Standardization of CAD Drawing Formats and GeoJSON-Based Processing for 3D Spatial Data Extraction of Underground Utilities

Abstract

1. Introduction

2. Materials and Methods

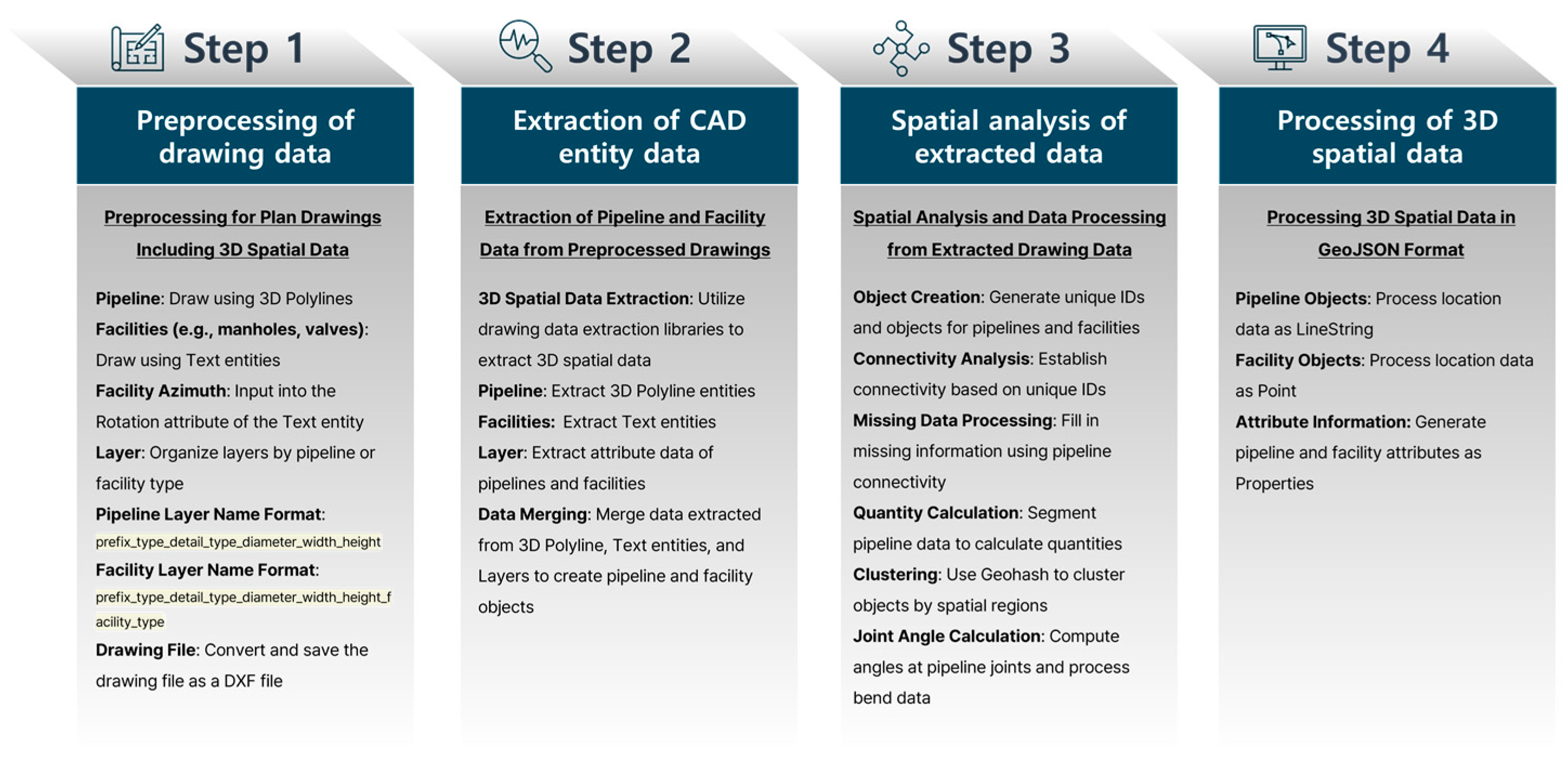

2.1. Overview

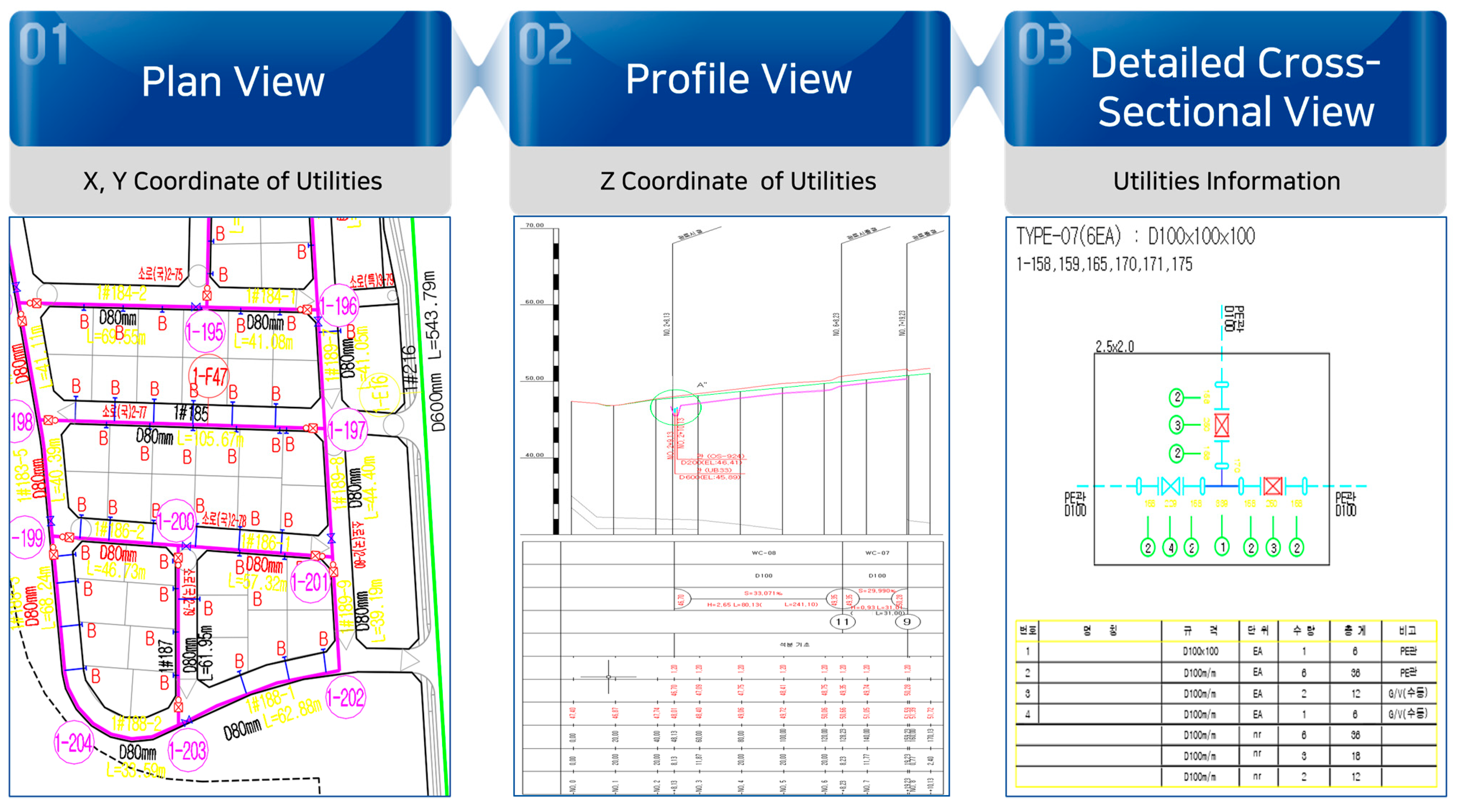

2.2. Integration of 2D Drawings

- Plan view: provides the X-Y alignment and layout of pipelines relative to their surroundings;

- Profile view: includes depth information along the Z-axis and connections to structures such as manholes;

- Detailed cross-sectional view: displays detailed specifications of individual infrastructure components, such as pipe diameters and materials.

