture pavement is also slowly decreasing with the continuous increase in vehicle load.

The strain level has a great influence on the fatigue life of warm-mixed rubber asphalt mixture. The fatigue life reflects the influence of external load on the fatigue life of asphalt pavement. The repeated action process of loading will lead to the fatigue damage accumulation of warm-mixed rubber asphalt mixture. The length of fatigue damage accumulation process is affected by the cohesion between aggregate and rubber asphalt. If the cohesion is large, the fatigue damage accumulation process is longer, and the fatigue damage occurs slowly. In the case of low strain level, the load acting on the mixture is small, so that the cohesion between aggregate and asphalt can be long enough to resist the bending tensile stress caused by load. At this time, there will be a relatively long fatigue life of warm-mixed rubber asphalt pavement. On the contrary, under the condition of high strain level, the load acting on the mixture is larger, because the stress loaded on the warm-mixed rubber asphalt mixture is close to its internal bending stress, so it is easily damaged when it is subjected to the load for the first time. Cracks easily occur after repeated loading, resulting in fatigue failure of warm-mixed rubber asphalt mixture. At high strain level, the fatigue life of warm-mixed rubber asphalt mixture pavement is short.

With the development of the economy and the continuous use of heavy-duty vehicles, the influence of heavy load on the fatigue life of warm-mixed rubber asphalt mixture in the stress absorption layer should be fully considered in the heavy-load design of warm-mixed rubber asphalt mixture pavement. In this way, the durability and performance of warm-mixed rubber asphalt mixture can be improved.

