Abstract

The quarrying and utilization of natural stones such as marble and granite are growing rapidly in developing countries. However, the processing, cutting, sizing, and shaping of these stones to render them functional generates huge quantities of waste and dust. These materials are often disposed of openly in the environment, and their potentially hazardous nature has negative repercussions on both the environment and human health. In this study, marble waste (MW) was used as a filler in the unsaturated polyester resin (UPR) matrix to enhance performance and characteristics while adding value to the waste and minimizing manufacturing costs. For this purpose, samples of UPR/MW composites were produced with 0, 5, 10, 15, and 20 wt.% of MW incorporated into the UPR. A full characterization that focused on the microstructure, thermal stability, and physical and mechanical properties was carried out. The results revealed that the use of 10 to 15% of MW improves mechanical performance, with increases from 17 to 26 kJ/m2, 14 to 17 MPa, and 794 to 1522 GPa in impact strength, tensile strength, and elastic modulus, respectively. By introducing a 20% MW filler, the composite loses its performance, particularly Shore D hardness, and becomes very brittle. Thermogravimetric analysis (TGA) indicated significant thermal stabilization, with a delay in the start decomposition temperature of 28 °C for 20 UPR/MW compared to 0 UPR/MW. Additionally, morphological and microstructural tests, namely, FT-IR, XRD, and SEM analysis, show a microstructural change, including the formation of crystalline phases, enhancing matrix-filler interactions due to the creation of Mg-O and Ca-O chemical bonds and the forming of filler agglomeration at high introduction rates that lead to defects in the microstructure. These results confirmed the mechanical results of the UPR/MW composites.

1. Introduction

As environmental concerns and sustainable development continue to grow, many researchers and industries have turned their attention to the recycling of waste materials and co-products in composite matrices. The use of waste and abandoned natural resources promotes not only sustainable development through the manufacture of innovative and sustainable products but also helps to protect the environment and recycle resources effectively [1,2,3].

Additionally, Algeria is one of Africa’s leading producers and manufacturers of high-quality marble [4]. Marble is defined as a metamorphic rock formed from limestone exposed to heat and metamorphic pressure [5], consisting mainly of the mineral calcite (CaCO3) and other secondary minerals, including clay minerals, micas, quartz, pyrite, iron oxides, and graphite [6]. Throughout history, marble has been used for sculptures and statues by ancient civilizations such as the Greeks and Romans. However, today’s overproduction of marble results in substantial quantities of powder and sand waste during the production process. Previously, Algeria produced up to 30,000 tons of marble and granite; however, current production has fallen to 14,000 tons [7]. Approximately 70% of this production is wasted during extraction, processing, and polishing stages [8]. The continued overproduction of marble has led to a significant accumulation of powder and sand dust waste, causing environmental challenges during manufacturing, extraction, and processing operations [6,9]. Responding to this issue, researchers have recognized the potential of using marble waste as an alternative building material or as a component of composites, with notable economic and environmental benefits [10,11].

Moreover, unsaturated polyester resins (UPRs) are widely used in various sectors, such as marine, automotive, and construction infrastructure. The chemical process for UPRs involves their creation by polyesterification or progressive ionic copolymerization. The resulting UPR solution is dissolved into an unsaturated monomer and then cross-linked by radical polymerization [12]. Their primary use is driven by their specific properties, which set them apart from other polymers, especially thermosetting resins, to which unsaturated polyester resins (UPRs) belong [13]. In fact, UPRs are the most widely used resins in the composite industry, accounting for around 75% of all resins [14], owing to their excellent wettability with reinforcements and superior thermal resistance [15].

In general, reinforcements are added to enhance the characteristics of the matrix, improving its mechanical properties, thermal stabilization, and reducing the cost of the composite [3]. These reinforcements vary in nature, shape, and size and can be either mineral (such as metal, glass, boron, and ceramic) or organic (such as wood, cotton, paper, polyester, and aramid). Fibrous reinforcements, such as glass, aramids, and carbon fibers, are the most commonly used [16]. However, non-fibrous reinforcements are employed less frequently and include spherical or non-spherical particles such as hollow glass microbeads, carbon microbeads, organic microbeads (epoxy, phenolic, etc.), and minerals like mica, calcium sulfates, calcium carbonates, clay, perlite, mullite, and kaolin.

In fact, Nayak et al. [17] demonstrated the benefits of using this waste and highlighted its impact on improving the mechanical properties of polymer-based composites filled with micro-sized waste marble. Çınar et al. [18] studied the mechanical and physical properties of composites produced from polyethylene terephthalate (PET) waste and marble powder to determine the impact of both the marble ratio and particle size on the composite properties. They found that Vickers’ hardness and bending values increased proportionally with higher marble ratios. Shandley et al. [19] investigated the variation in mechanical properties according to the filler content of unsaturated polyester resin developed and reinforced with marble powder to produce climbing holds. Tensile tests revealed that samples reinforced with marble powder required higher energy to break and that strain was substantially improved. Moreover, it was noted that the higher the marble content, the greater the impact loads.

Nayak et al. [20] examined the potential for developing a novel class of particle-reinforced polyester composites using waste marble as fillers in three different sizes (58, 110, and 155 mm) and with fillers in different weight proportions (0, 8, 16, 24, 32, and 40 wt.%). This study demonstrated that polyester-based composites containing micro-sized marble dust could be successfully manufactured using the solution casting technique, achieving notable improvements in compressive strength and impact load values. Both the filler content and the average particle size significantly impacted the mechanical properties of the composites.

Doan et al. [21] evaluated the potential of stone powders used as a filler in composite materials based on an unsaturated polyester resin matrix, where samples were prepared containing different filler contents (50, 55, 60, and 65 wt.%). The authors found that the bending and tensile strength of the composites increased consistently with higher stone powder content. Consequently, the hardness of the composites improved by up to 80% for those containing MW, making them an economical material while addressing waste reduction.

Niveen Jamal Abdulkader et al. [22] prepared polyester-based composite materials reinforced with low-cost industrial waste at weight fractions of powder content ranging from 1, 3, 5, 7, and 9 wt.% of marble particles using a manual technique. The results showed that composite materials reinforced with marble particles exhibited greater hardness, bending, and tensile strength compared to the base matrix. Additionally, the impact energy for the developed composite materials increased with the addition of more marble waste. The results indicated that the optimal marble waste content was 9 wt.%. The marble waste was well distributed within the matrix, and the results showed that ground marble powders enhanced the hardness of polyester composites by around 80%. The improvement was also affected by the particle size of the marble waste filler, with finer particle sizes yielding the greatest improvements.

Kumar et al. [23] studied the effects of marble dust particles treated with silane and untreated marble dust particles on the physical, mechanical, and thermomechanical properties of dental composites. It was found that marble dust particles treated with 9 wt.% silane exhibited superior mechanical properties, including peak hardness (96 HV), compressive strength (296 MPa), and flexural strength (80 MPa). Furthermore, the mechanical properties of the dental composite were improved by the addition of a marble filler and silane treatment. The dynamic mechanical properties and thermal degradation temperature also increased as the marble dust content rose. Awad et al. [24] investigated the effect of different particle sizes and weight percentages of marble dust particles on the thermal and mechanical properties when used as reinforcements in a polypropylene (PP) matrix composite. They found that the addition of marble dust to the PP matrix increased flexural strength by up to 40 wt.%. Beyond this percentage, particle agglomeration and a reduction in flexural strength were observed. Additionally, compressive strength increased with marble content, whereas the flexural strength of PP composites diminished with increasing particle size. Finally, the hardness of PP composites was significantly enhanced by the incorporation of marble dust particles.

Awad et al. [25] studied the combined effects of particle size and content of marble and granite dust on the physical and mechanical properties of high-density polyethylene (HDPE). Their findings revealed that mixing HDPE with marble and granite dust resulted in enhanced yield strength, hardness, and compressive strength, particularly when finer particle sizes were utilized.

In addition, Lendvai et al. [26] manufactured a recycled PET-based composite (r-PET) reinforced with marble dust (MD) and analyzed the microstructural and thermal properties of the composite. Their findings included a higher crystallization temperature with the incorporation of MD, as well as a slight increase in thermal stability with Thermal Gravimetric Analysis and an improvement in stiffness across the temperature range studied for MD-filled composites compared with pure r-PET, as shown by Dynamic Mechanical Analysis (DMA). Also, Singh et al. [27] optimized a polymer composite based on polylactic acid (PLA) and recycled polyethylene terephthalate (r-PET) containing 0, 5, 10, and 20 wt.% of marble dust. It was found that flexural strength improved with the addition of MD, while tensile and impact strength deteriorated with the addition of MD. In addition, a multicriteria decision-making (MCDM) technique was presented to optimize the optimal composition. It was concluded that the best rate of MD additions was 10%. Furthermore, Sharma et al. [28] examined the effect of adding MD as a filler in polymer composites reinforced with both non-woven and needled jute fibers. Improvements in mechanical properties were observed, except for tensile strength, which showed a proportional decrease with increasing filler content.

Very recently, Zhang et al. [29] developed a new cured hybrid UPR composite for crack repair in asphalt pavements. The UPR composite developed features such as excellent workability, less temperature sensitivity, with moderate processing time and rapid strength increase after repair. The composites developed features such as direct tensile strengths of up to 19 MPa and favorable durability with only 2–4% performance degradation. They concluded that UPR-based composites offer properties similar to those of an epoxy resin-based sealant, while costing half as much.

A promising way to address the requirements of sustainable material is the use of solid waste as a filler incorporated in the matrix of composite. The use of marble waste can be expected to avoid problems enhancing mechanical properties. To be precise, the marble waste incorporated in the UPR matrix is both beneficial to environmental protection and economic development while keeping/improving the mechanical, thermal, and microstructure performance of the composite. This research has enriched the database on mechanical properties, thermal stability, and their relationship with the microstructure. For this purpose, five composites, containing 0, 5, 10, 15, and 20 wt.% of marble waste, have been fabricated and tested for their microstructure (X-Ray Diffraction, Infrared Spectroscopy, and Thermogravimetric Analysis), physical (density), mechanical (tensile strength, Young’s modulus, and hardened and impact strength).