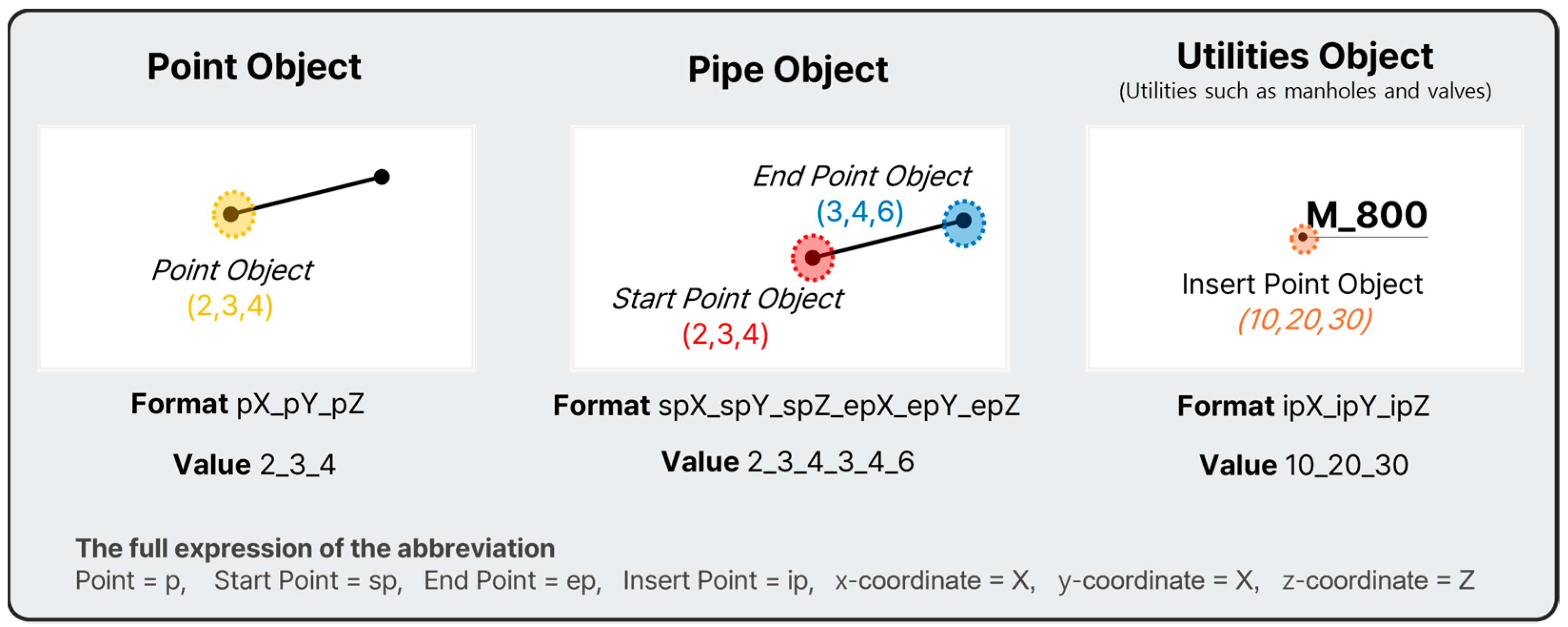

2.3. Standardization of CAD Formats

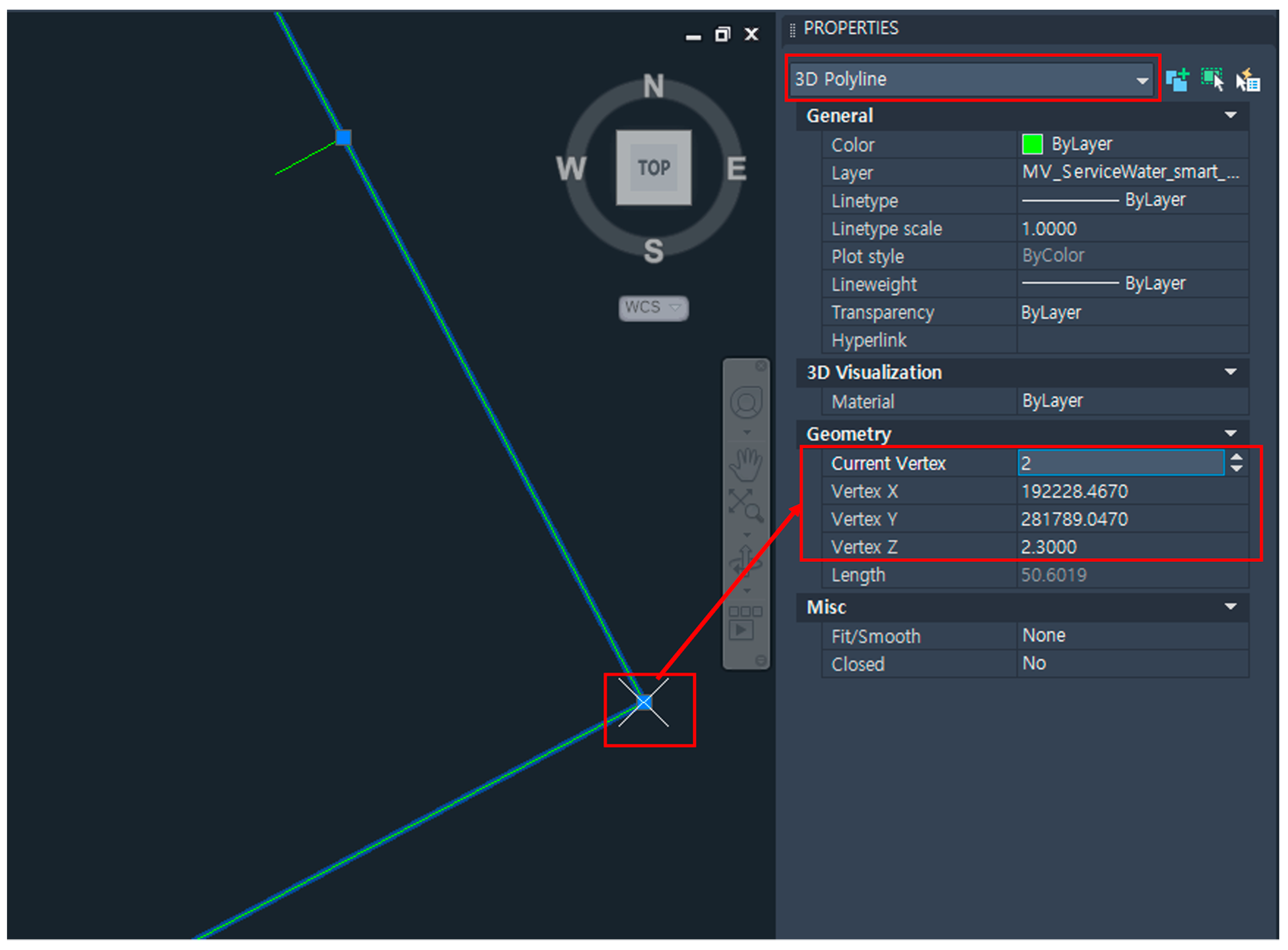

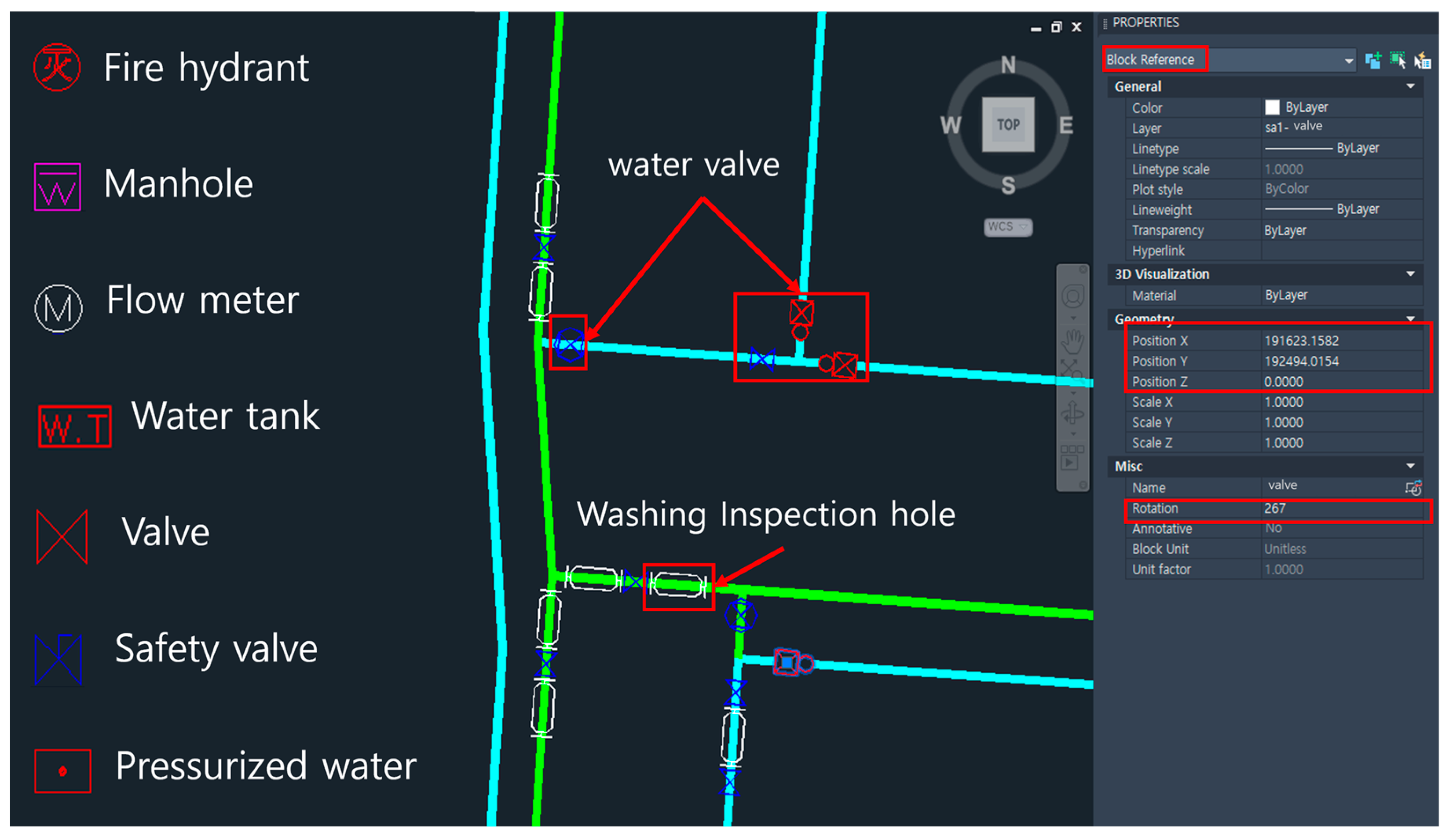

- 3D coordinate information (X, Y, Z): defines the precise spatial location of the underground facility in the three-dimensional space;

- Geometric information: specifies data representing the shape of the underground facility, such as diameter, width, and height;

- Attribute data: describe the attributes of the underground facility, including its type, orientation, and other relevant properties.