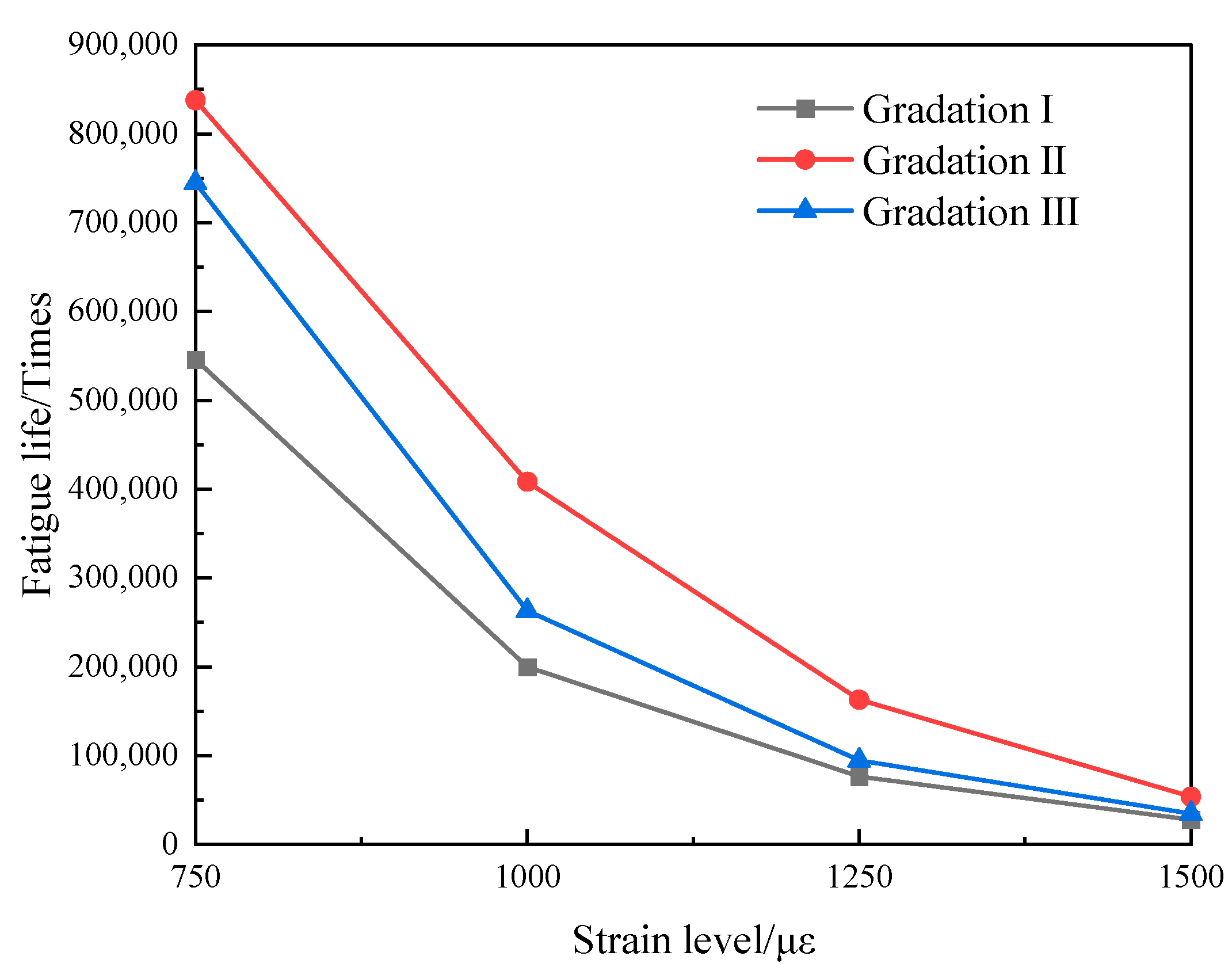

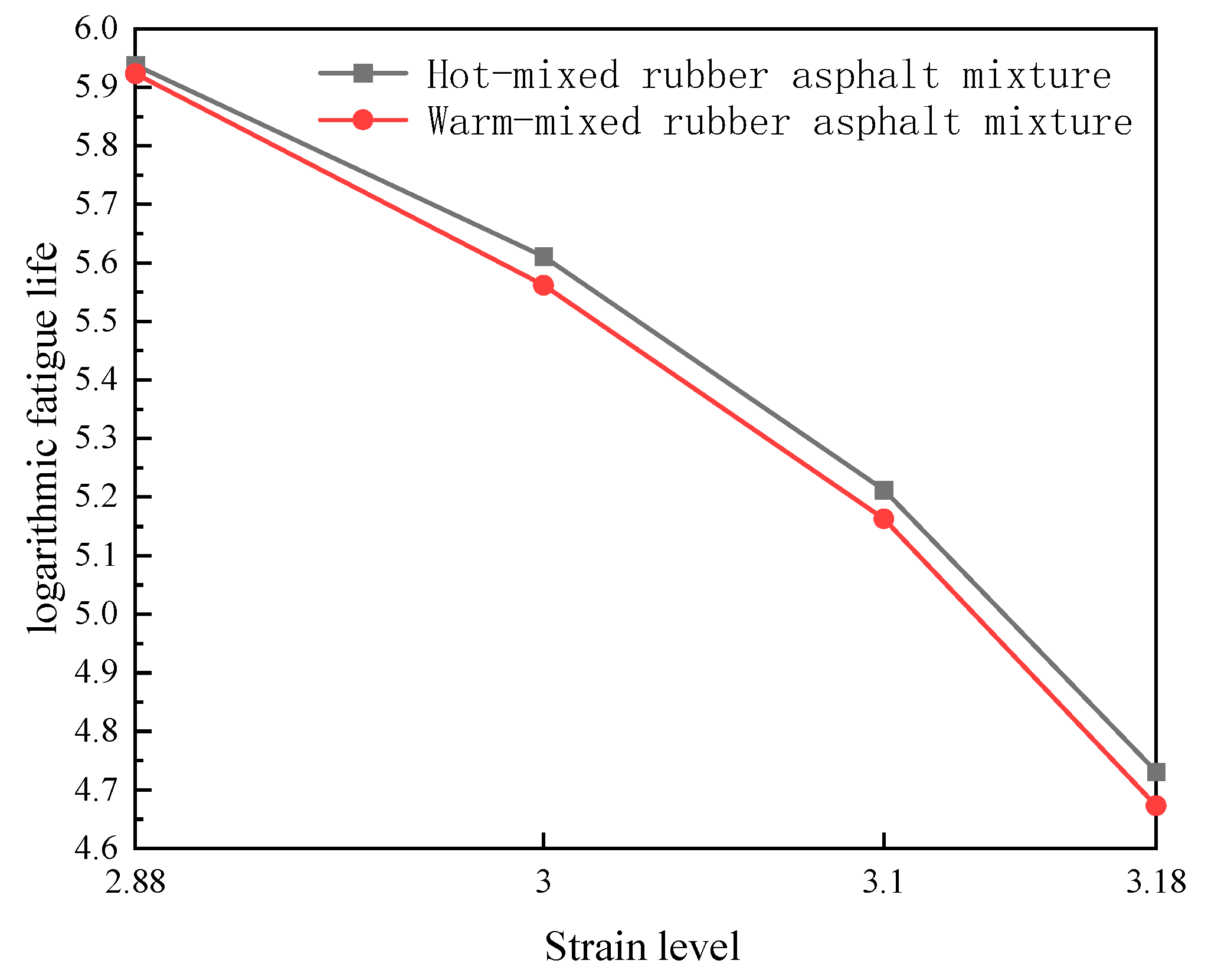

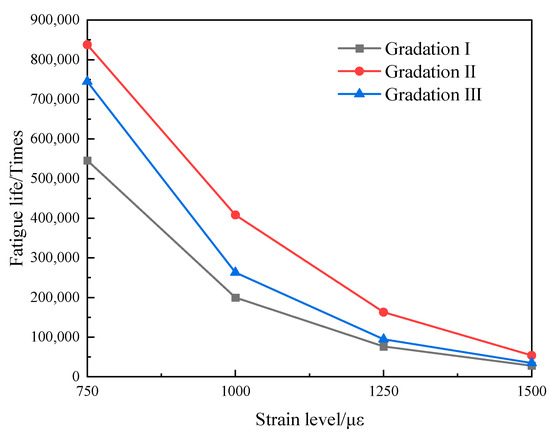

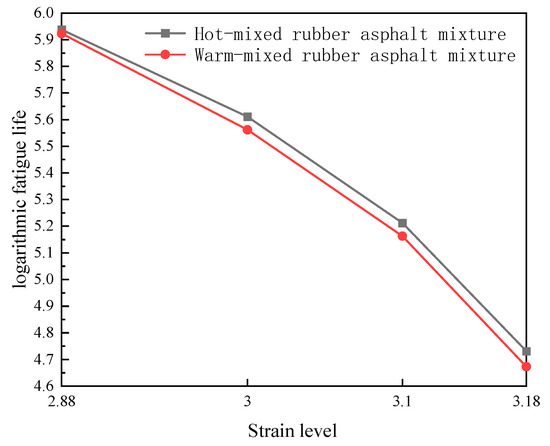

3.3.4. Comparison and Analysis of Fatigue Life of Warm-Mixed and Hot-Mixed Rubber Asphalt Mixture

By using gradation Ⅱ, the bending fatigue test of four-point loading trabeculae of hot-mixed rubber asphalt mixture and warm-mixed rubber asphalt mixture is carried out, and the comparison of experimental results is shown in Figure 6. On the double logarithmic coordinate axis, there is a good linear relationship between the logarithm of fatigue life of asphalt mixture and the logarithm of strain level [26], and the fatigue life of rubber asphalt mixture is fitted by double logarithm regression.

In the formula:

—the number of load times of trabecular specimen when it is damaged, where is the fatigue life;

—regression constant, related to the properties of the material itself;

—flexural strain of the middle span of trabecular bottom surface controlled during the test;

—regression constant, related to test conditions and material properties.

The sensitivity of the fatigue life of rubber asphalt mixture to the strain level is reflected by the regression constant n value, and the larger the n value is, the greater the sensitivity of the fatigue life to the strain level is. The position of the fatigue curve is reflected by the regression constant k value. The greater the k value, the closer the curve to the upward, meaning the better the anti-fatigue performance of the material [27]. In order to obtain the fatigue life–strain level curve of the mixture, logarithms of the horizontal and vertical coordinates of Figure 11 are taken, respectively, and the log-double fatigue curve regression was carried out.

Figure 11.

Comparison of fatigue tests of two kinds of mixtures.

Finally, the fatigue life–strain level curves of hot-mixed and warm-mixed asphalt are obtained, as shown in Figure 12. The logarithmic strain level fatigue life equation of hot-mixed and warm-mixed rubber asphalt mixture for fatigue test is shown in Table 5.

Figure 12.

Fatigue life–strain level curves of two kinds of mixtures.

Table 5.

Double logarithmic strain level fatigue life equation of hot-mixed and warm-mixed rubber asphalt mixture.