2. Materials and Methods

2.1. Raw Materials

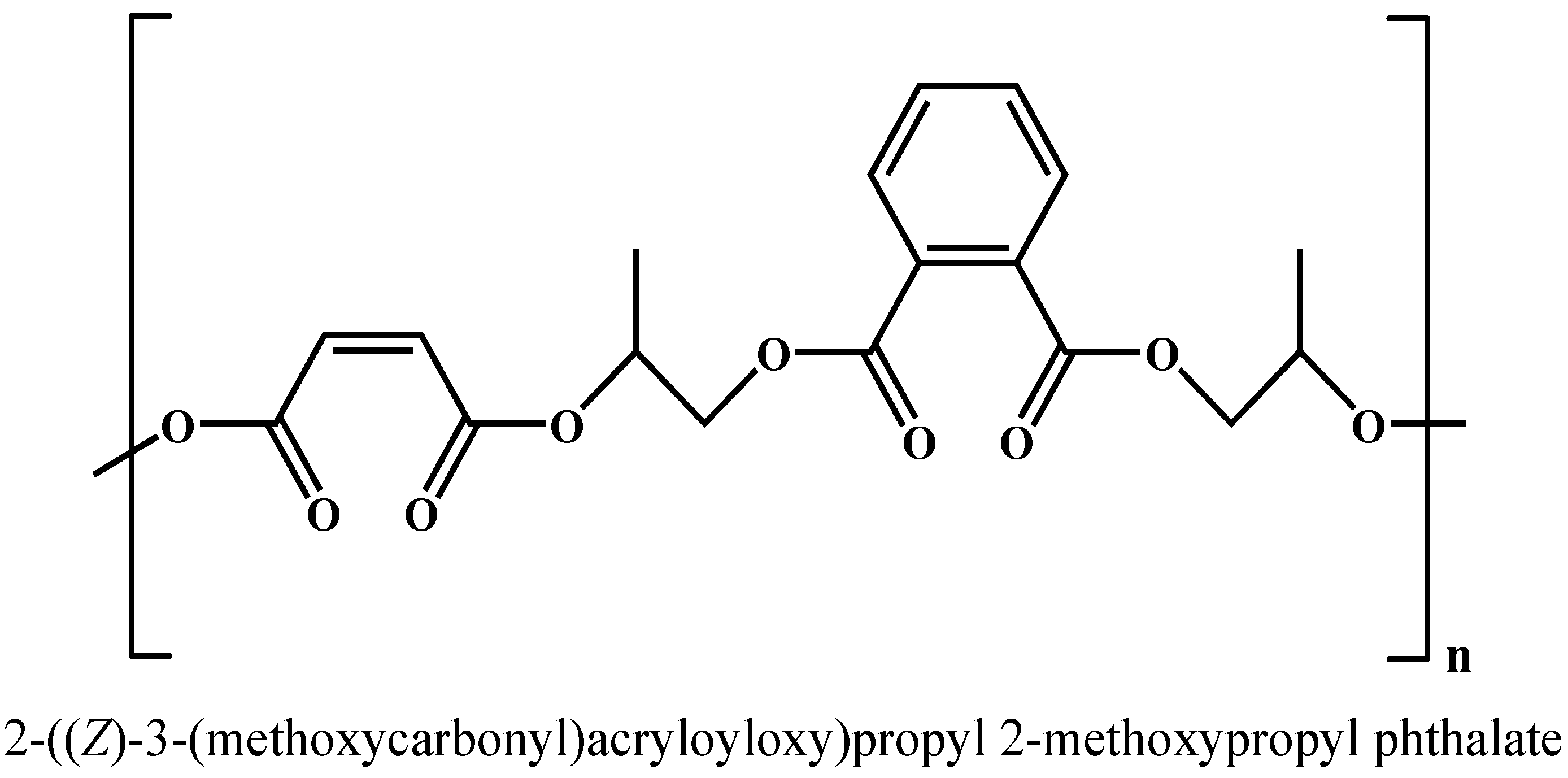

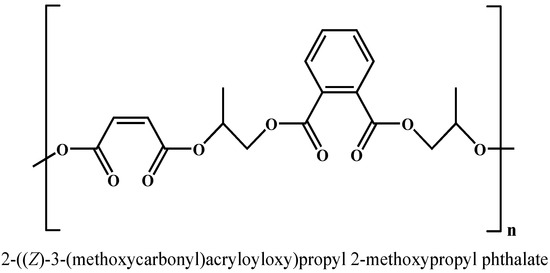

The resin used in this study was a thixotropic, pre-accelerated, medium-viscosity thermosetting Ortho phthalic-based unsaturated polyester resin (UPR), “TP200TICO”, manufactured by Turquoise Polyester Resin Chemistry San. Tic. Ltd. (İzmir, Turkey). Figure 1 illustrates the chemical formula of the UPR as reported in [30]. The curing of this resin was carried out using a solution of methyl ethyl ketone peroxide (PMEC dissolved in dimethyl phthalate), type “BUTANOX M-50”. The physical characteristics of the UPR and PMEC are provided in Table 1 [31,32]. Notably, the UPR and PMEC have comparable densities ranging between 1.08 and 1.18, but their viscosities differ by a factor of 1000, which enables rheological adjustments in the fresh state and ensures good structural homogeneity after curing. The mechanical, thermal, and electrical properties of the resin used are shown in Table 2. Its compressive strength and elastic modulus are 80 MPa and 2 GPa, respectively. For thermal and electrical conductivity, the values are 0.28 W/m·K and 3.7 mS/cm, respectively.

Figure 1.

Chemical formula of UPR.

Table 1.

Characteristics of the UPR and PMEC.

Table 2.

Physical and chemical properties of MW filler.

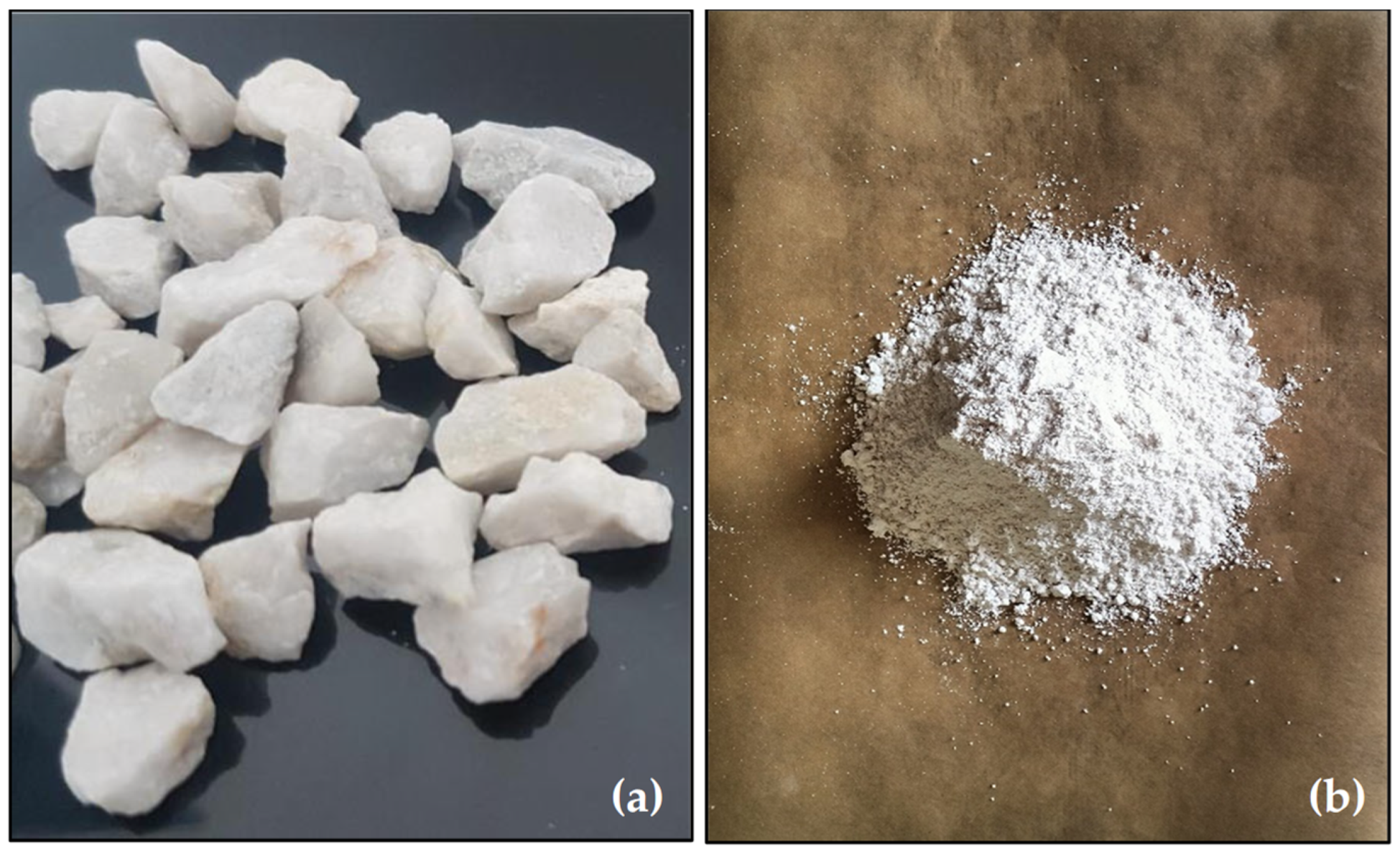

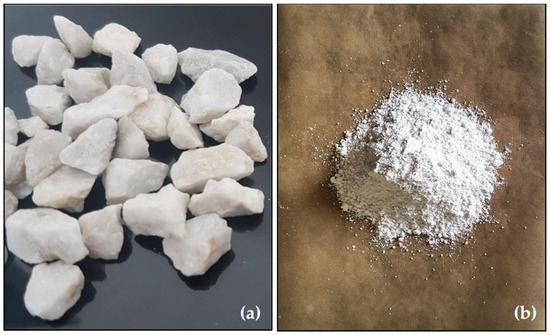

The UPR matrix was reinforced with a mineral filler derived from marble waste (MW), with a particle size of less than 80 µm, as shown in Figure 2a,b. The MW was sourced from the CHATT/FIL-FILA marble quarry, located about 25 km east of Skikda City, Algeria. Prior to use, the MW underwent treatment to ensure good homogenization with the UPR. Crushing of the MW was performed using a ball mill with a capacity of 10 kg. Details of its chemical composition and physical properties are provided in Table 2. Notably, MW is rich in calcium oxide (CaO), with content of more than 56%. It also exhibits significant fineness, expressed by the Specific Surface of Blaine (SSB) value of 5307 cm2/g, and a high density of 2.79. The mineralogical composition of marble is mainly dominated by calcite, which is soft, highly stable, and combines very well with resins. Calcite makes up a major part of marble, with a minor substitution of Ca by Mg, resulting in a harder and slightly more abrasive mineral, namely, dolomite, as highlighted by Babouri et al. [33].

Figure 2.

(a) Coarse aggregates from marble waste, and (b) MW filler < 80 μm.

2.2. Materials

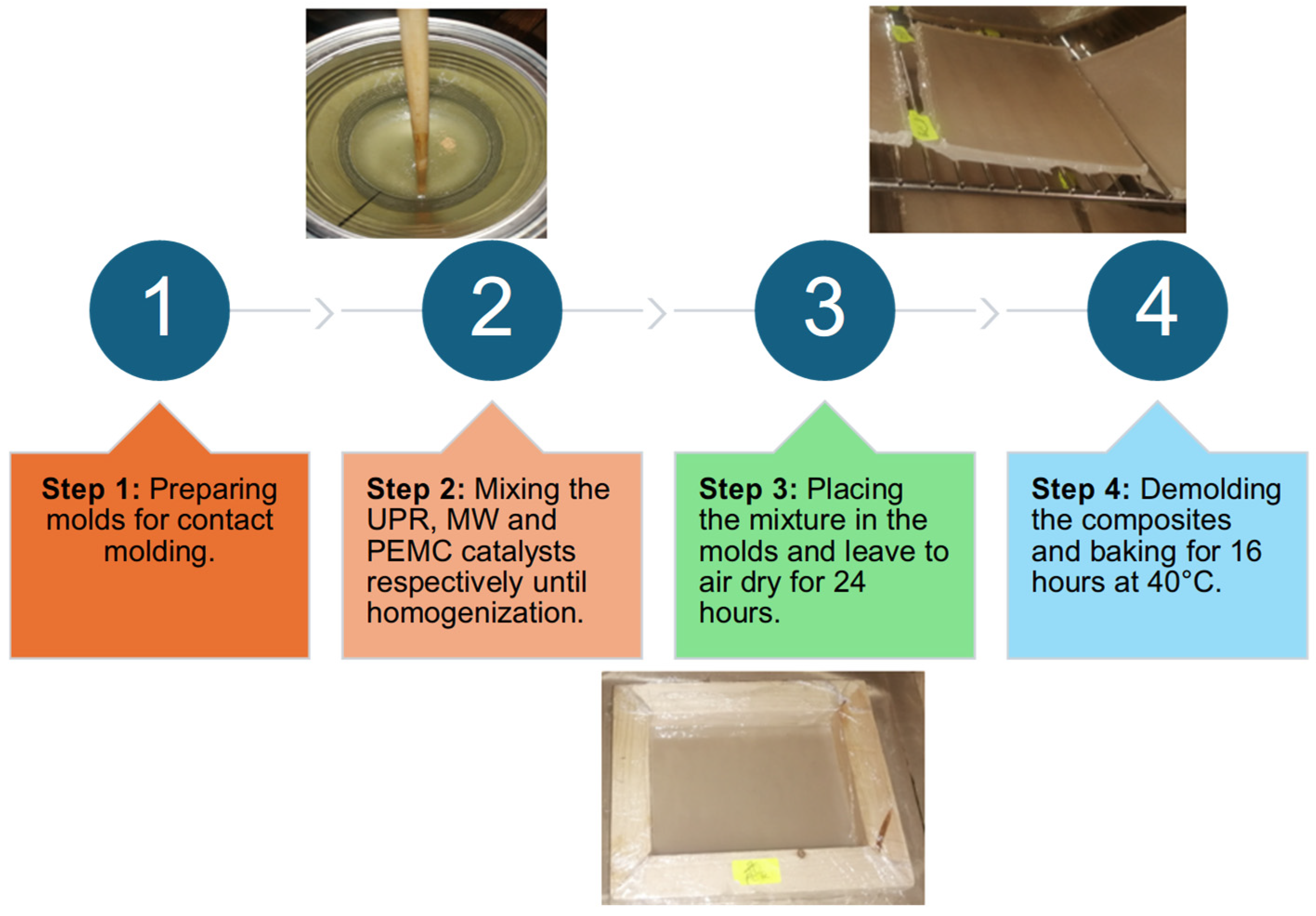

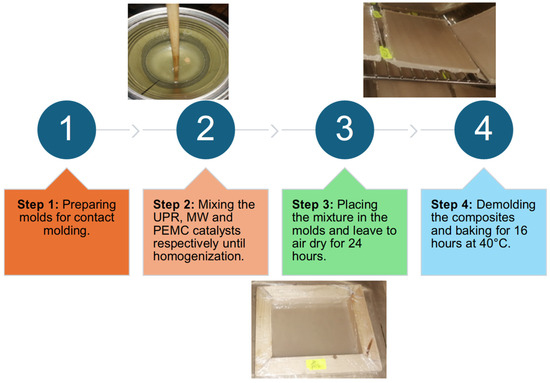

The samples were prepared as detailed in Figure 3. Initially, the UPR matrix was thoroughly mixed by hand using a manual mixing tool, with the MW reinforcement added in concentrations ranging from 0% to 20 wt.% of the UPR, with a stepwise variation of 5%. Subsequently, the PMEC catalyst, at 2% by weight of the UPR, was added and gently mixed until the mixture was uniformly homogenized. After mixing, the final mixture was poured into a pre-prepared wood mold, placed on a Teflon-coated glass plate measuring 113.6 × 173.6 × 4 mm3. The samples were left to cure at room temperature for 24 h before being demolded and then placed in the oven for post-curing at 40 °C for 16 h, according to the recommendations of Perrot et al. [14,34].