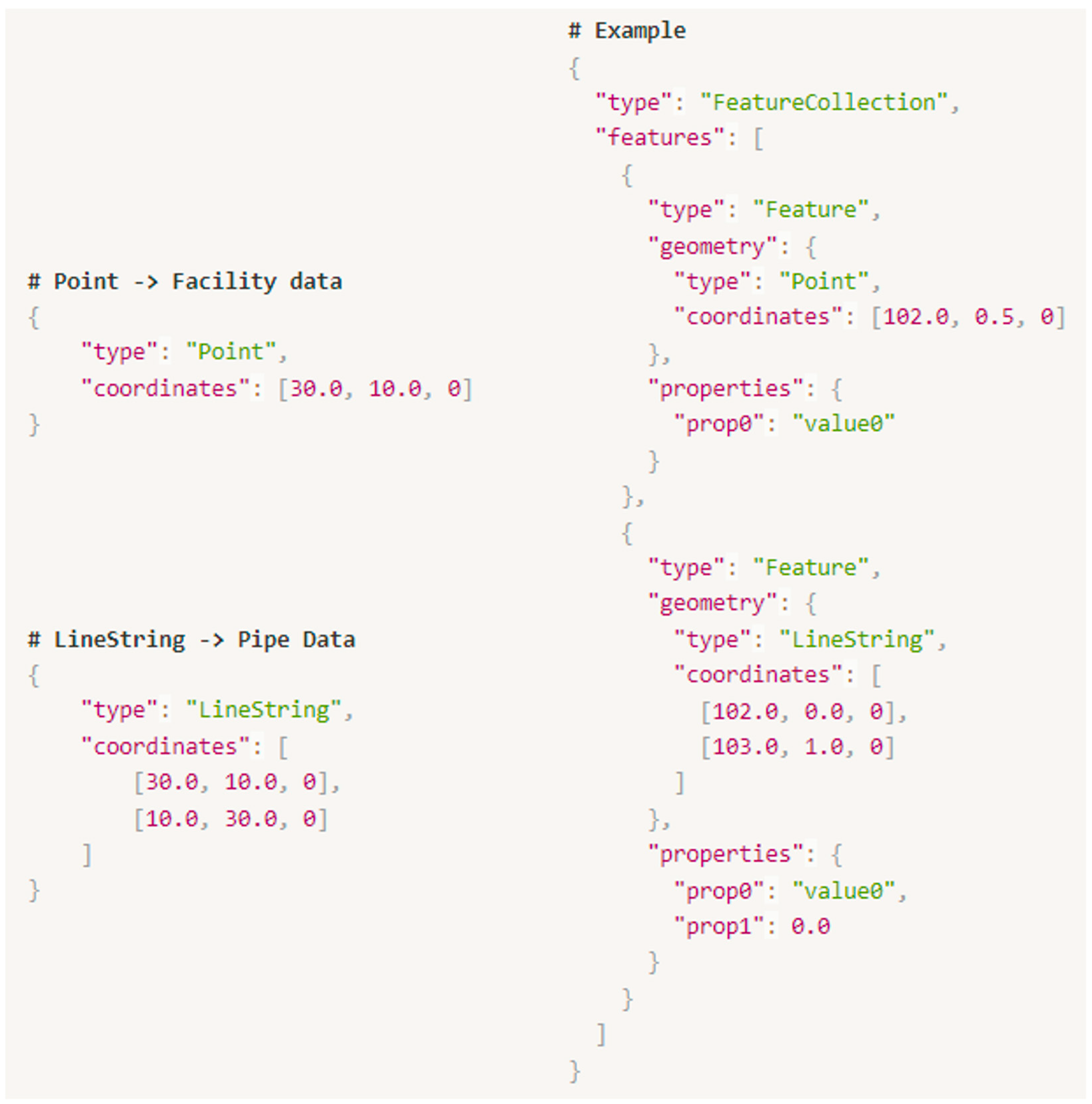

2.4. Standardization of GeoJSON Formats

- Extract CAD entity data from plan drawings containing 3D spatial information;

- Generate underground facility object data based on the extracted data;

- Perform spatial analyses on the underground facility objects to generate relational data;

- Map the generated object data to GeoJSON geometry types (Point, LineString) and attach location and attribute data to the GeoJSON objects.

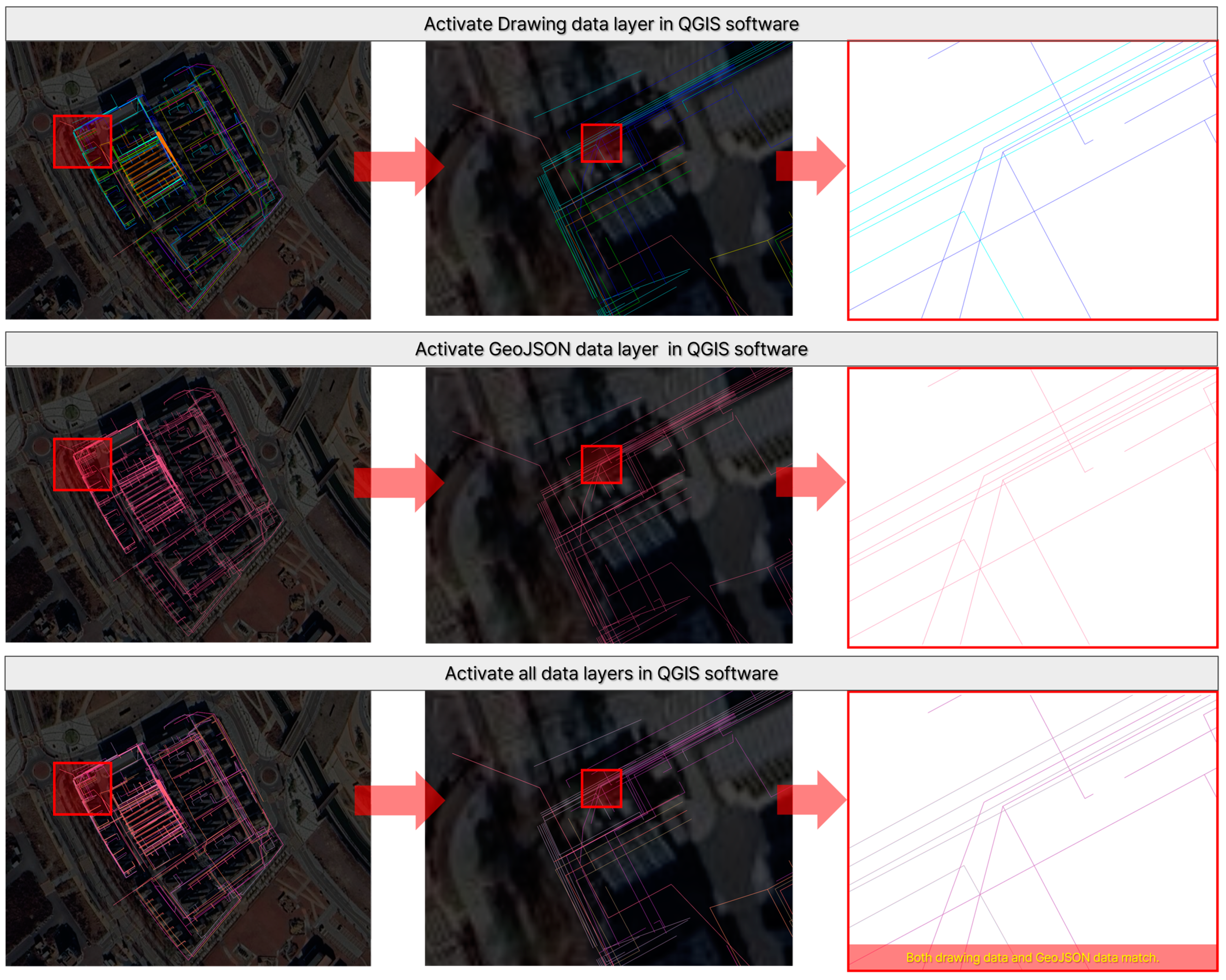

2.5. Accuracy Testing with Complex Environment

- Attribute verification: attributes such as diameter and material were cross-referenced with the original data to ensure consistency;

- Systematic testing: The methodology was applied to transform the facility data from the Smart Village in Section 1, Section 2 and Section 3 of Busan Eco-Delta City [18,19], a pilot smart city in South Korea. A random sampling inspection was conducted, analyzing 20 pipeline configuration cases to evaluate the robustness of the methodology.