As can be seen from Table 5 and Figure 12, in the double logarithmic coordinate system, the fatigue–strain curves of two kinds of rubber asphalt mixtures show a good linear relationship, and there are basically parallel fatigue curves of two kinds of rubber asphalt mixtures. The coefficient k of the fatigue curve equation of warm-mixed rubber asphalt mixture is slightly smaller than that of hot-mixed rubber asphalt mixture, which shows that the fatigue performance of hot-mixed rubber asphalt mixture is slightly better than that of warm-mixed rubber asphalt mixture. The n value of the fatigue curve equation of warm-mixed rubber asphalt mixture is slightly higher than that of hot-mixed rubber asphalt mixture. It shows that the sensitivity of fatigue life of warm-mixed rubber asphalt mixture to strain level is slightly higher than that of hot-mixed rubber asphalt mixture to strain level. The fluctuation range of n value is small, indicating that the sensitivity of rubber asphalt mixture to the applied strain level changes little with the change of hot-mixed and warm-mixed. The correlation coefficient of warm-mixed rubber asphalt mixture is slightly larger than that of hot-mixed rubber asphalt mixture.

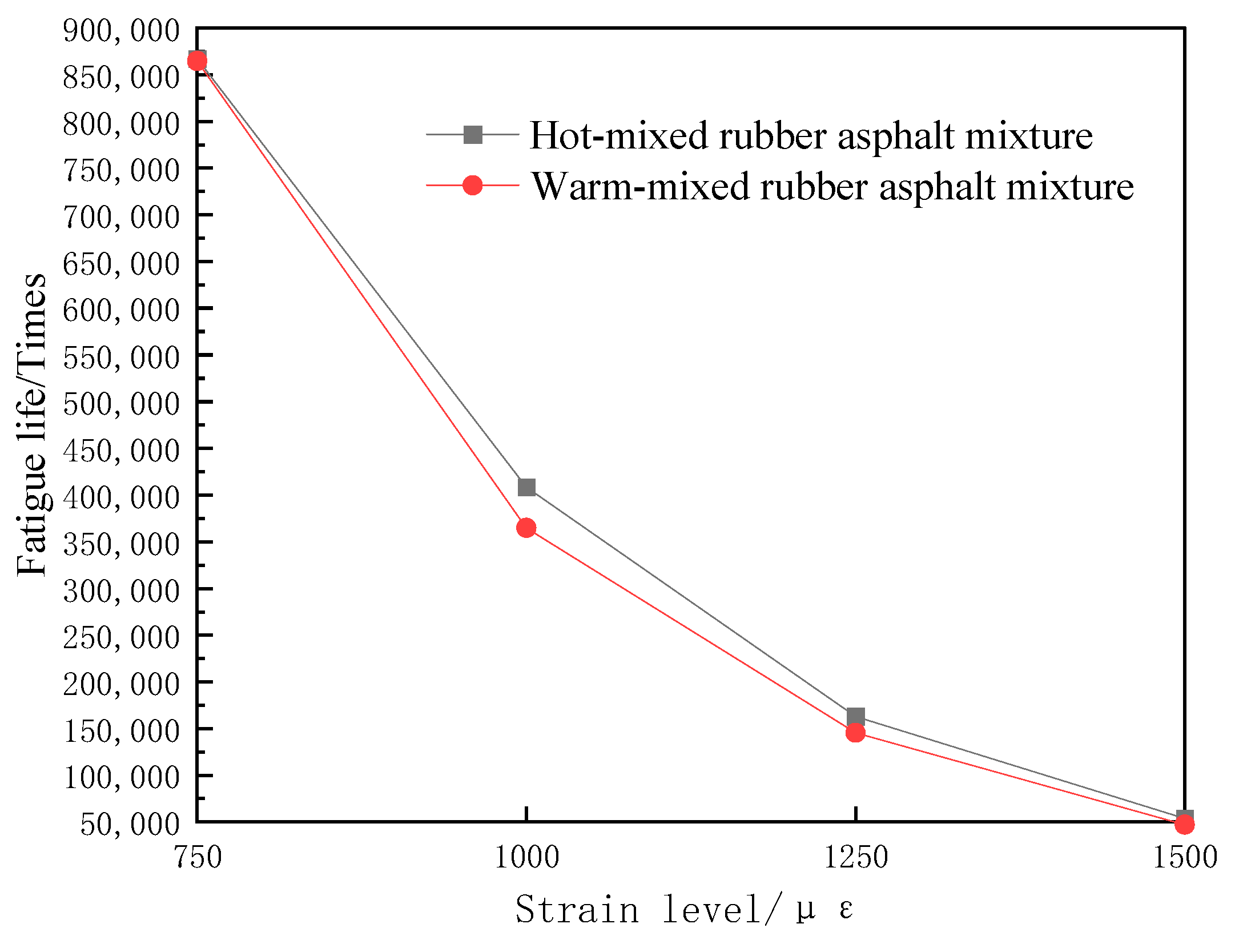

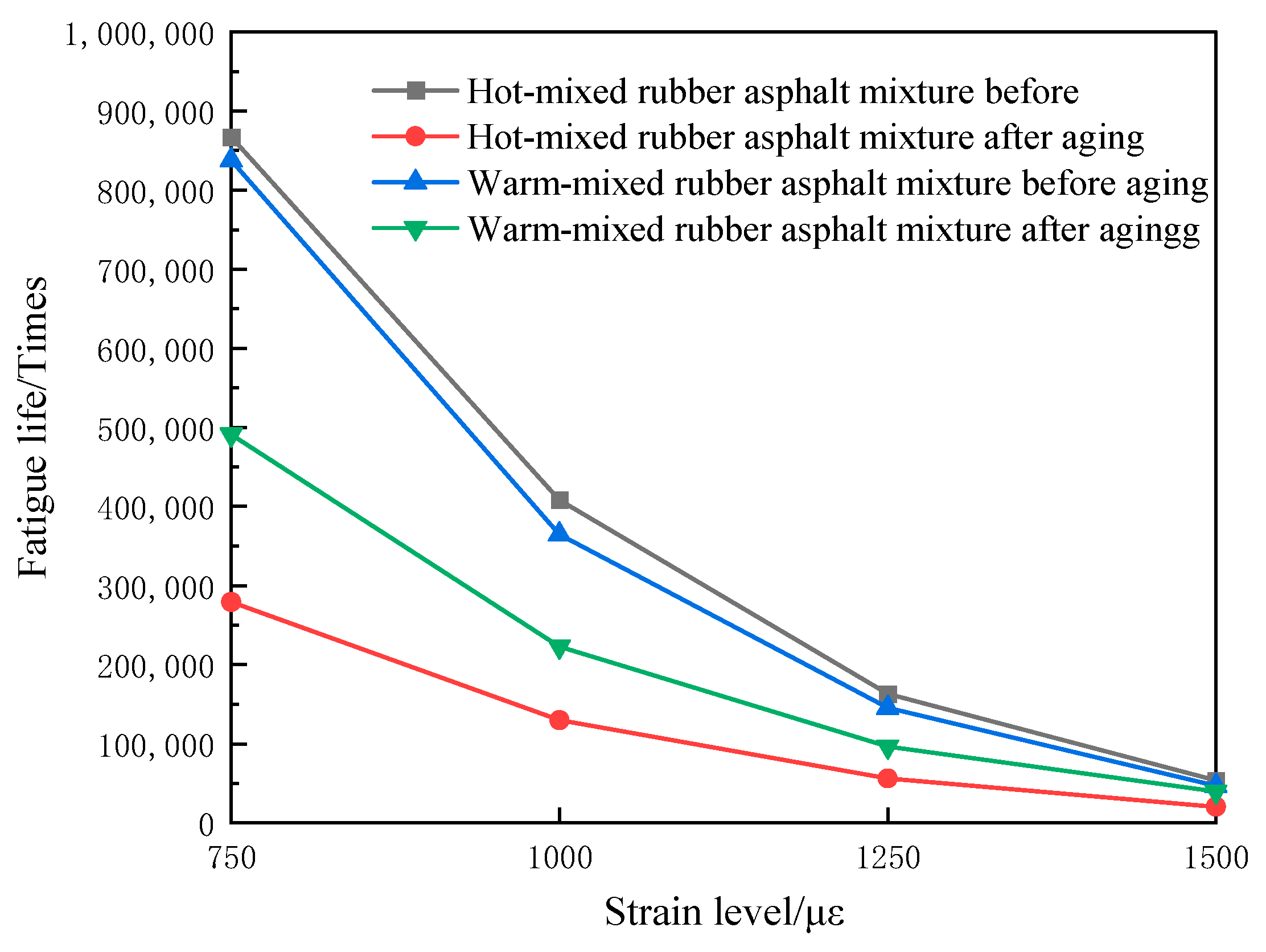

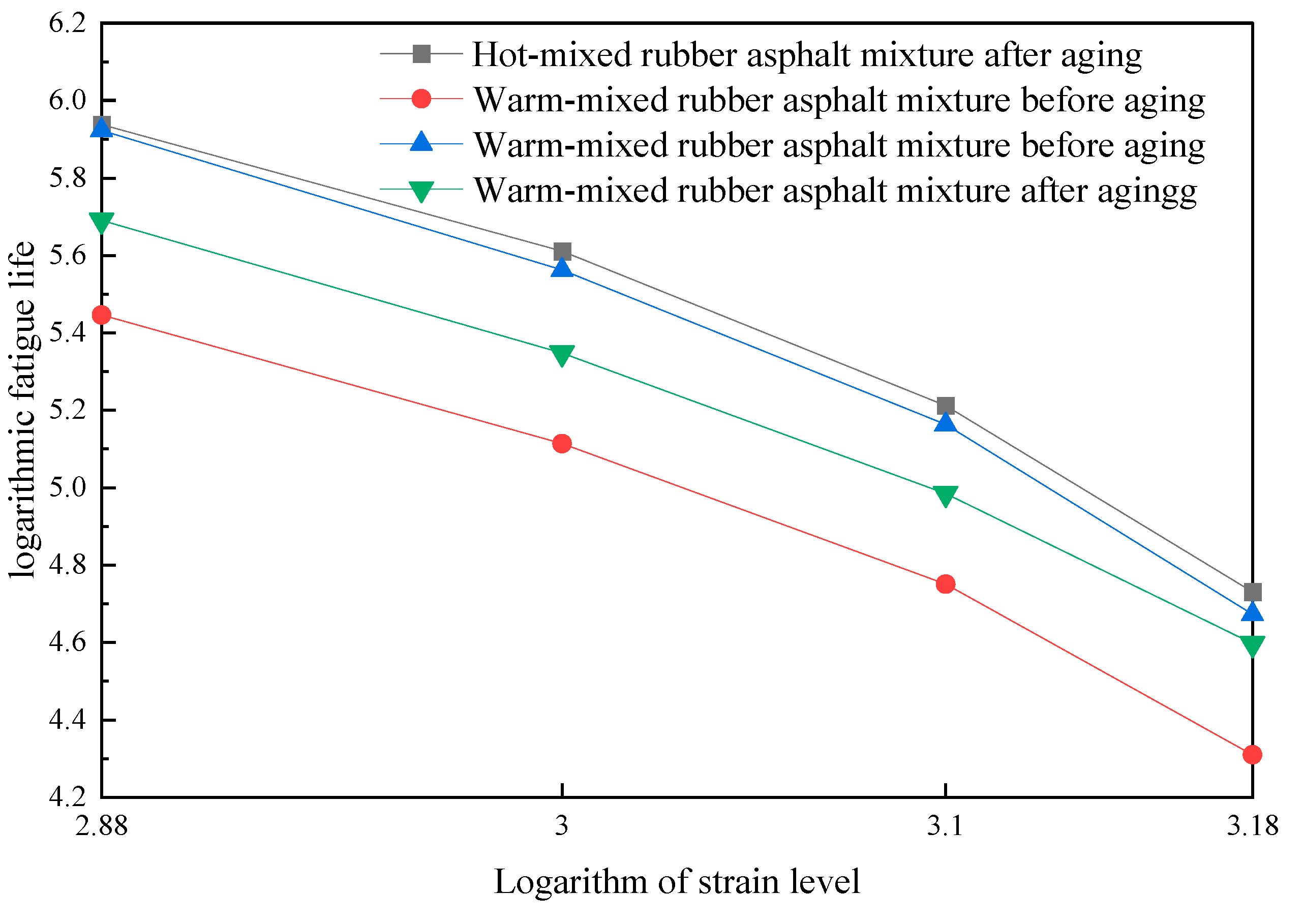

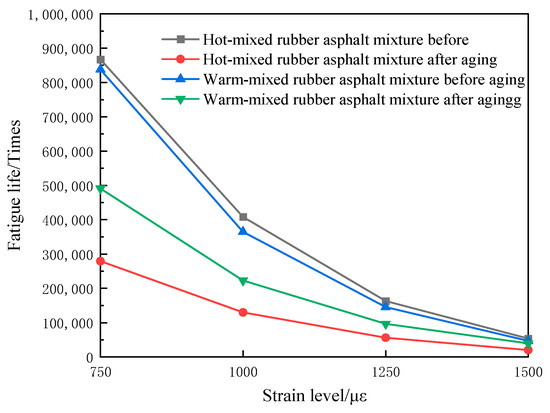

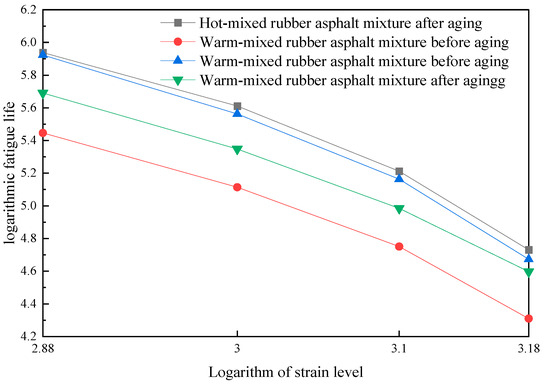

3.3.5. Effect of Aging on Fatigue Performance of Warm-Mixed and Hot-Mixed Mixture

Aging will make the anti-deformation ability of asphalt mixture worse, so fatigue cracking generally occurs in the later stage of the overall life of the pavement, and the fatigue performance of the material can no longer be represented by the initial performance of the material. Therefore, in the study of fatigue cracking of asphalt mixture, the aging factor cannot be