Figure 3.

Protocol of UPR/MW composite preparation.

2.3. Methods

2.3.1. Fourier Transform Infrared Spectroscopy (FT-IR)

FT-IR analysis was carried out on three powder samples of the composite studied using a Perkin Elmer Spectrum One Fourier Transform IR spectrometer (Oshawa, ON, Canada). Additionally, the developed composites were analyzed using a SHIMADZU IR Spirit Spectrum One (Noisiel, France). This device is operated through a microcomputer menu in the Spectrum data acquisition software known as Spectrum™ 10 software [35], allowing the recording of mid-infrared spectra depending on the source/separator/detector combination used. It covers a total range from 4500 to 400 cm−1 with an ideal resolution step of 0.5 cm−1 following the ASTM E168-16 standard [36] and ASTM E1252-98 standard [37].

2.3.2. Scanning Electron Microscopy (SEM)

SEM imaging was conducted using the JOEL Neoscop scanning electron microscope. This investigation facilitated the study of sample surface morphology and characterization of the microstructure, specifically focusing on the filler/matrix interface of the composites.

2.3.3. X-Ray Diffraction Analysis (XRD)

XRD analysis was performed on three powder samples of the composites studied using a BURKER D8 Advance diffractometer. The sample was irradiated with a copper metal anticathode (λCu Kα = 1.5406 Å), and the 2θ angle ranged from 10° to 90° with a step size of 0.020°. This technique allows for the determination of structural properties, crystal parameters, and the identification of different phases present in the sample. Two software packages were used for analysis. The first one is X’pert HighScore Plus, which identifies peaks in each alloy spectrum, and the second one is PDF2, which identifies phases using its extensive database of crystallographic information. These analyses provide insights into the composition and crystalline structure of the materials studied, aiding in understanding their properties and potential applications.

2.3.4. Thermogravimetric Analysis (TGA)

TGA was carried out on three samples of around 100 mg of powder for each composite studied. The instrument used was TA Instruments’ SDT Q600, in accordance with ASTM E1131-08 [38]. This apparatus includes a sealed chamber for controlling the sample atmosphere, where nitrogen gas is injected at a flow rate of 100 mL/min. It features an oven for precise temperature control, a microbalance for measuring sample weight, a thermocouple to monitor temperature, and a computer for data control and recording. During the analysis, the temperature was ramped up from room temperature to 525 °C at a constant rate of 20 °C/min [39]. This measurement was performed to investigate the thermal stability of the samples, providing insights into their decomposition temperatures and weight loss characteristics under controlled conditions.

2.3.5. Density

Density measurement tests were carried out on three samples of composites studied according to the NF EN ISO 1183-1 standard [40]. These samples were cut from the samples curing in the mold using a diamond disk under a water jet. The samples tested measure 115 × 20 × 4 mm3. The density (d) can be obtained by Equation (1):

where , are the mass of the sample weighted in air (g) and in fluid, respectively. is the density of the emersion liquid (g/cm3), and 0.0012 corresponds to the density of air in normal conditions.

2.3.6. Charpy Test

The Charpy tests were conducted on three samples of composites studied, using a CEAST Resil Impactor machine with a manual fracture, employing standardized specimens measuring 65 × 15 × 4 mm3, obtained from plate samples elaborated. These specimens were cut using a diamond disk under a water jet, following the ASTM D256 [41]. The Charpy impact test involves applying mechanical stress at high speed and energy deformation, causing the sample to fracture within a fraction of a second. This test is crucial for evaluating the brittleness of a specimen-material combination under specific experimental conditions. Brittleness in this context is characterized more by low elongation rather than low fracture energy [42]. The impact strength (Charpy impact strength) is typically determined by measuring the energy absorbed by the specimen during a fracture. This energy absorption is directly related to the material’s toughness and resistance to sudden impact. The impact strength is given by Equation (2) [43]:

where IS, h, b, and θ are the impact strength (KJ/m2), the sample thickness (m), the sample width (m), and the impact energy (KJ), respectively.

2.3.7. Tensile Strength Test

The tensile tests were conducted on three samples of composites studied measuring 115 × 20 × 4 mm3 and using a Zwick/Roell Z010 machine type BT1-FB010TN.D30. A displacement sensor (extensometer) was connected to a data acquisition unit to simultaneously record displacement and load data. The tensile samples were tested under standard temperatures and pressure conditions following the ASTM D885 standard [44]. During the tests, the rate of displacement was maintained at 2 mm/min. This controlled testing speed ensures consistent and accurate measurements of tensile properties such as ultimate tensile strength, yield strength, and elongation at break. These parameters provide essential insights into the mechanical behavior and performance of the material under tension. The tensile strength and strain are given by Equation (3) and Equation (4), respectively:

where Rr, Fr, and S0 are the stress at break (MPa), the load at break (N), and the initial section (mm2), respectively. And A%, Lu and L0 are the strain (%), the ultimate length after break (mm), and the initial length (mm), respectively.

2.3.8. Hardness Test

The hardness test is employed to measure the indentation caused by applying a steel ball or diamond cone under a standard load. Different sizes of indenters are used depending on the hardness range being tested. Hardness is a complex property that reflects a material’s resistance to deformation. The testing methods are typically adaptations of those originally developed for testing metals, following the ASTM D-2240 [45].

In our study, the hardness tests were conducted on three samples of composites studied with a thickness of 4 mm by using a Shore D Durometer. This instrument measures the depth of penetration of a sharp point into the material under a specified spring force. The displacement of the indenter is read on a scale graduated from 0 to 100, where 100 corresponds to zero penetration (maximum hardness), and 0 corresponds to the maximum penetration allowed by the instrument (minimum hardness). This measurement provides valuable insights into the material’s hardness characteristics, which are crucial for assessing its suitability for various applications.

3. Results

3.1. Fourier Transform Infrared Spectroscopy (FT-IR)

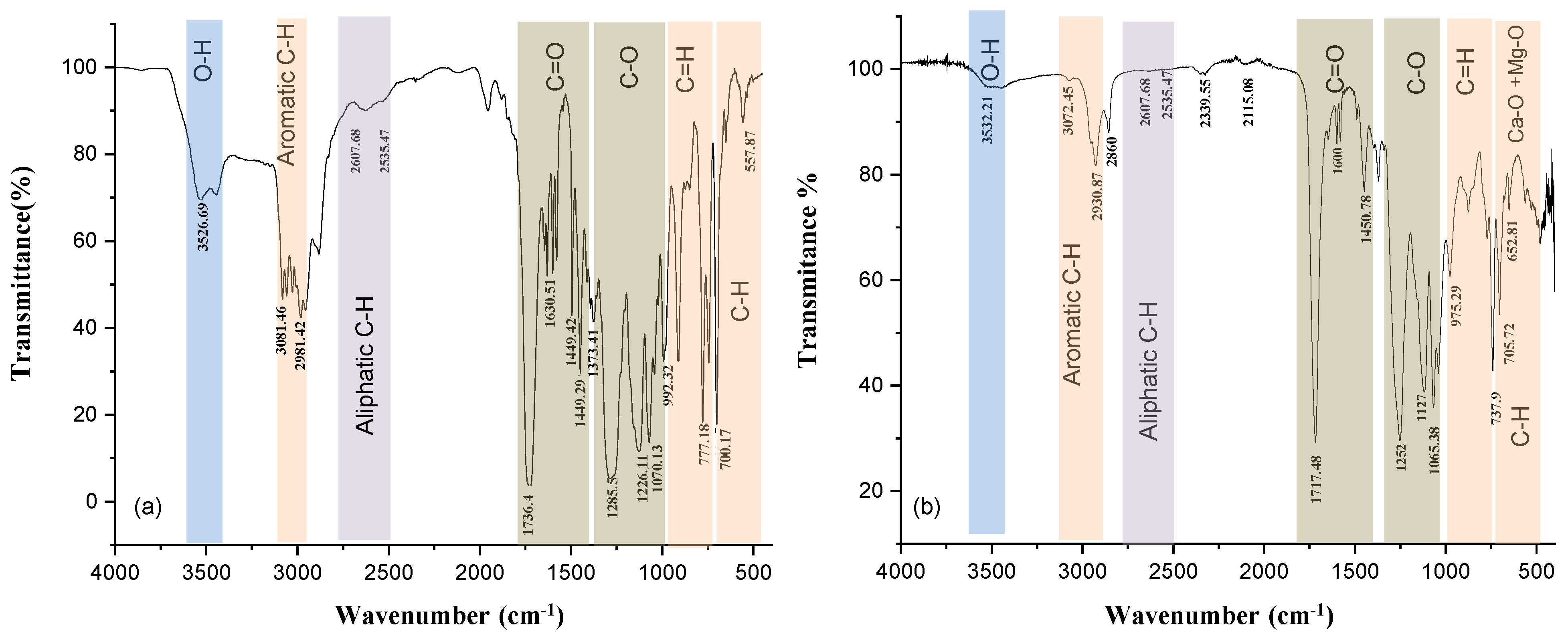

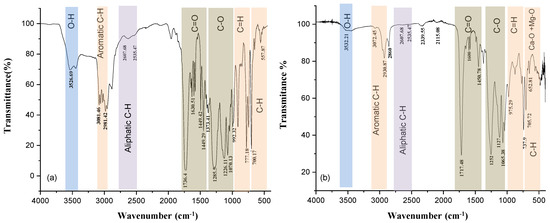

The FTIR results for the UPR are shown in Figure 4a. The FTIR spectrum shows a broad band characteristic of hydroxyl group O-H stretching vibrations between 3600 and 3400 cm−1 wavenumbers. The stretching vibrations of aromatic C-H are observed between 3090 and 3000 cm−1, while those of aliphatic C-H are detected between 2607 and 2535 cm−1, approximately. In addition, a strong band is observed around 1736 cm−1 wavenumbers and is characteristic of the carbonyl group C=O of the polyester [46,47,48], while the vibration bands of the aromatic ring are located around 1630, 1494, and 1450 cm−1. The region between 1400 and 1000 cm−1 is particularly complex because it is rich in bands and contains the deformation vibration of the polyester C-O bond [47,49]. According to the literature, the band at 872 cm−1 corresponds to para-disubstituted benzene stretching [50], while the peak at 700 cm−1 can be attributed to out-of-plane bending of the aromatic ring [46].

Figure 4.

IR Spectra of (a) UPR and (b) UPR/MW composites.

Regarding UPR/MW composites, their FTIR results are illustrated in Figure 4b. All spectra of the UPR/MW composites are similar, for all MW rates. Indeed, all spectra of UPR/MW composites are similar to those of pure UPRs, with the exception of an attenuation of all peaks between 3600 and 750 cm−1. This attenuation can be explained by the replacement of pure UPRs by MW. According to the literature, marble displays no peaks in this region between 4000 and 1600 cm−1 [26]. Moreover, a few additional peaks are present in the region between 750 and 400 cm−1 related to Ca-O and Mg-O bonding. This is due to the presence of MW particles in the composites. These peaks correspond to magnesium oxide and carbonates as shown by Khan et al. [51]. The presence of magnesium oxide and carbonates is confirmed by the X-ray diffraction results presented in Section 3.3, which show the presence of calcite (CaCO3) and dolomite (CaMg(CO3)2).