- The results confirmed that the CAD-based drawings were accurately converted to GeoJSON without any data loss during the transformation process.

3. Standardization of Plan Drawing Formats for Extracting 3D Spatial Information of Underground Utilities

3.1. Integration of Underground Pipeline Drawings for 3D Data Extraction

3.2. Integrated Management of BIM Technology and Barriers to Its Adoption

3.3. Integration of 3D Spatial Information for 2D Design Engineers

3.3.1. 3D Spatial Data for BIM Data Processing

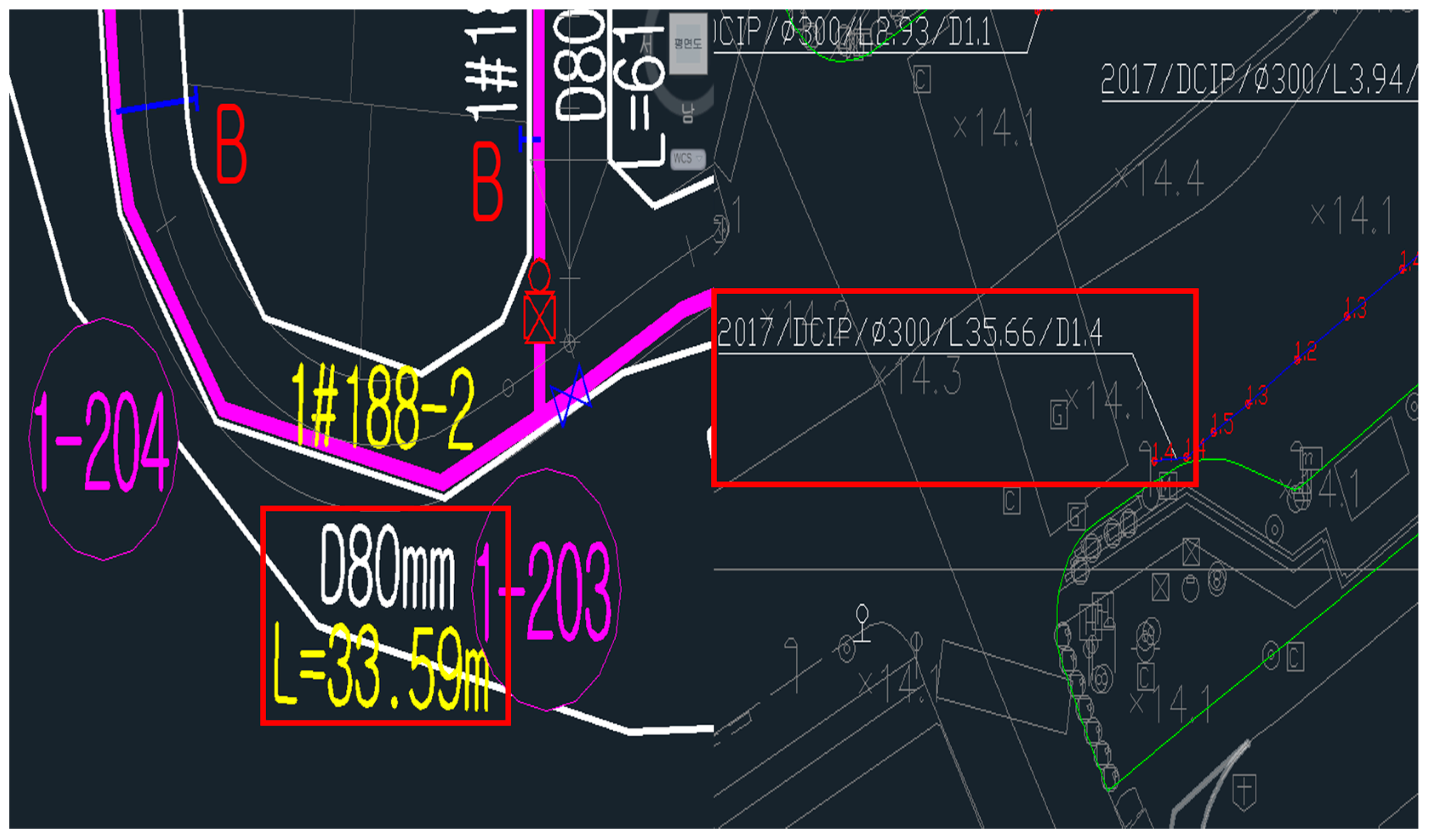

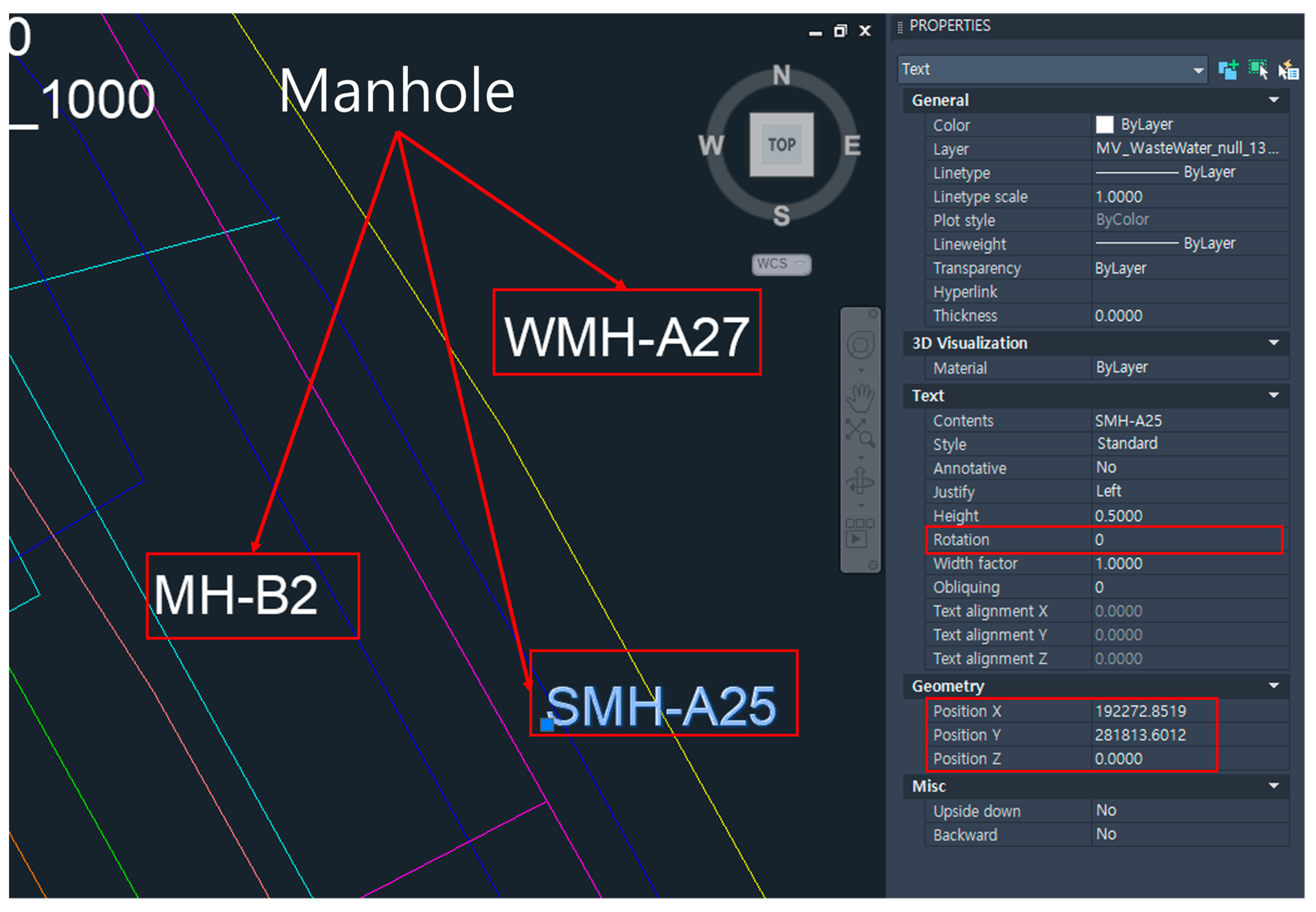

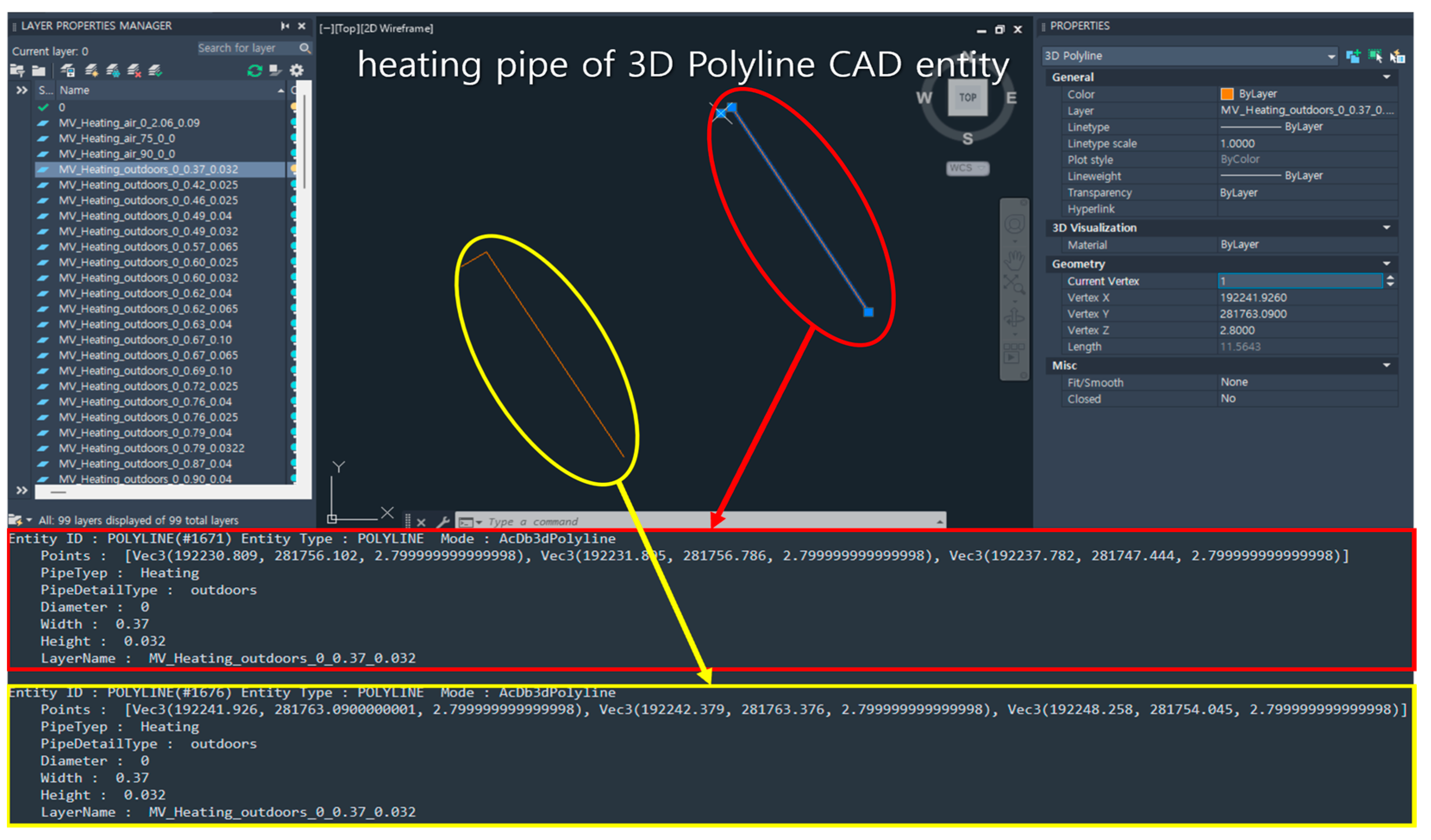

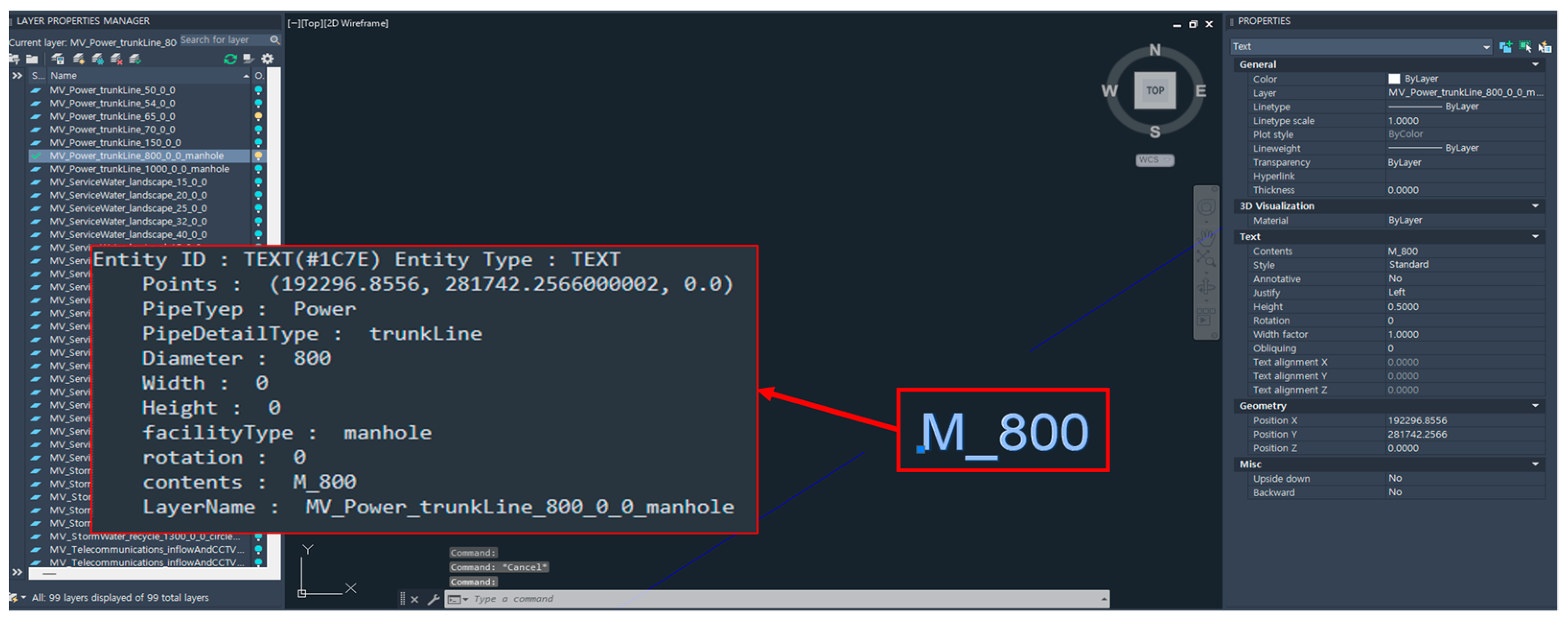

3.3.2. Plan Drawing Format Incorporating 3D Spatial Information

4. 3D Spatial Analysis of Underground Utilities Data

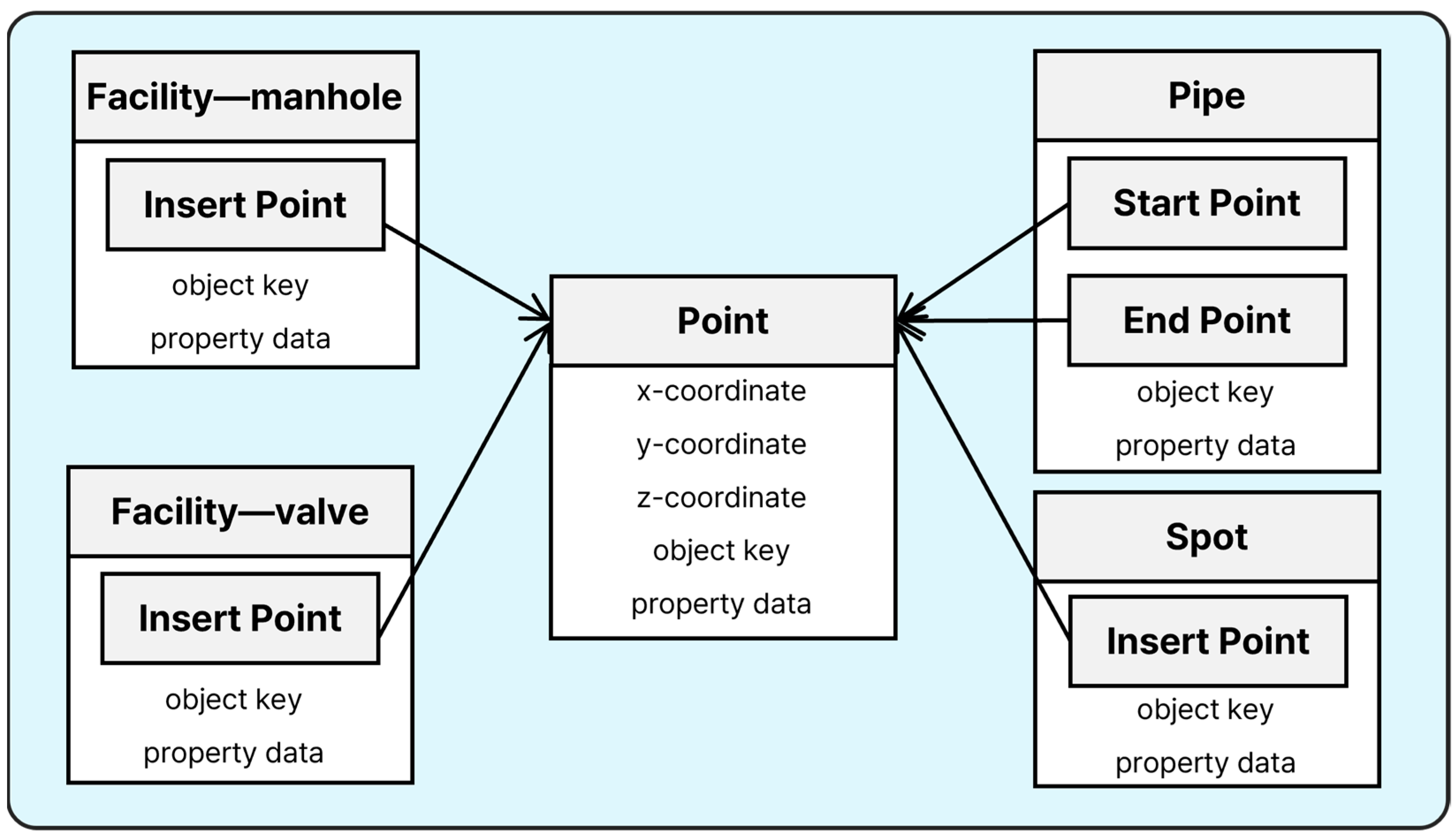

4.1. Data Extraction Process for Spatial Data Processing

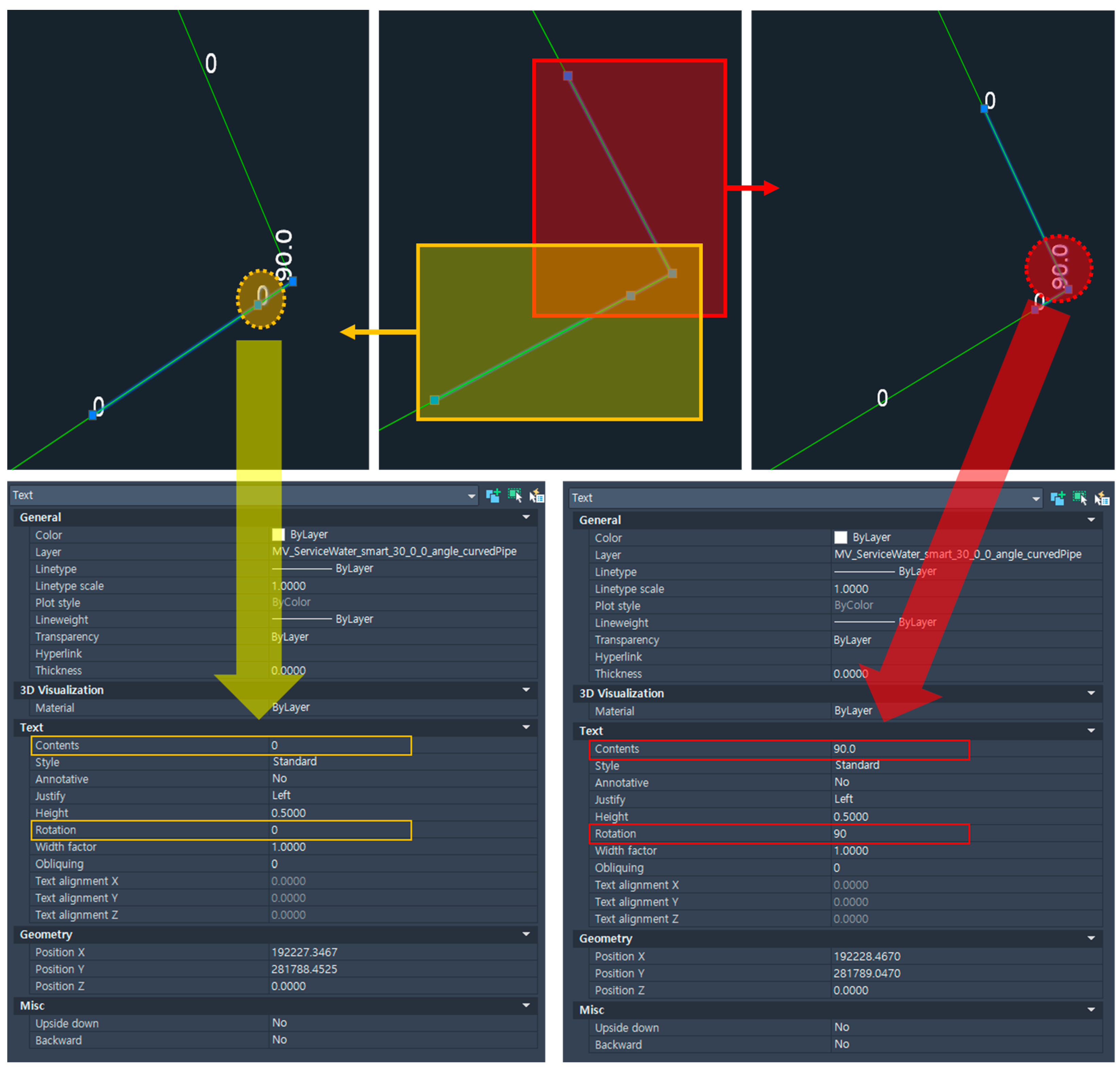

4.2. CAD Entity Data Extraction

4.3. Spatial Analysis and 3D Spatial Data Processing

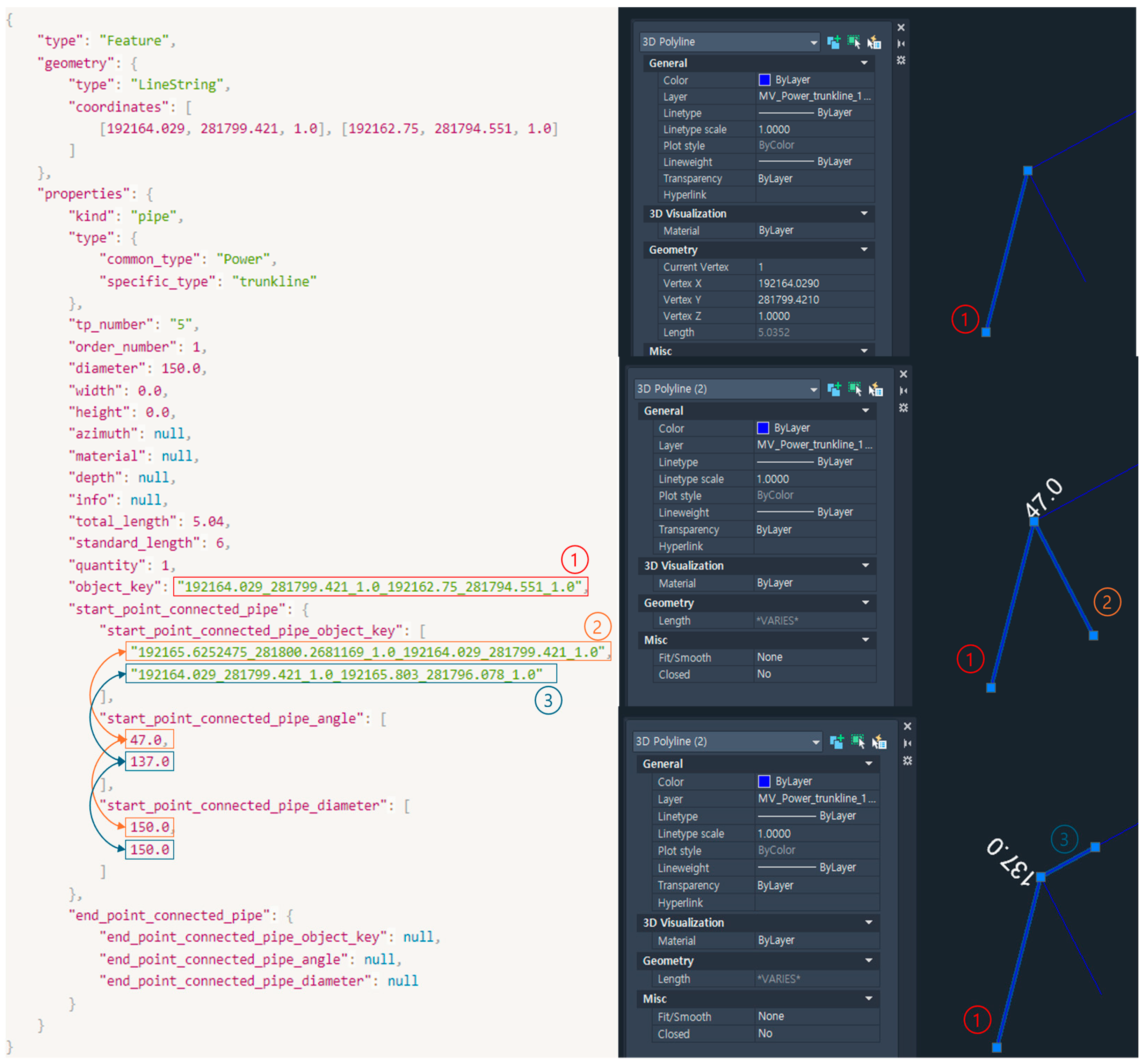

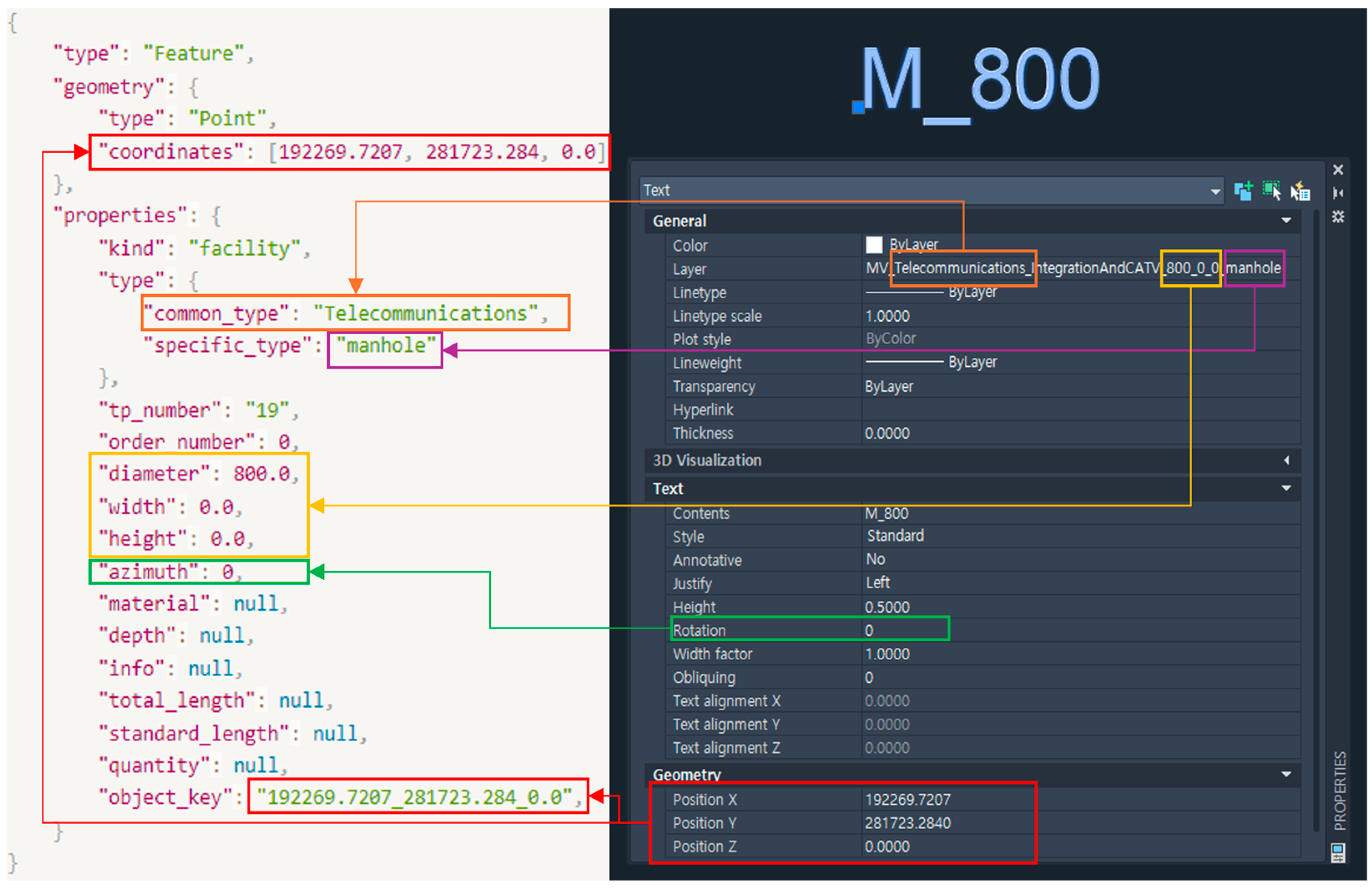

5. 3D Spatial Data in GeoJSON Format

5.1. Application of GeoJSON Format to Underground Utility Data

5.2. GeoJSON Data Generation

5.3. Accuracy Testing for Digital Conversion of Underground Utility Data

6. Development, Utilization, and Standardization of 3D Spatial Data for Underground Utilities

6.1. The Importance of Processing 3D Spatial Data

6.2. Utilization Strategies for GeoJSON-Based Spatial Data

- BIM is a technology that integrates and manages data throughout the entire lifecycle of a construction project, from planning and design to construction and maintenance. When 3D underground utility data are integrated with BIM, it helps prevent potential conflicts with underground resources during construction and allows for more efficient construction planning;