ignored. The fatigue performance of rubber asphalt mixture under different aging degrees was studied by four-point loading trabecular bending fatigue test. The fatigue life curve of rubber asphalt mixture before and after aging is shown in Figure 13. The influence of aging on the fatigue performance of the mixture is analyzed, and the test data of rubber–asphalt mixture before and after aging are regressed by double logarithm fatigue curve, and the regression results are shown in Figure 14.

Figure 13.

Fatigue life curve of warm-mixed and hot-mixed mixtures before and after aging.

Figure 14.

Double logarithmic fatigue life curves of warm-mixed and hot-mixed mixtures before and after aging.

The double logarithmic strain level fatigue life equation of warm-mixed and hot-mixed rubber asphalt mixture under different strain levels is shown in Table 6.

Table 6.

Double logarithmic fatigue life equation under different strain levels.

Referring to Figure 14 and Table 6, it can be seen that the linear regression characteristics of fatigue life of warm-mixed and hot-mixed rubber asphalt mixture are good before and after aging, and the k value of warm-mixed and hot-mixed rubber asphalt mixture after aging is less than that before aging, indicating that the fatigue performance of warm-mixed and hot-mixed rubber asphalt mixture decreases after aging. For warm-mixed and hot-mixed rubber asphalt mixture, the n value of rubber asphalt mixture after aging is less than that of rubber asphalt mixture before aging, indicating that the fatigue life sensitivity of warm-mixed and hot-mixed rubber asphalt mixture becomes smaller after aging. And the change value of fatigue life sensitivity of warm-mixed rubber asphalt mixture is less than that of hot-mixed rubber asphalt mixture. The results show that the fatigue life of warm-mixed and hot-mixed rubber asphalt mixture after aging