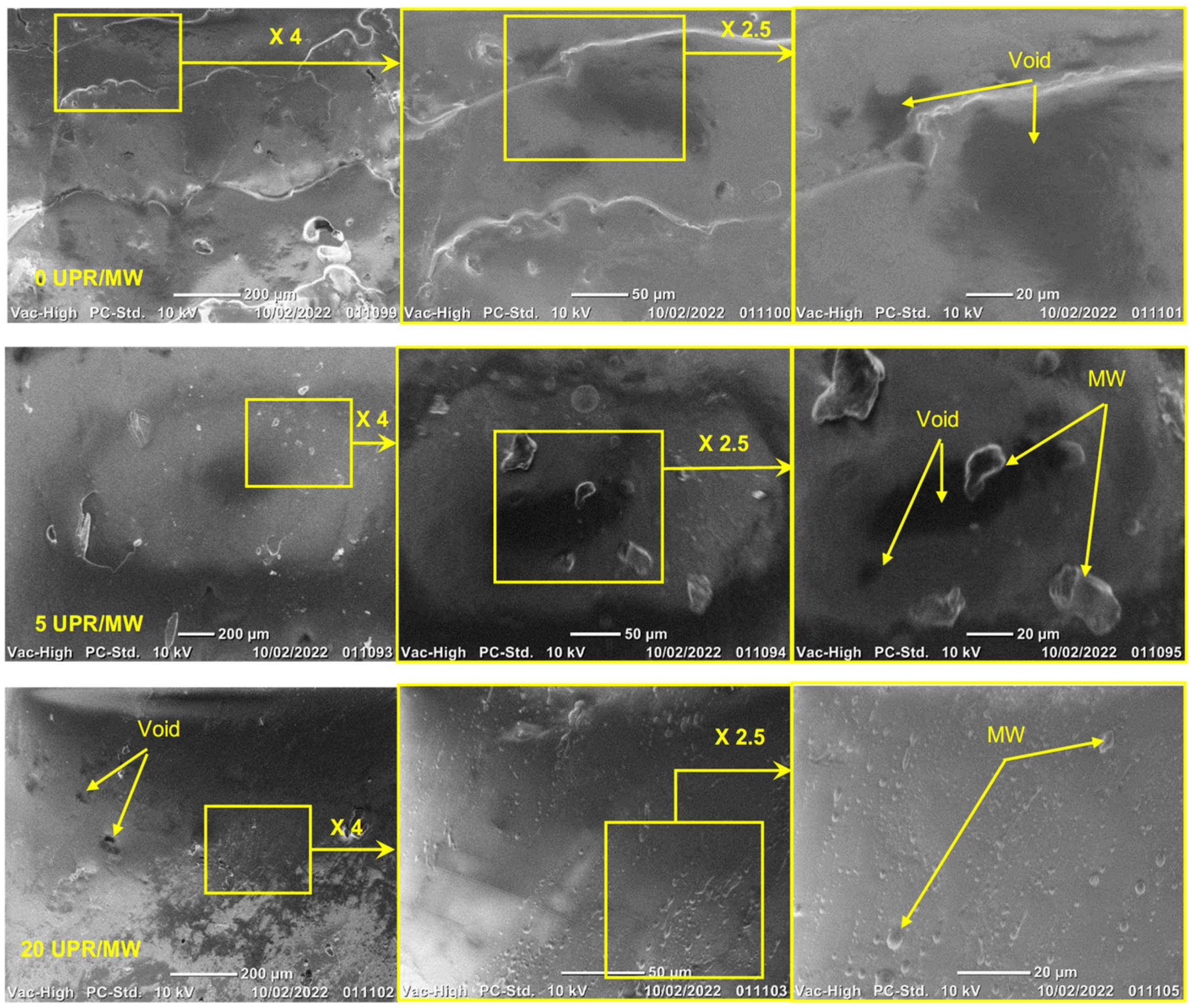

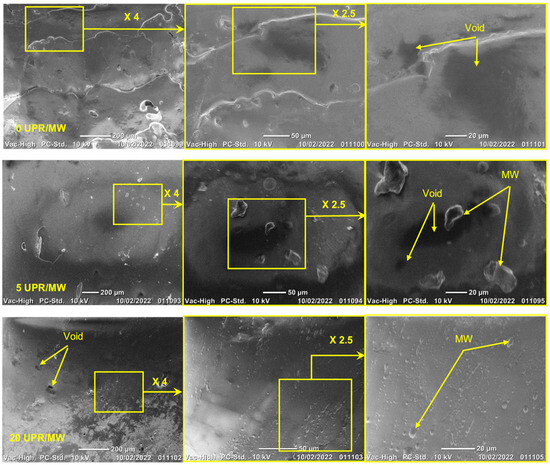

3.2. Scanning Electron Microscopy (SEM)

SEM images of the UPR and UPR/MW composites are presented in Figure 5. These images were taken to investigate the microstructure and morphology of the UPR matrix. The results illustrate the effective dispersion of marble particles within the matrix. The use of smaller fillers has improved their distribution in the polymer matrix, consequently enhancing the mechanical properties of these materials [52]. Additionally, the images reveal the presence of voids, which result from the evolution of volatile gases during the composite manufacturing and curing process [53]. Indeed, the gas released during the manufacture of UPR composites is mainly styrene [54], which results from the chemical reaction between the unsaturated polyester resin and the catalyst used as a diluent. The latter not only helps mixing before curing, but also contributes to polymerization while the resin is curing. The gas generated often remains confined within the matrix as an air bubble, forming unconnected pores [55]. As a result, mechanical properties are highly dependent on the defects and pores present in the microstructure. In the literature, two widely used solutions are available to overcome the problem of void formation. The first is to use resin transfer molding technologies. The second is vacuum vibrocompression. These solutions allow all air bubbles to be removed, thus improving mechanical properties [56,57].

Figure 5.

SEM images of the microstructure of composites: 0 UPR/MW, 5 UPR/MW, and 20 UPR/MW.

As demonstrated by the SEM images, porosity is observed and increases as the MW rate increases. Large pores can also be seen in the 20 UPR/MW matrix in the first image without magnification (bottom left). These voids have impacted the structural integrity of the samples, contributing to reduced mechanical properties [58]. When MW is excessively used, weakly polar ester groups that adsorb on the surface of the MW particles may decrease, leading to poor dispersion and the potential aggregation of MW particles [59]. SEM analysis reveals filler agglomeration, which becomes more pronounced. For the 20 UPR/MW point of view, noticeable areas of coarse agglomeration are observed, which led to bad filler dispersion. Decohesions at the interface between the matrix and these agglomerates appear more pronounced as the agglomerate size increases [60].

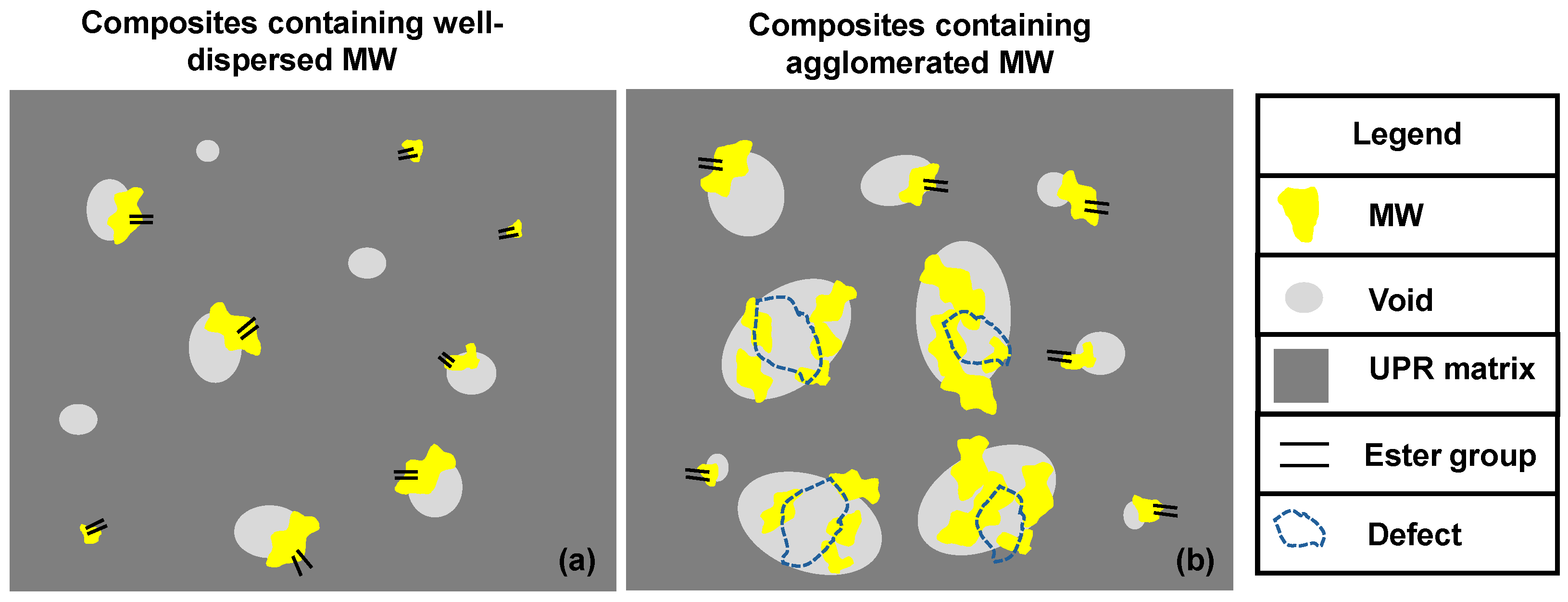

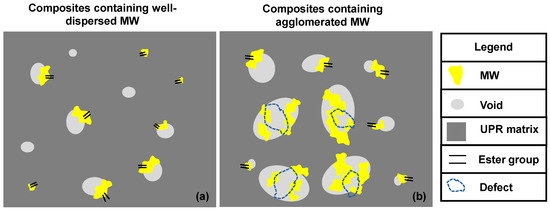

The agglomeration of fillers constitutes a major challenge associated with the incorporation of fillers in UPR-based matrices [61]. As shown in Figure 6, agglomeration leads to defect site formation and weakens the connection between the filler and the matrix [61,62], and the weakening effect is particularly distinct with high MW content. More specifically, compared to the control group, the MW-modified group (i.e., 20 UPR/MW) showed a drop in mechanical strength, notably the Shore D hardness presented in Section 3.8.

Figure 6.

Schematic diagram of microstructure in MW modified containing (a) well-dispersed MW and (b) agglomerated MW.

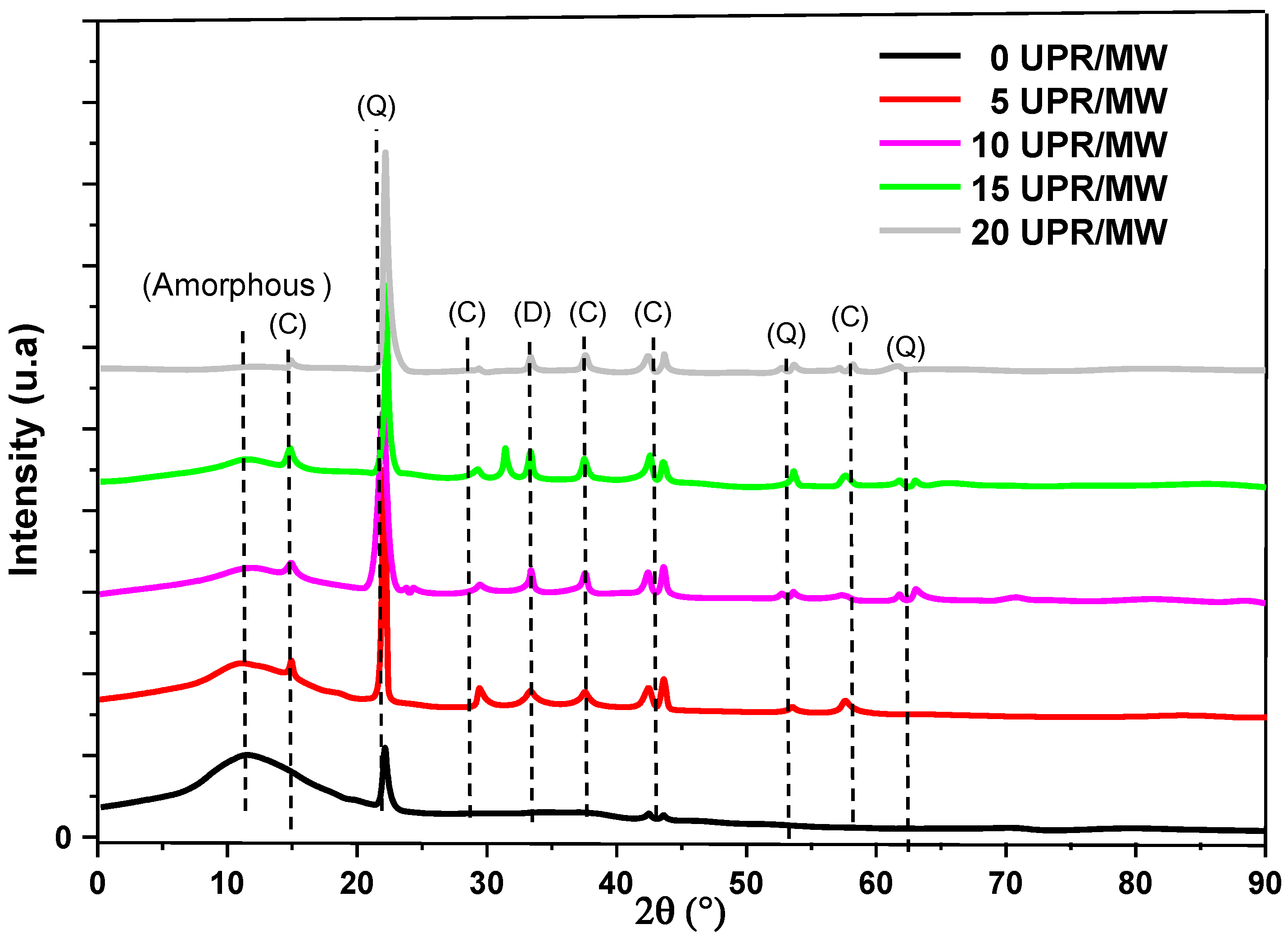

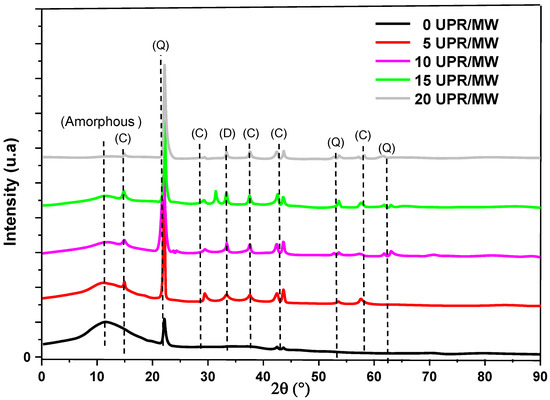

3.3. X-Ray Diffraction Analysis (XRD)

Figure 7 presents the XRD patterns of the composites studied. The analysis reveals both amorphous and crystalline phases within the composites. The amorphous phases originate from the UPR matrix, as evidenced by a broad peak centered at 12°, which is typical of organic polymers and indicative of the amorphous nature of the resin [63]. This peak reflects the disordered arrangement of polymer chains, contributing to the resin’s inherent flexibility and impact resistance.