- A digital twin based on 3D underground utility data enables real-time data monitoring, analysis, and prediction. This allows for the real-time assessment of the condition of underground utilities and enables immediate responses in the case of anomalies;

- Autonomous equipment, such as robots and drones, can perform autonomous construction and maintenance tasks based on 3D underground utility data. These technologies reduce reliance on human labor while increasing the accuracy and safety of operations;

- The development direction of smart construction technology through the standardization of 3D spatial data for underground utilities is as follows. 3D data, when analyzed using artificial intelligence (AI) technology, play a crucial role in anomaly detection and condition prediction of underground utilities. AI analyzes data collected from various sensors to predict the aging state of underground utilities, optimizing the timing and methods of maintenance based on these insights;

- In smart construction, large-scale data are integrated and managed through cloud platforms, enabling real-time collaboration and data sharing. In a cloud environment, 3D underground utility data can be accessed by various stakeholders at any time, significantly improving project efficiency;

- As intelligent maintenance systems that combine 3D underground utility data with sensor data are developed, predictive maintenance will become possible. This will help prevent accidents in advance and reduce emergency repair and recovery costs;

- The combination of digital twin technology and the Internet of Things (IoT) will open a new chapter in smart construction. IoT sensors collect real-time data on underground utilities, which are then reflected in the digital twin model, allowing for the real-time tracking and control of the condition of underground utilities.