is lower than that before aging, but the fatigue life of warm-mixed rubber asphalt mixture decreases less. The fatigue life loss rate is introduced to analyze the fatigue life loss degree of different rubber asphalt mixtures before and after aging. indicates that the fatigue equation coefficient k decreases after long-term aging, and the larger the F value is, the greater the fatigue life loss of asphalt mixture is; the smaller the F value is, the smaller the fatigue life loss of asphalt mixture is. F value is obtained from Equations (1) and (2) [28]:

In the formula, is the fatigue life loss rate (%) of rubber asphalt mixture after aging is simulated, is the loss of coefficient k in the logarithmic fatigue life equation before and after simulated aging, is the logarithmic fatigue life equation coefficient k value (%) of rubber asphalt mixture before simulated aging. , the fatigue life loss rate of warm-mixed and hot-mixed rubber asphalt mixture before and after aging, is shown in Table 7.

Table 7.

Fatigue life loss rate of rubber asphalt mixture before and after aging.

It can be seen from Table 6 that the fatigue life loss rate of hot-mixed rubber asphalt mixture is 76.6% higher than that of warm-mixed rubber asphalt mixture. From the point of view of the decrease in fatigue durability, the fatigue durability of aging hot-mixed rubber asphalt mixture decreases a lot, while the fatigue durability of warm-mixed rubber asphalt mixture decreases less. It was found that, with the addition of warm-mixed agent, the fatigue life loss rate of warm-mixed rubber asphalt mixture is 43.37% lower than that of hot-mixed rubber asphalt mixture, indicating that the use of warm-mixed agent can slow down the reduction rate of fatigue properties of rubber asphalt mixture used in stress absorption layer and effectively improve the aging resistance of rubber asphalt mixture.