Figure 7.

XRD results of composites studied: Q (Quartz: SiO2), C (Calcite: CaCO3), and D (Dolomite: CaMg(CO3)2).

The dominance of calcite in the MW composition plays a critical role in the composite’s mechanical and thermal performance. Calcite, known for its high compressive strength, provides a solid framework that distributes applied stress more effectively within the matrix. This is particularly evident in the increased tensile and impact strength of the composites with higher MW content. Dolomite (CaMg(CO3)2) [6,64], with its harder and slightly more abrasive nature, complements calcite by further reinforcing the composite and contributing to its wear resistance.

The introduction of crystalline phases such as calcite and dolomite also positively impacts the thermal stability of the composite, as evidenced by the TGA results (Section 3.4). These minerals resist thermal decomposition at higher temperatures, contributing to the observed increase in decomposition temperatures and thermal stability. The XRD results provide direct evidence of these thermally stable phases and their role in enhancing the composite’s resistance to thermal degradation.

The XRD patterns also reveal that the crystalline phases introduced by MW fillers integrate well with the UPR matrix, suggesting strong interfacial bonding. This interfacial cohesion is essential for efficient load transfer from the matrix to the filler, thereby improving the composite’s overall mechanical performance. However, at higher MW content, the potential for particle aggregation may disrupt the uniformity of the matrix–filler interface, leading to localized stress concentrations and a possible decline in mechanical properties.

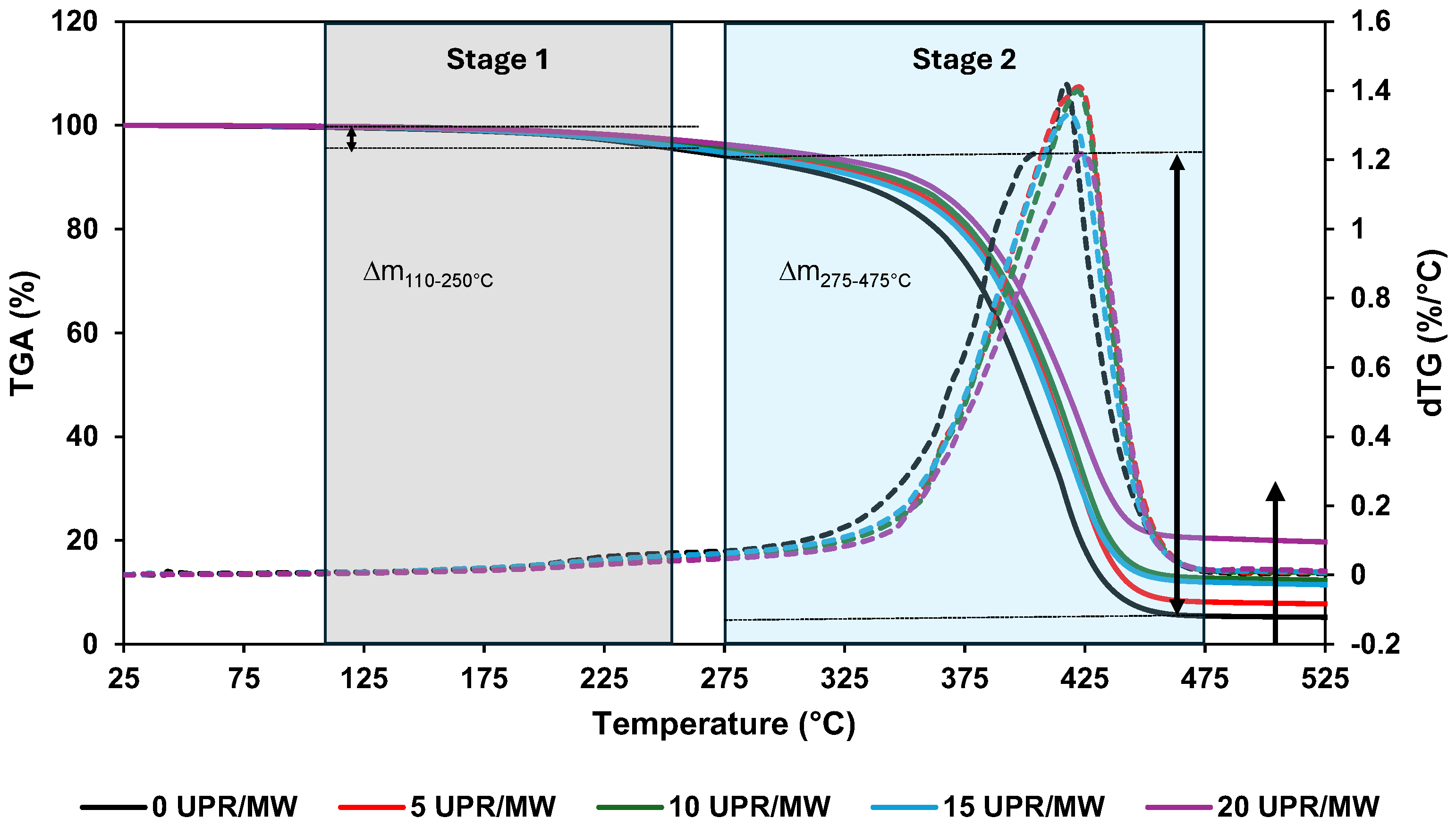

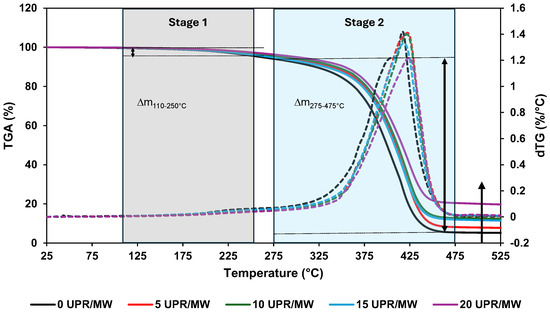

3.4. Thermogravimetric Analysis (TGA)

The TGA results and its derivate dTG for the UPR and UPR/MW composite samples are presented in Figure 8. Based on dTG curves, two distinct mass loss stages were revealed in agreement with confirmation from the literature [62]. The first stage is observed between 110 and 250 °C and generally associated with the loss of water molecules trapped in the pores. In the first stage, the composites show a mass loss of 4.2%, 3.19%, 2.57%, 2.88%, and 3.76% corresponding to 0 UPR/MW, 5 UPR/MW, 10 UPR/MW, 15 UPR/MW, and 20 UPR/MW, respectively. These results are in excellent agreement with those of the SEM images, which revealed the problems associated with the agglomeration effect and the low dispersion of MW fillers in the UPR matrix. The second stage occurs between 275 and 475 °C and corresponds to the loss of mass related to the decomposition of UPR polymers [65,66]. In addition, the percentage of residues increases proportionally with increasing MW filler content [67].

Figure 8.

Thermogravimetric analysis of UPR/MW composites studied: TGA in continuous line, and dTG in dashed line.

For UPR/MW composites, the delay in decomposition temperatures can be explained by the fact that the MW crystalline phases generally decompose around 650–800 °C, releasing carbon dioxide (CO2) from the calcite phase (CaCO3) [66,67]. In the second stage, the composites show a mass loss of 90.37%, 88.73%, 84.36%, 84.32%, and 77.5% corresponding to 0 UPR/MW, 5 UPR/MW, 10 UPR/MW, 15 UPR/MW, and 20 UPR/MW, respectively. These results are in concordance with the MW filler rate. Table 3 provides details of the start temperature of decomposition (Td_0), the final temperature of decomposition (Td_f), and the temperature corresponding to the maximum decomposition (Td_max) of the studied composites. The results show that the Td_0 and Td_max values increase with MW filler concentration, reflecting their thermal stability by delaying the decomposition start temperature by 28 °C for 20 UPR/MW compared with 0 UPR/MW. This indicates that the incorporation of MW fillers has an effect on the thermal stability of UPR/MW composites, as demonstrated by Lendvai et al. [26].

Table 3.

Td_0, Td_max and Td_f of UPR/MW composites studied.