6.3. Current Status of 3D Spatial Data Standardization

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- KPC (Korea Productivity Center). Labor Productivity Index by Industry in 2021. Korea Productivity Statistics. 2021. Available online: https://www.nafi.re.kr/new/report.do?articleNo=3293&attachNo=3967&mode=download (accessed on 16 November 2024).

- KIET (Korea Institute for Industrial Economics and Trade). The Current State of Digital Transformation in Korea and Policy Directions. KIET Research Report. 2024. Available online: https://www.kiet.re.kr/research/economyDetailView?detail_no=2979 (accessed on 16 November 2024).

- Du, S.; Hou, L.; Zhang, G.; Tan, Y.; Mao, P. BIM and IFC Data Readiness for AI Integration in the Construction Industry: A Review Approach. Buildings 2024, 14, 3305. [Google Scholar] [CrossRef]

- Padida, S.; Srinivas, K. Adoption of Metaverse in the Indian Construction Industry: An Overview. J. Smart Build. Constr. Technol. 2023, 5, 1–8. [Google Scholar] [CrossRef]

- McKinsey & Company. Korea’s Next S-Curve: A New Economic Growth Model for 2040. McKinsey & Company. 2024. Available online: https://www.mckinsey.com/kr/~/media/mckinsey/locations/asia/korea/our%20insights/koreas%20next%20s%20curve%20a%20new%20economic%20growth%20model%20for%202040/koreas-next-s-curve-a-new-economic-growth-model-for-2040-ko.pdf (accessed on 16 November 2024).

- Deloitte. Digital Construction: Bridging Productivity Gaps in the Construction Industry. Deloitte Global Report. 2024. Available online: https://www2.deloitte.com/content/dam/Deloitte/kr/Documents/technology-media-telecommunications/2024/kr-digital-construction-c.pdf (accessed on 16 November 2024).

- Choi, W.; Na, S.; Heo, S. Integrating Drone Imagery and AI for Improved Construction Site Management through Building Information Modeling. Buildings 2024, 14, 1106. [Google Scholar] [CrossRef]