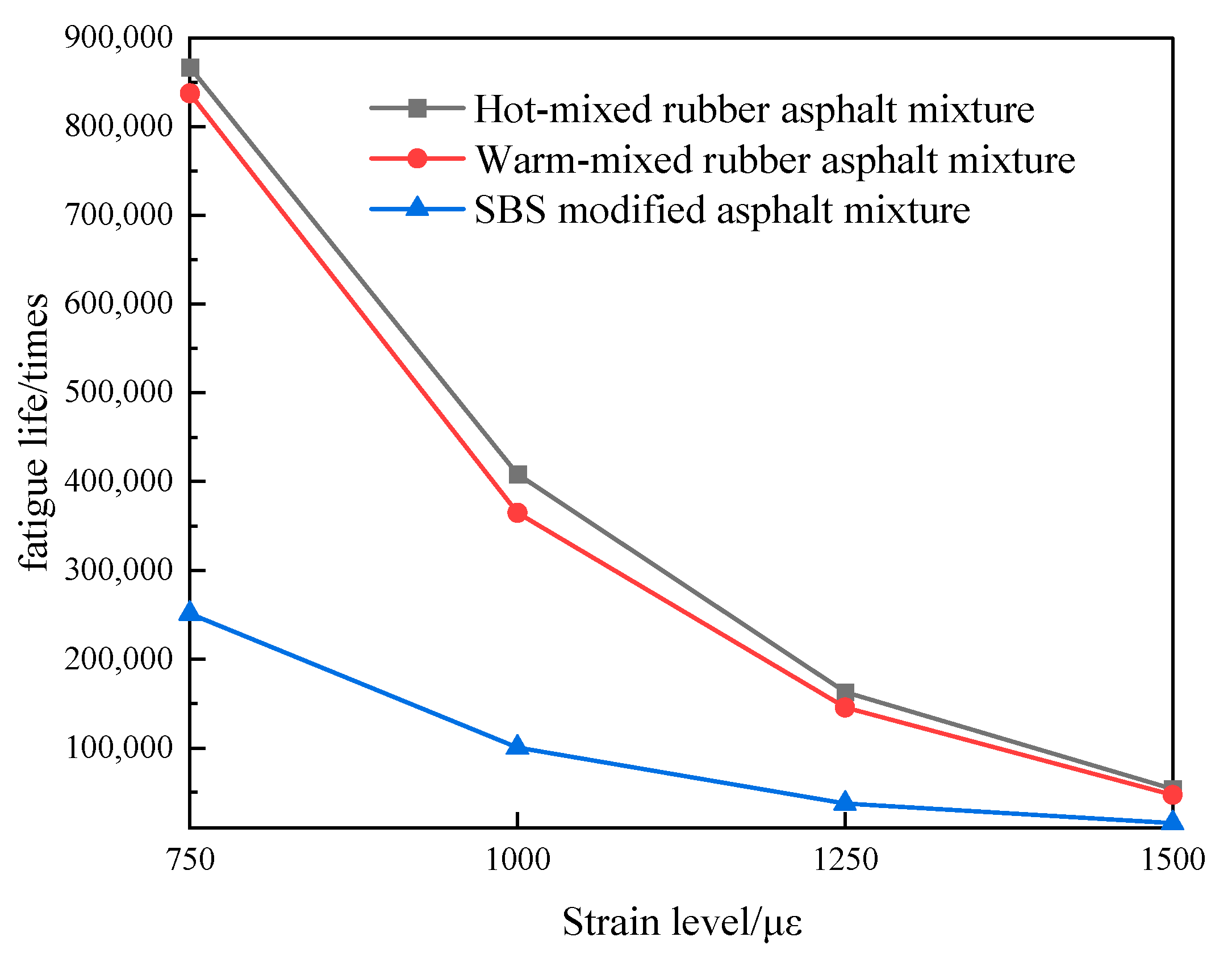

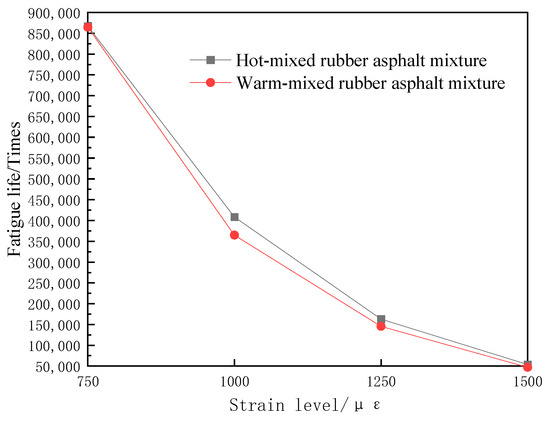

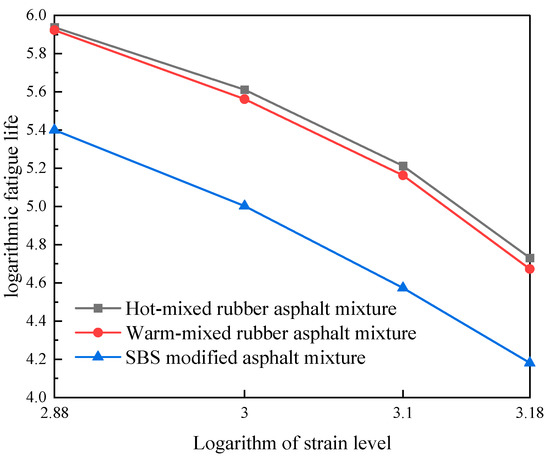

3.3.6. Comparison and Analysis of Fatigue Life of Three Kinds of Asphalt Mixture

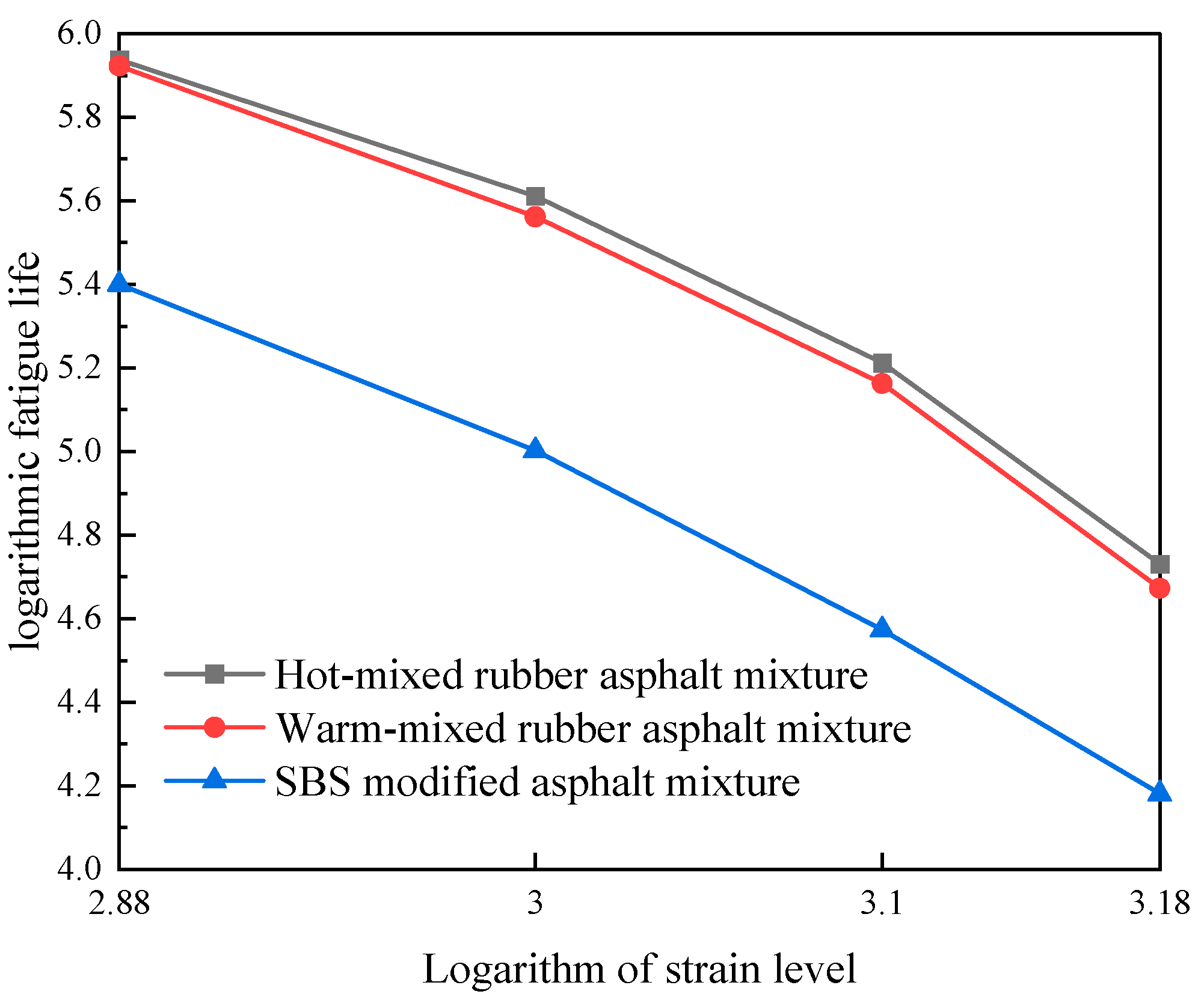

Gradation Ⅱ is used, and the four-point loading trabecular bending fatigue tests of hot-mixed rubber asphalt mixture, warm-mixed rubber asphalt mixture and SBS-modified asphalt mixture are carried out. The relationship between fatigue life and strain level under the condition of test temperature of 15 °C and loading frequency of 10 Hz is shown in Figure 15 and Figure 16.

Figure 15.

Comparison of fatigue test of the three kinds of asphalt mixtures.

Figure 16.

Fatigue life–strain level curves of the three kinds of asphalt mixtures.

The fatigue–strain equation of warm-mixed and hot-mixed rubber asphalt mixture is shown in Table 6. The fatigue–strain equation of hot-mixed SBS-modified asphalt mixture is , and the square of the correlation coefficient is 0.960. As can be seen from Figure 10, the fatigue life–strain level curves of the three kinds of asphalt mixtures are basically parallel, showing a good linear relationship. Comparing the values of coefficient k, it is observed that the coefficient of the fatigue curve equation for the warm-mixed rubber asphalt mixture is notably smaller than that of the hot-mixed rubber asphalt mixture, yet remarkably larger than that of the SBS-modified asphalt mixture. This suggests that the fatigue performance of the warm-mixed rubber asphalt mixture is essentially equivalent to that of the hot-mixed rubber asphalt mixture, but significantly superior to that of the SBS-modified asphalt mixture. The fatigue performance of SBS-modified asphalt mixture is the worst, compared with the other two kinds of rubber asphalt mixture. The n value of the fatigue curve equation of warm-mixed rubber asphalt mixture is slightly higher than that of hot-mixed rubber asphalt mixture, but much smaller than that of SBS-modified asphalt mixture, indicating that the sensitivity of fatigue life of warm-mixed rubber asphalt mixture to strain level is slightly higher than that of hot-mixed rubber asphalt mixture, but much less than that of SBS-modified asphalt mixture. SBS-modified asphalt mixture is the most sensitive to strain levels.

4. Summary and Conclusions

- The fatigue life of warm-mixed rubber asphalt mixture used as stress absorption layer is in the following order: gradation Ⅱ > gradation Ⅲ > gradation Ⅰ, and the fatigue life of warm-mixed rubber asphalt mixture corresponding to gradation Ⅱ is the highest. When the amount of rubber asphalt reaches the optimum amount of asphalt, the warm-mixed rubber asphalt mixture corresponding to gradation Ⅱ can obtain the maximum fatigue life. Under the condition of low strain, the warm-mixed rubber asphalt mixture has a longer fatigue life, and when the strain increases, the fatigue life decreases.