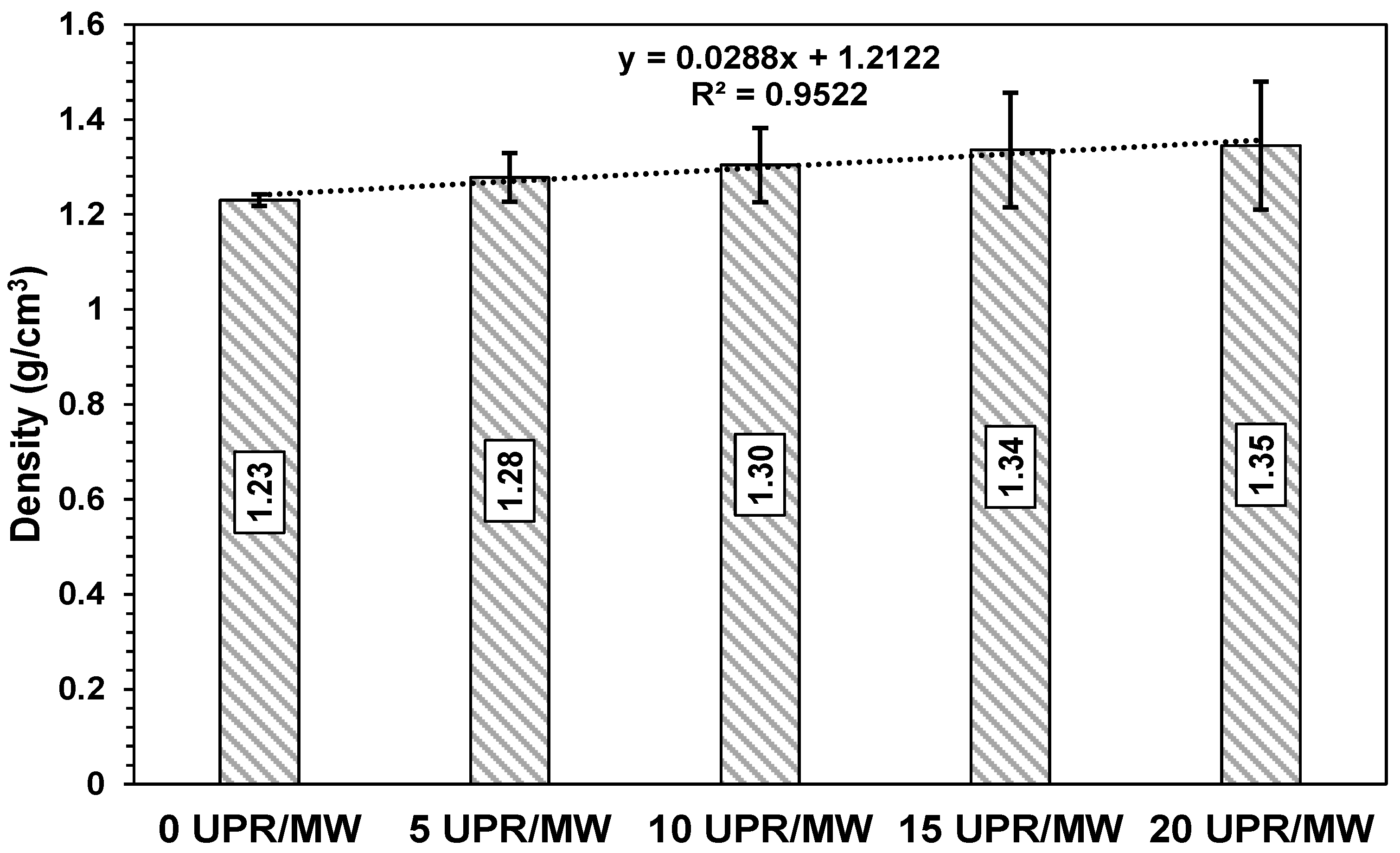

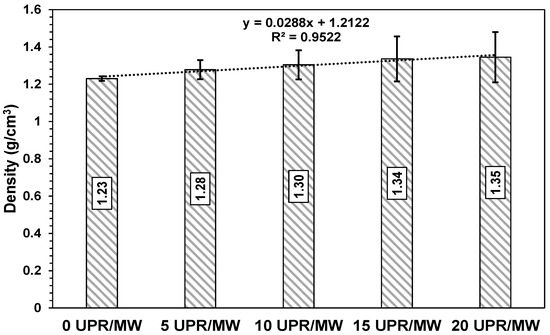

3.5. Density

Figure 9 shows the density values for UPR/MW composites. Density values increase with MW content, reaching 12.8% between 0 UPR/MW and 15 UPR/MW. This can be attributed to the MW density, which tends towards 2.79 g/cm3 as shown in Table 2. Furthermore, the 20 UPR/MW composites have approximately the same value as 15 UPR/MW. This can be explained by the agglomeration of fillers creating pores as observed by the SEM images presented in Section 3.2. However, this behavior gives an indication of the optimum incorporation rate, which is around 10 and 15% MW fillers, as demonstrated by Singh et al. [27]. Indeed, higher densities can improve mechanical properties and provide specific advantages in terms of durability and performance in different applications [68].

Figure 9.

Density values of composites studied.

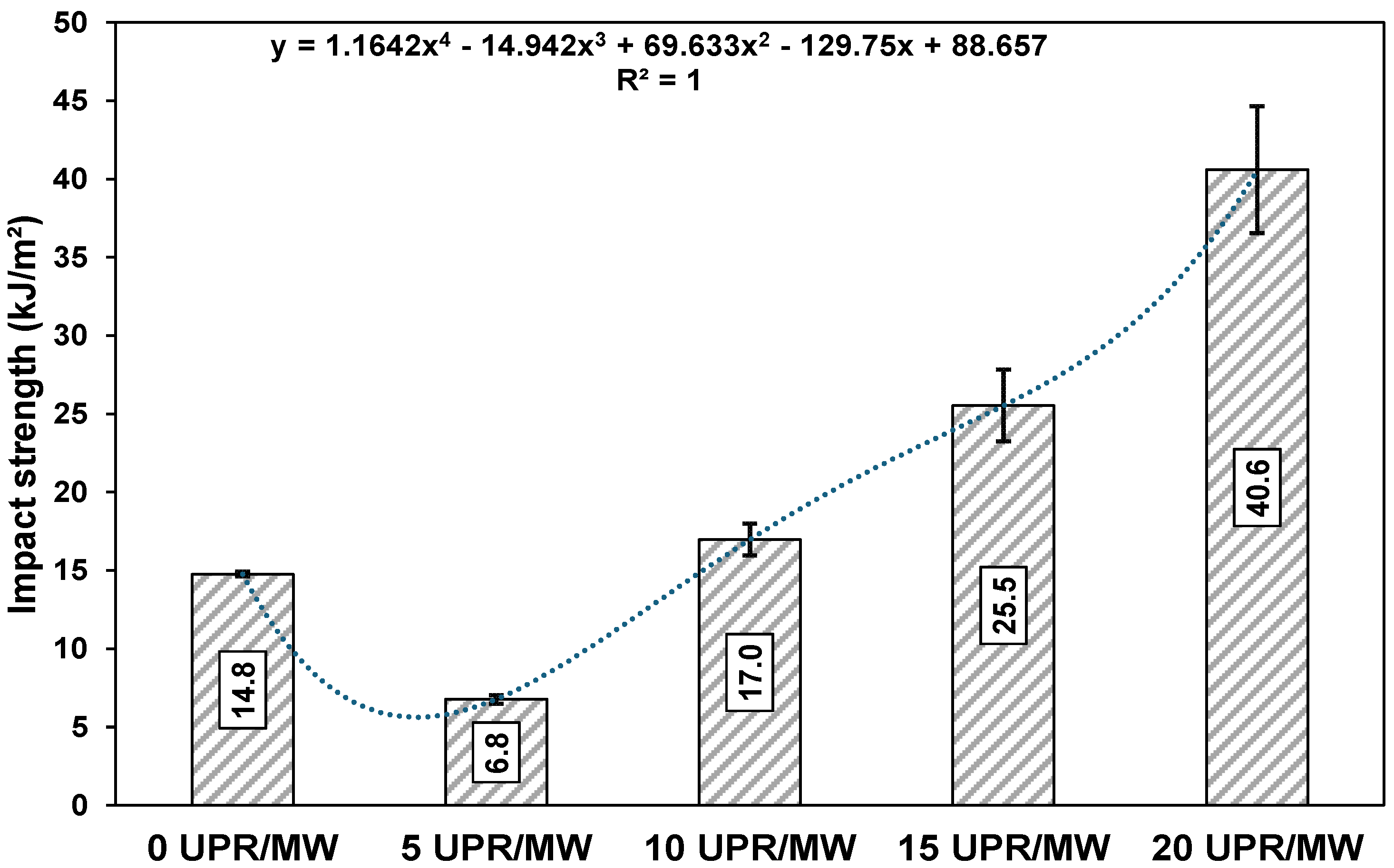

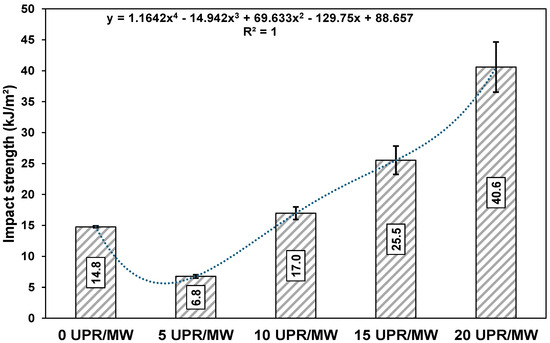

3.6. Charpy Test

Figure 10 shows the impact strength results, highlighting the positive effect of adding MW fillers. An initial decrease in impact resistance is observed at 5 UPR/MW; however, beyond this point, impact strength increases with the MW content, reaching a maximum of 40.6 KJ/m2 for 20 UPR/MW. This improvement can be attributed to the enhanced cohesion between the matrix and the filler, which promotes better energy absorption during impact [69].

Figure 10.

Impact strength results of UPR/MW composites.

In addition, the steady increase in impact strength with higher MW filler content suggests that the material benefits from improved interfacial adhesion, as demonstrated by FTIR analysis, which confirms chemical bonding between the matrix and the filler. This bonding likely compensates for potential defects caused by filler agglomeration at higher introduction rates.

Contrary to findings in the literature, which indicate that high MW filler content can negatively impact strength due to agglomeration and reduced stress transfer efficiency [17], the results of this study suggest that UPR/MW composites maintain effective stress transfer even at elevated MW levels. This behavior could be attributed to optimized processing conditions or the unique properties of the MW filler used, which mitigate the detrimental effects of agglomeration.

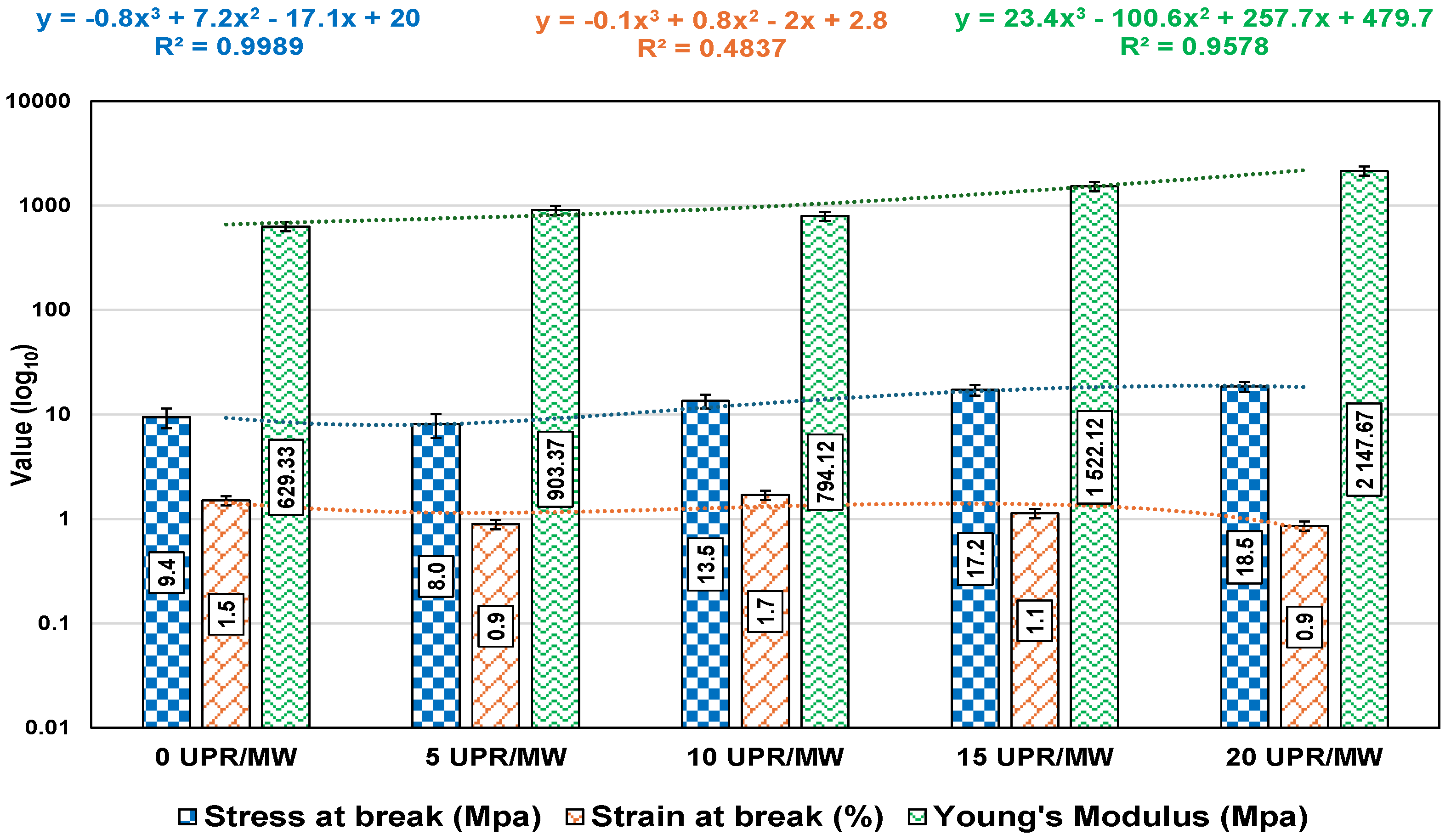

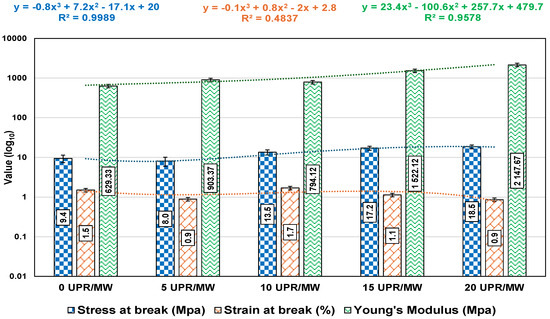

3.7. Tensile Strength Test

Figure 11 presents the tensile strength results, showing that the addition of MW fillers significantly enhances the tensile strength, reaching an optimum value of 18.5 MPa for the 20 UPR/MW composite. These results align with those obtained for impact strength and are consistent with findings in the literature [70]. This improvement can be attributed to the chemical bonding between the matrix and filler, as confirmed by FTIR analysis, which enhances stress transfer and contributes to higher tensile strength.

Figure 11.

Mechanical results of composites studied.

From the perspective of elastic behavior, a high MW content reduces ductility while improving yield strength. Specifically, the 20 UPR/MW composite demonstrates a higher Young’s modulus and reduced strain compared to other formulations, indicating increased brittleness. This trade-off highlights the influence of the MW filler on the mechanical behavior of the composite, with higher filler content leading to greater stiffness at the expense of flexibility.