- Iqbal, F.; Ahmed, S.; Amin, F.; Qayyum, S.; Ullah, F. Integrating BIM–IoT and Autonomous Mobile Robots for Construction Site Layout Printing. Buildings 2023, 13, 2212. [Google Scholar] [CrossRef]

- Republic of Korea Policy Briefing. Commercialization of Core Smart Construction Technologies by 2025. Available online: https://korea.kr/briefing/pressReleaseView.do?newsId=156371677 (accessed on 24 October 2024).

- MOLIT. Realization of Commercialization of Smart Construction Core Technology by 2025: Smart City Comprehensive Portal. Available online: https://smartcity.go.kr (accessed on 24 October 2024).

- Zhu, J.; Wu, P. Towards Effective BIM/GIS Data Integration for Smart City by Integrating Computer Graphics Technique. Buildings 2021, 13, 1889. [Google Scholar] [CrossRef]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A Literature Review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Yigitbas, E.; Nowosad, A.; Engels, G. Supporting Construction and Architectural Visualization through BIM and AR/VR: A Systematic Literature Review. Buildings 2023, 13, 12274. [Google Scholar] [CrossRef]

- Liu, C.; Yan, W.; Moure, P.; Fan, C.; Mehta, A. A Computational Design and Evaluation Tool for 3D Structures with Planar Surfaces. Buildings 2021, 11, 2103. [Google Scholar] [CrossRef]

- Noghabaei, M.; Heydarian, A.; Balali, V.; Han, K. A Survey Study to Understand Industry Vision for Virtual and Augmented Reality Applications in Design and Construction. Buildings 2020, 10, 2795. [Google Scholar] [CrossRef]

- GeoJSON. GeoJSON Format Specification (RFC 7946). Available online: https://geojson.org (accessed on 24 October 2024).

- EZDXF. DXF Reference—DXF Tags. Available online: https://ezdxf.mozman.at/docs/develop/dxftags.html (accessed on 16 November 2024).