- The fatigue life linear regression characteristics of warm-mixed and hot-mixed rubber asphalt mixture used as stress absorption layer are good, and the fatigue performance of hot-mixed rubber asphalt mixture is slightly better than that of warm-mixed rubber asphalt mixture.

- After aging, the fatigue life sensitivity of warm-mixed and hot-mixed rubber asphalt mixture becomes smaller, and the change of fatigue life sensitivity of warm-mixed rubber asphalt mixture is less than that of hot-mixed rubber asphalt mixture. The sensitivity of rubber asphalt mixture to applied strain level changes little with the change of hot-mixed and warm-mixed. After aging, the fatigue endurance reduction rate of hot-mixed rubber asphalt mixture is much faster than that of warm-mixed rubber asphalt mixture; warm-mixed agent can slow down the decrease rate of fatigue performance of rubber asphalt mixture and improve the aging resistance of rubber asphalt mixture.

- The fatigue life–strain level curves of the three kinds of asphalt mixtures used as stress absorption layer show a good linear relationship. The fatigue performance of the warm-mixed rubber asphalt mixture is basically the same as that of the hot-mixed rubber asphalt mixture, but much higher than those of the SBS-modified asphalt mixture. The sensitivity of fatigue life of warm-mixed rubber asphalt mixture to strain level is slightly higher than that of hot-mixed rubber asphalt mixture, but much less than that of SBS-modified asphalt mixture. SBS-modified asphalt mixture is the most sensitive to strain levels.

The anti-crack technology of stress absorption layer of warm-mixed rubber asphalt mixture expands the application range of rubber asphalt mixture. Compared with other anti-crack technologies, this technology has a better anti-crack effect. It can effectively solve the problems of interlayer adhesion, crack diffusion and transmission between asphalt overlay and cement concrete pavement or semi-rigid base and asphalt surface, and has a positive guiding and dissipating effect on crack dredging. This technology makes full use of waste resources, reduces the mixed temperature and compaction temperature of the mixture, improves the construction performance, and improves the working condition on the construction site. Of course, the new technology of warm-mixed rubber asphalt mixture for anti-reflective crack of stress absorption layer still needs to be explored and practiced continuously in practical engineering. It is necessary to carry out more in-depth dynamic mechanical response analysis of the overlay structure with original defects under moving load, formulate and improve the design code, expand the source of raw materials and reduce the cost, and constantly popularize this technology. At the same time, it is necessary to make breakthroughs in long-term tracking and evaluation of road performance and strengthening the evaluation of energy saving and environmental protection.