Notably, the optimal MW filler content, identified as being between 10% and 15%, achieves a balance between improving the elastic modulus and maintaining sufficient ductility. This suggests that the careful optimization of MW filler levels can result in composites with superior mechanical properties, suitable for applications requiring both strength and resilience.

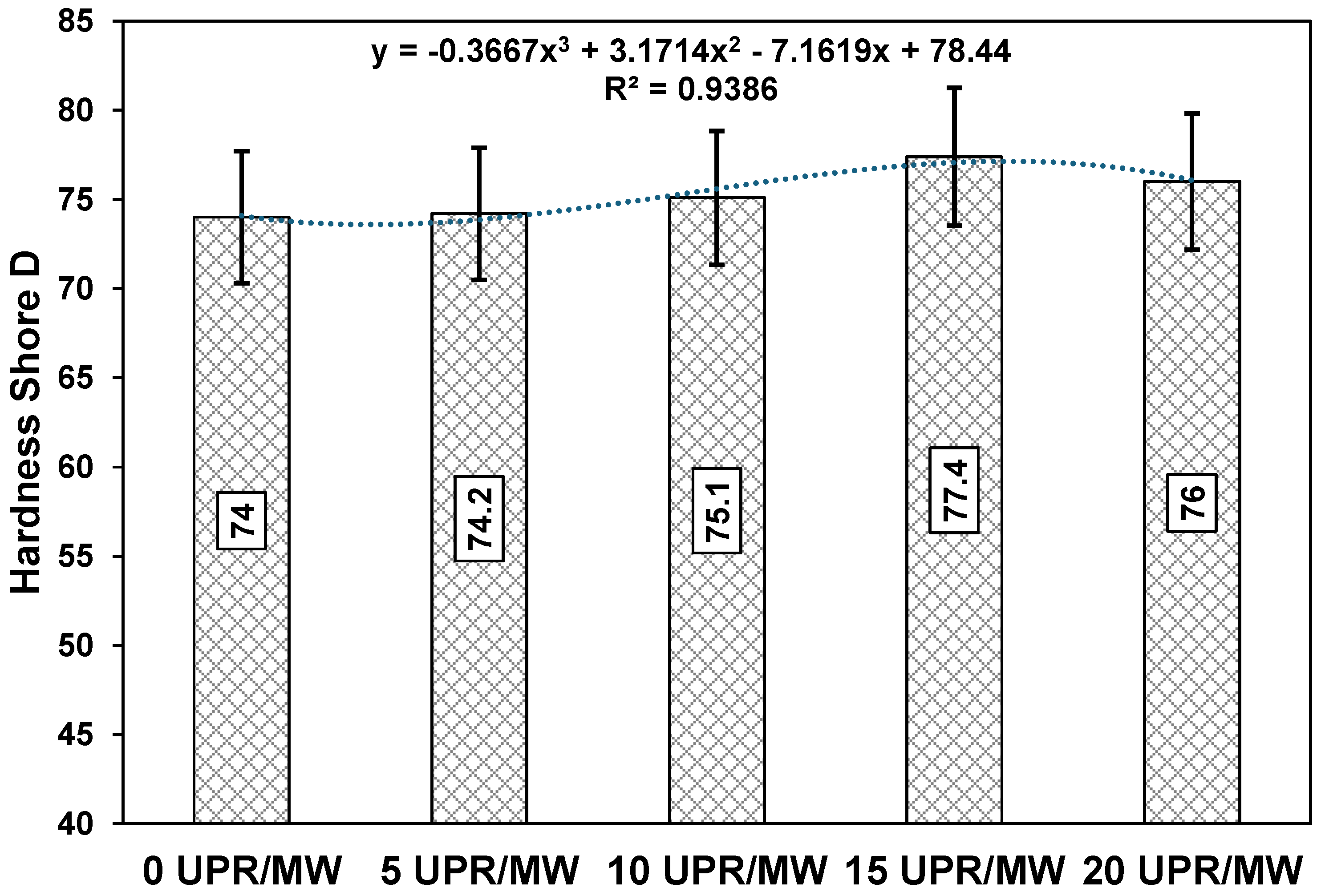

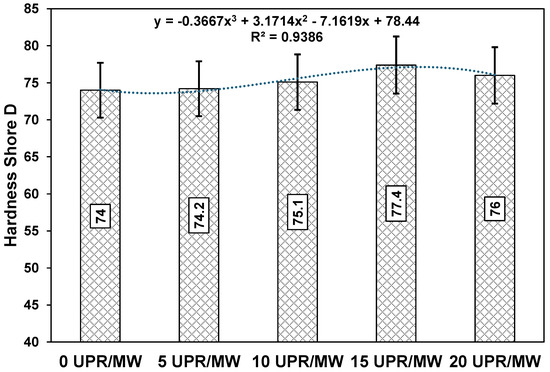

3.8. Hardened Test

Figure 12 illustrates the Shore D hardness values measured for the composites. The results indicate a progressive increase in hardness with the introduction of an MW filler, rising from 74 for 0 UPR/MW to 77.4 for 15 UPR/MW, representing a 4.6% improvement. This enhancement in hardness can be attributed to the better dispersion of MW fillers at incorporation rates below 20 wt.%, which promotes the formation of a solid interface between the matrix and fillers with fewer defects, as confirmed by SEM imaging analyses.

Figure 12.

Shore D hardness values of UPR/MW composites studied.

This well-dispersed structure reduces the penetration of the test ball into the material surface during hardness testing and enhances the wettability between the matrix and MW fillers. Improved wettability facilitates stronger adhesion and effective load transfer at the interface, thereby contributing to the observed increase in hardness [71,72].

At higher MW content (beyond 20 wt.%), the agglomeration effect may counteract these benefits, resulting in diminished improvements in hardness. This underscores the importance of optimizing filler incorporation rates to achieve the best balance between mechanical properties and processing efficiency.

4. Conclusions

This study provides valuable insights into the successful incorporation of marble waste as a reinforcing material in unsaturated polyester resin (UPR) composites. The mechanical properties and thermal stability of the composites were significantly improved by the introduction of marble waste, particularly at an optimum filler content of 10–15%. The observed increases in tensile strength, impact resistance, and hardness at these loading levels highlight the potential of marble waste to enhance the performance of UPR-based materials. Additionally, the improved thermal stability and density confirm the suitability of marble waste for applications requiring greater durability and higher structural strength.

FTIR, XRD, and TG analyses revealed that the incorporation of marble waste fillers induces important microstructural changes, such as the formation of crystalline phases and enhanced matrix-filler interactions, attributed to the creation of Mg-O and Ca-O chemical bonds. These structural changes are critical for improving the mechanical performance of the composites. However, at filler contents exceeding 20%, issues such as filler agglomeration and gap formation begin to negatively impact the material’s properties, underscoring the importance of optimizing the filler content.

Replacing 10–15% of unsaturated polyester resin with marble waste represents an effective strategy for developing durable, high-performance composites. These findings pave the way for future research into the long-term durability, environmental impact, and cost-effectiveness of UPR/MW composites, particularly for construction and infrastructure applications. Further studies are recommended to evaluate the effects of other potential additives that could further enhance the mechanical properties and environmental benefits of these materials.

Author Contributions

Conceptualization, R.B., L.B. and F.B.; methodology, R.B., L.B. and F.B.; validation, L.B., F.B., Y.E.M. and H.H.; formal analysis, R.B., F.B. and L.B; investigation, R.B., L.B. and F.B.; data curation, L.B.; writing—original draft preparation, R.B., L.B. and F.B.; writing—review and editing, L.B., F.B., Y.E.M. and H.H.; visualization, L.B. and F.B.; supervision, L.B. and F.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The experimental data presented in this paper are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Shao, J.; Ni, Y.; Yan, L. Oxidation of furfural to maleic acid and fumaric acid in deep eutectic solvent (DES) under vanadium pentoxide catalysis. J. Bioresour. Bioprod. 2021, 6, 39–44. [Google Scholar] [CrossRef]

- Madni, A.; Kousar, R.; Naeem, N.; Wahid, F. Recent advancements in applications of chitosan-based biomaterials for skin tissue engineering. J. Bioresour. Bioprod. 2021, 6, 11–25. [Google Scholar] [CrossRef]

- Zhang, C.; Khorshidi, H.; Najafi, E.; Ghasemi, M. Fresh, mechanical and microstructural properties of alkali-activated composites incorporating nanomaterials: A comprehensive review. J. Clean. Prod. 2023, 384, 135390. [Google Scholar] [CrossRef]

- Herrmann, J.; Attanasio, D.; Tykot, R.; van den Hoek, A. Aspects of the trade in colored marbles in Algeria. Afr. Romana 2012, 19, 1331–1342. [Google Scholar]

- Renella, G. Recycling and reuse of sediments in agriculture: Where is the problem? Sustainability 2021, 13, 1648. [Google Scholar] [CrossRef]

- Papatzani, S. A review on the valorization of marble dust/solids or slurry: Classification, current trends and potentials. Indian Concr. J. 2019, 93, 36–54. [Google Scholar]

- Zoubir, Y.H. China’s relations with Algeria: From revolutionary friendship to comprehensive strategic partnership. In China and North Africa: Between Economics, Politics and Security; I.B. Tauris: New York, NY, USA, 2021; p. 125. [Google Scholar]

- Seghir, N.T.; Mellas, M.; Sadowski, Ł.; Żak, A. Effects of marble powder on the properties of the air-cured blended cement paste. J. Clean. Prod. 2018, 183, 858–868. [Google Scholar] [CrossRef]

- Bakshi, P.; Pappu, A.; Patidar, R.; Gupta, M.K.; Thakur, V.K. Transforming Marble Waste into High-Performance, Water-Resistant, and Thermally Insulative Hybrid Polymer Composites for Environmental Sustainability. Polymers 2020, 12, 1781. [Google Scholar] [CrossRef]

- Jassim, N.W.; Hassan, H.A.; Mohammed, H.A.; Fattah, M.Y. Utilization of waste marble powder as sustainable stabilization materials for subgrade layer. Results Eng. 2022, 14, 100436. [Google Scholar] [CrossRef]

- Jain, A.K.; Jha, A.K.; Shivanshi. Geotechnical behaviour and micro-analyses of expansive soil amended with marble dust. Soils Found. 2020, 60, 737–751. [Google Scholar] [CrossRef]

- Athawale, A.A.; Pandit, J.A. Unsaturated polyester resins, blends, interpenetrating polymer networks, composites, and nanocomposites: State of the art and new challenges. In Unsaturated Polyester Resins; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–42. [Google Scholar]

- Pączkowski, P.; Głogowska, K. Preparation and Characterization of Quartz-Reinforced Hybrid Composites Based on Unsaturated Polyester Resin from Post-Consumer PET Recyclate. Materials 2024, 17, 1116. [Google Scholar] [CrossRef] [PubMed]

- Perrot, Y.; Baley, C.; Grohens, Y.; Davies, P. Damage resistance of composites based on glass fibre reinforced low styrene emission resins for marine applications. Appl. Compos. Mater. 2007, 14, 67–87. [Google Scholar] [CrossRef]

- Jules, E.J.; Lomov, S.; Verpoest, I. Characterization of random long fiber composites and prediction of the local stiffness properties. In Proceedings of the FPCM-7 Conference, Newark, DE, USA, 7–9 July 2004. [Google Scholar]

- Mokaddem, A.; Doumi, B.; Belkheir, M.; Touimi, A. Comparative Analysis on the Elastic Behavior of Composite Materials Based on Plant Fibers: Bamboo/Epoxy and Coconut/Epoxy. Curr. Mater. Sci. Former. Recent Pat. Mater. Sci. 2019, 12, 127–135. [Google Scholar] [CrossRef]

- Nayak, S.K.; Satapathy, A. Development and characterization of polymer-based composites filled with micro-sized waste marble dust. Polym. Polym. Compos. 2020, 29, 497–508. [Google Scholar] [CrossRef]

- Çınar, M.E.; Kar, F. Characterization of composite produced from waste PET and marble dust. Constr. Build. Mater. 2017, 163, 734–741. [Google Scholar] [CrossRef]

- Rajawat, A.S.; Singh, S.; Gangil, B.; Ranakoti, L.; Sharma, S.; Asyraf, M.R.M.; Razman, M.R. Effect of Marble Dust on the Mechanical, Morphological, and Wear Performance of Basalt Fibre-Reinforced Epoxy Composites for Structural Applications. Polymers 2022, 14, 1325. [Google Scholar] [CrossRef]

- Nayak, S.K.; Satapathy, A. Wear analysis of waste marble dust-filled polymer composites with an integrated approach based on design of experiments and neural computation. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 1846–1856. [Google Scholar] [CrossRef]