- K-Water. Eco-Delta City. Available online: https://www.kwater.or.kr/website/ecodeltacity/english/ (accessed on 16 November 2024).

- Busan Smart Village. Busan Smart Village. Available online: https://busan-smartvillage.com/ (accessed on 16 November 2024).

- Othman, I.; Gardezi, S.S.S.; Altan, H.; Abdalla, S.B. BIM-Based Research Framework for Sustainable Building Projects: A Strategy for Mitigating BIM Implementation Barriers. Appl. Sci. 2021, 11, 5397. [Google Scholar] [CrossRef]

- Ariono, B.; Wasesa, M.; Dhewanto, W. The Drivers, Barriers, and Enablers of BIM Innovation in Developing Countries: Insights from Systematic Literature Review and Comparative Analysis. Buildings 2022, 12, 1912. [Google Scholar] [CrossRef]

- Tran, T.V.; Tran, H.V.V.; Nguyen, T.A. A Review of Challenges and Opportunities in BIM Adoption for Construction Project Management. Eng. J. 2024, 28, 79–98. [Google Scholar] [CrossRef]

- Shawky, K.; Alnaser, A.A.; Shibeika, A.; Sherif, A. Developing Standard BIM Execution Plans for Complex Construction Projects. Appl. Sci. 2024, 14, 6614. [Google Scholar] [CrossRef]

- Yan, J.; Siow Wei, J.; Schrotter, G. Towards an Underground Utilities 3D Data Model for Land Administration. Remote Sens. 2019, 11, 1957. [Google Scholar] [CrossRef]

- Lee, Y.; Park, S.; Hong, C. Implementing a Digital Twin of an Underground Utility Tunnel for Geospatial Feature Extraction Using a Multimodal Image Sensor. Appl. Sci. 2023, 13, 9137. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, Y.D.; Moon, I.Y. Methods for Underground Facility Maintenance Using Smart Construction Technology. In Proceedings of the ICNGC 2023, Seoul, Republic of Korea, 20–23 December 2023; pp. 123–130. [Google Scholar]

- Mishra, S.; Hashmi, K.A.; Pagani, A.; Liwicki, M.; Afzal, M.Z. Towards Robust Object Detection in Floor Plan Images: A Data Augmentation Approach. Appl. Sci. 2021, 11, 11174. [Google Scholar] [CrossRef]

- Zhao, Y.; Deng, X.; Lai, H. A Deep Learning-Based Method to Detect Components from Scanned Structural Drawings for Reconstructing 3D Models. Appl. Sci. 2020, 10, 2066. [Google Scholar] [CrossRef]

- Bartoněk, D. Automatic Creation of 3D Documentation in CAD/BIM Based on Topology. Mathematics 2023, 11, 3758. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Liu, Y. A Hybrid Framework for High-Performance Modeling of Three-Dimensional Pipe Networks. ISPRS Int. J. Geo-Inf. 2019, 8, 441. [Google Scholar] [CrossRef]

- Shen, T.; Zhang, H.; Huo, L.; Sun, D. Spatial Data Fusion Model Design and Research for an Underground Pipeline in Urban Environment Scene Modeling. Appl. Sci. 2024, 14, 6760. [Google Scholar] [CrossRef]

- Ulu, M.; Kilic, E.; Türkan, Y.S. Prediction of Traffic Incident Locations with a Geohash-Based Model Using Machine Learning Algorithms. Appl. Sci. 2024, 14, 725. [Google Scholar] [CrossRef]

- Yu, M.; Eldawy, A.; Mokbel, M.F. SpatialSpark: A Framework for Large-Scale Spatial Data Processing. In Proceedings of the IEEE International Conference on Big Data (BigData), Orlando, FL, USA, 18 December 2021; Available online: https://spatialhadoop.cs.umn.edu/publications/ICDE15_industrial_522.pdf (accessed on 16 November 2024).

- Yu, J.; Zhang, Z.; Sarwat, M. Spatial Data Management in Apache Spark: The GeoSpark Perspective and Beyond. Geoinformatica 2019, 23, 37–78. [Google Scholar] [CrossRef]

- Ahmed, M.; Mokbel, M.F.; Eldawy, A. A Survey of Spatial and Spatio-Temporal Data Analytics Systems. In Proceedings of the IEEE Transactions on Knowledge and Data Engineering, Seoul, Republic of Korea, 13–17 April 2015; Volume 35, pp. 1–15. Available online: https://ieeexplore.ieee.org/abstract/document/7113382 (accessed on 16 November 2024).

- Stouffs, R.; Tekavec, J.; Stoter, J. Tools for BIM-GIS Integration (IFC Georeferencing and Conversions): Results from the GeoBIM Benchmark 2019. ISPRS Int. J. Geo-Inf. 2020, 9, 502. [Google Scholar] [CrossRef]

- Korea Testing & Research Institute. KTR Software Commissioned Test/Assignment Verification. Available online: https://www.ktr.or.kr/test-evaluation/led/contentsid/2003/index.do (accessed on 24 October 2024).

- Kang, T. Scan to BIM Mapping Process Description for Building Representation in 3D GIS. Appl. Sci. 2023, 13, 9986. [Google Scholar] [CrossRef]

- ISO 19152:2012; Geographic Information—Land Administration Domain Model (LADM). ISO: Geneva, Switzerland, 2024. Available online: https://www.iso.org (accessed on 24 October 2024).

- FIG. 3D Spatial Units and ISO 19152: LADM as a Base for 3D Cadastre. Available online: http://home.zcu.cz/~kjanecka/Publications/Janecka-3Dkatastr-GvP2014.pdf (accessed on 24 October 2024).

- OGC. OGC Standards and 3D Modeling: CityGML and InfraGML. Available online: https://www.ogc.org (accessed on 24 October 2024).

| Index | Pipeline | Facility |

|---|---|---|

| 1 | Prefix | Prefix |

| 2 | Type | Type |

| 3 | Detail type | Detail type |

| 4 | Diameter | Diameter |

| 5 | Width | Width |

| 6 | Height | Height |

| 7 | Facility type |

| Key | Description | Unit |

|---|---|---|

| kind | Pipe or facility | |

| common_type | The 7 types of underground facilities | |

| specific_type | Detailed types of underground facilities | |

| tp_number | Facility management number | |

| order_number | Sub-facility management number | |

| diameter | Diameter of the pipe | mm |

| width | Width of the pipe | m |

| height | Height of the pipe | m |

| azimuth | Rotation angle based on the north direction | degree |

| material | Material of the pipe | |

| depth | Depth to the top of the pipe | m |

| info | Detailed angle of the curved pipe and facility | degree |

| total_length | Length of the pipe | m |

| standard_length | Length of the pipe in design data | m |

| quantity | Pipe quantity calculation result | ea |

| object_key | Unique value of underground facility | |

| start_point_connected_pipe | Pipe connected to the starting point | |

| end_point_connected_pipe | Pipe connected to the end point | |

| start_point_connected_pipe_object_key | Unique value of the pipeline connected to the starting point | |

| end_point_connected_pipe_object_key | Unique value of the pipeline connected to the end point | |

| start_point_connected_pipe_angle | Angle of the elbow at the starting point of the pipe | degree |

| end_point_connected_pipe_angle | Angle of the elbow at the end point of the pipe | degree |

| start_point_connected_pipe_diameter | Diameter of the pipe connected to the starting point | mm |

| end_point_connected_pipe_diameter | Diameter of the pipe connected to the end point | mm |

| Equipment Specification | Description |

|---|---|

| CPU | Intel(R) Core(TM) Ultra 7 155H 1.40Ghz |

| RAM | 32 GB |

| HDD | 1 TB |

| NIC | Intel(R) Wi-Fi 6 AX211 160MHz |

| OS | Windows Pro 11, 64bit |

| S/W, Module | Python 3.11.9 Extract Geojson v1.0 |

| Network | TCP/IP |

| Test data file | File name: BIM_sample.dxf File size: 813 kb |

| Data extraction accuracy (%) | (number of successful object extractions/number of selected objects) × 100 |

| Number of data comparisons | Select a random object and compare it 20 times |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Kim, Y.; Moon, I.-Y. Standardization of CAD Drawing Formats and GeoJSON-Based Processing for 3D Spatial Data Extraction of Underground Utilities. Buildings 2024, 14, 3980. https://doi.org/10.3390/buildings14123980

Lee J, Kim Y, Moon I-Y. Standardization of CAD Drawing Formats and GeoJSON-Based Processing for 3D Spatial Data Extraction of Underground Utilities. Buildings. 2024; 14(12):3980. https://doi.org/10.3390/buildings14123980

Chicago/Turabian StyleLee, Jongseo, Yudoo Kim, and Il-Young Moon. 2024. "Standardization of CAD Drawing Formats and GeoJSON-Based Processing for 3D Spatial Data Extraction of Underground Utilities" Buildings 14, no. 12: 3980. https://doi.org/10.3390/buildings14123980

APA StyleLee, J., Kim, Y., & Moon, I.-Y. (2024). Standardization of CAD Drawing Formats and GeoJSON-Based Processing for 3D Spatial Data Extraction of Underground Utilities. Buildings, 14(12), 3980. https://doi.org/10.3390/buildings14123980