Funding

The author is very grateful for the funding of the following fund projects: Study on the performance of warm-mixed rubber asphalt mixture for stress absorption layer in cold area, Harbin Science and Technology Bureau, self-funded project of Harbin Science and Technology Plan, No. ZC2022ZJ013004.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Chang, H. Performance of rubber asphalt stress absorbing layer used to prevent reflection cracks. China Highw. 2023, 15, 116–117. [Google Scholar]

- Quan, D. Study on the application of rubber asphalt mixture in municipal pavement repair engineering. Fujian Build. Mater. 2023, 256, 13–16. [Google Scholar]

- Deng, G. Rearch on Fatigue Performance and Damage Mechanism of Asphalt Under Repetitive Loading with Variable Stresses. Master’s Thesis, South China University of Technology, Guangzhou, China, 2023; pp. 3–5. [Google Scholar]

- Zhao, Y. Application of High Elastic Asphalt in Stress Absorption Layer. Master’s Thesis, Southwest Jiaotong University, Guangzhou, China, 2021; pp. 1–3. [Google Scholar]

- Chen, Q.; Lin, Y. Study on the Effect of Different Warm Mixing Agents on Property of Warm-mixed Rubber Asphalt Mixture. J. Munic. Technol. 2022, 40, 164–168. [Google Scholar]

- Nan, Y. Experimental study on properties of warm mixed rubber modified asphalt mixture. Fujian Transp. Technol. Basic Inf. 2021, 53–56. [Google Scholar]

- Zhang, L.; Meng, H.; Li, Y.; Wang, H.; Wang, S. Experimental Study on Engineered High-content Rubber Asphalt Performance. J. Highw. Transp. Res. Dev. 2024, 41, 71–78. [Google Scholar]

- Ma, T. Application of high performance stress absorbing layer in highway engineering. Jiangxi Build. Mater. 2024, 17, 27–30. [Google Scholar]

- Li, Y.; Chen, J.; Wang, S.; Huang, M.; Huang, K. Multi-scale research nn mechanical characteristics of splitting fatigue damage of asphalt mixture. J. Changsha Univ. Sci. & Technol. (Nat. Sci.) 2022, 19, 1–10. [Google Scholar]

- Liu, J. Study on fatigue performance of all-thick asphalt pavement. TranspoWorld 2022, 36, 90–92. [Google Scholar]

- Bai, X.; Yuan, F.; Shi, P. Development of a ternary composite asphalt warm mix. J. Suzhou Univ. Sci. Technol. (Nat. Sci. Ed.) 2022, 39, 51–56. [Google Scholar]

- Yang, G.; Chen, Q.; Li, Y.; Bao, X. Thermal stability analysis of warm mixed rubber asphalt. TranspoWorld 2022, 11, 24–26. [Google Scholar]

- Wang, W.; Qiu, Y. Present stituation and prospect of organic reduced sticky additive for warm mix asphalt. New Chem. Mater. 2017, 451, 210–211. [Google Scholar]

- Pan, R. Performance of warm mixed rubber asphalt mixture of stress absorbing layer. J. Chang’an Univ. (Nat. Sci. Ed.) 2019, 39, 49–56. [Google Scholar]

- Feng, X.; Kang, Q. Effect of laboratory compaction method on voidage and mechanical properties of hot mixed asphalt mixture. J. China Foreign Highw. 2020, 40, 291–297. [Google Scholar]

- Ma, Z.; Ji, Z.; Huang, Y.; Zheng, B. Experimental Study on Compaction Temperature of Foam Warrrrrubber Asphalt Mixture. Highway 2020, 65, 279–285. [Google Scholar]

- Guan, H.; Zhang, Q.; Xu, Y.; Chen, S. Laboratory Rutting Test for Bituminous Mixture at Medium Temperature. J. Highw. Transp. Res. Develornnent 2010, 27, 38–42. [Google Scholar] [CrossRef]

- Yan, X.; Zhanu, S.; Li, Y.; Hu, X. Analysis of Temperature Field of Asphalt Pavement by Site Measurement in Full-Depth. Master’s Thesis, Chang’an, China, 2016. [Google Scholar]

- Shen, Q.; Wu, B.; Shen, Y.; Fan, Z. Research on mechanical properties of asphalt mixture fatigue damage under stress control mode. J. Jilin Jianzhu Univ. 2020, 37, 38–44. [Google Scholar]

- Chen, Y. Comparative Study on Fatigue Characteristics of Asphalt Mixture Under Uniaxial Tensile and Four-Pointbending Loading Mode. Master’s Thesis, Chang’an University, Xi’an, China, 2023; pp. 34–37. [Google Scholar]

- Liu, X.; Li, X. Study on Asphalt Mixture Fatigue Performance Using Different Aging Methods. Pet. Asph. 2018, 32, 38–43. [Google Scholar]

- Liao, J. Analysis of fatigue failure criterion of factory mixed hot recycled asphalt mixture. Traffic Technol. Manag. 2023, 4, 47–51. [Google Scholar]

- Liu, Q. Study on the Aging Performance and its Mechanism of High Content Rubber Asphalt Binder. Master’s Thesis, Shijiazhuang Railway University, Shijiazhuang, China, 2024; pp. 17–19. [Google Scholar]

- Liu, J. Study on Bending Fatigue Properties of Rubber Concrete. Master’s Thesis, Shijiazhuang Railway University, Shijiazhuang, China, 2024; pp. 17–19. [Google Scholar]

- Gullibiya, E. Analysis of influence of fine aggregate content on pavement performance of AC-25C asphalt pavement. Hunan Commun. Sci. Technol. 2020, 46, 65–68. [Google Scholar]

- Tian, X.-X. Study on durability of rubber asphalt mixture based on uniaxial compression creep test. Gansu Sci. Technol. 2020, 36, 92–94. [Google Scholar]

- Zhu, Y. Study on The Fatigue Performance of Superpaveasphalt Mixture and Fractional Grey Predictionmodel. Master’s Thesis, Inner Mongolia University, Hohhot, China, 2023; pp. 27–29. [Google Scholar]

- Liang, B.; Lan, F.; Zheng, J. Research and Development of Relationship Between Aging Mechanismand Fatigue Properties of Asphalt. Mater. Rep. 2021, 35, 14. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).