- Doan, T.T.L.; Brodowsky, H.M.; Gohs, U.; Mäder, E. Re-use of marble stone powders in producing unsaturated polyester composites. Adv. Eng. Mater. 2018, 20, 1701061. [Google Scholar] [CrossRef]

- Abdulkader, N.J.; Abdula, A.M.; Ahmed, S.S. Mechanical Properties of Polyester Matrix Composites Reinforced with Waste Marble Particles. IOP Conf. Ser. Mater. Sci. Eng. 2020, 978, 012034. [Google Scholar] [CrossRef]

- Kumar, S.R.; Patnaik, A.; Bhat, I. Development and characterization of marble dust-filled dental composite. J. Compos. Mater. 2017, 51, 1997–2008. [Google Scholar] [CrossRef]

- Awad, A.; El-Gamasy, R.; El-Wahab, A.A.A.; Abdellatif, M.H. Mechanical behavior of PP reinforced with marble dust. Constr. Build. Mater. 2019, 228, 116766. [Google Scholar] [CrossRef]

- Awad, A.; El-Wahab, A.A.A.; El-Gamsy, R.; Abdel-Latif, M.H. A study of some thermal and mechanical properties of HDPE blend with marble and granite dust. Ain Shams Eng. J. 2019, 10, 353–358. [Google Scholar] [CrossRef]

- Lendvai, L.; Singh, T.; Ronkay, F. Thermal, thermomechanical and structural properties of recycled polyethylene terephthalate (rPET)/waste marble dust composites. Heliyon 2024, 10, e25015. [Google Scholar] [CrossRef]

- Singh, T.; Pattnaik, P.; Shekhawat, D.; Ranakoti, L.; Lendvai, L. Waste marble dust-filled sustainable polymer composite selection using a multi-criteria decision-making technique. Arab. J. Chem. 2023, 16, 104695. [Google Scholar] [CrossRef]

- Sharma, A.; Choudhary, M.; Agarwal, P.; Biswas, S.K.; Patnaik, A. Effect of micro-sized marble dust on mechanical and thermo-mechanical properties of needle-punched nonwoven jute fiber reinforced polymer composites. Polym. Compos. 2020, 42, 881–898. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, K.; Liu, F.; Kang, H. Development and performance of a novel hybrid toughened unsaturated polyester resin (UPR) composite for crack repair of asphalt pavement. Constr. Build. Mater. 2024, 416, 135274. [Google Scholar] [CrossRef]

- Polymex-Laboratoire D’analyse, D’étude et Expertise Chimique. Available online: https://polymex.fr/piscine-polyester-defectueuse (accessed on 31 October 2024).

- Safety Information Form tp220tico tixotropic Polyester Resin, N°29204, “Regulation of the Ministry of Environment and Ur-banization of the T.C. on Safety Data Sheets for Hazardous Substances and Mixtures”. Available online: https://www.turkuazpolyester.com.tr/dil/eng (accessed on 31 October 2024).

- Nouryon Product Data Sheet Butanox M-50. 2021. Available online: https://www.nouryon.com/globalassets/inriver/resources/pds-butanox-m-50-thermoset-composites-glo-en.pdf (accessed on 31 October 2024).

- Babouri, L.; Biskri, Y.; Khadraoui, F.; El Mendili, Y. Mechanical performance and corrosion resistance of reinforced concrete with marble waste. Eur. J. Environ. Civ. Eng. 2022, 26, 4112–4129. [Google Scholar] [CrossRef]

- Perrot, Y. Influence des Propriétés de la Matrice sur le Comportement Mécanique de Matériaux Composites Verre/Polyester Utilisés en Construction Navale de Plaisance-Cas des Résines Polyester Limitant les Émissions de Styrène. Doctoral Dissertation, Université de Bretagne Sud, Vannes, France, 2006. [Google Scholar]

- Spectrum™ 10 software. Available online: https://www.perkinelmer.com/fr/product/software-kit-spectrum-10-lx108873 (accessed on 31 October 2024).

- ASTM E168-16; Standard Practices for General Techniques of Infrared Quantitative Analysis. ASTM: West Conshohocken, PA, USA, 2023.

- ASTM E1252-98; Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM A1131-08; Standard Test Method for Compositional Analysis by Thermogravimetry. ASTM International: West Conshohocken, PA, USA, 2014.

- Wikberg, H.; Maunu, S.L. Characterization of thermally modified hard and softwoods by 13C CPMAS NMR. Carbohydr. Polym. 2004, 58, 461–466. [Google Scholar] [CrossRef]

- NF EN ISO 1183-1; Plastiques—Méthodes de Détermination de la Masse Volumique des Plastiques non Alvéolaires—Partie 1: Méthode par Immersion, Méthode du Pycnomètre en Milieu Liquide et Méthode par Titrage. ISO: Geneva, Switzerland, 2019.

- ASTM D-256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM: West Conshohocken, PA, USA, 2023.

- Yao, B.; Zhou, Z.; Duan, L.; Chen, Z. Anisotropic Charpy impact behavior of novel interpenetrating phase composites. Vacuum 2018, 155, 83–90. [Google Scholar] [CrossRef]

- Tanks, J.; Sharp, S.; Harris, D. Charpy impact testing to assess the quality and durability of unidirectional CFRP rods. Polym. Test. 2016, 51, 63–68. [Google Scholar] [CrossRef]

- ASTM D882; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM D2240-15; Standard Test Method for Rubber Property—Durometer Hardness. ASTM: West Conshohocken, PA, USA, 2021.

- Aldas, M.; Pavon, C.; De La Rosa-Ramírez, H.; Ferri, J.M.; Bertomeu, D.; Samper, M.D.; López-Martínez, J. The Impact of Biodegradable Plastics in the Properties of Recycled Polyethylene Terephthalate. J. Polym. Environ. 2021, 29, 2686–2700. [Google Scholar] [CrossRef]

- Ekinci, A.; Öksüz, M.; Ates, M.; Aydin, I. Thermal and Mechanical Properties of Polypropylene/Post-consumer Poly (ethylene terephthalate) Blends: Bottle-to-Bottle recycling. J. Polym. Res. 2022, 29, 433. [Google Scholar] [CrossRef]

- Ali, F.; Hossain, S.; Lithi, I.J.; Ahmed, S.; Chowdhury, A.S. Fabrication and characterization of sustainable composites from animal fibers reinforced unsaturated polyester resin. Heliyon 2024, 10, e33441. [Google Scholar] [CrossRef]

- Kiemle, D.J.; Silverstein, R.M.; Webster, F.X. Identification Spectrométrique de Composés Organiques-3ème Édition; De Boeck Superieur: Louvain-la-Neuve, Belgium, 2016. [Google Scholar]

- Lubna, M.M.; Salem, K.S.; Sarker, M.; Khan, M.A. Modification of Thermo-Mechanical Properties of Recycled PET by Vinyl Acetate (VAc) Monomer Grafting Using Gamma Irradiation. J. Polym. Environ. 2018, 26, 83–90. [Google Scholar] [CrossRef]

- Khan, A.; Patidar, R.; Pappu, A. Marble waste characterization and reinforcement in low density polyethylene composites via injection moulding: Towards improved mechanical strength and thermal conductivity. Constr. Build. Mater. 2021, 269, 121229. [Google Scholar] [CrossRef]

- Lo, J.; Anders, M.; Centea, T.; Nutt, S. The effect of process parameters on volatile release for a benzoxazine–epoxy RTM resin. Compos. Part A Appl. Sci. Manuf. 2016, 84, 326–335. [Google Scholar] [CrossRef]

- Bogiatzidis, C.; Zoumpoulakis, L. Thermoset Polymer Matrix Composites of Epoxy, Unsaturated Polyester, and Novolac Resin Embedding Construction and Demolition Wastes powder: A Comparative Study. Polymers 2021, 13, 737. [Google Scholar] [CrossRef]

- Chu, F.; Wang, W.; Zhou, Y.; Xu, Z.; Zou, B.; Jiang, X.; Hu, Y.; Hu, W. Fully bio-based and intrinsically flame retardant unsaturated polyester cross-linked with isosorbide-based diluents. Chemosphere 2023, 344, 140371. [Google Scholar] [CrossRef]

- Wang, R.; Liu, X.; Yang, F.; Gao, S.; Zhou, S.; Kong, Y. Neighboring Cu toward Mn site in confined mesopore to trigger strong interplay for boosting catalytic epoxidation of styrene. Appl. Surf. Sci. 2021, 537, 148100. [Google Scholar] [CrossRef]

- Rassmann, S.; Reid, R.G.; Paskaramoorthy, R. Effects of processing conditions on the mechanical and water absorption properties of resin transfer moulded kenaf fibre reinforced polyester composite laminates. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1612–1619. [Google Scholar] [CrossRef]

- Ribeiro, C.E.G.; Rodriguez, R.J.S.; de Carvalho, E.A. Microstructure and mechanical properties of artificial marble. Constr. Build. Mater. 2017, 149, 149–155. [Google Scholar] [CrossRef]

- Wang, J.G.; Wu, L.; Zhou, J.X.; Qi, X.Y.; Yi, D.L. Preparation and Characterization of Marble/Unsaturated Polyester Resin Composite Materials. Adv. Mater. Res. 2011, 152–153, 825–828. [Google Scholar] [CrossRef]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Diao, X.; Song, Y.; Pan, S.; Cai, X.; Shi, T.; Wang, L. Enhanced dynamic compressive performance of silicon carbide whiskers-modified mortars. Constr. Build. Mater. 2024, 432, 136626. [Google Scholar] [CrossRef]

- de Azevedo, N.H.; de Matos, P.R.; Gleize, P.J.; Betioli, A.M. Effect of thermal treatment of SiC nanowhiskers on rheological, hydration, mechanical and microstructure properties of Portland cement pastes. Cem. Concr. Compos. 2021, 117, 103903. [Google Scholar] [CrossRef]

- Ding, P.; Qu, B. Synthesis and characterization of exfoliated polystyrene/ZnAl layered double hydroxide nanocomposite via emulsion polymerization. J. Colloid Interface Sci. 2005, 291, 13–18. [Google Scholar] [CrossRef]

- Farsane, M.; Saadouni, K.; Lhasnaoui, S.; Akhiate, A.; Anouar, A.; Chah, S.; Bouzziri, M. Effect of Recycled Ceramic Waste Content on the Properties of Unsaturated Polyester Resin. Preprints 2019, 2019120274. [Google Scholar] [CrossRef]

- El Mendili, Y.; Chateigner, D.; Orberger, B.; Gascoin, S.; Bardeau, J.-F.; Petit, S.; Duée, C.; Le Guen, M.; Pilliere, H. Combined XRF, XRD, SEM-EDS, and Raman analyses on serpentinized harzburgite (nickel laterite mine, New Caledonia): Implications for exploration and geometallurgy. ACS Earth Space Chem. 2019, 3, 2237–2249. [Google Scholar] [CrossRef]

- Salemane, M.; Baruwa, A.; Makhatha, M. Investigating the chemical stability and thermal functionality of DMPT promoted TiO2 nanoparticles on unsaturated polyester resin. Results Eng. 2024, 22, 102116. [Google Scholar] [CrossRef]

- de Souza, F.; Bragança, S.R. Thermogravimetric analysis of limestones with different contents of MgO and microstructural characterization in oxy-combustion. Thermochim. Acta 2013, 561, 19–25. [Google Scholar] [CrossRef]

- Barcina, L.; Espina, A.; Suárez, M.; García, J.; Rodríguez, J. Characterization of monumental carbonate stones by thermal analysis (TG, DTG and DSC). Thermochim. Acta 1997, 290, 181–189. [Google Scholar] [CrossRef]

- Ror, C.K.; Tejyan, S.; Kumar, N. Effect of marble dust reinforcement in composites for different applications: A review. Mater. Today Proc. 2022, 60, 1120–1124. [Google Scholar] [CrossRef]

- Kumar, T.N.; Vikas, B.; Krishna, M.R.; Jyothi, Y.; Imran, S. Development of composite slabs of marble powder embedded epoxy resin. Mater. Today Proc. 2018, 5, 13031–13035. [Google Scholar] [CrossRef]

- Albdiry, M.; Ku, H.; Yousif, B. Impact fracture behaviour of silane-treated halloysite nanotubes-reinforced unsaturated polyester. Eng. Fail. Anal. 2013, 35, 718–725. [Google Scholar] [CrossRef]

- Gagliardi, S.; Arrighi, V.; Ferguson, R.; Telling, M. Restricted dynamics in polymer-filler systems. Phys. B Condens. Matter 2001, 301, 110–114. [Google Scholar] [CrossRef]

- Attallah, M.S.; Mohammed, R.A.; Abdel-Rahim, R.H. Characterization of Unsaturated Polyester Filled with Waste Coconut Shells, Walnut Shells, and Carbon Fibers. Fluid Dyn. Mater. Process. 2023, 19, 2449–2469. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).